Novel double-turbine hydraulic torque converter

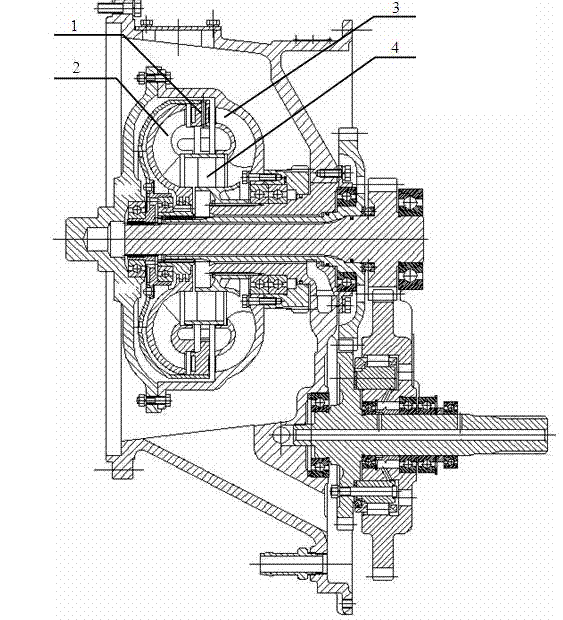

A hydraulic torque converter, twin-turbo technology, applied in the direction of belt/chain/gear, fluid transmission, mechanical equipment, etc., can solve the problem of high engine fuel consumption, reduce loader reliability, power performance and fuel economy , affecting the performance of the whole machine, etc., to achieve the effects of excellent fuel economy, reasonable torque, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

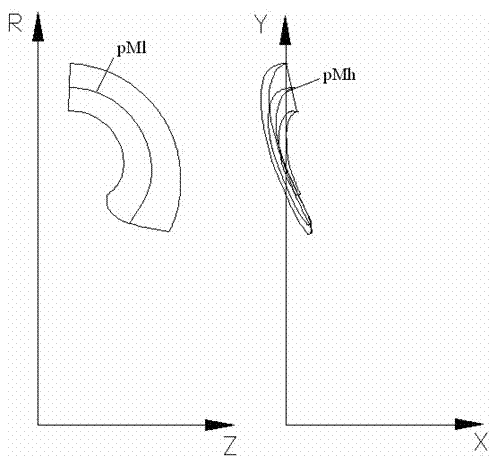

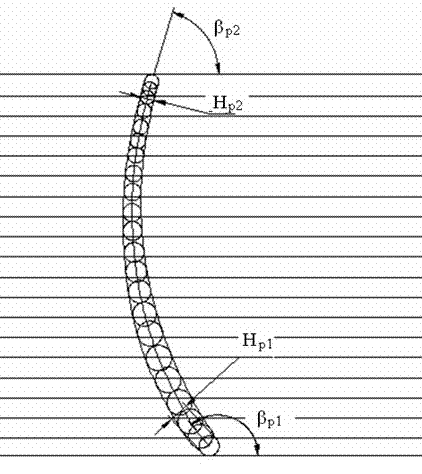

Embodiment 1

[0024] The diameter of the circulation circle is 288mm; the inlet angle of the streamline in the middle of the pump impeller blade is β p1 =116°~120°, the outlet angle of the middle streamline is β p2 =70°~75°, the thickness H of the inlet edge of the middle annulus p1 =4.80~5.00mm, thickness H of the outlet edge of the middle annulus p2 =3.20~3.50mm; the inlet angle of the I-stage turbine blade is β 1 =88°~92°, the outlet angle is β 2 =148°~151°, round head radius R at the inlet side 1 =4.60~4.90mm, round head radius R at the exit side 2 =0.90~1.10mm; the inlet angle of the middle streamline of the II-stage turbine blade is β 1 =55°~60°, the outlet angle of the middle streamline is β 2 =130°~136°, the thickness H of the inlet side of the middle annulus II1 =3.00~3.50mm, the thickness H of the outlet edge of the middle annulus II2 =1.50~1.80mm; the inlet angle of the guide wheel blade is β s1 =76°~80°, the outlet angle is β s2 =30°~35°, round head radius ...

Embodiment 2

[0027] The diameter of the circulation circle is 290mm; the inlet angle of the streamline in the middle of the pump impeller blade is β p1 =112°~115°, the outlet angle of the middle streamline is β p2 =76°~77°, the thickness H of the inlet side of the middle annulus p1 =5.00~5.30mm, the thickness of the outlet edge of the middle annulus H p2 =3.10~3.40mm; the inlet angle of the I-stage turbine blade is β 1 =96°~98°, the outlet angle is β 2 =148°~149°, round head radius R at the inlet side 1 =5.20~5.50mm, round head radius R at the exit side 2 =0.80~1.00mm; the inlet angle of the middle streamline of the II-stage turbine blade is β 1 =56°~58°, the outlet angle of the middle streamline is β 2 =135°~140°, the thickness H of the inlet side of the middle annulus II1 = 3.10~3.40mm, thickness H of the outlet edge of the middle annulus II2 = 1.90~2.20mm; the inlet angle of the guide wheel blade is β s1 =75°~77°, the outlet angle is β s2 =32°~34°, round head radiu...

Embodiment 3

[0030] The diameter of the circulation circle is 295mm; the inlet angle of the streamline in the middle of the pump impeller blade is β p1 =105°~110°, the outlet angle of the middle streamline is β p2 =77°~80°, the thickness H of the inlet side of the middle annulus p1 =4.90~5.10mm, thickness H of the outlet edge of the middle annulus p2 =2.80~3.10mm; the inlet angle of the I-stage turbine blade is β 1 =90°~96°, the outlet angle is β 2 =150°~155°, round head radius R at the inlet side 1 =5.30~5.60 mm, round head radius R at the exit side 2 =0.90~1.20 mm; the inlet angle of the streamline in the middle of the stage II turbine blade is β 1 =59°~65°, the outlet angle of the middle streamline is β 2 =135°~138°, the thickness H of the inlet side of the middle annulus II1 =2.90~3.20 mm, thickness H of the outlet edge of the middle annulus II2 =2.00~2.30 mm; the inlet angle of the guide wheel blade is β s1 =72°~76°, the outlet angle is β s2 =34°~38°, round head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com