Testing bench for stalling torque of electric tool

A technology of electric tools and test benches, applied in force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as easy to generate jitter, difficult to read instantaneous force, and potential safety hazards, so as to avoid measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

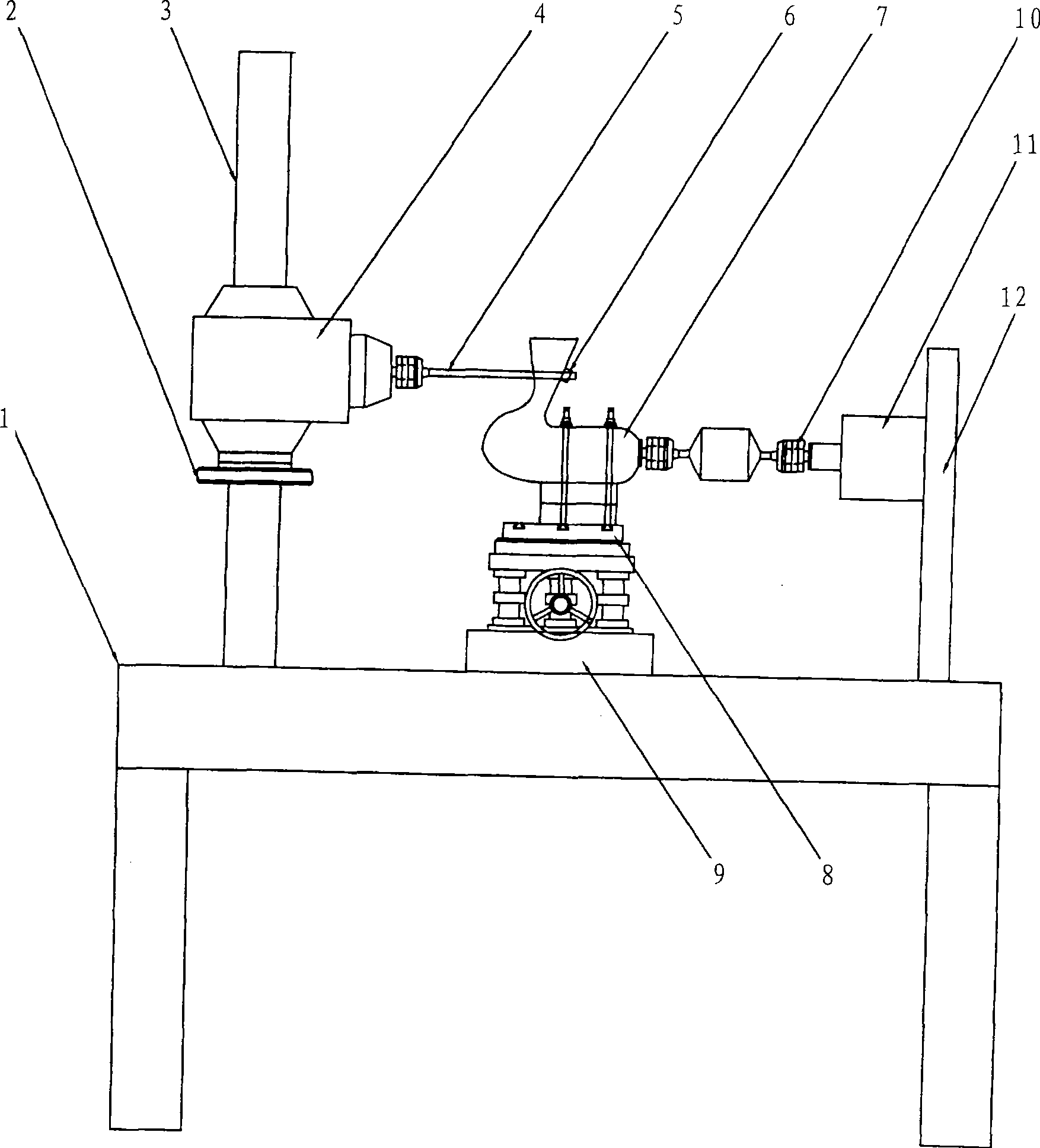

[0010] Refer to attached figure 1 , a stall torque test bench for electric tools, which includes a frame 1, a motor table 2, a column 3, a linear stepper motor 4, a drive screw 5, a switch actuator 6, a tiltable clamping table 8, and a three-dimensional working Table 9, static sensor 11 and support seat 12, wherein the column 3 is fixed on the frame 1, the motor workbench 2 is mounted on the column 3, the motor workbench 2 can move up and down and be clamped and fixed at an appropriate position; linear stepping The motor 4 is fixed on the motor table 2; one end of the driving screw 5 is connected with the linear stepper motor 4, and the other end is connected with the switch actuator 6; the three-dimensional workbench 9 is fixed on the frame 1, and can be tilted and clamped One side of the table 8 is hinged with the three-dimensional worktable 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com