Control method and system used for excavator electric control pump

A control method and control system technology, which is applied in the field of construction machinery, can solve the problems of high engine smoke, decreased performance of the excavator, and low efficiency, so as to avoid power loss, improve overall efficiency, and overcome system instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

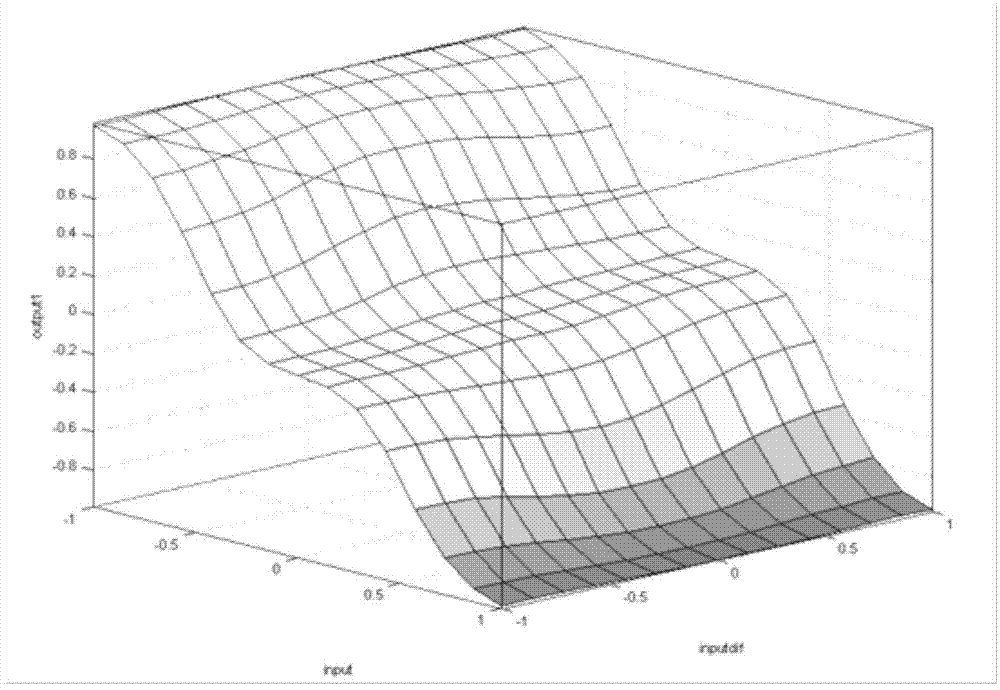

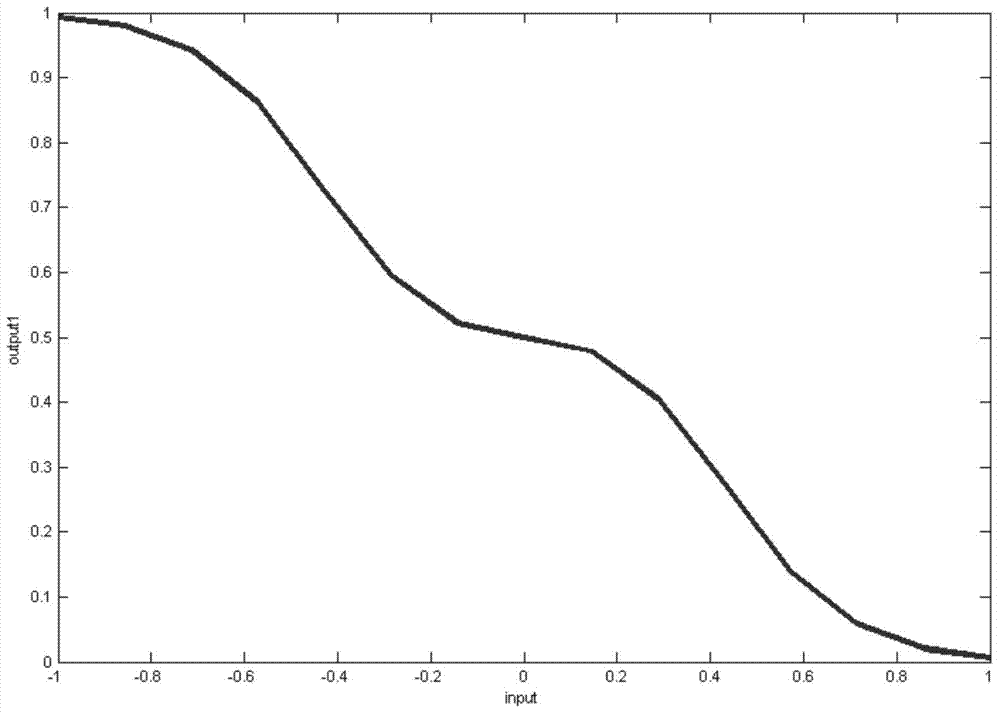

[0030] Combine below Figure 1 to Figure 4 The preferred embodiment of the method for controlling the electronically controlled pump of the excavator according to the present invention will be described.

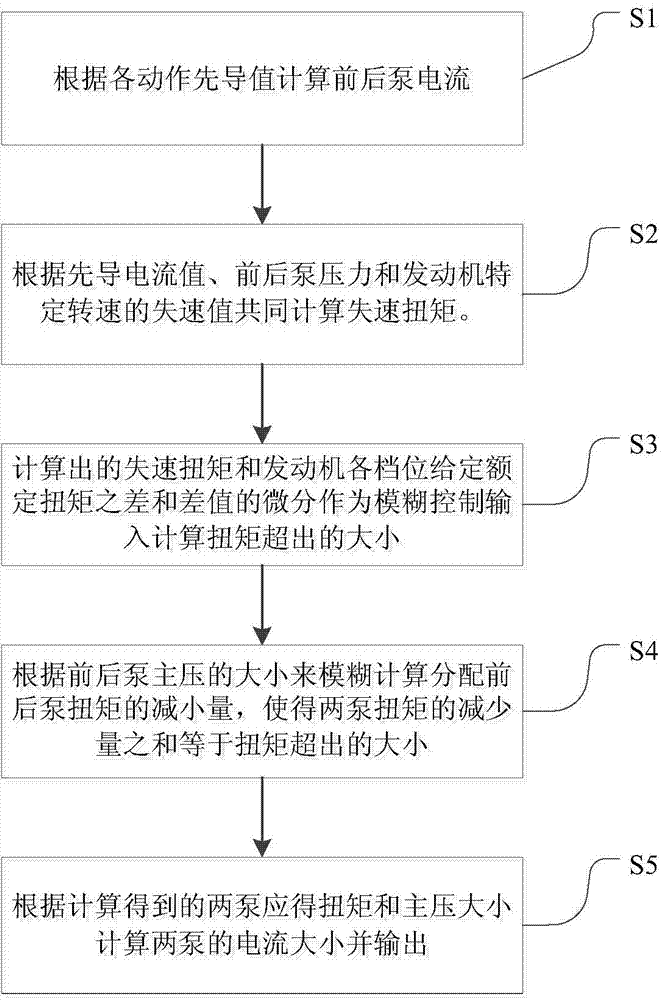

[0031] The current control algorithm of the front and rear pumps of the electronically controlled pump is mainly calculated based on the main pressure of the front and rear pumps, current feedback of the front and rear pumps, each action pilot, working mode, engine gear and speed. Its specific control process is as follows: figure 1 shown.

[0032] After relying on the engine, hydraulic pump and the pilot handle sensor to obtain all the required input acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com