A three-phase asynchronous motor with improved stall torque and reduced stall current

A locked-rotor current, three-phase asynchronous technology, used in asynchronous induction motors, electric components, and connection with control/drive circuits, etc., can solve problems such as waste of resources, save maintenance time, improve locked-rotor torque, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and specific examples.

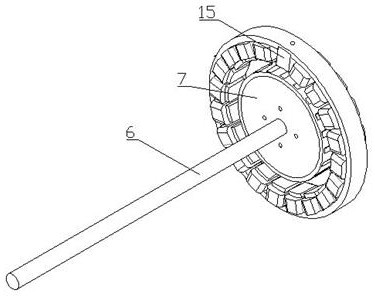

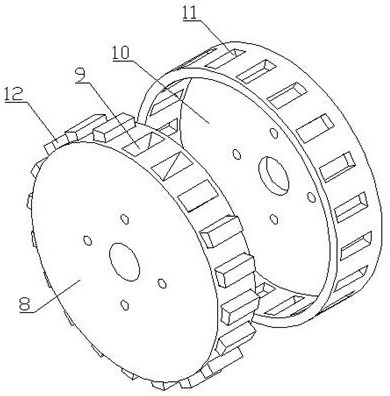

[0019] Such as Figure 1-7 As shown, a three-phase asynchronous motor that improves the blocking torque reduces the plug current, including the seat 1, the end cover 2, the casing 3, the rectifier 4, the junction box 5, the rotating shaft 6, the eccentric drive portion 7, the The front end of the seat 1 has a vertical end cap 2 by bolts, and the rear end is mounted with a horizontal casing 3 by bolts, and the front right end of the base 1 is fixed to a level of rectifier 4, the rectifier 4 The right end is fixed to a horizontal junction box 5, and the interior of the base 1 has a horizontal rotating shaft 6, and an eccentric drive portion 7 is mounted inside the base 1.

[0020] The eccentric drive portion 7 includes an eccentric mount 8, an eccentric mounting groove 9, a restricted seat 10, an eccentricary slot 11, a limit magnet 12, an eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com