Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Solidification microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

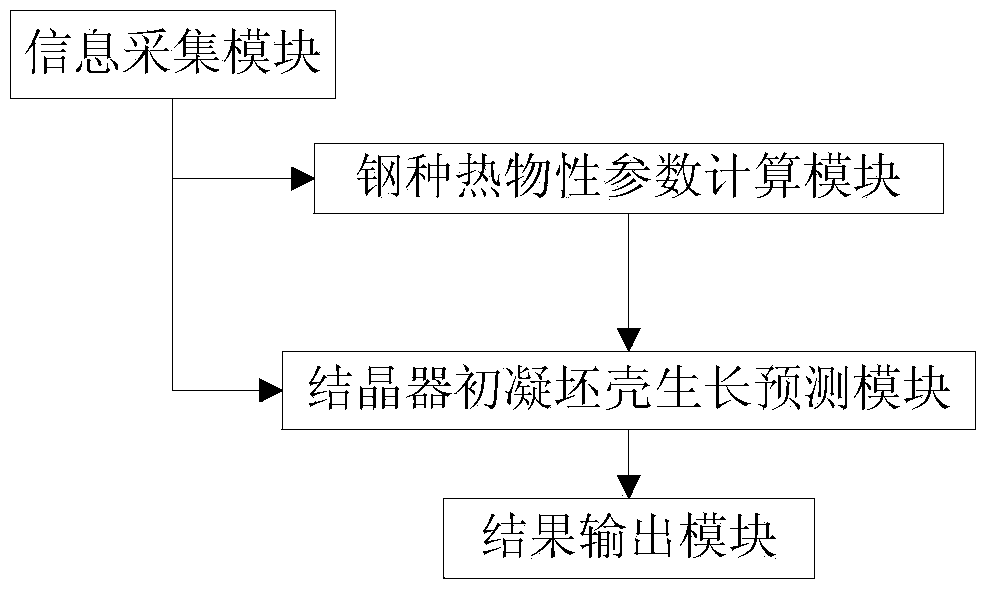

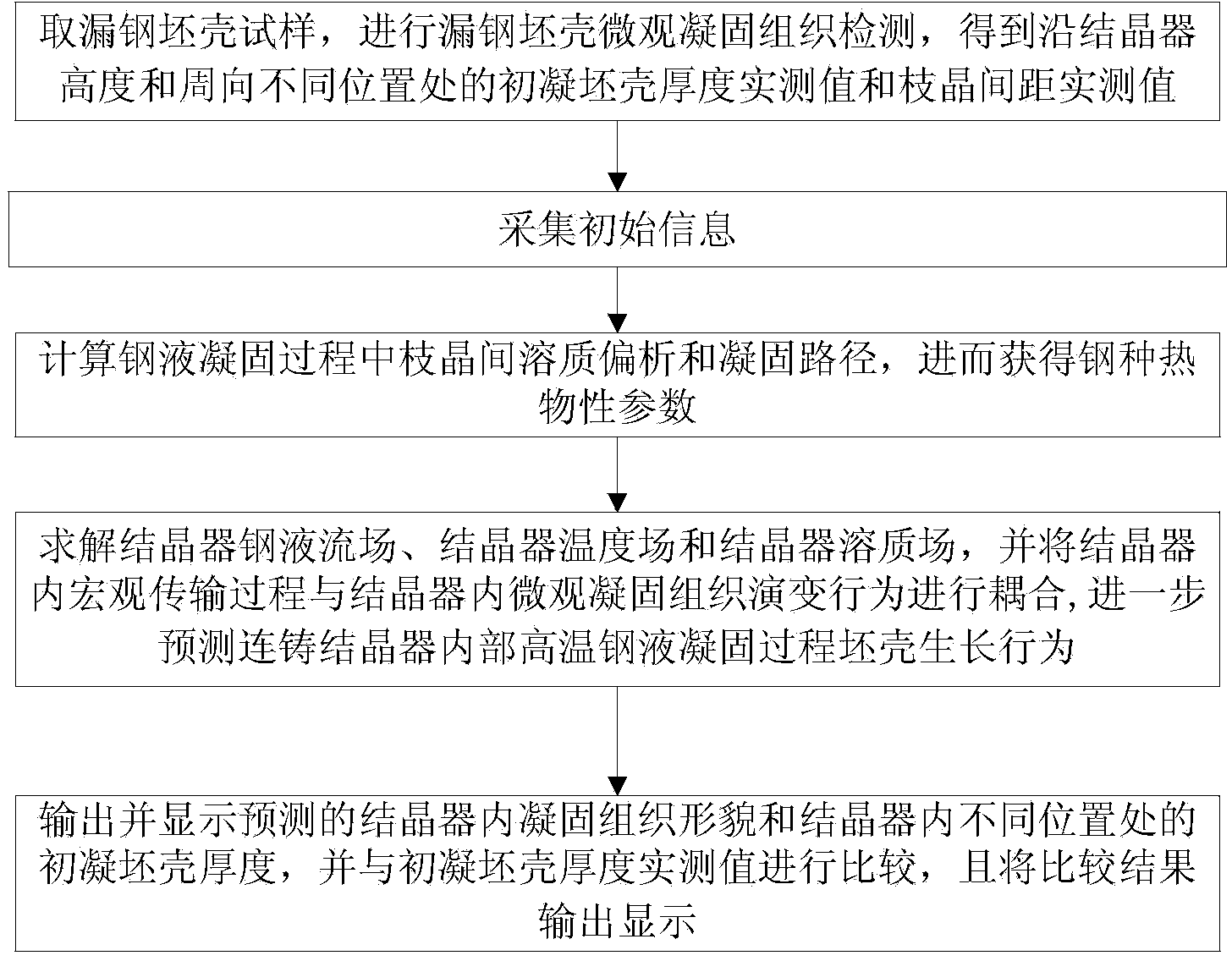

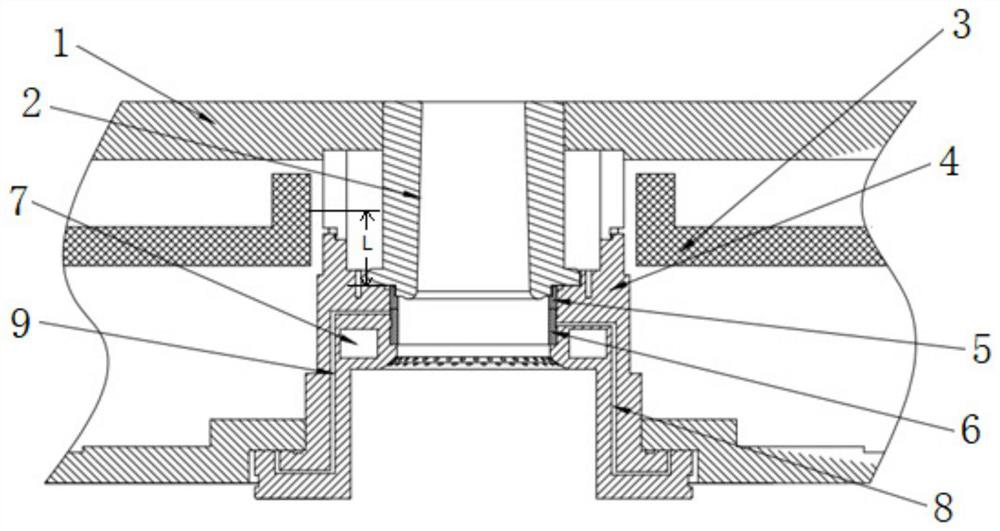

Prediction system and method for thickness of initially solidified shell in continuous steel casting crystallizer

ActiveCN104384469APredict growth behaviorPredicting Microscopic Solidification BehaviorMetallurgyPrediction system

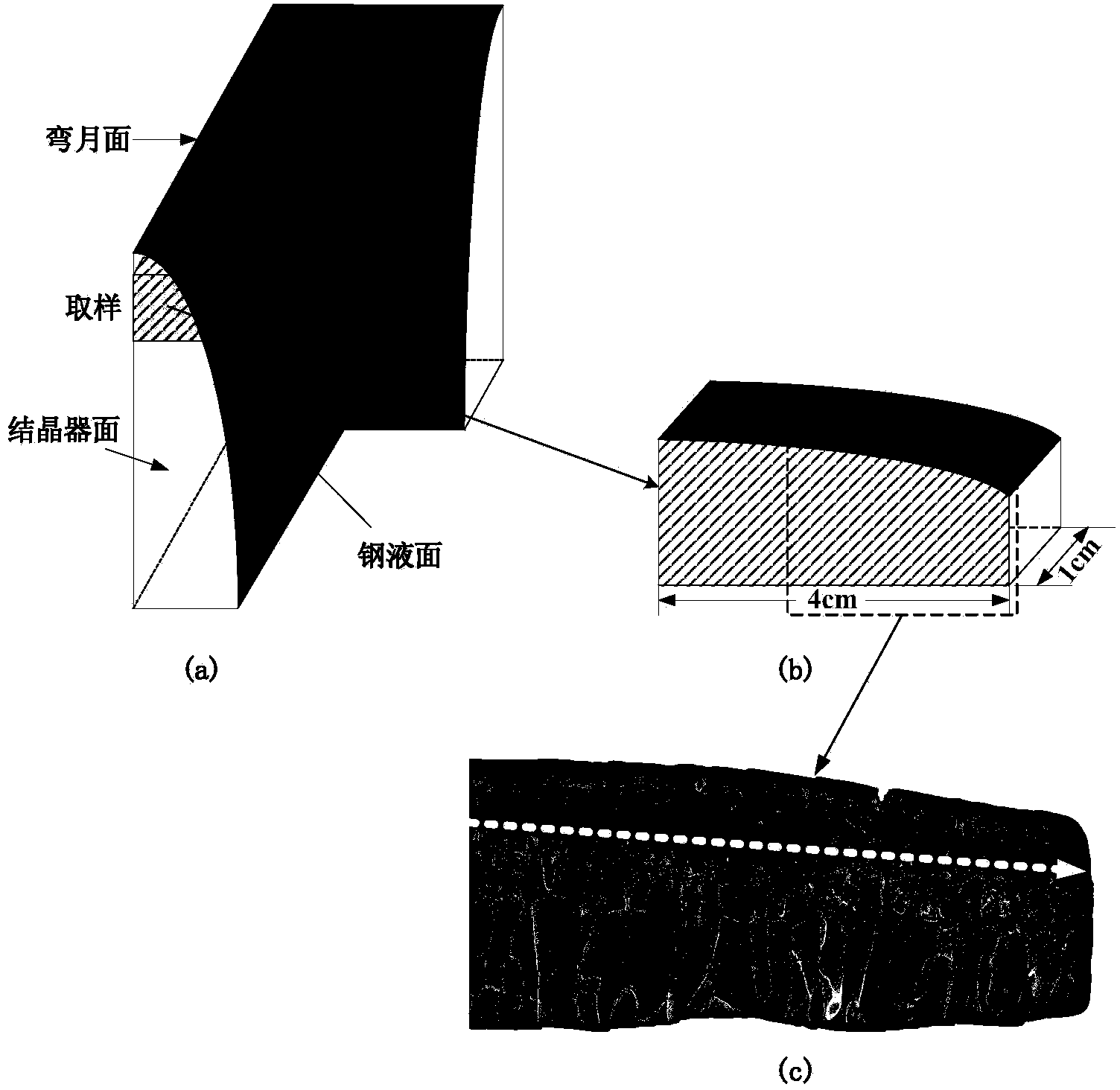

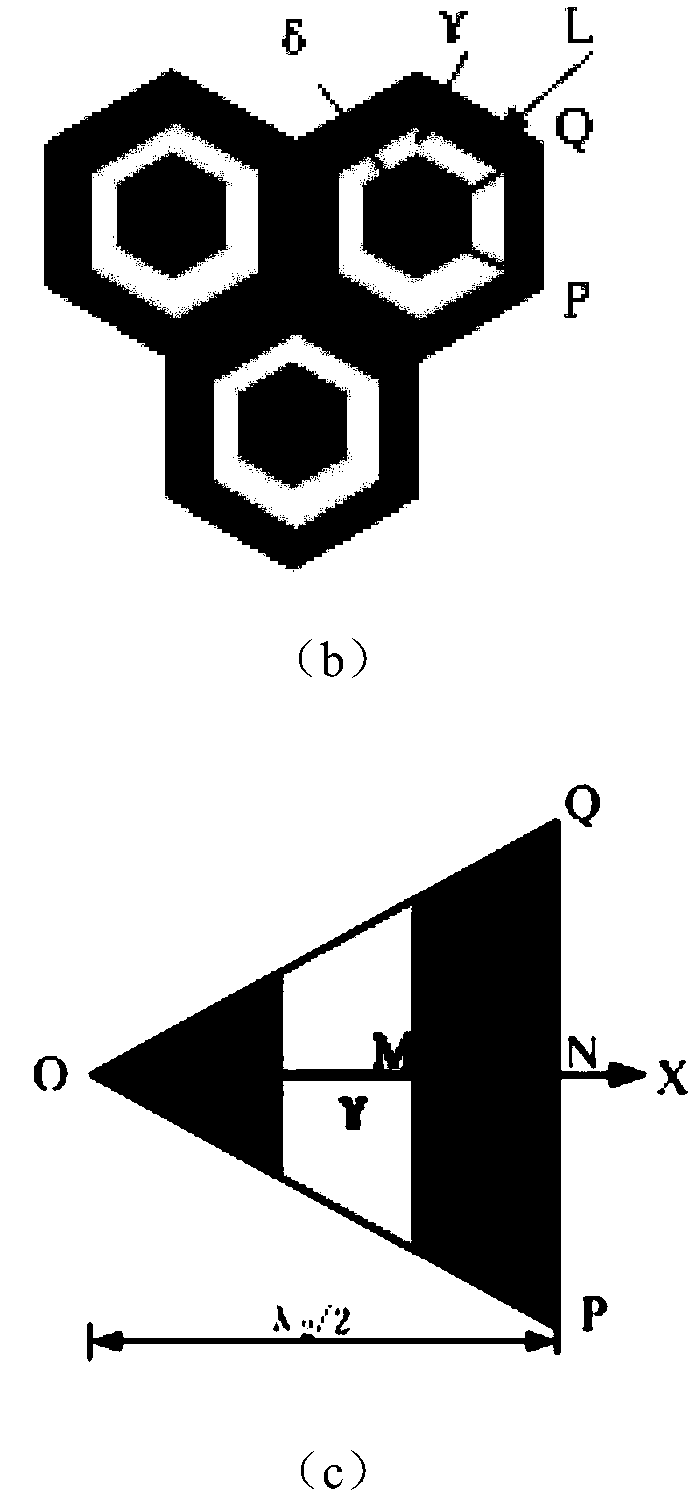

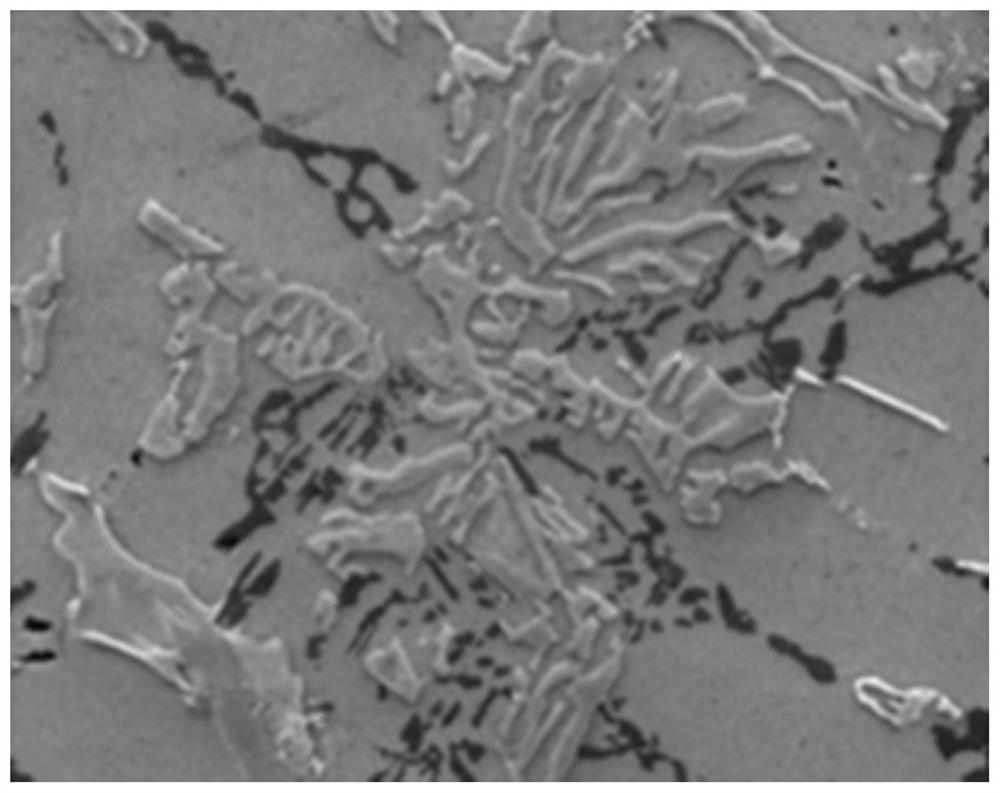

The invention provides a prediction system and method for the thickness of an initially solidified shell in a continuous steel casting crystallizer. The system comprises an information collection module, a steel grade thermophysical parameter calculation module, a crystallizer initially solidified shell growth prediction module and a result output module. The method comprises the following steps: detecting a bleed-out shell microcosmic solidification structure; collecting initial information; computing the interdendritic solute segregation and solidification path in a molten steel solidification process to obtain a steel grade thermophysical parameter; solving a crystallizer molten steel flow field, a crystallizer temperature field and a crystallizer solute field, coupling a macroscopic transport process in the crystallizer and the evolution behavior of the microcosmic solidification structure in the crystallizer, and further predicting the shell growth behavior in the solidification process of high-temperature molten steel in the continuous steel casting crystallizer; outputting and displaying the comparative results of the predicted morphology of the solidification structure in the crystallizer, the predicted initially solidified shell thicknesses in different positions in the crystallizer and the actual thickness of the initially solidified shell. The system and the method can accurately predict the microcosmic solidification behavior of the initially solidified shell in the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

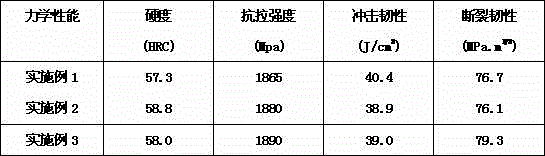

H13 die steel and preparation method thereof

The invention relates to H13 die steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The H13 die steel comprises the following chemical elements in percentage by weight: 0.40 to 0.46 percent of C, 6.00 to 6.30 percent of Cr, 0.50 to 0.65 percent of V, 0.30 to 0.45 percent of Mo, 0.85 to 1.05 percent of Mn, 1.25 to 1.55 percent of Si, 0.12 to 0.25 percent of W, 0.008 to 0.018 percent of Nb, 0.008 to 0.015 percent of Ta, 0.08 to 0.12 percent of Ti, 0.003 to 0.006 percent of B, 0.08 to 0.15 percent of Al, 0.03 to 0.06 percent of N, 0.06 to 0.12 percent of Y, less than 0.025 percent of S, less than 0.030 percent of P and the balance of Fe. The H13 die steel has the advantages that: the content of precious alloy elements, namely molybdenum and vanadium is low, the H13 die steel is not required to be forged, and forging can be replaced by casting, so that the cost of the H13 steel is obviously reduced; the performance of the H13 steel can be obviously improved, and a tungsten slag iron alloy is recycled; a solidification structure can be obviously refined, and the mechanical property of the H13 steel is improved; and the H13 steel has high wear resistance and is used as a hot working die, and the service life is prolonged.

Owner:江苏环立板带轧辊有限公司

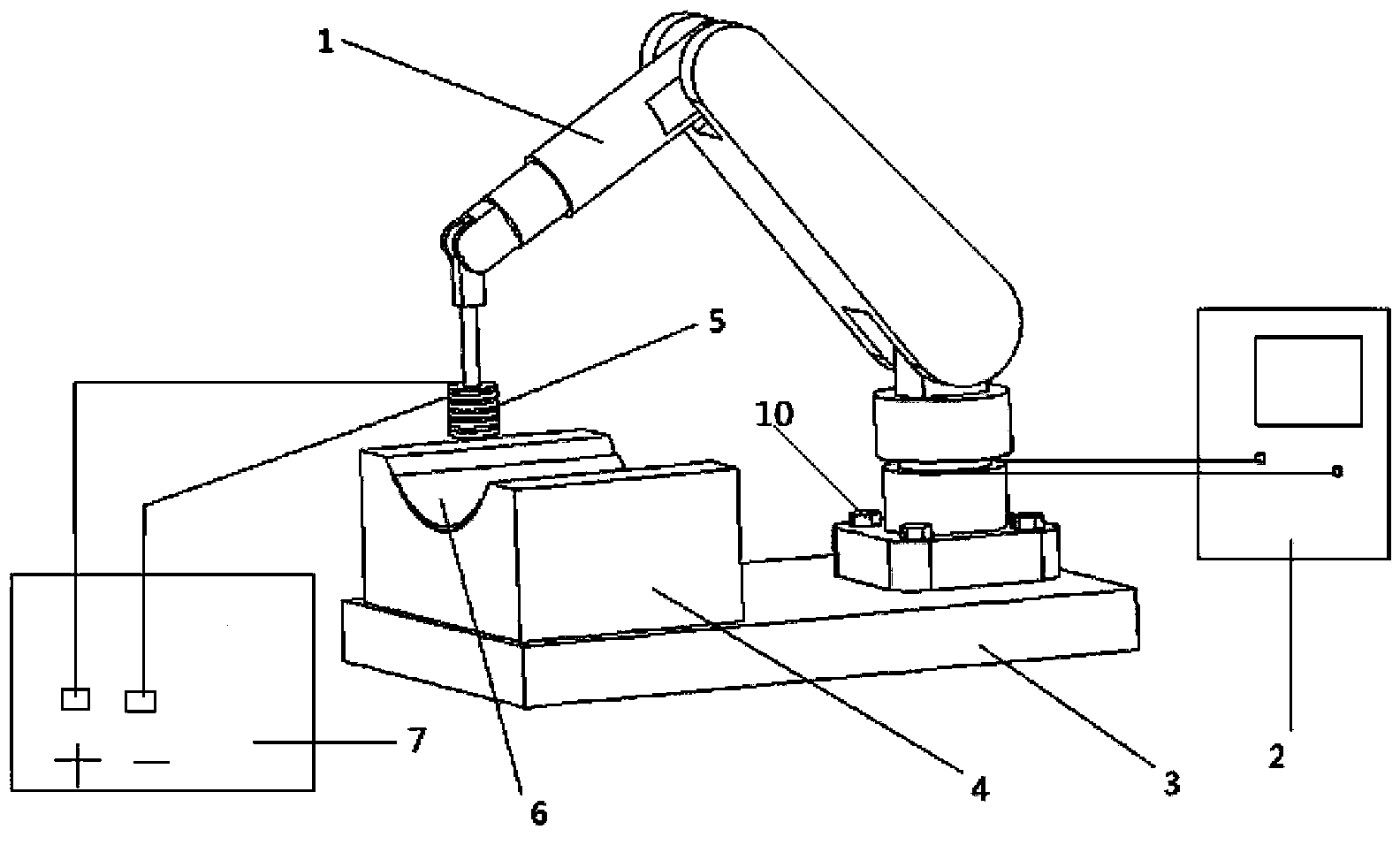

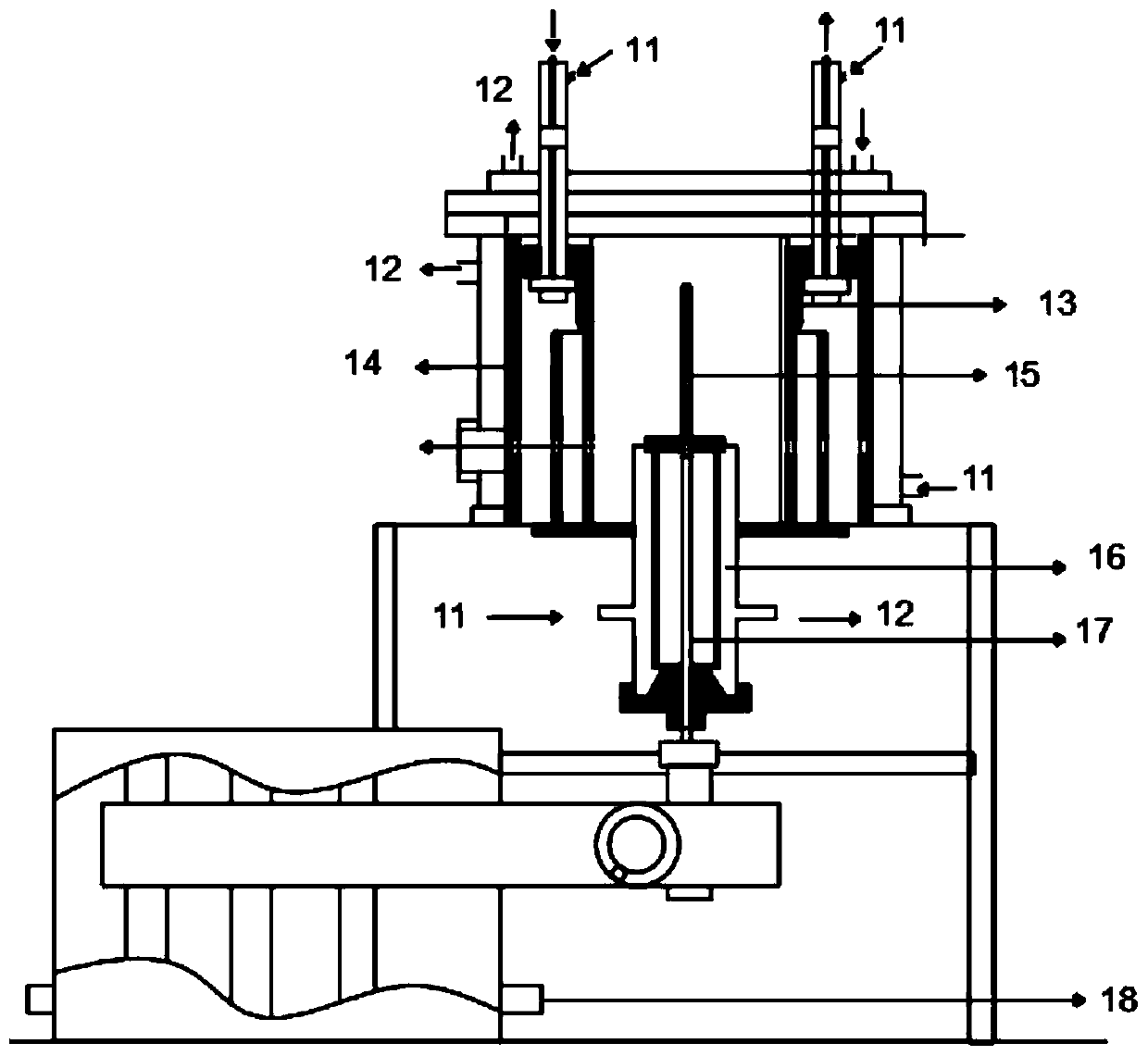

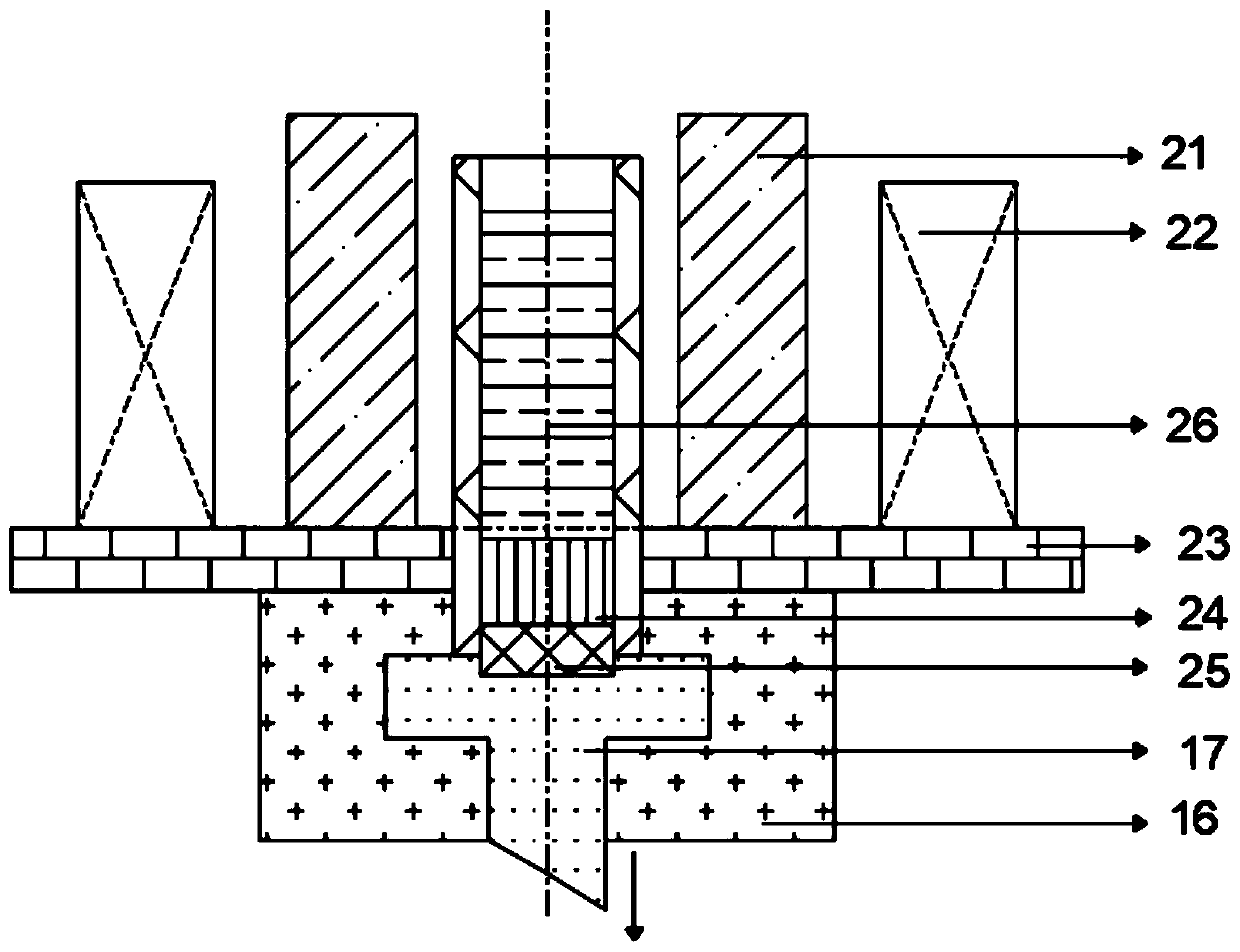

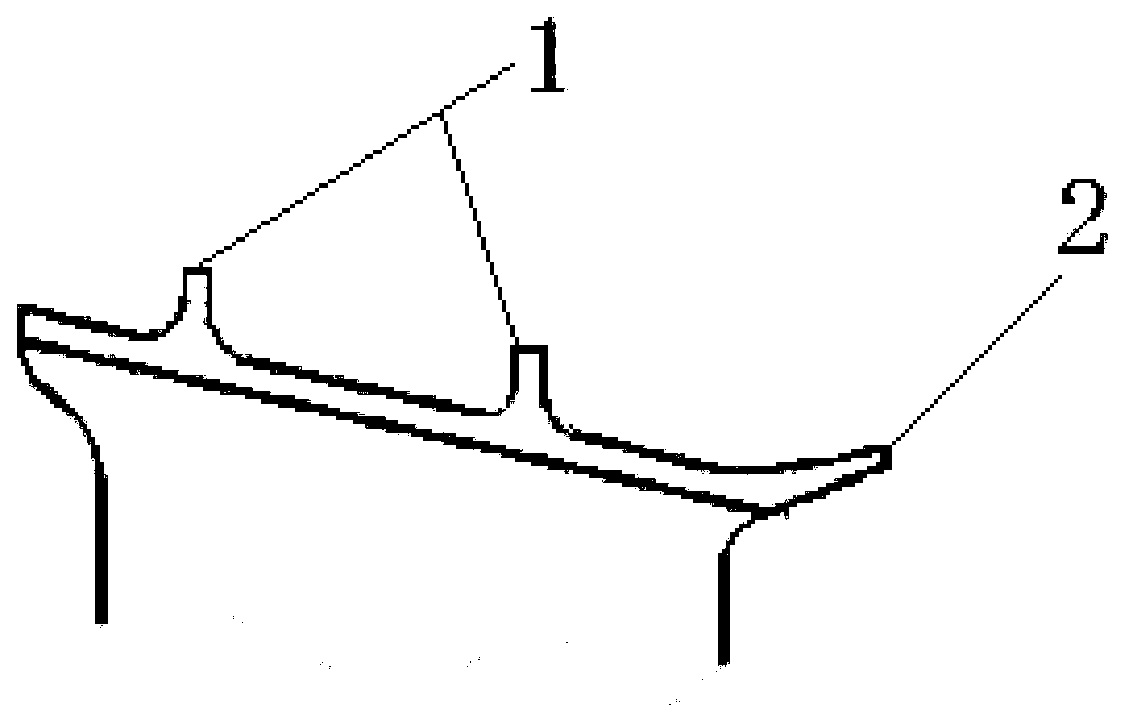

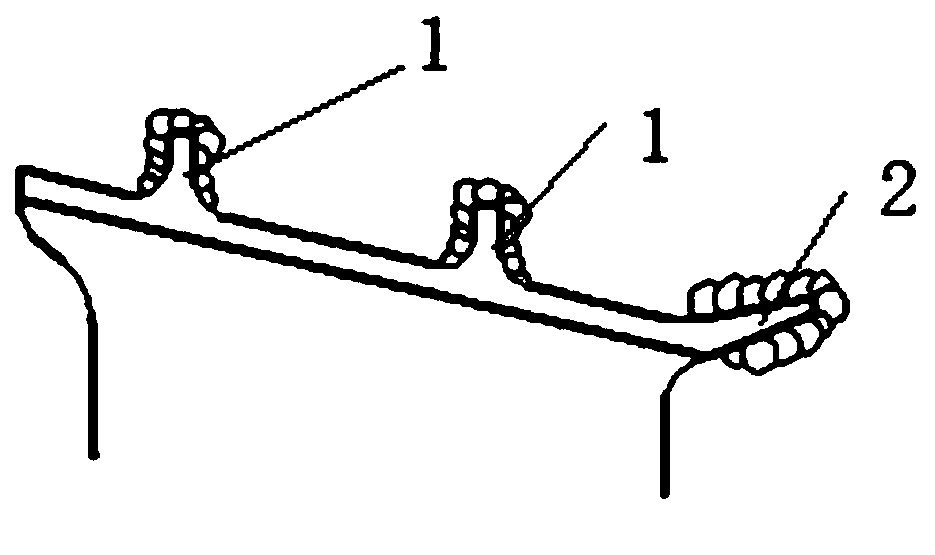

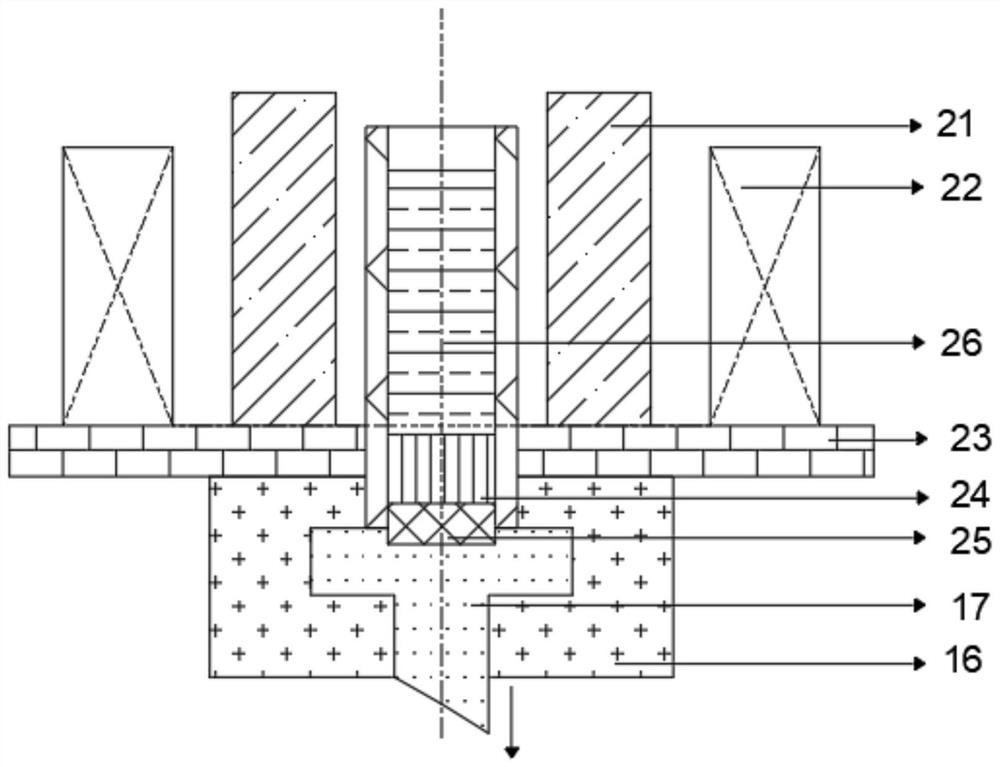

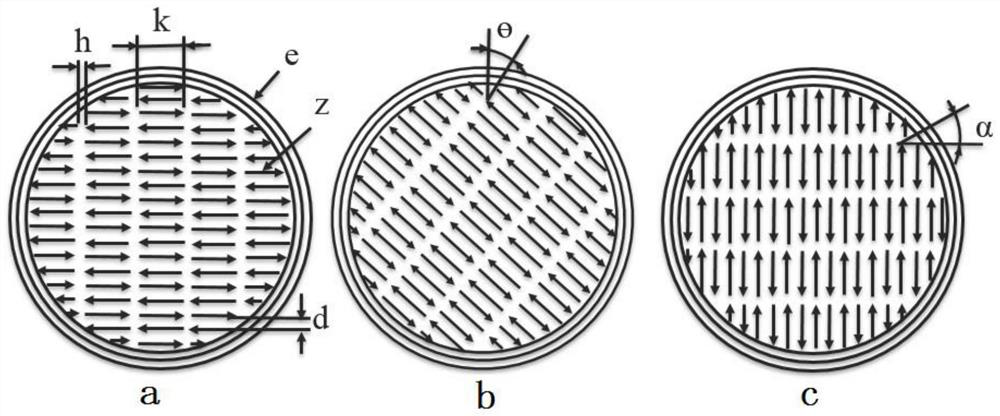

Forming device and forming method of electromagnetic induction assisting prestress

InactiveCN103406419AEasy to transformAchieving Electroplastic Bending FormingMetallic materialsEngineering

The invention discloses a forming device and a forming method of electromagnetic induction assisting prestress. A forming mold and a manipulator are fixed on the upper portion of a base. An electromagnetic coil is mounted at the chuck part of the manipulator, wire connecting of an electromagnetic induction control system is completed correspondingly, the electromagnetic coil is ensured to generate a pulsed magnetic field successfully in the forming process, and induced current is generated on a sheet material. The sheet material is placed on the mold, and a vacuum bag is placed on the sheet material and is evacuated through an evacuating device, so that the sheet material is pressed on the mold tightly, and effect of vacuum compaction is achieved. A computer control system is operated to form the electromagnetic induction assisting prestress. According to the forming device, when the pulsed magnetic field of the inducing coil penetrates a workpiece, the workpiece generates the induced current, plastic deformation capacities of metal materials are improved by the current, crystallizing process of amorphous alloy is promoted, solidification structure of the alloy is refined, deforming resistance during the forming process is reduced, springback amount is reduced, forming accuracy and comprehensive mechanical properties are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

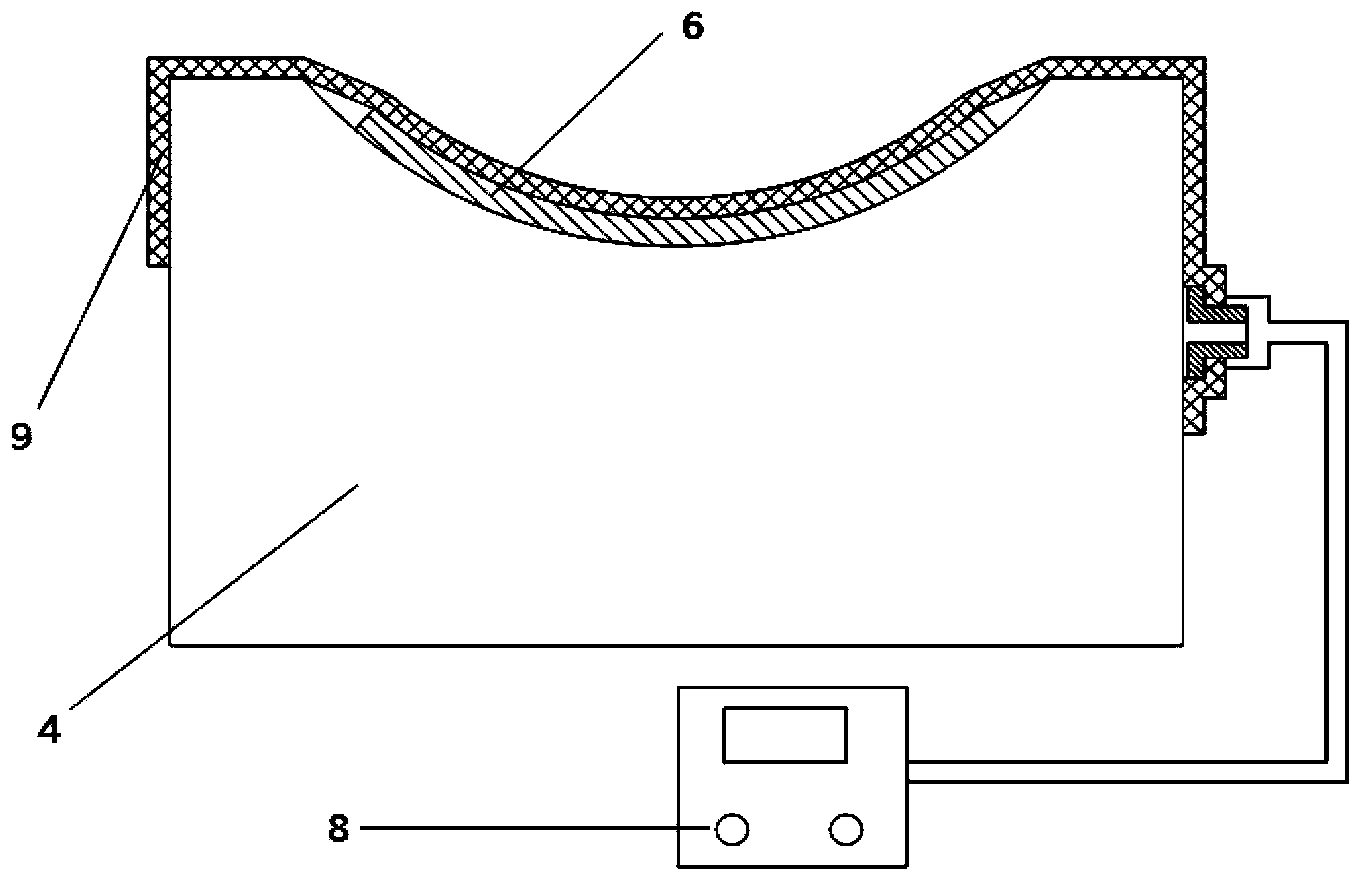

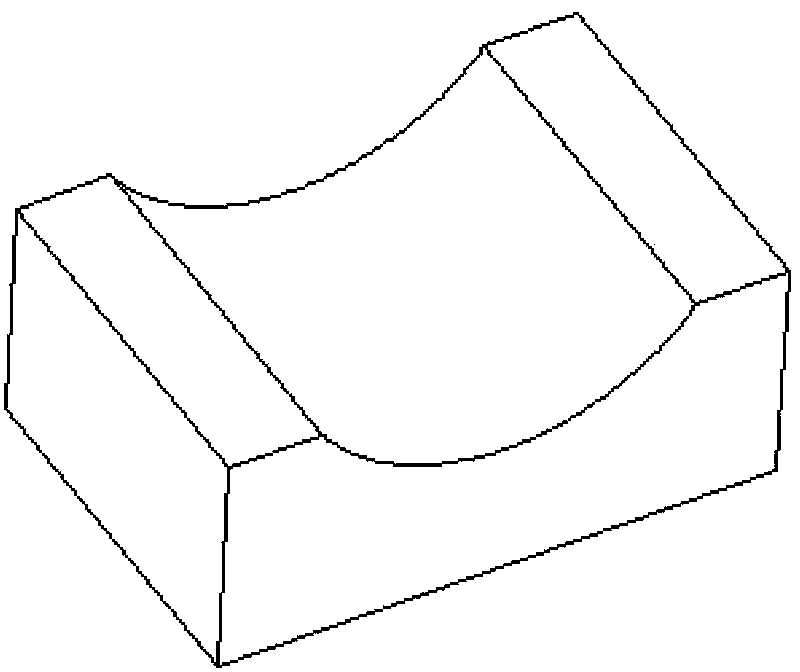

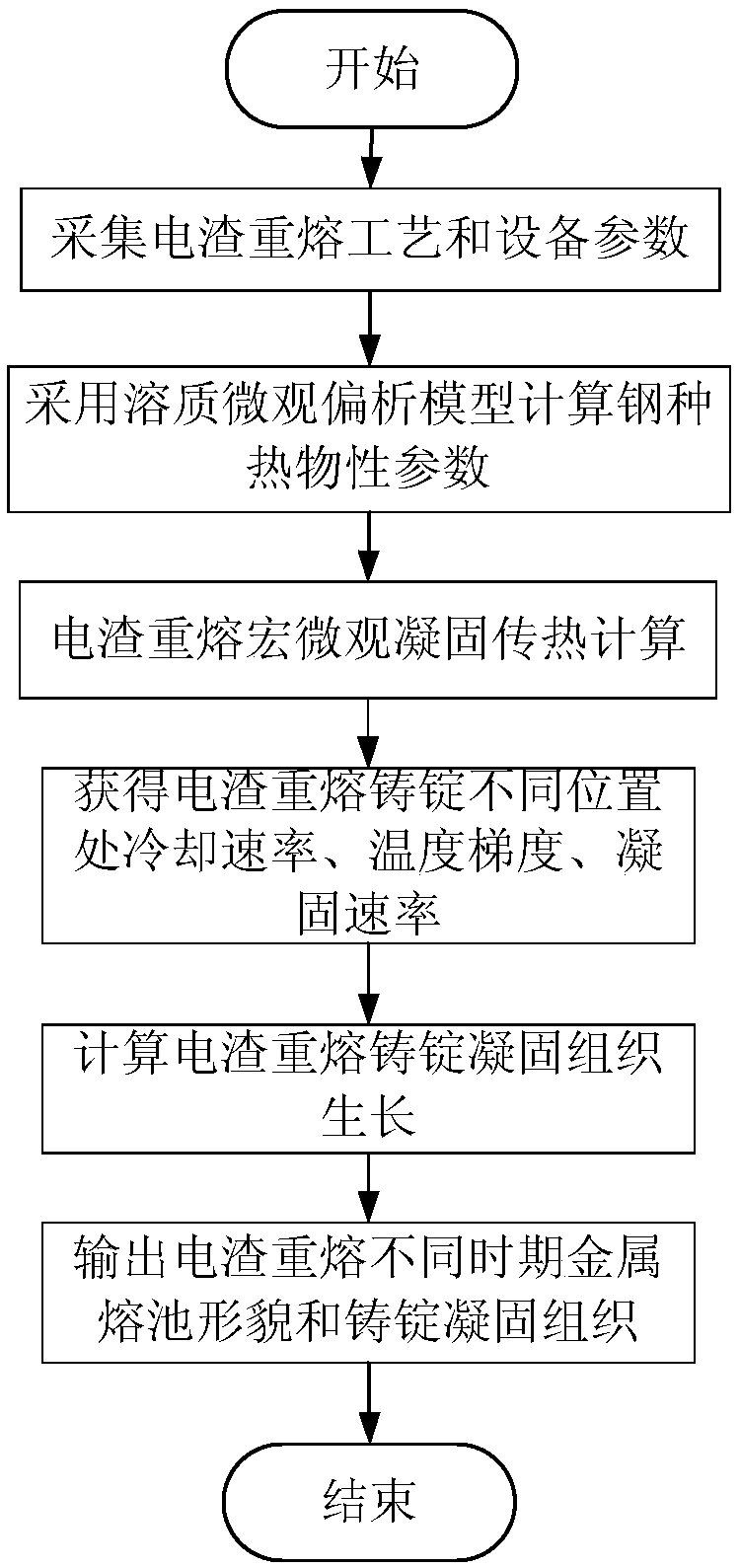

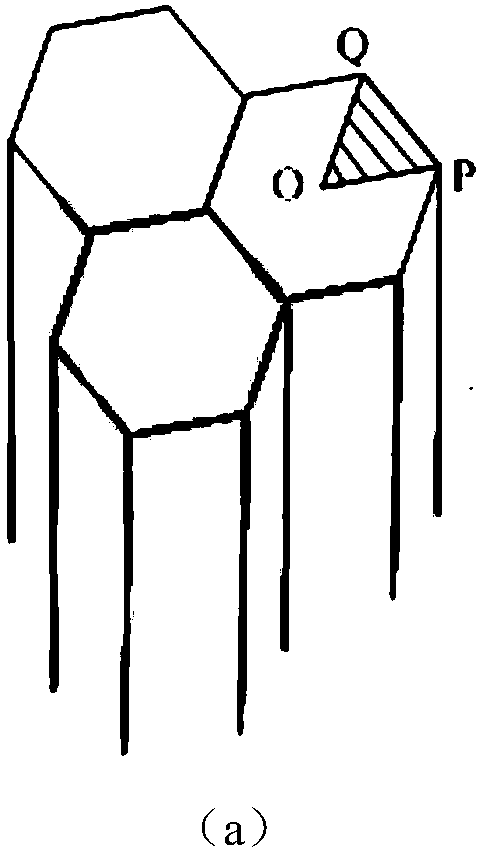

Method for predicting solidification microstructure of electroslag remelting ingot

InactiveCN108897972ALow costImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsMathematical modelProcess conditions

The invention provides a method for predicting solidification microstructure of electroslag remelting ingot, which relates to the technical field of metallurgical smelting. A method for predict solidification microstructure of electroslag remelting cast ingot include collecting equipment parameters and process parameter of electroslag remelting, and obtaining thermophysical parameter data of steelgrade by adopting solute microsegregation model according to composition of electroslag remelting steel grade; Then a macro-and micro-scale mathematical model of ESR process is established. Finally,the parameters of electroslag remelting process and thermophysical parameters of steel are used as the input values of macro-and micro-scale mathematical model of electroslag remelting process to predict the morphology of solidification structure of ingot under different electroslag remelting process conditions. The method for predicting solidification microstructure of electroslag remelting casting ingot provided by the invention has the advantages of low cost, high efficiency, comprehensive analysis and the like compared with the experimental measurement method, and can provide intuitionistic and reliable information for optimizing electroslag remelting process conditions.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

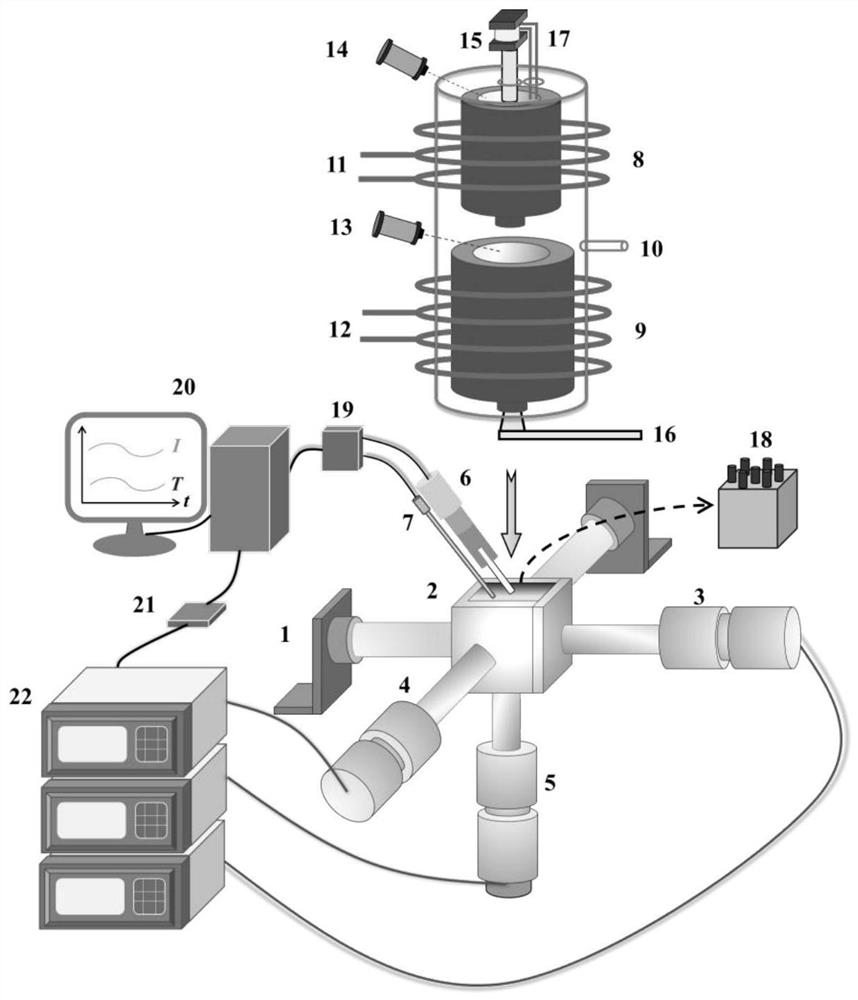

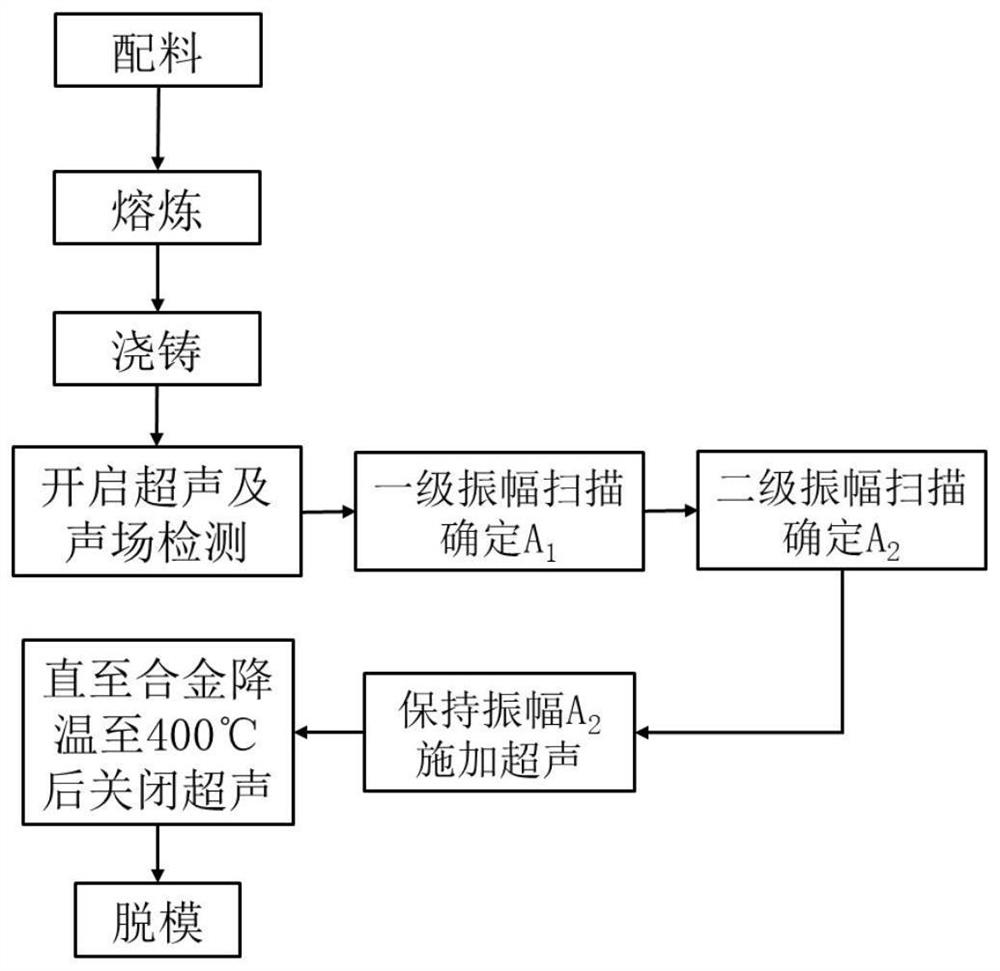

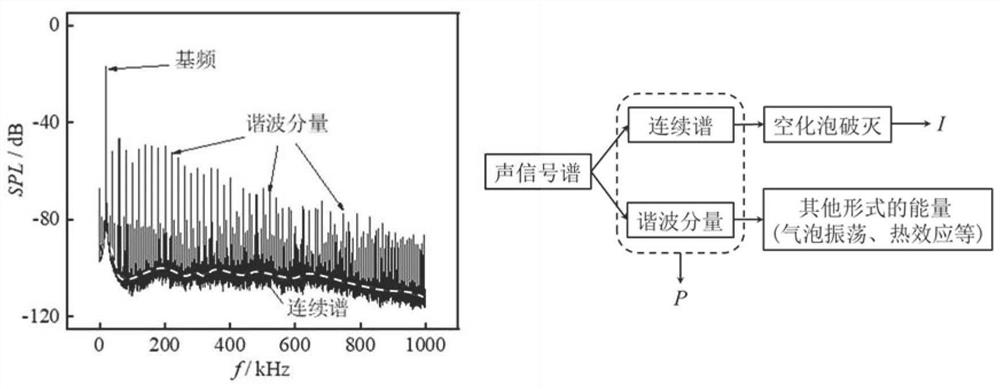

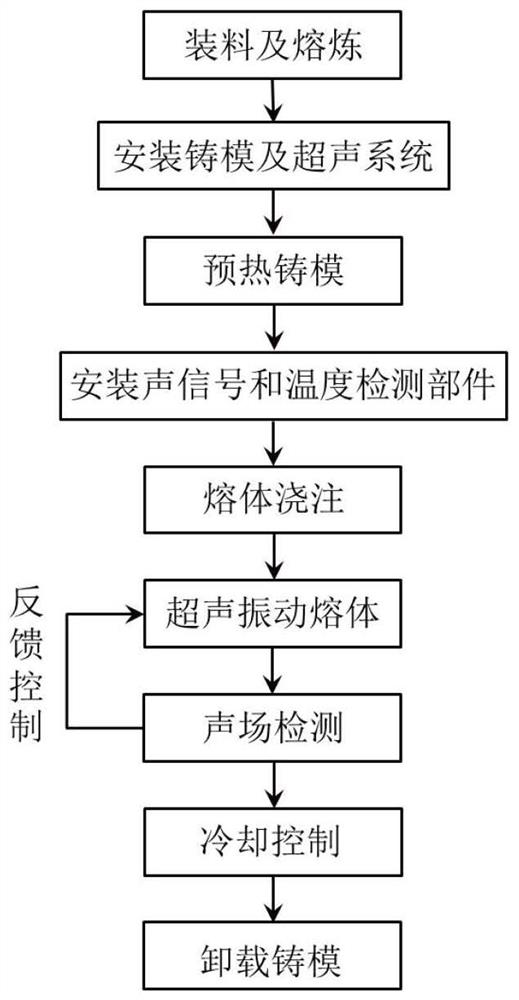

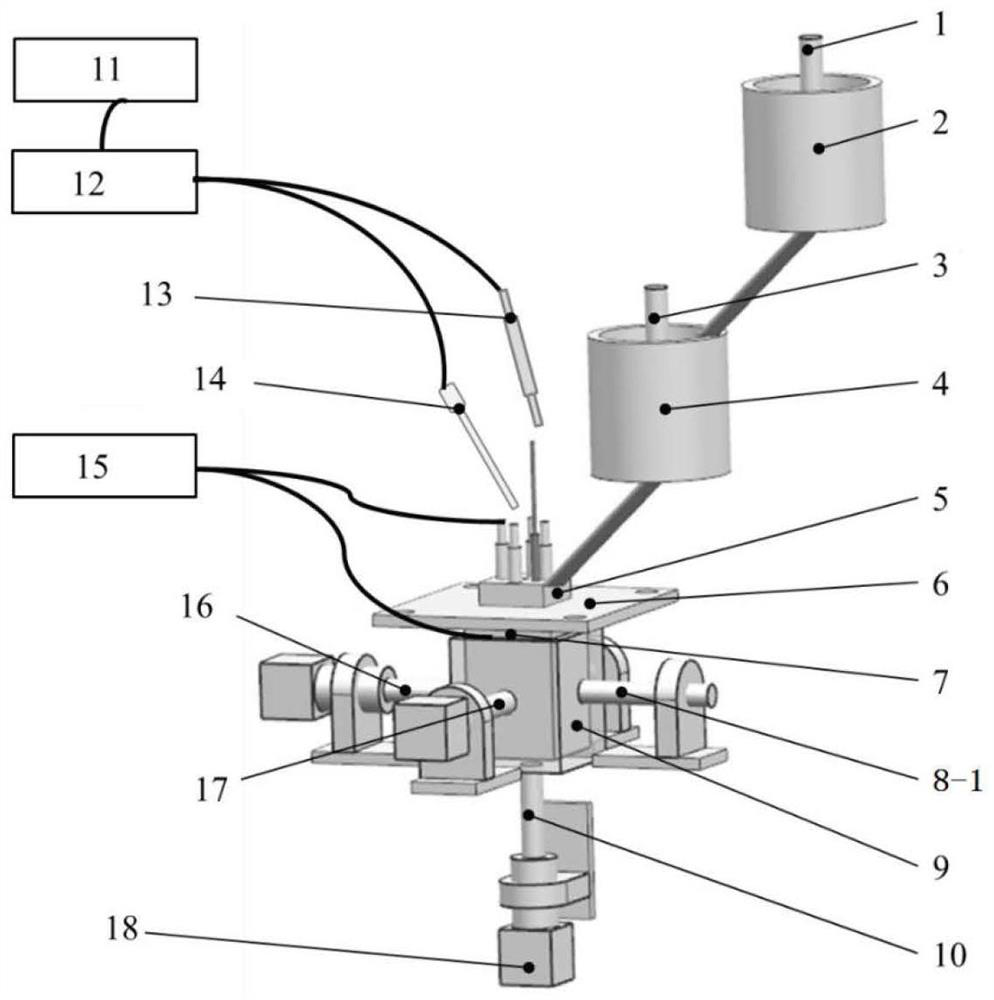

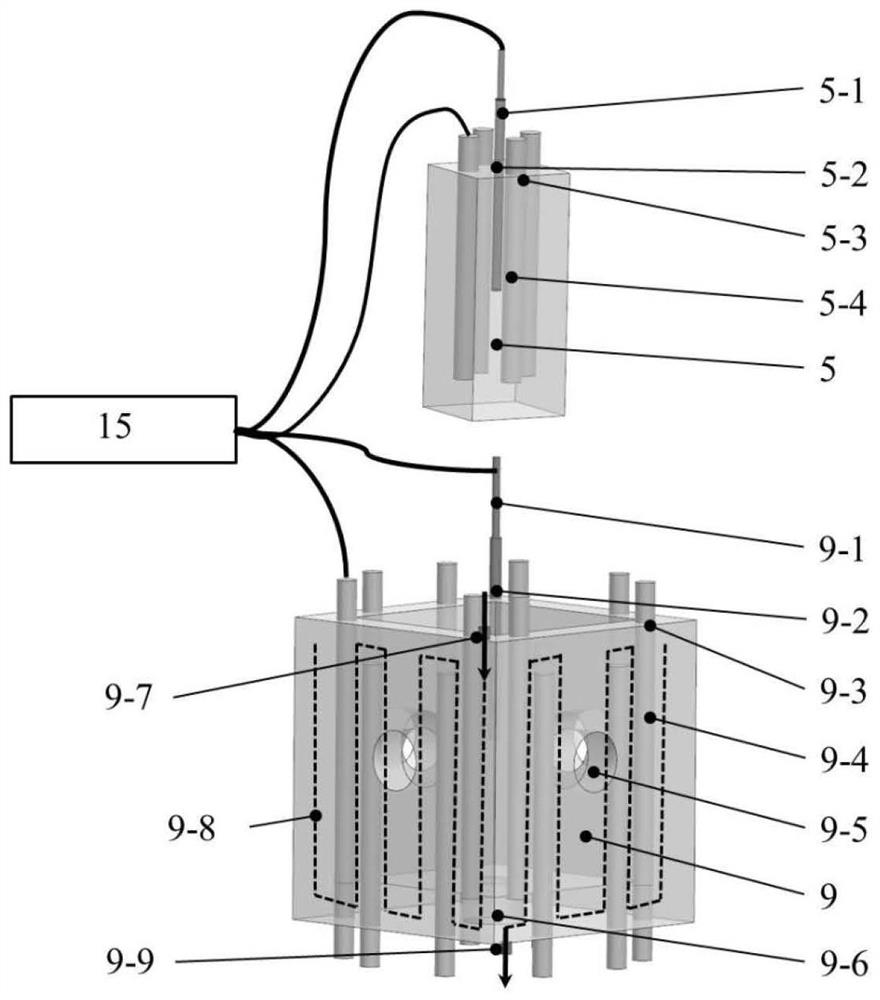

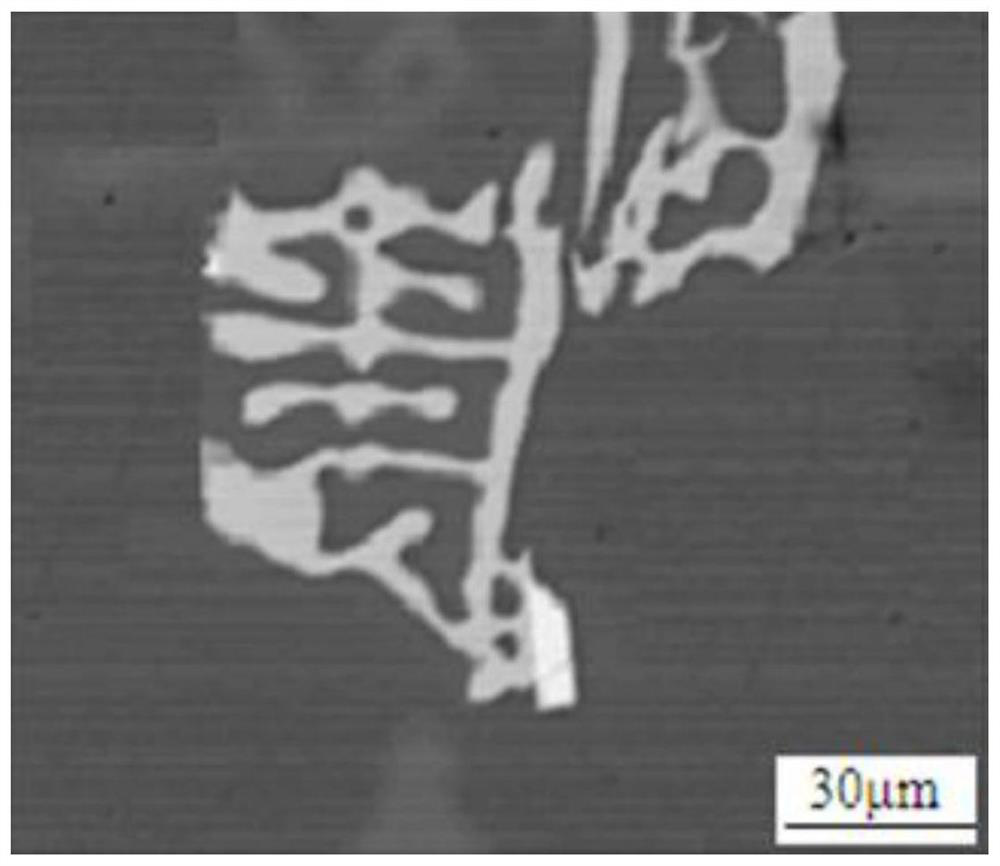

Method for preparing Mg-Al-Zn-Mn-Cu multi-component alloy through combination of three-dimensional ultrasound and sound field detection

ActiveCN114058890ASolve the problem that adding is difficult to melt evenlyLarge cavitation volumeCasting safety devicesBreaking strengthCavitation

The invention provides a method for preparing an Mg-Al-Zn-Mn-Cu multi-component alloy through combination of three-dimensional ultrasound and sound field detection, and belongs to the technical field of advanced material preparation and processing. According to the invention, a uniform and high-strength ultrasonic field is obtained in the melt by adopting a three-dimensional mutually orthogonal ultrasonic field, so that a larger cavitation volume is realized, the defects of fast ultrasonic energy attenuation and small action range of a single-beam ultrasonic wave are overcome, and the limitation of deformation and dissolution of an amplitude-change pole caused by high-temperature erosion is also overcome; through real-time monitoring of the high-temperature sound field detection system, measurement and regulation of reaction ultrasonic energy such as sound pressure and cavitation sound intensity are achieved, and regulation of alloy solidification structures and application performance is achieved. The result of the embodiment shows that the alpha-Mg structure in the alloy prepared through the method is remarkably refined, meanwhile, the beta-Mg17Al12 phase is changed into dispersed and mutually-connected net distribution, the yield strength is 113 MPa, the plastic ductility is 5.3%, and the breaking strength is 206 MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

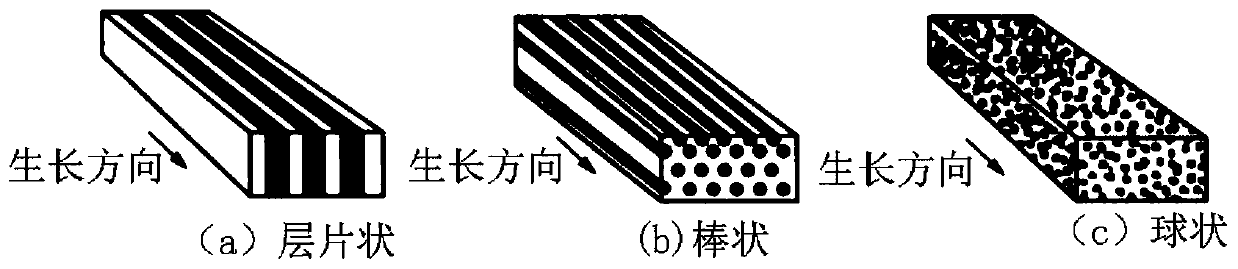

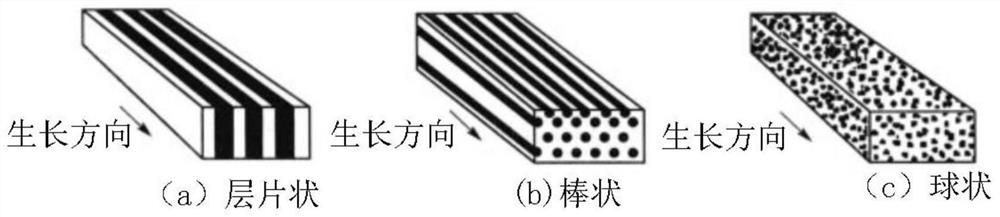

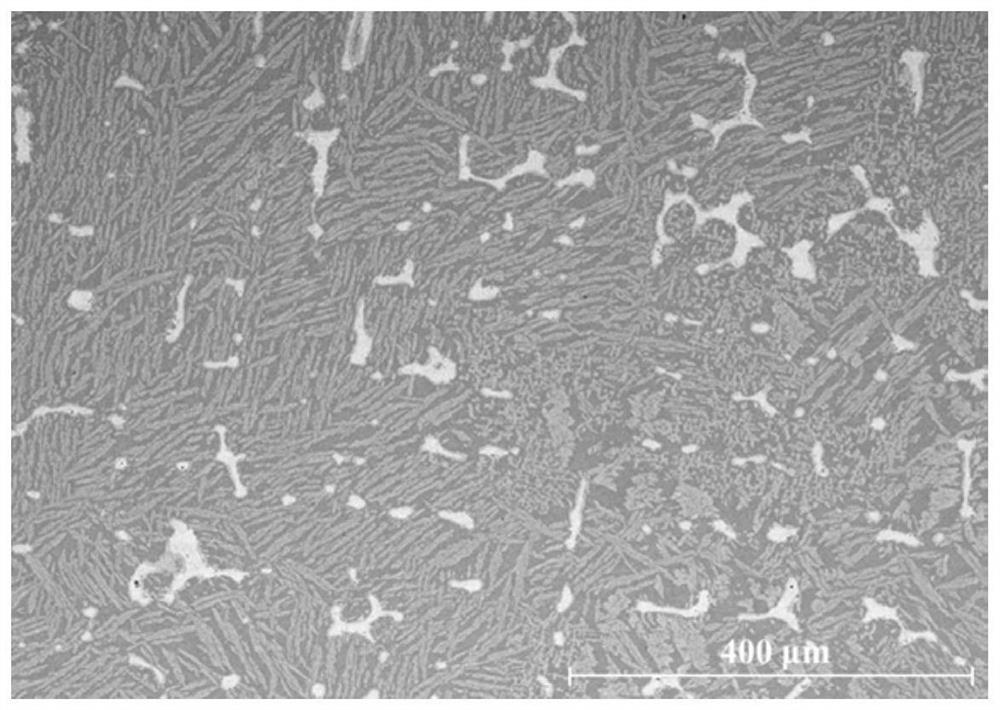

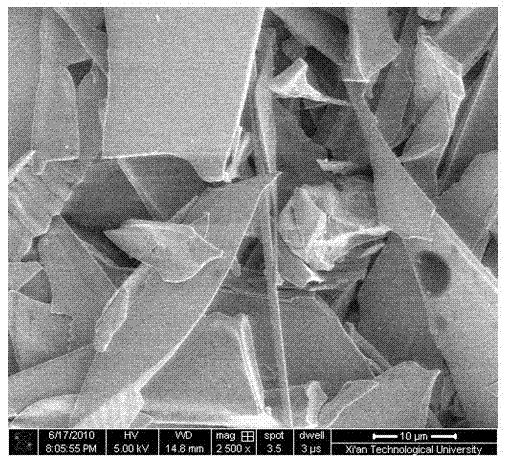

Method for preparing Fe-Al-Ta multifunctional integrated material through Bridgeman directional solidification technology

The invention discloses a method for preparing a Fe-Al-Ta multifunctional integrated material through the Bridgeman directional solidification technology. Through changing of the solidification rate of a Fe-Al-Ta ternary alloy in different areas, the solidification structure character is changed, and accordingly the Fe-Al-Ta multifunctional integrated material is obtained. In the low solidification rate, the structure is lamellar eutectic, and along with increasing of the solidification rate, the structure is converted into rod-like eutectic; and when the solidification rate is further increased, the structure is gradually converted into spherical eutectic. Since the solidification structures different in solidification rate are different in performance, the material performance can be changed by changing the solidification rates of different areas, accordingly, the material performance is centralized, simplified and diverse, the material integrating multiple functions is prepared, andthe comprehensive performance of the material is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for repairing wear and cracks of blade crown and sealing teeth of blade

ActiveCN110819982AReduce labor intensitySimple processing technologyMetallic material coating processesTurbine bladeSubstructure

Owner:AECC AVIATION POWER CO LTD

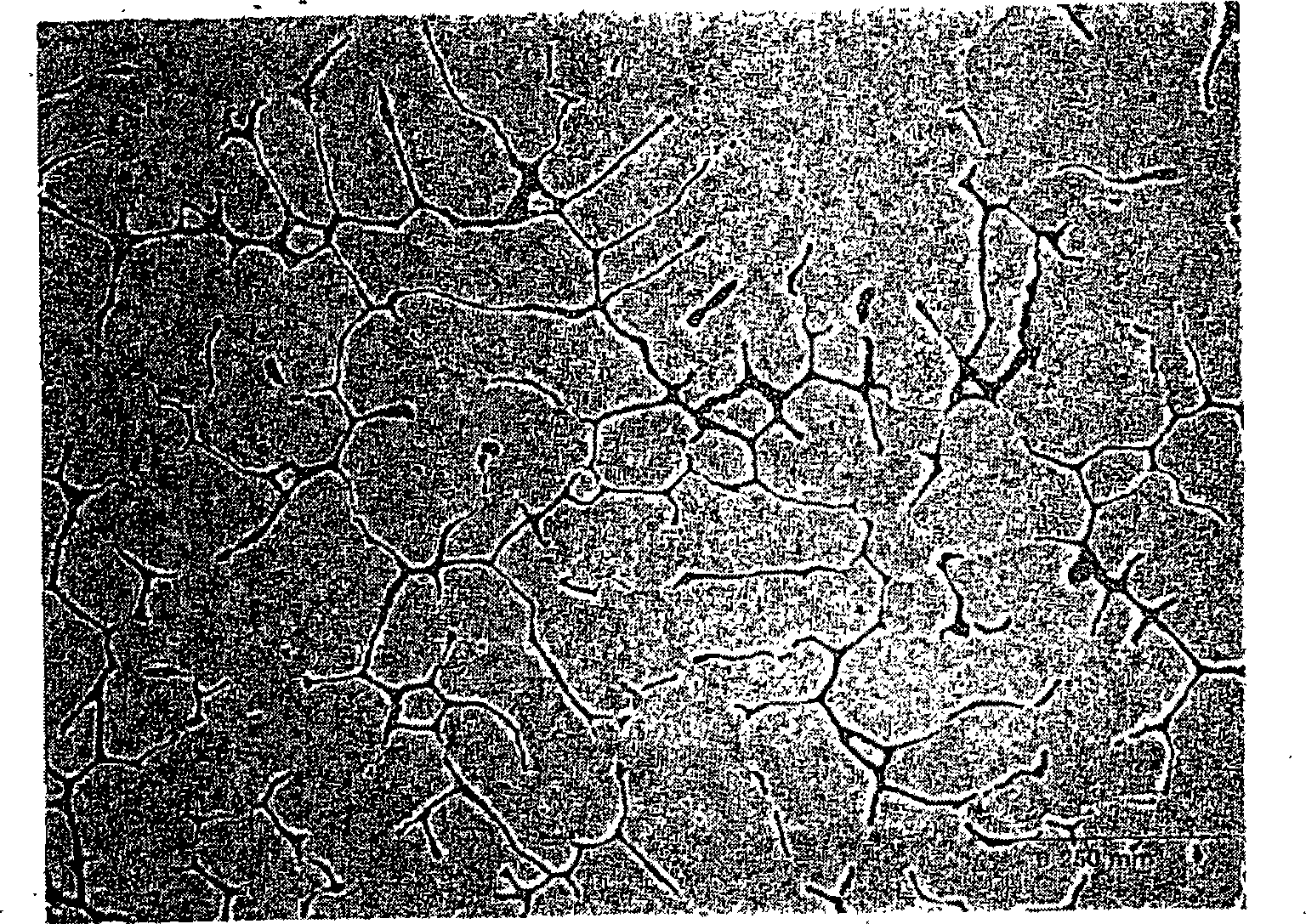

Solidification microstructure of aggregate molded shaped castings

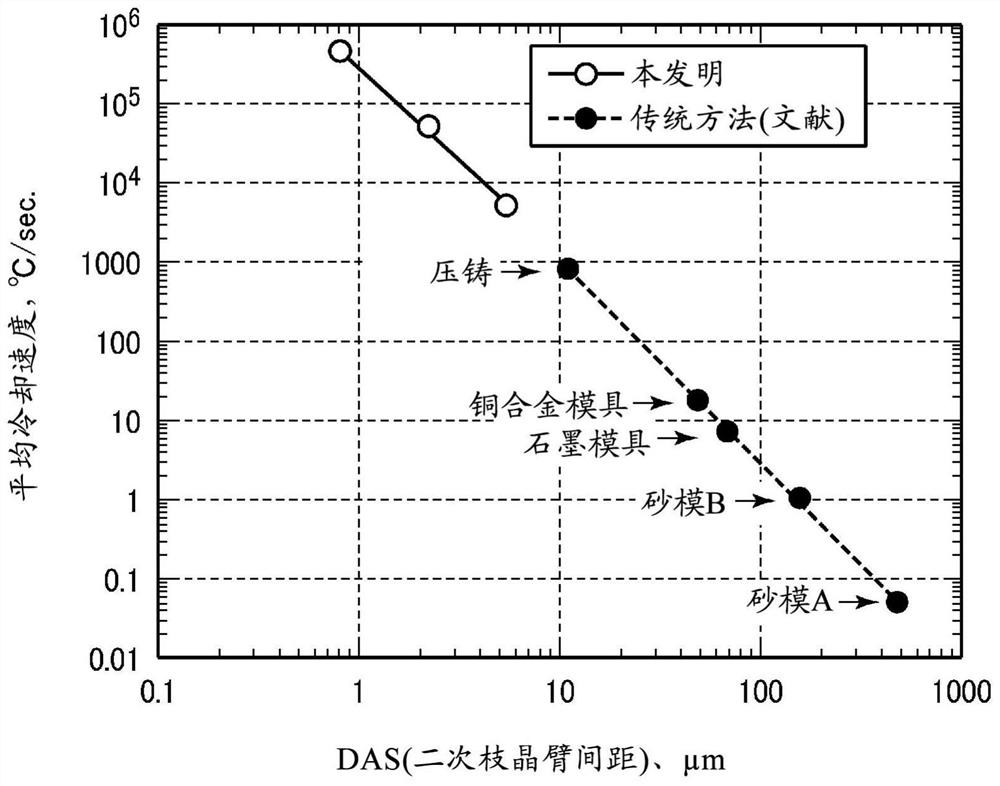

A shaped metal casting made in an aggregate mold comprises fine solidification microstructure that is finer than the solidification microstructure of an analogous metal casting made from conventional molding processes. The solidification microstructure may be up to five times finer than the solidification microstructure of a conventionally prepared casting. In preferred embodiments, as a result of directional solidification, the fine solidification microstructure is substantially continuous from a distal end of the casting to a proximal end of the casting, and exhibits greatly enhanced soundness. Because of the control of the uniformity of freezing of the casting, its properties are substantially uniform.

Owner:ALOTECH LTD +1

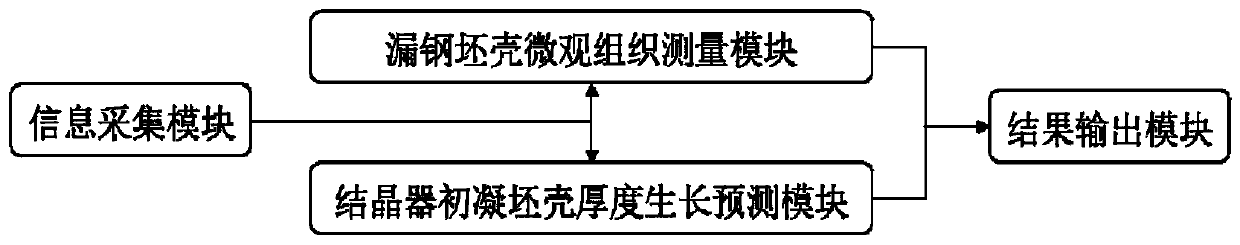

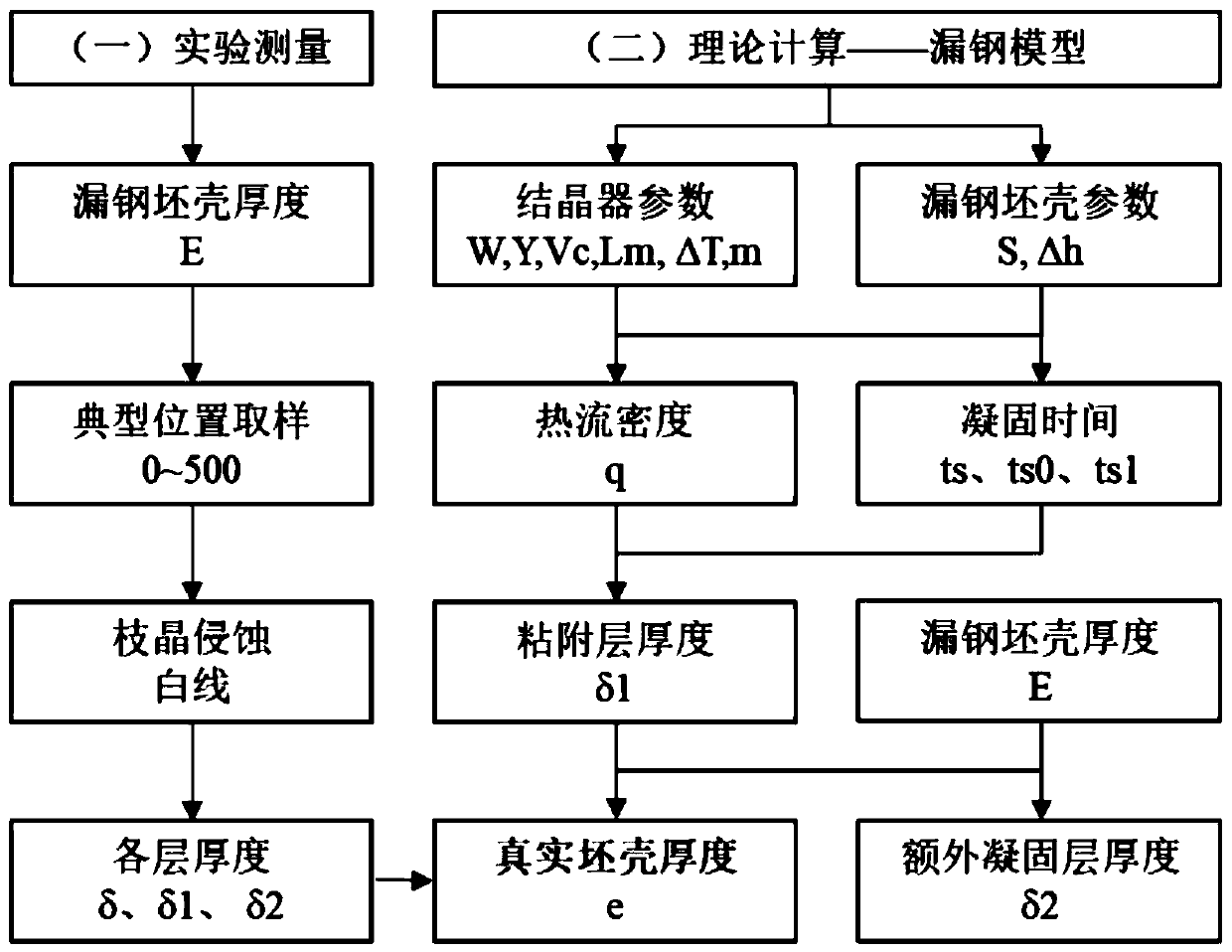

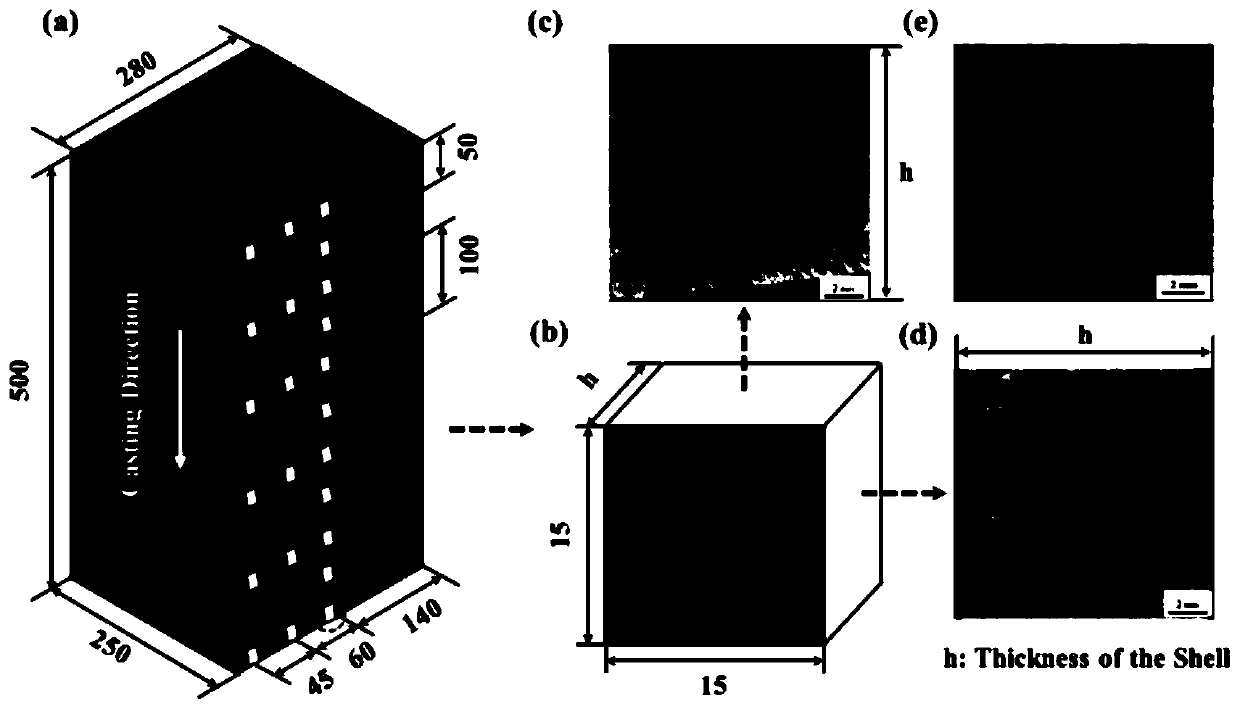

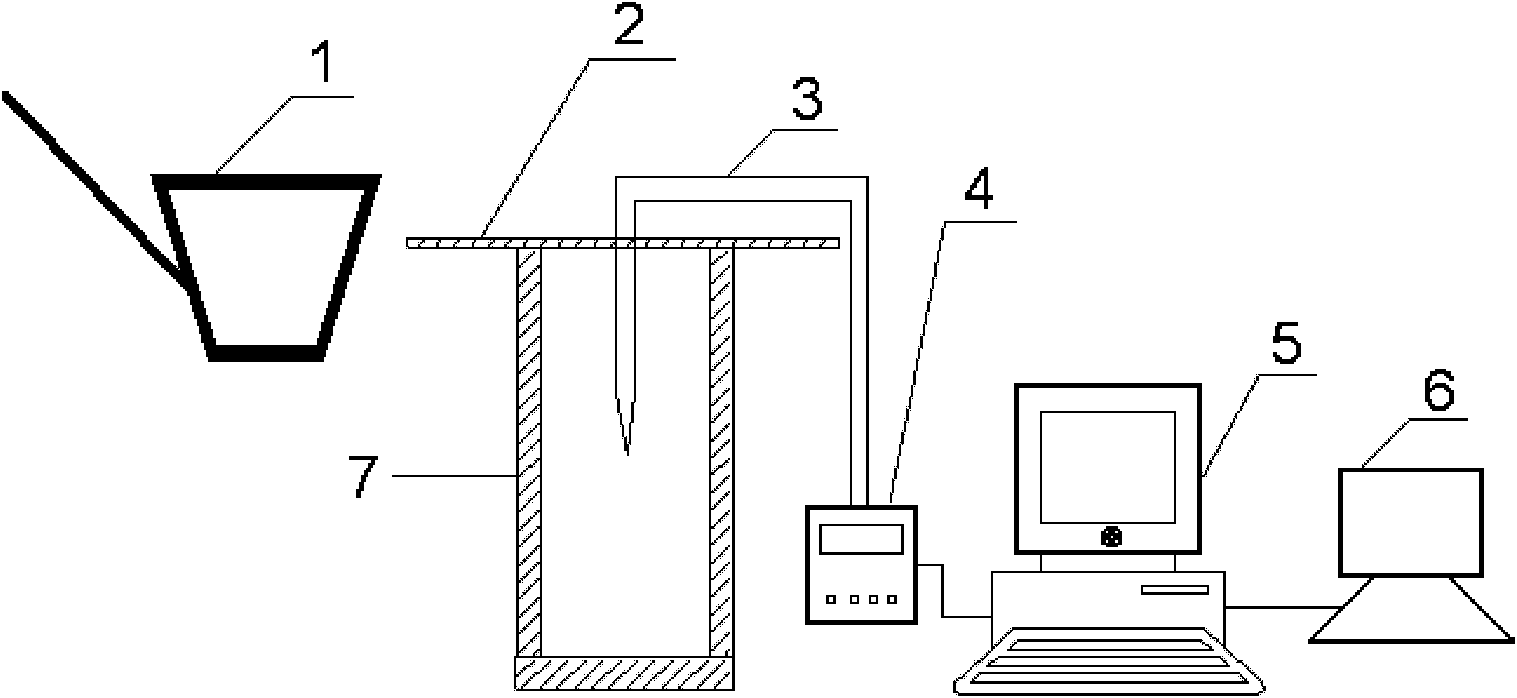

System and method for measuring and predicting real initial setting blank shell thickness in crystallizer

ActiveCN110851997ADisadvantages of Avoiding Detection Technical ErrorsThe calculation formula is simpleDesign optimisation/simulationEngineeringMolten steel

The invention provides a system and method for measuring and predicting the real initial setting billet shell thickness in a crystallizer. The system comprises an information acquisition module, a bleed-out billet shell microstructure measurement module, a crystallizer initial setting billet shell thickness growth prediction module and a result output module. The method comprises the following steps: collecting equipment parameters and process parameters of the continuous casting crystallizer; eroding a microcosmic solidification structure of a bleed-out billet shell; dividing the thicknessesof a steady-state billet shell layer, an extra solidification layer and an adhesion layer in the bleed-out billet shell; establishing a bleed-out process model, solving the molten steel descending rate and the bleed-out time, calculating the thickness of an adhesion layer in combination with casting blank heat transfer, and then calculating the thickness of a steady-state blank shell layer and thethickness of an additional solidification layer through solidification coefficients; and outputting and displaying the measured and predicted real initial setting blank shell thickness in the crystallizer. According to the invention, the real initial setting billet shell thickness in the crystallizer can be accurately measured and predicted through continuous casting of the bleed-out billet shell.

Owner:UNIV OF SCI & TECH BEIJING

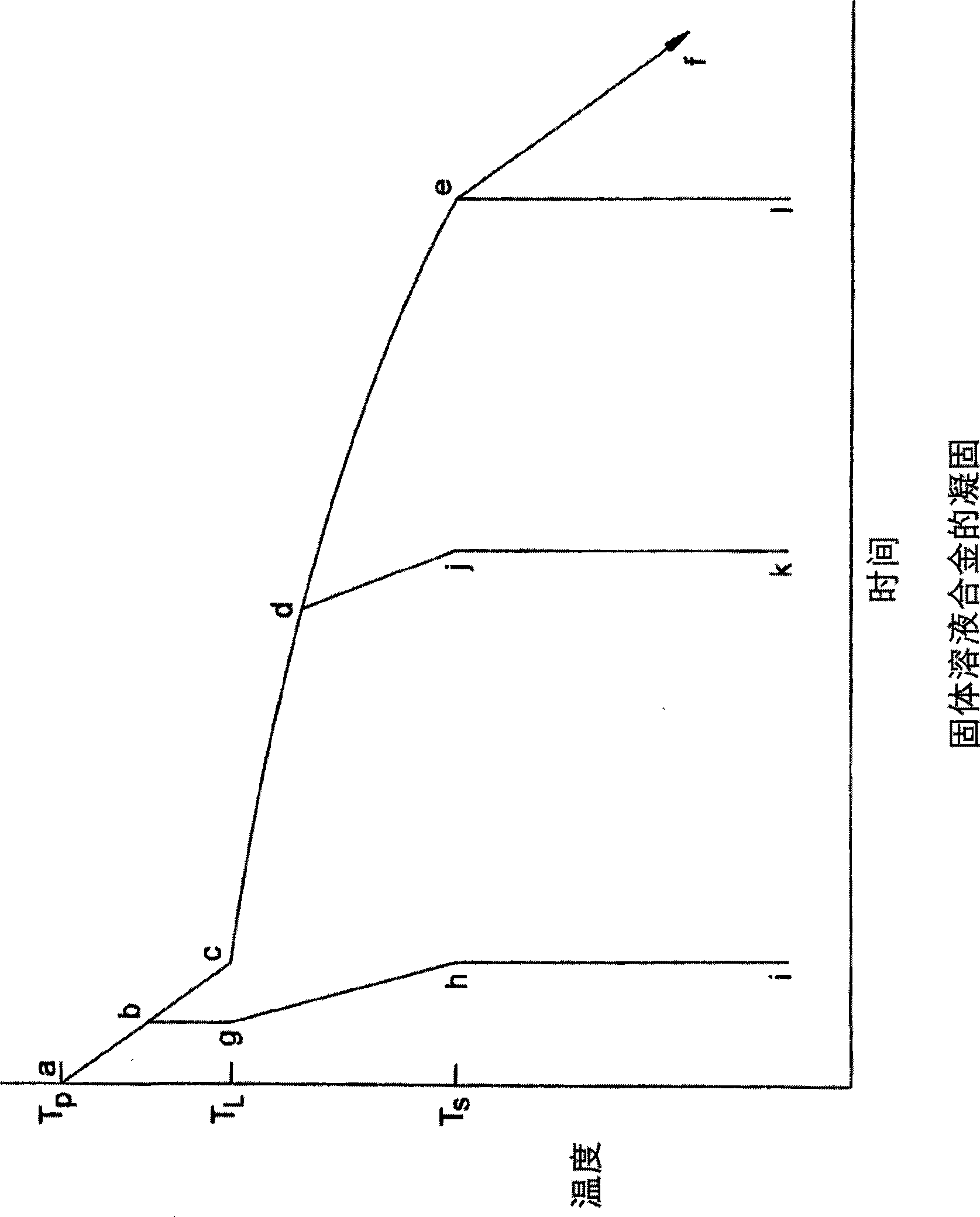

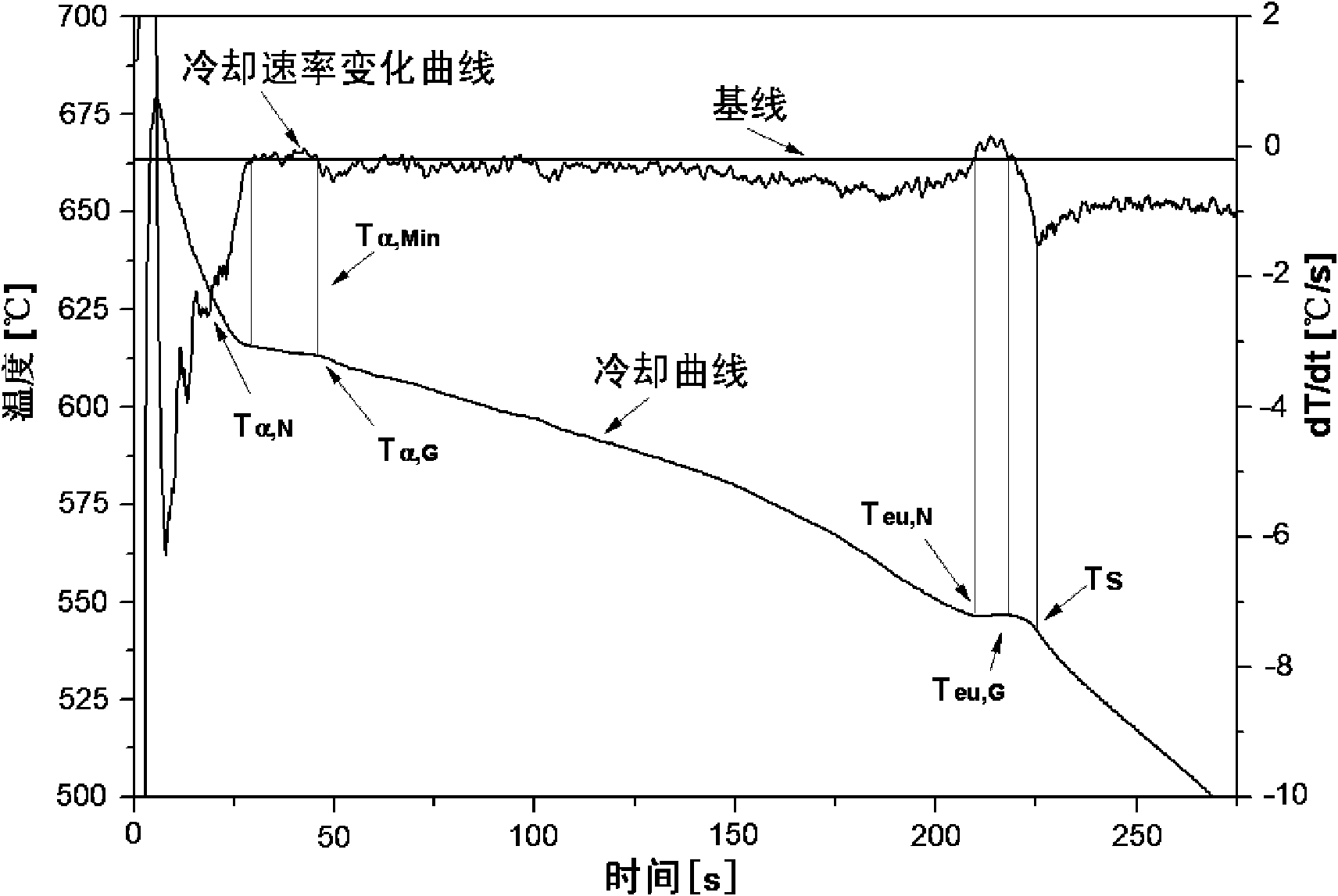

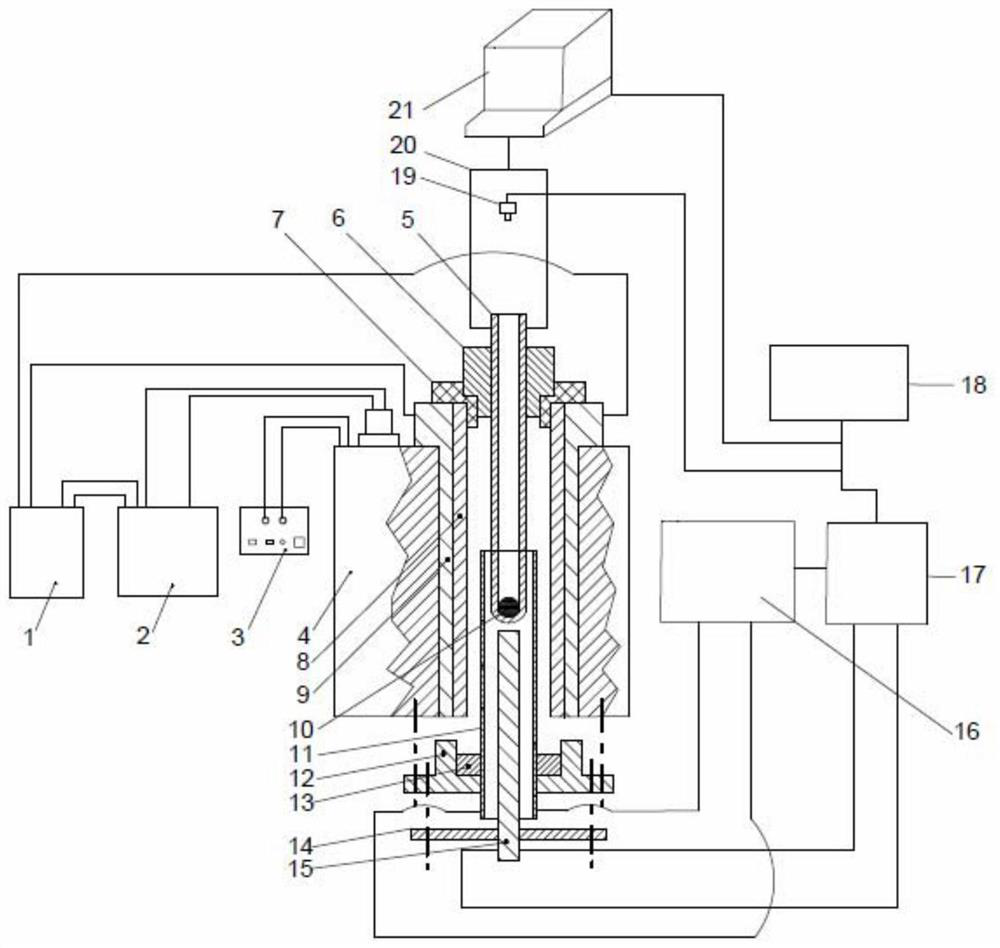

Method and device for carrying out online component detection and solidification structure control on magnesium alloy

InactiveCN102430750AReduce analysis costsShort detection cycleCasting safety devicesChemical compositionHeat capacity

The invention discloses a method for carrying out online component detection and solidification structure control on a magnesium alloy, and provides a corresponding implementing device. In the method, a magnesium alloy melt is extracted by using a quantitative casting ladle, a heat capacity of the melt is controlled by a constant-volume die, a temperature of the melt is measured by adopting a thermoelectric couple in real time, change of the temperature with time in a process of solidifying the melt is acquired and recorded by a temperature acquisition system, solidification reaction characteristic parameters are compared by calling a casting magnesium alloy database through a computer, chemical composition, and contents of a modificator and a refining agent in the alloy melt are regulated, and finally, a solidification structure is controlled. According to a classical solidification theory, components in a molten alloy are detected before pouring, and an analysis result is predicted according to the solidification structure, and contents of alloy elements related to the melt are regulated, thus the method has the advantages of stable result, high reliability, short analysis period, high automatic level, low analysis cost, simpleness and easiness in operation, has capabilities of effectively improving casting quality, reducing production cost and decreasing production period, and is suitable for flushing and casting in a magnesium alloy melting site.

Owner:SHANGHAI HAOHUA MOLD

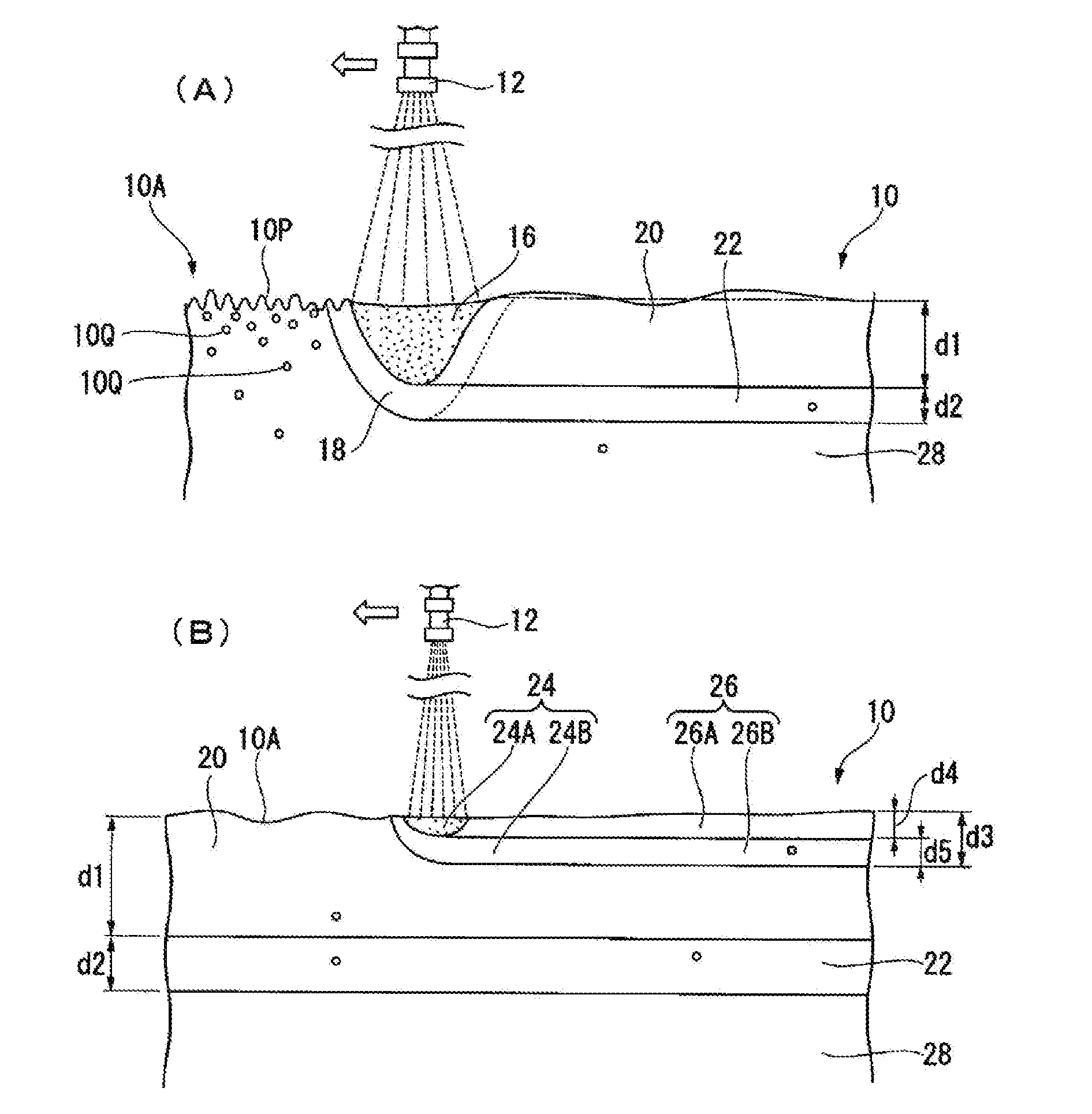

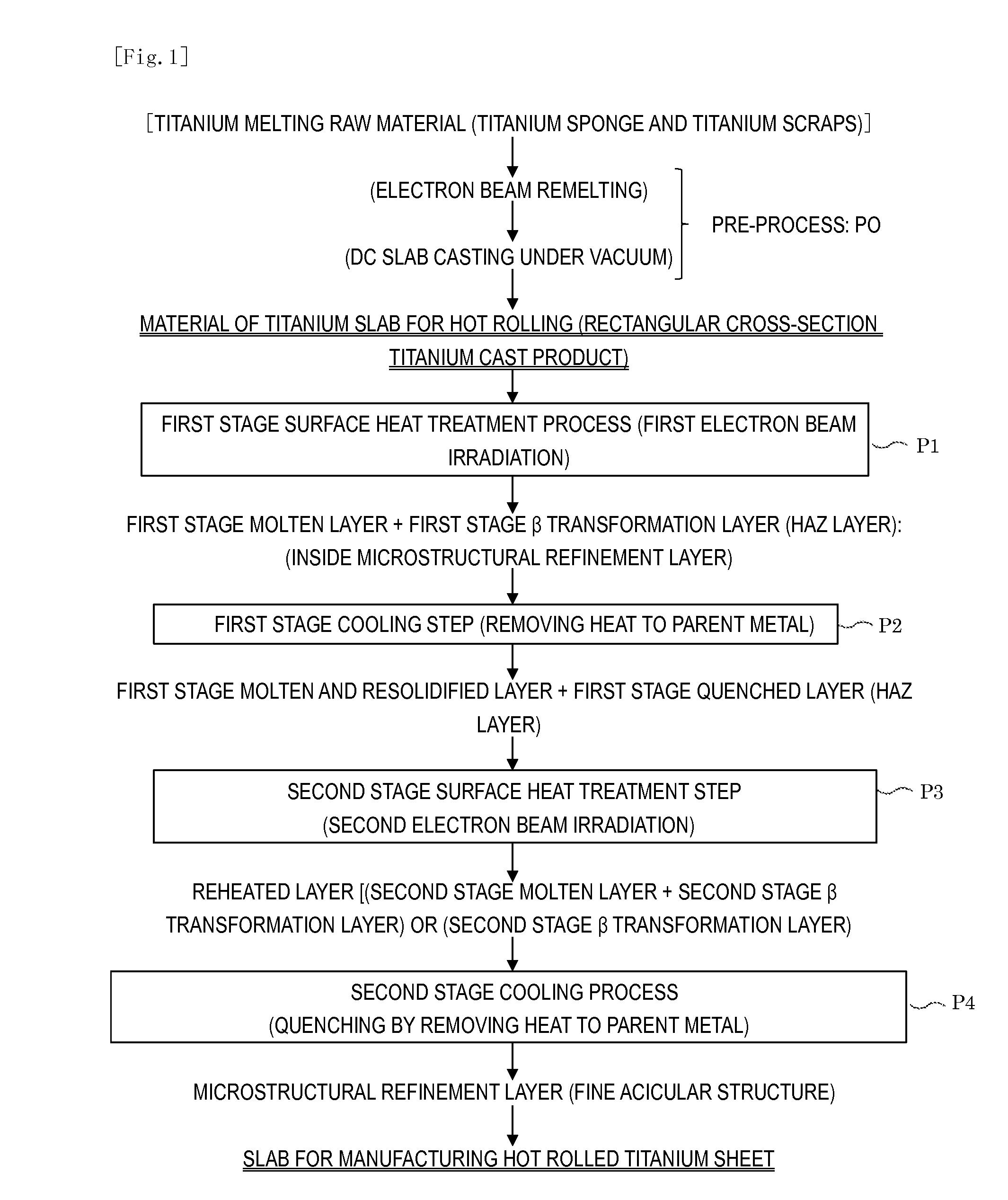

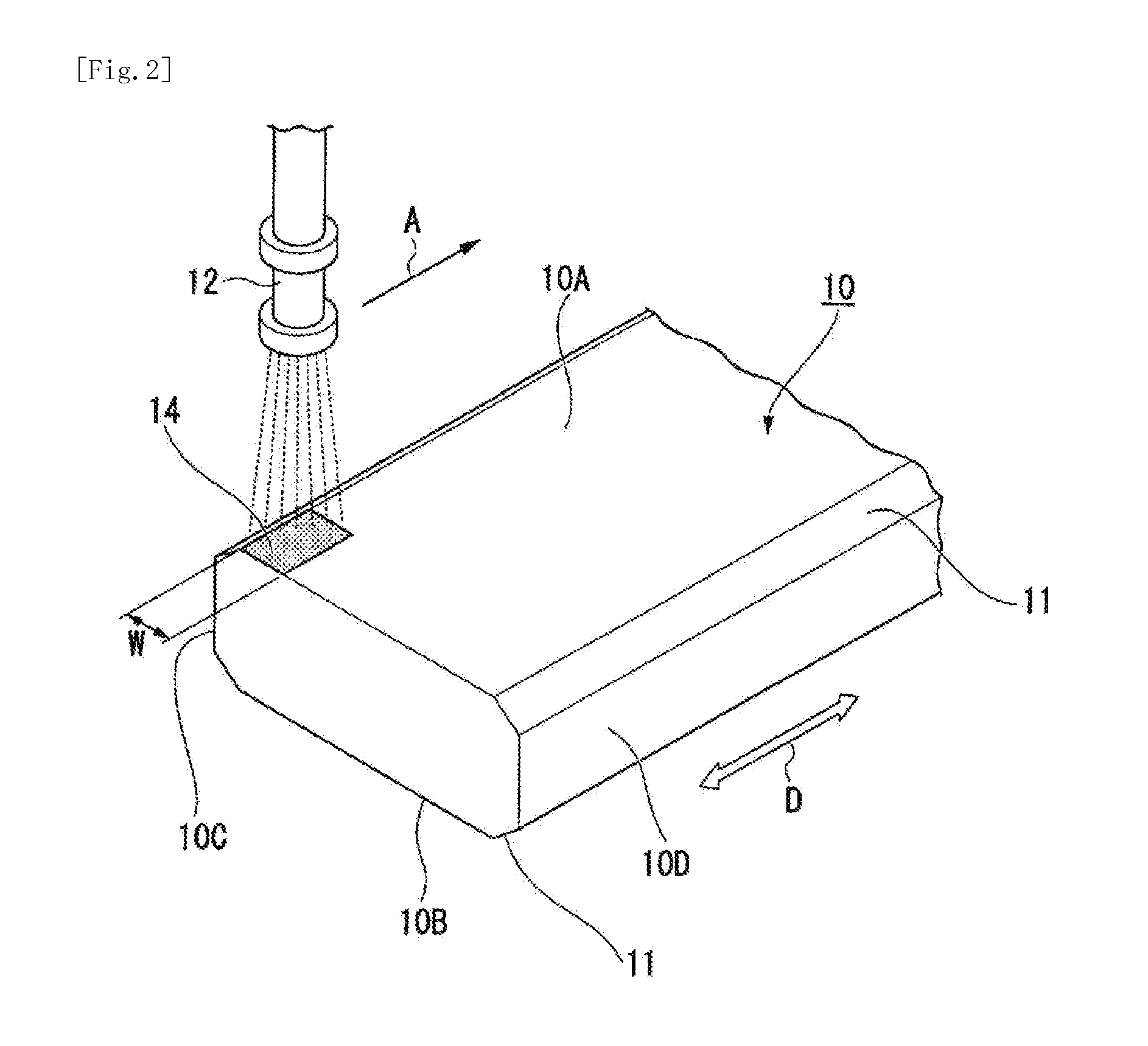

Titanium cast product for hot rolling and method for manufacturing same

ActiveUS20160038983A1Surely and stably be preventedLow costWork manipulationMetal rolling arrangementsSurface layerCommercially pure titanium

There is provided a titanium cast product for hot rolling composed of commercially pure titanium, the titanium cast product including: a microstructural refinement layer having acicular microstructure on an outermost layer of a surface layer to be rolled; and an inside microstructural refinement layer having acicular microstructure provided in an inside of the microstructural refinement layer. Cast solidification microstructure is present more inward than the inside microstructural refinement layer. The microstructural refinement layer has finer microstructure than the inside microstructural refinement layer. The microstructural refinement layer is present in a range of a depth of 1 mm or more and less than 6 mm from the surface. The inside microstructural refinement layer is present in an inside of the microstructural refinement layer in a range of a depth of 3 mm or more and 20 mm or less from the surface.

Owner:NIPPON STEEL CORP

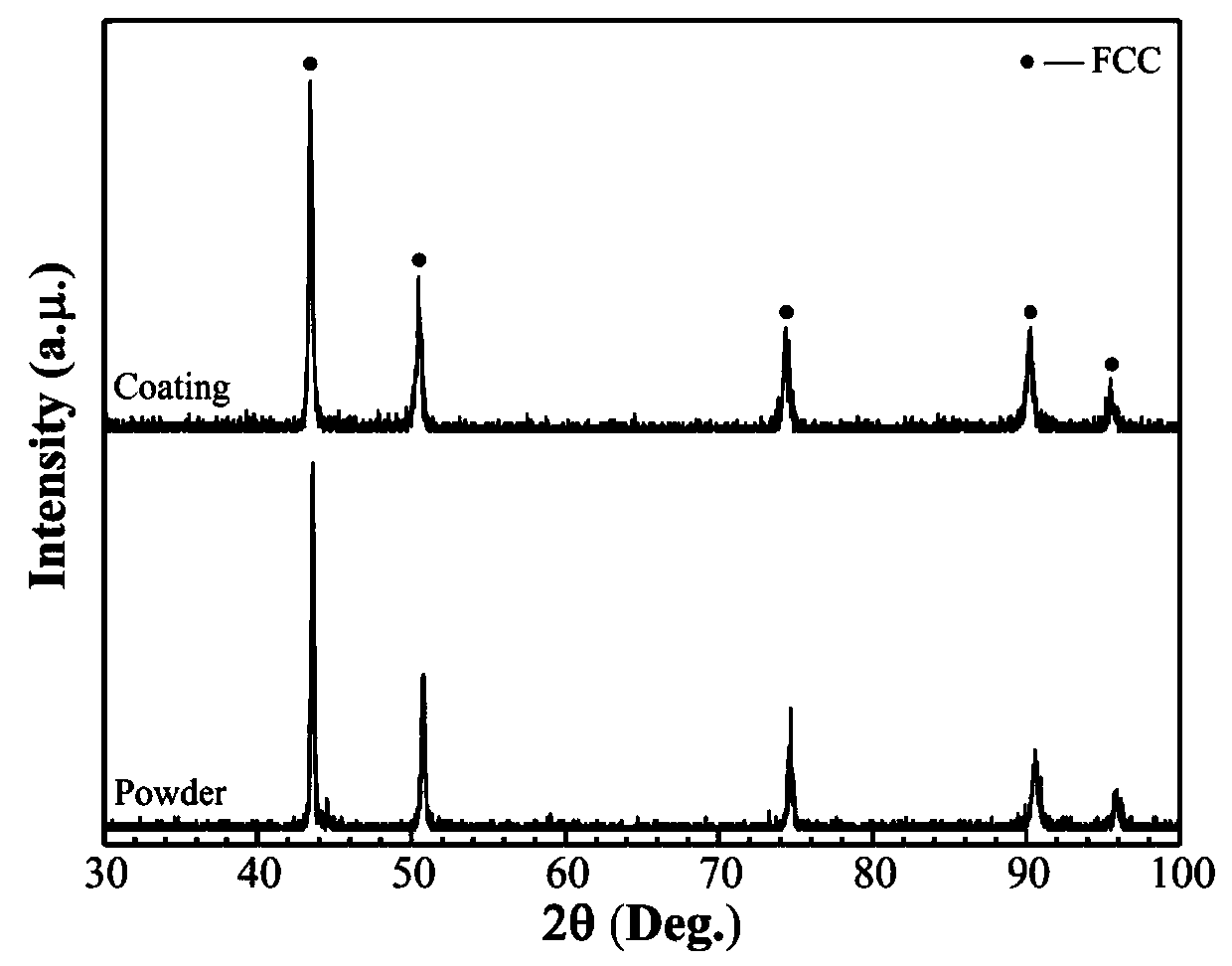

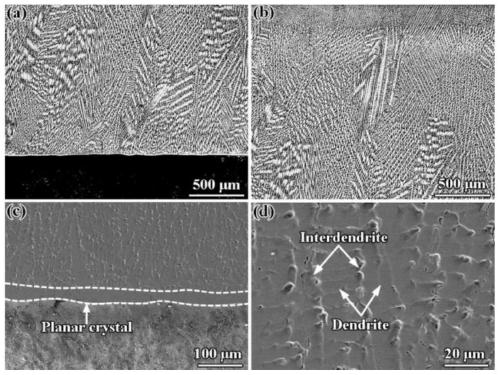

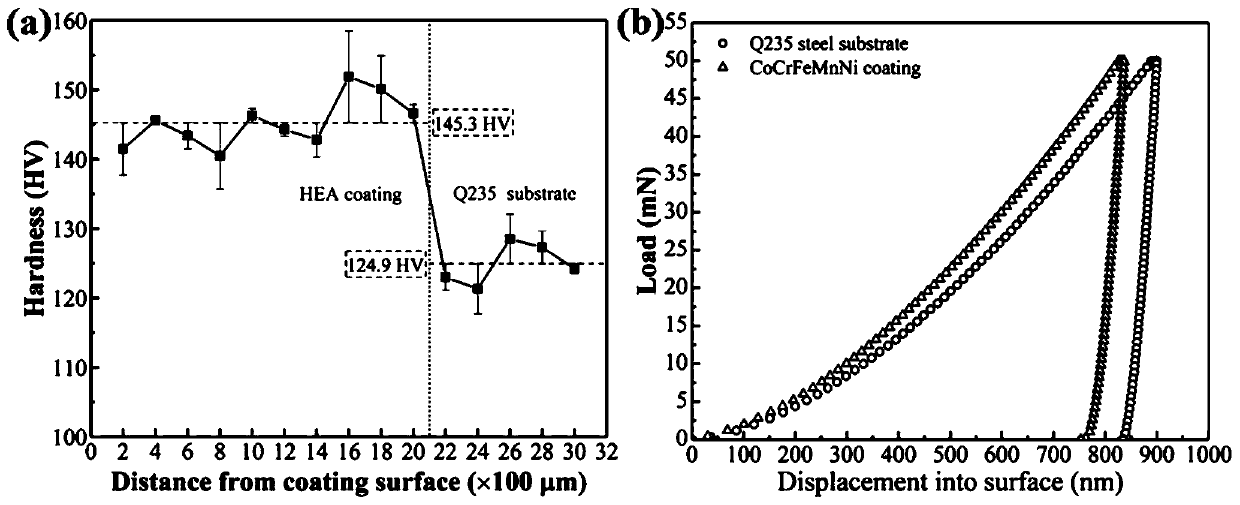

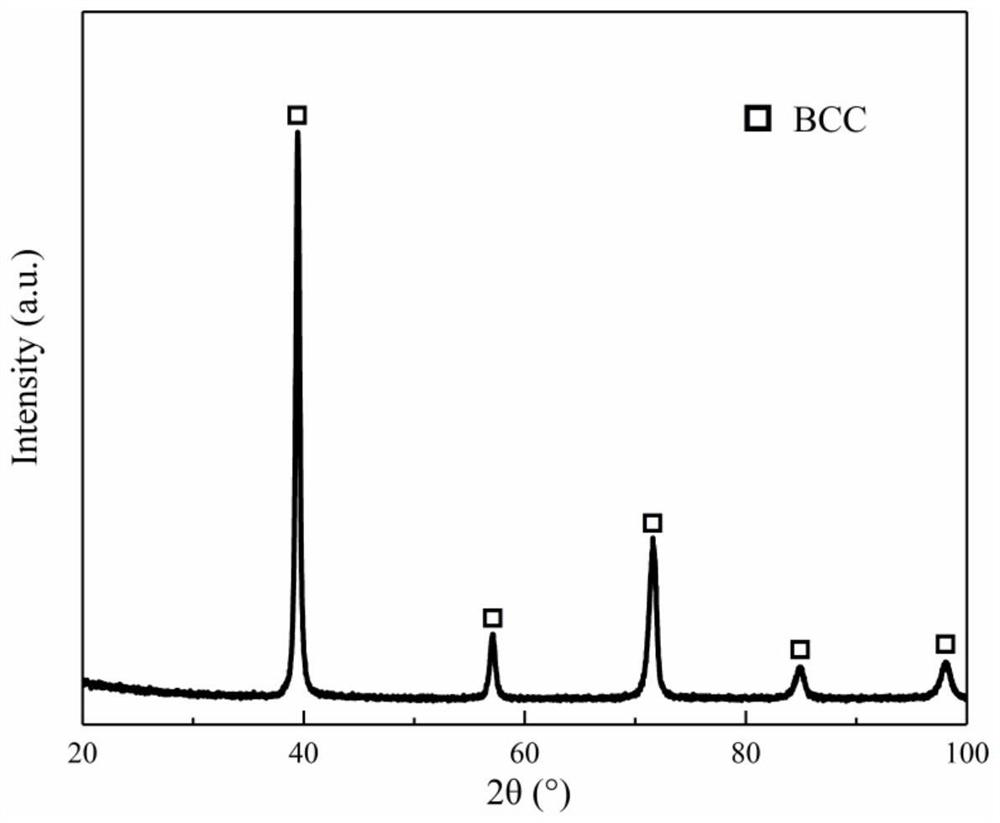

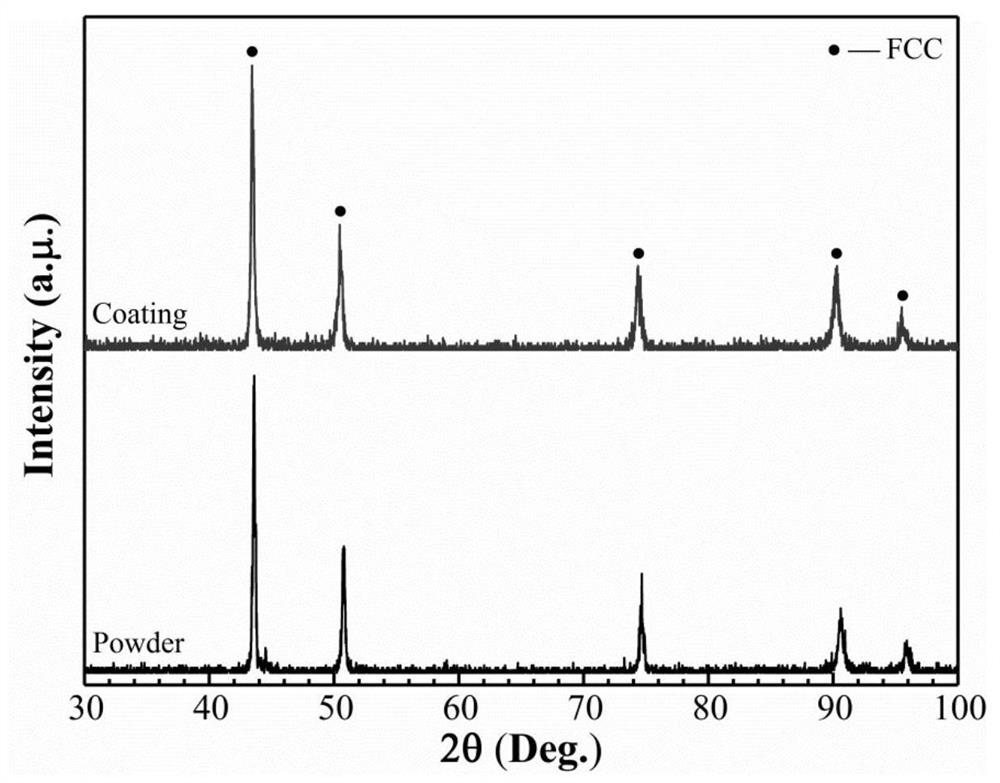

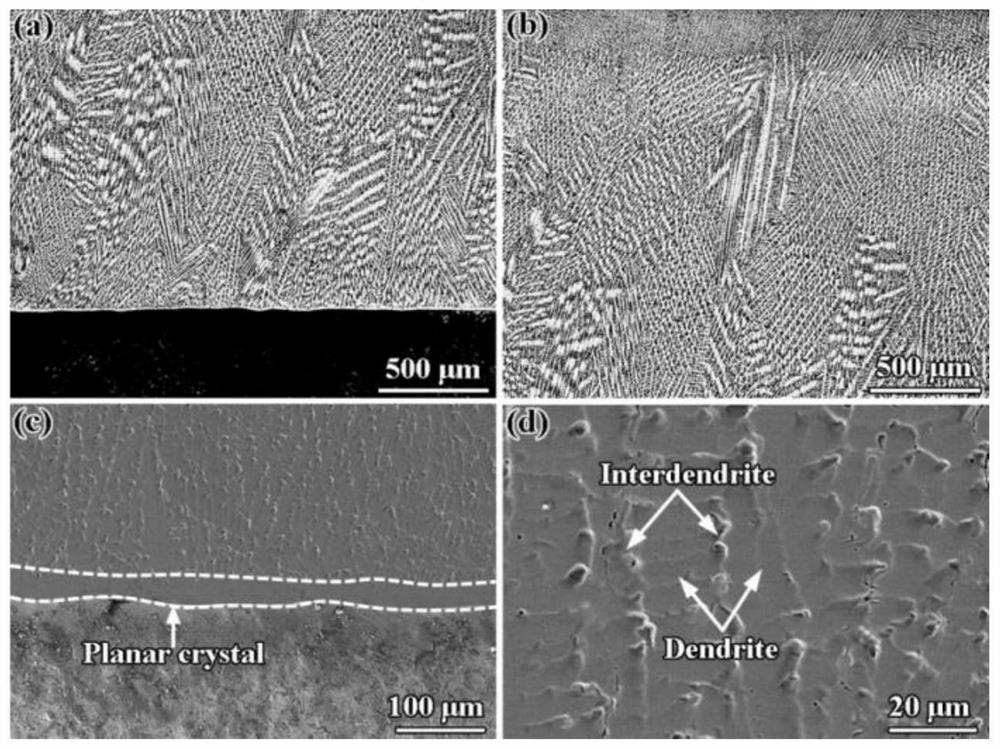

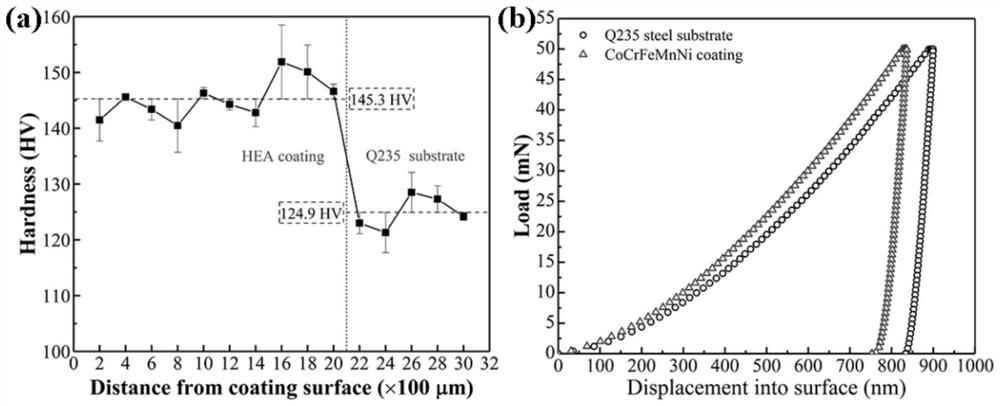

High-hardness high-entropy alloy coating and preparation method and application thereof

ActiveCN111364040ALow wear resistanceSmall volume wear rateMetallic material coating processesHigh entropy alloysMilling cutter

The invention discloses a high-hardness high-entropy alloy coating and a preparation method and application thereof. The high-entropy alloy coating comprises the following components and atoms of CoCrFeMnNiTixVy, wherein x = 0.3-1, y = 0.1-1. The high-entropy alloy coating can be applied to a high-temperature-resistant frictional wear material, and particularly can be applied to a milling cutter coating, a high-temperature rotating shaft coating or a high-temperature friction disc coating. The preparation method of the high-entropy alloy coating comprises the steps of powder mixing, drying, pretreatment of a base material and cladding of the coating. The plasma cladding CoCrFeMnNiTiV high-entropy alloy coating prepared through the method is composed of a V-rich BCC1 phase and a Ti-rich BCC2 phase, and the solidification structure of the plasma cladding CoCrFeMnNiTiV high-entropy alloy coating is of a cellular dendritic crystal structure. The average hardness of the CoCrFeMnNiTiV high-entropy alloy coating reaches 942.8 HV0. 3, and is 7.5 times that of matrix Q235 steel.

Owner:NANJING INST OF TECH +2

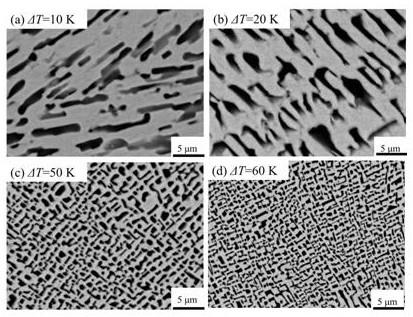

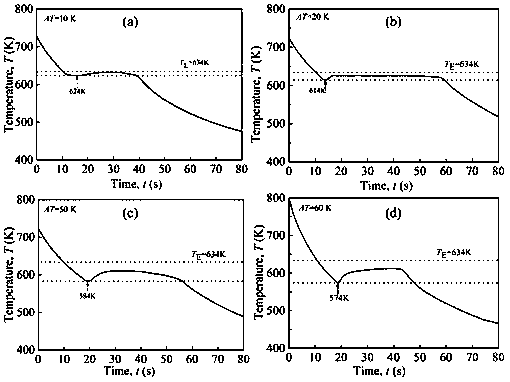

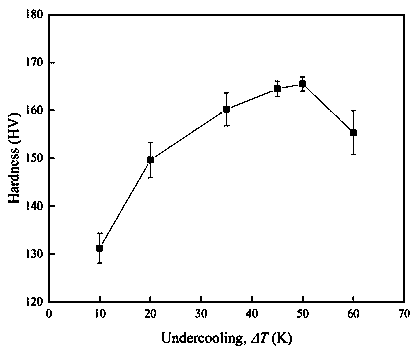

AuGe eutectic alloy solidification structure regulation and control method and AuGe eutectic alloy material prepared through method

The invention discloses an AuGe eutectic alloy solidification structure regulation and control method and an AuGe eutectic alloy material prepared through the method. The method comprises the following steps of (1) preparing an AuGe alloy; and (2) regulation and control of a solidification structure. Through the cladding melting purification and cyclical superheating technology by regulating and controlling parameters such as the type and viscosity of a cladding agent, the superheating degree of an alloy melt and the superheating cycle index, the solidification rate and the supercooling degreeof the AuGe eutectic alloy can be changed, and the AuGe eutectic alloy solidification structure can be regulated and controlled. The method is simple and easy to implement and provides a new path forimproving the processing formability of the AuGe eutectic alloy.

Owner:YUNNAN UNIV

A system and method for predicting the thickness of the initial solidified billet shell in a steel continuous casting crystallizer

ActiveCN104384469BPredict growth behaviorPredicting Microscopic Solidification BehaviorMolten steelPrediction system

A system and method for predicting the initial solidification shell thickness in a steel continuous casting mold. The system includes an information collection module, a steel type thermophysical parameter calculation module, a crystallizer initial solidification shell growth prediction module and a result output module; the method Including: detection of the microscopic solidification structure of the billet shell; collecting initial information: calculating the solute segregation and solidification path between dendrites during the solidification process of the molten steel to obtain the thermal physical parameters of the steel; solving the molten steel flow field and crystallizer temperature field of the mold and the solute field of the crystallizer, and coupled the macroscopic transport process in the crystallizer with the evolution behavior of the microscopic solidification structure in the crystallizer to further predict the shell growth behavior during the solidification process of high-temperature molten steel inside the continuous casting mold; the predicted solidification in the crystallizer The structure morphology and the thickness of the initially solidified shell at different positions in the crystallizer are output and displayed, as well as the comparison results with the actual thickness of the initially solidified shell. The invention can accurately predict the microscopic solidification behavior of the initial solidification shell in the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

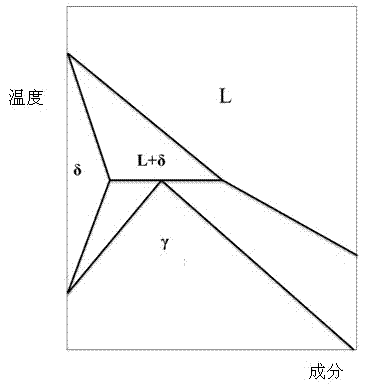

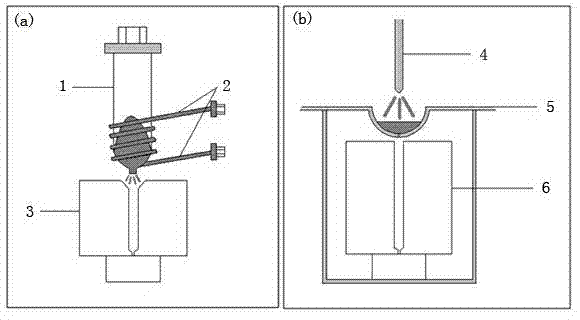

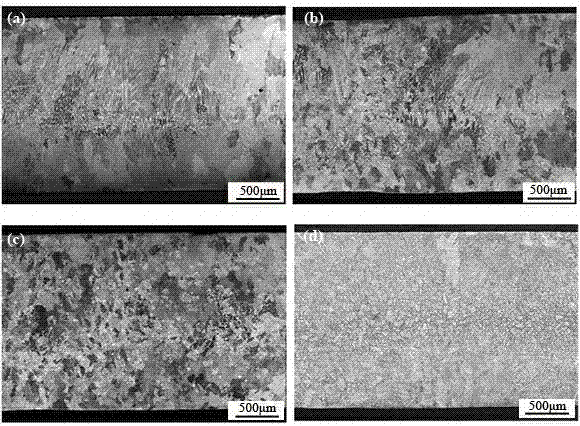

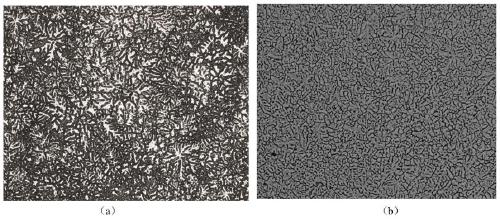

Method for improving isometric crystal rate of casting blanks through two-phase competition in peritectic alloy

InactiveCN102896304AIncrease equiaxed crystal ratioImprove coagulation tissueCrystal systemElectric arc furnace

The invention relates to a method for improving isometric crystal rate of casting blanks through two-phase competition in peritectic alloy. By means of the method, the isometric crystal proportion of the casting blanks is improved by utilizing two-phase competition during peritectic alloy solidification, and the quality of the casting blanks is improved. The peritectic system alloy Fe-Ni and Fe-Mn alloy serve as the objects, and the method for improving isometric crystal rate in the two-phase competition in the peritectic alloy under (inferior) fast sodification condition is provided. The method comprises the following processing steps: a) adopting a vacuum arc furnace to melt Fe-Ni and Fe-Mn alloy; b) preparing a thin belt through a vacuum spraying method, wherein the thickness of the thin belt is 2.0mm; c) adopting 5% of natal and Oberhofers corrosive liquid to corrode metallographic structures; and d) preparing microscopic structures, wherein the observation part of a sample is a cross section of the thin belt. By means of the method for improving the isometric crystal rate of casting blanks through two-phase competition in peritectic alloy, inner quality of the blanks can be improved, segregation is reduced, inner quality of other peritectic alloy steel is improved, the isometric crystal rate of solidification structures of the blanks is improved, and the quality of the casting blanks is improved.

Owner:SHANGHAI UNIV

H13 die steel and preparation method thereof

The invention relates to H13 die steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The H13 die steel comprises the following chemical elements in percentage by weight: 0.40 to 0.46 percent of C, 6.00 to 6.30 percent of Cr, 0.50 to 0.65 percent of V, 0.30 to 0.45 percent of Mo, 0.85 to 1.05 percent of Mn, 1.25 to 1.55 percent of Si, 0.12 to 0.25 percent of W, 0.008 to 0.018 percent of Nb, 0.008 to 0.015 percent of Ta, 0.08 to 0.12 percent of Ti, 0.003 to 0.006 percent of B, 0.08 to 0.15 percent of Al, 0.03 to 0.06 percent of N, 0.06 to 0.12percent of Y, less than 0.025 percent of S, less than 0.030 percent of P and the balance of Fe. The H13 die steel has the advantages that: the content of precious alloy elements, namely molybdenum and vanadium is low, the H13 die steel is not required to be forged, and forging can be replaced by casting, so that the cost of the H13 steel is obviously reduced; the performance of the H13 steel can be obviously improved, and a tungsten slag iron alloy is recycled; a solidification structure can be obviously refined, and the mechanical property of the H13 steel is improved; and the H13 steel has high wear resistance and is used as a hot working die, and the service life is prolonged.

Owner:江苏环立板带轧辊有限公司

Method for preparing fe-al-ta multifunctional integrated material by Bridgman directional solidification technology

The method of preparing Fe-Al-Ta multifunctional integrated material by Bridgman directional solidification technology changes the solidification structure characteristics by changing the solidification rate of different regions of the Fe-Al-Ta ternary alloy, thereby obtaining Fe-Al-Ta All-in-one material. At low solidification rate, the structure is lamellar eutectic. As the solidification rate increases, the structure transforms into rod-like eutectic. When the solidification rate increases further, the structure gradually transforms into spherical eutectic. Since solidification structures with different solidification rates have different properties, the properties of the material can be changed by changing the solidification rate in different regions, so that the properties of the material can be centralized, simplified and diversified, and a material with multiple functions can be prepared. The overall performance of the material is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

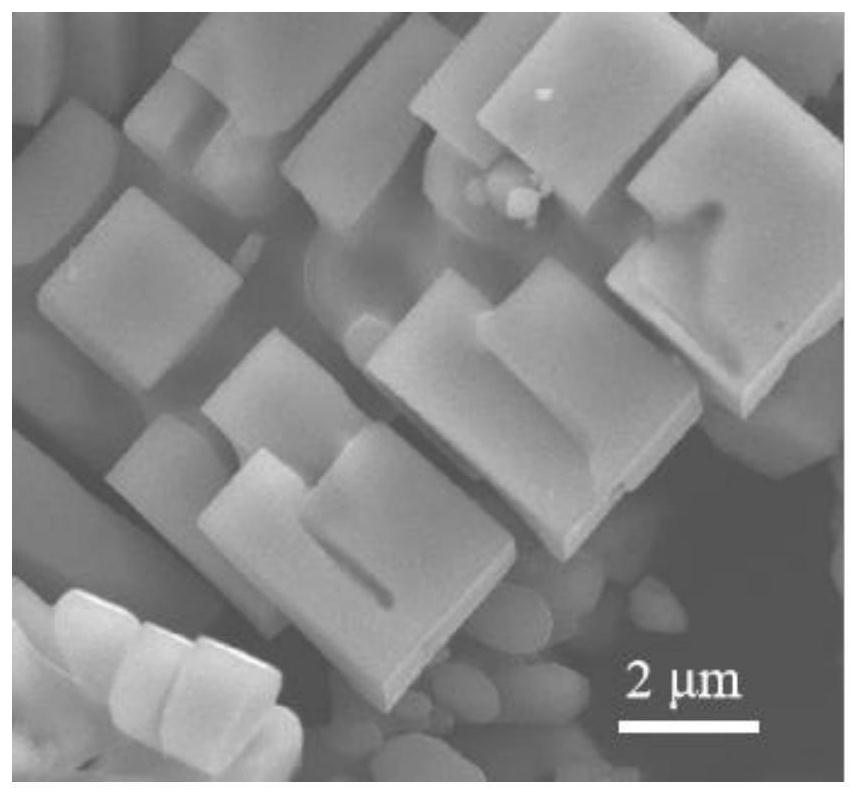

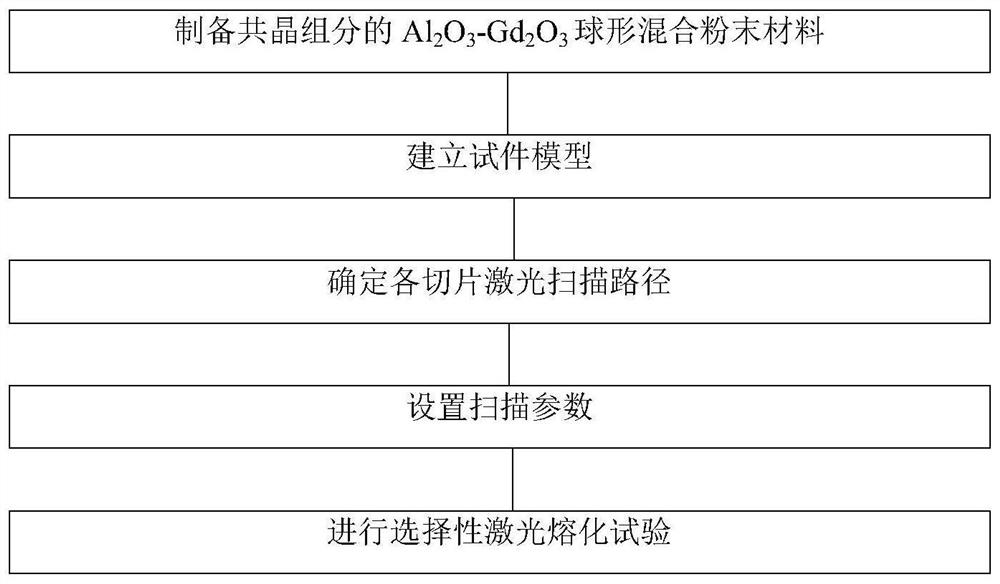

Method for preparing cylindrical Al2O3-GdAlO3 binary eutectic ceramic through selective laser melting

ActiveCN112895061AFast formingHigh energy absorptionAdditive manufacturing apparatusFeeding arrangmentsSelective laser meltingOxide ceramic

The invention relates to a method for preparing cylindrical Al2O3-GdAlO3 binary eutectic ceramic through selective laser melting. The method is characterized in that the cylindrical Al2O3-GdAlO3 binary eutectic ceramic is obtained by using a CO2 laser through a selective laser melting method, the size of the Al2O3-GdAlO3 binary eutectic ceramic is phi 20 * 2 millimeters <3>, the obtained eutectic ceramic is fine and compact in microstructure and presents a typical mutually-intertwined three-dimensional network eutectic solidification structure morphology, a melt material in a laser scanning area obtains a higher degree of supercooling and increases the nucleation rate, so that the eutectic structure is refined, and the mechanical property of a sample is improved. According to the method, the maximum scanning rate can reach 5000 mm / s, the energy absorption rate is high by selecting the CO2 laser, complete melting and solidification forming of the oxide ceramic material are better facilitated, the cylindrical sample with a curved surface structure can be prepared, the potential of one-step rapid forming of the large-size solidification eutectic ceramic sample with a complex shape is achieved, through a subsequent optimization process, the large-size Al2O3-GdAlO3 eutectic ceramic sample with higher quality is expected to be prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

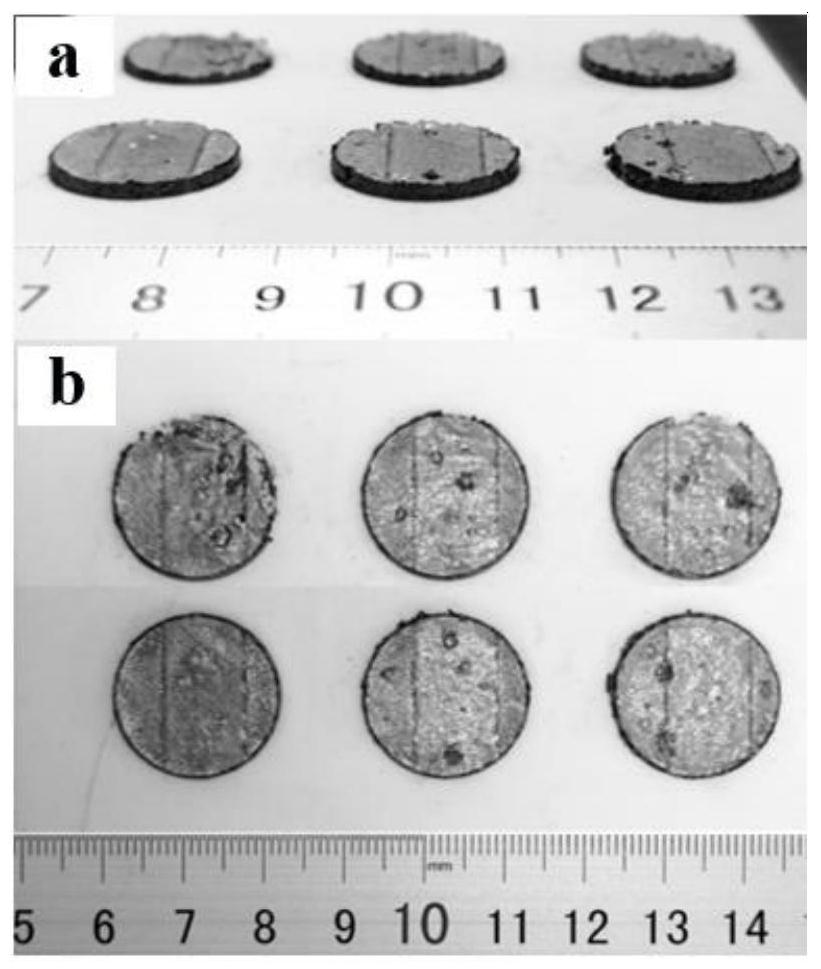

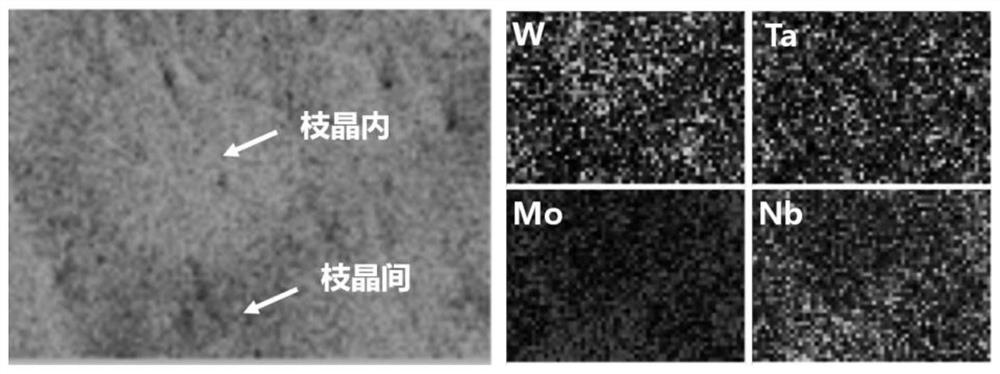

Strengthening and toughening regulation and control method for refractory high-entropy alloy

PendingCN114134355AOvercome room temperature brittlenessHigh strengthIngot castingHigh entropy alloys

The invention discloses a strengthening and toughening regulation and control method for a refractory high-entropy alloy. The method comprises the following steps: (1) preparing a refractory high-entropy alloy cast ingot; (2) observing the alloy structure morphology of the ingot casting sample, and analyzing the distribution rule of different elements by using an energy disperse spectroscopy; (3) redesigning alloy components according to distribution characteristics of different elements; and (4) the optimized new alloy components are prepared into cast ingots, and the refractory high-entropy alloy subjected to strengthening and toughening regulation and control is obtained. Based on the solidification structure characteristics of the alloy, the room temperature brittleness of the WTaMoNb series refractory high-entropy alloy is overcome by directly regulating and controlling the content of segregation elements in the brittle refractory high-entropy alloy; the alloy phase structure is not changed, the microstructure morphology is in a dendritic crystal form, and the comprehensive mechanical properties at room temperature and high temperature are improved. The invention provides a new thought and a new method for solving the problem of room-temperature brittleness of the refractory high-entropy alloy.

Owner:SOUTHEAST UNIV +1

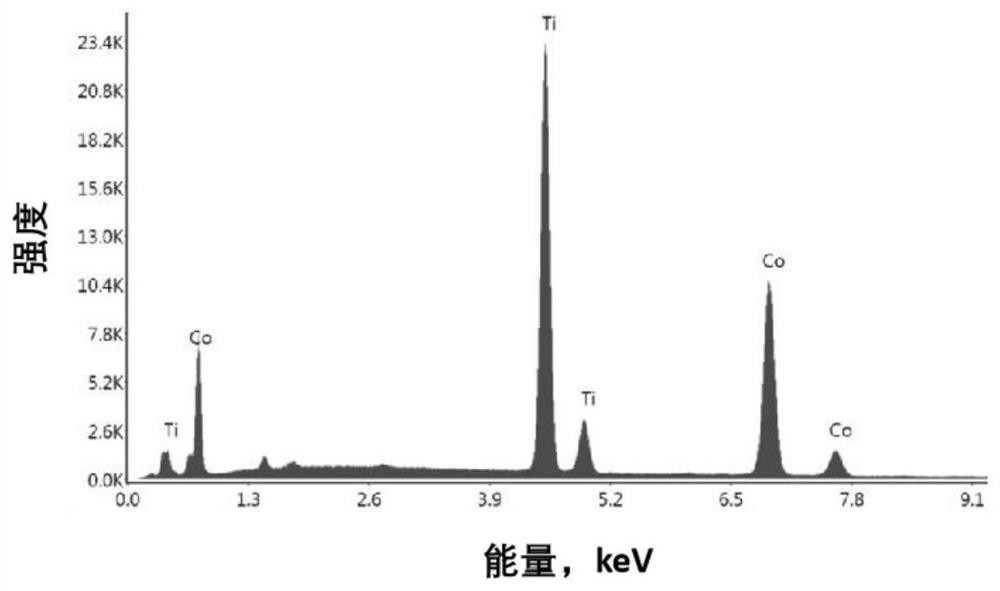

A kind of high-hardness high-entropy alloy coating and its preparation method and application

ActiveCN111364040BLow wear resistanceSmall volume wear rateMetallic material coating processesHigh entropy alloysMilling cutter

The invention discloses a high-hardness high-entropy alloy coating and its preparation method and application. The composition and atomic ratio of the high-entropy alloy coating are as follows: CoCrFeMnNiTi x V y , wherein x=0.3~1, y=0.1~1. The high-entropy alloy coating can be applied to high-temperature friction and wear materials, especially can be applied to milling cutter coating, high-temperature rotating shaft coating or high-temperature friction disc coating. The preparation method of the high-entropy alloy coating includes powder mixing, drying, pretreatment of base material and cladding coating. The plasma cladding CoCrFeMnNiTiV high-entropy alloy coating prepared by the invention is composed of a V-rich BCC1 phase and a Ti-rich BCC2 phase, and its solidification structure is a cellular dendrite structure. The average hardness of CoCrFeMnNiTiV high-entropy alloy coating reached 942.8HV 0.3 , 7.5 times that of the base Q235 steel.

Owner:NANJING INST OF TECH +2

Casting mold of high alloyed alloy cast rod and preparation method thereof

The invention provides a high-alloy alloy casting rod casting crystallizer and a preparation method thereof. The casting crystallizer includes a water tank, a draft tube, a crystallizer and an electromagnetic coil assembly, and the draft tube is embedded in the water tank; the crystallizer is set In the chamber of the water tank, the upper end of the crystallizer is sealed and connected with the lower end of the draft tube, and the lower end of the crystallizer is sealed and connected with the side wall at the opening of the water tank; at least a first graphite ring is provided in the crystallizer, and the first graphite The rings are respectively connected to the water supply and gas supply systems, and a layer of vapor film is formed between the first graphite ring and the alloy casting rod; the electromagnetic coil assembly includes at least a plurality of L-shaped electromagnetic coils, and the plurality of electromagnetic coils They are all set close to the top of the crystallizer. By setting the first graphite ring and designing the electromagnetic coil into an L-shaped structure, the crystallizer can effectively improve the problems of coarse and uneven solidification structure and serious component segregation of high-alloy alloy cast rods, and at the same time improve the surface quality of the cast rods. Significant improvement.

Owner:LOUDI WENCHANG TECH

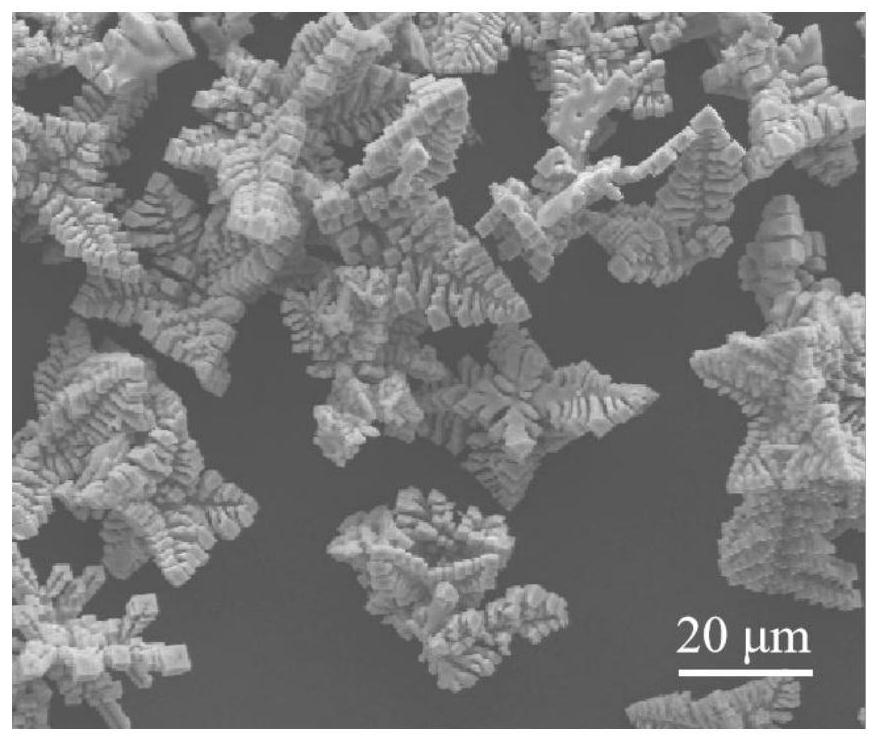

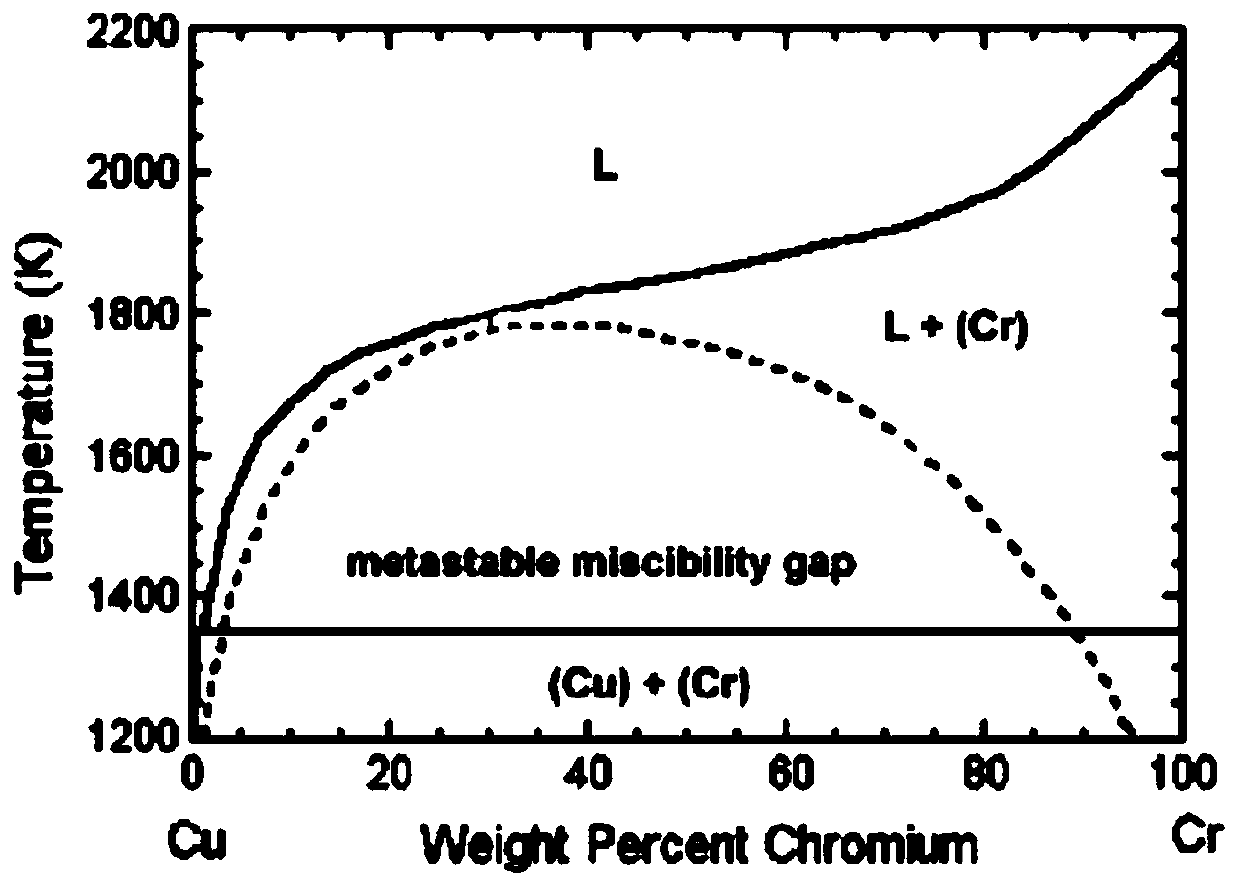

A kind of solidification preparation method of cu-cr electric contact alloy

The invention discloses a solidification preparation method of a Cu-Cr contact alloy, and belongs to the technical field of preparation of Cu-Cr contact alloy materials. TiB2 nucleating agent particles are added into the Cu-Cr alloy, when a fusant is cooled till liquid-liquid phase change occurs, the nucleating agent particles can serve as the nucleating substrate of Cr-rich phase liquid drops, thus the nucleating rate of the Cr-rich phase liquid drops is dramatically improved, and formation of a dispersion type Cu-Cr alloy composite solidification structure can be promoted. The solidificationpreparation method can be used for preparing high-quality Cu-Cr contact alloy materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

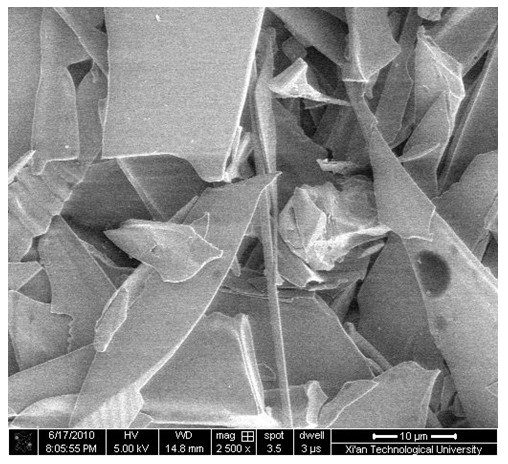

Method for fast preparing micron-level lamellar barium titanate powder

ActiveCN102115160ASimple processReduce process linksNanotechnologyTitanium compoundsBarium titanatePhysical chemistry

The invention relates to a method for fast preparing micron-level lamellar barium titanate powder. The prior art is complex in technology, long in preparation period, and low in production efficiency. The method sequentially comprises the following steps of: preparing KF-BaTiO3 or BaTiO3 melting body of a hypo eutectic component, and cooling and solidifying the melting body to obtain a solidified tissue; and ultrasonically cleaning the other phases in the solidified tissue to obtain sheet BaTiO3 crystalloid powder. The method specifically comprises the steps: (1) mixing BaCO3 power, TiO2 power with KF power, performing the ball milling by the polytetrafluoroethylene during mixing, performing the polytetrafluoroethylene to the agate, performing the ball milling and mixing for 6 hours with water-free ethanol medium, and drying for later use; (2) heating in a common crucible resistance furnace to be melted to obtain the melting body, and keeping the temperature for 1-4 hours for later use; (3) cooling the melting body to be solidified so as to obtain the solidified tissue; and ultrasonically cleaning to remove the KF and the other impurities in the solidified tissue.

Owner:XIAN TECH UNIV

A method of improving the force magnetic property of alcocrcufeni high entropy alloy by using magnetic field

ActiveCN109972066BHigh saturation magnetizationImprove mechanical propertiesHigh entropy alloysIngot

The invention provides a method for improving the mechanical and magnetic properties of an AlCoCrCuFeNi high-entropy alloy through a magnetic field. The method includes the steps that Al, Co, Cr, Cu,Fe and Ni raw materials are smelted through a vacuum non-consumable electric arc smelting method, and an AlCoCrCuFeNi high-entropy alloy button ingot is obtained. An obtained high-entropy alloy buttonis placed in the magnetic field of 2-10 T for vacuum solidification, the yield strength sigma<y> of the obtained AlCoCrCuFeNi high-entropy alloy is 777-952 MPa, the tensile strength sigma is 1633-1903 MPa, the hardness is 374-413 HV, the saturation magnetization M<s> is 26.4-34.5 emu / g, and the shape of a solidification structure of the AlCoCrCuFeNi high-entropy alloy has no significant change. According to the method for improving the mechanical and magnetic properties of the AlCoCrCuFeNi high-entropy alloy through the magnetic field, the magnetic field is applied to the solidification process of the high-entropy alloy, and the purpose of simultaneously improving the mechanical and magnetic properties of the AlCoCrCuFeNi high-entropy alloy is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

IN718 alloy structure optimization method based on three-dimensional wall vibration type controllable ultrasonic field device

ActiveCN114774820ASolve the problem that it is difficult to smelt uniformlyFast meltingFoundry mouldsFoundry coresCavitationCasting mold

The invention provides an IN718 alloy structure optimization method based on a three-dimensional wall vibration type controllable ultrasonic field device, and relates to the technical field of advanced material preparation and processing. According to the method, wall vibration type treatment is conducted on the IN718 alloy melt from the bottom of a casting mold through ultrasonic waves, a proper smelting-pouring-ultrasonic regulation and control scheme is formulated for the IN718 alloy, meanwhile, in order to guarantee the optimal effect of ultrasonic treatment, the sound field change rule in the melt in the solidification process is measured in real time, and the sound field change rule of the melt in the solidification process is measured in real time. And ultrasonic experiment parameters are regulated and controlled in real time through the measured total cavitation sound pressure level, so that the solidification structure of the IN718 alloy is regulated and controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A casting aluminum alloy for high power density piston and its preparation method

The present invention relates to a cast aluminum alloy used for high power density pistons and a preparation method thereof, wherein, a cast aluminum alloy is characterized in that: in terms of mass percentage, the cast aluminum alloy comprises the following components: Si: 11.0 ~12.6%, Cu: 3.5~4.5%, Mg: 0.7~1.2%, Ni: 2.2~3.2%, Fe: 0.6~0.8%, Mn: 0.25~0.35%, Sc: 0.10~0.15%, Zr: 0.13~ 0.17%, Ti: 0.13-0.17%, V: 0.08-0.12%, and the balance is Al and unavoidable impurities. Heat-resistant aluminum alloy is based on the thermodynamic analysis of the material system, microstructure control and experimental testing, by appropriately increasing and adjusting the relative addition of elements such as Fe, Ni, Cu, etc., to increase the 350‑420 °C high temperature support strengthening phase Al 9 FeNi, Al 15 Si 2 (Fe,Mn) 3 、Al 3 CuNi, Al 7 Cu 4 The content of Ni makes the solidification structure present scattered network, petal and diffuse stripe distribution. These high-temperature strengthening phases can hinder the grain boundary slip and dislocation movement in the alloy, and improve the heat resistance and grain boundary. Strength and creep resistance.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Method for fast preparing micron-level lamellar barium titanate powder

ActiveCN102115160BSimple processReduce process linksNanotechnologyTitanium compoundsBarium titanatePhysical chemistry

The invention relates to a method for fast preparing micron-level lamellar barium titanate powder. The prior art is complex in technology, long in preparation period, and low in production efficiency. The method sequentially comprises the following steps of: preparing KF-BaTiO3 or BaTiO3 melting body of a hypo eutectic component, and cooling and solidifying the melting body to obtain a solidified tissue; and ultrasonically cleaning the other phases in the solidified tissue to obtain sheet BaTiO3 crystalloid powder. The method specifically comprises the steps: (1) mixing BaCO3 power, TiO2 power with KF power, performing the ball milling by the polytetrafluoroethylene during mixing, performing the polytetrafluoroethylene to the agate, performing the ball milling and mixing for 6 hours with water-free ethanol medium, and drying for later use; (2) heating in a common crucible resistance furnace to be melted to obtain the melting body, and keeping the temperature for 1-4 hours for later use; (3) cooling the melting body to be solidified so as to obtain the solidified tissue; and ultrasonically cleaning to remove the KF and the other impurities in the solidified tissue.

Owner:XIAN TECH UNIV

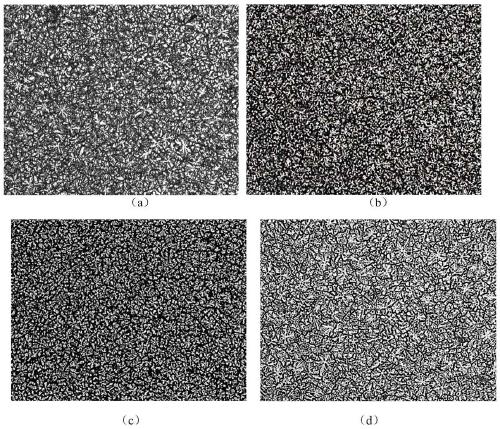

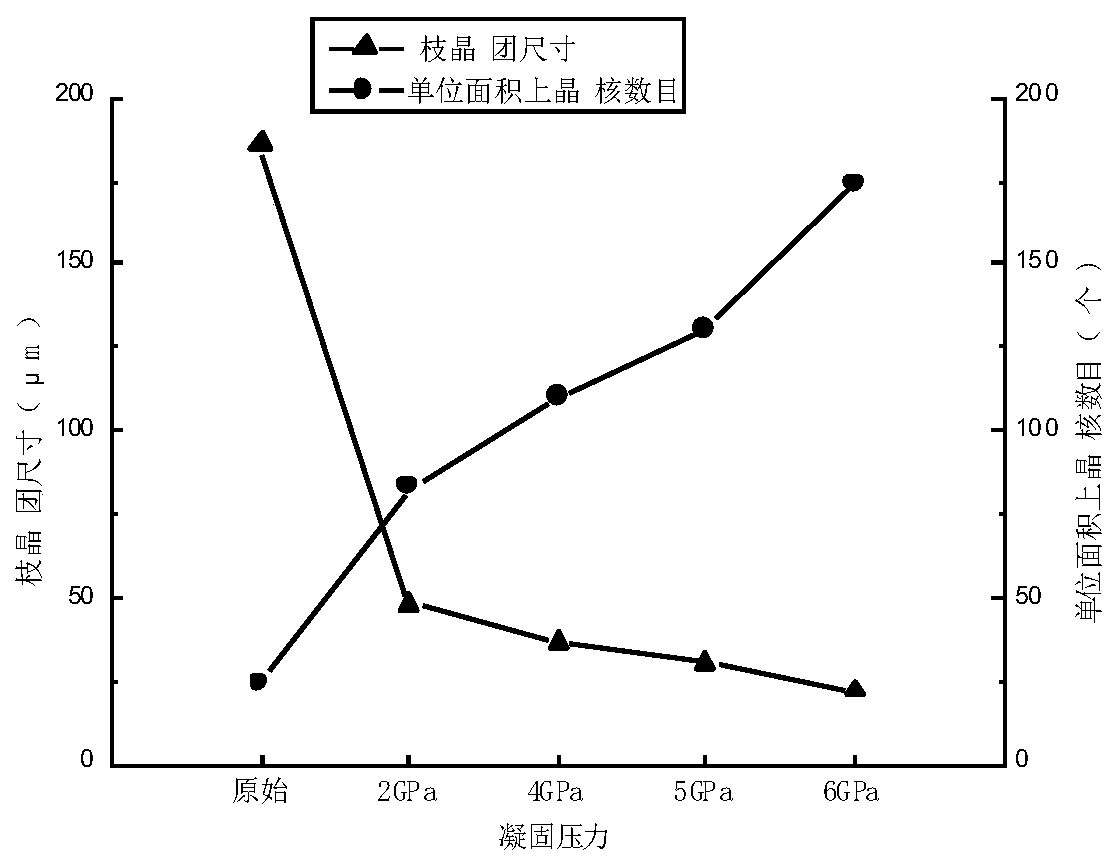

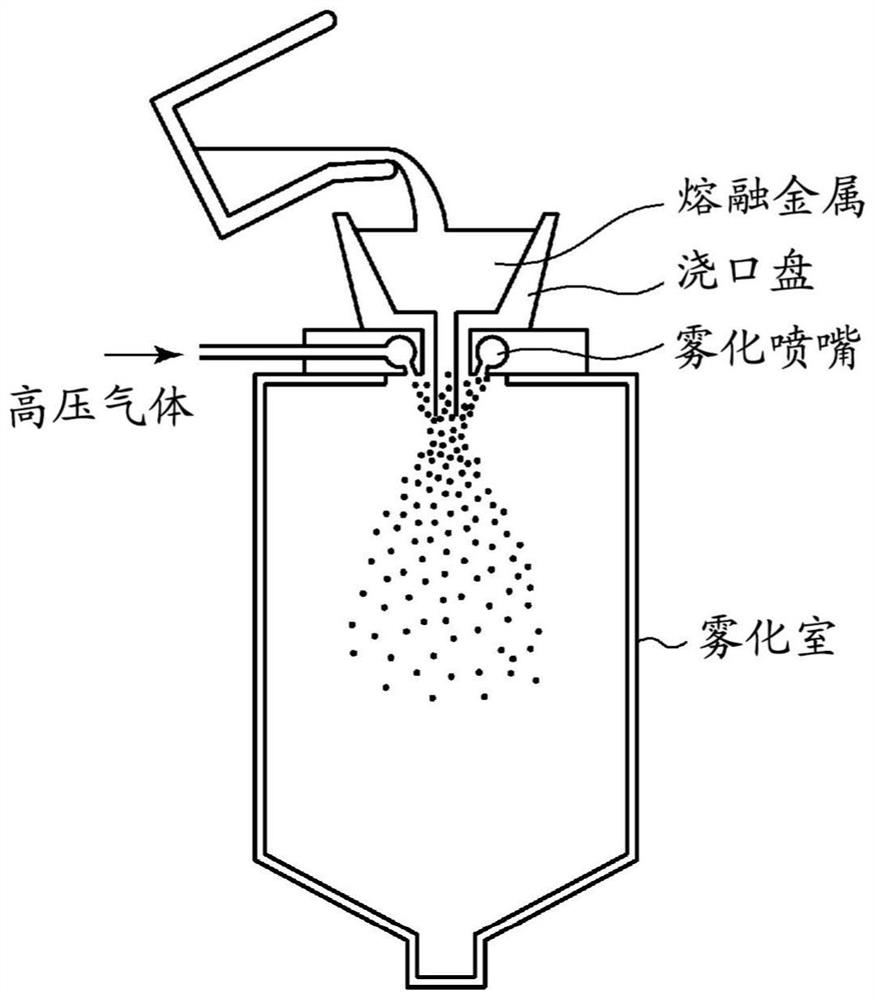

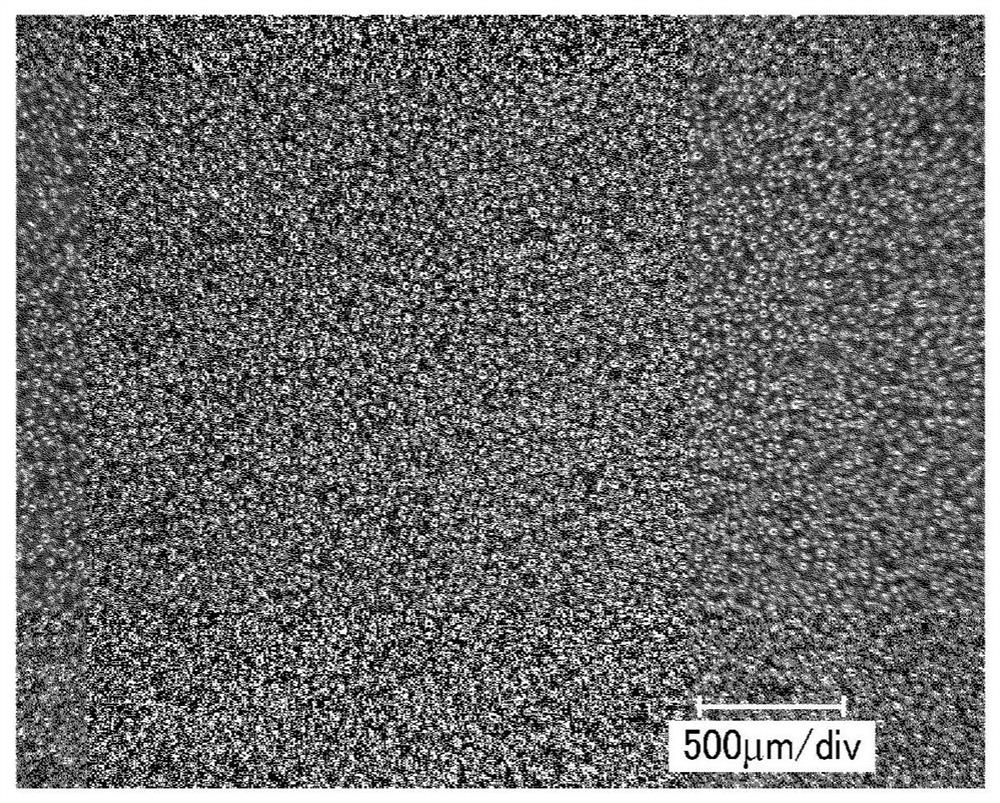

mg-zn-cu-zr-(cr-ca) alloy under gpa level high pressure and its preparation method

The present invention proposes a Mg‑Zn‑Cu‑Zr‑(Cr‑Ca) alloy and a preparation method under GPa level high pressure. A six-sided hydraulic press is used to prepare the Mg‑Zn‑Cu‑Zr‑(Cr,Ca) alloy at 2 GPa. Solidification was carried out under high pressure of ~6GPa, and the solidification structure characteristics, distribution patterns of solute elements such as Zn, Cu and Ca, heterogeneous crystal nuclei and strengthening and toughening mechanisms during high-pressure solidification were studied using EBSD, SEM and other analytical methods. The results show that the primary crystal α-Mg of the high-pressure solidification alloy is a regular equiaxed crystal, and the average grain size gradually refines from 186 μm under normal pressure to 22 μm under 6GPa; the solid solubility of Zn in the α-Mg matrix It gradually increases from 3.63% under normal pressure to 6.23% under 6GPa, and the intergranular second phase gradually changes from a network under normal pressure to an intermittently distributed island or granular shape under 6GPa; MgZn 2 ,Mg 2 Ca and Cr 2 The Zr phase is a strong and effective heterogeneous nucleation substrate for α-Mg crystals during high-pressure solidification, which greatly increases the number of crystal nuclei during the solidification process. The strength of the alloy increases as the solidification pressure increases, and the maximum resistance during compression increases from 240MPa under normal pressure to 520MPa under 6GPa.

Owner:NORTHEASTERN UNIV LIAONING

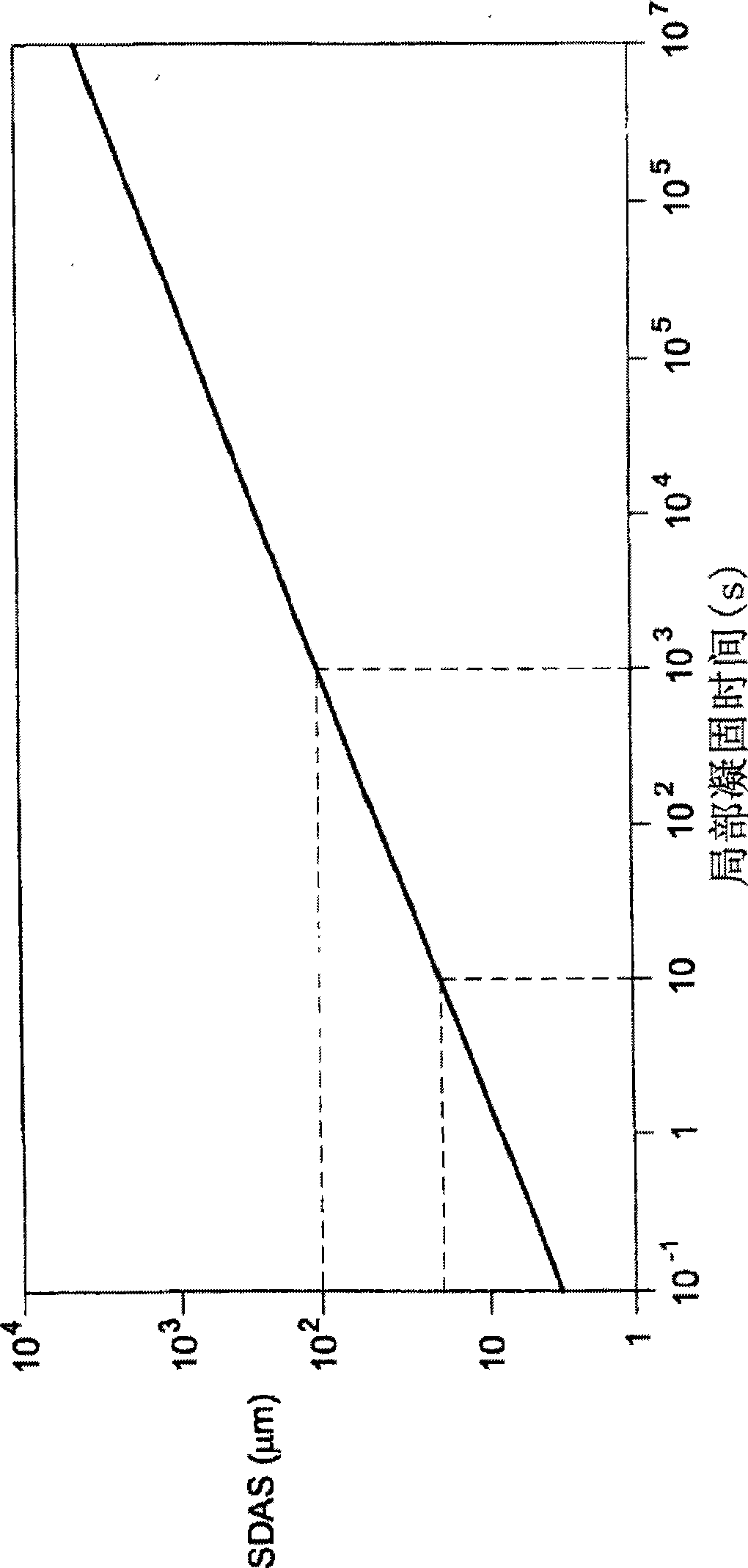

Low thermal expansion alloy excellent in low temperature stability and manufacturing method thereof

ActiveCN113195763BAdditive manufacturing apparatusIncreasing energy efficiencyThermal dilatationAlloy

The present invention provides a low thermal expansion alloy containing, in mass %, C: 0.015% or less, Si: 0.10% or less, Mn: 0.15% or less, Ni: 35.0 to 37.0%, Co: less than 2.0%, and Ni +0.8Co: 35.0-37.0%, the remainder is composed of Fe and unavoidable impurities, the alloy has a solidification structure with a secondary dendrite arm spacing of 5 μm or less, and an average thermal expansion coefficient of 0±0.2 at 100-70°C In the range of ppm / °C, and the Ms point is below -196°C.

Owner:NIPPON CHUZO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com