AuGe eutectic alloy solidification structure regulation and control method and AuGe eutectic alloy material prepared through method

A technology of solidification structure and eutectic alloy, applied in the field of AuGe eutectic alloy solidification structure control, alloy material, alloy solidification structure control, can solve the problems of poor processing performance, alloy brittleness, poor processing formability and wide application of eutectic solder, etc. Achieve the effect of improving the forming performance, solving the coarse structure, and improving the processing and forming performance of the AuGe eutectic alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Laboratory equipment:

[0028] High frequency induction melting furnace;

[0029] Infrared thermometer (model Impack IGA320 / 23).

[0030] The method for controlling the solidification structure of the AuGe eutectic alloy in this embodiment includes the following steps:

[0031] Step (1), AuGe alloy preparation

[0032] Gold flakes (Au) with a purity of 99.99% and germanium blocks (Ge) with a purity of 99.99% were weighed at a ratio of 88:12 by mass, and about 2 g of a mixture was prepared.

[0033] Put the prepared mixture into the graphite crucible, then place it in the middle of the vacuum induction coil, and evacuate to 3.6×10 -4 Pa, turn on the power to start melting the alloy, the heating rate is 3 K / s, the alloy is melted, and the alloy is remelted three times to obtain a master alloy with uniform composition.

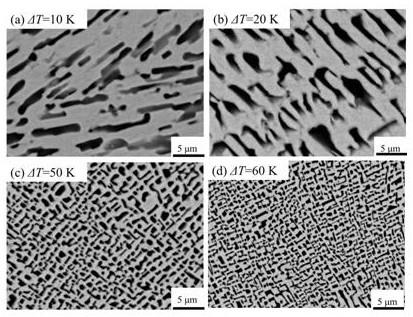

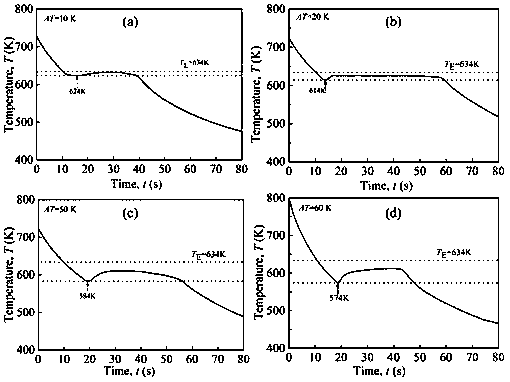

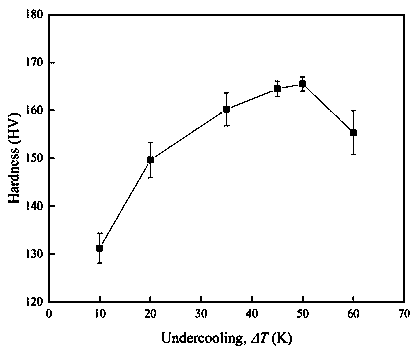

[0034] Step (2), control the solidification structure to obtain a regular grid-like eutectic structure.

[0035] After cleaning the quartz tube with...

Embodiment 2

[0039] The method for controlling the solidification structure of the AuGe eutectic alloy in this embodiment includes the following steps:

[0040] Step (1), AuGe alloy preparation

[0041] Gold flakes (Au) with a purity of 99.99% and germanium blocks (Ge) with a purity of 99.99% were weighed at a ratio of 88:12 by mass, and about 2 g of a mixture was prepared.

[0042] Put the prepared mixture into the graphite crucible, then place it in the middle of the vacuum induction coil, and evacuate to 3.6×10 -4 Pa, turn on the power to start melting the alloy, the heating rate is 3-5 K / s, the alloy is melted, and the alloy is remelted 3 times to obtain a master alloy with uniform composition.

[0043] Step (2), control the solidification structure to obtain a regular grid-like eutectic structure.

[0044] The quartz tube was cleaned with alcohol, injected with acetone, cleaned in an ultrasonic oscillator for 5 min, and dried for use. Then the smelted master alloy was cleaned in a...

Embodiment 3

[0048] The method for controlling the solidification structure of the AuGe eutectic alloy in this embodiment includes the following steps:

[0049] Step (1), AuGe alloy preparation

[0050] Gold flakes (Au) with a purity of 99.99% and germanium blocks (Ge) with a purity of 99.99% were weighed according to a mass percentage of 88:12, and about 2 g of a mixture was prepared.

[0051] Put the prepared mixture into the graphite crucible, then place it in the middle of the vacuum induction coil, and evacuate to 3.6×10 -4 Pa, turn on the power to start melting the alloy, the heating rate is 4K / s, the alloy is melted, and the alloy is remelted 3 times to obtain a master alloy with uniform composition.

[0052] Step (2), control the solidification structure to obtain a regular grid-like eutectic structure.

[0053] The quartz tube was cleaned with alcohol, injected with acetone, cleaned in an ultrasonic oscillator for 5 min, and dried for use. Then the smelted master alloy was cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com