Biochemical analyzer feeding unit dissolving and stirring mechanism

A biochemical analyzer and stirring mechanism technology, applied in the field of biochemistry, can solve the problem of the absence of eddy current effect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

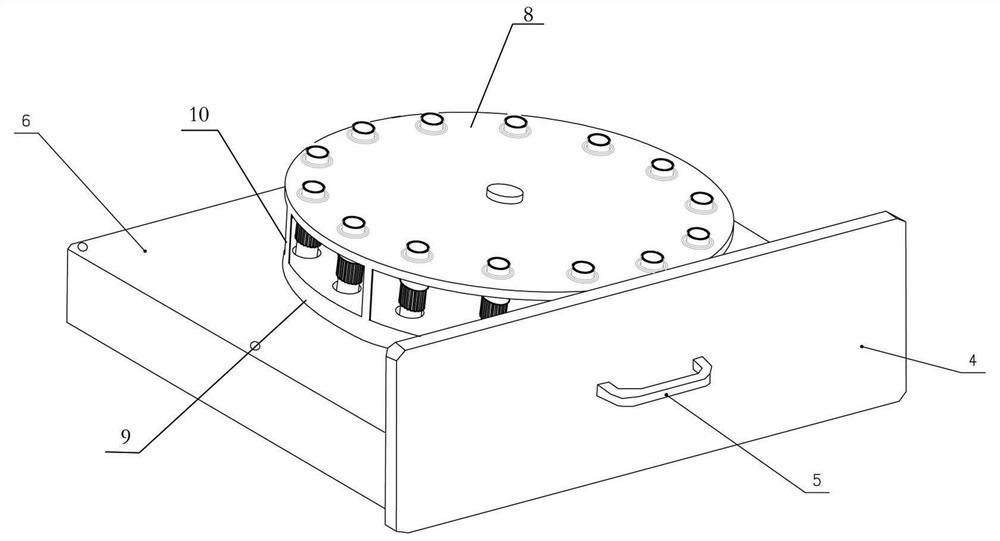

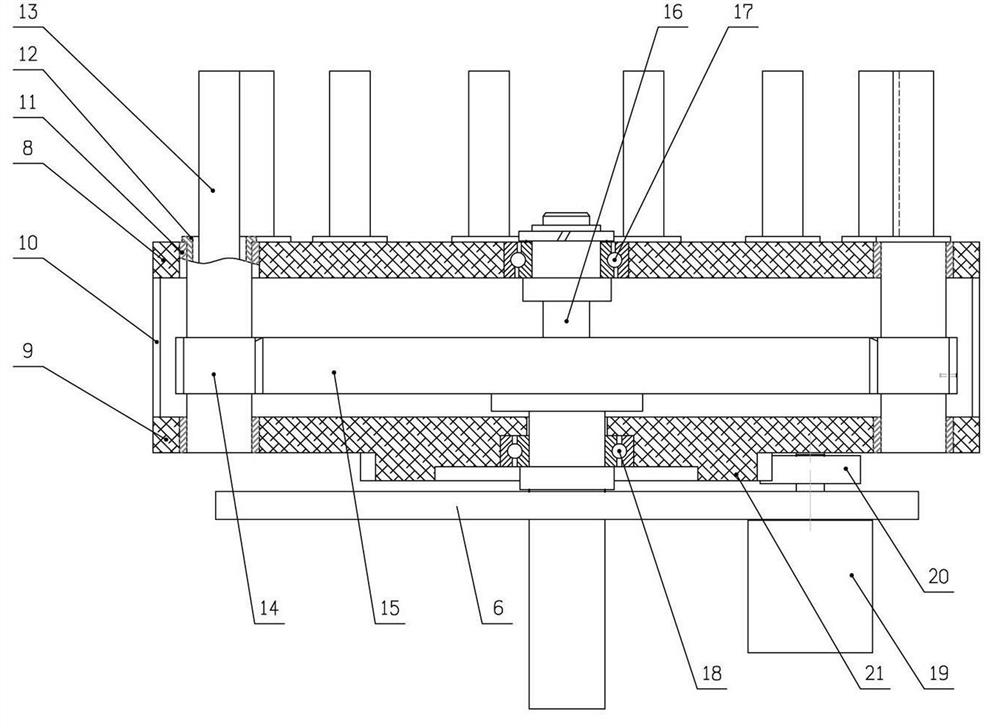

[0035] Embodiment 1: The present invention discloses a dissolving and stirring mechanism of a feed unit of a biochemical analyzer, such as figure 1 As shown, it includes an upper disc carrier plate 8 and a lower disc carrier plate 9, both of which are fixed together by an edge link 10, and the edge link 10 can be replaced by a plate structure, so that the upper disc carrier plate 8 and the lower disc carrier plate The disk carrier plate 9 is a whole and can rotate synchronously, and this mechanism is applied as Figure 4 Inside the biochemical analyzer shown.

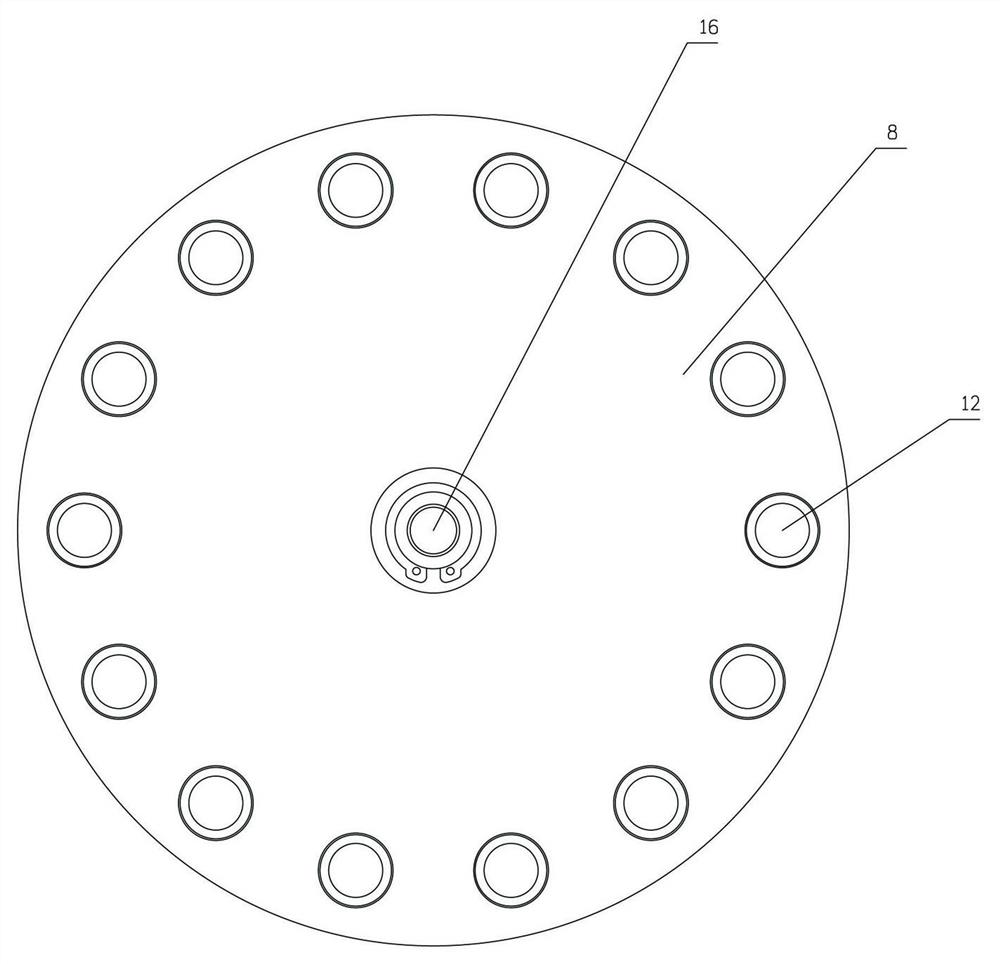

[0036] like figure 2 As shown, the centers of the upper disc carrier plate 8 and the lower disc carrier plate 9 are respectively equipped with a mandrel 16 through a bearing assembly, specifically, the upper end of the mandrel 16 is installed at the center of the upper disc carrier plate 8 through a thrust bearing 17 In the shaft hole, the lower end of the mandrel 16 is installed in the central shaft hole of the lowe...

Embodiment 2

[0043] Embodiment 2: On the basis of Embodiment 1, further, between the upper disk carrier plate 8 and the lower layer disc carrier plate 9, a transition gear 32 is installed through a bearing, such as Figure 8 and Figure 9 As shown, the rotating shafts of each transition gear 32 are respectively installed in the corresponding shaft holes of the upper disc carrier plate 8 and the lower disc carrier plate 9 through bushings, each transition gear 32 meshes with the corresponding edge gear 14 respectively, and each transition gear 32 is also meshed with sun gear 15 simultaneously. from Figure 9 It can be seen that each transition gear 32 meshes with two adjacent edge gears 14 respectively.

Embodiment 3

[0044] Embodiment 3: On the basis of Embodiment 2, two transition gears 32 arranged radially are designed, and the two transition gears arranged radially mesh respectively to form a gear set, and the gear set meshes with the edge gear 14 and Mesh with the sun gear 15. This design can extend the transmission path and reduce the speed ratio. Simultaneously, this design can also set the lumen at the center of the rotating shaft of each transition gear to accommodate the corresponding reagent container parts. Corresponding drum parts 12 are distributed at different radial positions for selective applications that require different degrees of agitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com