Automatic snow shoveling and loading device

An automatic and compacting device technology, applied in the engineering field, which can solve the problems of single function and inability to remove the ice surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

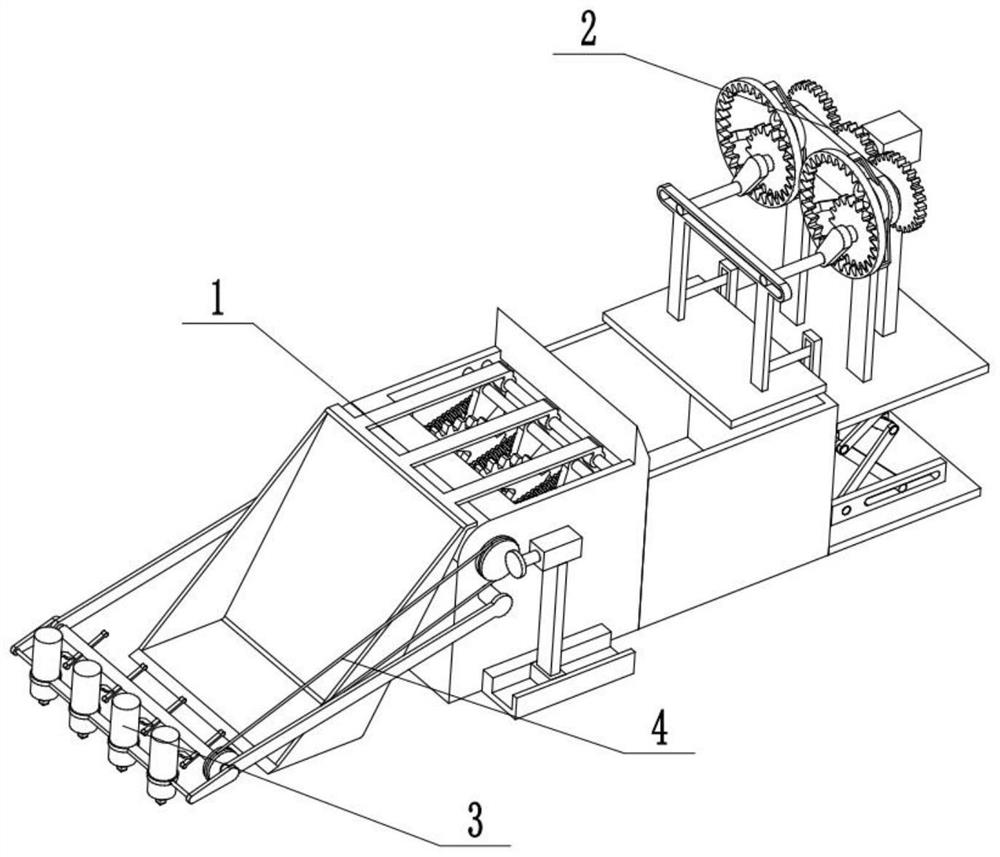

[0028] Combine below Figure 1-12 Description of this embodiment, an automatic snow plowing and loading device, including a snow collection device 1; a compaction device 2; an ice breaking device 3; a belt 4, the snow collection device 1 is connected with the compaction device 2, 1 is connected with the ice breaking device 3 through the belt 4.

specific Embodiment approach 2

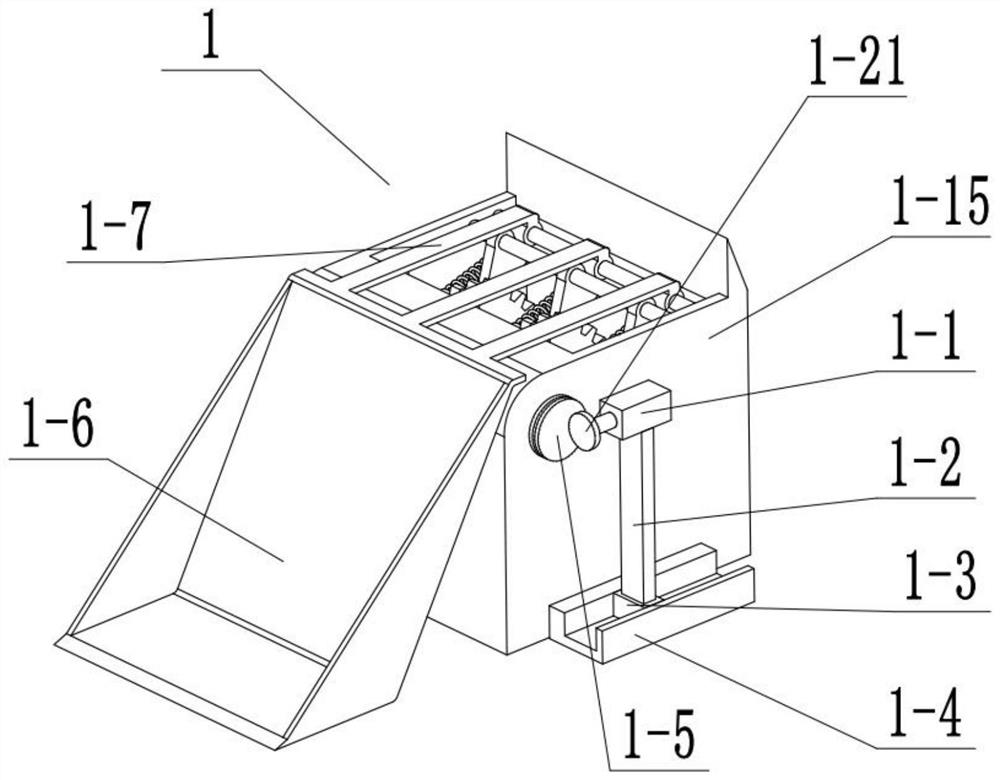

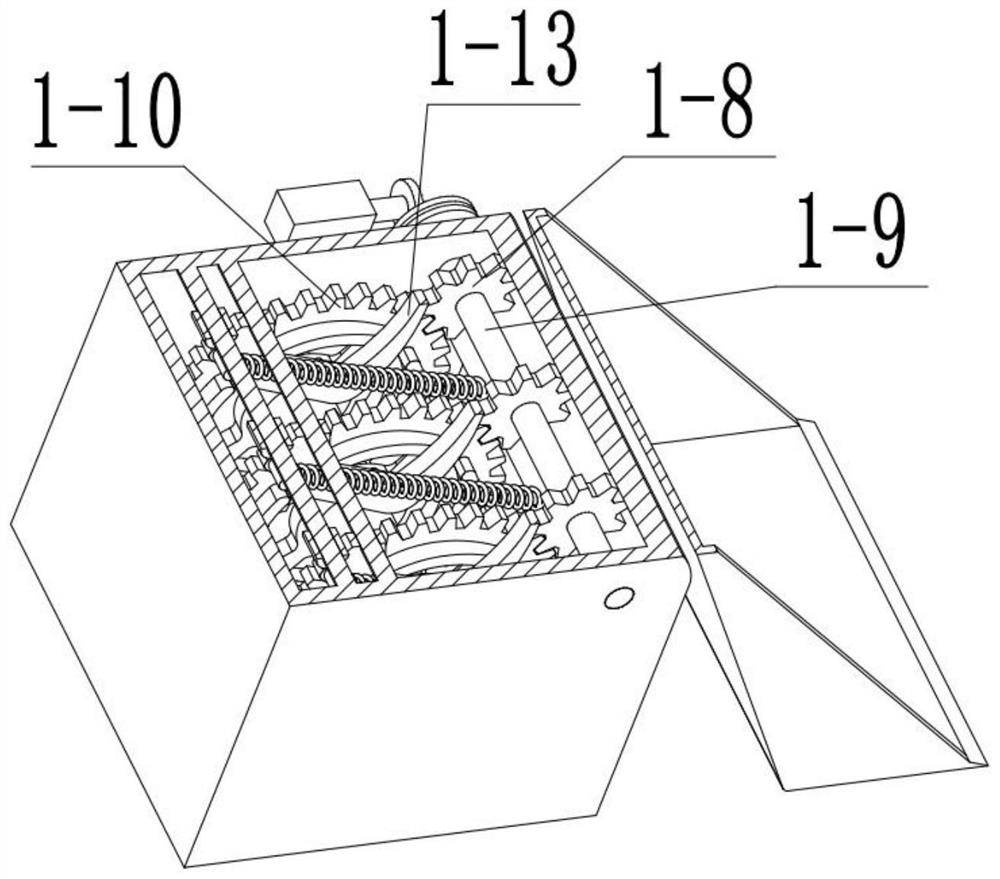

[0030] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain Embodiment 1, the snow harvesting device 1 includes a motor 1-1; a support rod 1-2; a slider 1-3; a chute 1-4; One 1-5; snow bucket 1-6; support rod two 1-7; gear one 1-8; fixed rod one 1-9; gear two 1-10; bump one 1-11; bump two 1- 12; power hook 1-13; fixed rod two 1-14; shell 1-15; fixed rod three 1-16; fixed rod four 1-17; tension spring 1-18; fixed column 1-19; fixed rod five 1 -20; Runner two 1-21, motor 1-1 is fixedly connected with support rod one 1-2, support rod one 1-2 is fixedly connected with slide block 1-3, slide block 1-3 is slidably connected in chute 1 On -4, the chute 1-4 is fixedly connected with the shell 1-15, the motor 1-1 is fixedly connected with the second runner 1-21, the first runner 1-5 is connected with the second runner 1-21, and three supports Rod two 1-7 are all fixedly connected with snow bucket 1-6, three gears one 1-8 are all fixedly connected w...

specific Embodiment approach 3

[0033] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the compacting device 2 includes motor two 2-1; gear three 2-2; gear four 2-3; connecting rod one 2-4; One 2-5; connecting frame 2-6; connecting rod two 2-7; hinged column one 2-8; gear five 2-9; internal gear 2-10; bracing frame 2-11; hinged column two 2-12; Connecting rod three 2-13; Small cylinder one 2-14; Transverse groove 2-15; Support rod two 2-16; Small cylinder two 2-17; Vertical groove 2-18; Compacting plate 2-19; 2-20; Support rod three 2-21; Support rod four 2-22, upper bearing plate 2-23; Upper notch 2-24; Upper hinged column one 2-25; Upper hinged column two 2-26; Connecting rod Four 2-27; Connecting rod five 2-28; Connecting rod six 2-29; Connecting rod seven 2-30; ; Lower hinge column one 2-35; Lower hinge column two 2-36; Pressure bar one 2-37; Pressure bar two 2-38, motor 2-1 is fixedly connected with gear three 2-2, two gears four 2- 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com