Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Nisil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

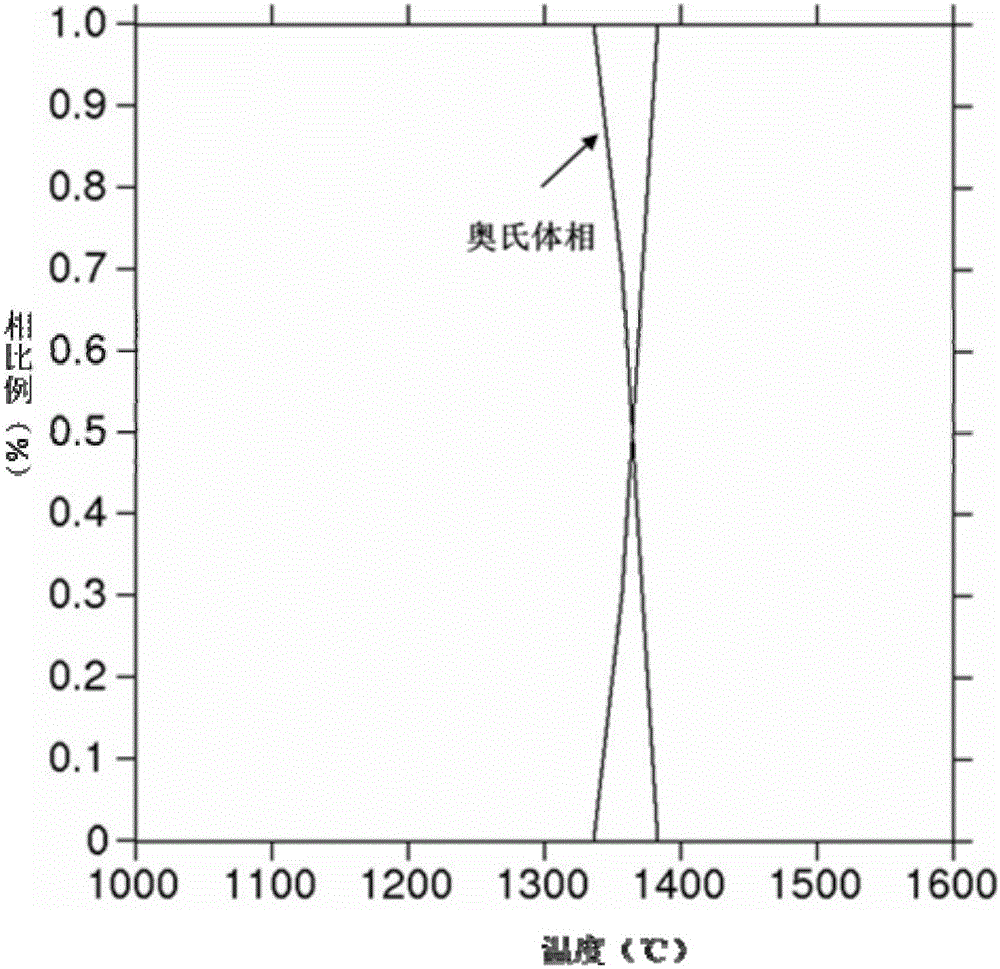

Nisil is an alloy of nickel (95.5% wt.) and silicon (4.4% wt.) with traces of Mg (0.1% wt.),which is non magnetic. Nisil melts at 1341 - 1420 °C, has a density of 8.58 g/cm³, and electrical resistivity of 0.365 Ω⋅mm²/m at 20 °C.

High-strength shipbuilding section and production method thereof

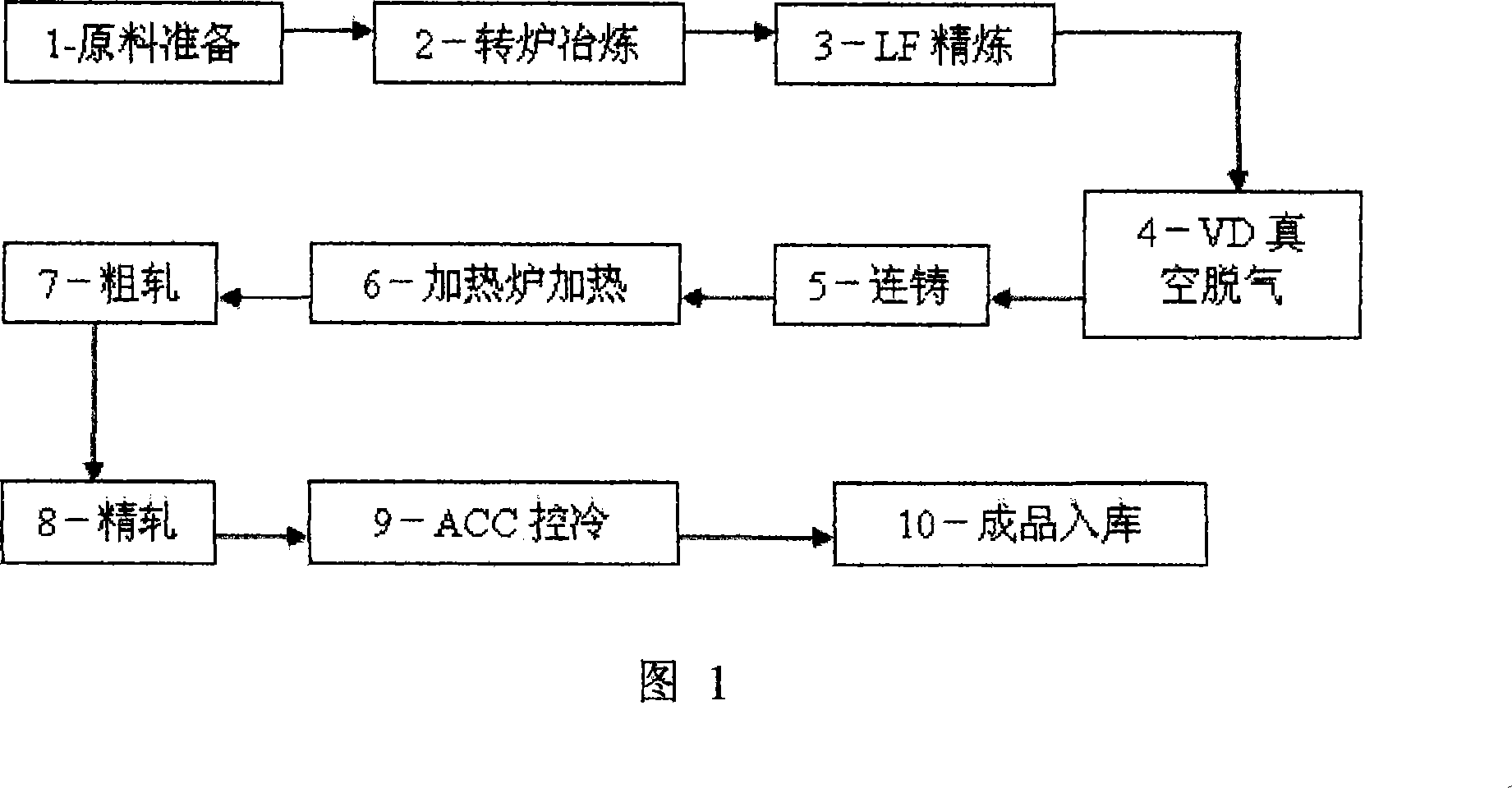

The invention discloses a high-strength marine steel plate and a production method thereof. The mass percentages of main chemical components of the high-strength marine steel plate are: carbon=0.05%-0.10%, silicon=0.30-0.50%, manganese=1.20%-1.60%, Phosphorus ≤ 0.02%, sulfur ≤ 0.010%, niobium = 0.02% ~ 0.05%, titanium = 0.008 ~ 0.02%, aluminum = 0.02% ~ 0.06%, nickel = 0.0 ~ 0.40%, chromium = 0 ~ 0.70%, molybdenum = 0 ~0.60%, copper=0~0.70%, vanadium=0.0~0.05%, nitrogen≤0.008%. The production process is: raw material preparation (1), converter smelting (2), LF refining (3), VD vacuum degassing (4), continuous casting (5), heating furnace heating (6), rough rolling (7), Finish rolling (8), AGC controlled cooling (9) and storage of finished products (10).

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

High-strength corrosion-resisting nickel base alloy and manufacturing method thereof

InactiveCN102628127AWill not affect the comprehensive application performanceNo destabilizationRare-earth elementNiobium

The invention relates to a high-strength corrosion-resisting nickel base alloy and a manufacturing method thereof. The high-strength corrosion-resisting nickel base alloy comprises the following chemical components by weight percent: not more than 0.04% of carbon (C), about 20.0%-26.0% of chromium (Cr), about 6.0%-10.0% of cobalt (Co), about 4.0%-8.0% of tungsten (W), not more than 1.0% of molybdenum (Mo), not more than 1.0% of Ferrum (Fe), not more than 0.5% of silicon (Si), not more than 0.5% of manganese (Mn), about 0.8%-1.3% of niobium (Nb), about 0.3%-0.7% of titanium (Ti), about 0.6%-1.0% of aluminum (Al), about 0.1%-0.4% of zirconium (Zr), not more than 0.003% of boron (B), tiny lanthanum (La) or rare-earth element (Re), and the balance of nickel (Ni) and inevitable impurity element. Vacuum melting and electroslag remelting are adopted, and then solution treatment and ageing treatment are performed.

Owner:丹阳恒庆复合材料科技有限公司

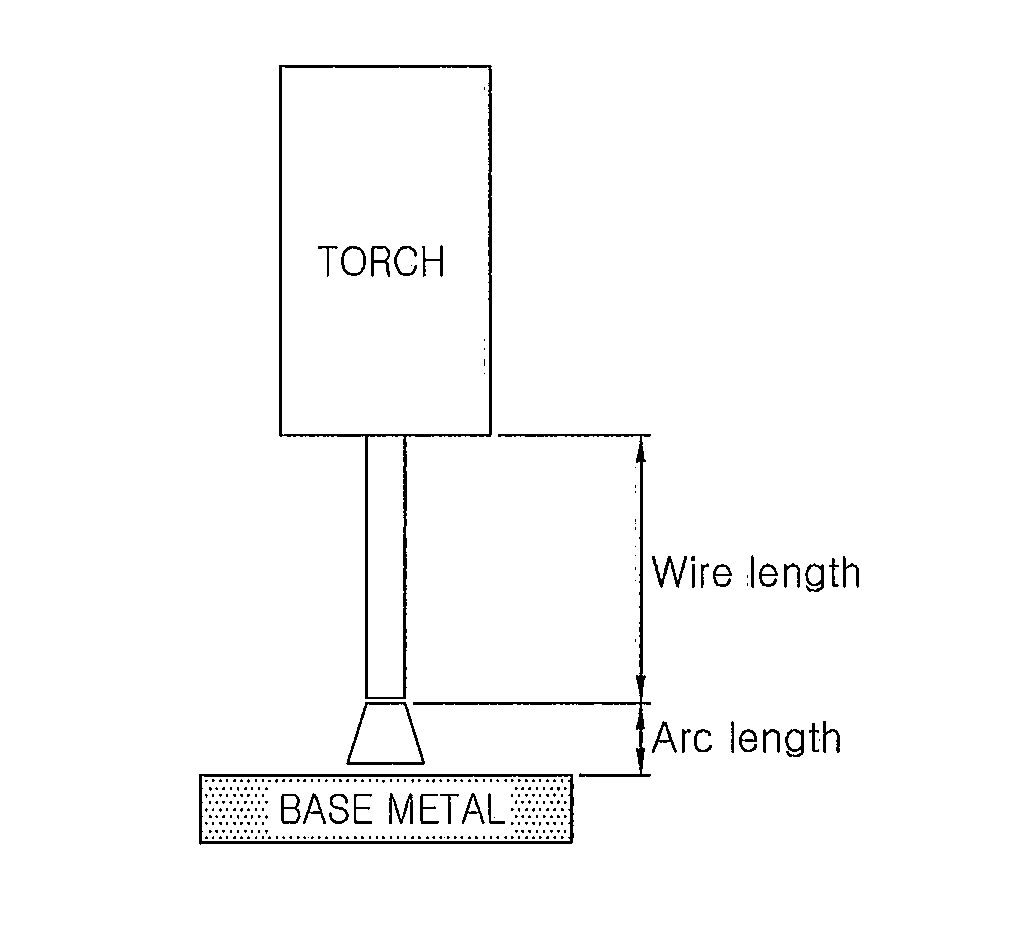

Welding alloy and articles for use in welding, weldments and method for producing weldments

A nickel, chromium, iron alloy and method for use in producing weld deposits and weldments formed therefrom. The alloy comprises, in weight percent, about 28.5 to 31.0% chromium; about 0 to 16% iron, preferably 7.0 to 10.5% iron, less than about 1.0% manganese, preferably 0.05 to 0.35% manganese; about 2.1 to 4.0% niobium plus tantalum, preferably 2.1 to 3.5% niobium plus tantalum, and more preferably 2.2 to 2.8% niobium plus tantalum; 0 to 7.0% molybdenum, preferably 1.0 to 6.5%, and more preferably 3.0 to 5.0% molybdenum; less than 0.50% silicon, preferably 0.05 to 0.30% silicon; 0.01 to 0.35% titanium; 0 to 0.25% aluminum; less than 1.0% copper; less than 1.0% tungsten; less than 0.5% cobalt; less than about 0.10% zirconium; less than about 0.01% sulfur; less than 0.01% boron, preferably less than 0.0015% boron, and more preferably less than 0.001% boron; less than 0.03% carbon; less than about 0.02% phosphorous; 0.002 to 0.015% magnesium plus calcium; and balance nickel and incidental impurities. The method includes the steps of forming a welding electrode from the above alloy composition and melting the electrode to form a weld deposit. A preferred weldment made from the alloy and method includes an alloy substrate in the form of a tubesheet of a nuclear reactor.

Owner:AREVA NP INC +1

Welding alloy and articles for use in welding, weldments and method for producing weldments

A nickel, chromium, iron alloy and method for use in producing weld deposits and weldments formed therefrom. The alloy comprises, in weight percent, about 28.5 to 31.0% chromium; about 0 to 16% iron; less than about 1.0% manganese; about 2.1 to 4.0% niobium plus tantalum; 1.0 to 6.5% molybdenum; less than 0.50% silicon; 0.01 to 0.35% titanium; 0 to 0.25% aluminum; less than 1.0% copper; less than 1.0% tungsten; less than 0.5% cobalt; less than about 0.10% zirconium; less than about 0.01% sulfur; less than 0.01% boron; less than 0.03% carbon; less than about 0.02% phosphorous; 0.002 to 0.015% magnesium plus calcium; and balance nickel and incidental impurities. The method includes the steps of forming a welding electrode from the above alloy composition and melting the electrode to form a weld deposit. A preferred weldment may be in the form of a tubesheet of a nuclear reactor.

Owner:AREVA NP INC +1

Metal pastes and use thereof in the production of silicon solar cells

InactiveUS20110240124A1Conductive materialSemiconductor/solid-state device manufacturingElectrically conductiveNisil

Owner:EI DU PONT DE NEMOURS & CO

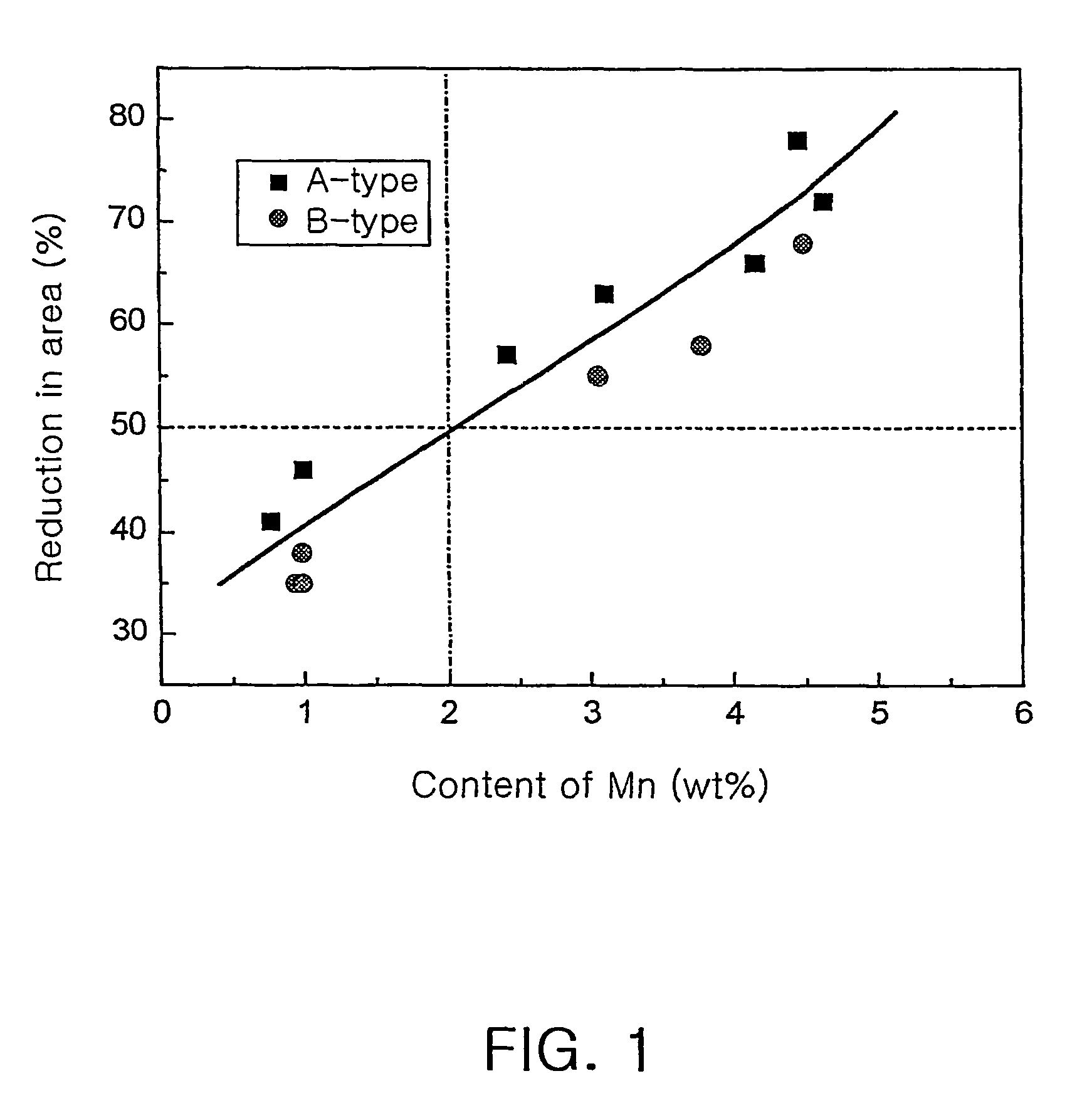

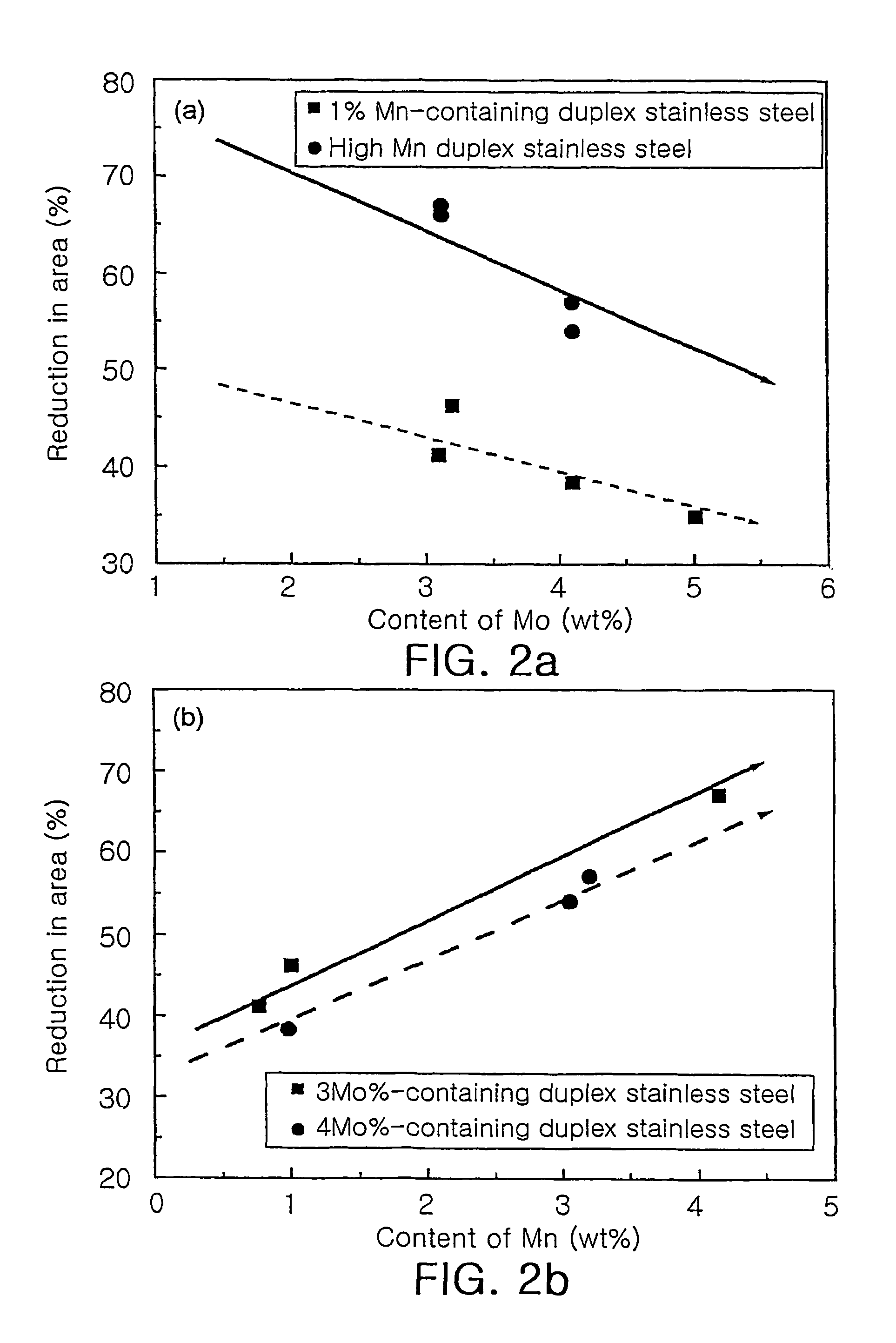

High manganese duplex stainless steel having superior hot workabilities and method for manufacturing thereof

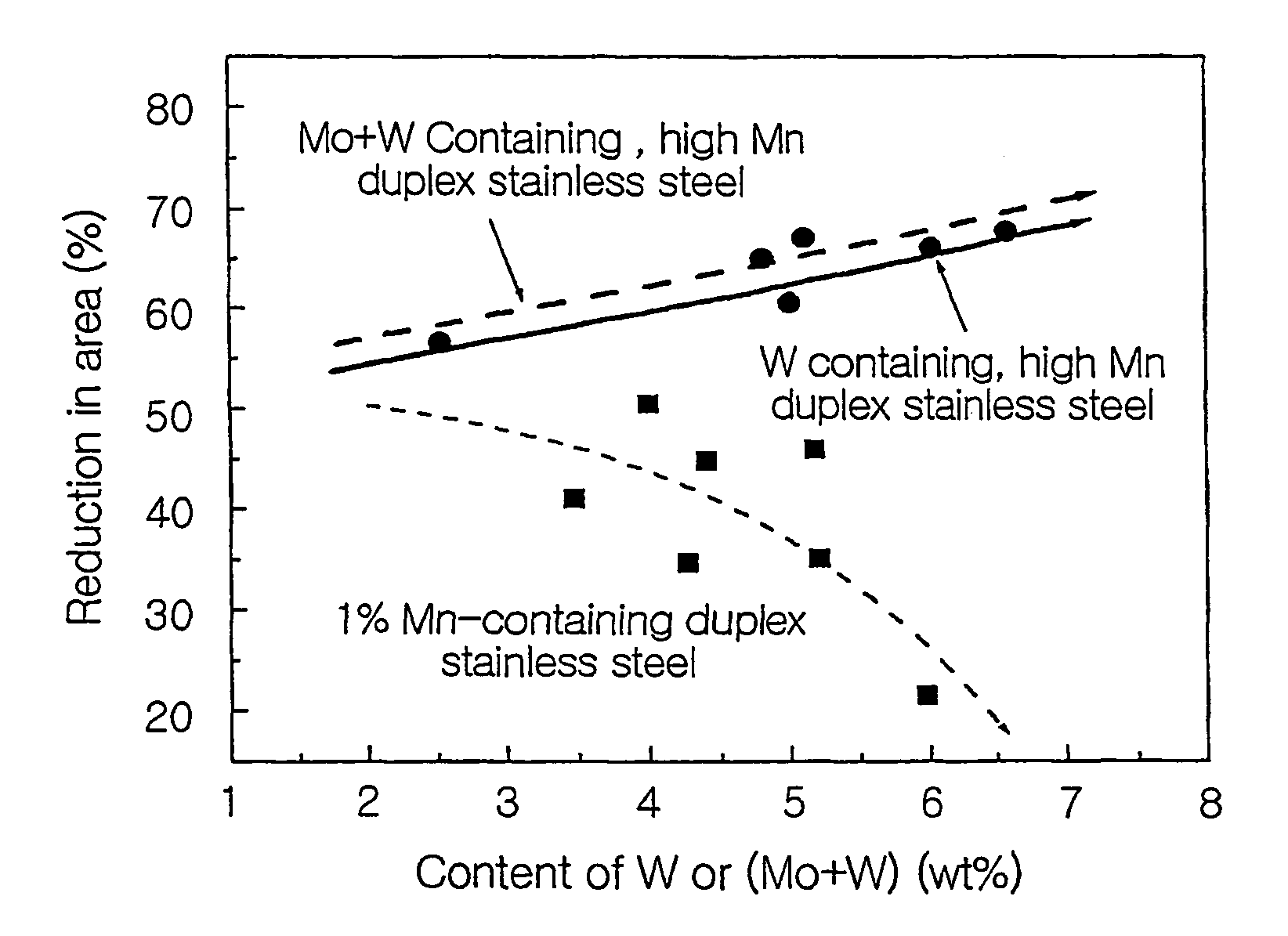

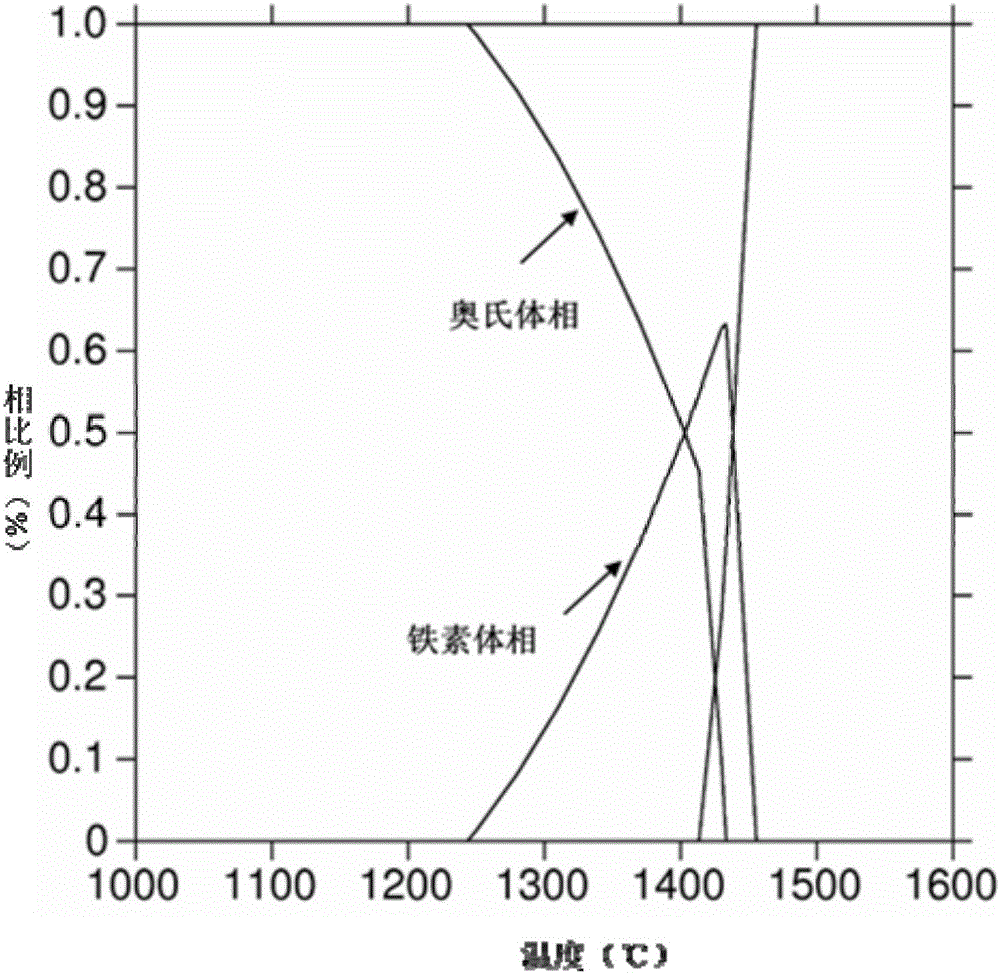

A high manganese duplex stainless steel with excellent hot workability, comprising (in weight %): less than 0.1% of C; 0.05-2.2% of Si; 2.1-7.8% of Mn; 20-29% of Cr; 3.0-9.5% of Ni; 0.08-0.5% of N; less than 5.0% of Mo and 1.2-8% of W, alone or composite; the balance Fe and inevitable impurities; and a method for manufacturing the duplex stainless steel, comprising the steps of: solution heating the duplex stainless steel composition at a temperature of 1,050 to 1,250° C., hot working at a starting temperature of 1,130 to 1,280° C. and then ending at a temperature greater than 1,000° C., and then cooling within the temperature range from 1,000 to 700° C. at a cooling rate of more than 3° C. / min. The duplex stainless steel exhibits a reduction in area of more than 50% at 1,050° C., and possesses a yield strength of more than 400 MPa, and a corrosion rate of less than 0.36 mm / year, after solution heating.

Owner:RES INST OF IND SCI & TECH

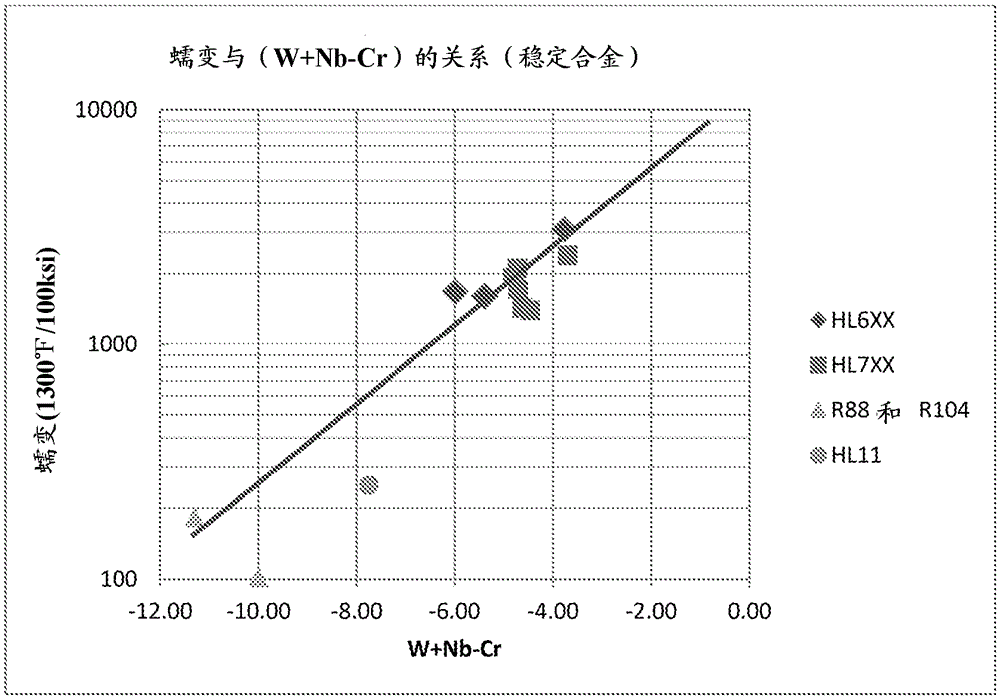

Superalloys and components formed thereof

ActiveCN105492639AImproved high temperature and pressure holding propertiesImproved creep characteristicsEfficient propulsion technologiesNiobiumHafnium

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and hold time fatigue crack growth behavior. A particular example of a component is a powder metallurgy turbine disk of a gas turbine engine. The gamma-prime nickel-base superalloy contains, by weight: 16.0 to 30.0% cobalt; 9.5 to 12.5% chromium; 4.0 to 6.0% tantalum; 2.0 to 4.0% aluminum; 2.0 to 3.4% titanium; 3.0 to 6.0% tungsten; 1.0 to 4.0% molybdenum; 1.5 to 3.5% niobium; up to 1.0% hafnium; 0.02 to 0.20% carbon; 0.01 to 0.05% boron; 0.02 to 0.10% zirconium; the balance essentially nickel and impurities. The superalloy has a W+Nb-Cr value of at least-6, is free of observable amounts of sigma and eta phases, and exhibits a time to 0.2% creep at 1300 Fahrenheit and 100 ksi of at least 1000 hours.

Owner:GENERAL ELECTRIC CO

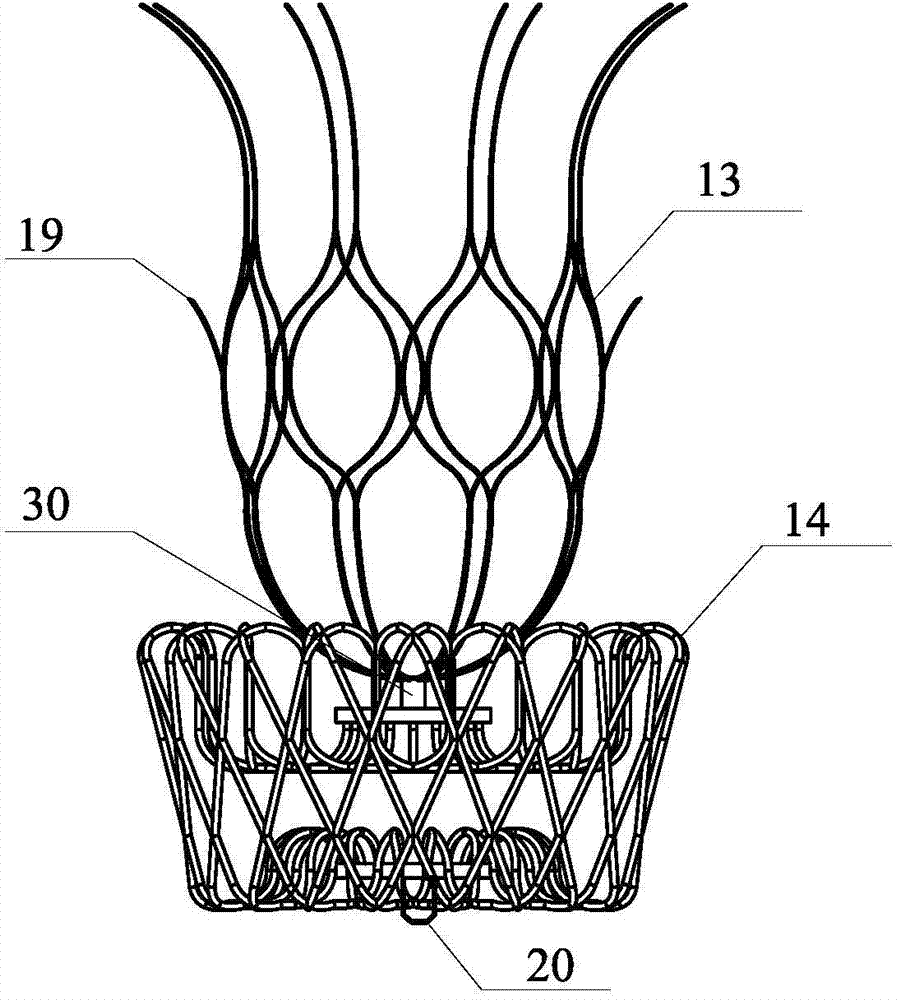

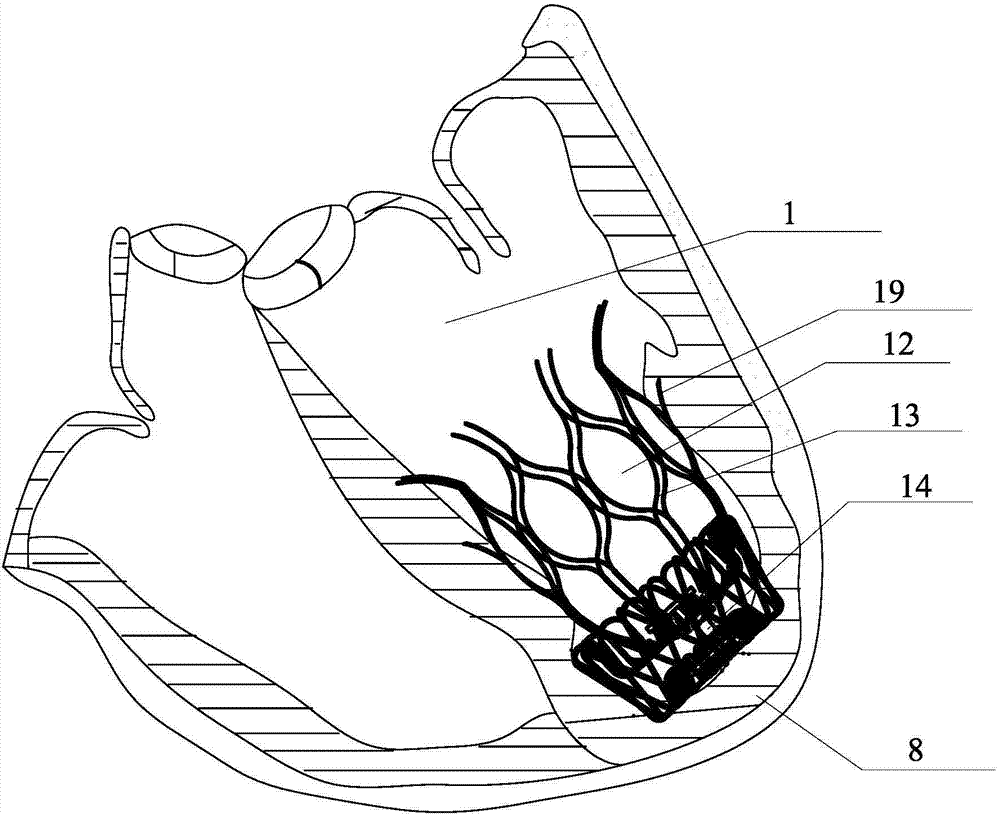

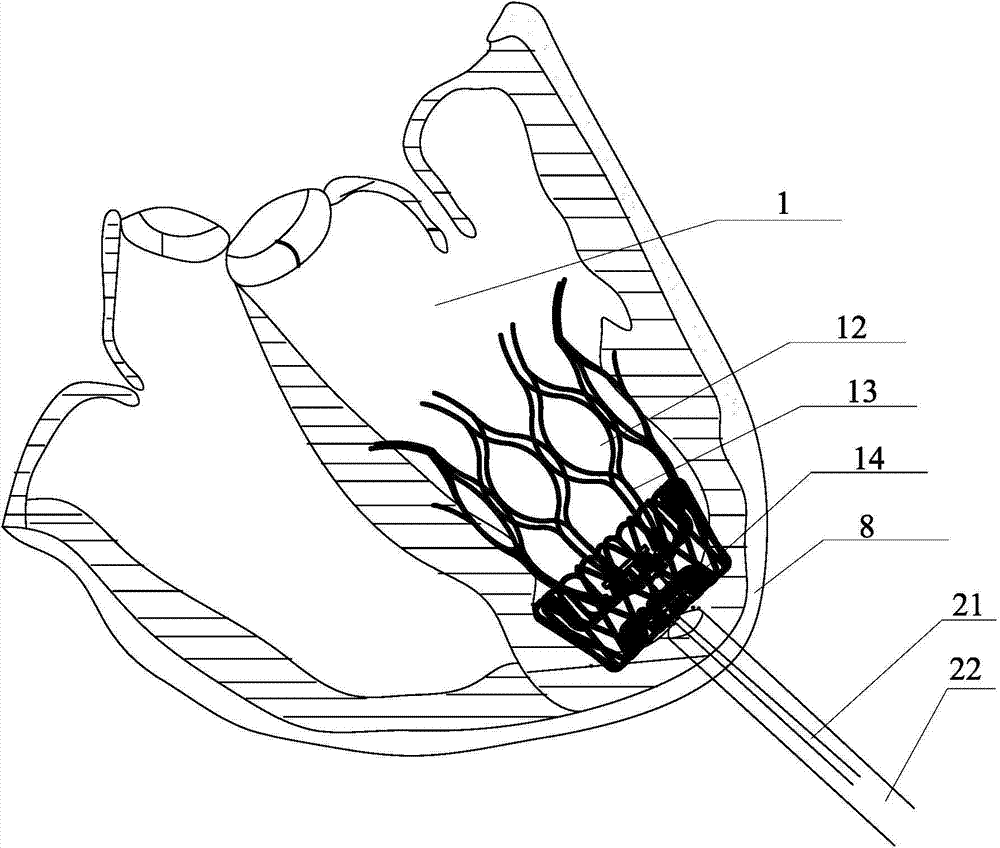

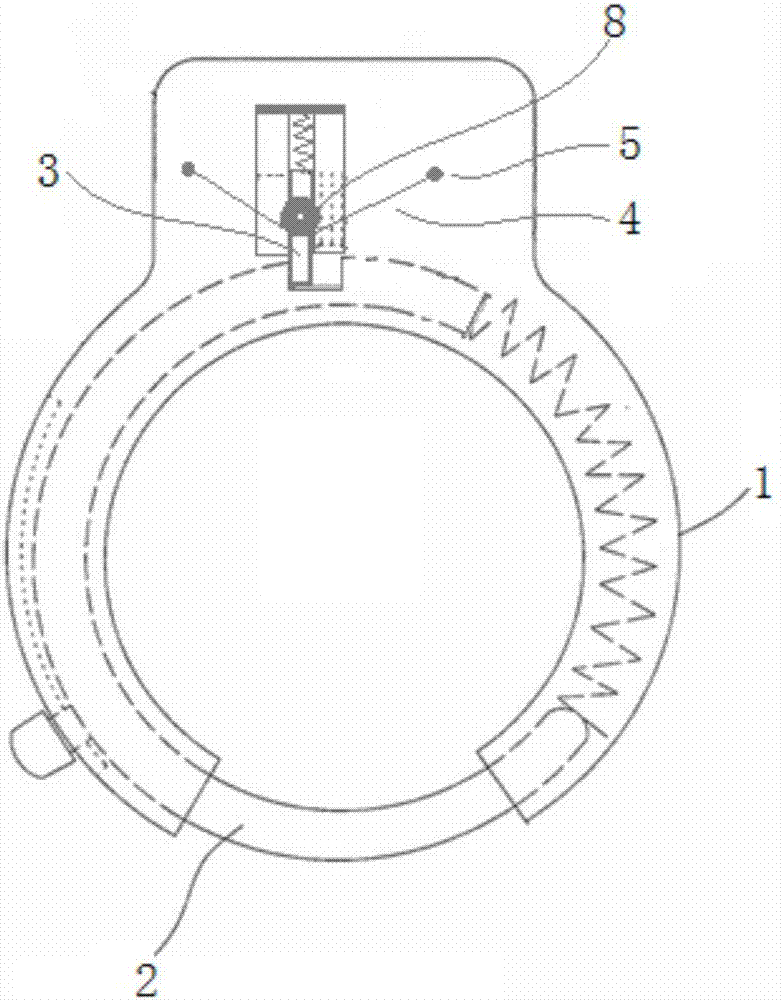

Left ventricle volume reduction device

ActiveCN104739460AEasy to operateReduce surgical riskAnnuloplasty ringsOcculdersClosed loopCardiac muscle

The invention discloses a left ventricle volume reduction device. Two-section design is adopted. The left ventricle volume reduction device comprises a base and a body. The base is of a cage structure. The body is formed by conducting laser cutting on a whole nickel-titanium alloy tube and designed in multiple layers of meshes. The meshes are designed into a closed-loop structure, the top end of the body is provided with anchor thorns inclining upwards, in the placing process, the anchor thorns can prick into the cardiac muscle of the left ventricle wall, the effect of anchoring the left ventricle volume reduction device is achieved, the lower end of the body is connected with a tubular structure, the tubular structure is connected with the base, and the base is woven into a woven mesh structure through nickel-titanium wires and thermally treated into a disc shape. The left ventricle volume reduction device can be repeatedly positioned and is stable in fixation.

Owner:SHENZHEN KYD BIOMEDICAL TECH CO LTD

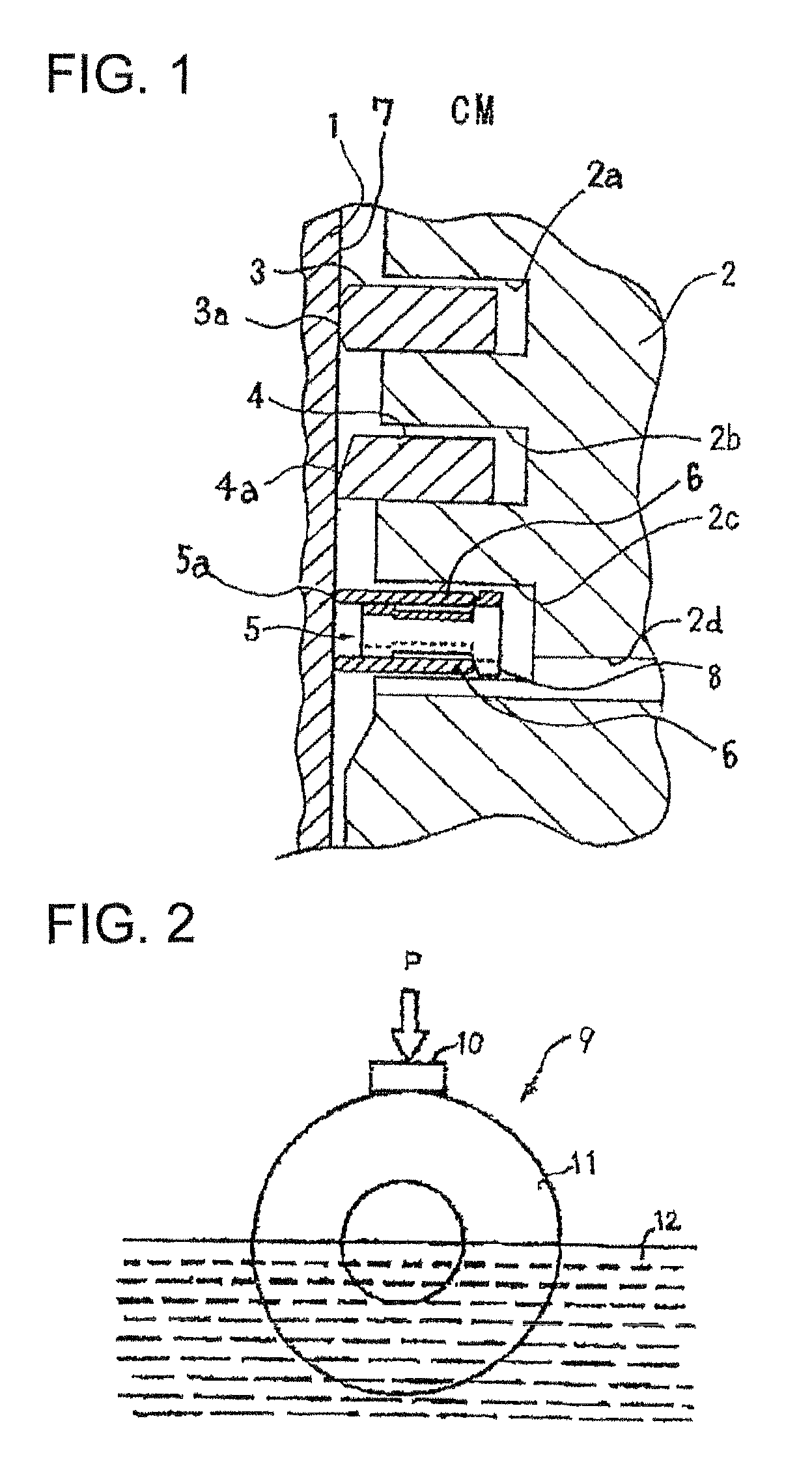

Combination of a cylinder liner and a piston ring

InactiveUS7493882B2Reduce weightReduce frictionPiston ringsCylinder headsPiston ringSurface roughness

A combination of a cylinder liner and a piston ring, wherein the cylinder liner includes, silicon: 23.0-28.0% by weight, magnesium: 0.80-2.0% by weight, copper: 3.0-4.5% by weight, iron: 0.25% by weight or less, nickel: 0.01% by weight or less, wherein surface roughness profile of the inner circumference surface has Rz=0.5 to 1.0 μm, Rk=0.2 to 0.4 μm, Rpk=0.05 to 0.1 μm, Rvk=0.08 to 0.2 μm, wherein the piston ring includes carbon: 0.6-0.7% by weight, chrome: 13-14% by weight, molybdenum: 0.2-0.4% by weight, silicon: 0.25-0.50% by weight, manganese: 0.2-0.5% by weight, and wherein carbides with the diameter of 5.0 μm and less are 4-10%.

Owner:NIPPON PISTONRING CO LTD

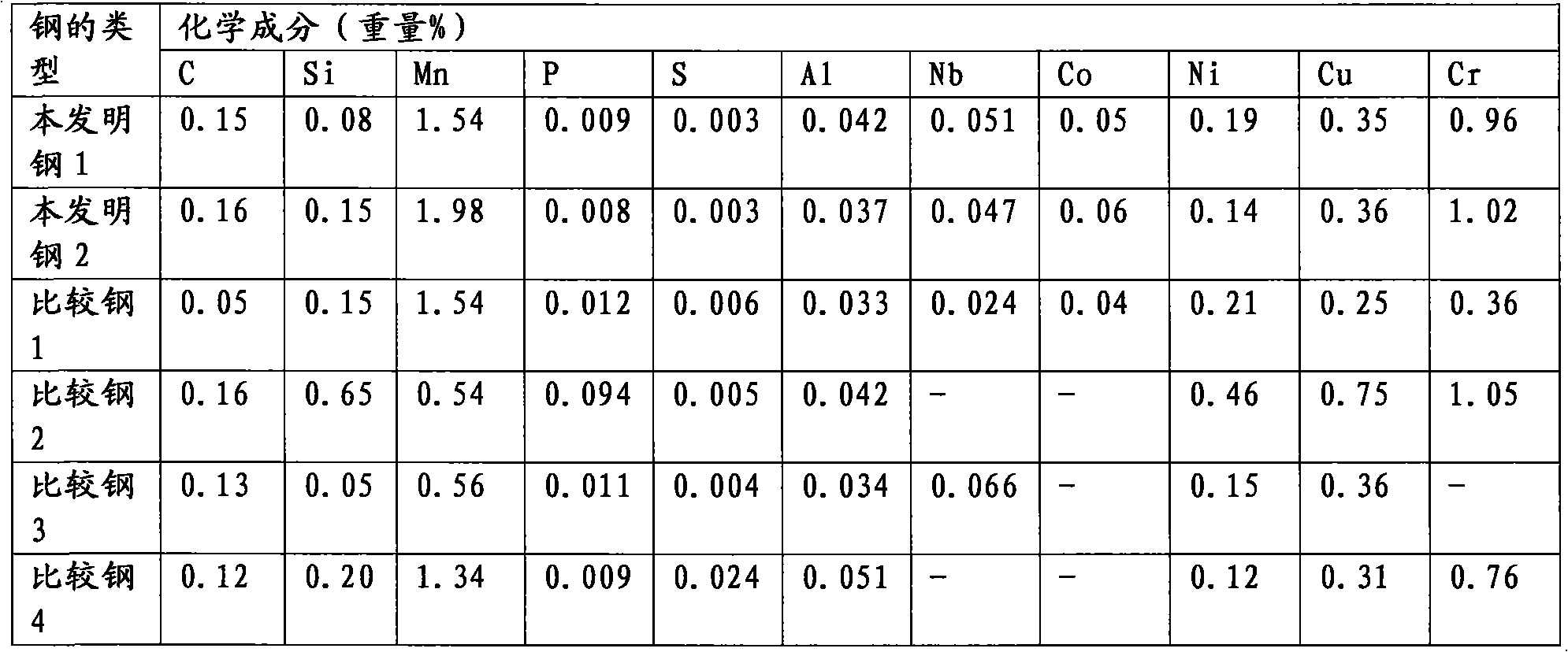

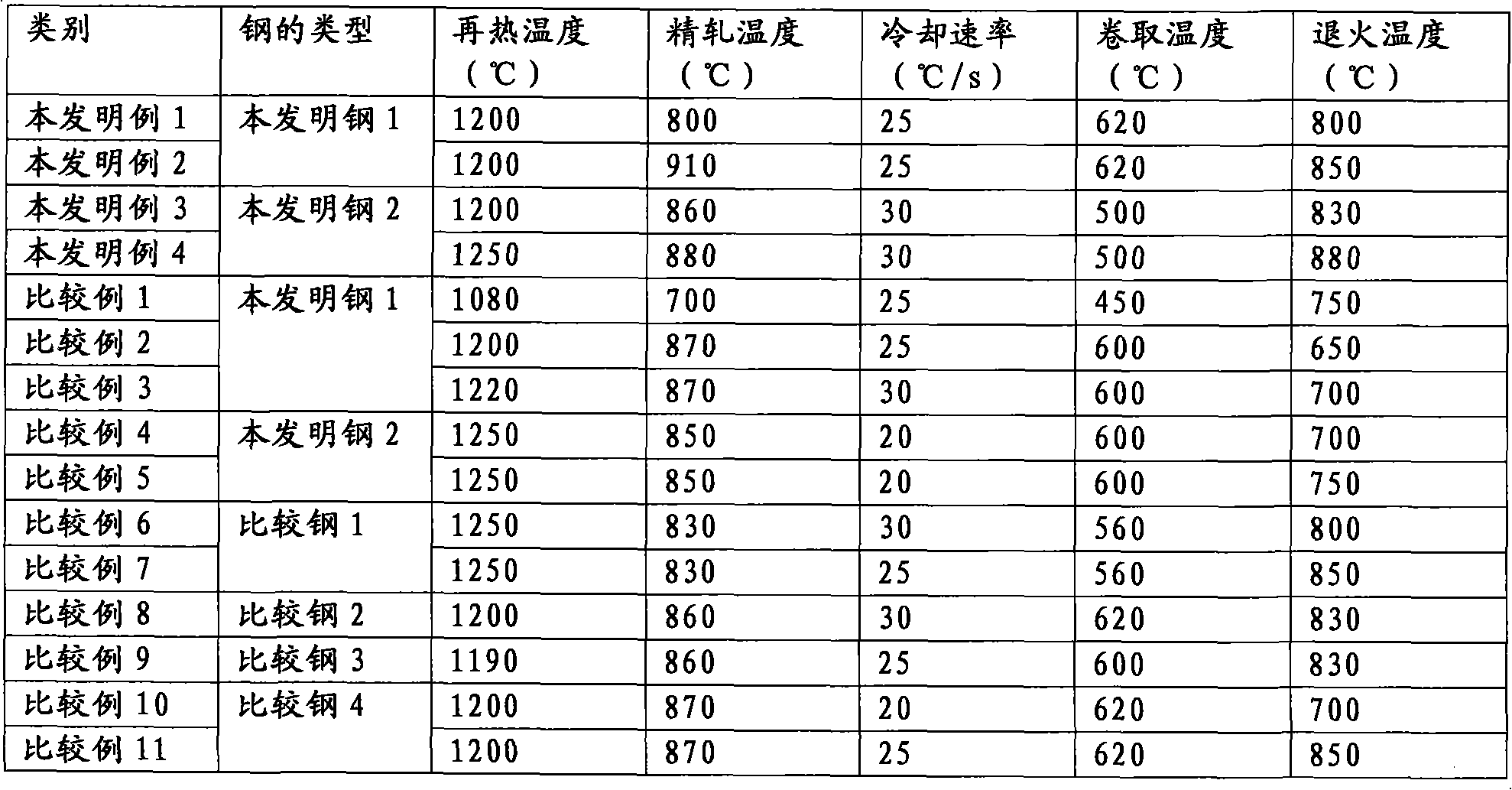

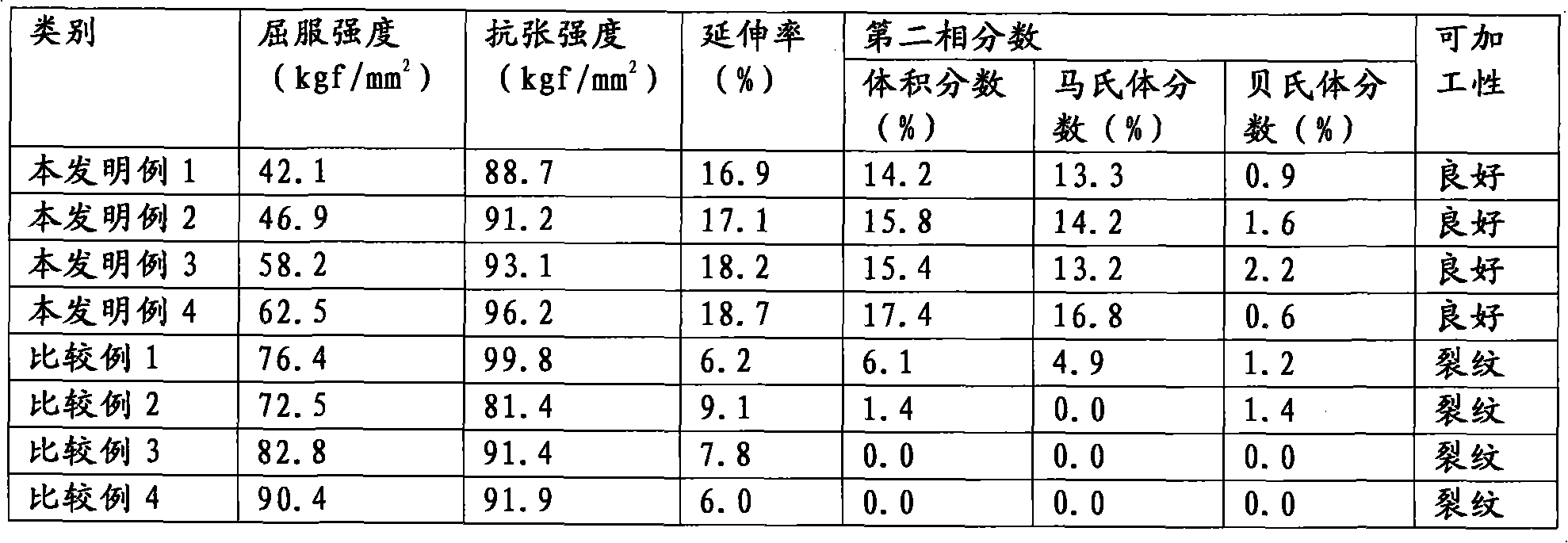

Formable high strength cold-rolled steel sheet with excellent weather resistance and method manufacturing the same

There are provided a formable high strength cold-rolled steel sheet with excellent weather resistance and a tensile strength of 80 or more kgf / mm, a method for manufacturing the same. The formable cold-rolled steel sheet includes, by weigh: carbon (C): 0.10 to 0.20%, silicon (Si): 0.05 to 0.25%, manganese (Mn): 1.0 to 2.5%, phosphorus (P): 0.02% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.02 to 0.07%, niobium (Nb): 0.02 to 0.08%, nickel (Ni): 0.05 to 0.30%, copper (Cu): 0.1 to 0.5%, chromium (Cr): 0.8 to 1.5% and cobalt (Co): 0.01 to 0.10%, and the balance of Fe and other inevitable impurities, wherein a low-temperature transformation structure is present in a volume of 10 to 30% and the balance is a ferrite structure.

Owner:POHANG IRON & STEEL CO LTD

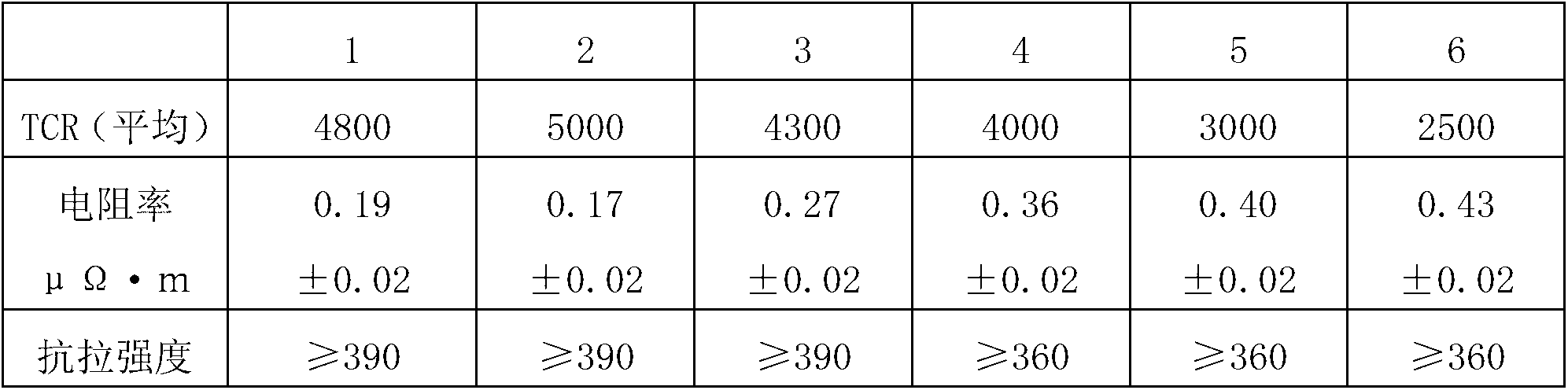

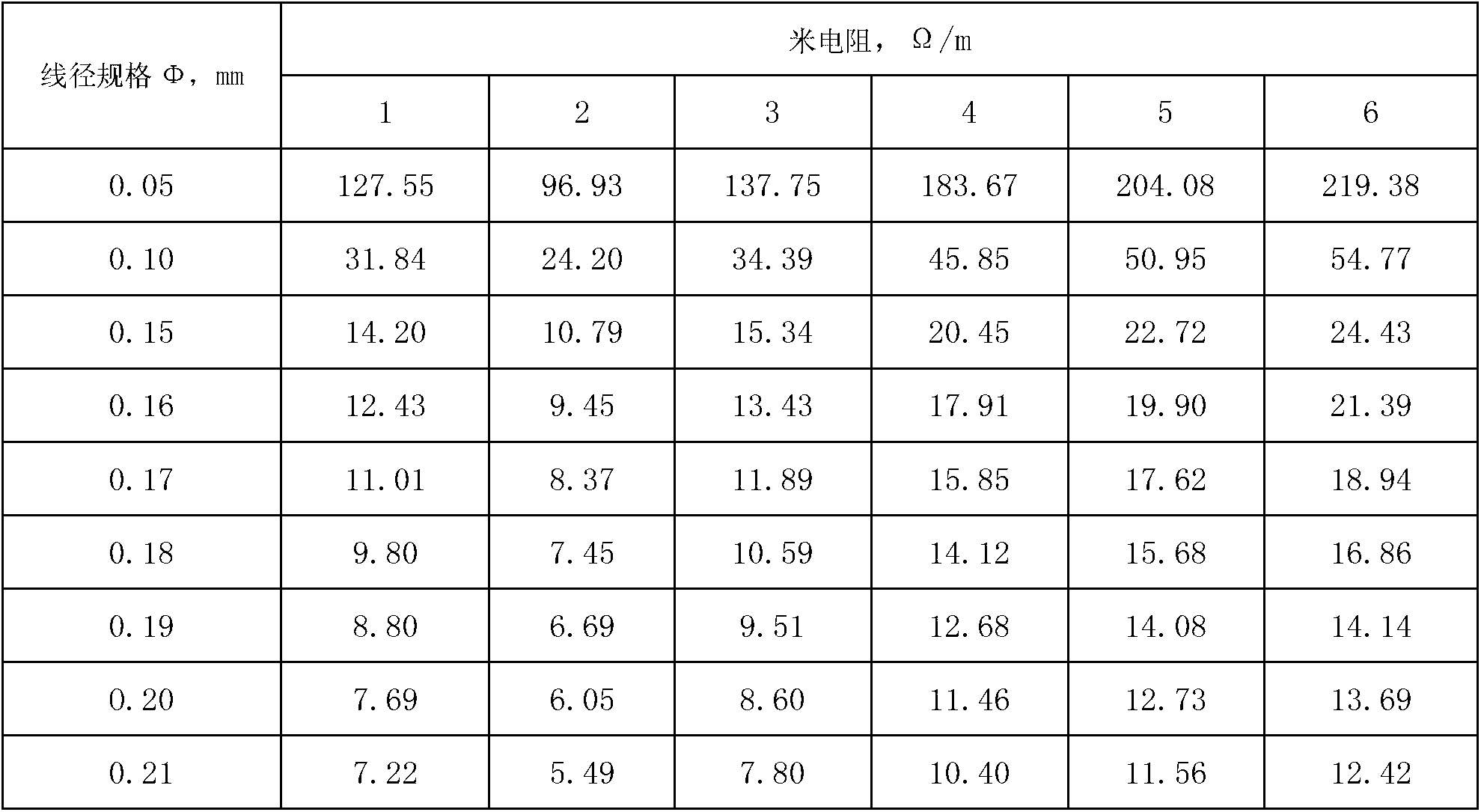

Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

ActiveCN103060615AMeet requirements such as more sensitive temperature controlExtended service lifePositive temperature coefficient thermistorsProcess efficiency improvementMisch metalRare earth

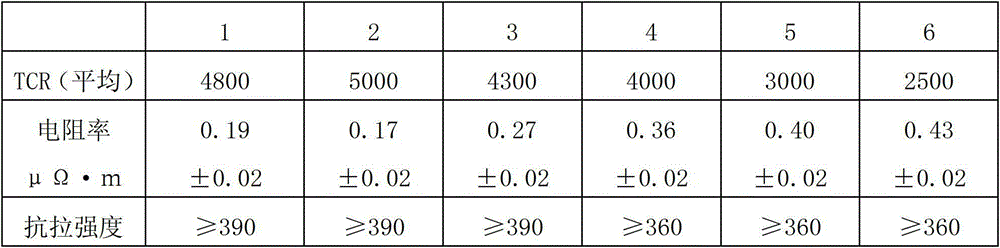

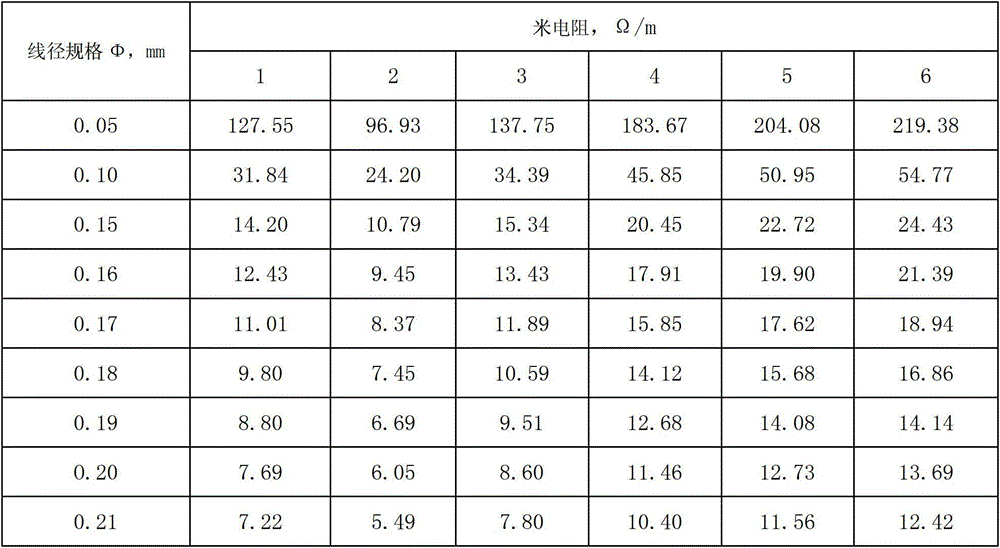

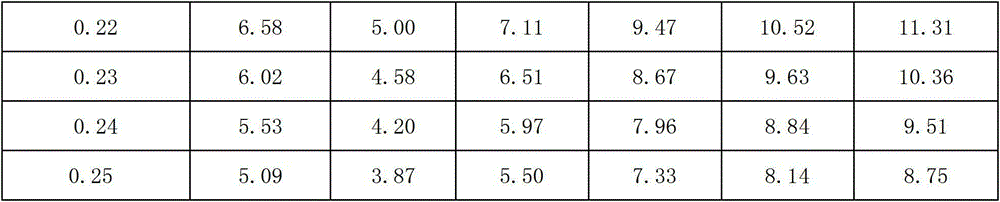

The invention discloses a positive temperature coefficient (PTC) thermal resistance alloy wire and a preparation method thereof. The alloy wire comprises the chemical ingredients by weight percent of 45-82.0% of nickel, 0.1-0.6% of silicon, 0.22-0.35% of manganese, 0.02-0.04% of yttrium, 0.04-0.06% of misch metal, 0.05% or less of carbon, 0.01% or less of sulphur, 0.001% or less of phosphorus and the balance of iron. The mean resistance temperature coefficient at 0-150 DEG C is 2500*10(-6) per DEG C to 5000*10(-6) per DEG C by changing the matching content of the components; the PTC thermal resistance alloy wire of which the resistance temperature coefficient which is urgently needed at present and higher than 3000*10(-6) per DEG C is included; the highest mean resistance temperature coefficient can be 5000*10(-6) per DEG C, and the requirements of more sensitive temperature control of novel electrical equipment can be met.

Owner:JIANGSU HUAXIN ALLOY

Powder sinter process for preparing permanent-magnet Al-Ni-Co-Ti alloy

A permanent-magnet Al-Ni-Co-Ti alloy is prepared from Al (6-8 wt.%), Co (36.1-37.9 wt.%), Cu (2.5-5 wt.%), Nb (0.2-1.5 wt.%), Ni (10-14 wt.%), Ti (5-8 wt.%), and Fe (the banance) through 4-stage sintering, cooling in furnace or in argon gas to 100 deg.c, and heat treatment. Its density can reach 7.3g / cu.cm.

Owner:HANGZHOU PERMANENT MAGNET GRP

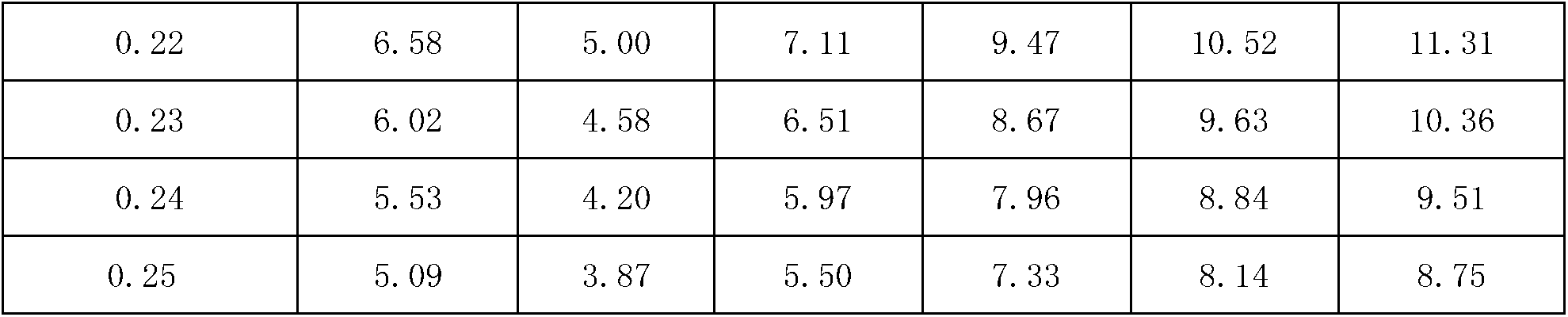

High-hardness non-magnetic nickelless stainless steel and manufacturing method thereof

The invention discloses high-hardness non-magnetic nickelless stainless steel. The steel is composed of, by weight, 0.15%-0.20% of C, 0.2%-0.8% of Si, 17.0%-19.0% of Mn, 13.5%-14.5% of Cr, 0.25%-0.30% of N, 0.5%-0.8% of Cu, 0.0015%-0.0040% of B, and the balance Fe and inevitable impurities, and the elements simultaneously meet the following relations that the sum of C and N is larger than or equal to 0.43%, (Cr+Mo+1.5*Si) / (30*N+30*C+0.25*Cu+0.5*Mn) is greater than or equal to 1.00 but smaller than or equal to 1.20, and the temperature of Md <30 / 50> is lower than or equal to -100 DEG C. The steel is in a full austenitic mode (without delta phase being produced) in the solidification process, the hardness reaches HV425-497 at the room temperature, and the yield strength is 1100-1350 MPa. Meanwhile, the steel is kept non-magnetic after reaching high strength through deformation hardening at the room temperature and is nickelless, and demagnetizing heat treatment is not needed after deformation, so that the cost is remarkably reduced; and the steel can be widely applied to spinning, electron, instruments and meters and other industries with the requirements for high hardness, abrasion resistance and non-magnetism.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Nickel-Chromium-Iron-Molybdenum Corrosion Resistant Alloy and Article of Manufacture and Method of Manufacturing Thereof

A solid-solution nickel-based alloy for use in sour gas and oil environments, including, in percent by weight: chromium: min. of 21.0 and max. of 24.0%; iron: min. of 17.0 and max. of 21.0%; molybdenum: min. of 6.5 and max. of 8.0%; copper: min. of 1.0 and max. of 2.5%; tungsten: min. of 0.1 and max. of 1.5%; sol. nitrogen: min. of 0.08 and max. of 0.20%; manganese: max. of 4.0%; silicon: max. of 1.0%; carbon: max of. 0.015%; aluminum: max of 0.5%; and a total amount of niobium, titanium, vanadium, tantalum, and zirconium: max of 0.45%; the balance being nickel and incidental impurities, along with a method of manufacturing an article from the alloy, and an article of manufacture formed from the alloy.

Owner:HUNTINGTON ALLOYS CORP (US)

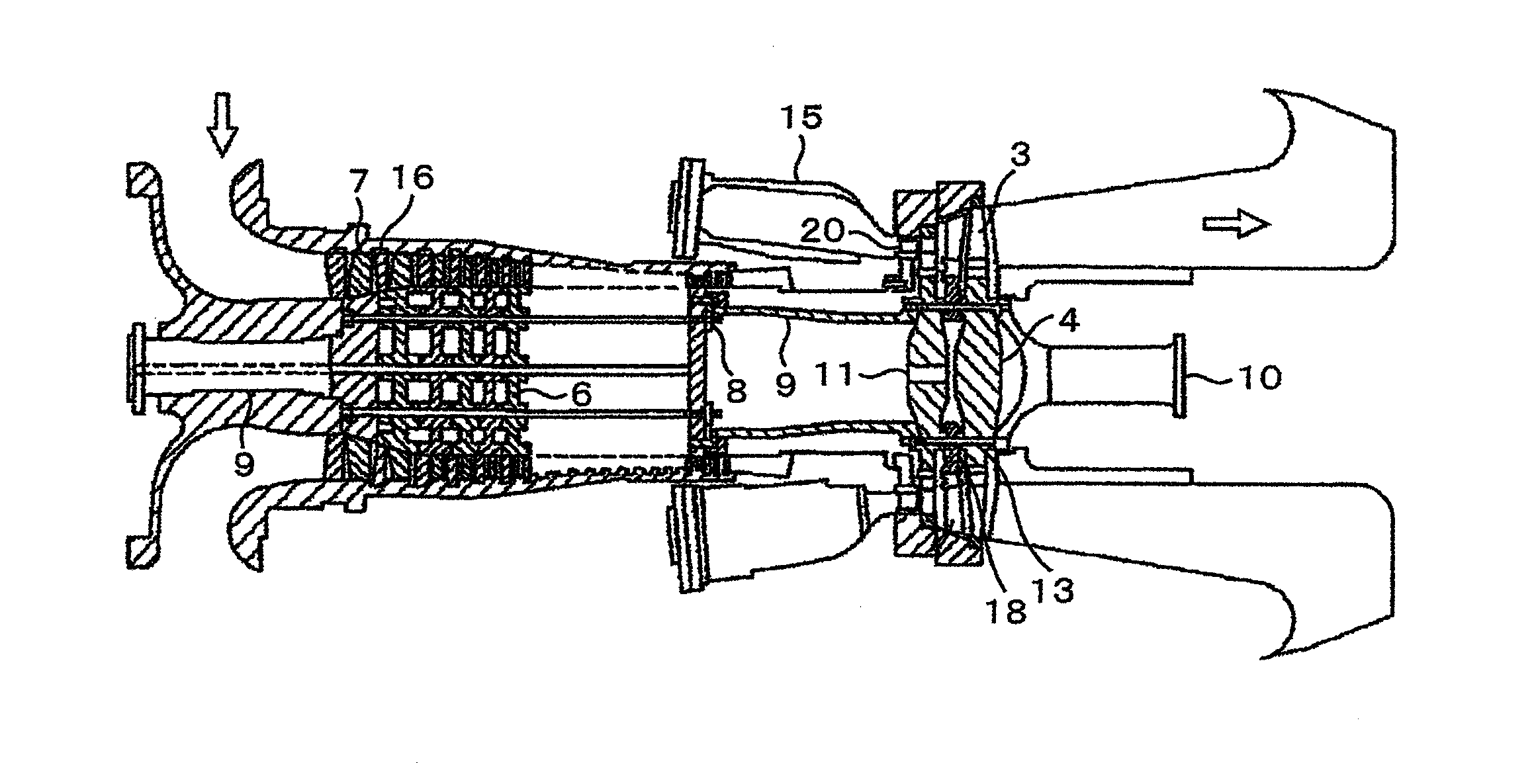

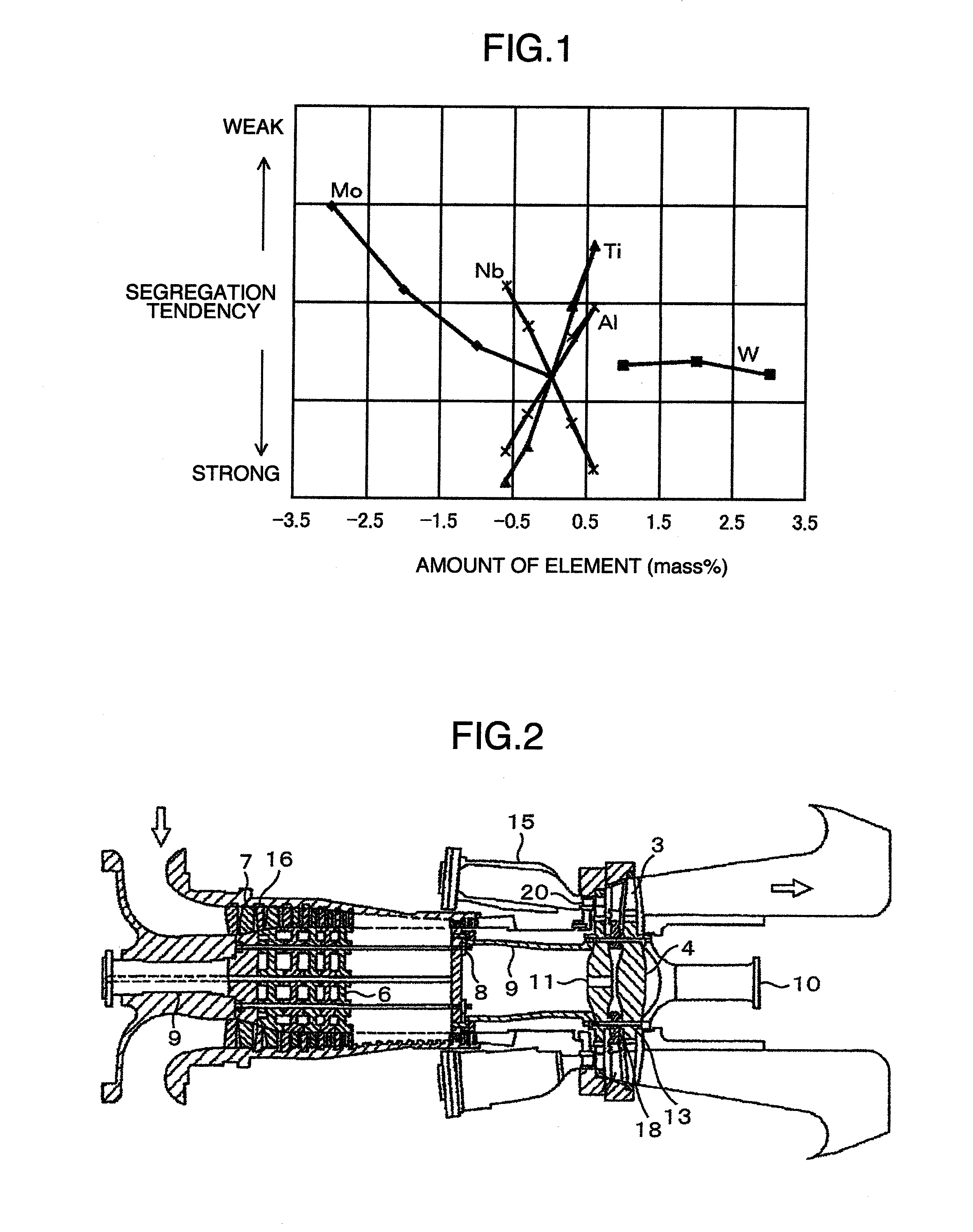

Ni-based heat resistant alloy, gas turbine component and gas turbine

ActiveUS20120141293A1High strengthImprove gas efficiencyBlade accessoriesReaction enginesNiobiumAlloy

A Ni-based heat resistant alloy has a composition of, by mass percent, carbon: 0.001 to 0.1%, chromium: 16 to 22%, aluminum: 0.5 to 1.5%, molybdenum: 0.1 to 2.0%, tungsten: 0.1 to 6.0%, niobium: 3.5 to 5.5%, titanium: 0.8 to 3.0%, iron: 16 to 20%, and the balance being nickel and inevitable impurities. A parameter Ps indicating a segregation tendency is in a range of Ps≧−3.5. The parameter Ps is represented by Formula (1).Ps=1.05×Al content+0.6×Ti content−0.8×Nb content−0.3×Mo content (1)

Owner:MITSUBISHI POWER LTD

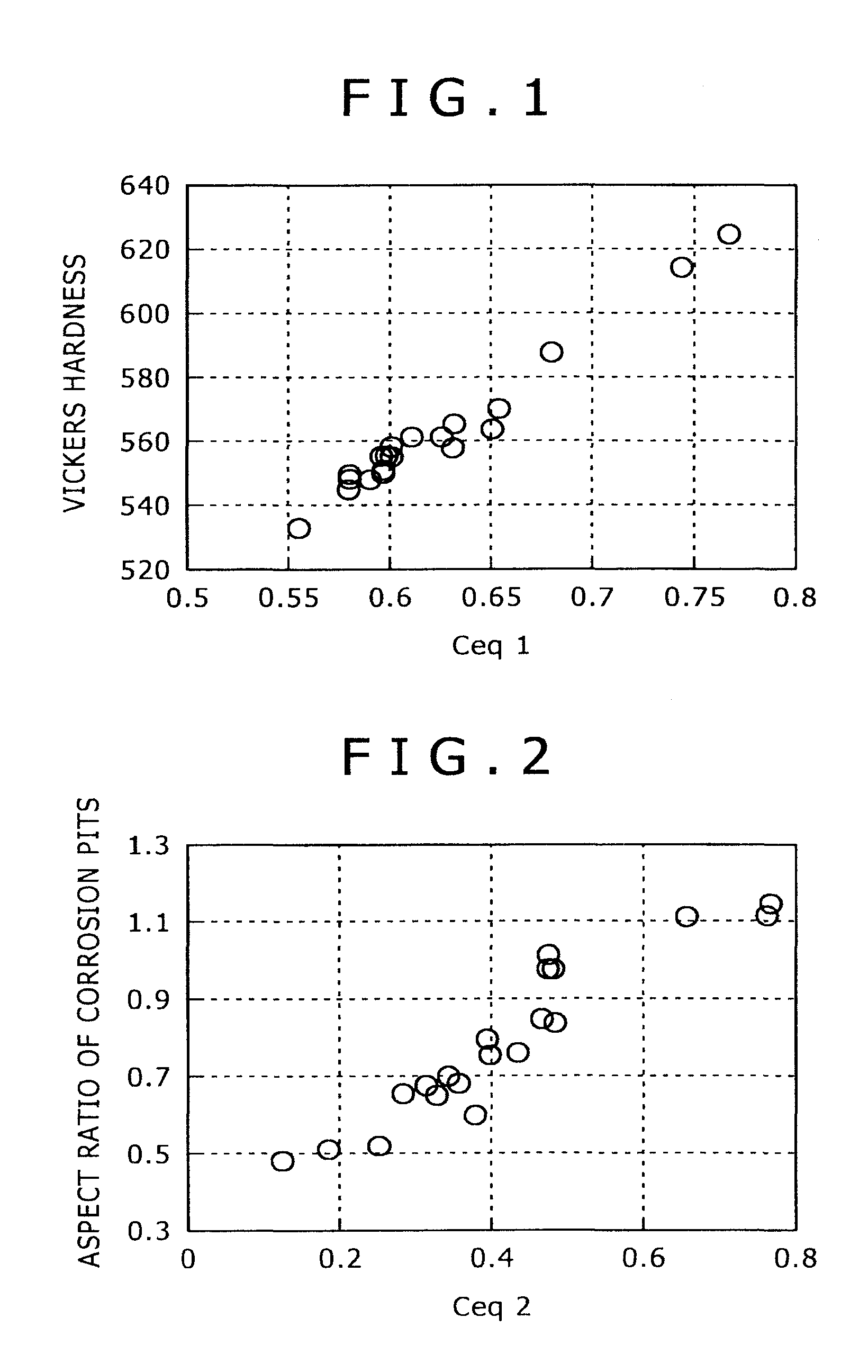

Steel wire material for spring and its producing method

ActiveUS20110303327A1High strengthImprove stress conditionFurnace typesHeat treatment process controlFracture reductionNiobium

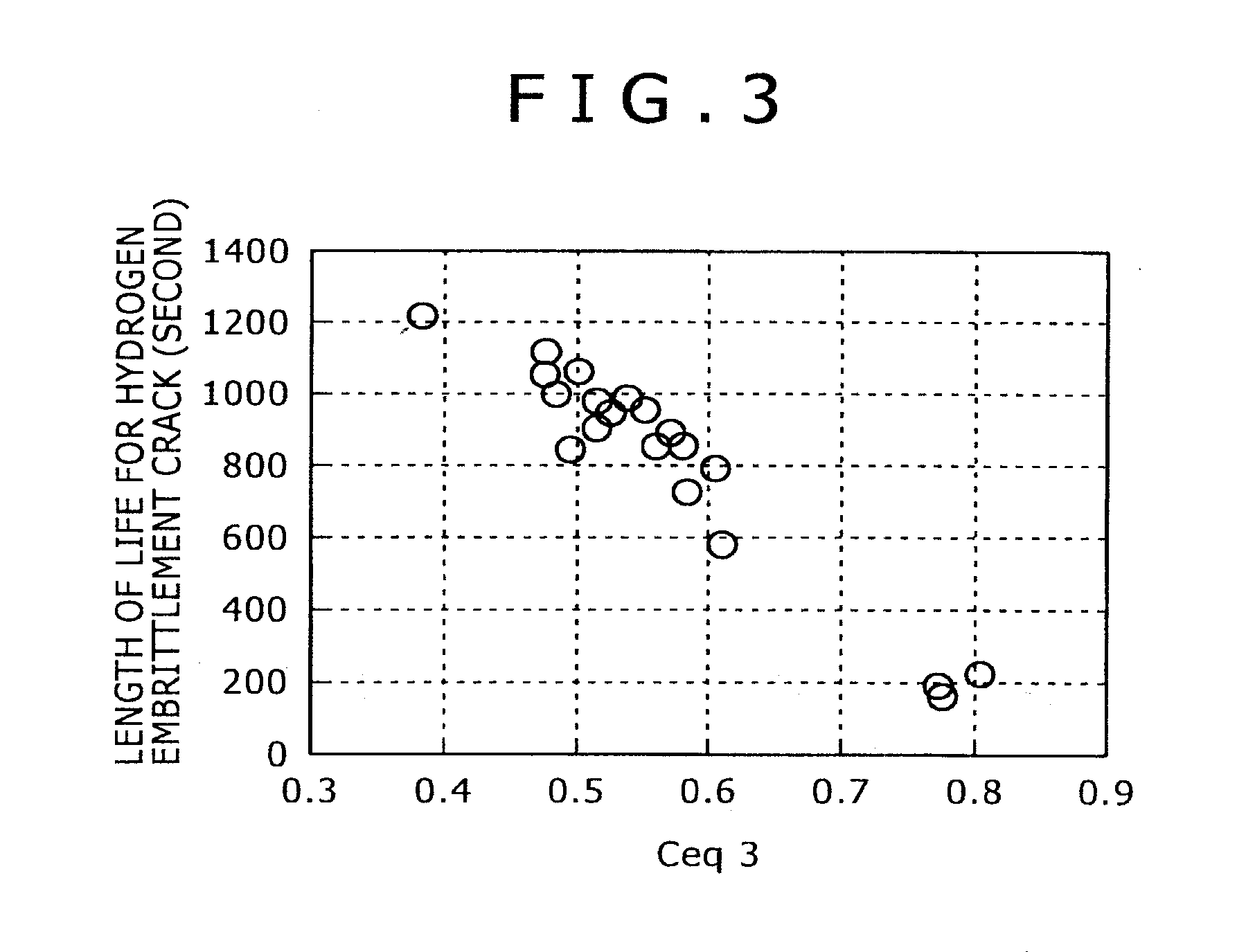

The steel wire material for a spring of the invention contains; C: 0.37-0.54%, Si: 1.7-2.30%, Mn: 0.1-1.30%, Cr: 0.15-1.1%, Cu: 0.15-0.6%, Ti: 0.010-0.1%, Al: 0.003-0.05%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, whole decarburized layer depth is 0.20 mm or less, and fracture reduction of area is 25% or more. It alternately may contain; C: 0.38-0.47%, Si: 1.9-2.5%, Mn: 0.6-1.3%, Ti: 0.05-0.15%, Al: 0.003-0.1%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, Ceq1 in the equation (1) below is 0.580 or more, Ceq2 in the equation (2) below is 0.49 or less, and Ceq3 in the equation (3) below is 0.570 or less.Ceq1=[C]+0.11[Si]−0.07[Mn]−0.05[Ni]+0.02[Cr] (1)Ceq2=[C]+0.30[Cr]−0.15[Ni]−0.70[Cu] (2)Ceq3=[C]−0.04[Si]+0.24[Mn]+0.10[Ni]+0.20[Cr]−0.89[Ti]−1.92[Nb] (3)(In the above equations, [ ] shows the content (mass %) of each element in steel.)

Owner:KOBE STEEL LTD

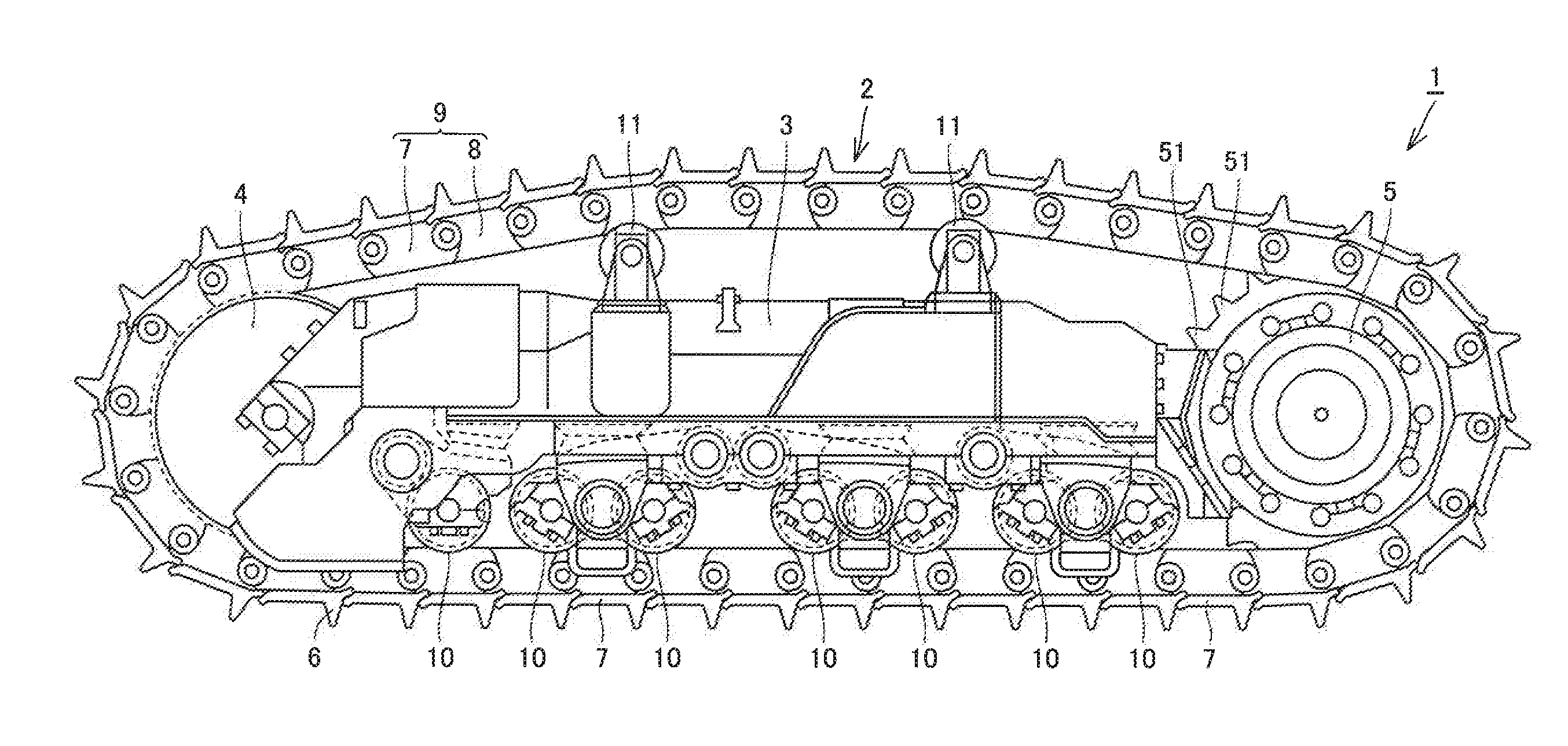

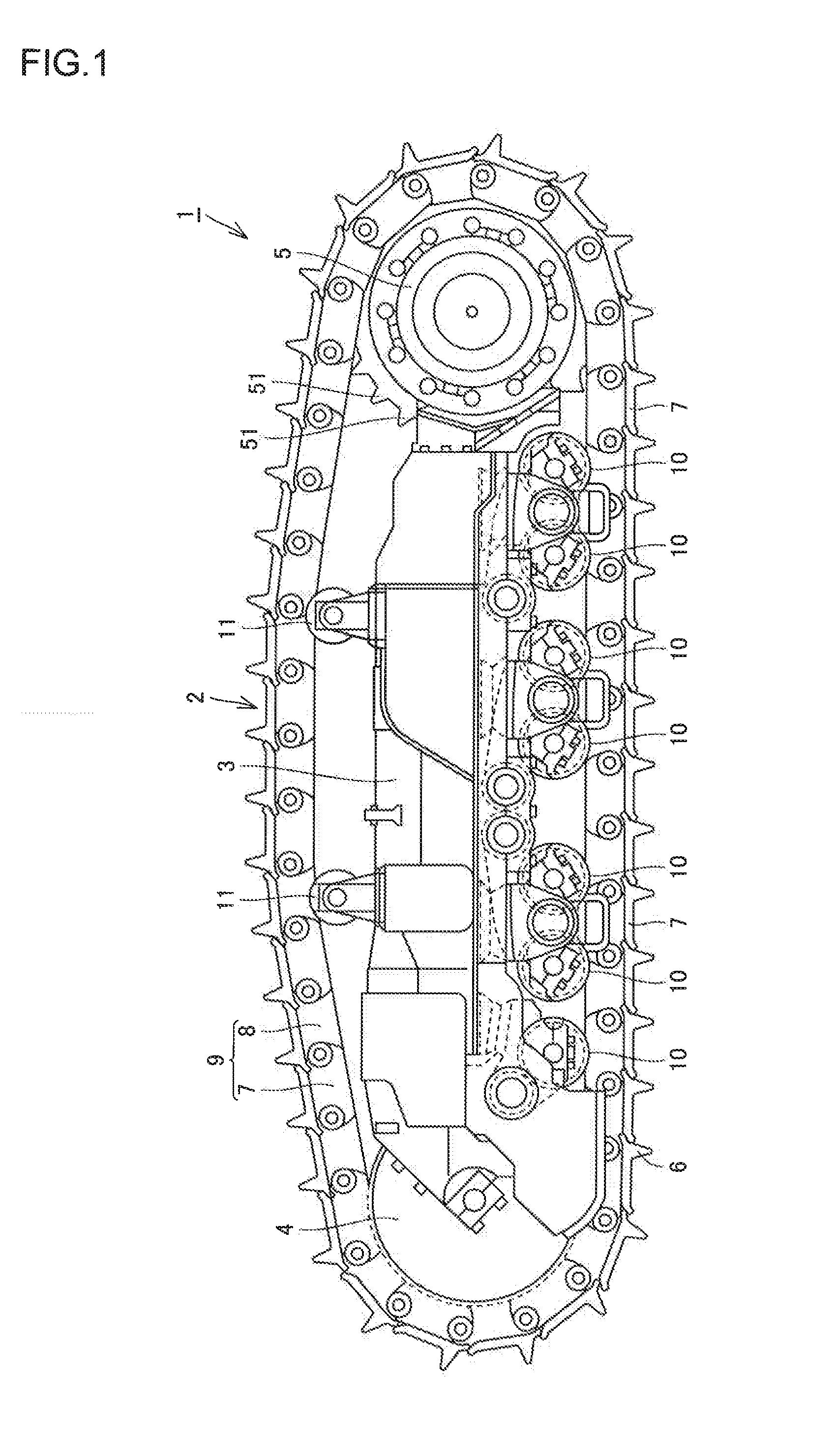

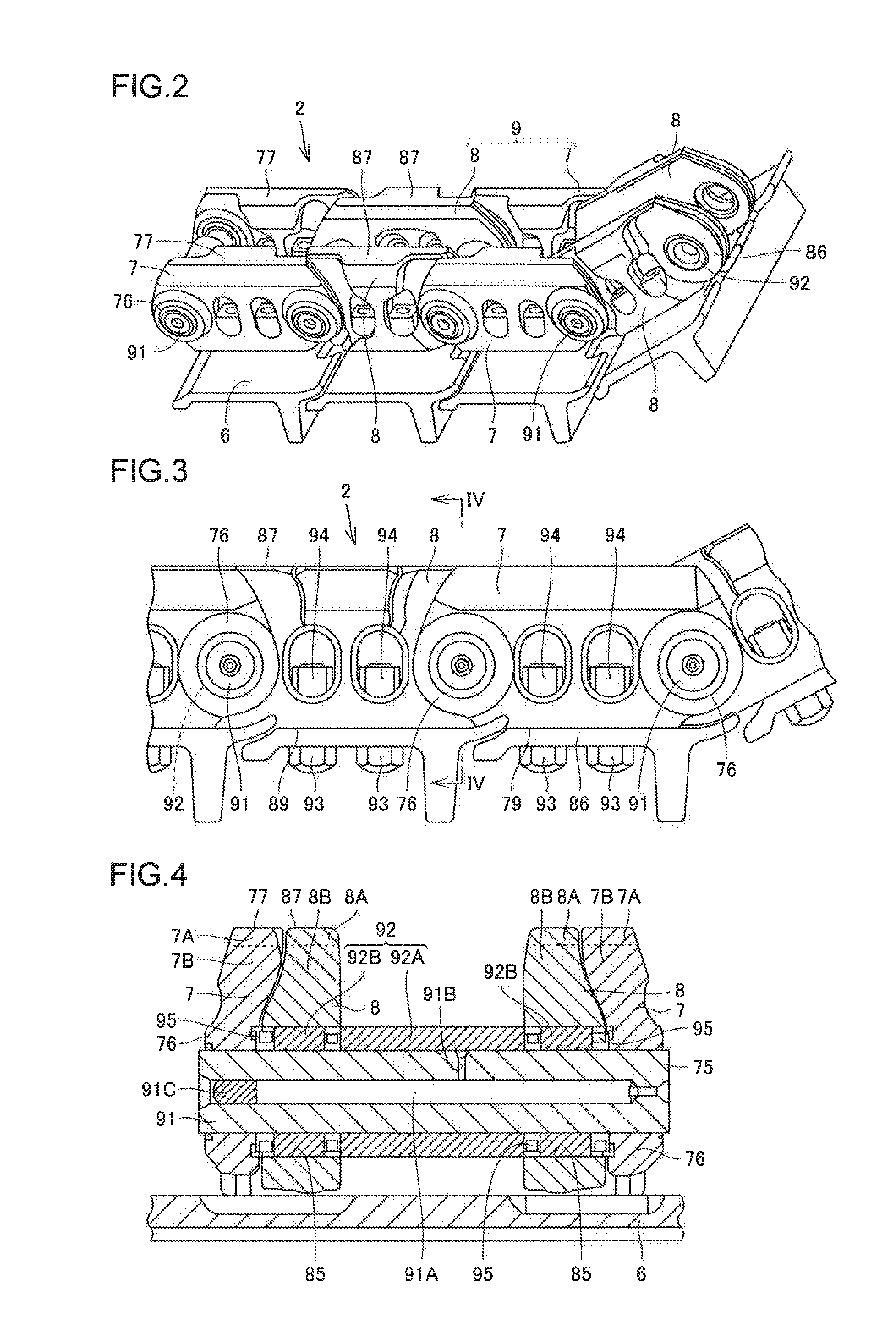

Steel for tracked undercarriage component, and track link

A steel for a tracked undercarriage component is used as a material constituting a track link (9), for example, and contains: not less than 0.39% by mass and not more than 0.45% by mass of carbon, not less than 0.2% by mass and not more than 1.0% by mass of silicon, not less than 0.10% by mass and not more than 0.90% by mass of manganese, not less than 0.002% by mass and not more than 0.005% by mass of sulfur, not less than 0.1% by mass and not more than 3.0% by mass of nickel, not less than 0.70% by mass and not more than 1.50% by mass of chromium, and not less than 0.10% by mass and not more than 0.60% by mass of molybdenum, with the balance made of iron and unavoidable impurities.

Owner:KOMATSU LTD

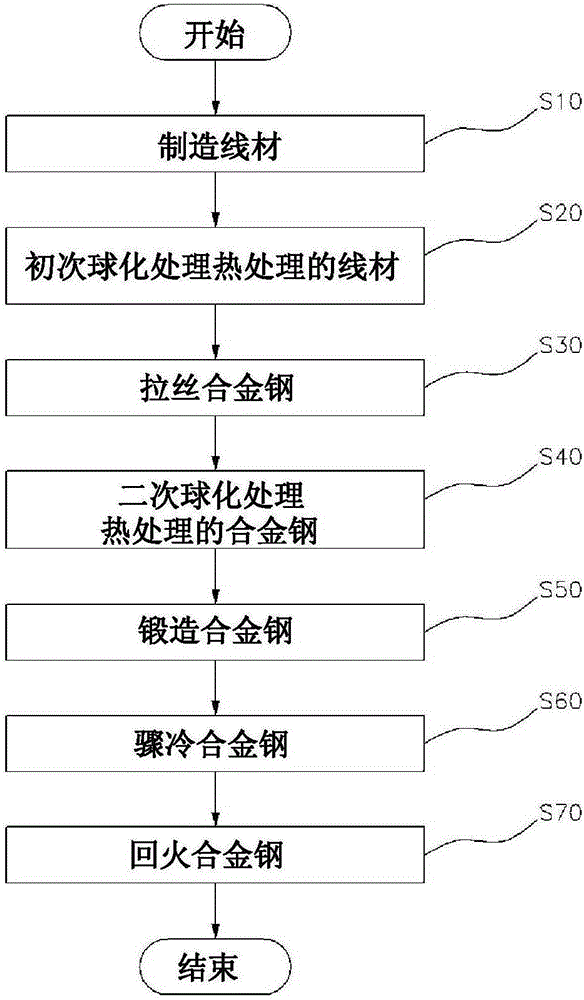

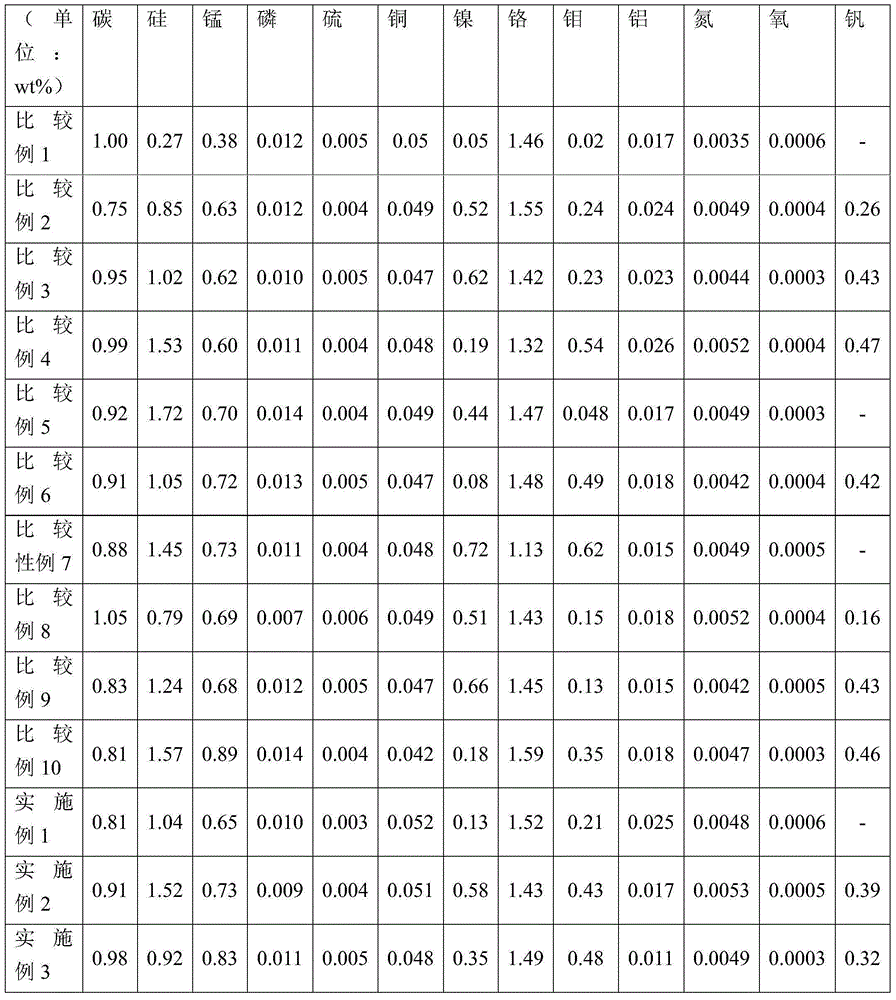

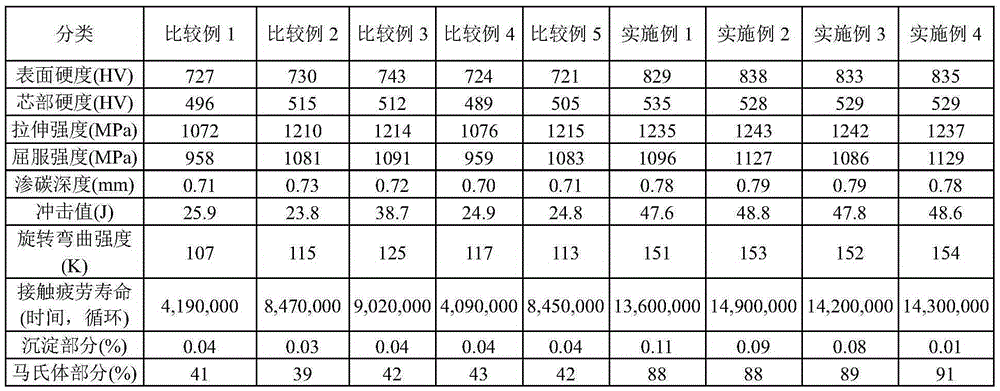

Bearing steel having improved fatigue durability and method of manufacturing the same

The present invention relates to a steel composition for bearing having improved fatigue durability and a method of manufacturing the same. The steel composition comprises: an amount of about 0.08 to 1.0 wt % of carbon (C); an amount of about 0.9 to 1.6 wt % of silicon (Si); an amount greater than 0 wt % and of about 0.03 wt % or less of phosphorus (P); an amount greater than 0 wt % and of about 0.01 wt % or less of sulfur (S); an amount of about 0.01 to 0.1 wt % of copper (Cu); an amount of about 0.01 to 0.06 wt % of aluminum (Al); an amount greater than 0 wt % and of about 0.006 wt % or less of nitrogen (N); an amount greater than 0 wt % and of about 0.001 wt % or less of oxygen (O); one or more selected from the group consisting of: an amount of about 0.5 to 1.00 wt % of manganese (Mn), an amount of about 0.1 to 0.6 wt % of nickel (Ni), an amount of about 1.4 to 1.55 wt % of chromium (Cr), an amount of about 0.2 to 0.5 wt % of molybdenum (Mo), and an amount greater than 0 wt % and of about 0.4 wt % or less of vanadium (V); and iron (Fe) constituting the balance of the weight of the steel composition, all wt % based on the total weight of the alloy steel composition.

Owner:HYUNDAI MOTOR CO LTD

Sucker rod in super II level

InactiveCN1959059AReduce loadReduce power consumptionDrilling rodsHeat treatment process controlManganeseQuenching

The present invention relates to a super-H-grade pumping rod. The chemical components of steel material for making said pumping rod include (by wt%) 0.07%-0.13% of carbon, 0.40%-1.20% of silicone, 1.60%-2.2% of manganese, 0.60%-1.70% of chrome, 0.20%-0.40% of molybdenum, nickel content is less than or equal to 0.3%, copper content is less than or equal to 0.20%, phosphorus content is less than or equal to 0.025%, sulfur content is less than or equal to 0.25% and the rest is iron. Said pumping rod successively is undergone the processes of quenching treatment and tempering treatment, its quenching temperature is 900 deg.C-950 deg.C, heat-insulating for 1 hr, then making tempering treatment, tempering temperature is 330 deg.C-370 deg.C, heat-insulating for 2 hr, then air cooling.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Hard alloy material for preparing bevelling machine special cutter and preparation method thereof

InactiveCN109321797AHigh hardnessImprove wear resistanceChemical vapor deposition coatingManganeseTitanium carbonitride

The invention discloses a hard alloy material for preparing a bevelling machine special cutter. The hard alloy material is composed of a hard alloy matrix and a coating; the hard alloy matrix is composed of, by mass, 80%-85% of a hard phase, 5%-10% of a bonding phase, 3%-5% of an inhibiting phase and 2%-5% of a hardening phase; the hard phase is composed of, by mass, 65%-71% of tungsten carbide, 22%-28% of titanium carbide and 3%-7% of tungsten boride; the bonding phase is composed of, by mass, 62%-71% of cobalt, 15%-21% of hydroxy nickel powder, 10%-13% of manganese, 3%-5% of hydroxy iron powder and 1%-2% of tungsten powder; the inhibiting phase is composed of, by mass, 80%-87% of vinylene carbonate, 5%-8% of titanium dioxide, 3%-6% of niobium carbide, 3%-6% of tantalum carbide, 1%-3% ofchromium carbide and 0.5%-2% of vanadium carbide; and the hardening phase is composed of, by mass, 51%-60% of zirconium carbide, 25%-42% of green silicon carbide, 4%-9% of yttrium oxide and 3%-7% of zirconium dioxide; and the coating is a titanium nitride-titanium carbonitride-aluminum oxide composite coating.

Owner:CHENGXI SHIPYARD

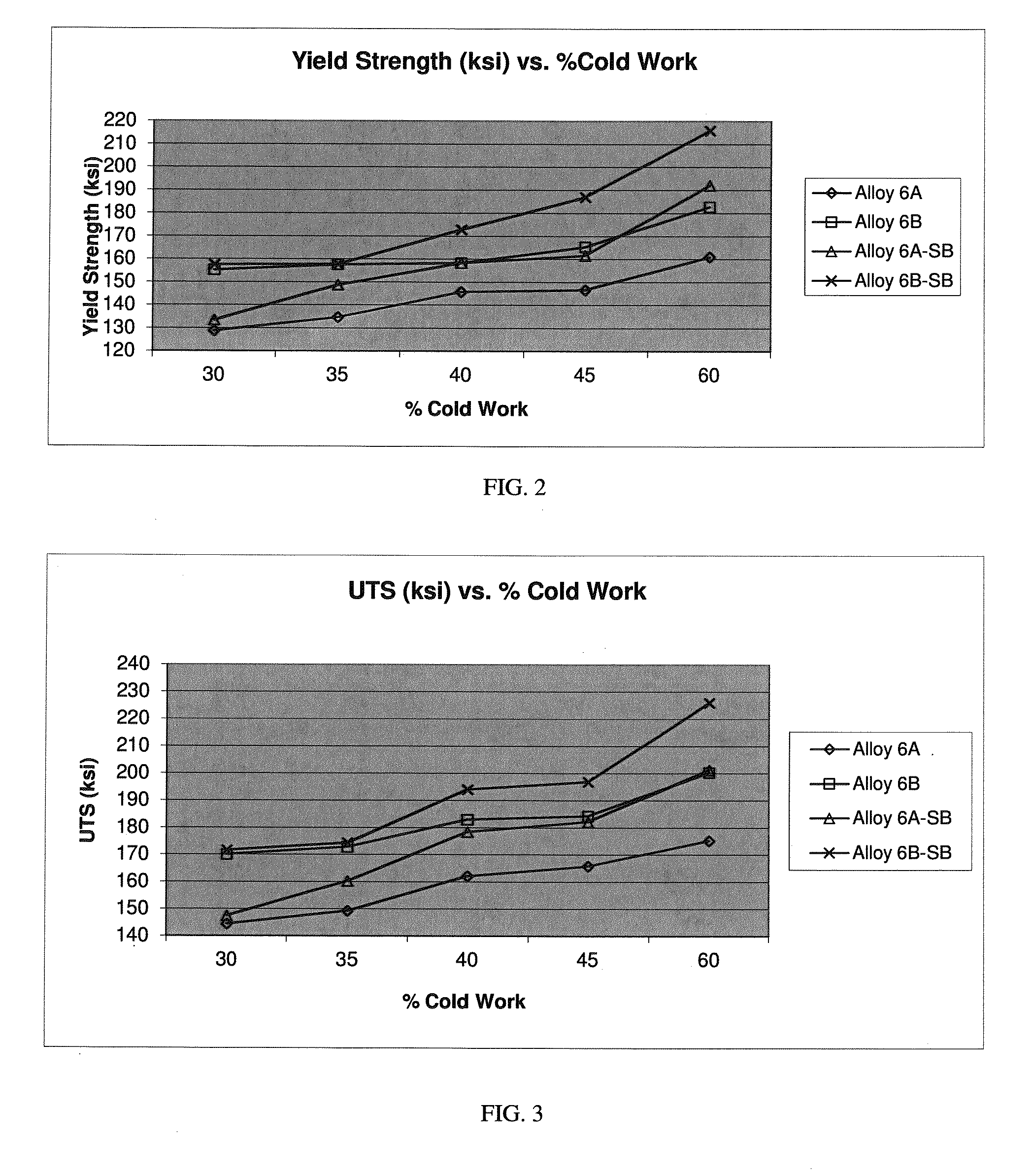

Flux-Cored Arc Welding Wire for Providing Superior Toughness and Weldability to a Welded Joint at a Low Temperature, and Welded Joint Using Same

ActiveUS20130284713A1Improve low temperature impact toughnessHigh strength physical propertyArc welding apparatusWelding/cutting media/materialsRare earthManganese

Provided are a flux cored arc welding wire able to improve low-temperature toughness of a weld joint and a weld joint using the same, in which the flux cored arc welding wire includes 0.01 wt % to 0.1 wt % of carbon (C), 0.3 wt % to 1.4 wt % of silicon (Si), 1.0 wt % to 3.0 wt % of manganese (Mn), 4.0 wt % to 7.5 wt % of titanium (Ti)+TiO, 0.01 wt % to 3.0 wt % of nickel (Ni), 0.01 wt % to 0.2 wt % of boron (B), 0.02 wt % to 0.42 wt % of yttrium (Y) or 0.02 wt % to 0.56 wt % of a rare earth metal (REM), and iron (Fe) as well as other unavoidable impurities as a remainder.

Owner:POHANG IRON & STEEL CO LTD

Austenitic stainless steel

ActiveUS9803267B2High mechanical strengthImprove ductilityPitting resistance equivalent numberManganese

Austenitic stainless steel is disclosed herein. In the described embodiments, the austenitic stainless steel comprises 16.00 wt % of Chromium to 30.00 wt % of Chromium; 8.00 wt % of Nickel to 27.00 wt % of Nickel; no more than 7.00 wt % of Molybdenum; 0.40 wt % of Nitrogen to 0.70 wt % of Nitrogen, 1.0 wt % of Manganese to 4.00 wt % of Manganese, and less than 0.10 wt % of Carbon, wherein the ratio of the Manganese to the Nitrogen is controlled to less than or equal to 10.0. Austenitic stainless steel based on specified minimum PREN (Pitting Resistance Equivalent Number) values is also disclosed. (1) PRE=wt % Cr+3.3×wt % (Mo)+16 wt % N>=25 for N in range of 0.40-0.70. (2) PRE=wt % Cr+3.3×wt % (Mo+W)+16 wt % N>=27 for N in range of 0.40-0.70 with W present.

Owner:UPL LLC

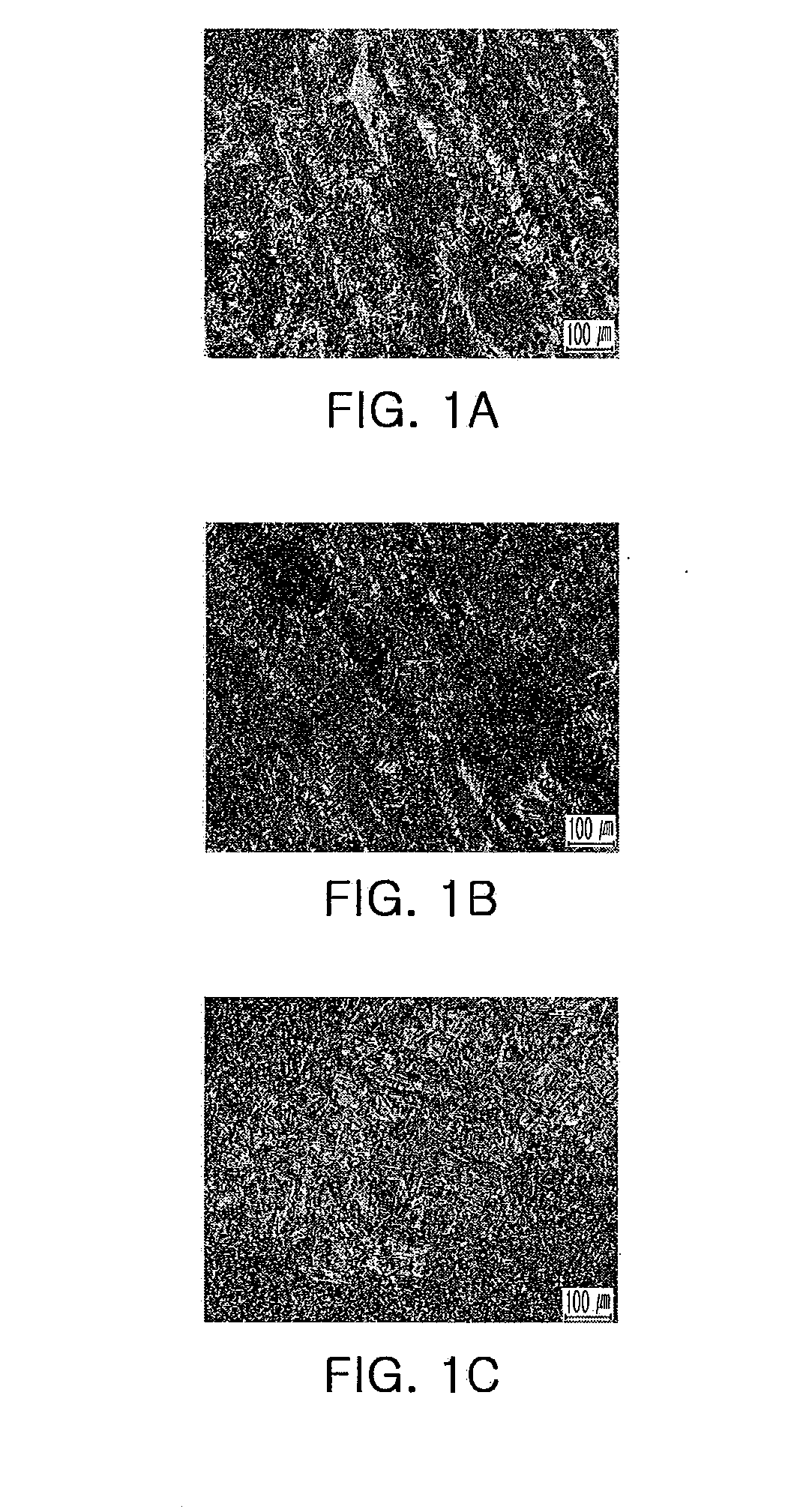

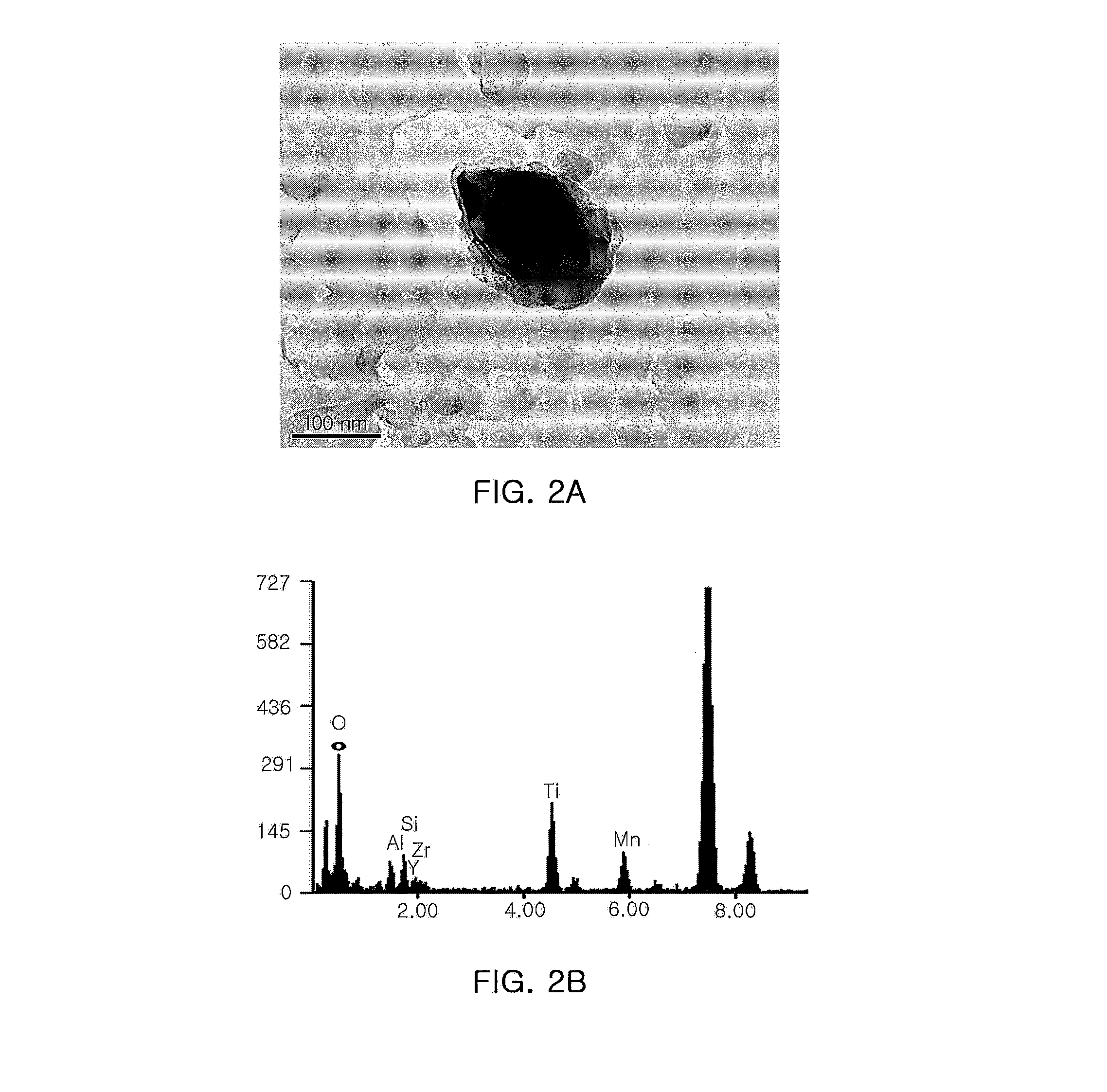

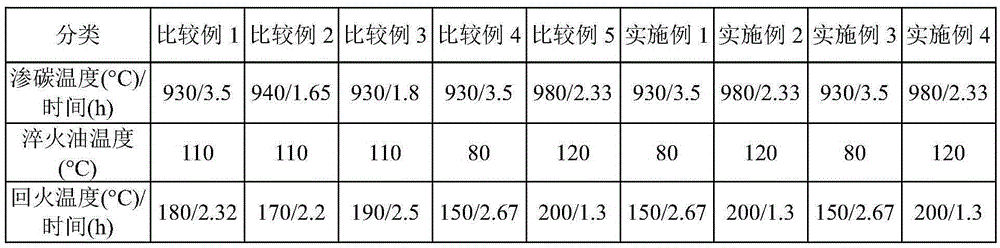

Carburizing alloy steel having improved durability and method of manufacturing the same

ActiveCN106065455AReduce thicknessIncreased durabilitySolid state diffusion coatingQuenching agentsNiobiumManganese

The invention provides carburizing alloy steel having improved durability and a method of manufacturing the same. A carburizing alloy steel includes 0.1 to 0.35 wt % of carbon (C), 0.1 to 2 wt % of silicon (Si), 0.1 to 1.5 wt % of manganese (Mn), 0.5 to 1.5 wt % of chromium (Cr), 0.2 to 0.5 wt % of molybdenum (Mo), 0.1 to 0.6 wt % of nickel (Ni), more than 0 wt % and less than or equal to 0.07 wt % of niobium (Nb), more than 0 wt % and less than or equal to 0.5 wt % of vanadium (V), more than 0 wt % and less than or equal to 0.5 wt % of titanium (Ti), more than 0 wt % and less than or equal to 0.015 wt % of nitrogen (N), 0.00002 to 0.00005 wt % of boron (B), based on the total weight of the alloy steel, iron (Fe) as a main component.

Owner:HYUNDAI MOTOR CO LTD

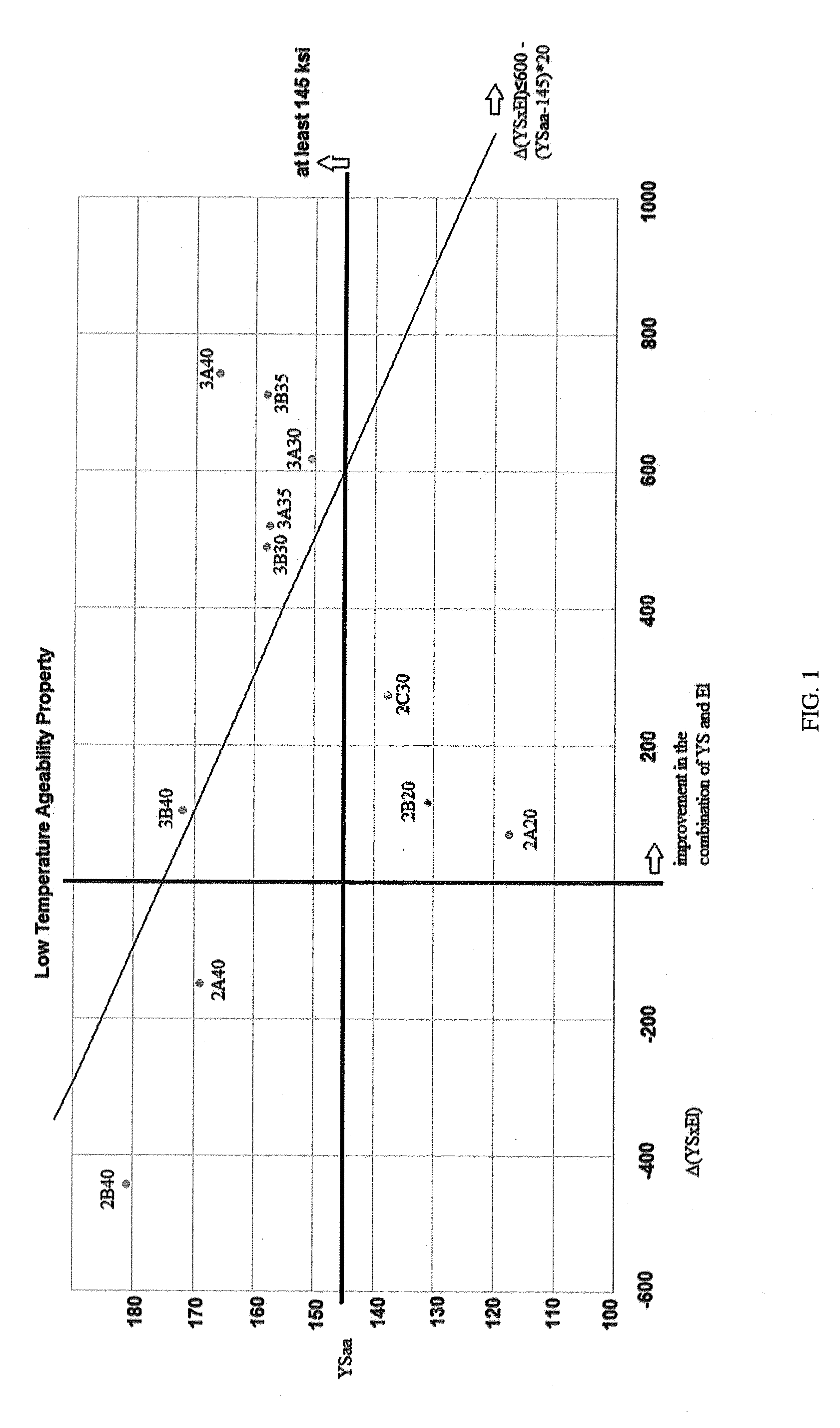

Weld metals with superior low temperature toughness and used for joining high strength low alloy steels

InactiveCN1232673CHigh strengthImprove low temperature toughnessArc welding apparatusWelding/cutting media/materialsManganeseOxygen

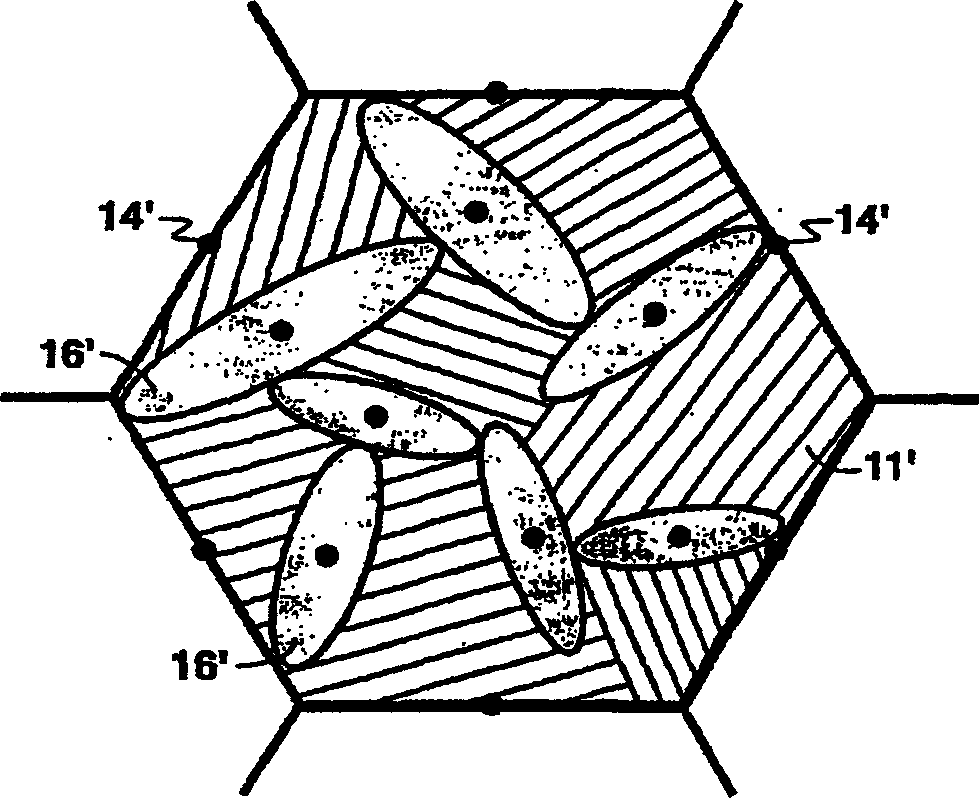

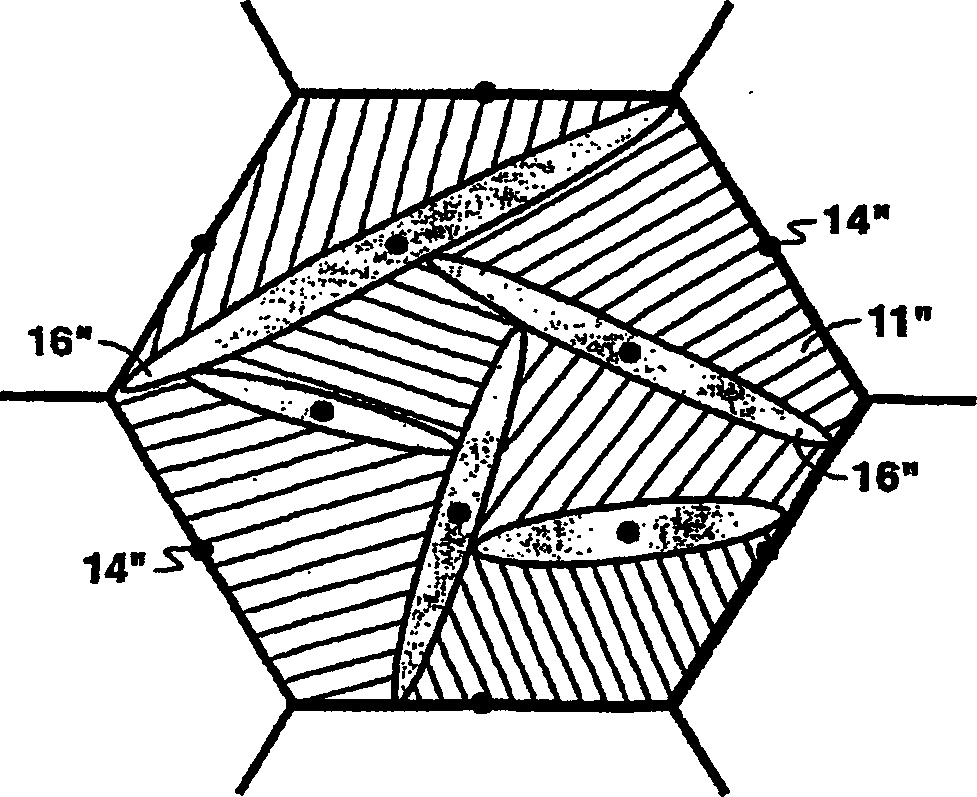

Provides weld metal suitable for joining high-strength, low-alloy steels. In the microstructure of the weld metal, acicular ferrite (16') is dispersed in hard components (11') such as lath martensite, and its yield strength is at least about 690MPa (100ksi), which is determined by Charpy V shape Notch energy vs. temperature curves have a DBTT of less than about -50°C (-58°F). The weld metal contains about 0.04-0.08 wt% carbon; about 1.0-2.0 wt% manganese; about 0.2-0.7 wt% silicon; about 0.30-0.80 wt% molybdenum; about 2.3-3.5 wt% nickel; weight percent oxygen; and at least one of the following additional elements: (i) up to about 0.04 weight percent zirconium, and (ii) up to about 0.02 weight percent titanium.

Owner:EXXONMOBIL UPSTREAM RES CO

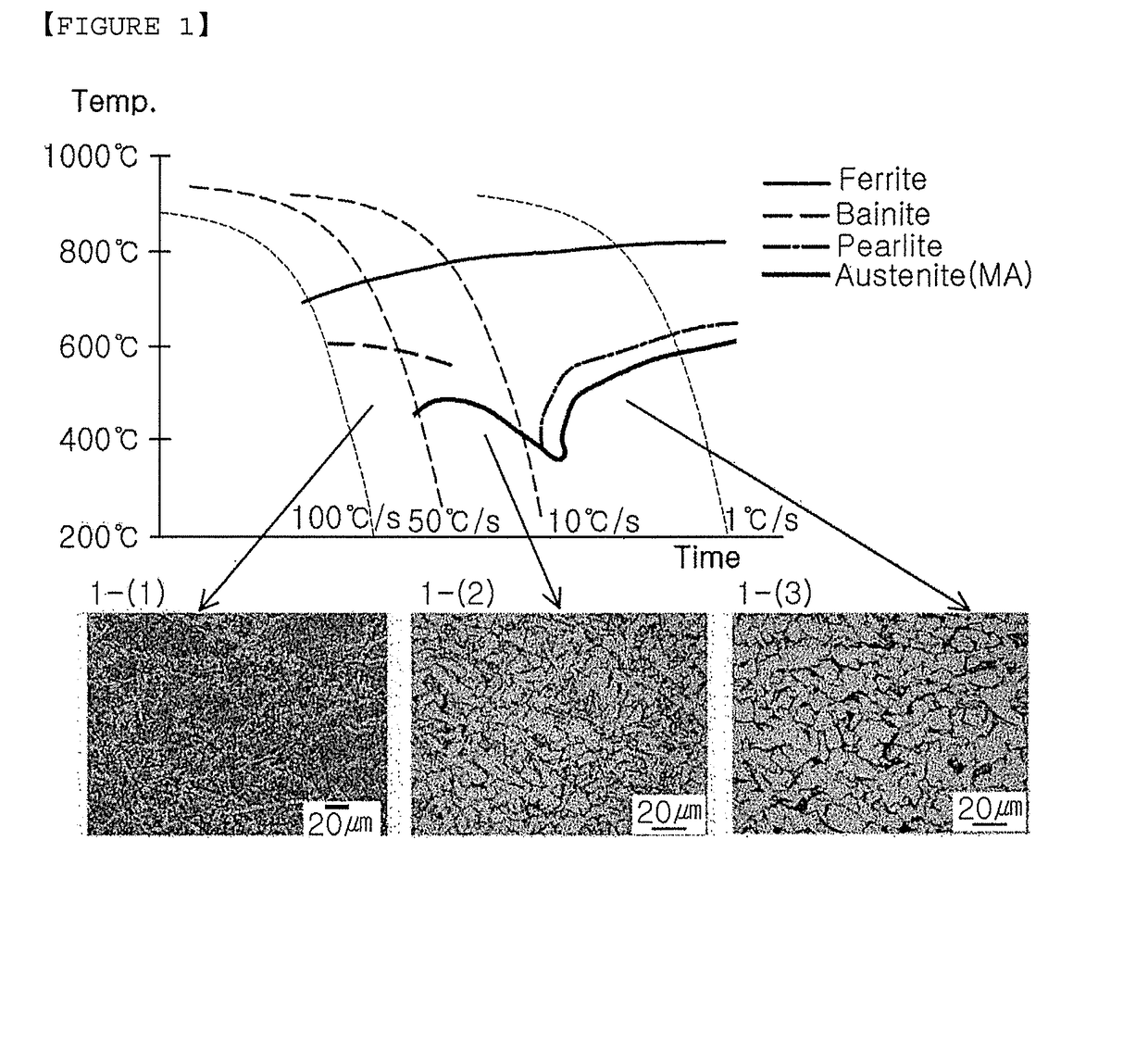

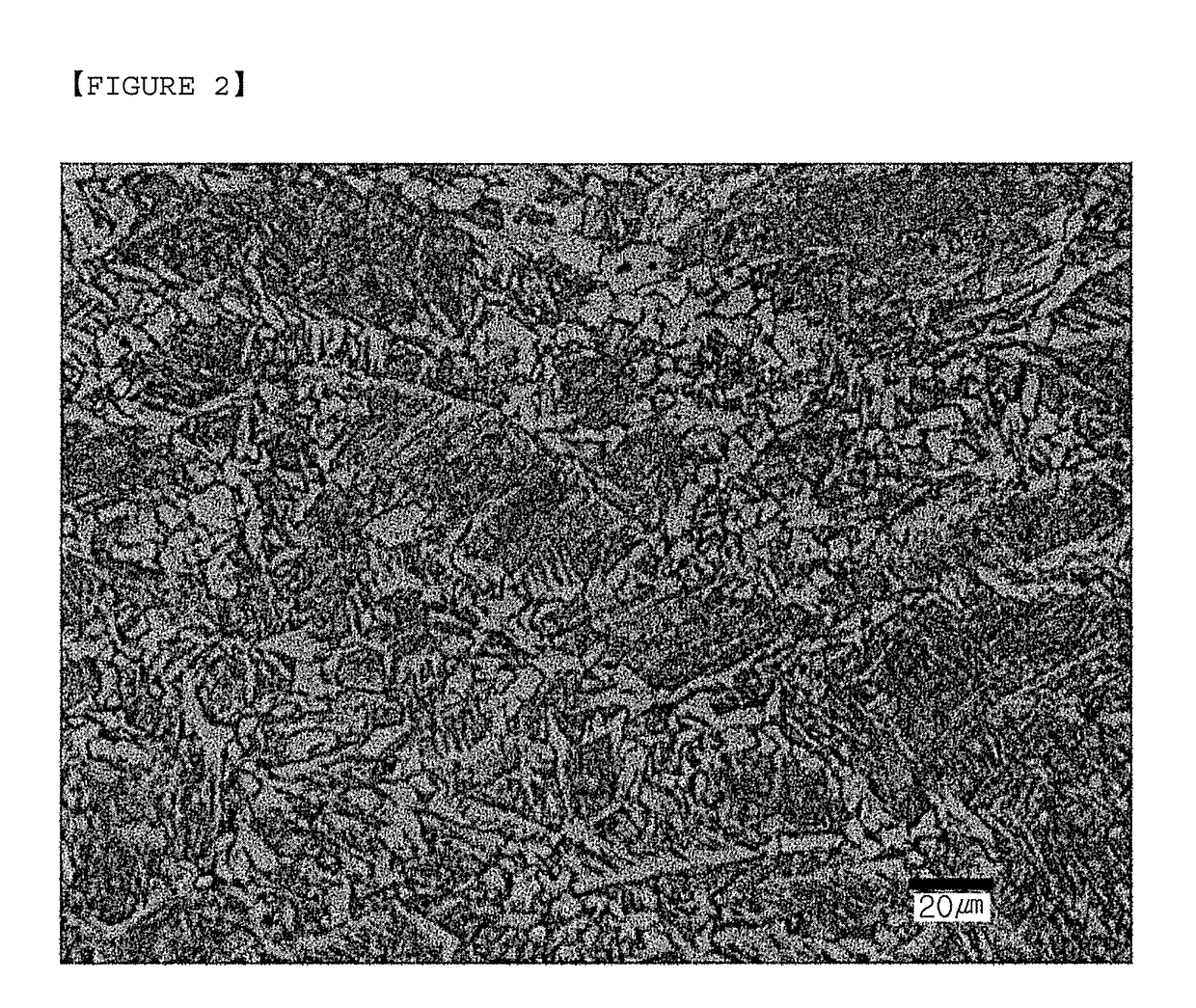

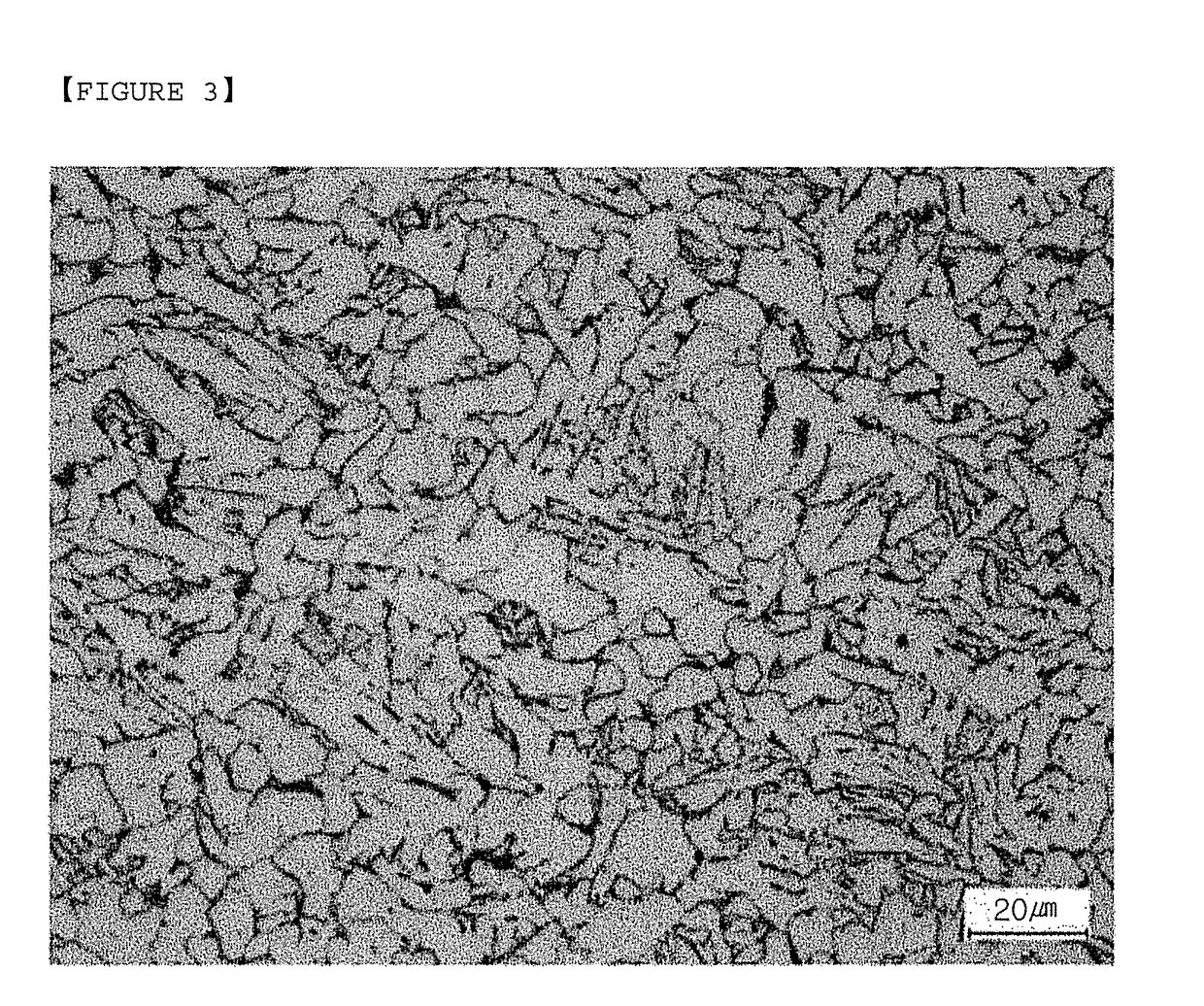

Low yield ratio and high-strength steel having excellent stress corrosion cracking resistance and low temperature toughness

InactiveUS20180371588A1Excellent stress corrosion cracking resistanceLow yield ratioNiobiumManganese

An aspect of the present invention relates to a low yield ratio and high-strength steel having excellent stress corrosion cracking resistance and low temperature toughness, the steel comprising, by weight, 0.02-0.10% of carbon (C), 0.5-2.0% of manganese (Mn), 0.05-0.5% of silicon (Si), 0.05-1.0% of nickel (Ni), 0.005-0.1% of titanium (Ti), 0.005-0.5% of aluminum (Al), 0.005% of less of niobium (Nb), 0.015% or less of phosphorus (P), 0.015% or less of sulfur (S), and the balanced amount of Fe and inevitable impurities, the microstructure of which comprises: by area, 60% or more of acicular ferrite and a balanced amount of one or more phases of bainite, polygonal ferrite and martensite-austenite constituent (MA).

Owner:POHANG IRON & STEEL CO LTD

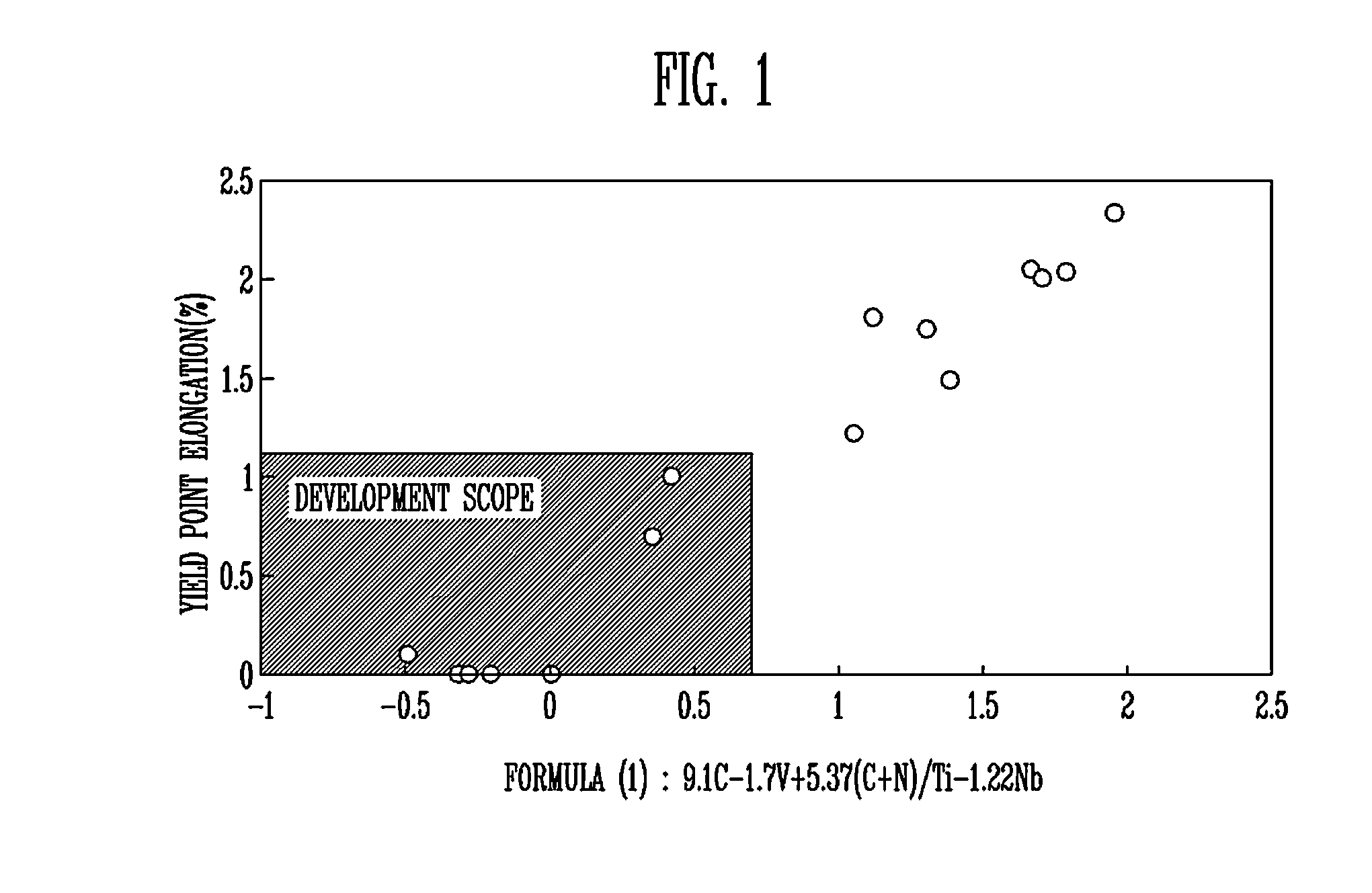

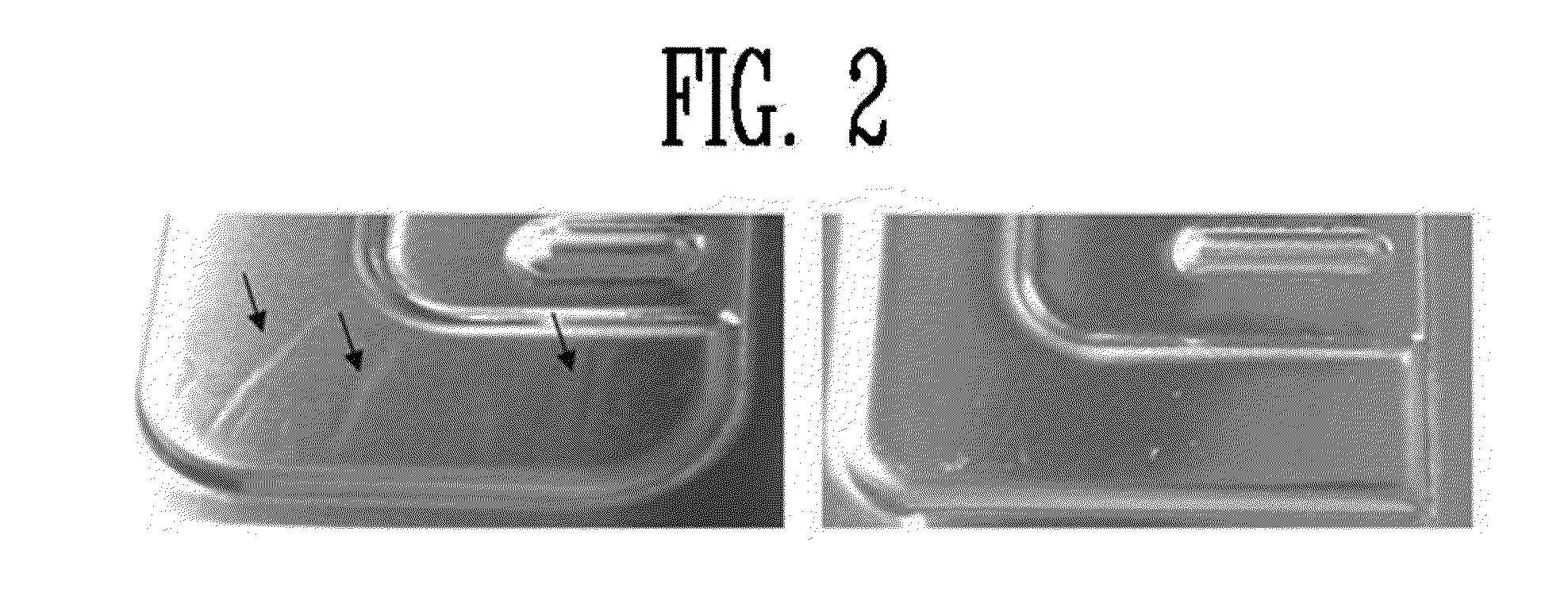

Stainless Steel Having Superior Surface Quality and Moldability for Fuel Cell Divider Sheet, and Method for Manufacturing Same

ActiveUS20140338796A1Reduce pointsFinal product manufactureHeat treatment process controlFuel cellsAlloy

Provided is a ferrite-based stainless steel having superior moldability when molding a fuel cell divider sheet from a material by controlling yield point elongation in accordance with alloy components. The ferrite-based stainless steel comprises, in weight percentages: no more than 0.02% of C; no more than 0.02% of N; no more than 0.4% of Si; no more than 0.2% of Mn; no more than 0.04% of P; no more than 0.02% of S; 25.0-32.0% of Cr; 0-1.0% of Cu; no more than 0.8% of Ni; no more than 0.01-0.5% of Ti; no more than 0.01-0.5% of Nb; no more than 0.01-1.5% of V; and residual Fe and inevitable elements, wherein the content of Ti, Nb, V, C, and N in terms of weight % of steel uses Formula (1) to render a yield point elongation of the material of no more than 1.1%, and wherein a steel material has superior moldability.9.1C−1.76V+5.37(C+N) / Ti−1.22Nb≦0.7. Formula (1)

Owner:POHANG IRON & STEEL CO LTD

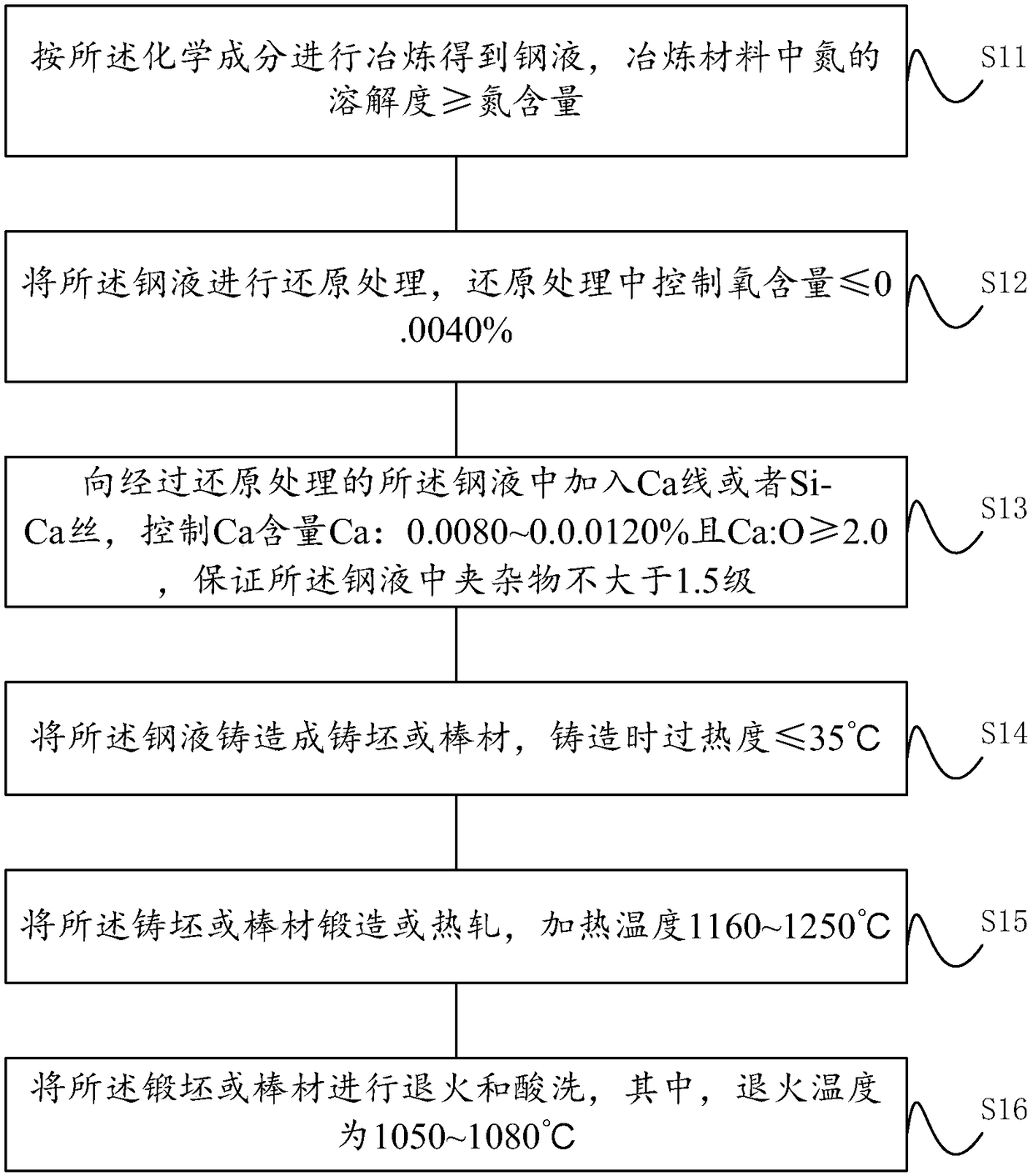

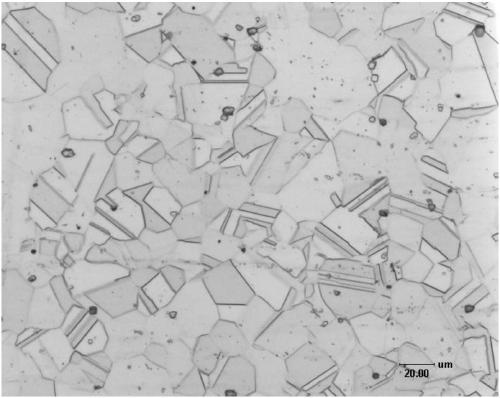

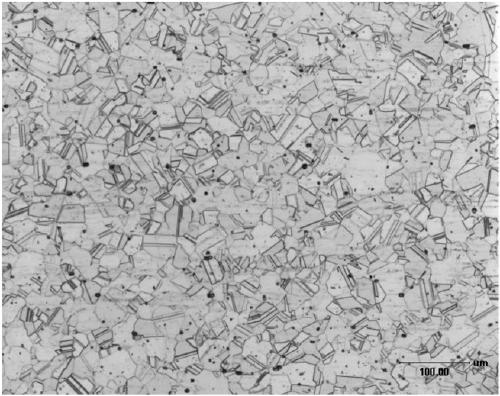

Stainless steel and manufacturing method thereof

The invention discloses a stainless steel and a manufacturing method thereof, belonging to the technical field of metal smelting. The objective of the invention is to overcome the problem of poor stability of austenitic stainless steel in the prior art. The stainless steel comprises the following chemical components by mass: 0.02 to 0.08% of carbon (C), 0.2 to 1.0% of silicon (Si), 2.0 to 4.0% ofmanganese (Mn), 17.0 to 18.5% of chromium (Cr), 8.0 to 10.0% of nickel (Ni), 0.12 to 0.20% of nitrogen (N), 1.00 to 2.00% of copper (Cu), 2.1 to 3.3% of molybdenum (Mo), 0.10 to 0.20% of niobium (Nb),0.0015 to 0.0025% of boron (B), 0.0080 to 0.0120% of calcium (Ca) and no more than 0.0040 % of oxygen (O), with the balance being iron (Fe) and unavoidable impurities.

Owner:ZTE CORP

Article and method for forming an article

ActiveCN106119608AAdditive manufacturing apparatusIncreasing energy efficiencyNiobiumWorking temperature

An article and a method for forming the article are disclosed. The article comprising a composition, wherein the composition comprises, by weight percent, about 20.0% to about 22.0% chromium (Cr), about 18.0% to about 20.0% cobalt (Co), about 1.0% to about 2.0% tungsten (W), about 3.0% to about 6.0% niobium (Nb), about 0.5% to about 1.5% titanium (Ti), about 2.0% to about 3.0% aluminum (Al), about 0.5% to about 1.5% molybdenum (Mo), about 0.03% to about 0.18% carbon (C), up to about 0.15% tantalum (Ta), up to about 0.20% hafnium (Hf), up to about 0.20% iron (Fe),balance nickel (Ni) and incidental impurities. The amount of Al is present according to the following formula:Al<=(0.5*Ti)+3.75. The composition is weldable, has a microstructure comprising between about 35 vol % and 45 vol % gamma prime (gamma') and is substantially devoid of Eta and reduced content of TCP phases at elevated working temperatures. A method of making an article and a method of operating a gas turbine are also disclosed.

Owner:GENERAL ELECTRIC CO

Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

ActiveCN103060615BMeet requirements such as more sensitive temperature controlGuaranteed performance and stabilityPositive temperature coefficient thermistorsProcess efficiency improvementMisch metalRare earth

The invention discloses a positive temperature coefficient (PTC) thermal resistance alloy wire and a preparation method thereof. The alloy wire comprises the chemical ingredients by weight percent of 45-82.0% of nickel, 0.1-0.6% of silicon, 0.22-0.35% of manganese, 0.02-0.04% of yttrium, 0.04-0.06% of misch metal, 0.05% or less of carbon, 0.01% or less of sulphur, 0.001% or less of phosphorus and the balance of iron. The mean resistance temperature coefficient at 0-150 DEG C is 2500*10(-6) per DEG C to 5000*10(-6) per DEG C by changing the matching content of the components; the PTC thermal resistance alloy wire of which the resistance temperature coefficient which is urgently needed at present and higher than 3000*10(-6) per DEG C is included; the highest mean resistance temperature coefficient can be 5000*10(-6) per DEG C, and the requirements of more sensitive temperature control of novel electrical equipment can be met.

Owner:JIANGSU HUAXIN ALLOY

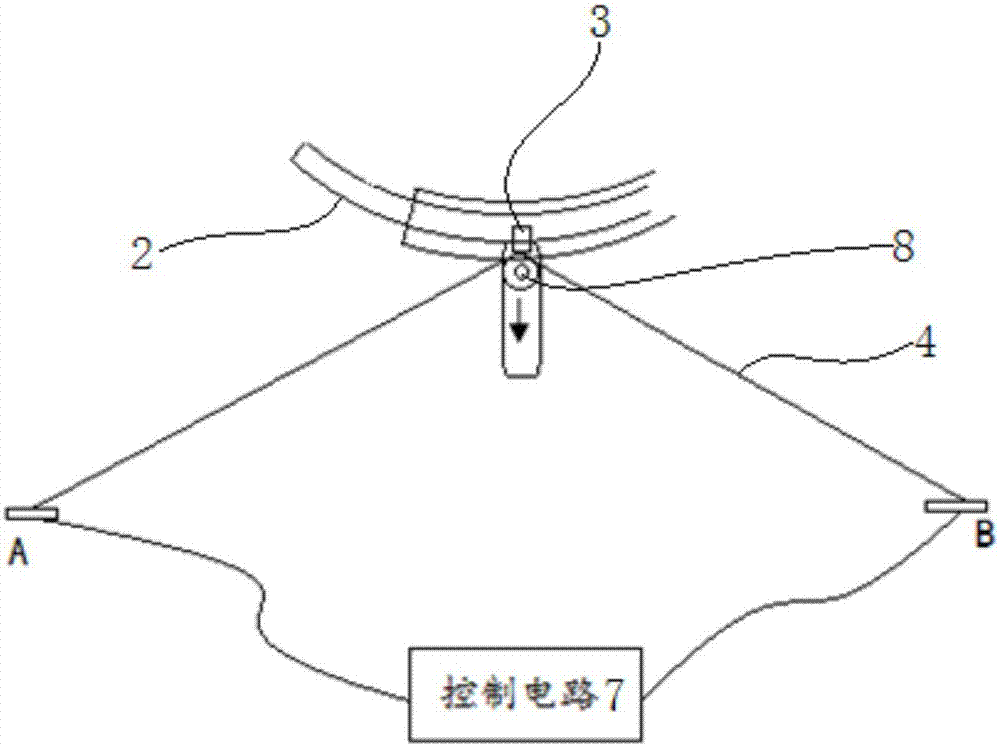

Wireless-controlled lock control method

InactiveCN107386812ALow costReduce power consumptionNon-mechanical controlsPadlocksWireless controlTitanium alloy

Owner:DYNAMICODE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com