Hard alloy material for preparing bevelling machine special cutter and preparation method thereof

A cemented carbide and beveling machine technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of wasting labor, affecting assembly quality, flanging and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

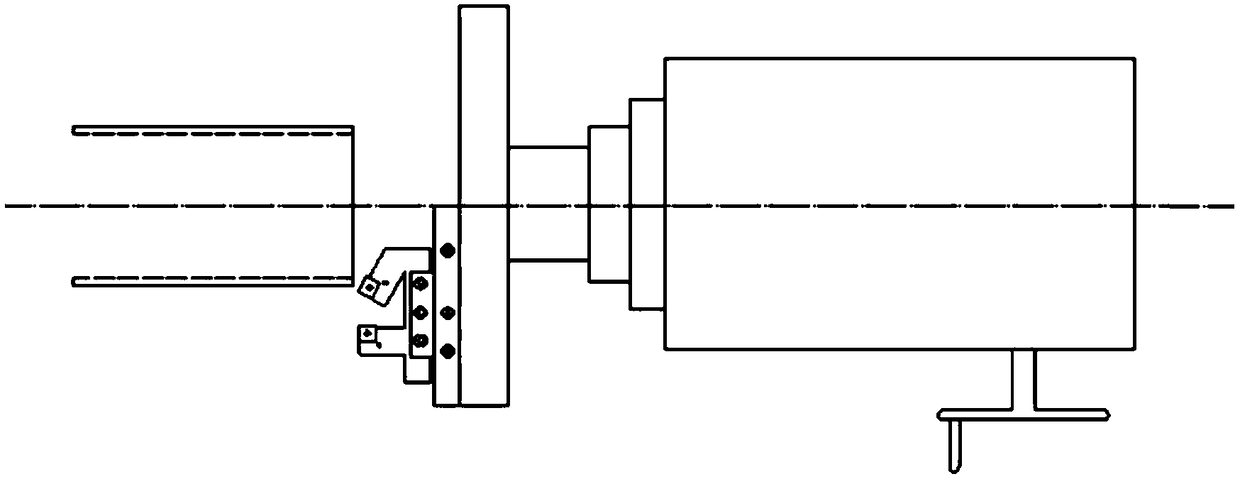

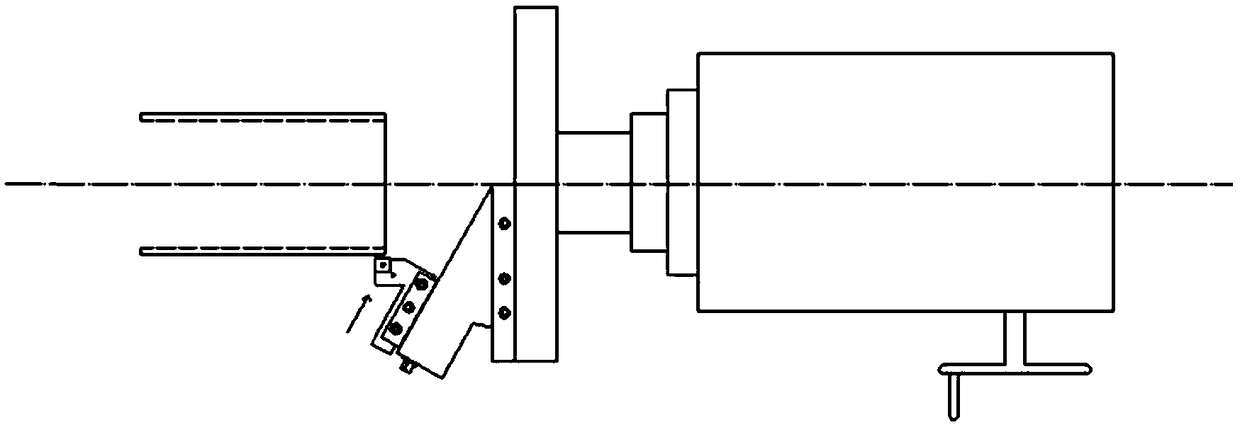

Image

Examples

Embodiment 1

[0033] A method for preparing a cemented carbide material for a special tool for a beveling machine, comprising the following steps:

[0034] (1) Preparation of cemented carbide substrate;

[0035] a. Wet grinding: Weigh the hard phase, binding phase, inhibiting phase and hardening phase materials respectively: 80% hard phase, 10% binding phase, 5% inhibiting phase, 5% hardening phase; The mass phase is composed of the following raw materials in mass percentage: 71% tungsten carbide, 25% titanium carbide, 4% tungsten boride; the bonding phase is composed of the following raw materials in mass percentage: 62% cobalt, 21% nickel hydroxy powder, % manganese, 3% hydroxy iron powder, 1% tungsten powder; the suppressed phase is composed of the following raw materials in mass percentage: 80% vinylene carbonate, 5% titanium dioxide, 6% niobium carbide, 6% tantalum carbide, 1% carbide Chromium and 2% vanadium carbide; the hardening phase is made up of the following mass percent raw ma...

Embodiment 2

[0052] A method for preparing a cemented carbide material for a special tool for a beveling machine, comprising the following steps:

[0053] (1) Preparation of cemented carbide substrate;

[0054] a. Wet grinding: Weigh the hard phase, binding phase, inhibiting phase and hardening phase materials respectively: 85% hard phase, 5% binding phase, 5% inhibiting phase, 5% hardening phase; The mass phase is composed of the following raw materials in mass percentage: 71% tungsten carbide, 23% titanium carbide, 6% tungsten boride; the bonding phase is composed of the following raw materials in mass percentage: 71% cobalt, 15% nickel hydroxide powder, % manganese, 3% hydroxy iron powder and 1% tungsten powder; the inhibited phase is composed of the following raw materials in mass percentage: 87% vinylene carbonate, 5% titanium dioxide, 3% niobium carbide, 3% tantalum carbide, 1% carbide Chromium and 1% vanadium carbide; the hardening phase is composed of the following raw materials i...

Embodiment 3

[0068] A method for preparing a cemented carbide material for a special tool for a beveling machine, comprising the following steps:

[0069] (1) Preparation of cemented carbide substrate;

[0070] a. Wet grinding: Weigh the hard phase, binding phase, inhibiting phase and hardening phase materials respectively: 83% hard phase, 8% binding phase, 4% inhibiting phase, 5% hardening phase; The mass phase is composed of the following raw materials in mass percentage: 70% tungsten carbide, 25% titanium carbide, 5% tungsten boride; the bonding phase is composed of the following raw materials in mass percentage: 65% cobalt, 18% nickel hydroxy powder, 12 % manganese, 3% hydroxy iron powder and 2% tungsten powder; the suppressed phase is composed of the following raw materials in mass percentage: 85% vinylene carbonate, 5% titanium dioxide, 5% niobium carbide, 3% tantalum carbide, 1% carbide Chromium and 1% vanadium carbide; the hardening phase is composed of the following raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com