Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Measurement Profiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Profilometer is a measuring instrument used to measure a surface's profile, in order to quantify its roughness.

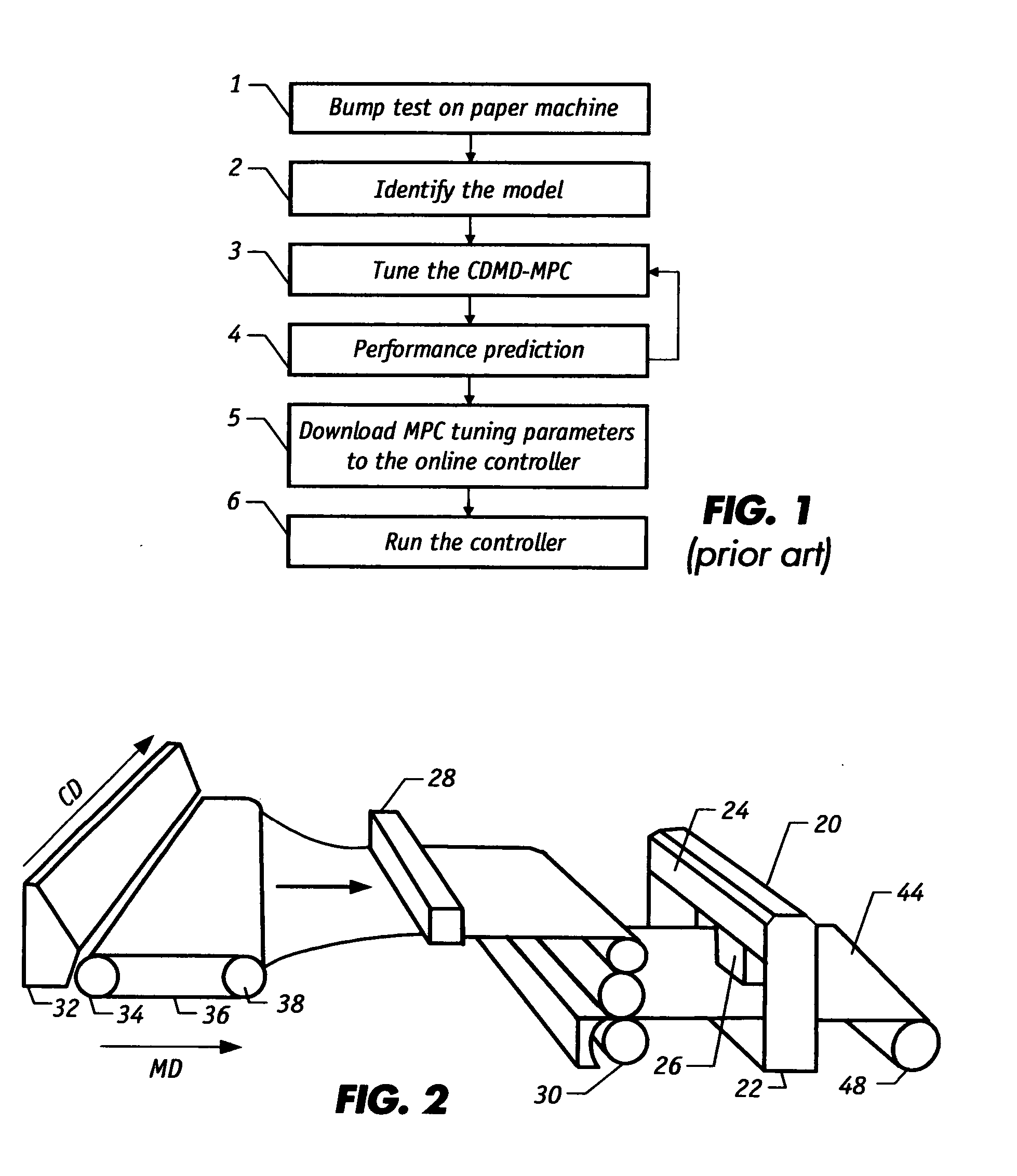

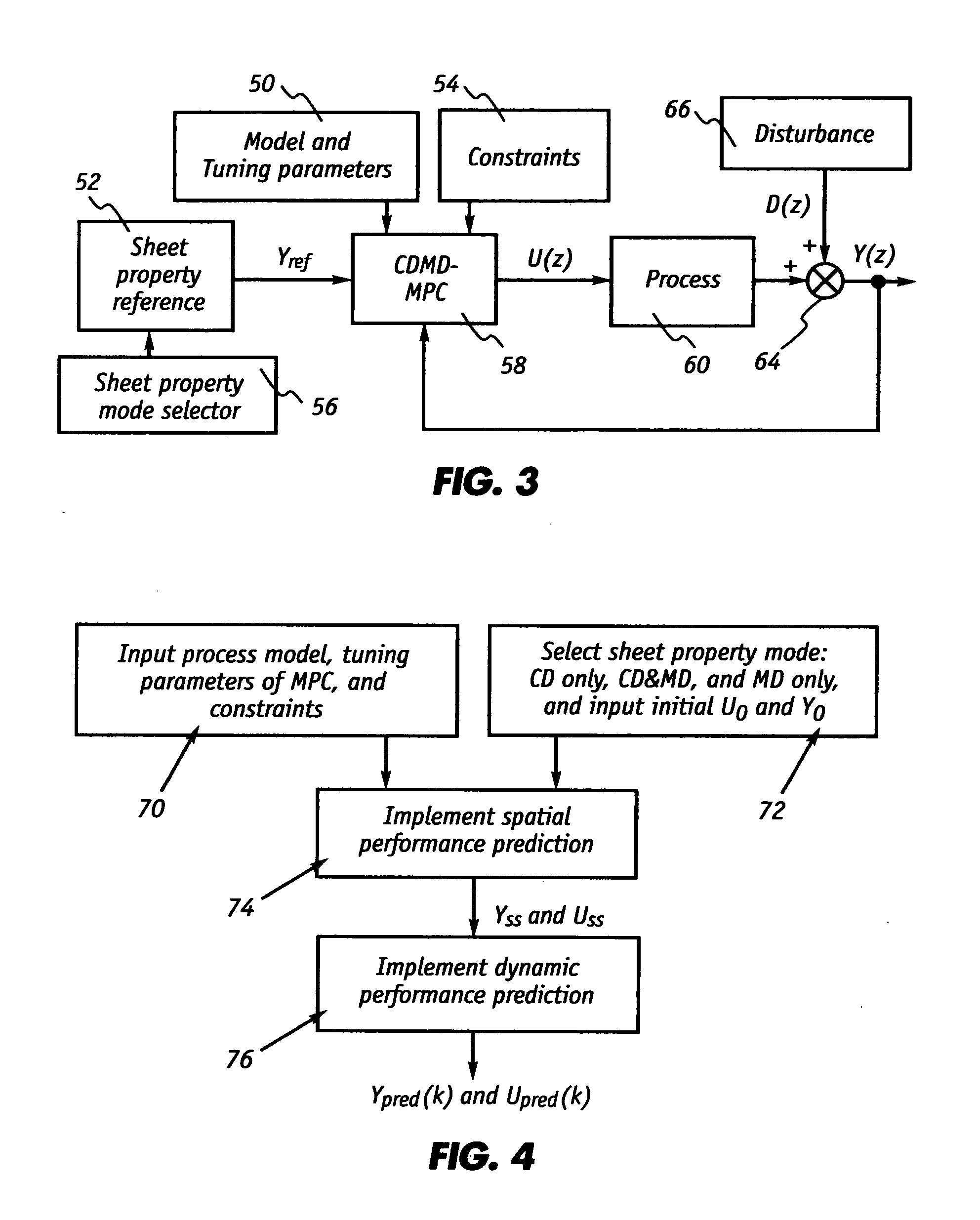

Fast performance prediction of multivariable model predictive controller for paper machine cross-directional processes

ActiveUS7454253B2Efficient solutionMinimize the differenceElectric/magnetic detection for well-loggingDigital differential analysersPredictive controllerActuator

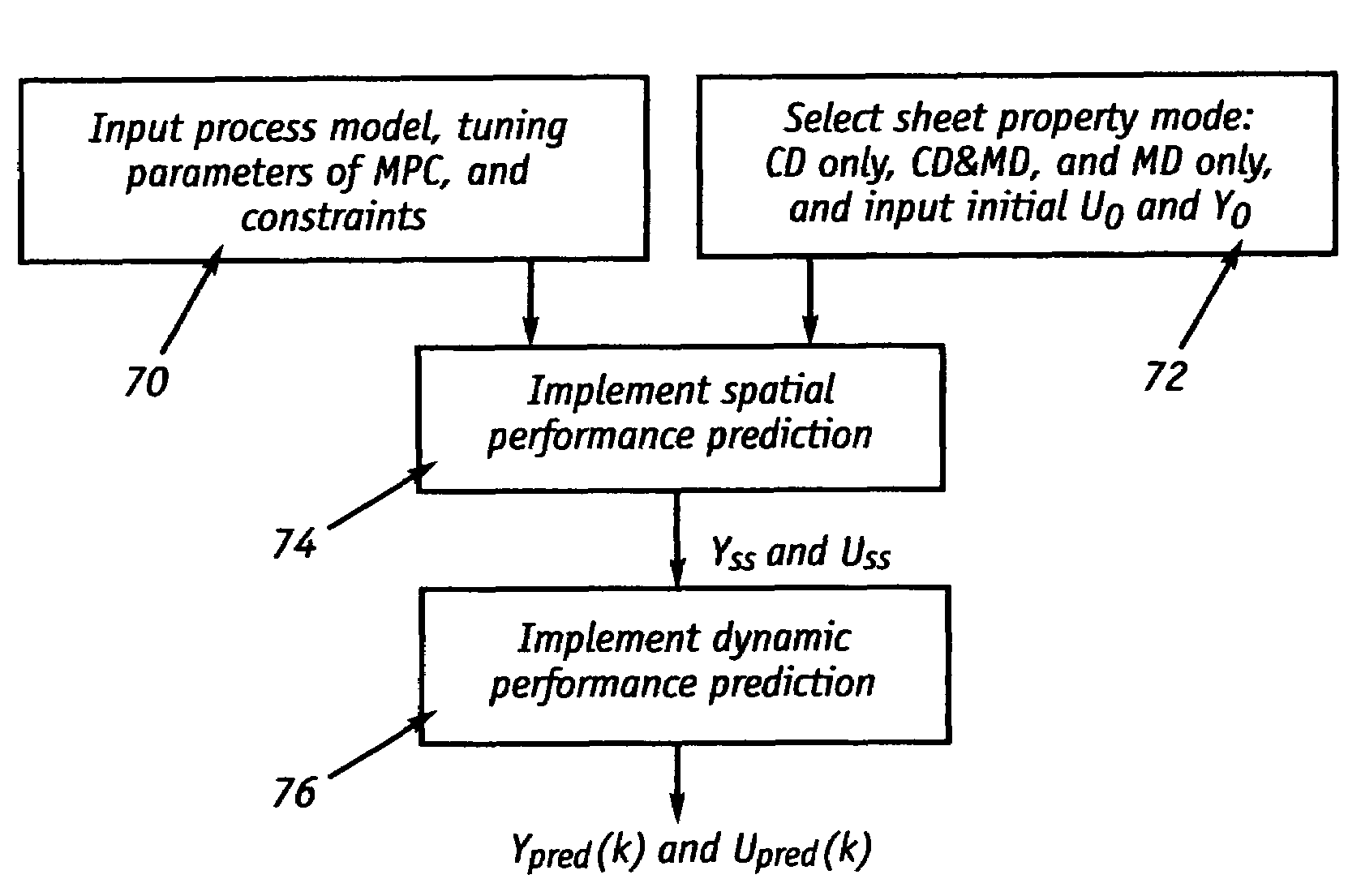

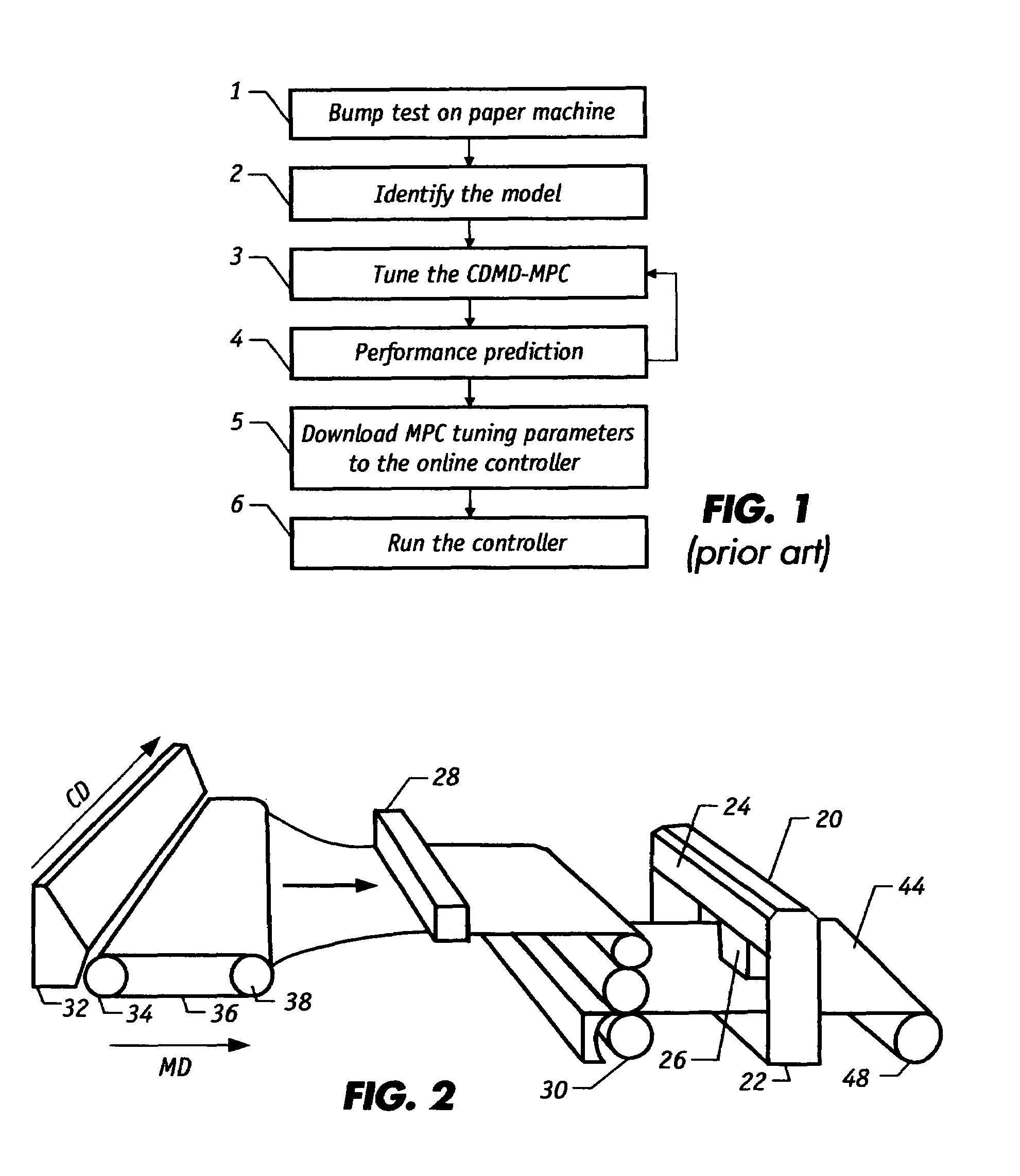

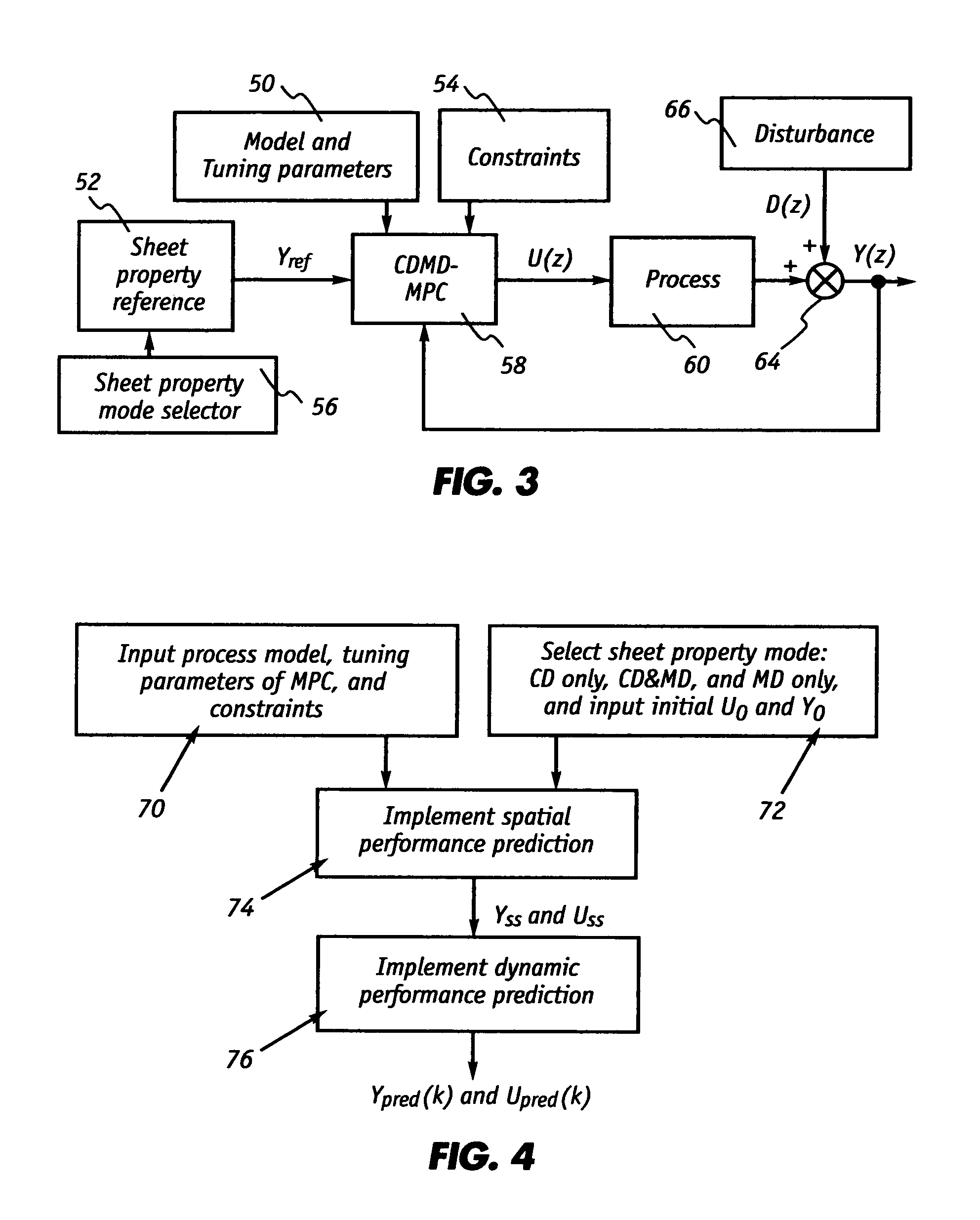

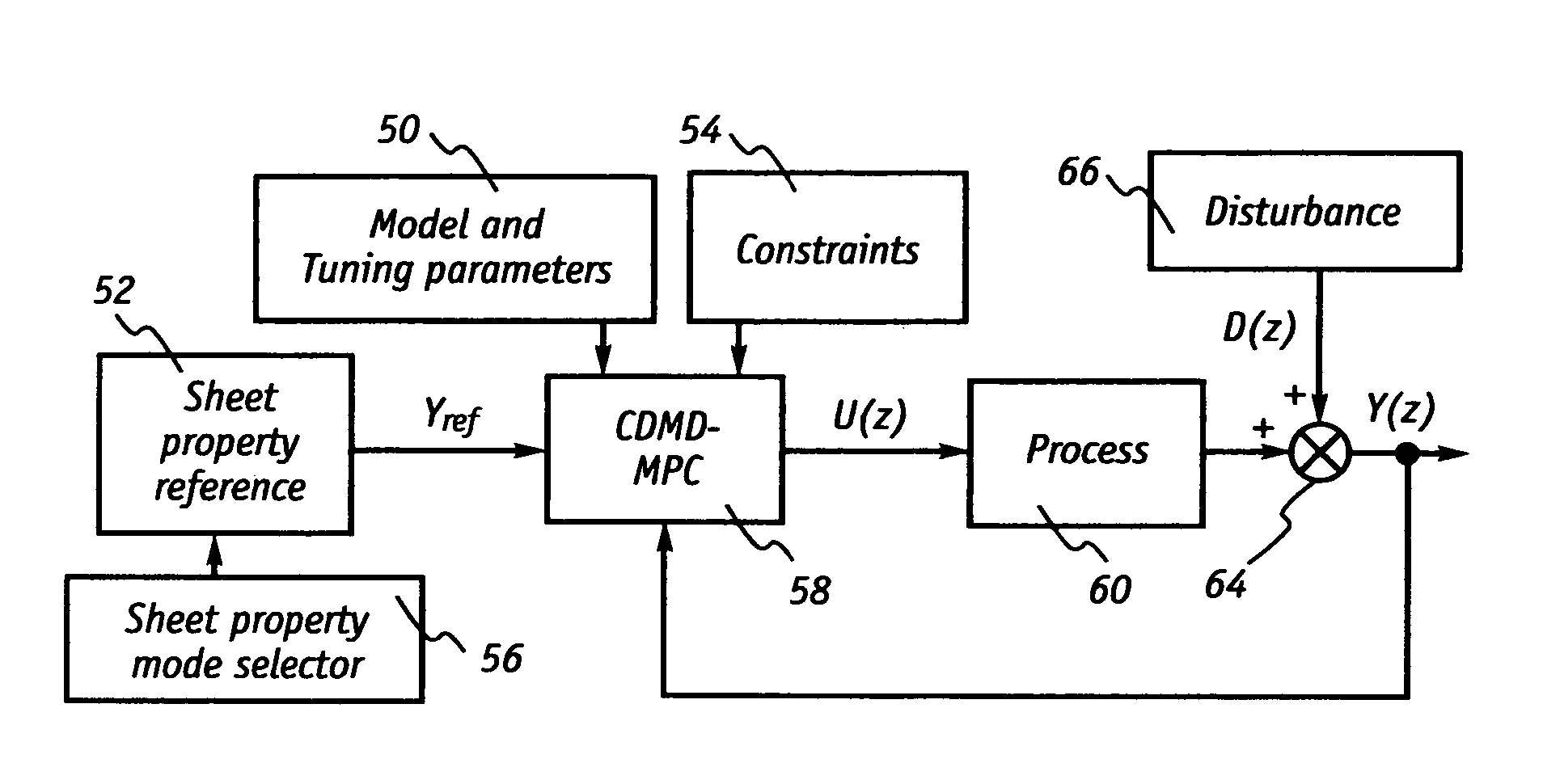

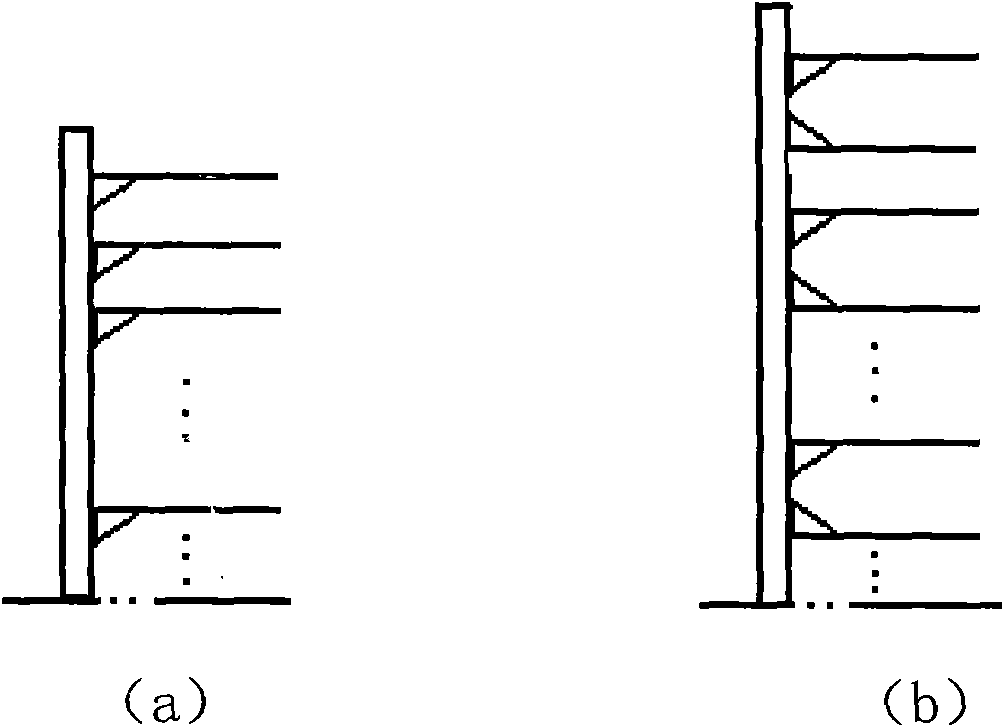

A technique for fast performance prediction of multivariable model predictive controllers (MPC) for large-scale spatially-distributed dynamic systems is provided. When operating an MPC for a two-dimensional sheetmaking process, the controller's performance can be separated into spatial performance and dynamic performance. The steady-state spatial performance for different sheet property modes is first predicted, thereafter, the dynamic performance is predicted on the basis of the steady-state actuator profiles. During the steady-state spatial performance prediction, the original MPC's cost function is approximated to be a steady-state cost function. Then the steady-state measurement profiles and the actuator profiles are calculated through the steady-state cost function. The actuator profiles in time series can be efficiently solved by minimizing the difference between the actuator profiles and the steady-state actuator profiles in the face of constraints. Finally, the model can be employed to expeditiously compute the measurement profiles in times series.

Owner:HONEYWELL ASCA INC

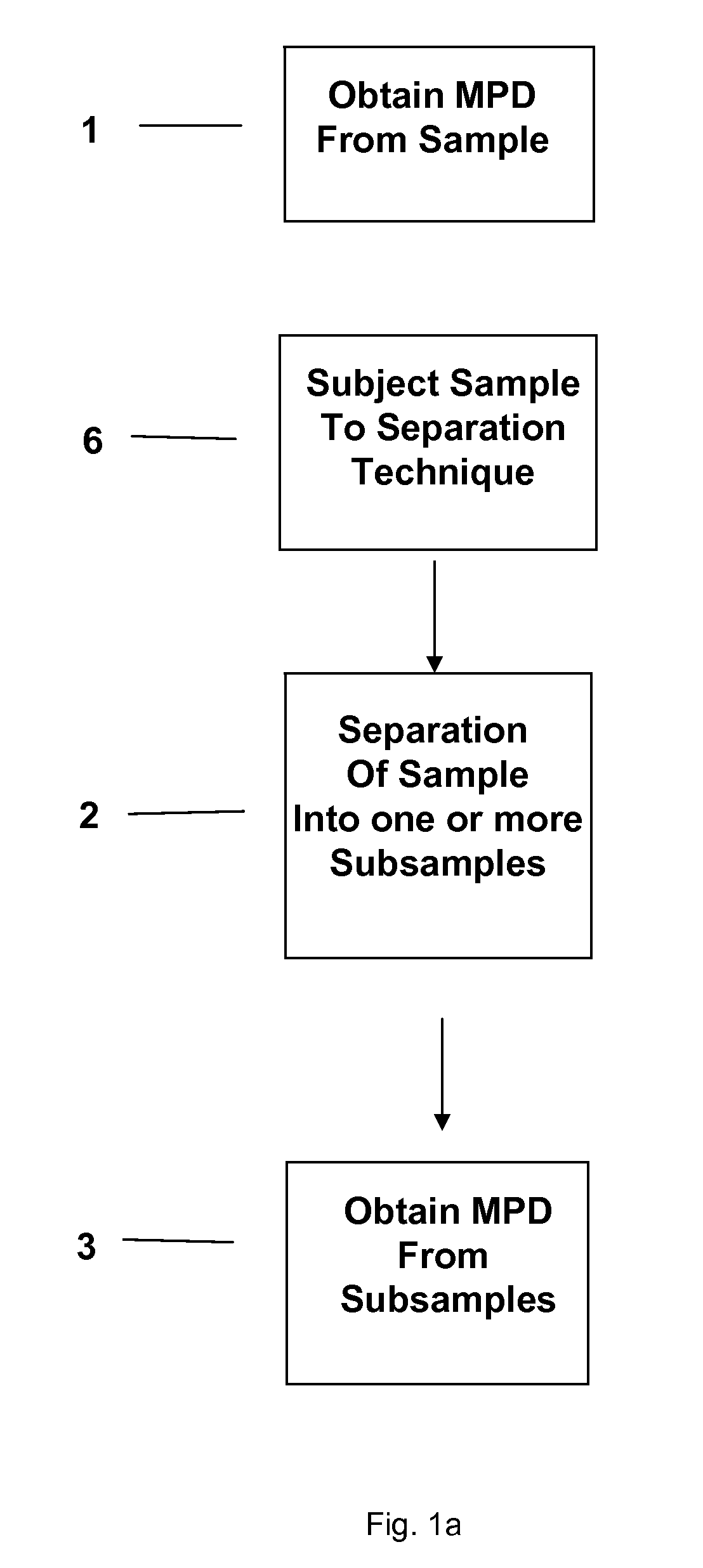

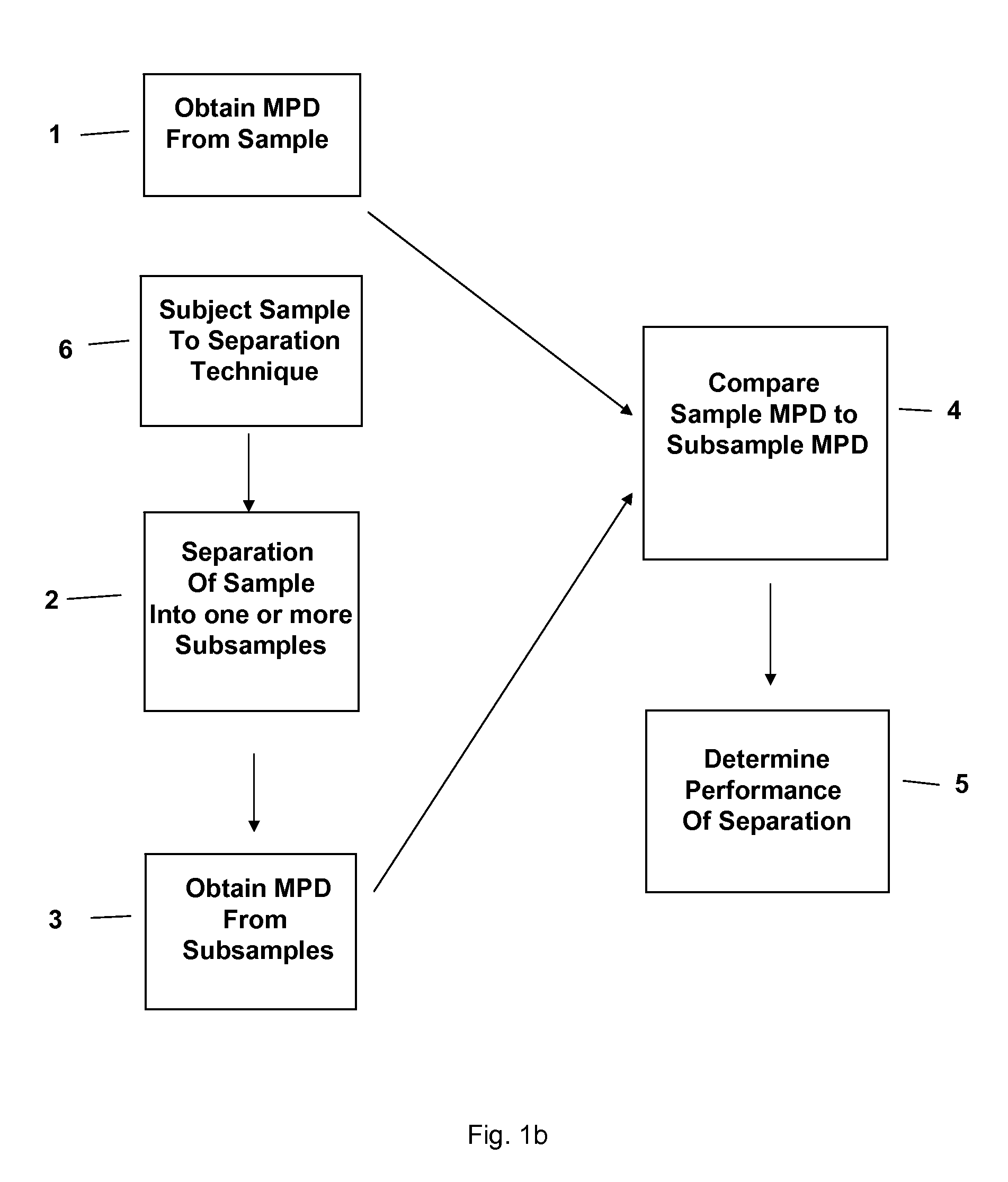

Separation technology method and identification of error

InactiveUS20100050737A1Optical radiation measurementParticle separator tubesCapillary electrophoresisElectrophoresis

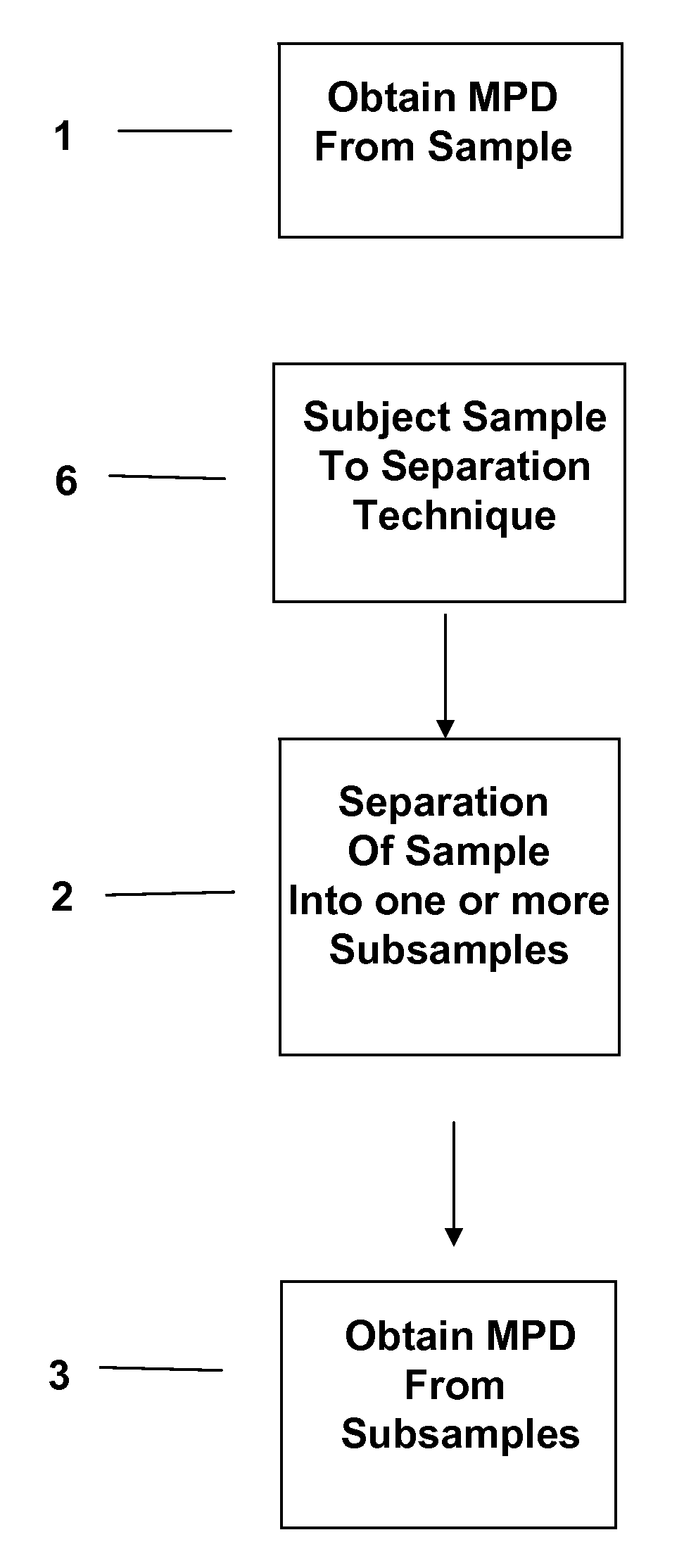

The present invention relates to a method and accompanying device for separating a known or unknown sample into one or more subsamples. By comparing the subsample's measurement profile data to the sample measurement profile data, the performance of the separation can be determined. The separation could be chromatography [such as high-performance liquid chromatography (HPLC), gas chromatography (GC), or the like], electrophoresis [such as capillary electrophoresis (CE) or the like], or another separation technique. The measurement profile data could be ultraviolet / visible (UV / Vis) spectra, mass spectra (MS), or another measurement technique.

Owner:WOLTERS ANDREW MARK

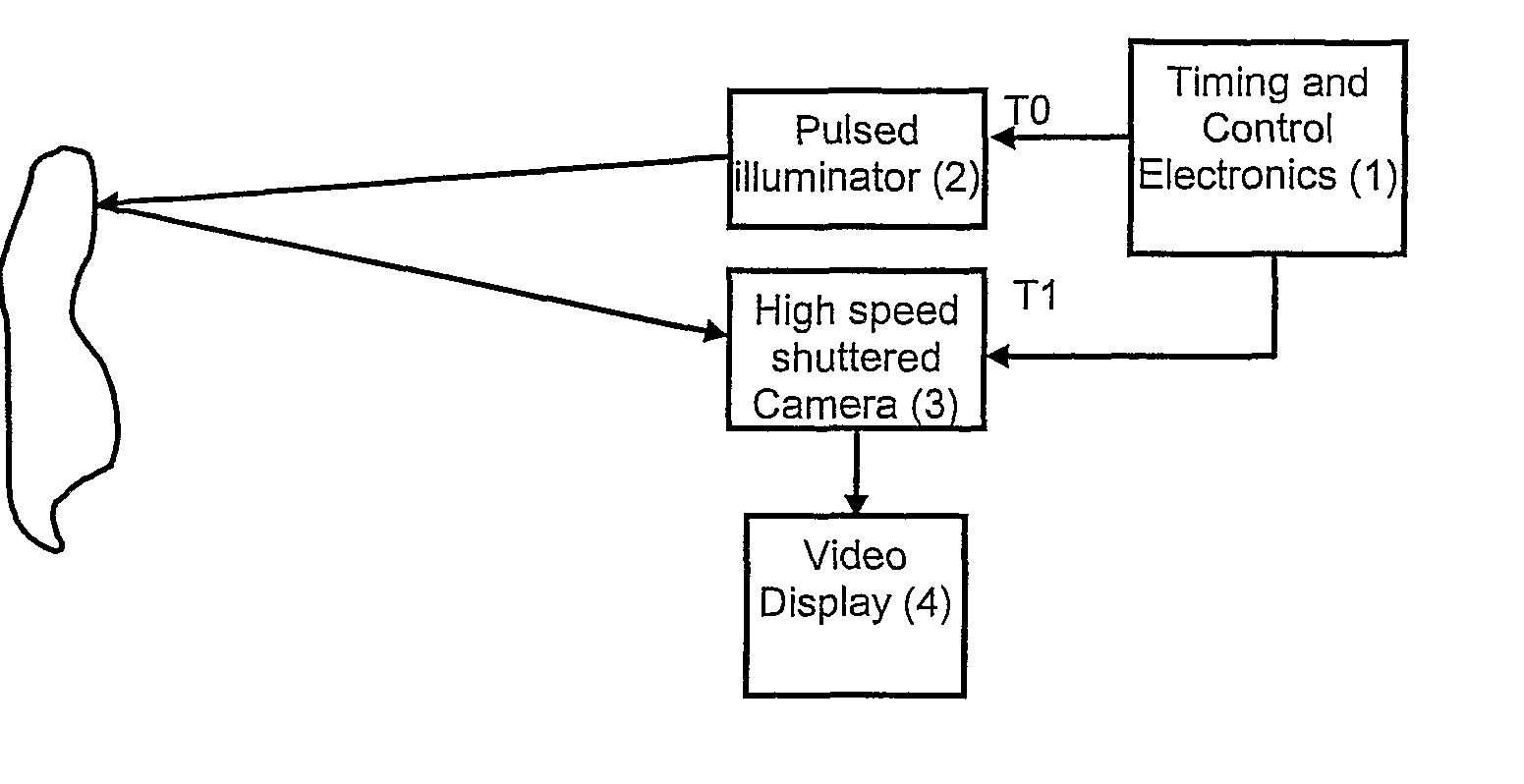

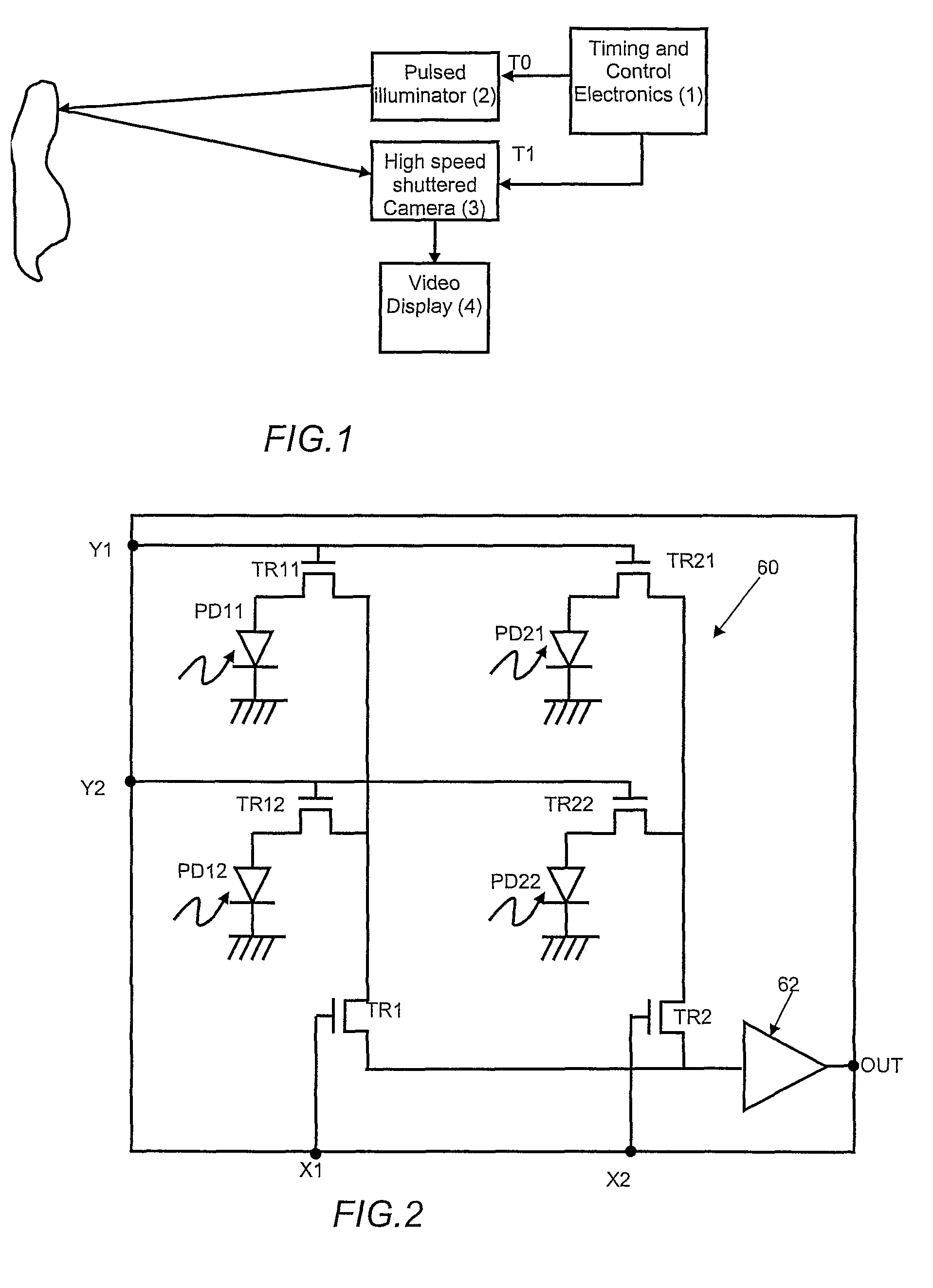

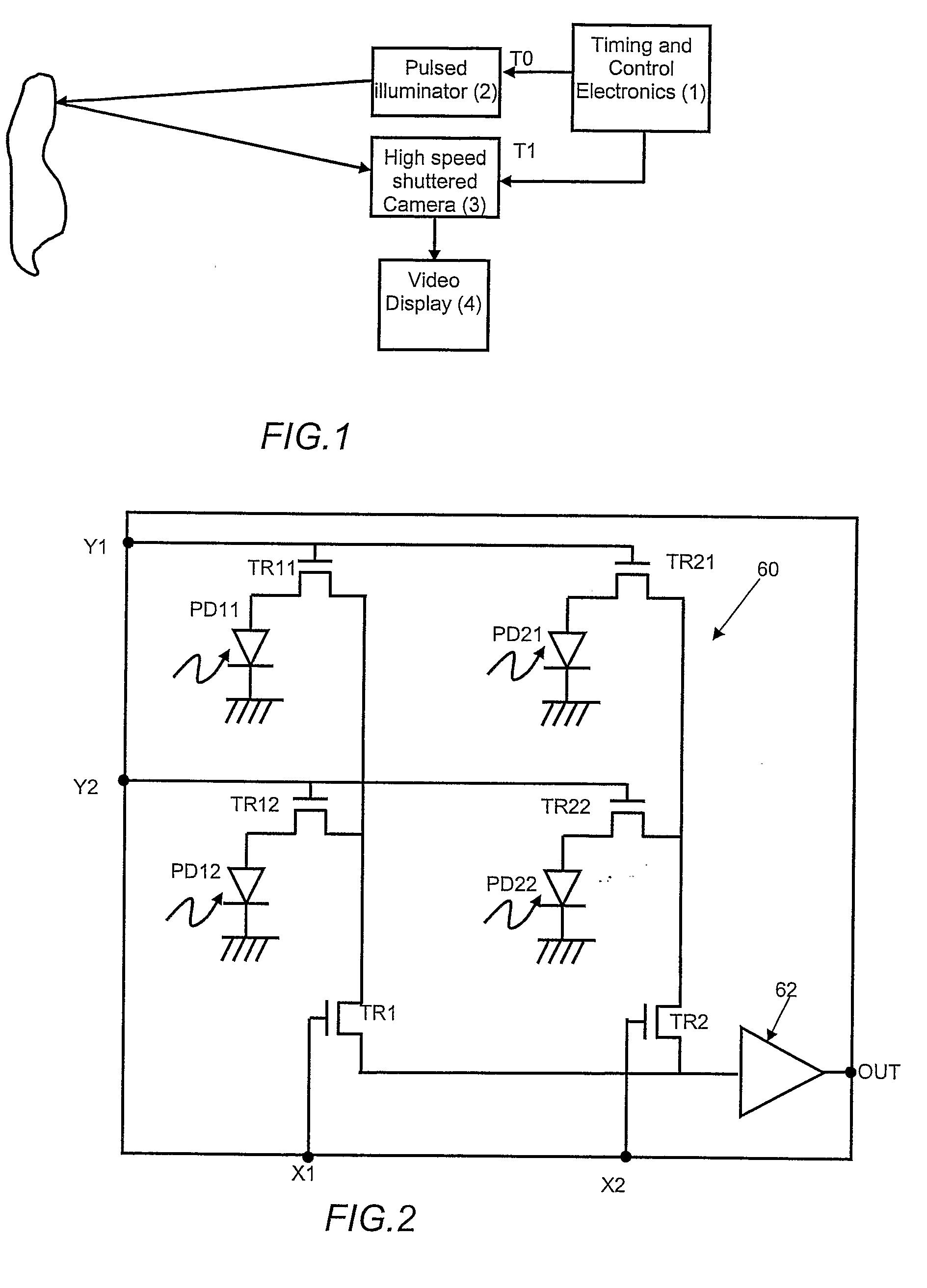

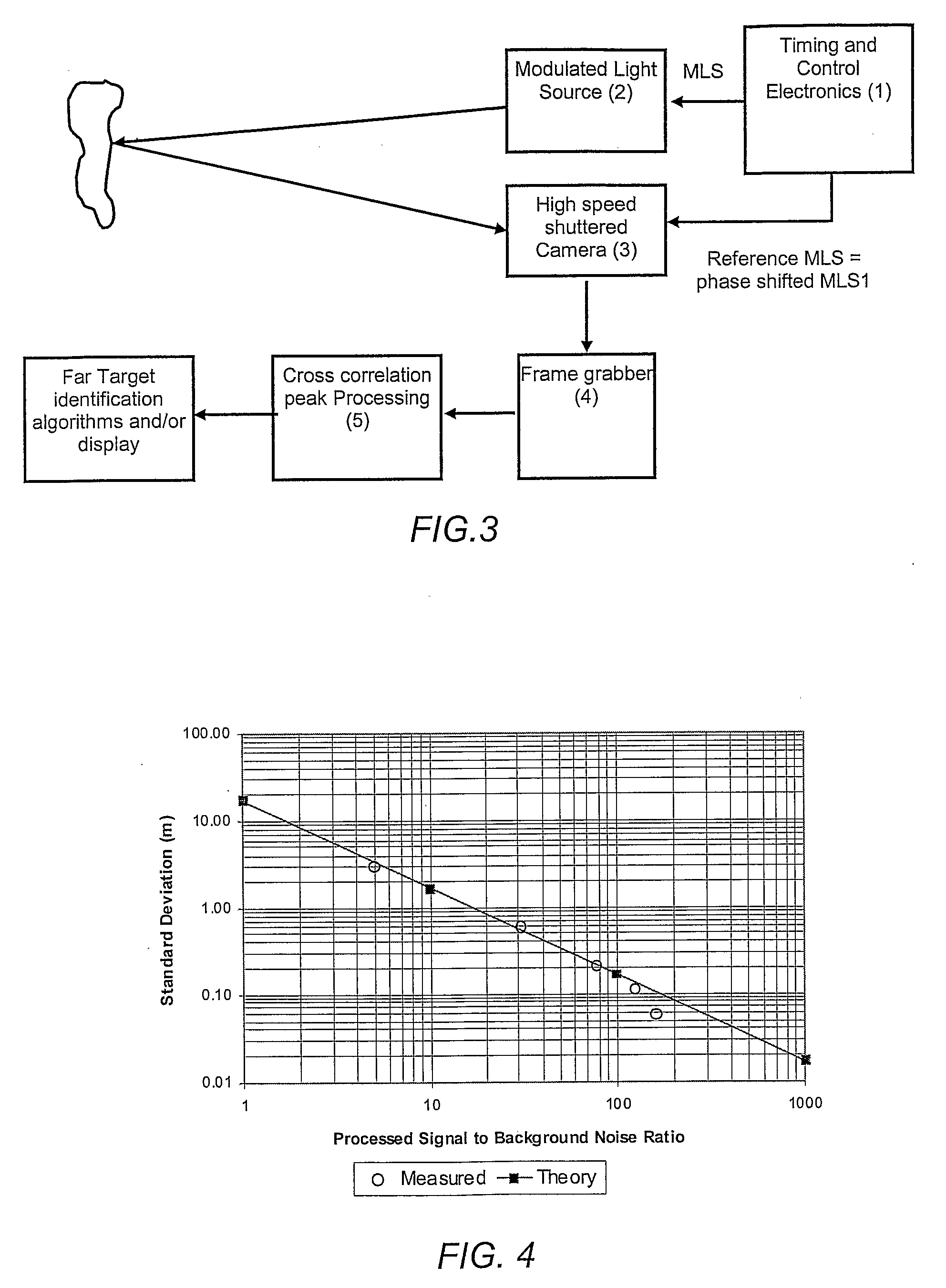

Surface profile measurement

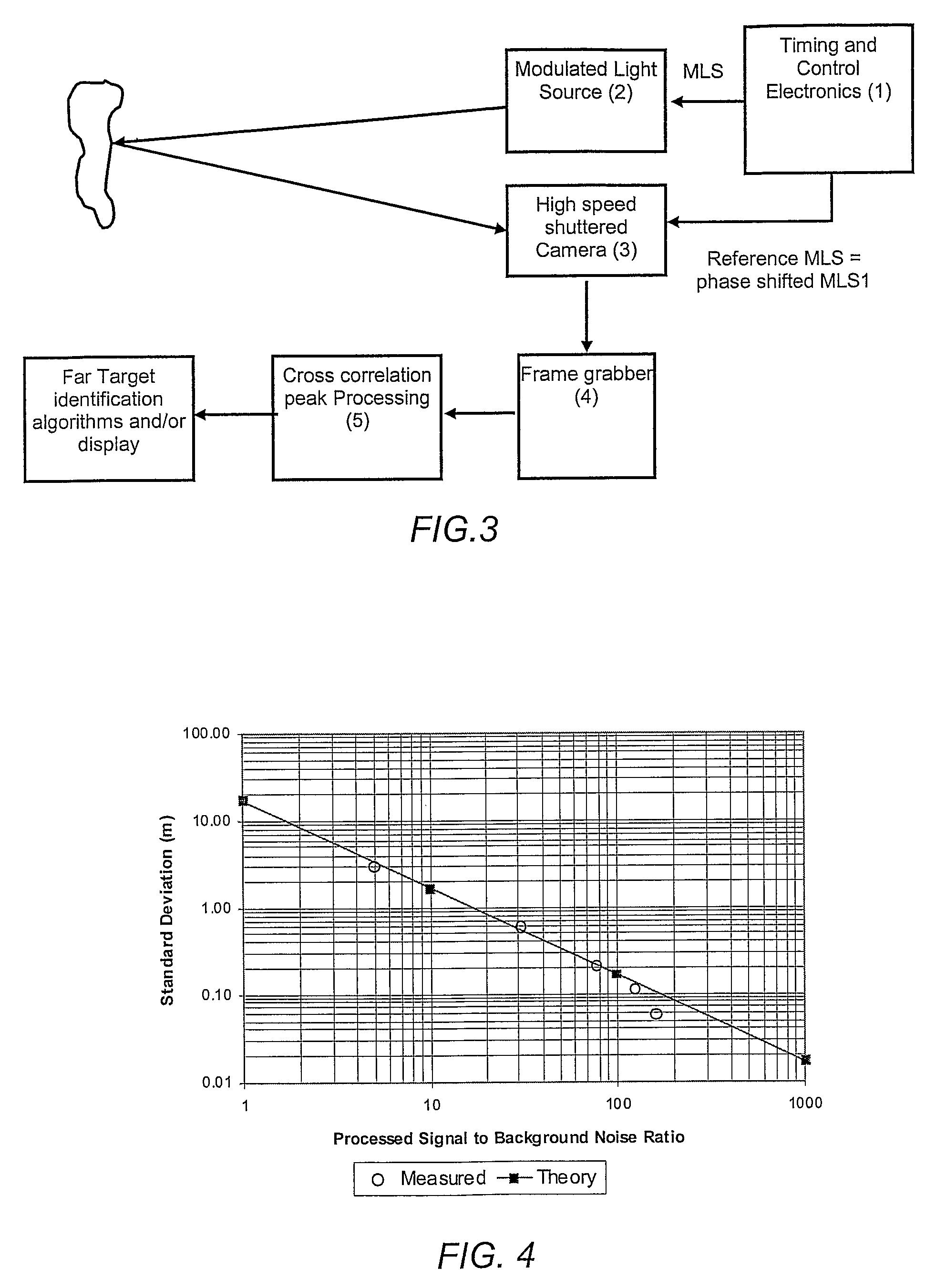

InactiveUS7834985B2No noiseOptical rangefindersElectromagnetic wave reradiationEngineeringTime windows

An imaging system has a transmission system (2) for transmitting a modulated optical signal and a reception system (3) for receiving a received optical signal which is a reflected and delayed version of the transmitted signal. The reception system includes a controllable shutter arrangement for allowing reception in a controllable time window. A memory (4) collects reception data derived from different time windows, and a measure of distance is obtained corresponding to a maximum correlation between the received optical signal and the timing of the controllable time window. Surface profile information is derived from multiple distance measurements.The shutter arrangement enables the distance measurement (and the subsequent profile calculation) to be free from noise from other scattering sources.

Owner:INSTRO PREC

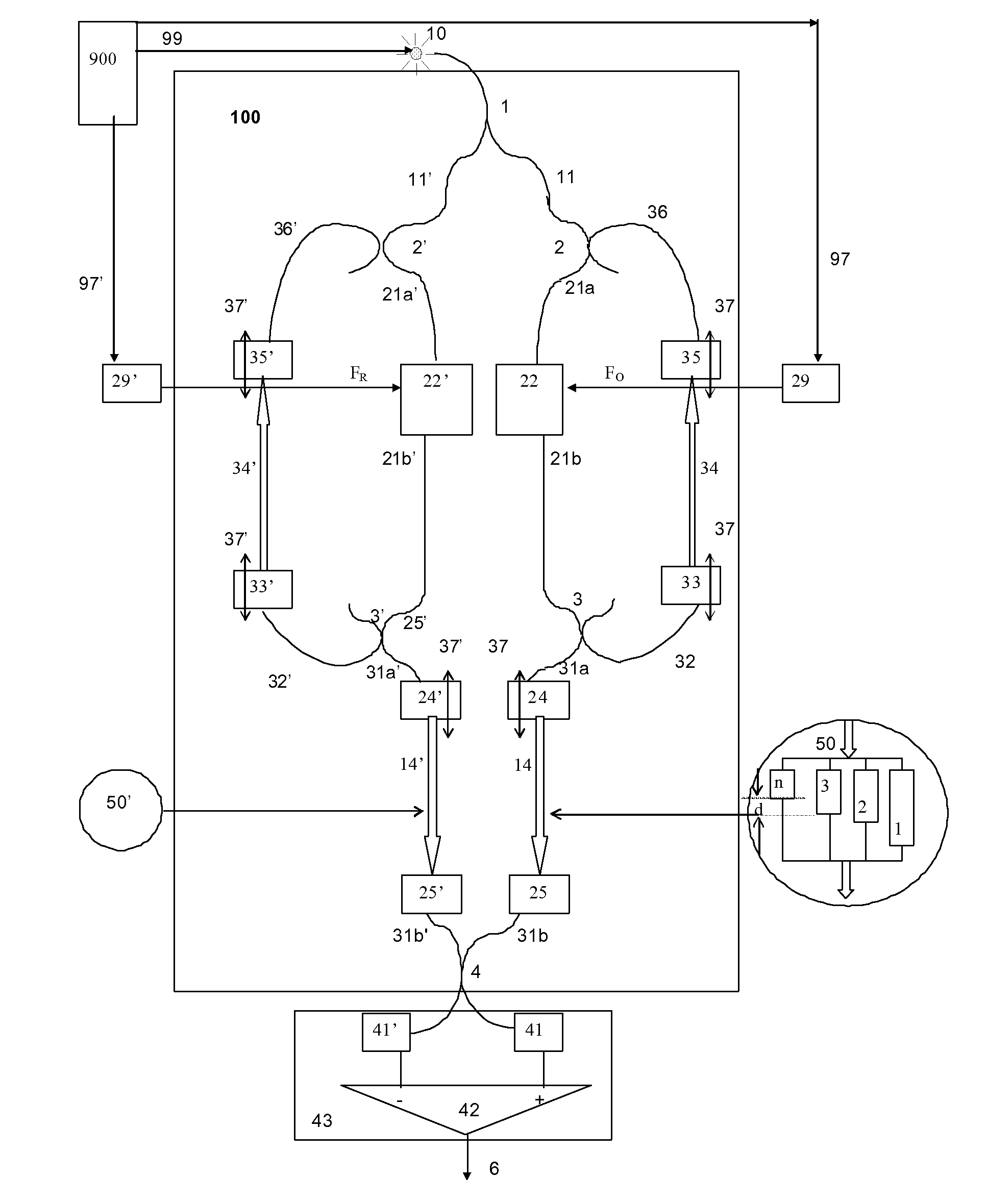

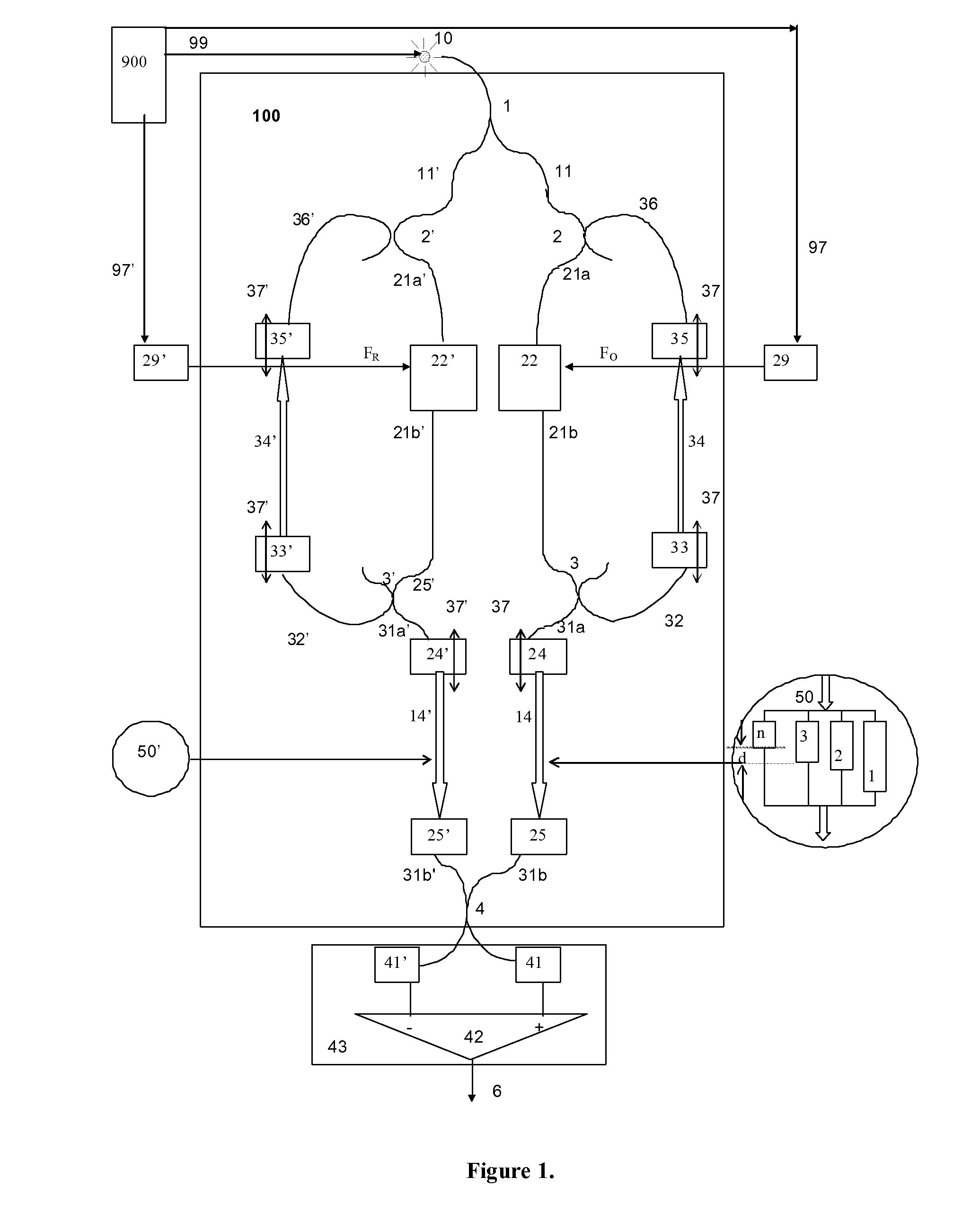

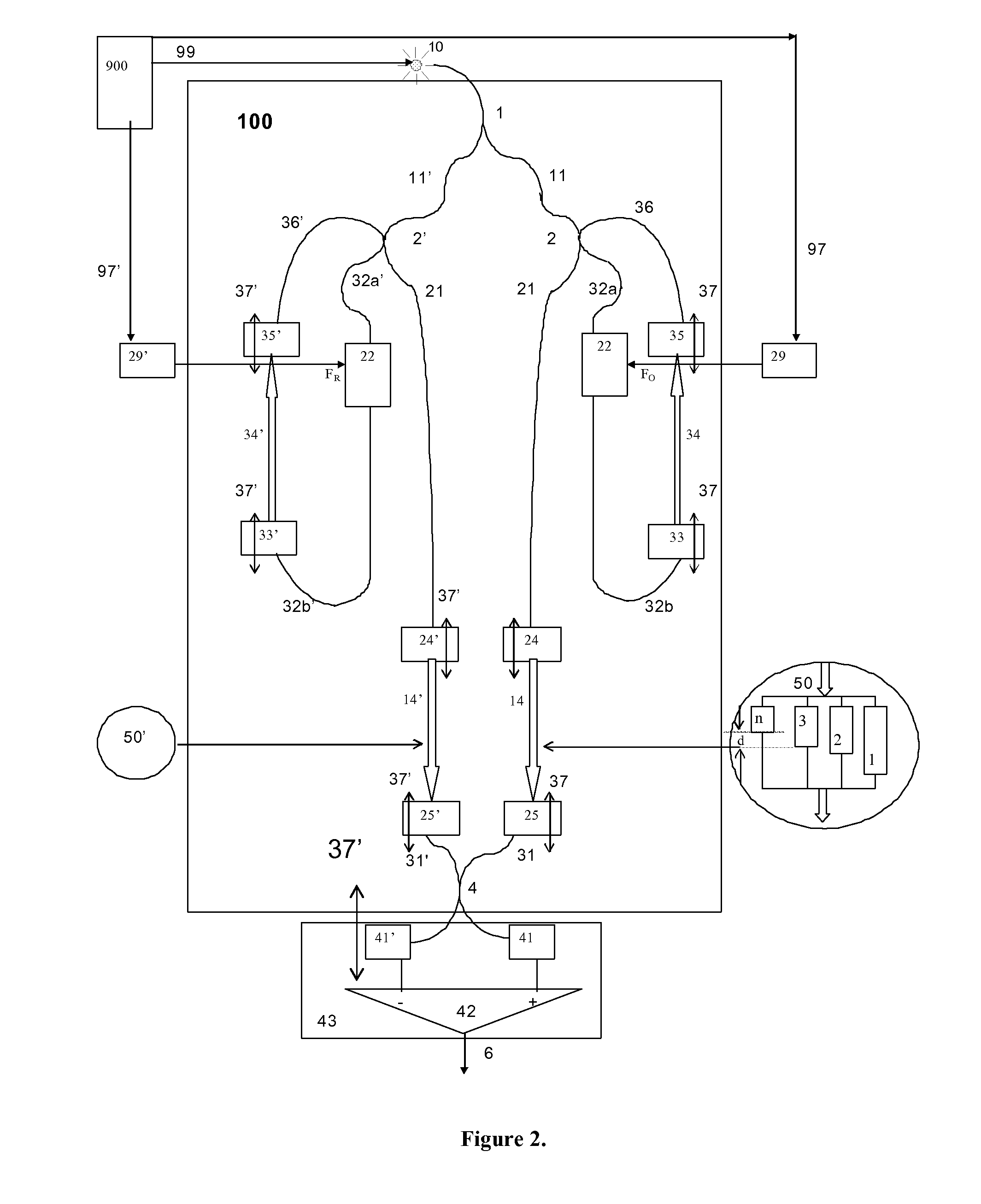

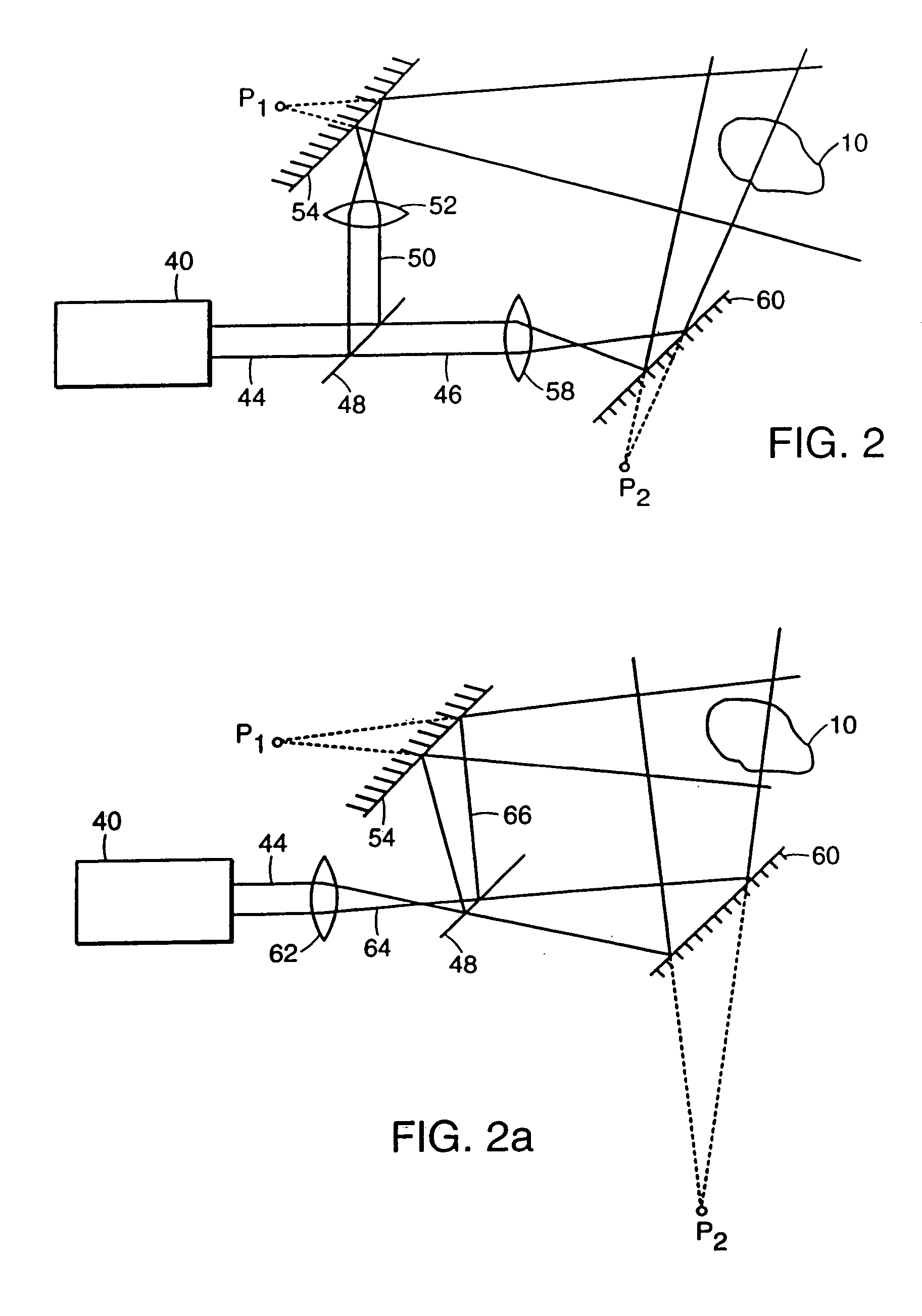

Multiple Path Interferometer and Method

ActiveUS20110109911A1Loss of previous configurations is eliminatedEliminate lossRadiation pyrometryDiagnostics using lightLow noisePath length

The invention discloses an optical interferometer which can be used to provide simultaneous measurements over multiple path lengths and methods to employ such an interferometer as to achieve a variety of functions covering simultaneous measurements at different depths separated by an increment of a multiple differential delay matched in the interferometer as well as imaging. Optical sensors, optical coherence tomography (OCT) set-ups, optical sensing methods and OCT methods are disclosed which can provide: (i) multiple en-face images at several depths with dynamic dispersion compensation, (ii) fast acquisition of cross sections, (iii) fast acquisition of 3D volumes of a scattering object while maintaining dynamic focus; (iv) fast acquisition of long axial measurement profiles, non mechanical, with dynamic focus, range scalable, with applications in tracking and OTDR. Methods are disclosed on the combination of scanning regimes and modes of operation to achieve versatile functionality in measurements, in the 3D imaging of moving tissue such as the eye, heart, or moving embryos or functional / low noise imaging by making use of angular compounding or polarisation. A method for elimination of axial movement effects in measuring the flow profile is also disclosed.

Owner:UNIVERSITY OF KENT

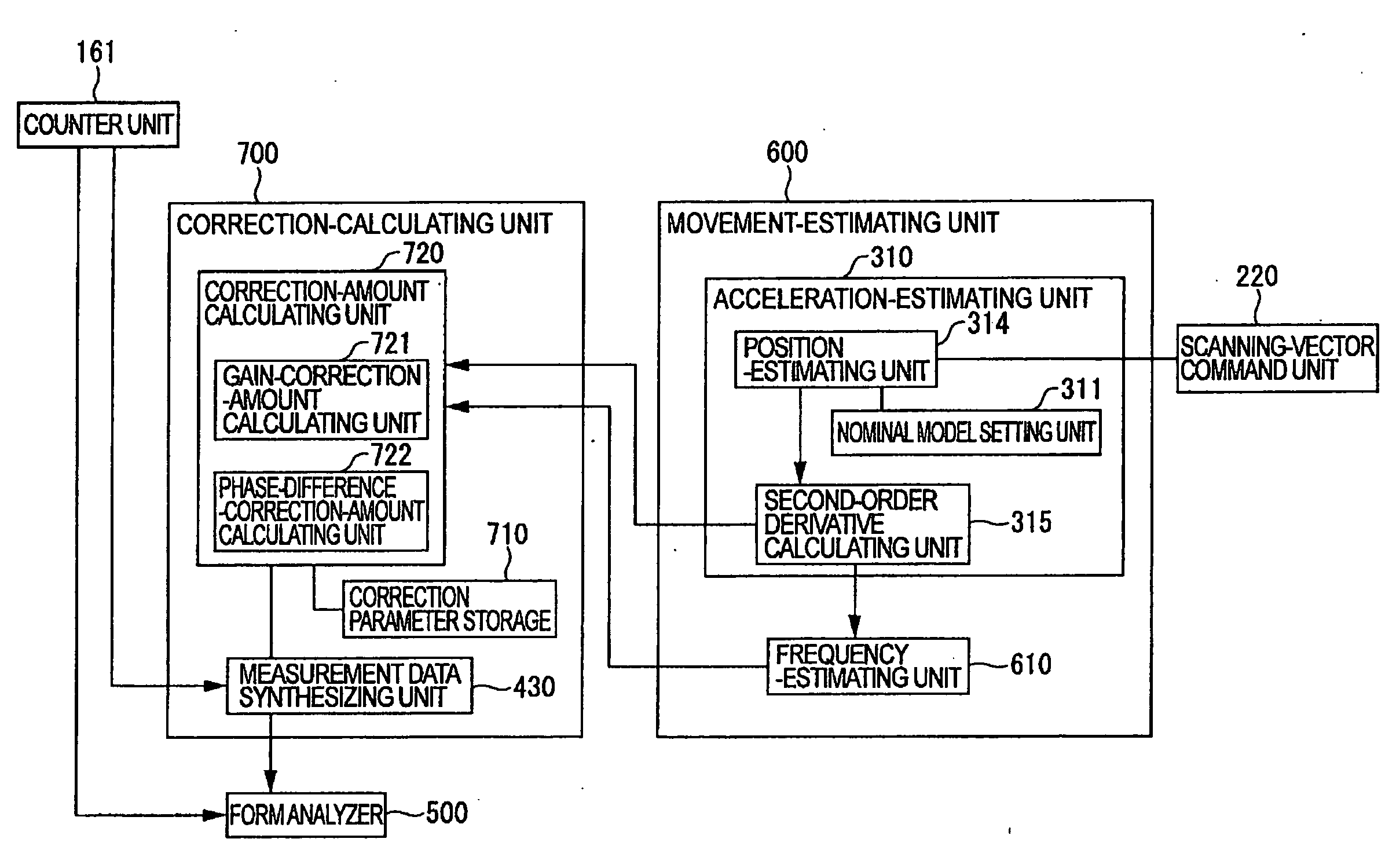

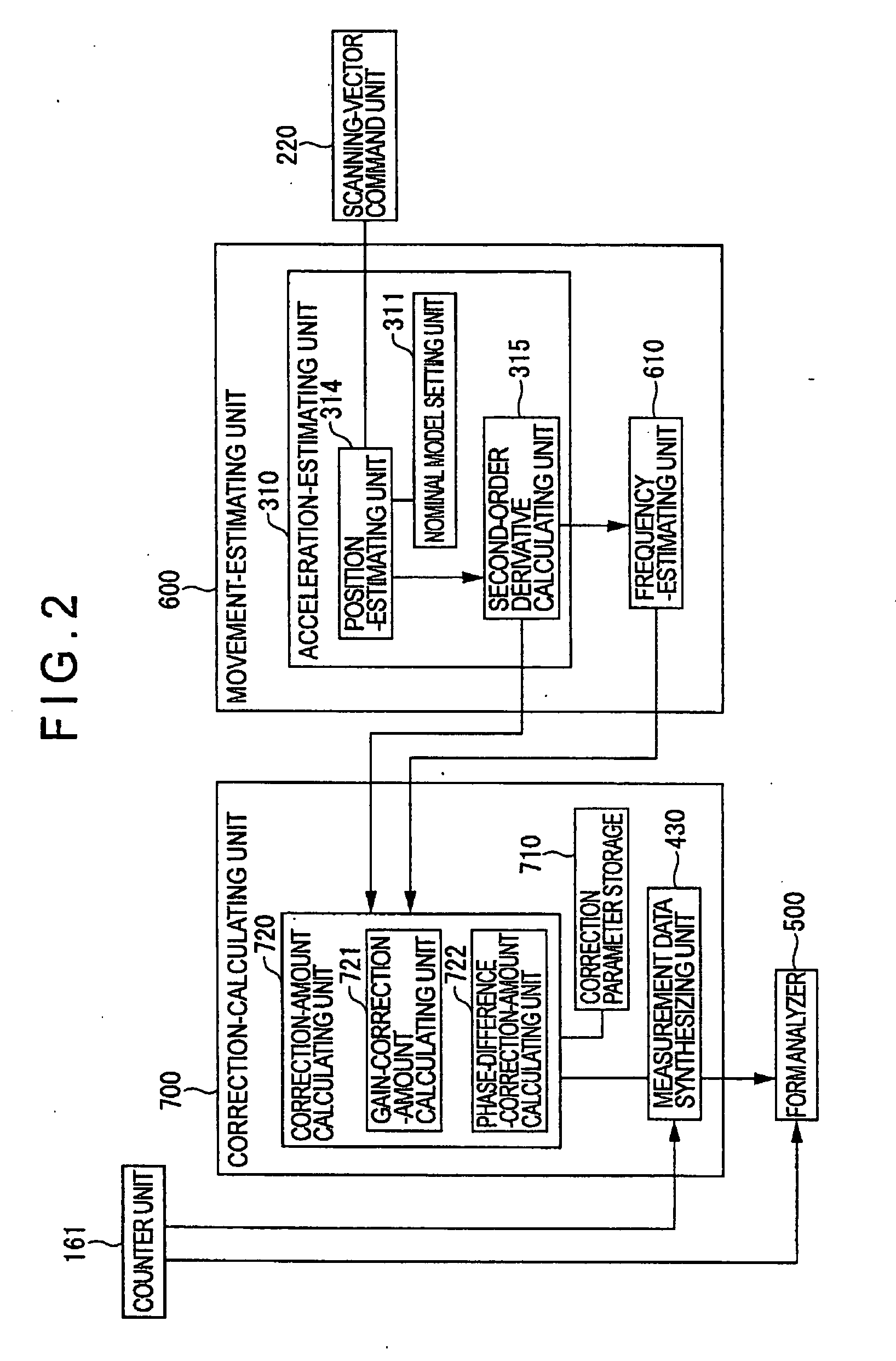

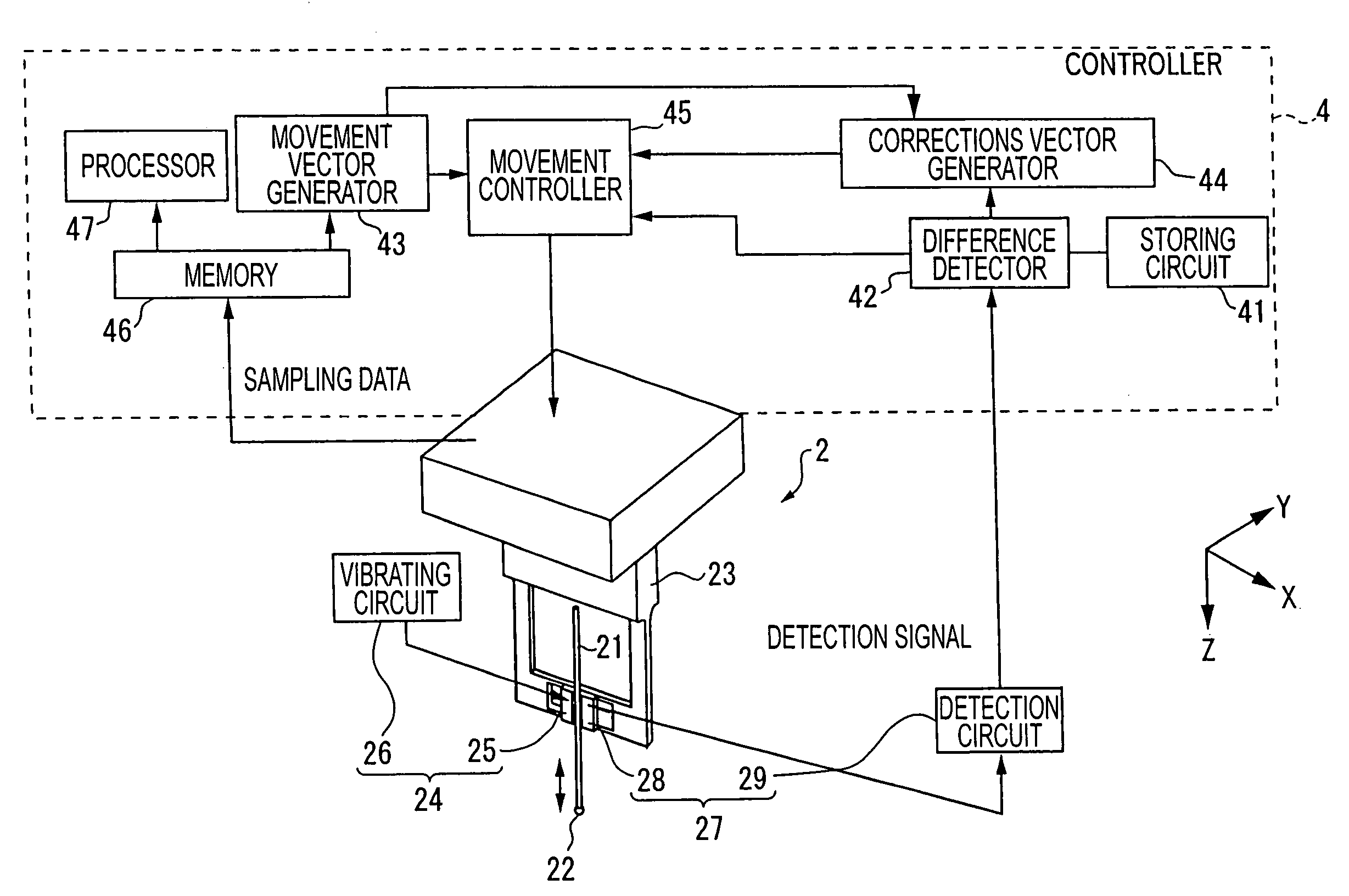

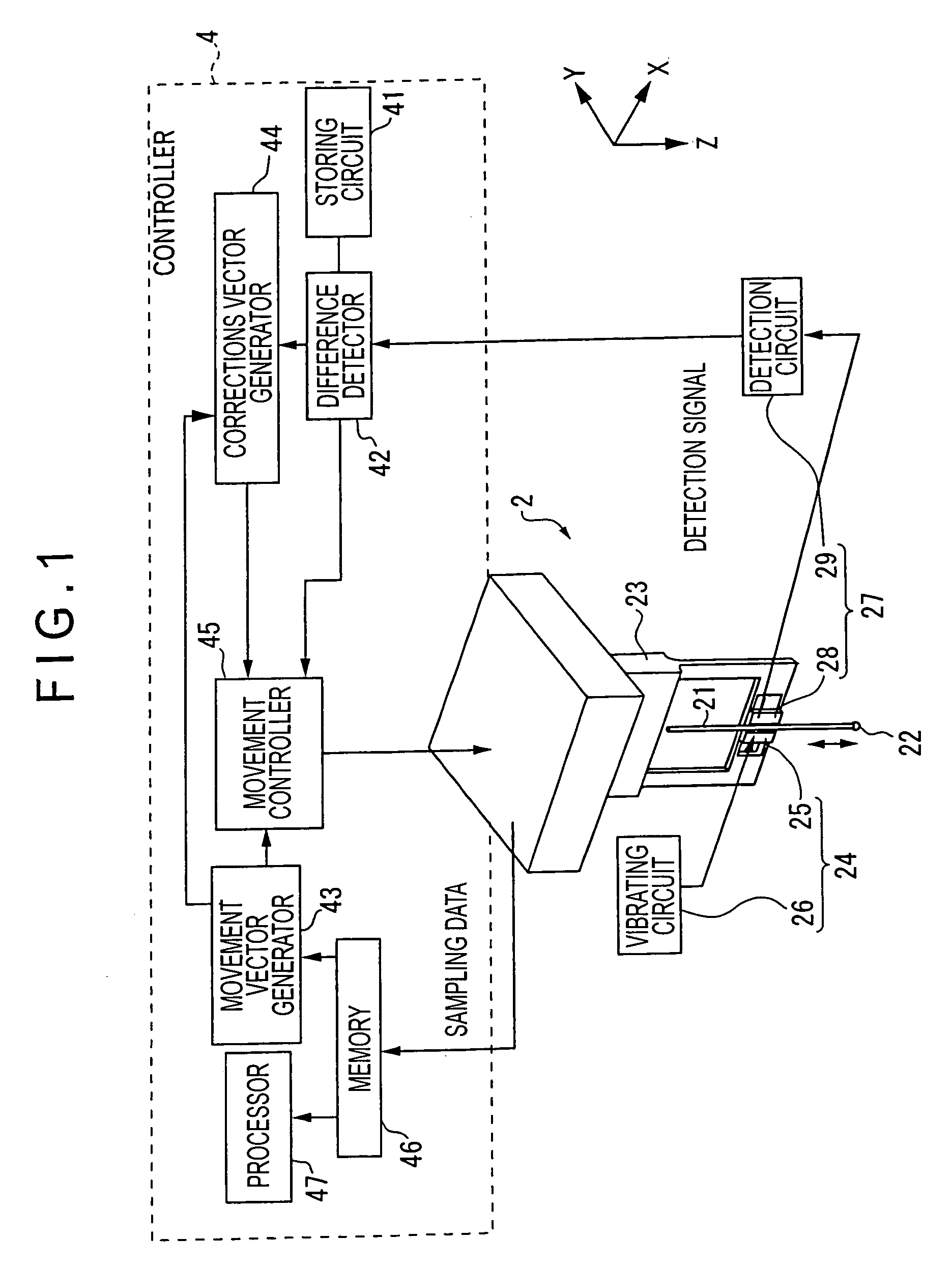

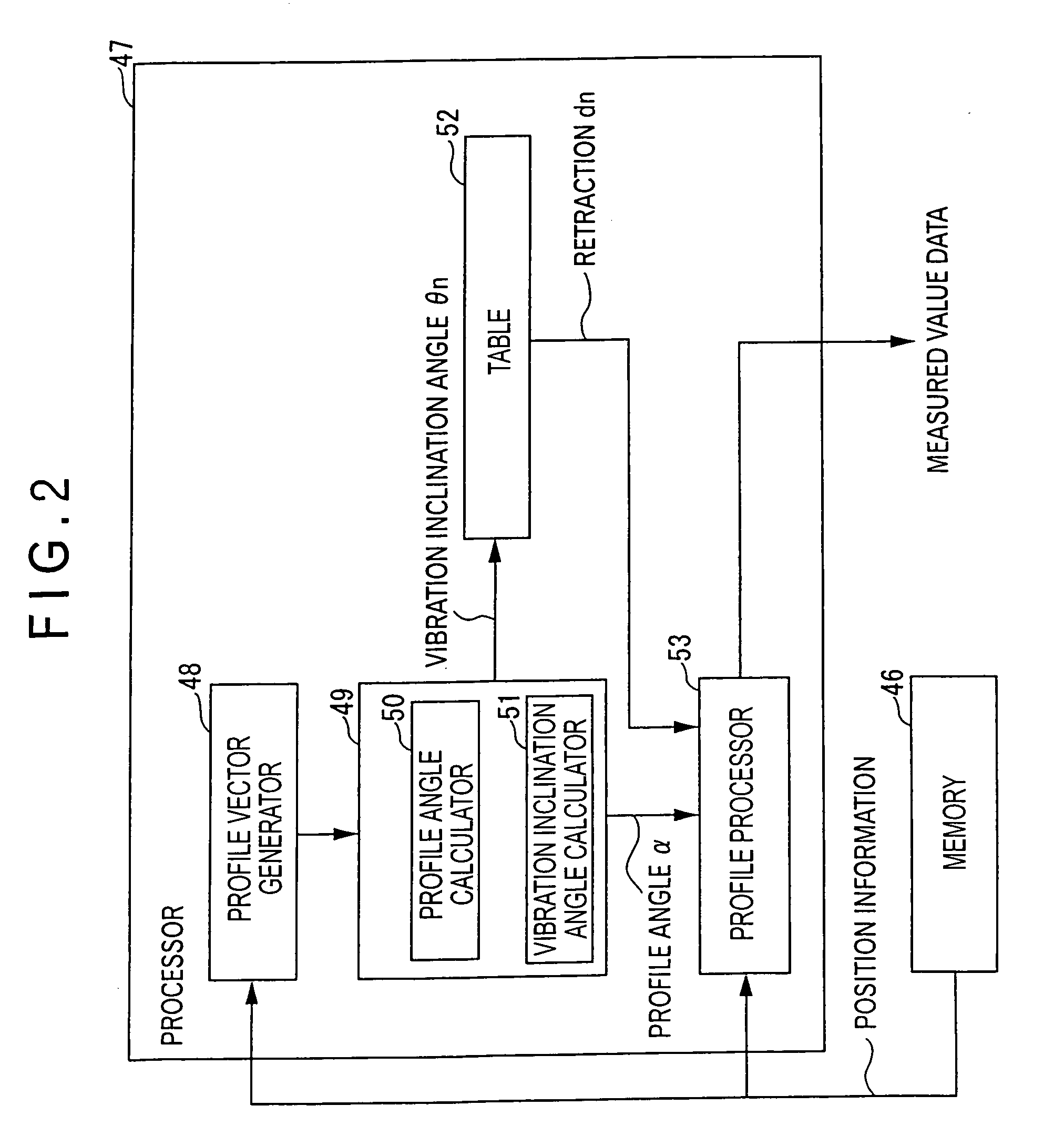

Surface-profile measuring instrument

ActiveUS20080065341A1Improve measurement productivityMechanical counters/curvatures measurementsMeasurement/indication equipmentsObservational errorMeasuring instrument

A surface-profile measuring instrument includes a movement-estimating unit (600) that estimates an movement state of a drive mechanism in accordance with a scanning vector command issued by a scanning vector commanding unit (220) to calculate an estimated movement state quantity, and a correction calculating unit (700) that corrects a detection value of a drive sensor in accordance with the estimated movement state quantity calculated by the movement estimating unit (600).The movement-estimating unit (600) has a nominal model setting unit (311) in which a nominal model as a frequency transfer characteristics from the scanning vector commanding unit to the probe of the scanning probe is set. The correction-calculating unit (700) includes a correction-amount calculating unit (720) that calculates a correction amount for correcting a measurement error generated by a deformation of the drive mechanism in accordance with the movement thereof and a measurement data synthesizing unit (430) that synthesizes the detection value of the drive sensor and the displacement sensor and the calculated correction-amount calculated by the correction-amount calculating unit (720).

Owner:MITUTOYO CORP

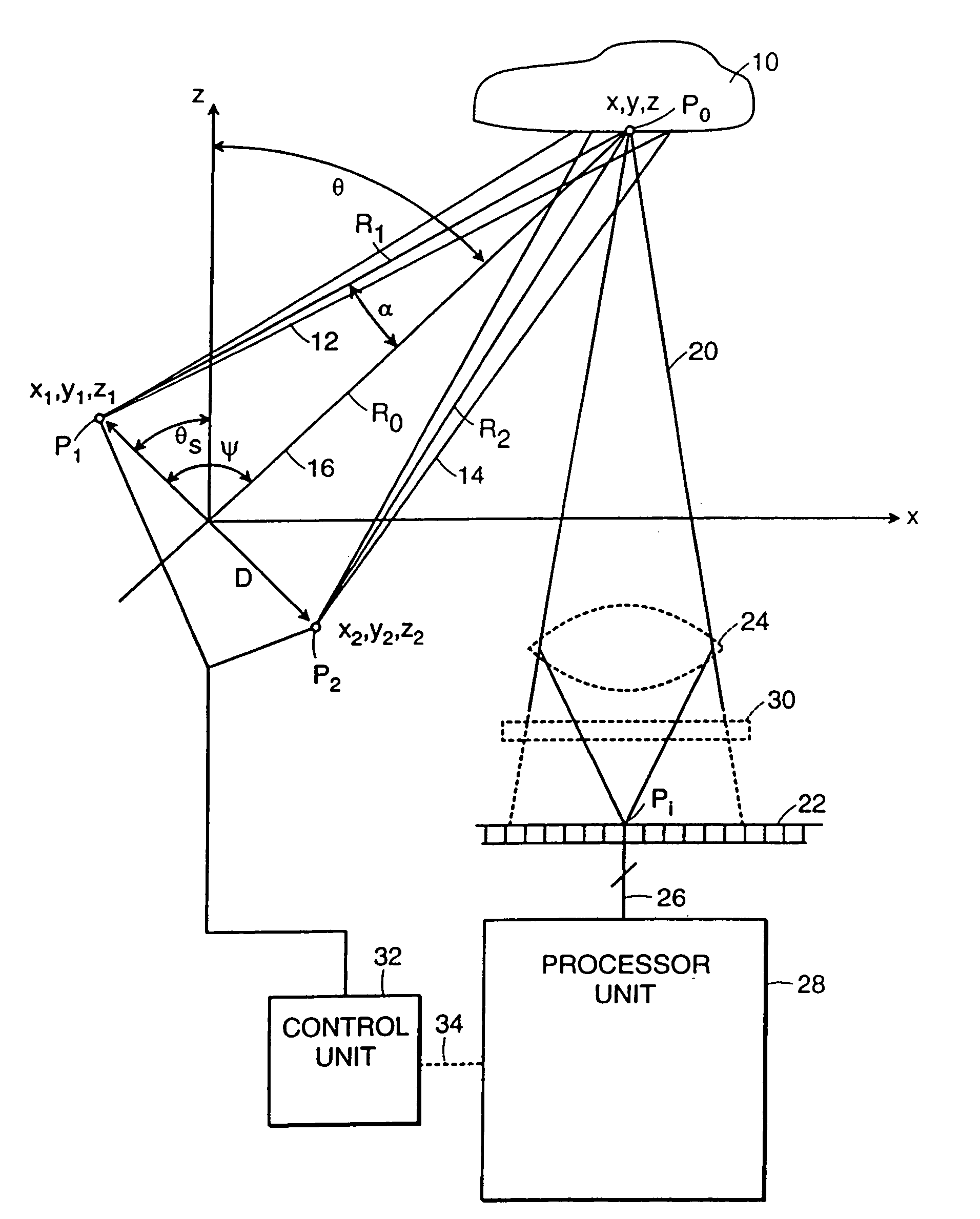

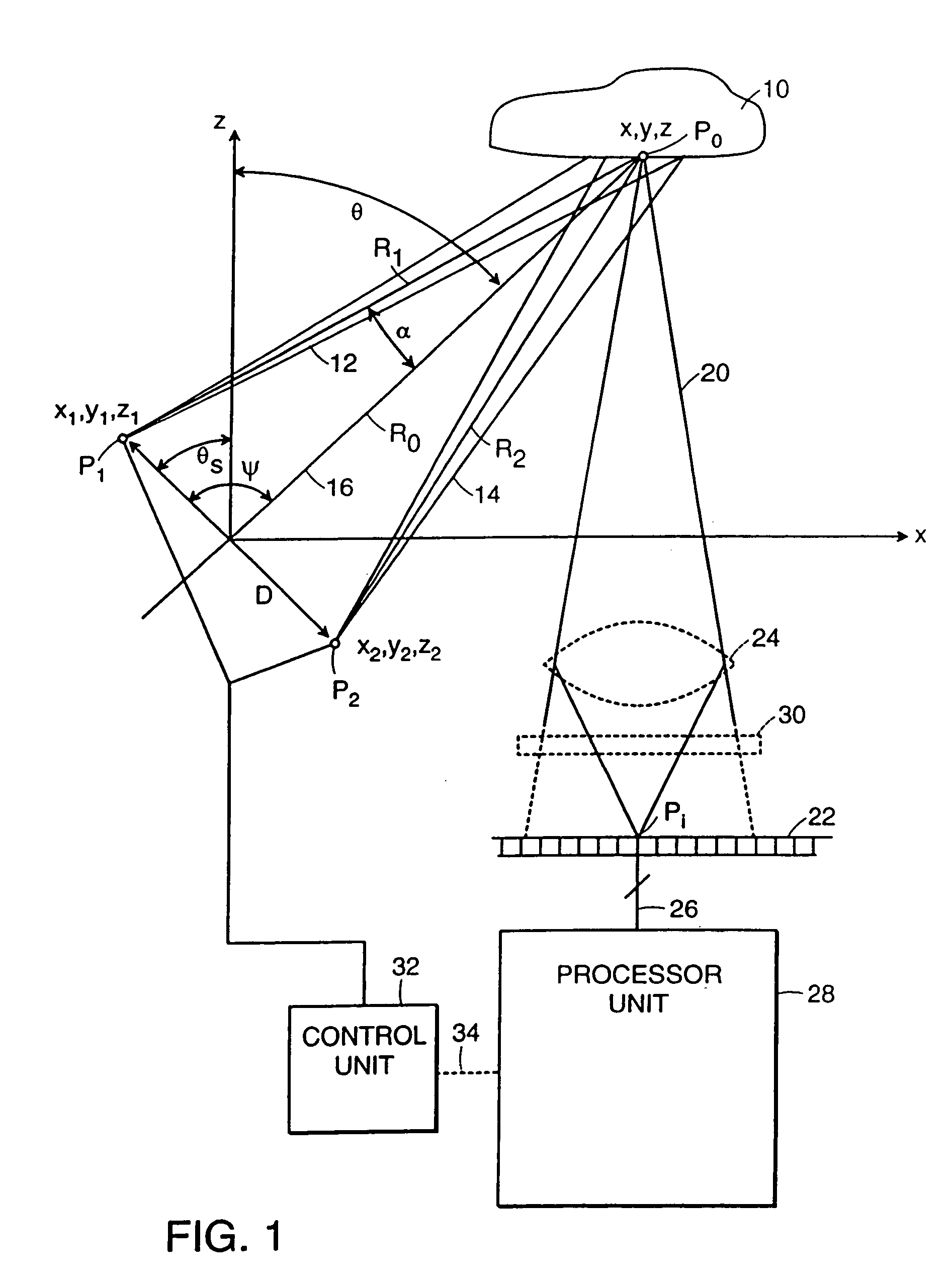

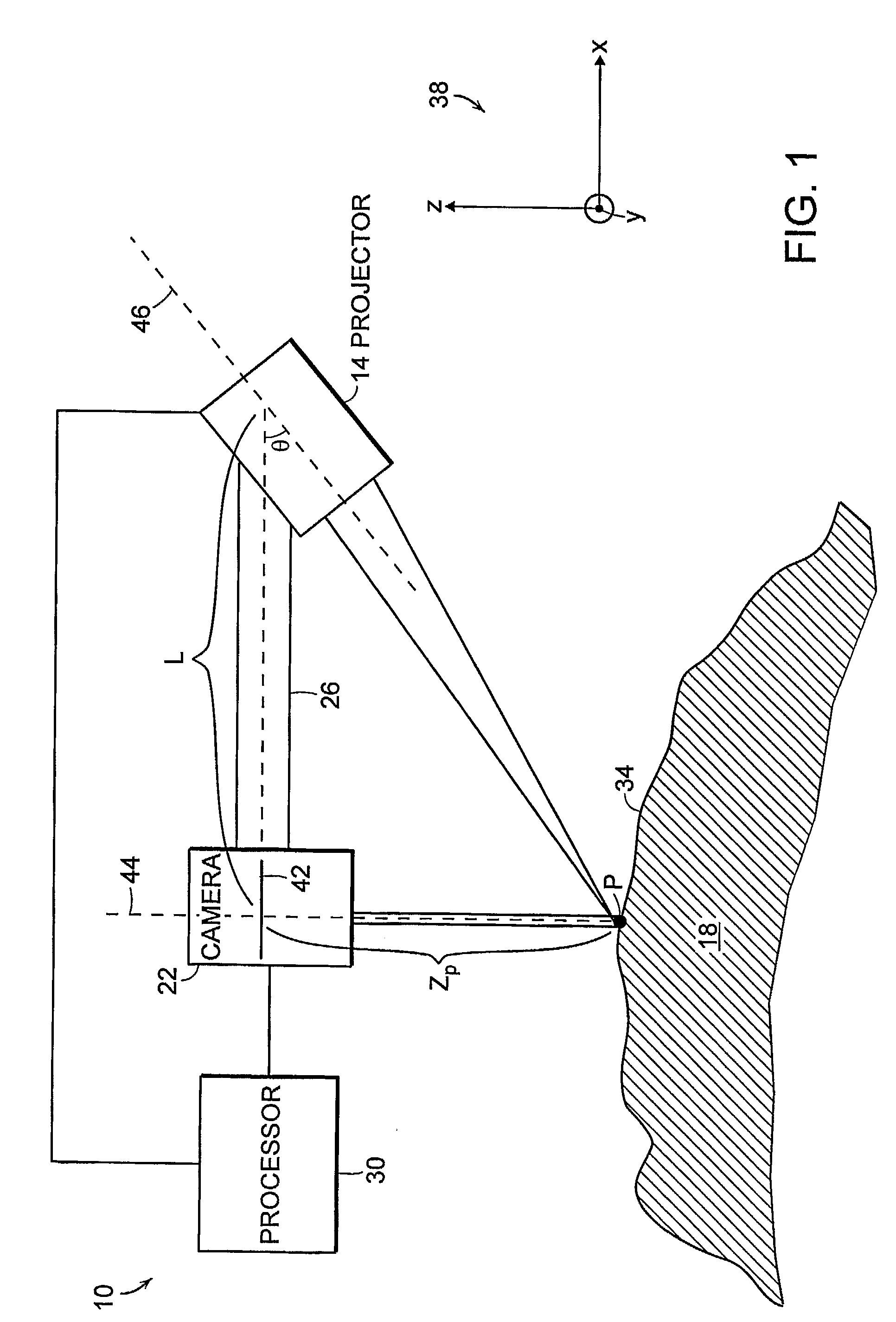

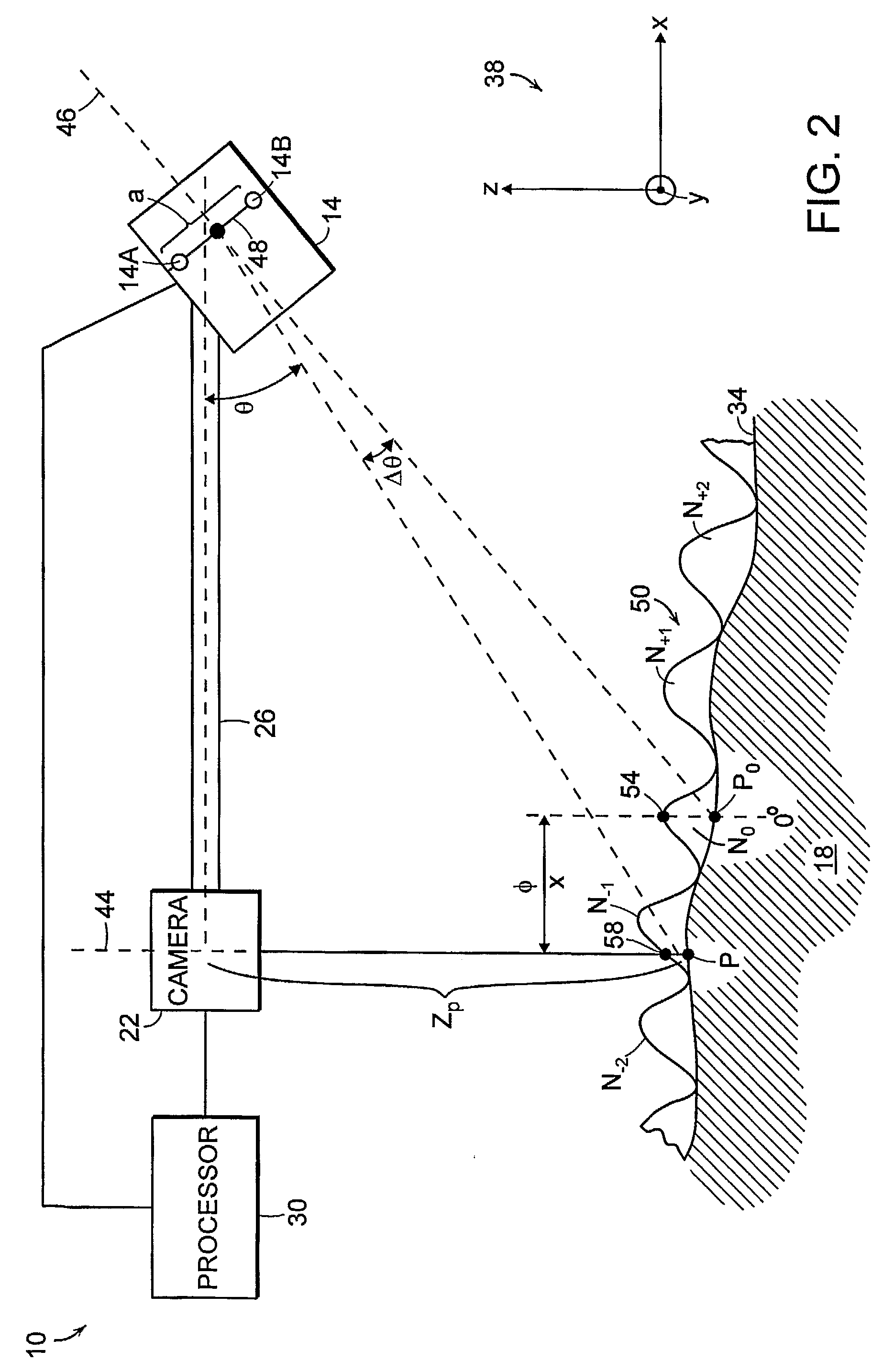

Apparatus and methods for surface contour measurement

InactiveUS20060012802A1Reduce impactReduce measurementUsing optical meansSpectral widthControl system

Apparatus and methods of measuring three-dimensional position information of a point on the surface of an object. The invention also relates to an apparatus for projecting fringes onto a surface of an object including two sources of radiation separated by a distance, each source having a spectral distribution, and being coherent with respect to the other of the sources, a control system moving each of the sources relative to the other of the sources, and a detector positioned to receive radiation scattered from the point on the surface of the object. In another embodiment, the two sources of radiation include, an initial source of a beam of radiation having a spectral width, a beam separator in optical communication with the initial source of a beam of radiation generating a first optical beam and a second optical beam, and an imaging system optically connected to the beam separator.

Owner:MASSACHUSETTS INST OF TECH

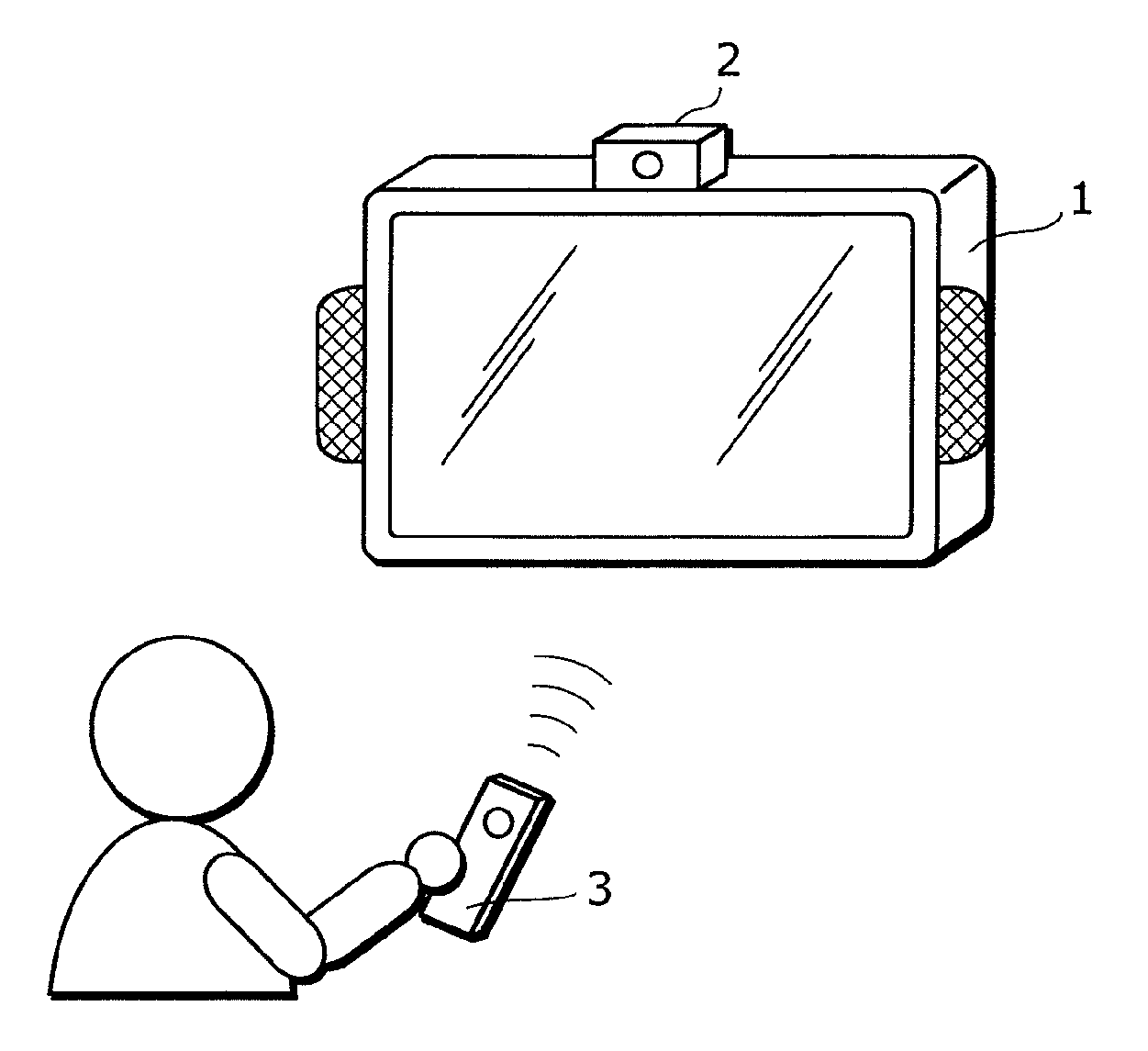

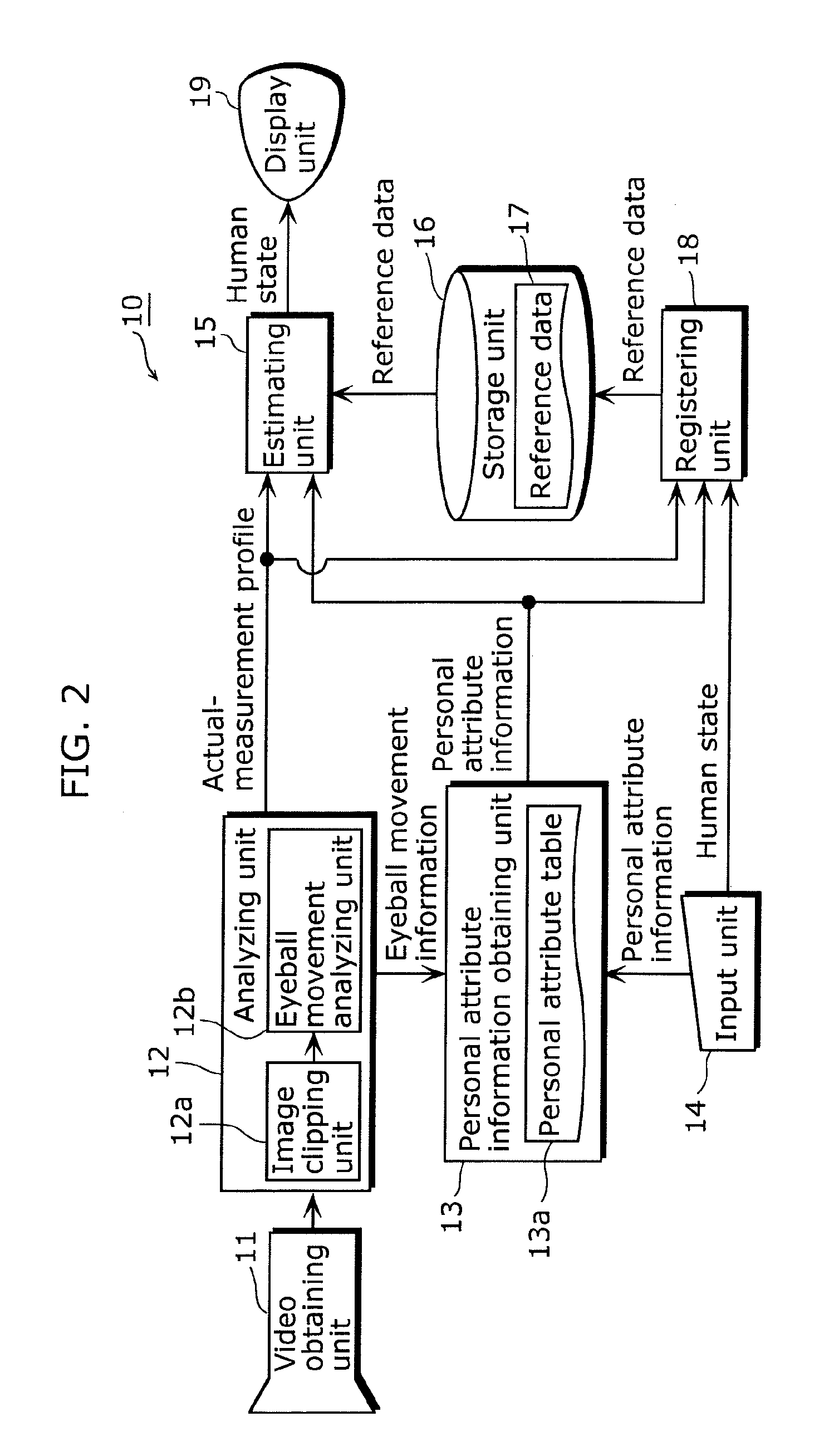

Human state estimating device and method

ActiveUS20100191156A1High precisionImprove State Estimation AccuracyPerson identificationEye diagnosticsComputer visionArtificial intelligence

To provide a human state estimating device which accurately estimates a human state. The human state estimating device includes: a storage unit (16) which stores reference data (17) in which a human state and a reference profile including a horizontal component of a standard microsaccade in the human state are corresponded to each other, for each of plural personal attribute information; a video obtaining unit (11) which obtains video of a user's eyeball, with an eyeball rotation angle accuracy of 0.05 degrees or higher, and a measuring speed of 120 samples per second or higher; an analyzing unit (12) which generates an actual-measurement profile including the horizontal component of the microsaccade, from fixational eye movement shown in the video; a personal attribute information obtaining unit (13) which obtains the user's personal attribute information; and an analyzing unit which estimates the human state by searching, in the reference data (17), for a reference profile that corresponds to the obtained personal attribute information and is closest to the actual-measurement profile.

Owner:PANASONIC CORP

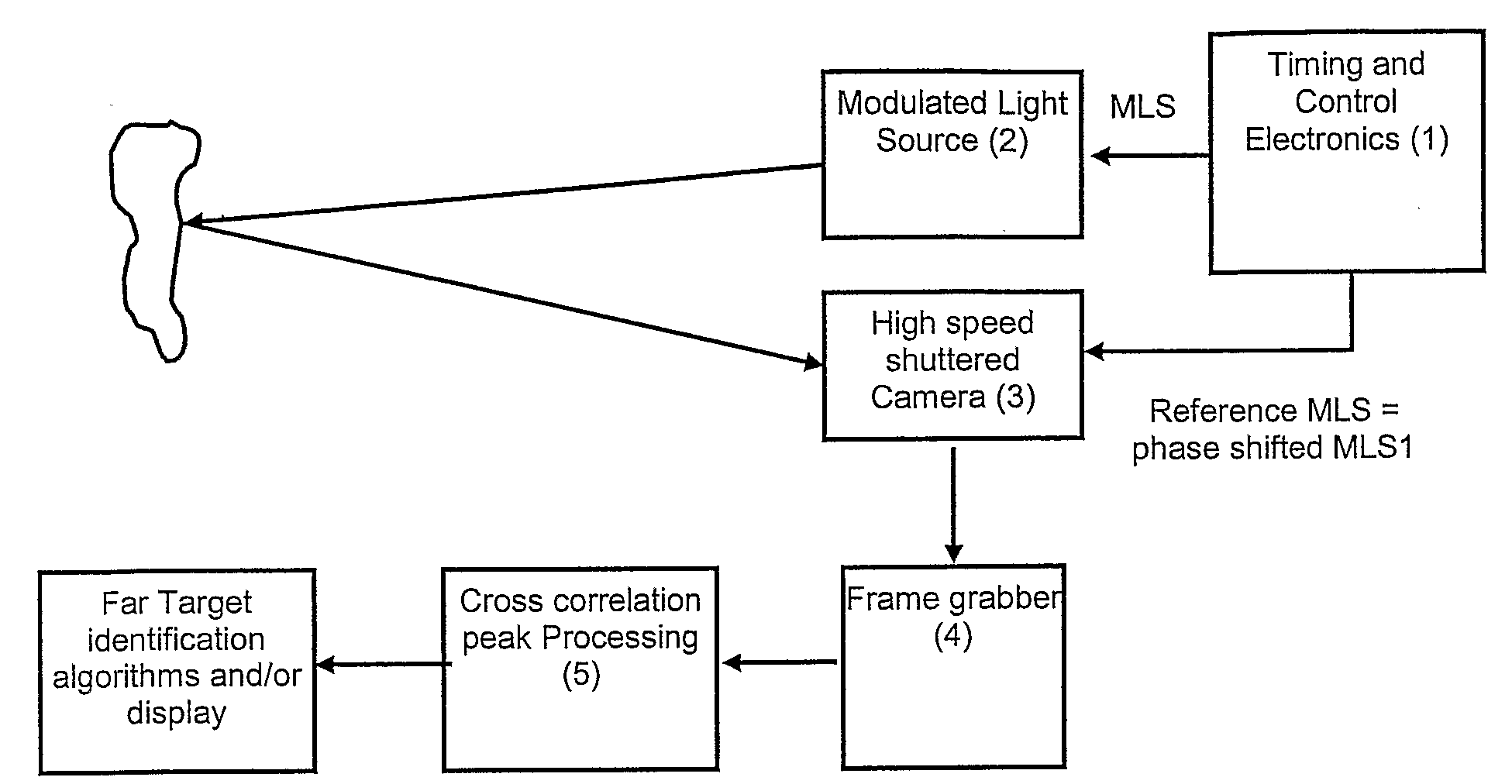

Surface profile measurement

InactiveUS20090091738A1No noiseOptical rangefindersElectromagnetic wave reradiationTime windowsImage system

An imaging system has a transmission system (2) for transmitting a modulated optical signal and a reception system (3) for receiving a received optical signal which is a reflected and delayed version of the transmitted signal. The reception system includes a controllable shutter arrangement for allowing reception in a controllable time window. A memory (4) collects reception data derived from different time windows, and a measure of distance is obtained corresponding to a maximum correlation between the received optical signal and the timing of the controllable time window. Surface profile information is derived from multiple distance measurements.The shutter arrangement enables the distance measurement (and the subsequent profile calculation) to be free from noise from other scattering sources.

Owner:INSTRO PREC

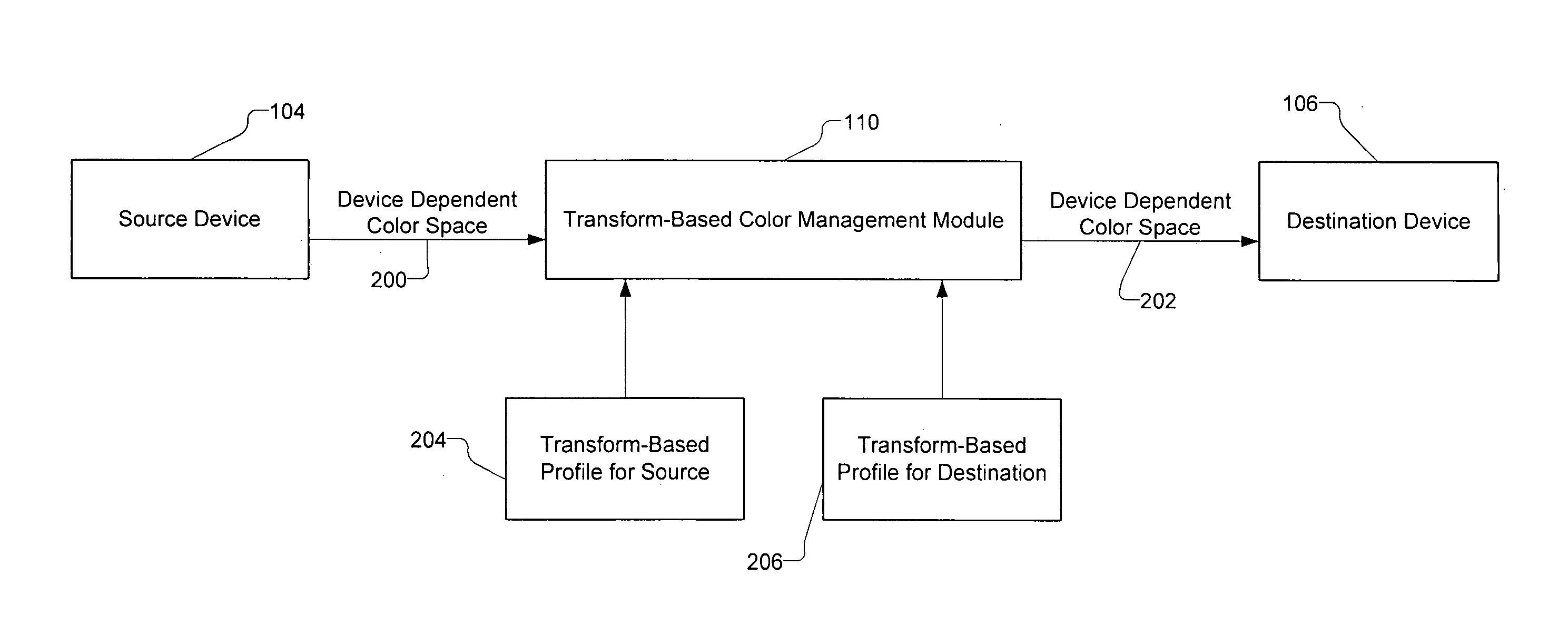

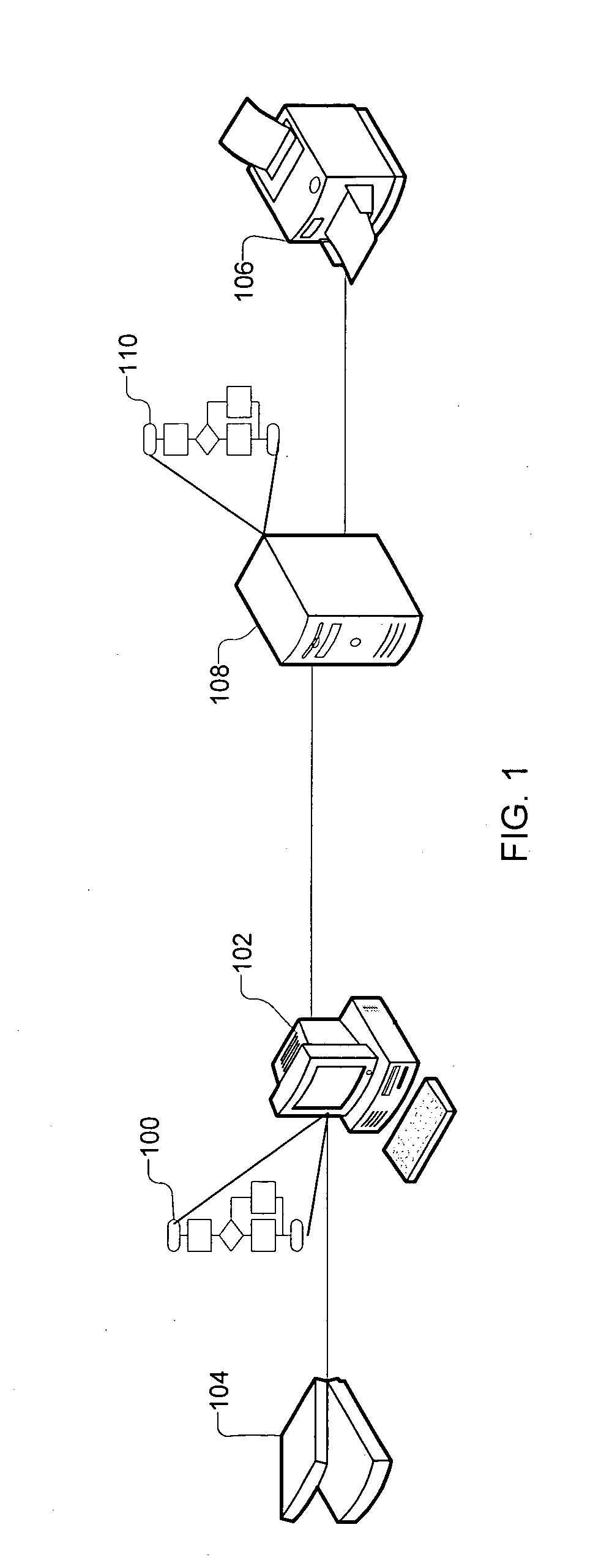

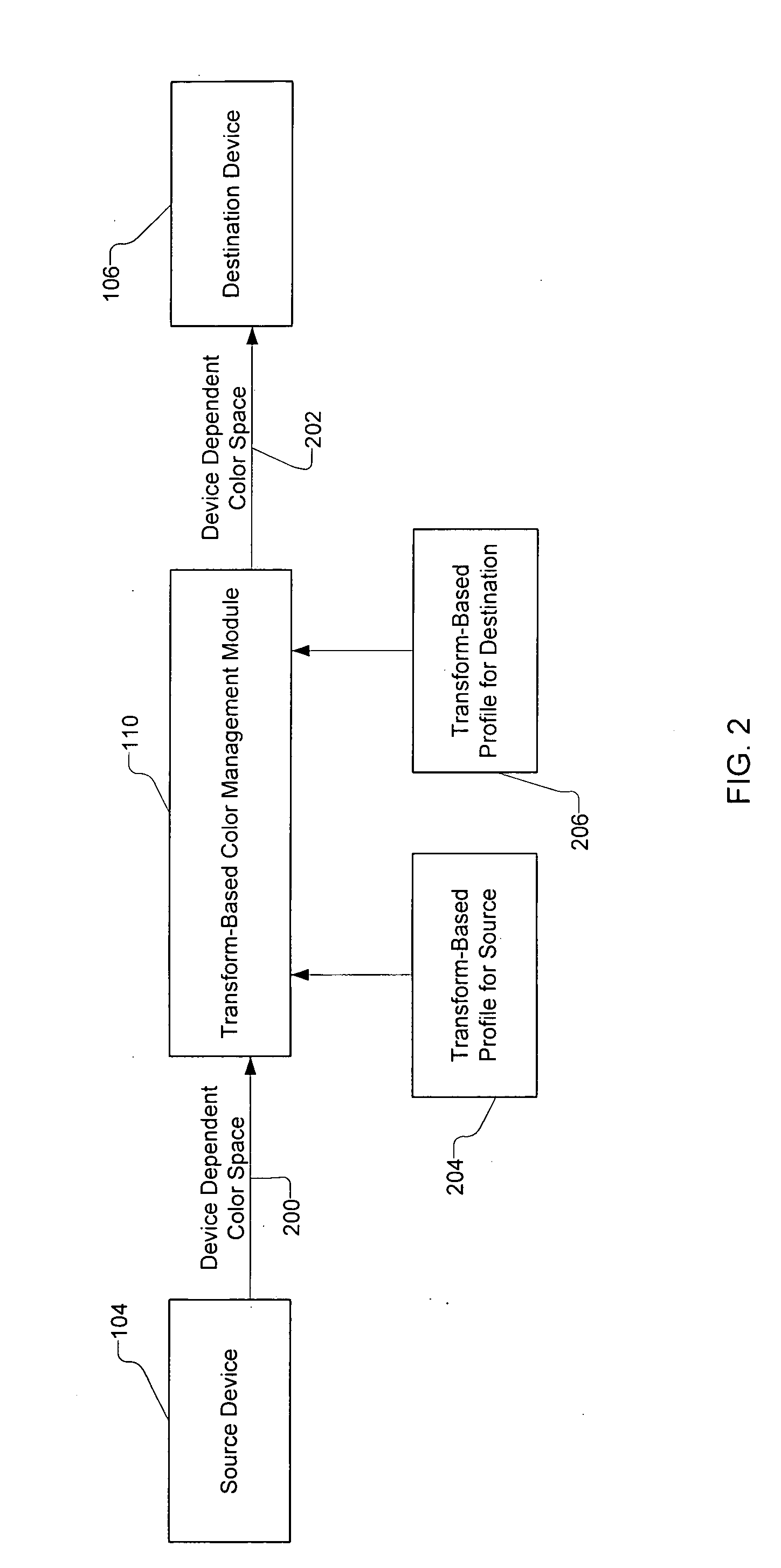

Creation of transform-based profiles by a measurement-based color management system

ActiveUS20060250623A1Digitally marking record carriersDigital computer detailsGeneration processGamut

A method and apparatus for generating transform-based color profiles by a measurement-based Color Management System (CMS). The measurement-based CMS generates the transform-based profile wherein the measurement-based color system is parameterized by color data and procedures. The CMS may use a reference Profile Connection Space (PCS) loaded from a measurement profile, thus enabling user configuration of the generation process. The reference PCS may also be set to include a gamut that is appropriate for an eventual color-output device. In addition, a Gamut Mapping Model (GMM) used in the generation process is user-selectable as well as a Device Model (DM). The DM may also be supplied as a pluggable module. The CMS also features user-selectable mapping from an International Color Consortium (ICC) intent to a PCS profile and to a DM. The features of the CMS may be used in an application, stand-alone profiling tool or in an operating system utility.

Owner:MICROSOFT TECH LICENSING LLC +1

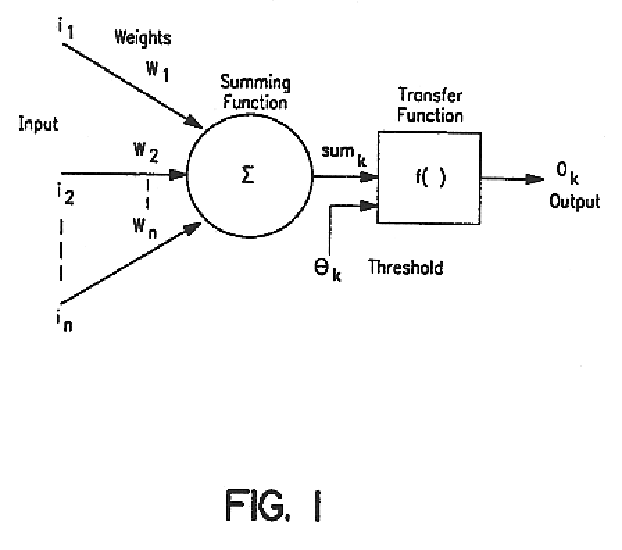

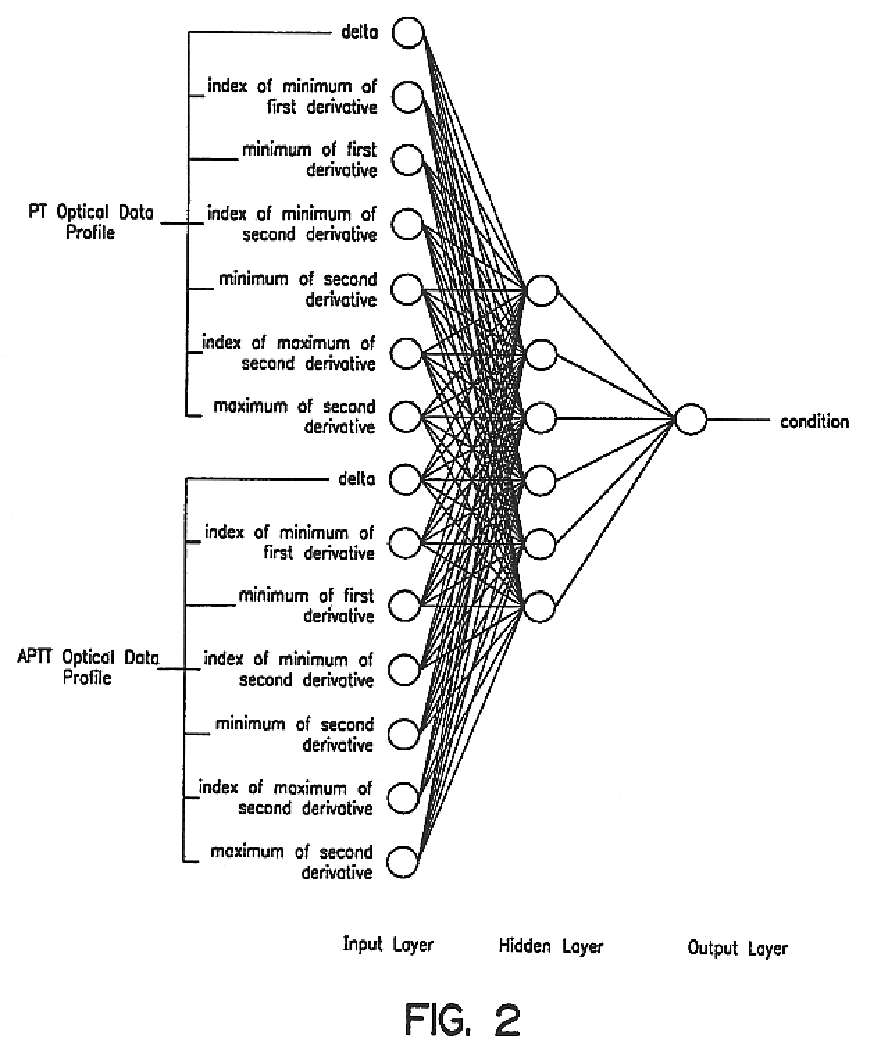

Method and apparatus for predicting the presence of haemostatic dysfunction in a patient sample

InactiveUS6898532B1Predict dysfunctionMedical simulationAnalogue computers for chemical processesFunctional disturbancePredictor variable

A method is disclosed for predicting the presence of haemostatic dysfunction. At least one time-dependent measurement on an unknown sample is performed and a respective property of the sample is measured over time so as to derive a time-dependent measurement profile. One or more predictor variables, including initial slope, are defined which sufficiently define the data of the time-dependent measurement profile. A model is then derived that represents the relationship between the abnormality and the set of predictor variables. Subsequently, the model is utilized to predict haemostatic dysfunction, such as septicemia or disseminated intravascular coagulation (DIC).

Owner:BIOMERIEUX INC

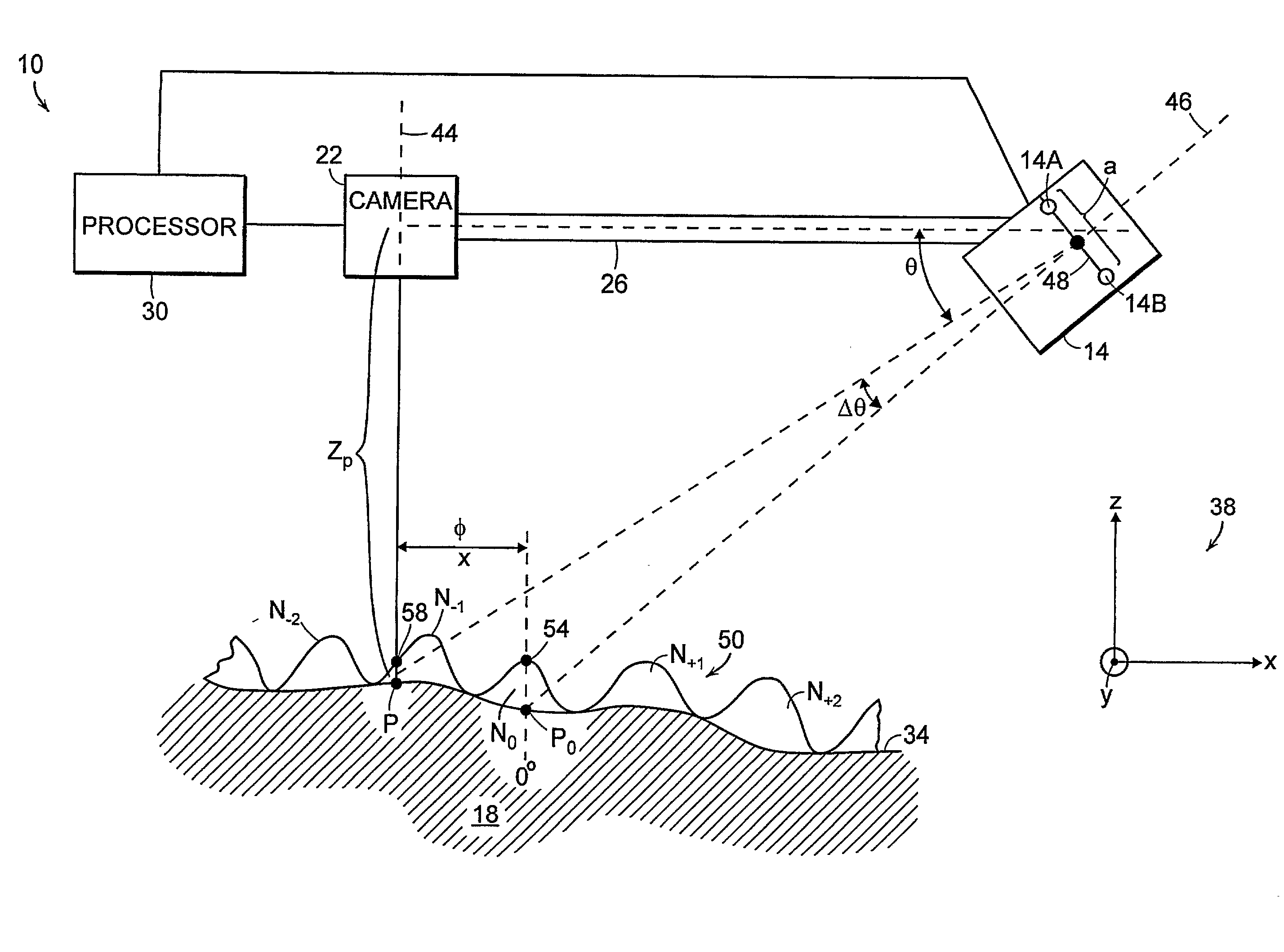

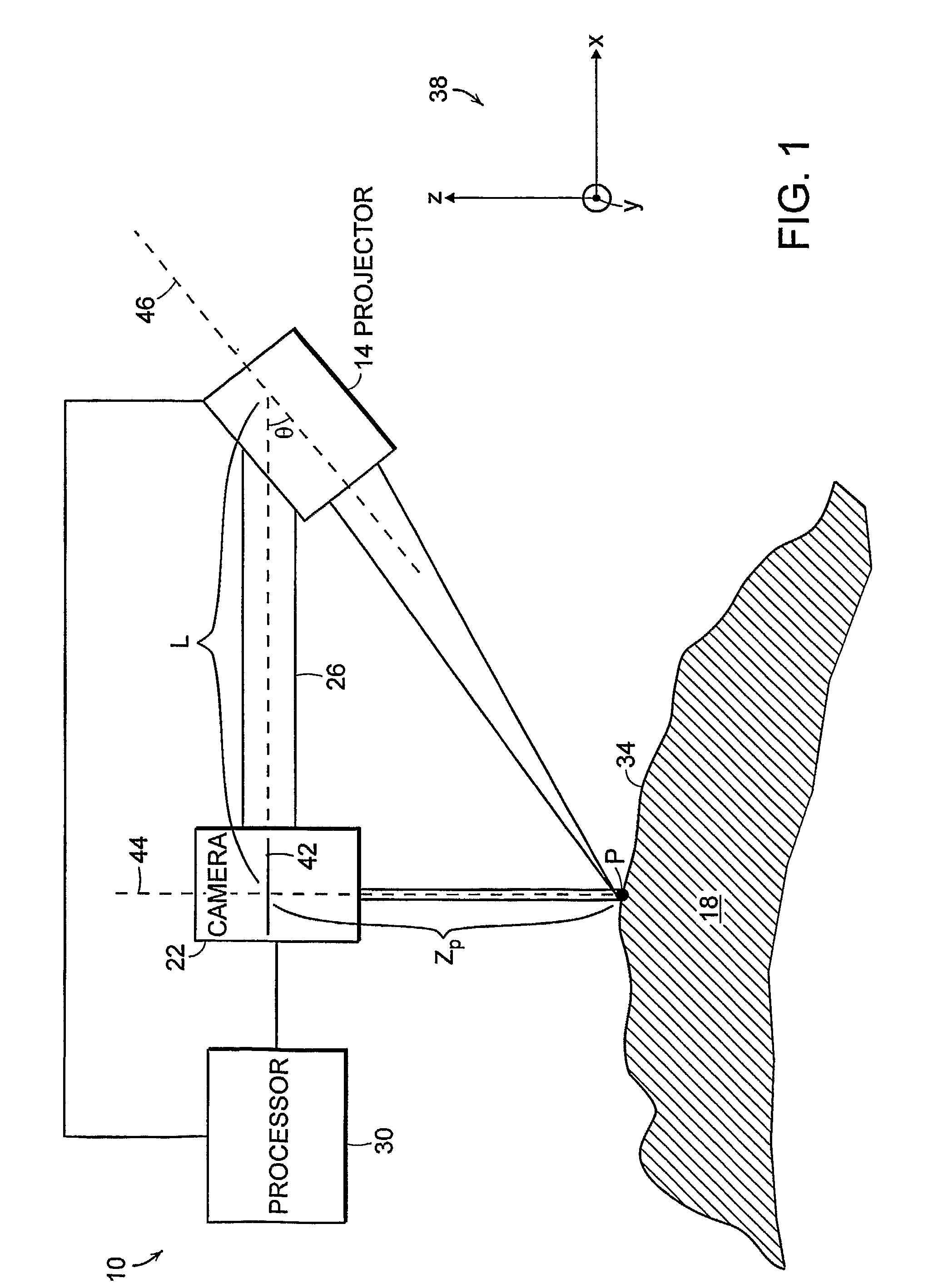

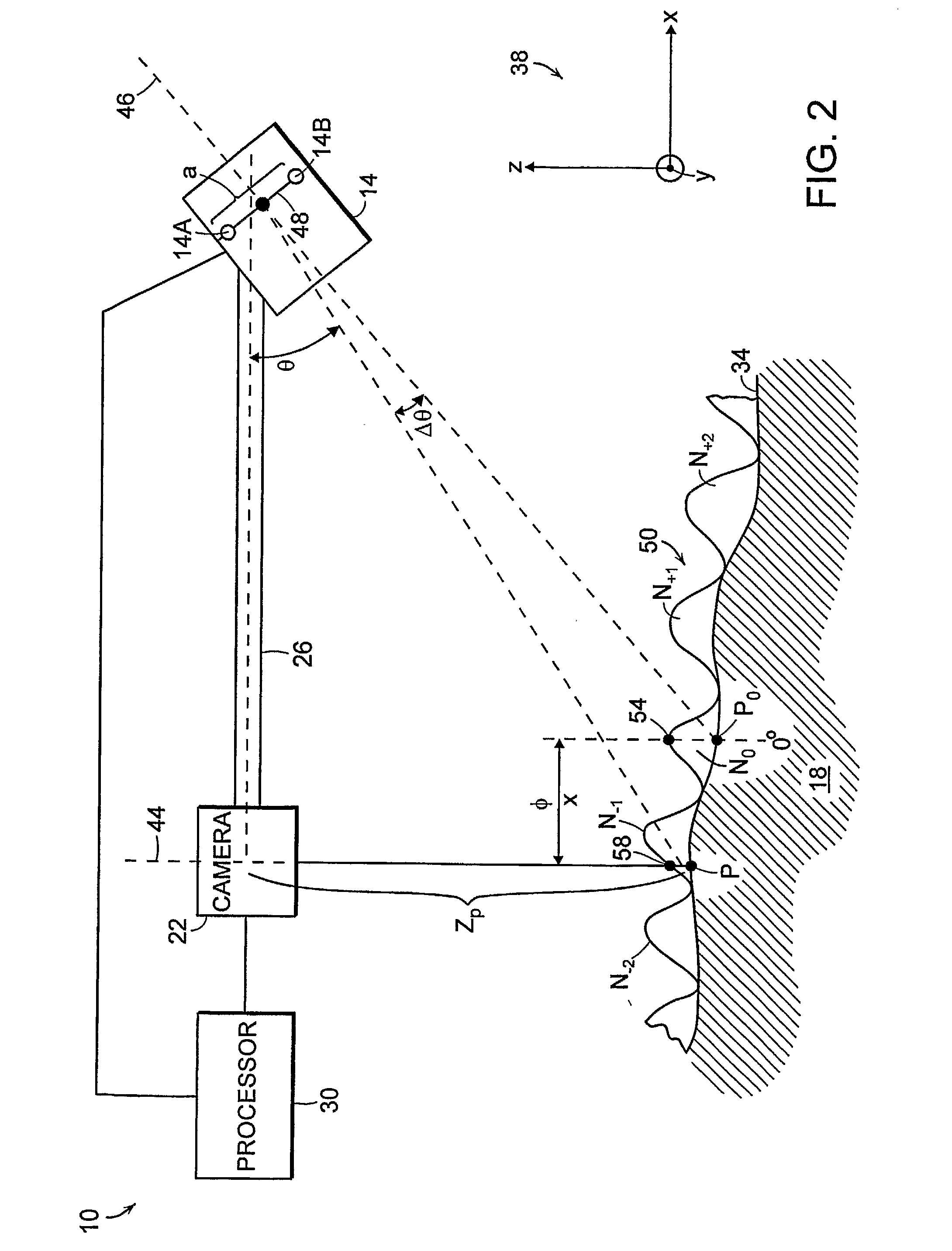

Determining Positional Error of an Optical Component Using Structured Light Patterns

Described is an interferometric surface contour measurement system for projecting structured light patterns onto an object. The measurement system includes an interferometric projector, an imager, and a processor. The imager is rigidly coupled to the projector to maintain a stable relationship to the projected, structured light pattern. The imager receives the structured light pattern and together with the processor, determines whether the projected image includes a positional error. In some embodiments, the projector is a multi-channel projector, each channel having an optical axis spatially separated from the others, one of the channels including the imager and dedicated for determining positional error. In other embodiments, the projector is a single-channel projector projecting a structured light pattern onto the object, a portion of the structured light pattern being tapped-off for determining positional error.

Owner:DIMENSIONAL PHOTONICS INT

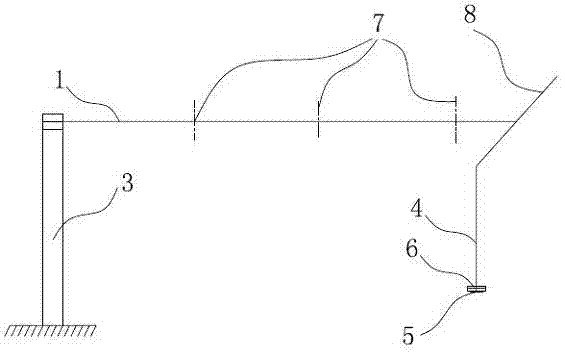

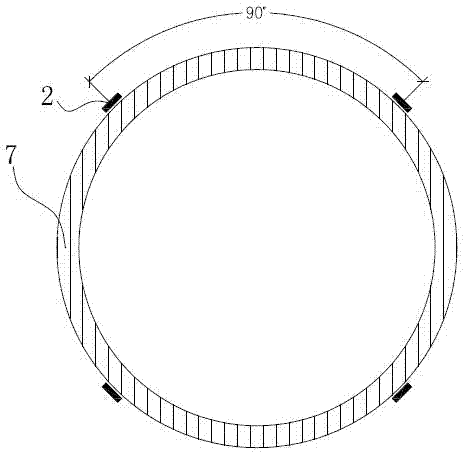

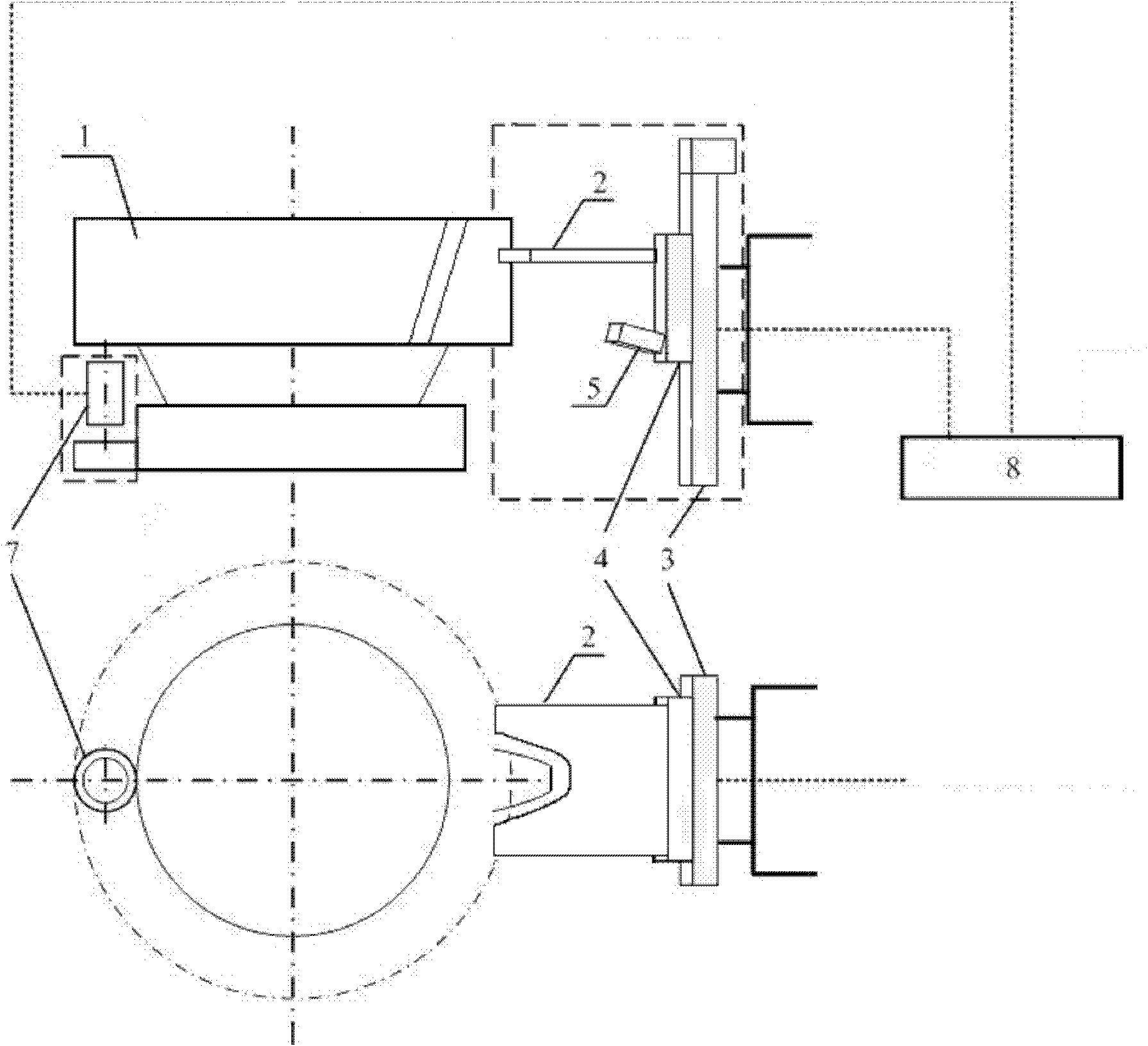

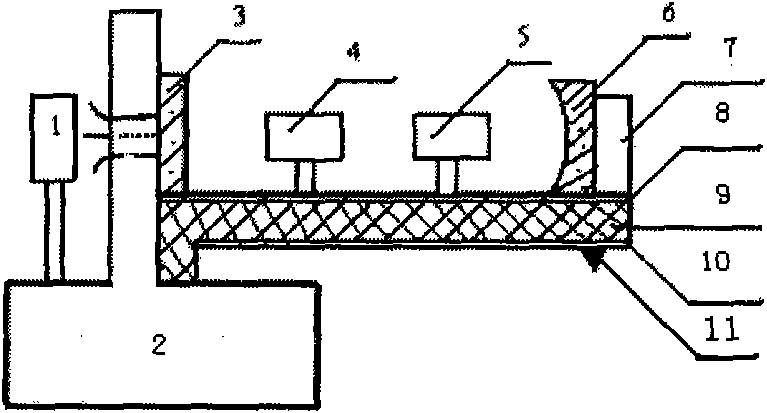

Torsion calibration device and method for measurement beam used for ship model wave load test

InactiveCN103033314ASimple structureEasy to operateForce/torque/work measurement apparatus calibration/testingMeasurement ProfilesPhysics

The invention provides a torsion calibration device for a measurement beam used for a ship model wave load test. The torsion calibration device for the measurement beam used for the ship model wave load test comprises a measurement beam. A beam surface of a measurement profile of the measurement beam is provided with a foil gage. One end of the measurement beam is fixed on a support, and the other end of the measurement beam is fixedly connected with a rod piece. The rod piece is vertical to the axis of the measurement beam. A tray is hung on one end of the rod piece through steel wire ropes, and weights can be placed on the tray. The distance between one end of the rod piece and a hanging end is equal to the distance between the other end of the rod piece and the hanging end. The torsion calibration device for the measurement beam used for the ship model wave load test provides a torsion calibration method for a measurement beam used for a ship model wave load test. According to the torsion calibration method for the measurement beam used for the ship model wave load test, by independently conducting gradation loading and weight unloading on two ends of the rod piece, the strain of each measurement profile is collected, fitting coefficients of the weight acting force and the strain are obtained, and a coefficient factor of the strain of each measurement profile of the measurement beam and a torsion in the wave load which is actually suffered by each measurement profile of the ship model is counted. The coefficient factor between the strain of each measurement profile of the measurement beam and a torsion in the sea load which is actually suffered by each measurement profile of the ship model can be demarcated through the torsion calibration device and the method for the measurement beam used for the ship model wave load test.

Owner:CHINA SHIPBUILDING INDUSTRY CORPORATION

Surface profile measuring instrument and surface profile measuring method

ActiveUS7100429B2Accurate measurementMechanical counters/curvatures measurementsElectric/magnetic contours/curvatures measurementsMeasuring instrumentAcoustics

Owner:MITUTOYO CORP

Device and method for measuring the profile of a surface

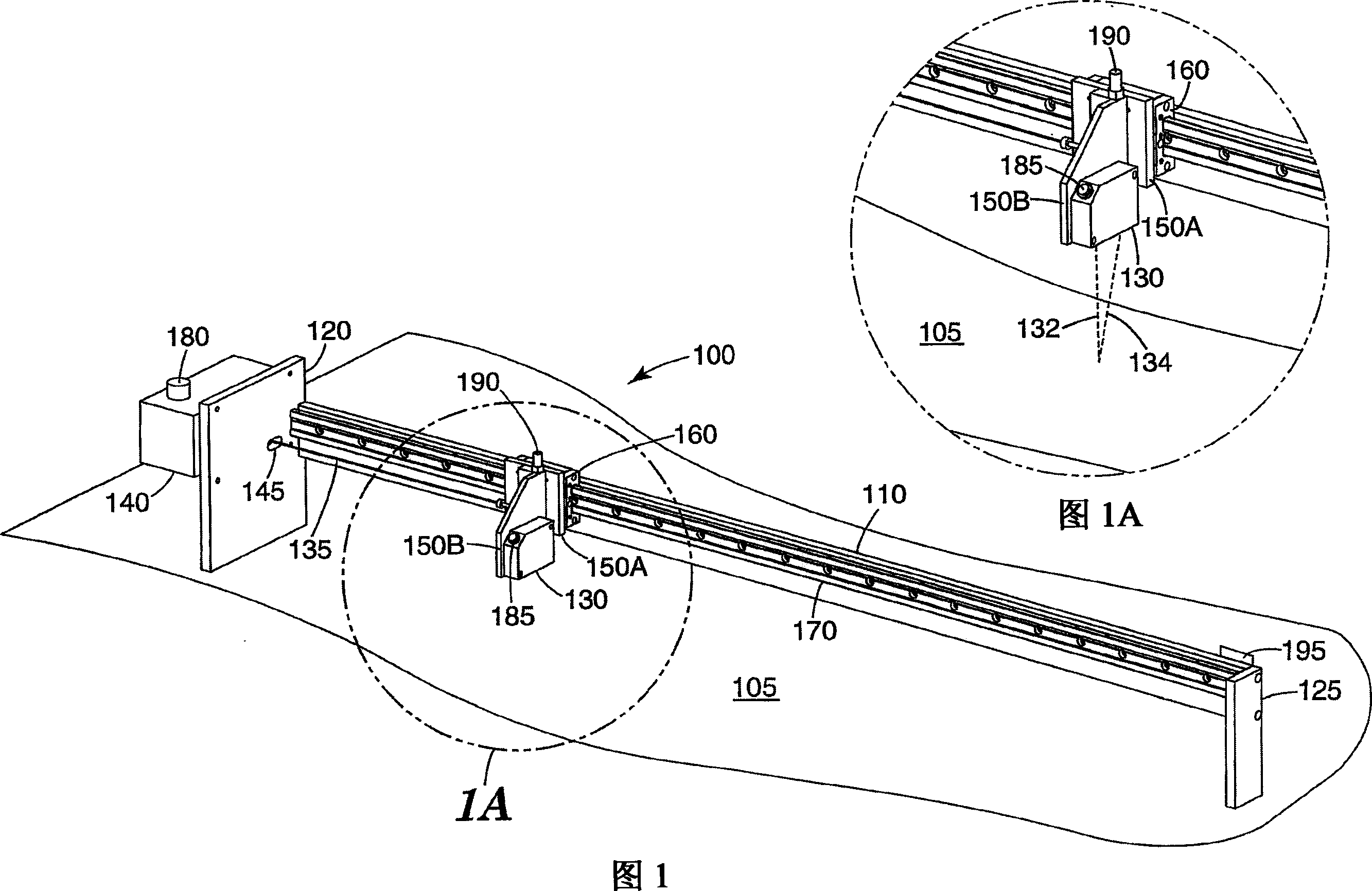

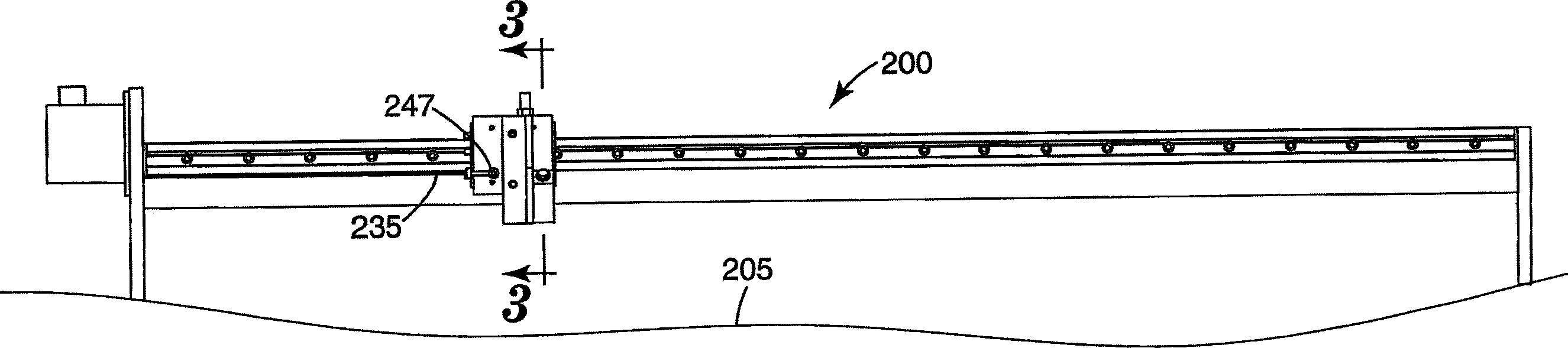

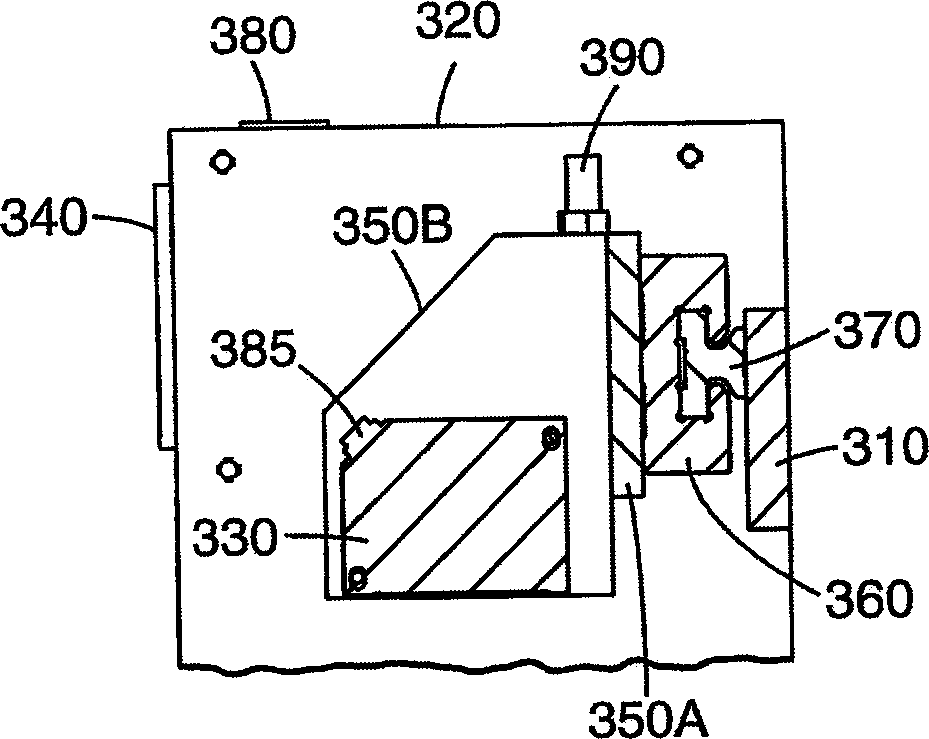

The invention provides a surface profile measurement device for use on rigid or semi-rigid substrates, such as floors. The device includes (a) a beam; (b) at least one beam support mounted on the beam; (c) a sensor assembly slidably connected to said beam and adapted for measuring the distance to the surface; and (d) a transducer assembly adapted for measuring the position of said sensor assembly along said beam.

Owner:3M INNOVATIVE PROPERTIES CO

Device and method for bending moment calibration of measurement beam for ship model wave load test

InactiveCN103018006ASimple structureEasy to operateHydrodynamic testingClassical mechanicsCoefficient of relationship

The invention belongs to the technical field of ship model wave load test and relates to a device and a method for bending moment calibration of a measurement beam for ship model wave load test. The device for bending moment calibration of the measurement beam for ship model wave load test comprises the measurement beam, strain gauges are arranged on the beam surface at positions of measurement profiles of the measurement beam, one end of the measurement beam is fixed on the support, a tray is hung at the other end of the measurement beam via a steel wire rope, and weights can be placed on the tray. The method for bending moment calibration of the measurement beam for ship model wave load test includes: by the aid of a mode of stepwise loading and then stepwise unloading of the weights, collecting strain of each measurement profile, computing fitting coefficient of acting force of the weights and the strain, and computing coefficient of relationship between the strain of each measurement profile of the measurement beam and bending moment in actually born wave load of each measurement profile of a ship model by the aid of the fitting coefficient and space between each measurement profile and the hanging end. The device and the method are capable of calibrating the coefficient of relationship between the strain of each measurement profile of the measurement beam and the bending moment in the actually born wave load of each measurement profile of the ship model.

Owner:中国船舶重工集团公司第七〇二研究所

Fast performance prediction of multivariable model predictive controller for paper machine cross-directional processes

ActiveUS20070239310A1Efficient solutionMinimize the differenceElectric/magnetic detection for well-loggingDigital differential analysersPredictive controllerEngineering

A technique for fast performance prediction of multivariable model predictive controllers (MPC) for large-scale spatially-distributed dynamic systems is provided. When operating an MPC for a two-dimensional sheetmaking process, the controller's performance can be separated into spatial performance and dynamic performance. The steady-state spatial performance for different sheet property modes is first predicted, thereafter, the dynamic performance is predicted on the basis of the steady-state actuator profiles. During the steady-state spatial performance prediction, the original MPC's cost function is approximated to be a steady-state cost function. Then the steady-state measurement profiles and the actuator profiles are calculated through the steady-state cost function. The actuator profiles in time series can be efficiently solved by minimizing the difference between the actuator profiles and the steady-state actuator profiles in the face of constraints. Finally, the model can be employed to expeditiously compute the measurement profiles in times series.

Owner:HONEYWELL ASCA INC

Biaxially oriented polyproplyene film

ActiveUS20080102247A1Excellently balanced high withstand voltageReduce film thicknessSynthetic resin layered productsInsulatorsPolymer sciencePolypropylene

The present invention relates to a biaxially oriented polypropylene film containing: a polypropylene resin as a main component thereof, having a weight average molecular weight of 100,000 or more and 500,000 or less, the weight average molecular weight being determined by gel permeation chromatography, wherein at least one surface of the biaxially oriented polypropylene film has a protrusion volume of 2.0×104 μm3 or more and 3.0×104 μm3 or less, the protrusion volume being determined in an area of 560 μm×745 μm using a super-depth surface profile measurement microscope by determining an average plane of the surface based on distances between plural points on the surface and an irradiation source of the super-depth surface profile measurement microscope and measuring a volume of protrusions projecting from the average plane.

Owner:OJI PAPER CO LTD

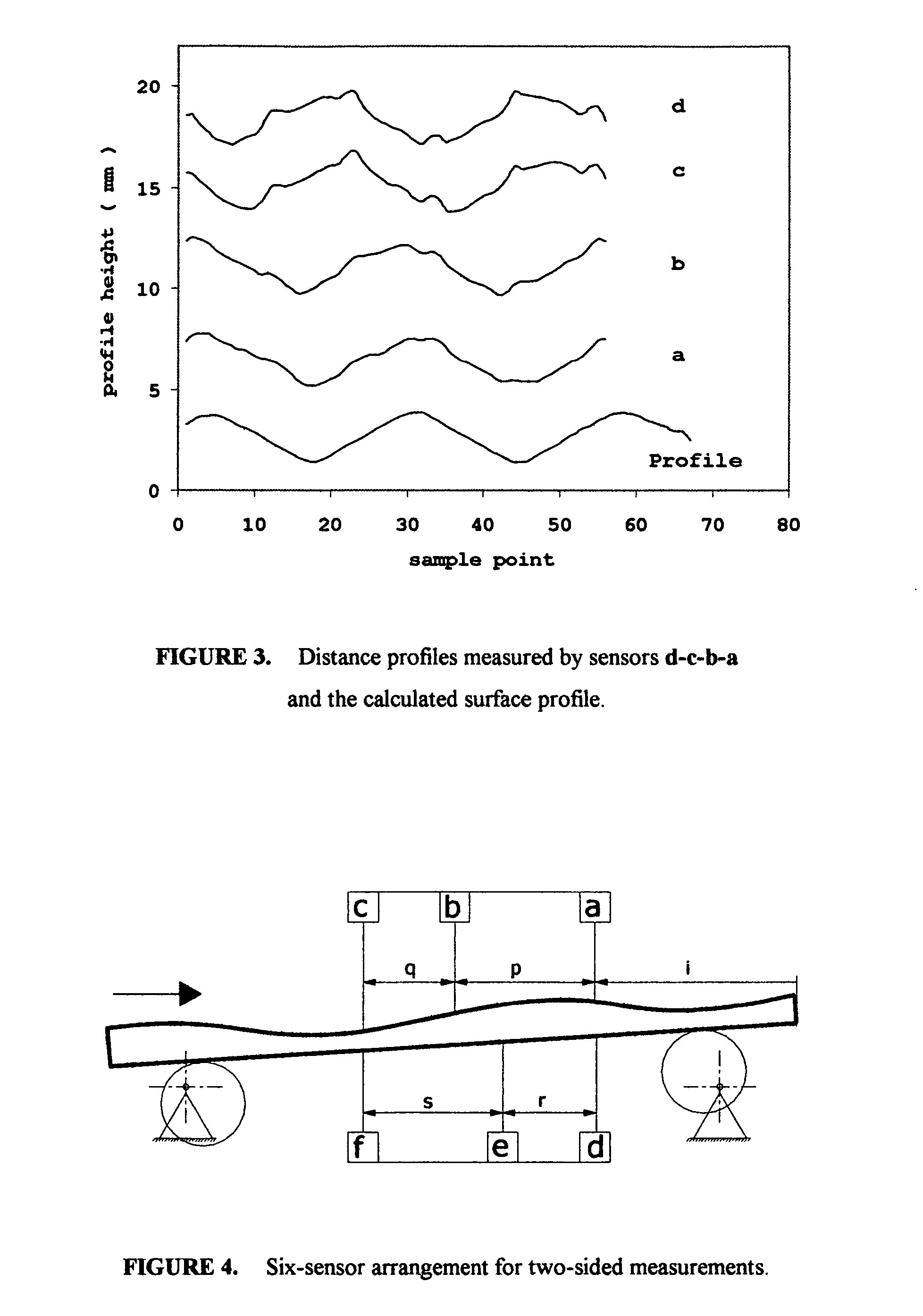

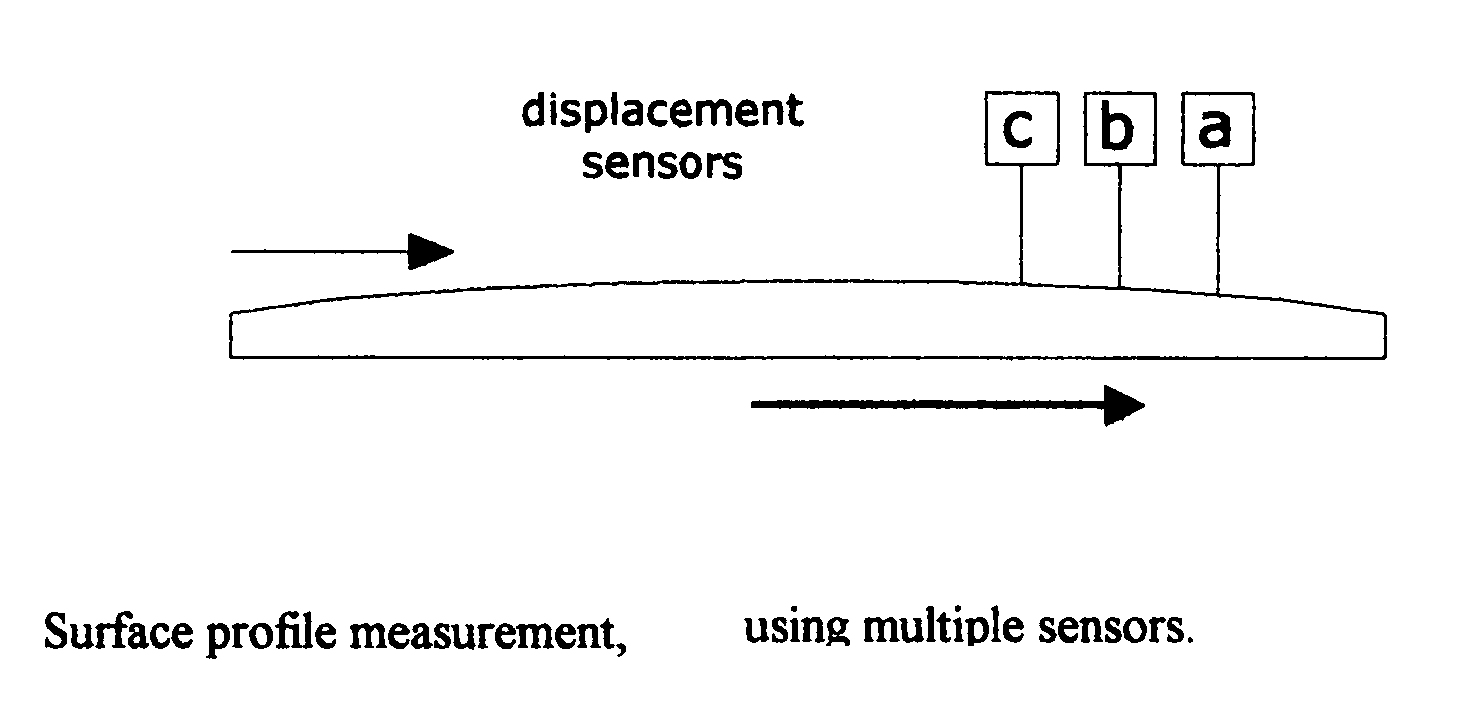

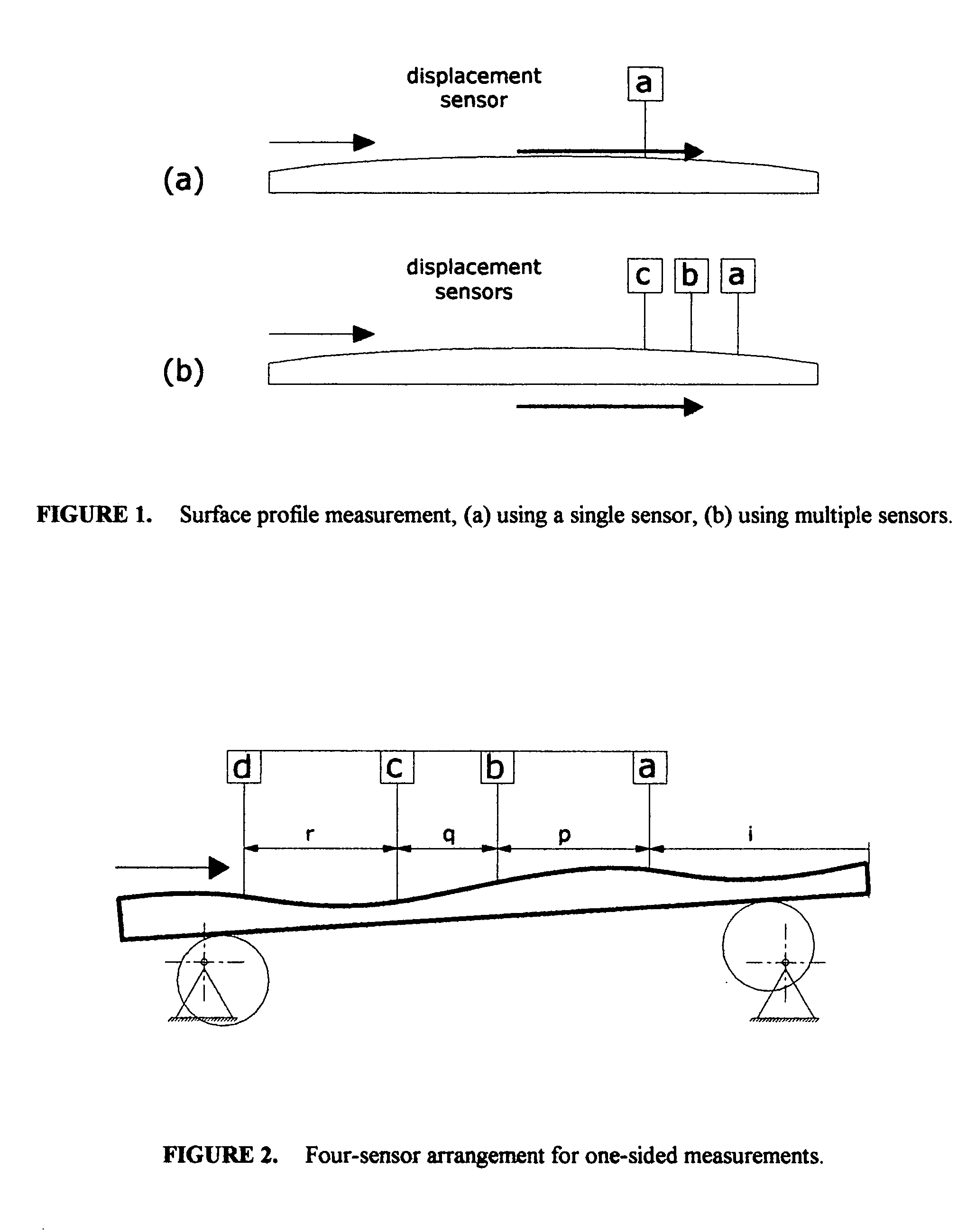

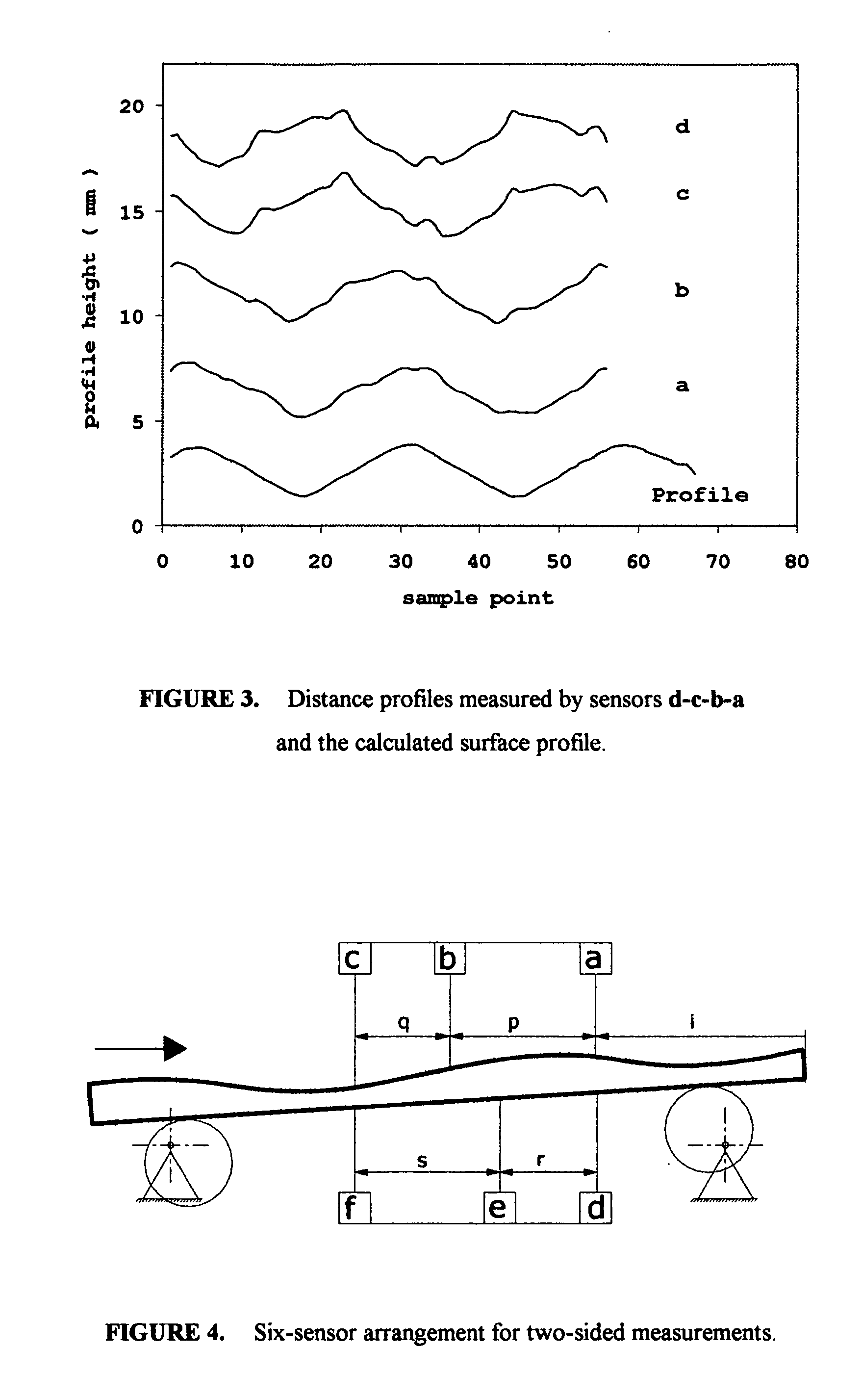

Surface profile measurement, independent of relative motions

ActiveUS7003894B2Simple methodEasy to adaptMechanical counters/curvatures measurementsWind musical instrumentsSensor arraySurface level

Owner:FPINNOVATIONS INC

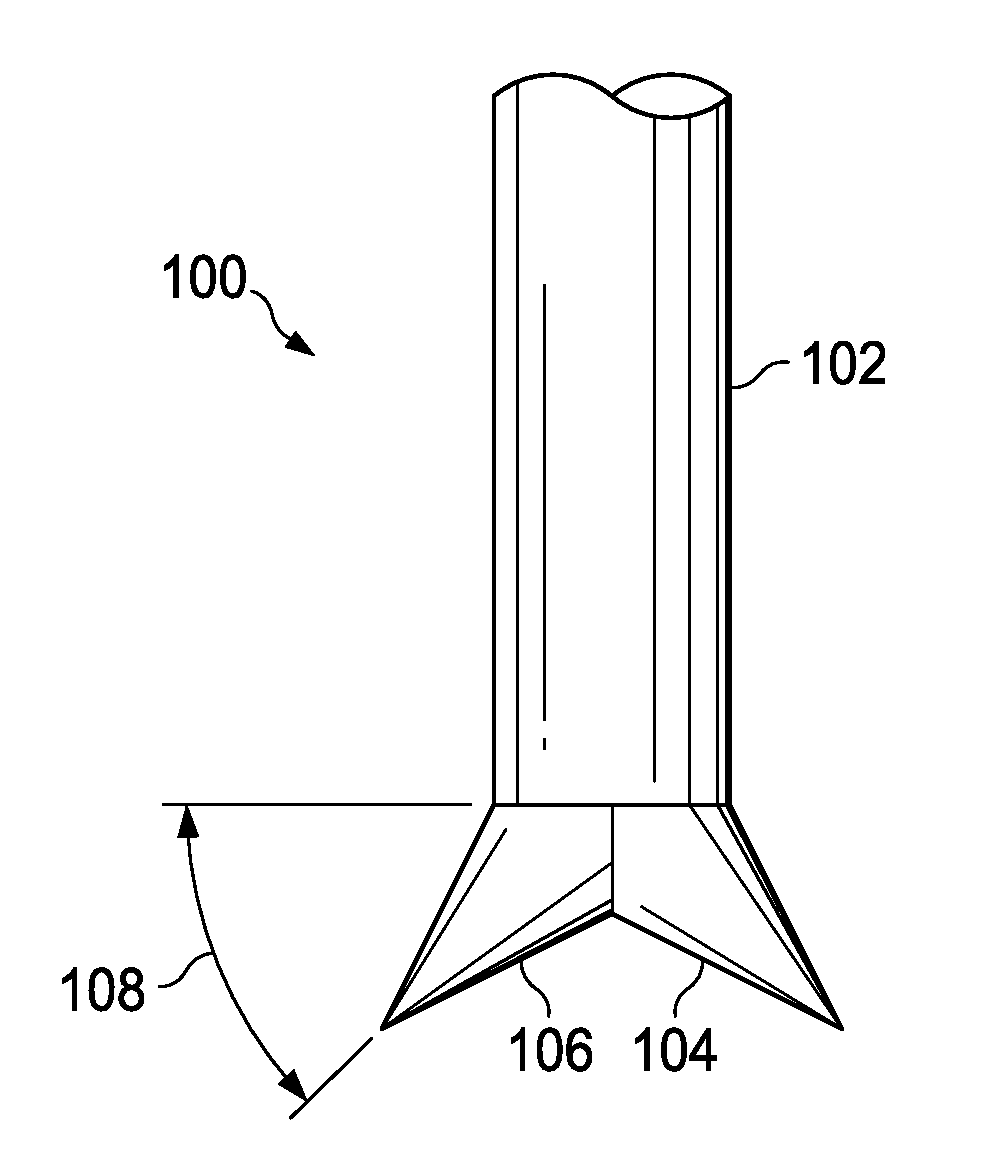

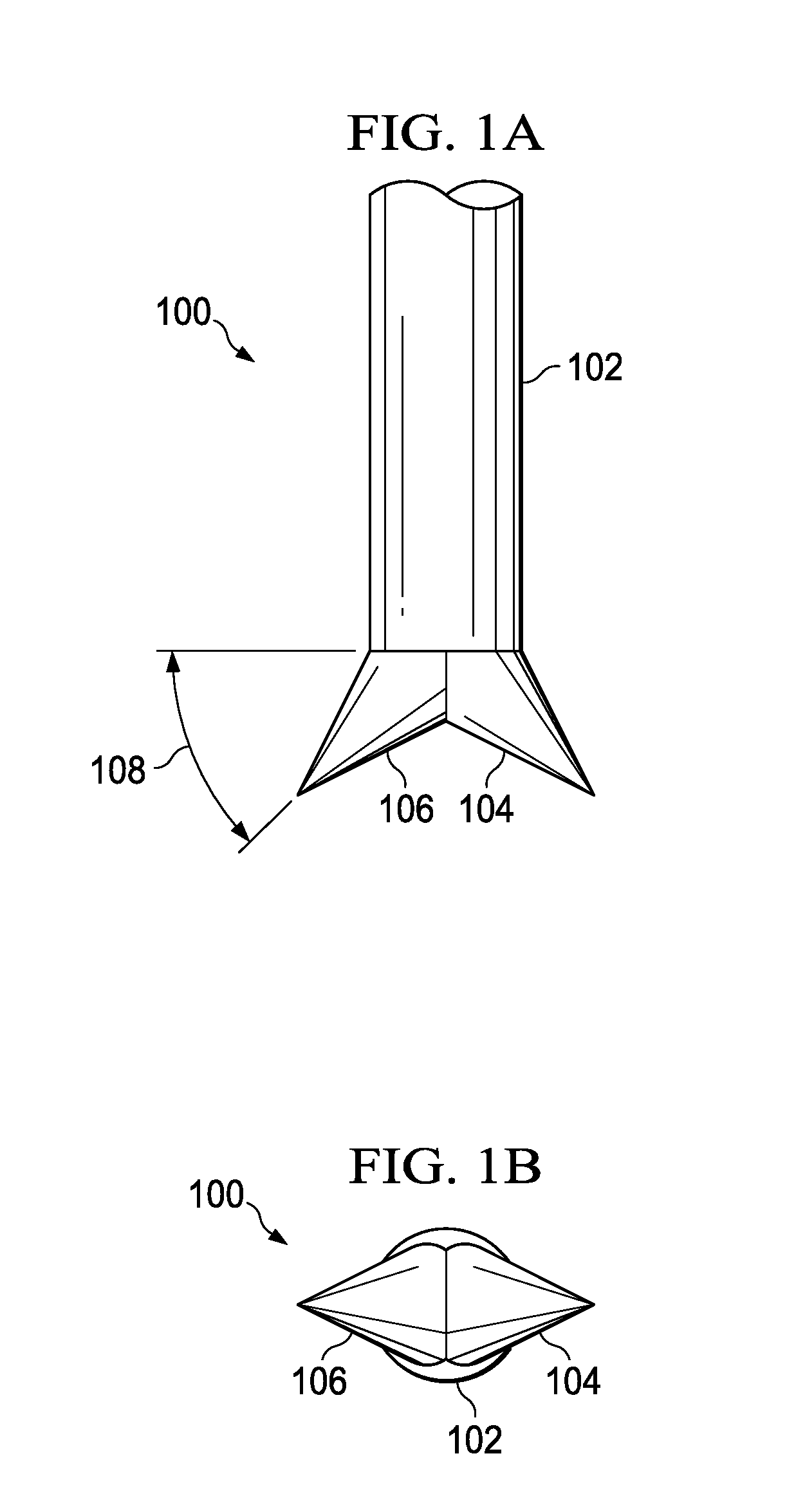

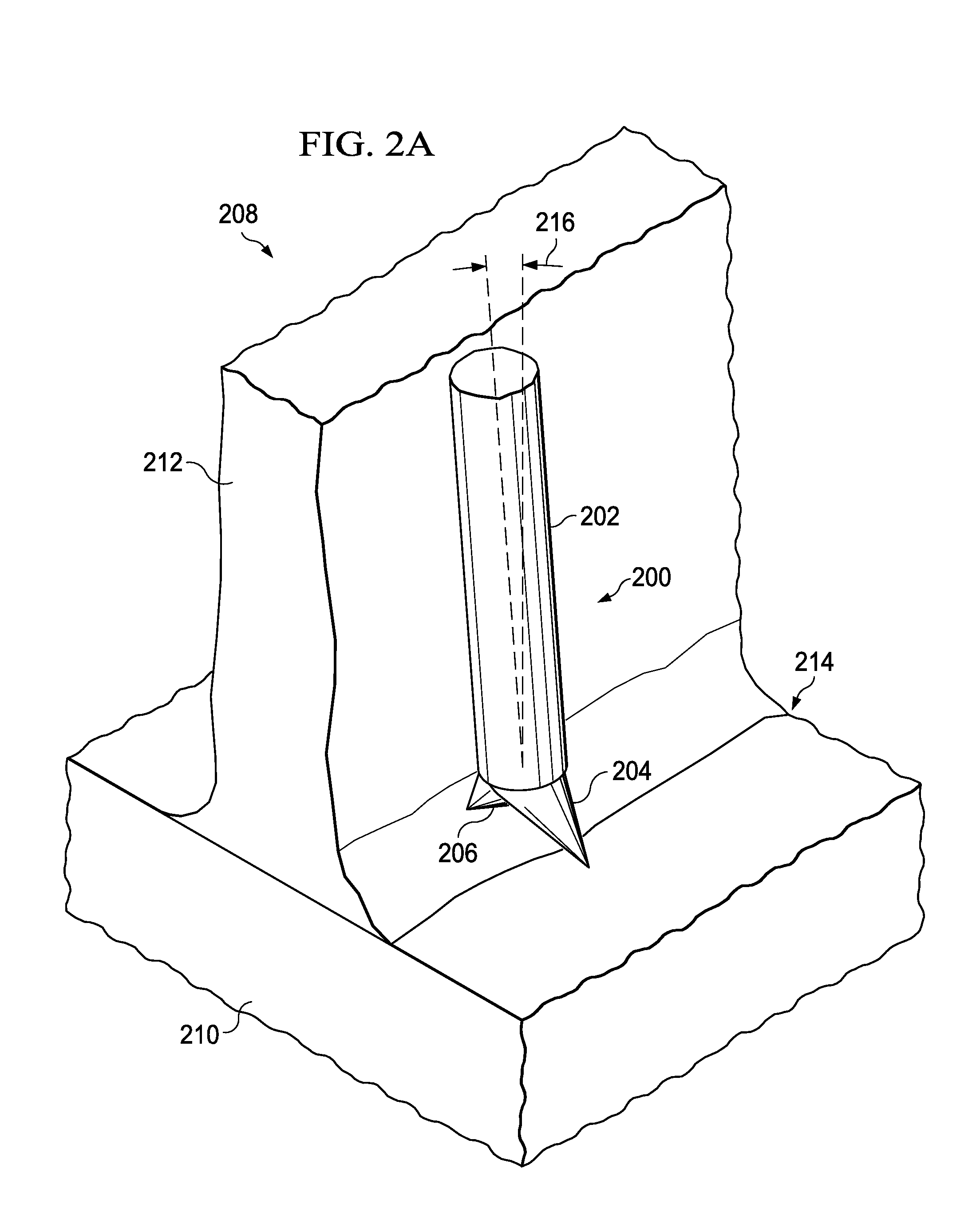

Rocking y-shaped probe for critical dimension atomic force microscopy

ActiveUS20090100917A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAtomic force microscopyCritical dimension

Measuring surface profiles of structures on integrated circuits is difficult when feature sizes are less than 100 nanometers. Atomic force microscopy provides surface profile measurement capability on flat horizontal surfaces, but has difficulty with three-dimensional structures such as MOS transistor gates, contact and via holes, interconnect trenches and photoresist patterns. An atomic force microscopy probe with two atomically sharp tips configured to facilitate measurements of three-dimensional structures is disclosed. A method of making such measurements using the disclosed probe and a method of fabricating an IC encompassing the method are also claimed.

Owner:TEXAS INSTR INC

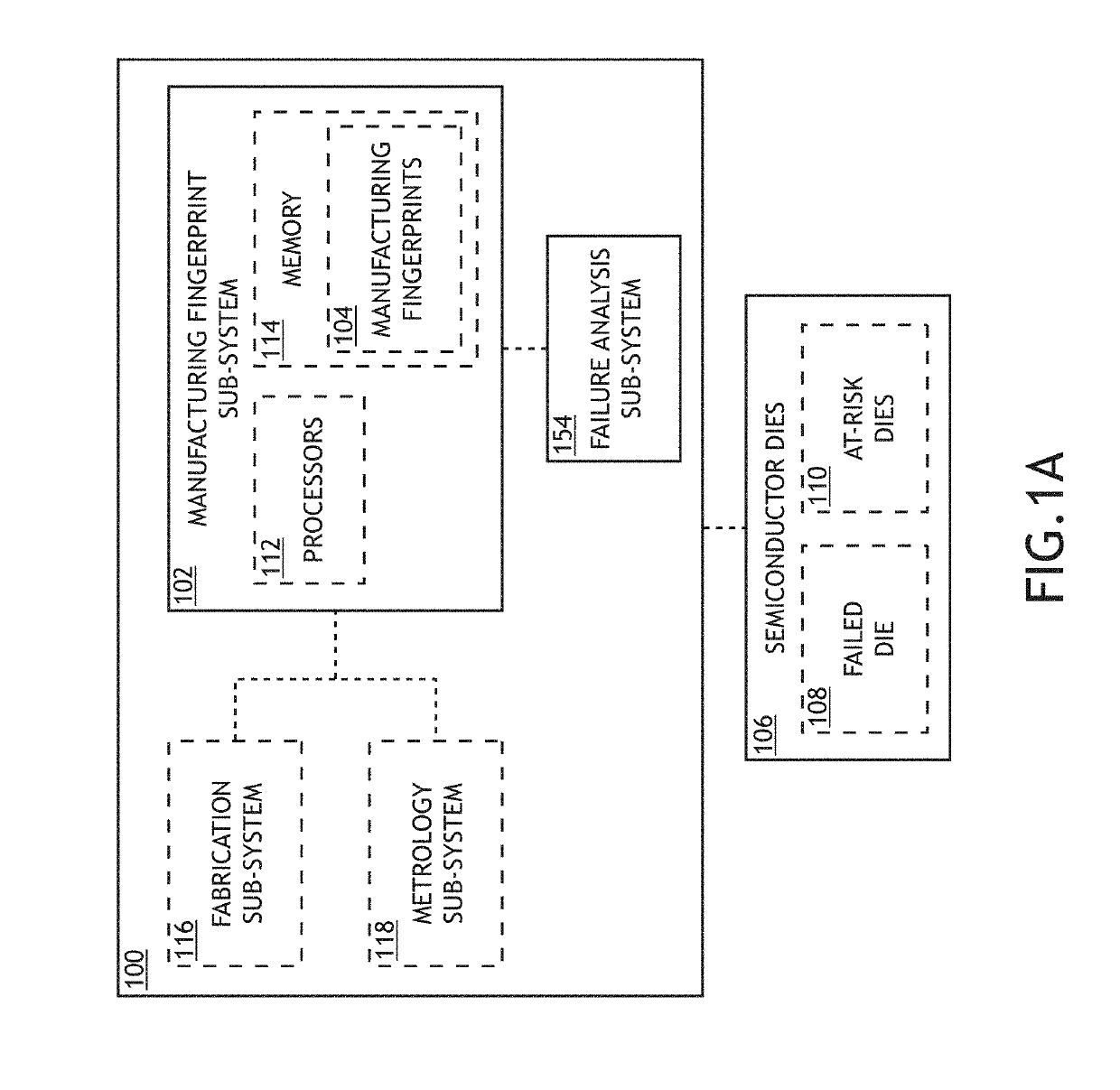

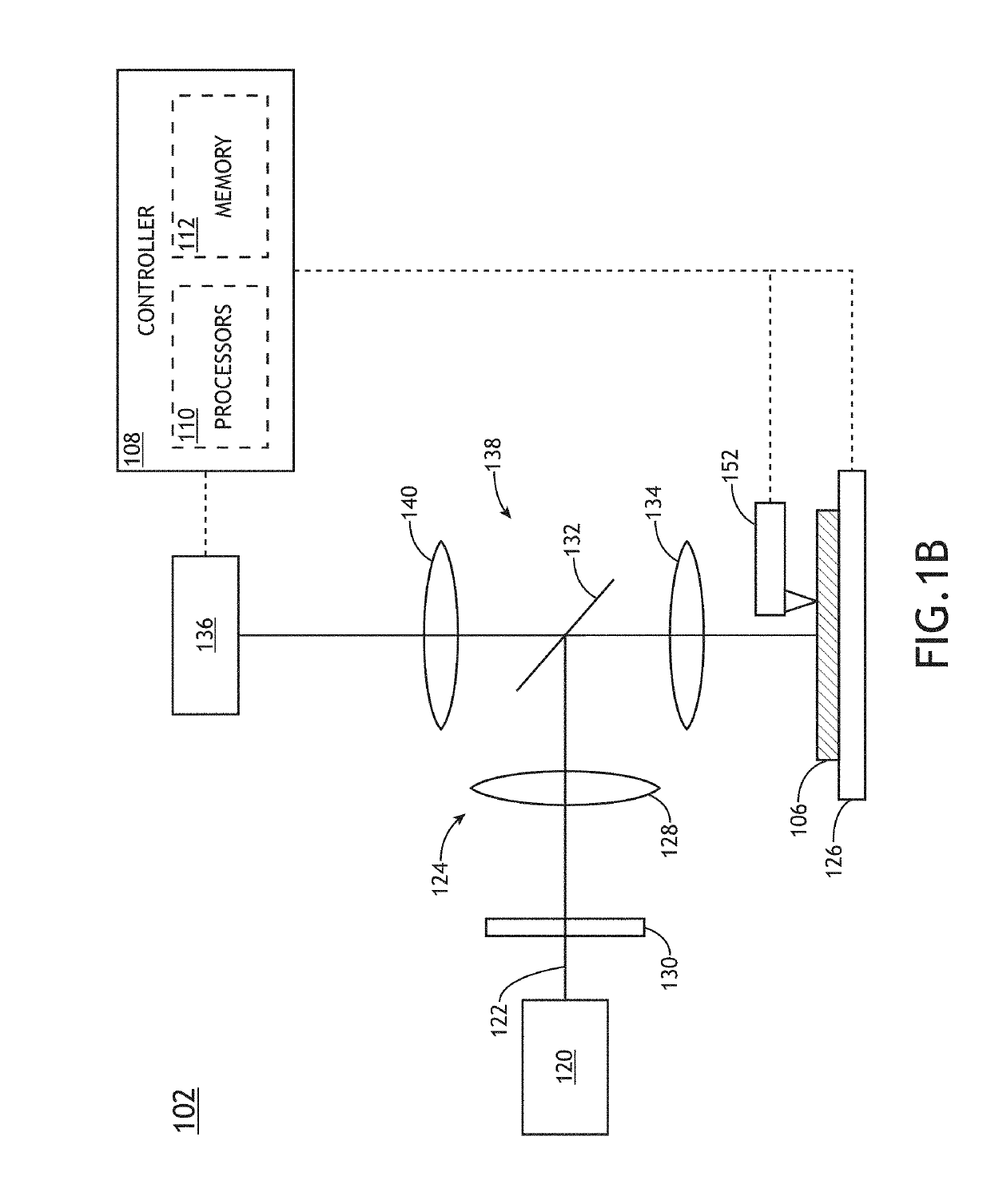

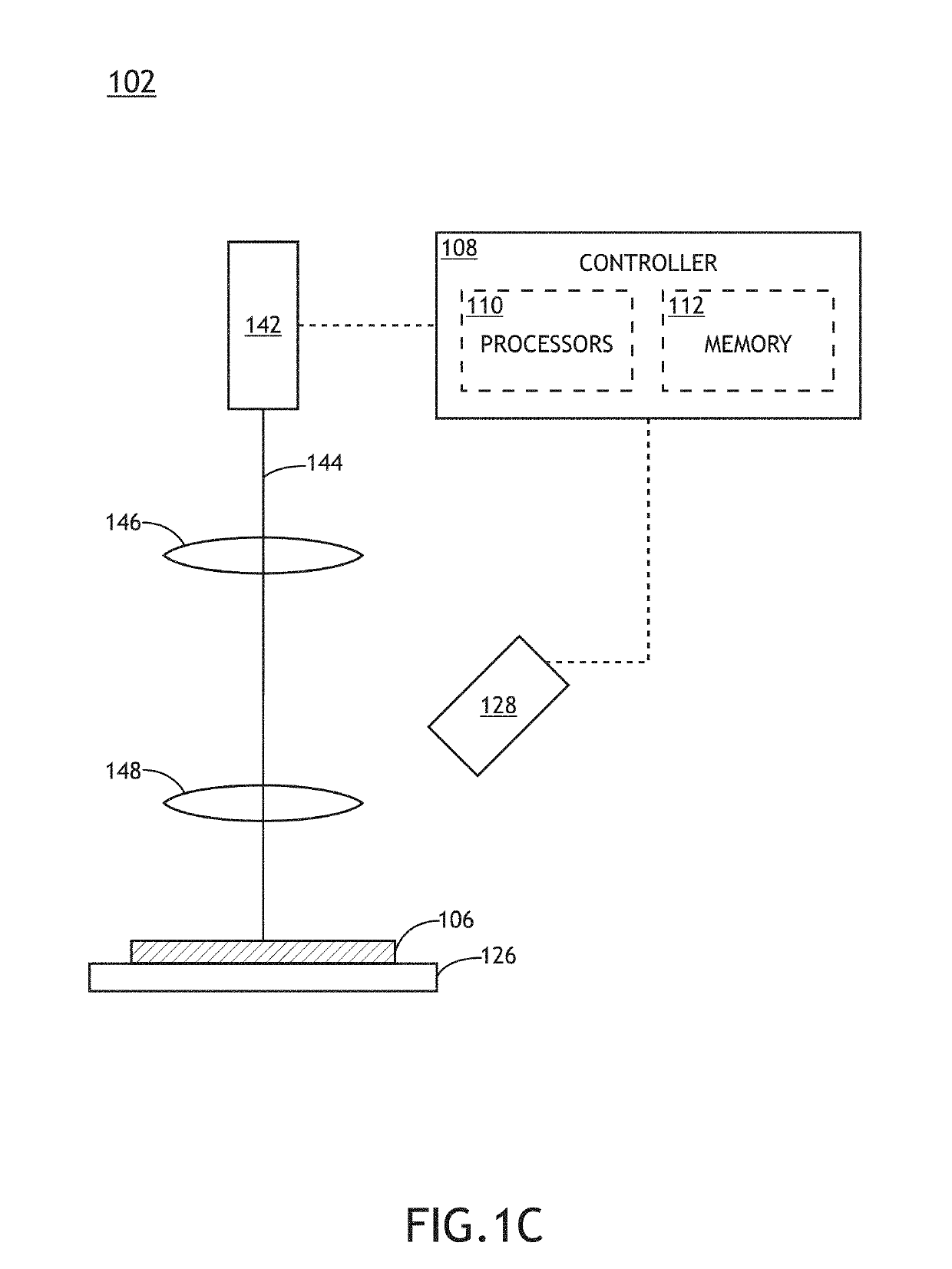

Targeted Recall of Semiconductor Devices Based on Manufacturing Data

ActiveUS20190295908A1Sacrificing all of its material advantageSemiconductor/solid-state device testing/measurementElectronic circuit testingMetrologySemiconductor chip

A system for providing a targeted recall includes a metrology sub-system for performing in-line measurements on semiconductor dies after one or more fabrication steps to generate in-line measurement profiles, a failure analysis sub-system for determining a manufacturing fingerprint of a failed die, and a controller. The metrology sub-system may further perform one or more measurements of the semiconductor dies after one or more packaging steps to generate package characterization profiles. The controller may generate manufacturing fingerprints for the semiconductor dies based on the in-line measurement profiles and the package characterization profiles, which are referenced to unique electronic chip identifiers. The controller may further identify at-risk dies by comparing the manufacturing fingerprints of the semiconductor dies with the manufacturing fingerprint of the failed die and direct a targeted recall for the one or more at-risk dies.

Owner:KLA TENCOR TECH CORP

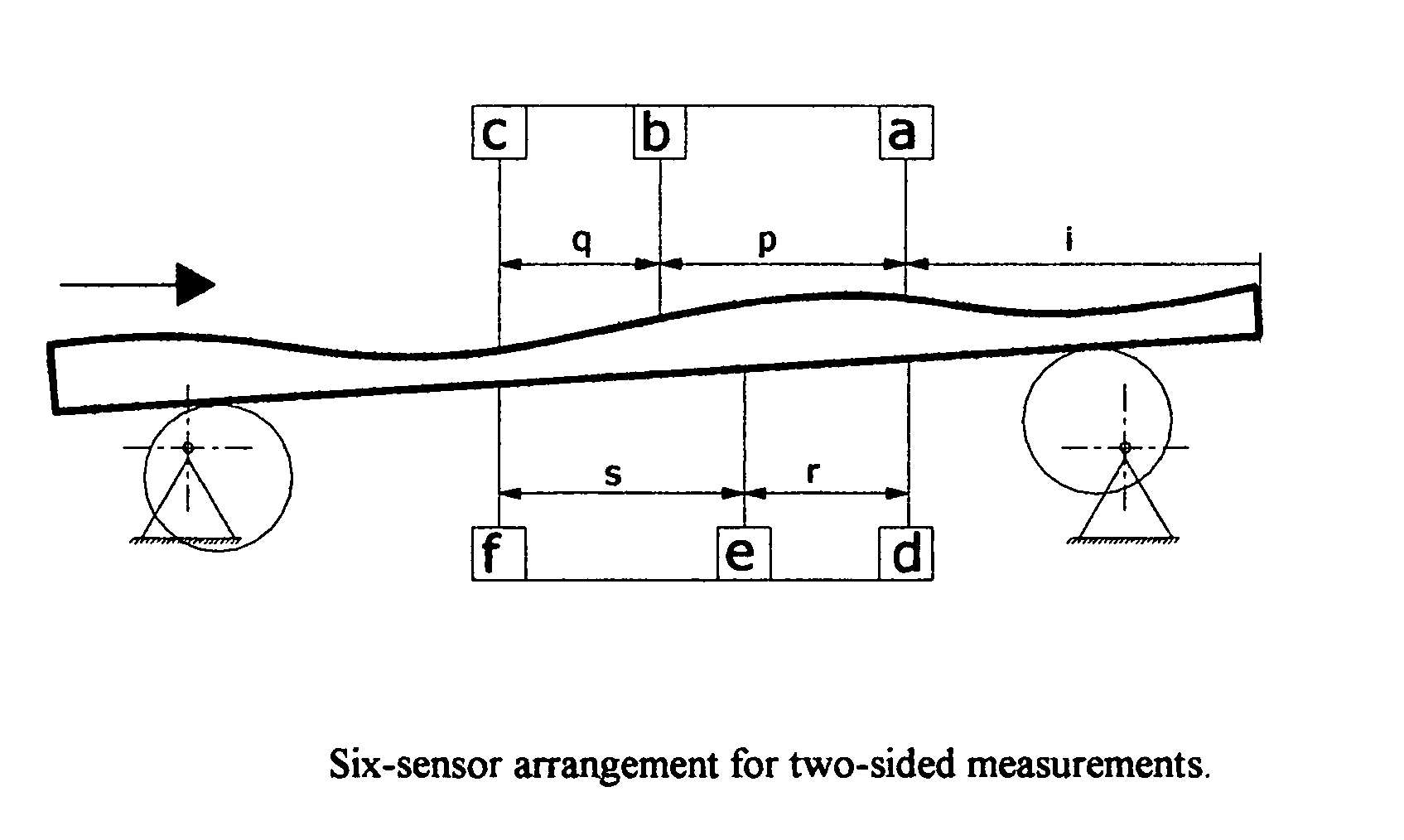

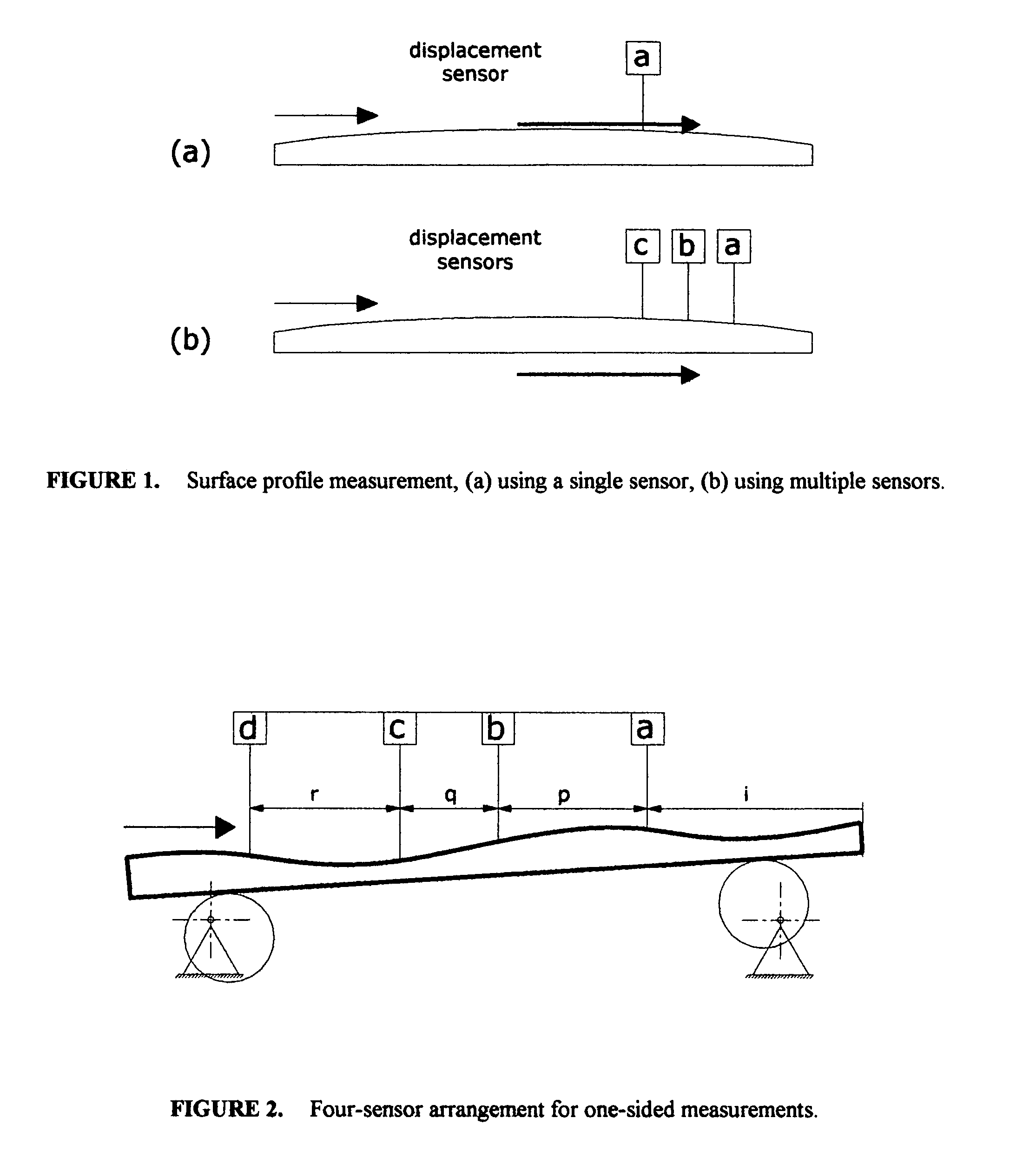

Surface profile measurement, independent of relative motions

ActiveUS20050204572A1High measurement accuracyEasy to adaptMechanical counters/curvatures measurementsWind musical instrumentsSensor arrayEngineering

A general method is disclosed for using distance sensors to measure the surface profile and twist of objects, even in the presence of rigid-body motions in the measurement directions between the surface and the sensors. The method involves making multiple sequential measurements from a group of sensors while the object moves longitudinally relative to the sensors. The surface height features of the measured object appear in delayed sequence as the observed surface moves longitudinally relative to the sensor array. However, any rigid-body motions in the measurement directions appear simultaneously at all sensors. Mathematical procedures are used to separate the delayed and simultaneous components of the measurements, from which the surface height profile is determined. The invention can handle many different measurement types, including simultaneous measurement of the surfaces of two-sided objects, measurement of surface twist and two-dimensional surface scanning.

Owner:FPINNOVATIONS INC

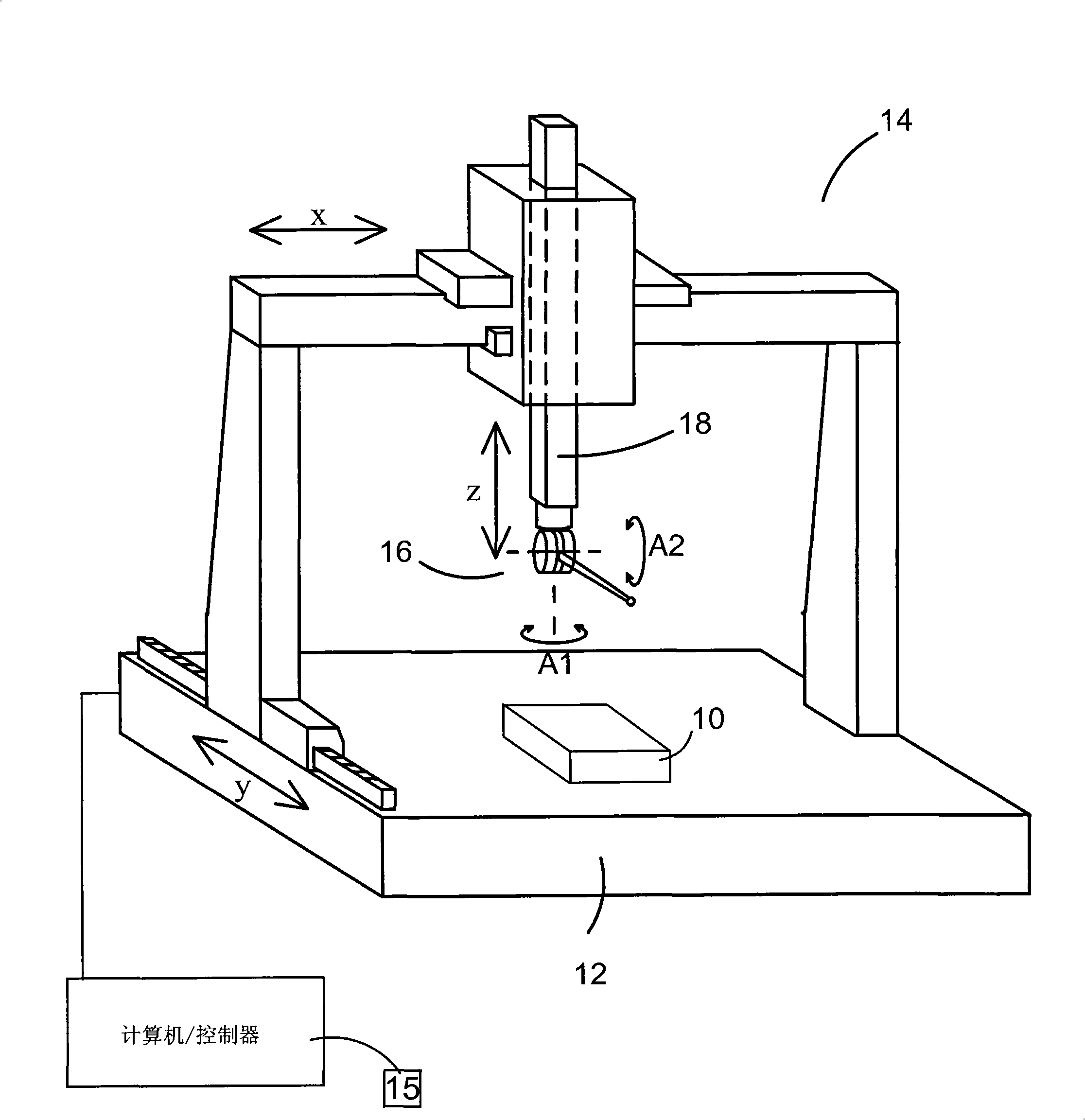

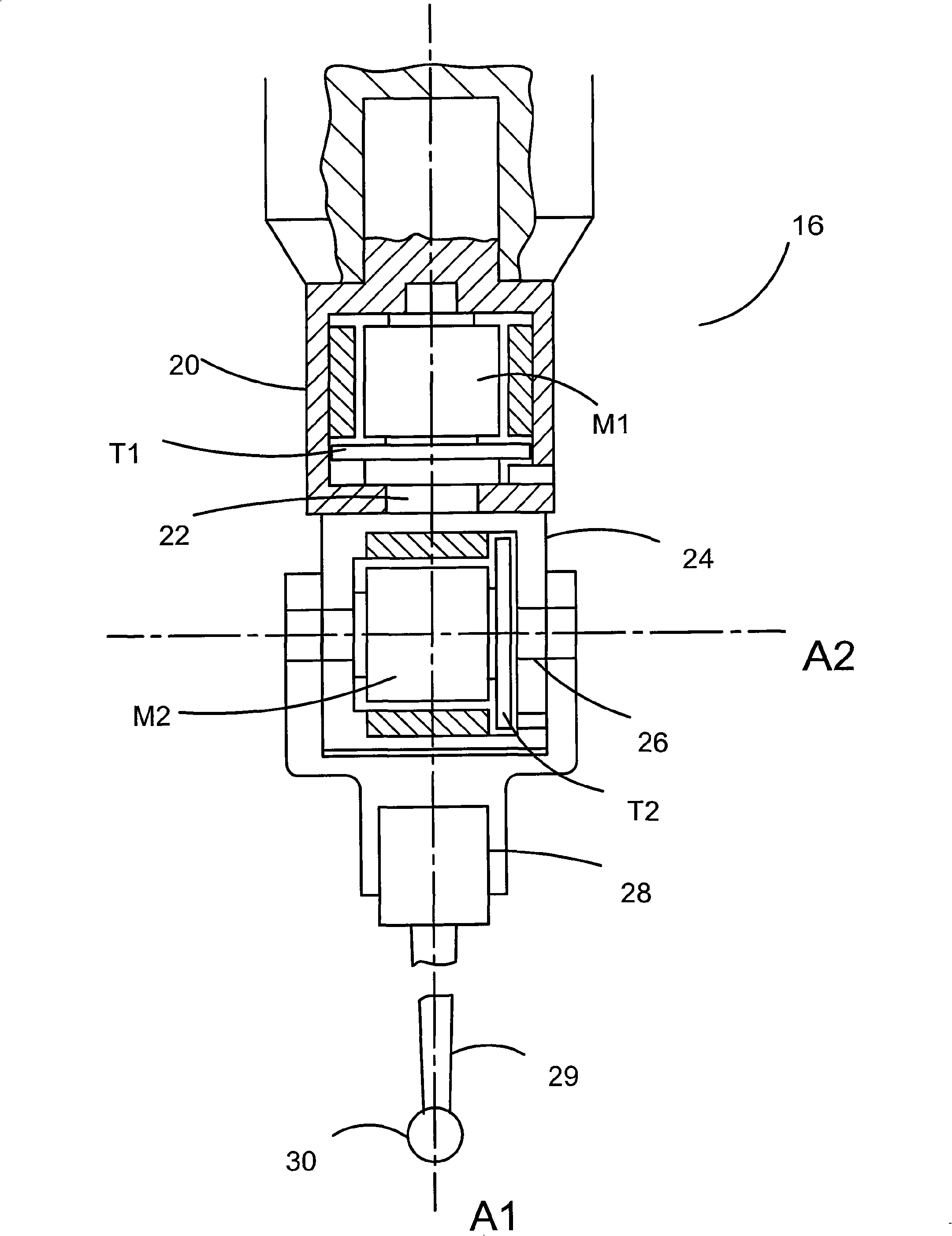

Apparatus and method of measuring workpieces

A method and apparatus for measuring a surface using a surface sensing device mounted on a scanning head on a member of a coordinate positioning apparatus. The coordinate positioning apparatus may be operated to produce relative movement between the scanning head and the surface profile and the scanning head includes a drive for producing rotational movement of the surface sensing probe about oneor more axis. A desired measurement profile on the surface which the surface sensing device will track and the desired motion of the orientation of the surface sensing device as the surface' sensing device follows the measurement profile are defined. This data is used to derive the required path of the relative motion between the member of the coordinate positioning apparatus and the surface, such that the surface sensing device prescribes a trajectory along the measurement profile.

Owner:RENISHAW PLC

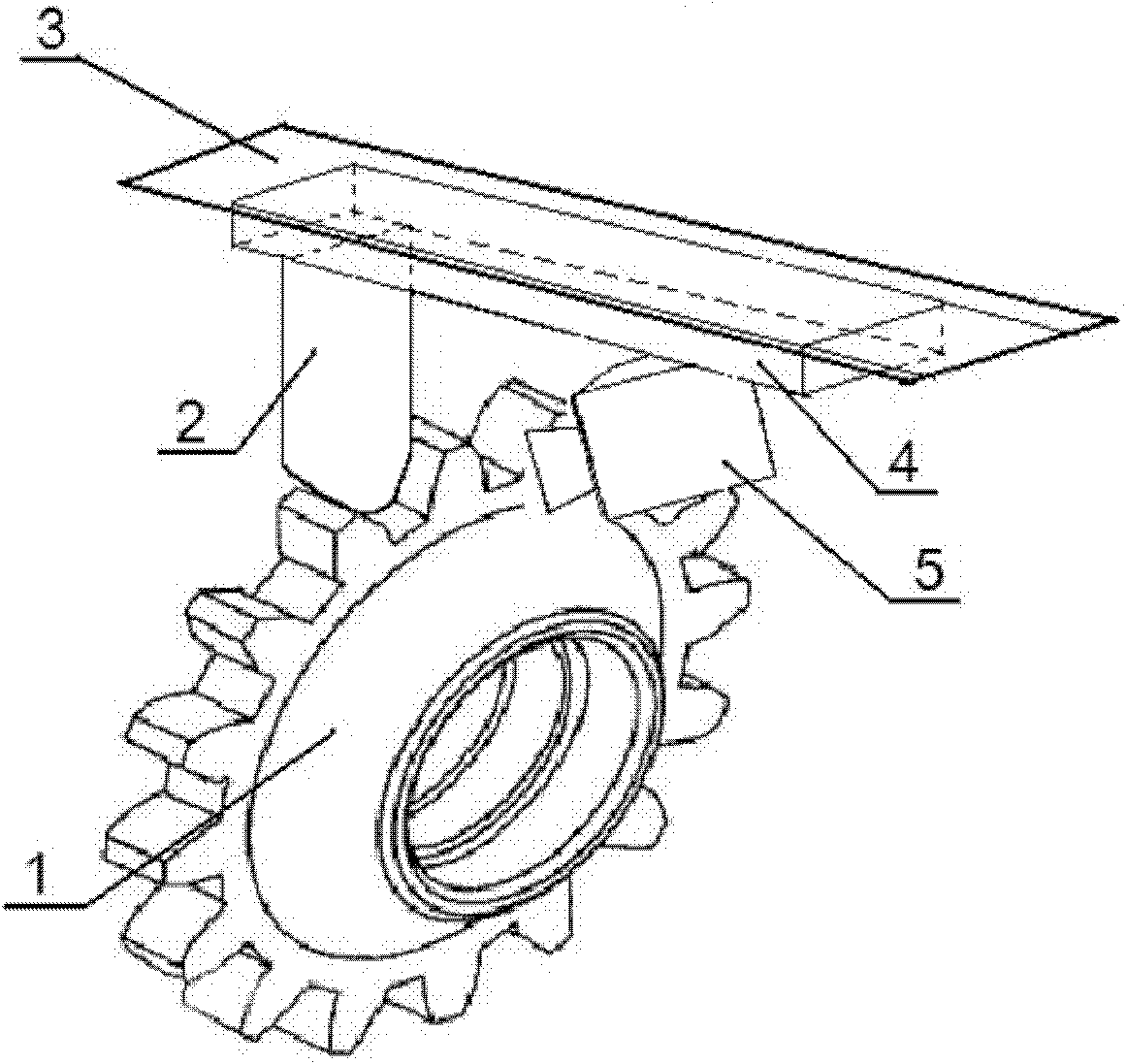

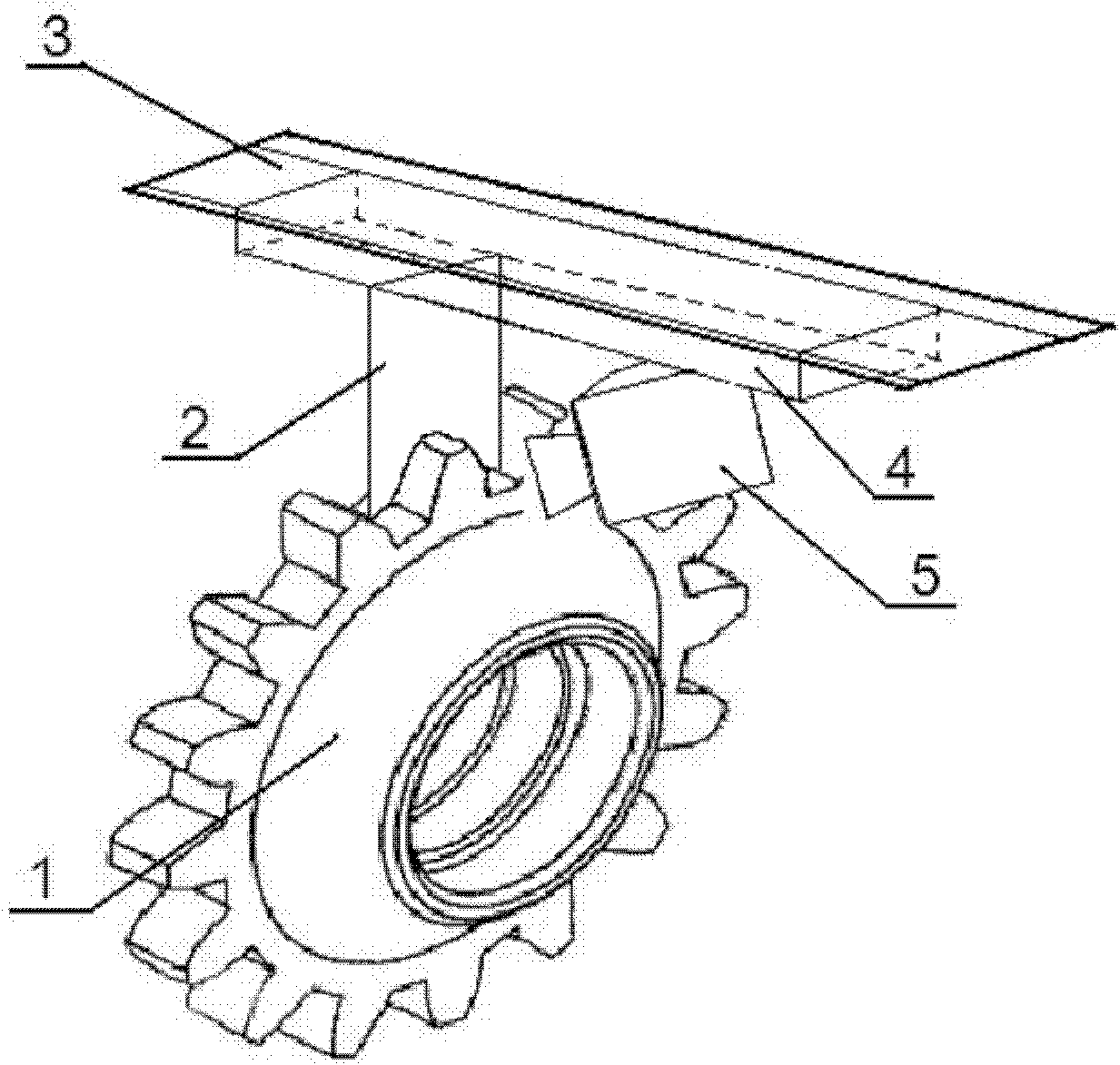

Gear and moulding structure outline measuring method based on template near-field light projection scanning

InactiveCN101782374AComplete geometryComplete parametersUsing optical meansImage resolutionTemplate based

The invention relates to a gear and moulding structure outline measuring method based on template near-field light projection scanning. A template which is same with the cross section of teeth or a tooth groove of a measured gear is manufactured according to the shape of a measured gear and placed into the tooth groove of the measured gear; then, an illuminating light source is installed at one side of the template, and the outline data of the surface of an object are obtained by utilizing a triangular relationship comprising a CCD or an image sensor and an edge projection; and aiming at each tooth on the gear, the measured gear is rotated by an angular division coding device to carry out repeated measurement to completely measure the geometrical shape and parameter of the whole gear. The invention can realize micron-grade shadow projection, therefore, the measurement precision along the surface normal direction can reach more than 5 microns in the outline measurement of moulding structures, such as a counter gear, and the like. The transverse resolution reaches more than 20 microns, and the measurement speed reaches more than 5,000 point / second. The invention is particularly suitable for the quality detection of gear processing. The technology can also be used for the surface outline measurement of other structural elements.

Owner:XI AN JIAOTONG UNIV

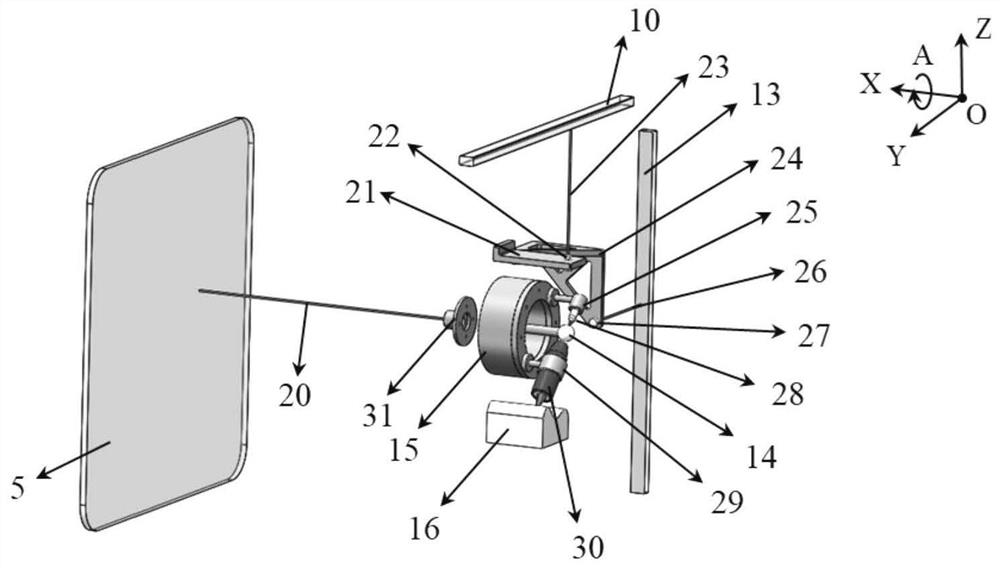

High-precision free-form surface profiling measurement device and method based on three-dimensional measurement frame

PendingCN113834438AMeet the testing processHigh precisionUsing optical meansLinear motionMeasurement device

The invention discloses a high-precision free-form surface profiling measurement device and method based on a three-dimensional measurement frame. Three linear motion tables, two rotary tables and an angular displacement table are combined to form a six-axis linkage mechanism, and a high-precision displacement sensor is driven to move in six degrees of freedom in a three-dimensional space relative to a measured object, so that scanning measurement of a free-form surface with complex geometric characteristics such as high curvature and large rise is realized. In addition, the three-dimensional measurement frame is constructed through the high-precision displacement sensor, so that an error transfer chain is blocked, and various error sources such as straightness errors and positioning errors in the scanning process are compensated. The device and method are suitable for fast detection of the surface type of the free-form surface, can also be used for surface type detection of aspheric, spherical and planar elements, have the advantages of being good in universality, high in measurement speed and high in measurement precision, not only can solve the measurement problem in the current free-form surface manufacturing process, but also can meet the detection process of planar, spherical, aspheric and other optical elements.

Owner:ZHEJIANG UNIV

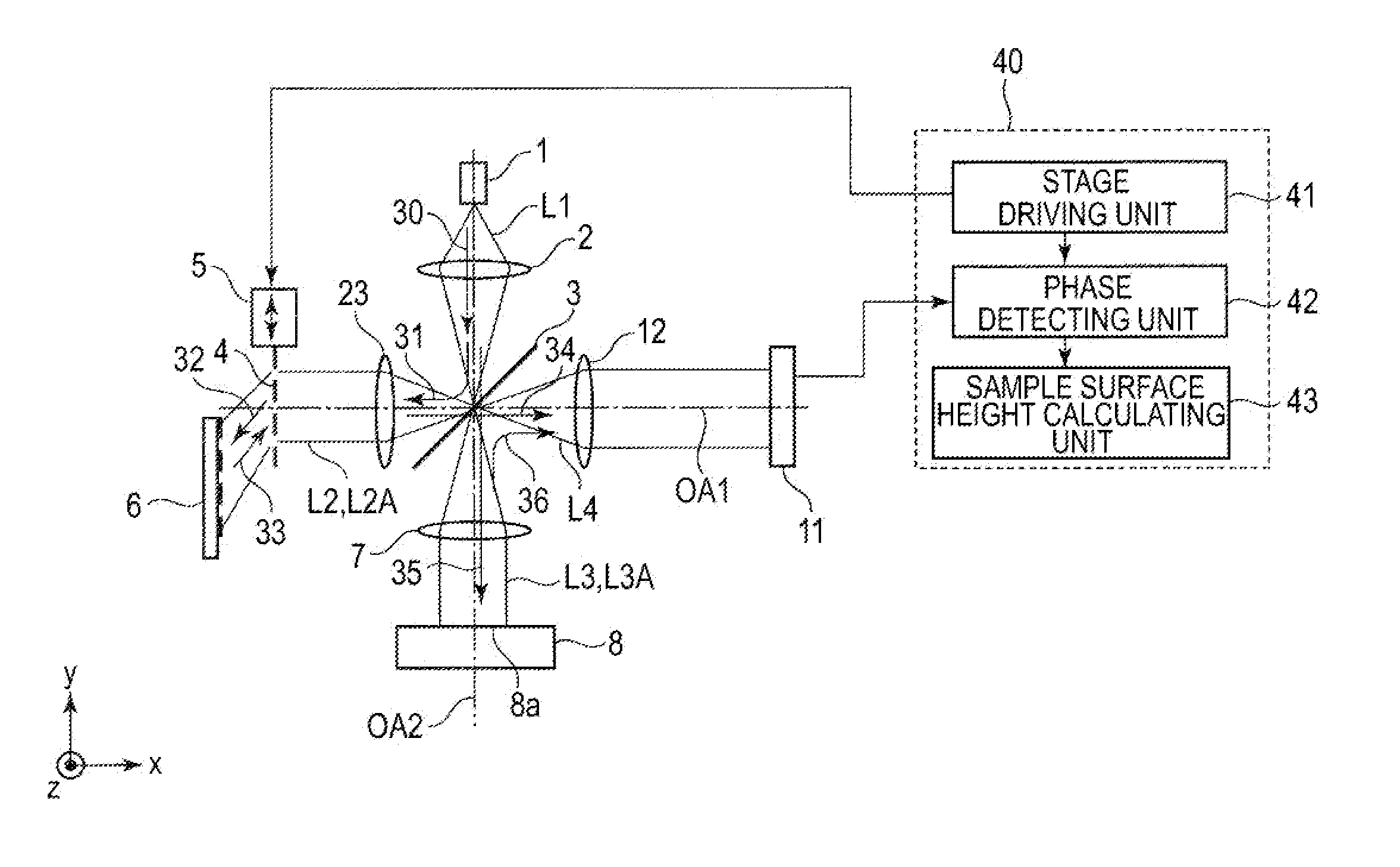

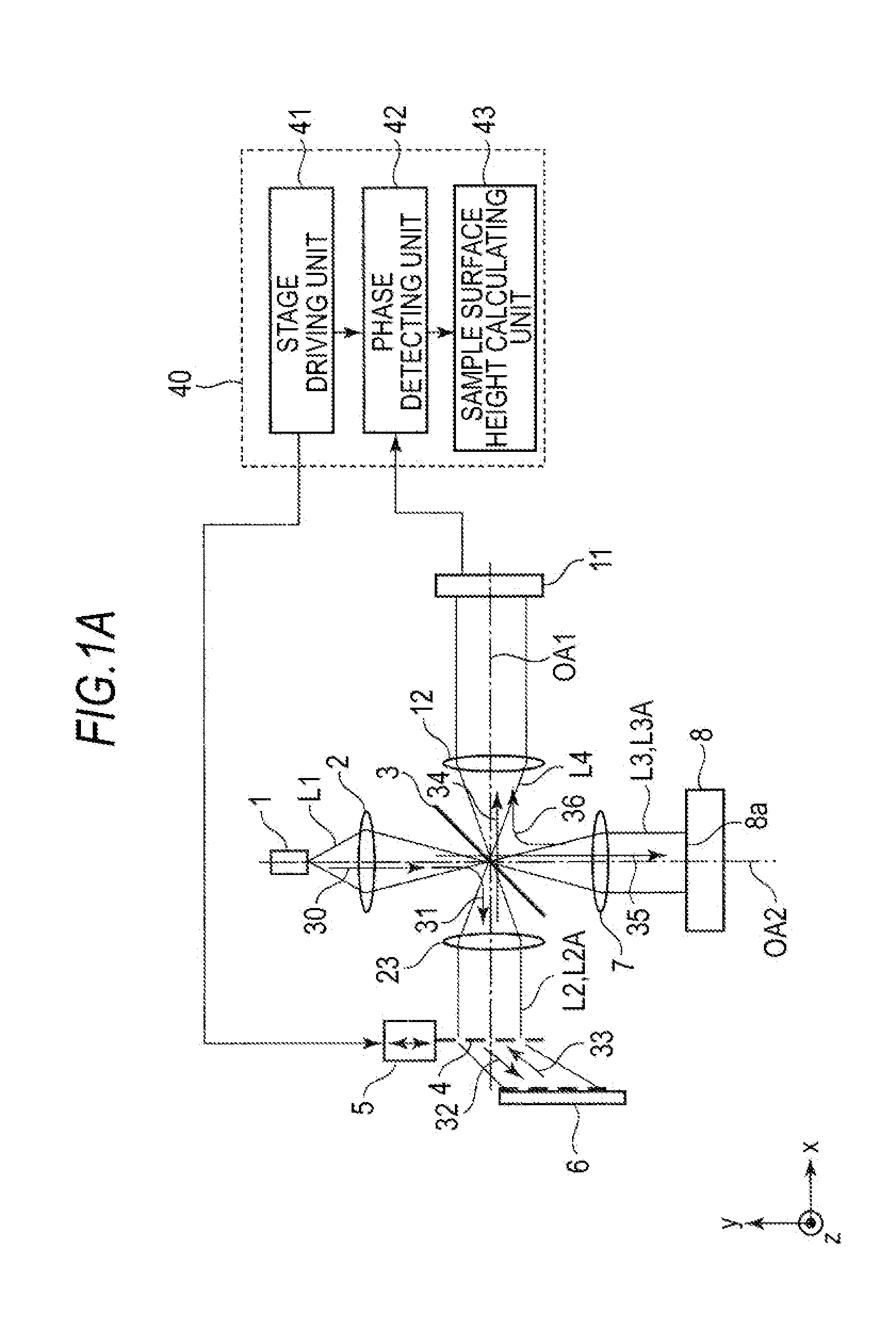

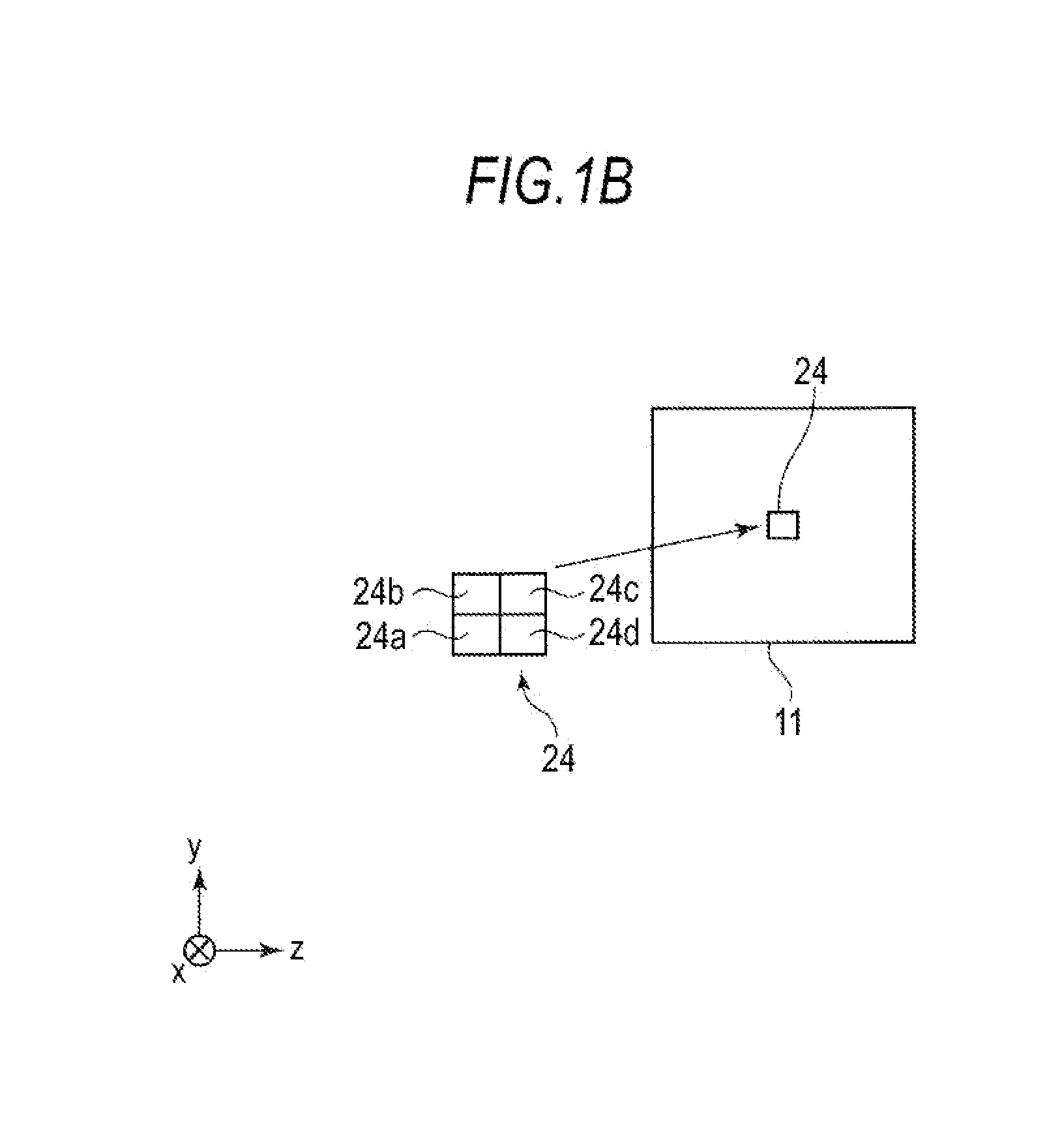

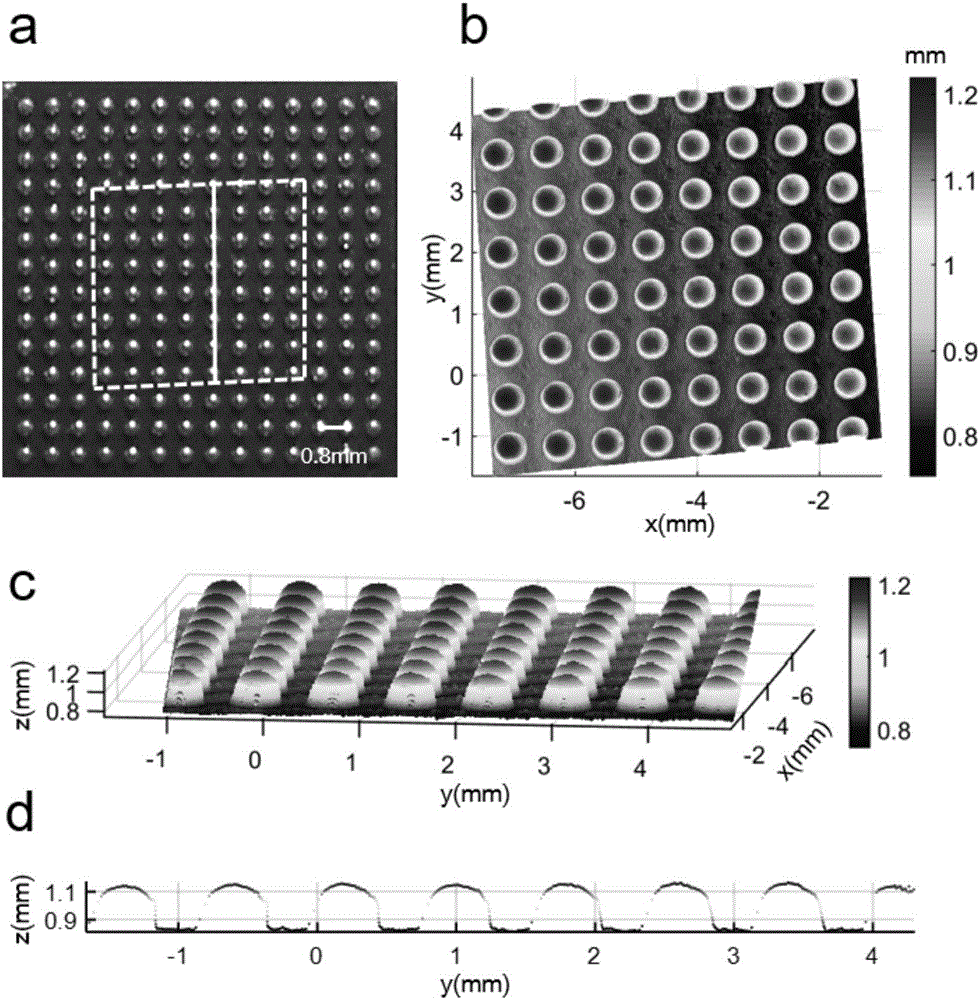

Surface profile measuring apparatus and method

A surface profile measuring apparatus includes a reflection unit to reflect a reference beam diffracted by a first diffraction grating and cause the reflected reference beam to be incident on the first diffraction grating again, a detection unit to receive an interference beam in which the reference beam diffracted again by the first diffraction grating and a measuring beam reflected by a sample surface optically interfere with each other, and detect an interference intensity signal for each, wavelength in the interference beans, a shifting unit to shift the first diffraction grating in a direction perpendicular to a grating groove direction of the first diffraction grating, a calculation unit to calculates a phase on a basis of the interference intensity signal for each wavelength varying with a degree of shift, and a measurement unit to measure the sample surface.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Three-dimensional microscopic surface profile measuring device based on Greenough-type stereomicroscope and a method of device

The invention discloses a three-dimensional microscopic surface profile measuring device based on a Greenough-type stereomicroscope and a method of the device. A camera and a projector are installed in two imaging light paths of the Greenough-type stereomicroscope, so driving structured light three-dimensional microscopic surface profile measuring is achieved. During measuring, when a measurement system is calibrated, the method is combined with a phase shift profile measuring technology for non-linear fitting calibration between height and a fringe phase on the microscope projection light paths, then internal and external parameters of the camera light path are calibrated by means of a perspective model, accordingly a homograph matrix of the camera is obtained, height distribution information of three-dimensional point cloud data of a to-be-detected object is obtained according to the relation between the height and the phase, and then transverse position distribution of the three-dimensional point cloud data of the object is obtained according to an equation set determined by the obtained homograph matrix of the camera. The device and the method have the advantages of being simple, efficient and low in cost, and three-dimensional point cloud data of tiny object surface can be quickly obtained by projecting multiple sets of phase shift period fringes and combining system calibration parameters.

Owner:NANJING UNIV OF SCI & TECH

Fabry-Perot resonator cavity resonance luminescence cantilever beam system

ActiveCN101556836ADetect deflectionAbility to detect deformationSurface/boundary effectInstrumental componentsCavity resonanceLuminescence

The invention discloses a Fabry-Perot resonator cavity resonance luminescence cantilever beam system. The system mainly consists of an photoelectric conversion component, a substrate, a fixed Fabry-Perot resonator cavity mirror, a resonator cavity inner light source, a sample chamber, a movable Fabry-Perot resonator cavity mirror, a resonator cavity outer light source, upper piezoelectric ceramics for excitation, a silicon micro-cantilever beam, lower piezoelectric ceramics for excitation and a probe. The Fabry-Perot resonator cavity resonance luminescence cantilever beam system can emit variable resonance frequency light which is modulated by vibration; and can detect spectral components of samples to be detected and cantilever beam flexure and deformation ability which is caused by external factors. Furthermore, the system can be applied to various technical fields, such as sensing and detection of chemical constituents and molecular biosamples, measurement of ultra-precision mechanical surface contour, physical spectrum constituent analysis and the like.

Owner:CHINA JILIANG UNIV

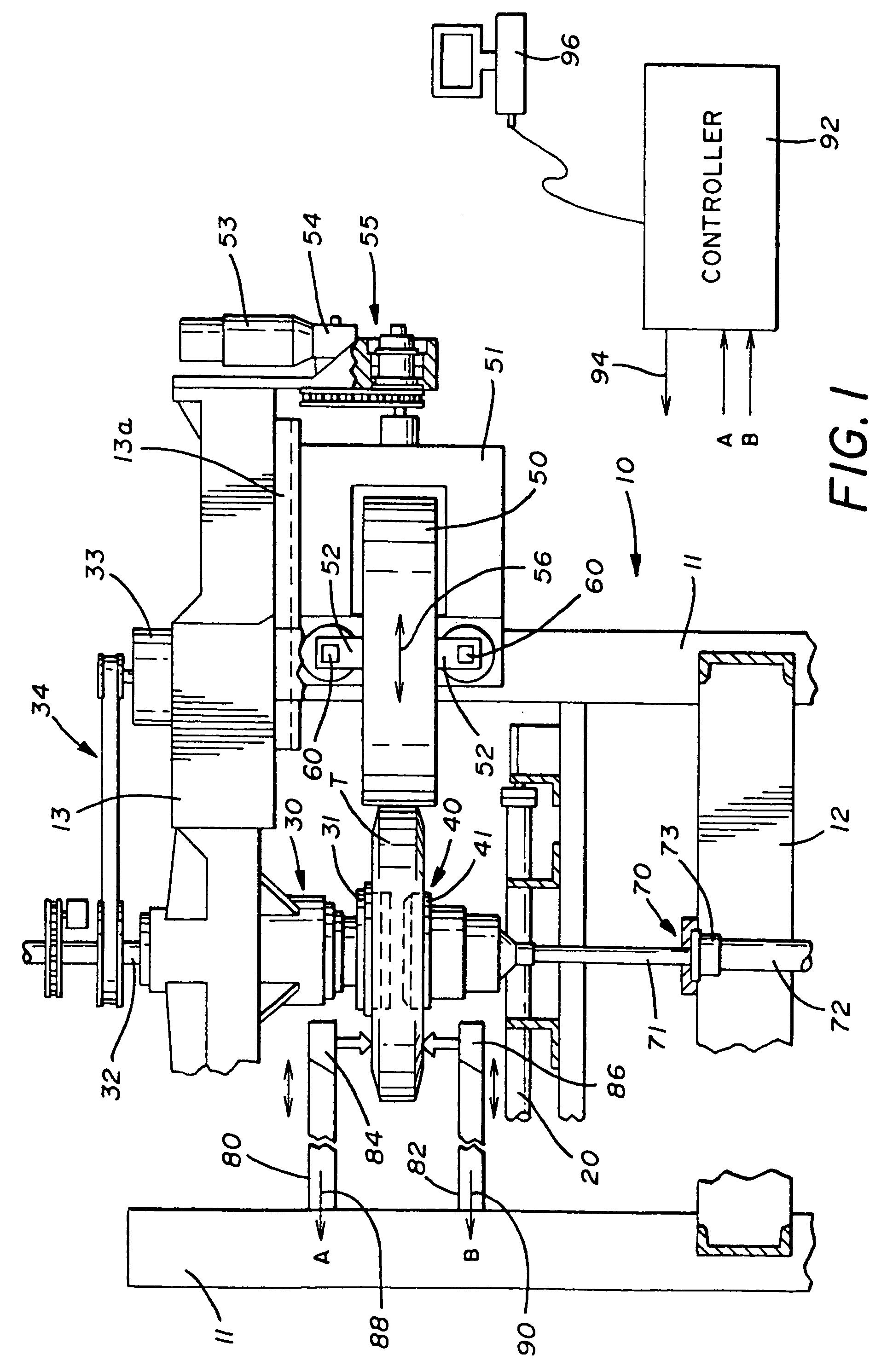

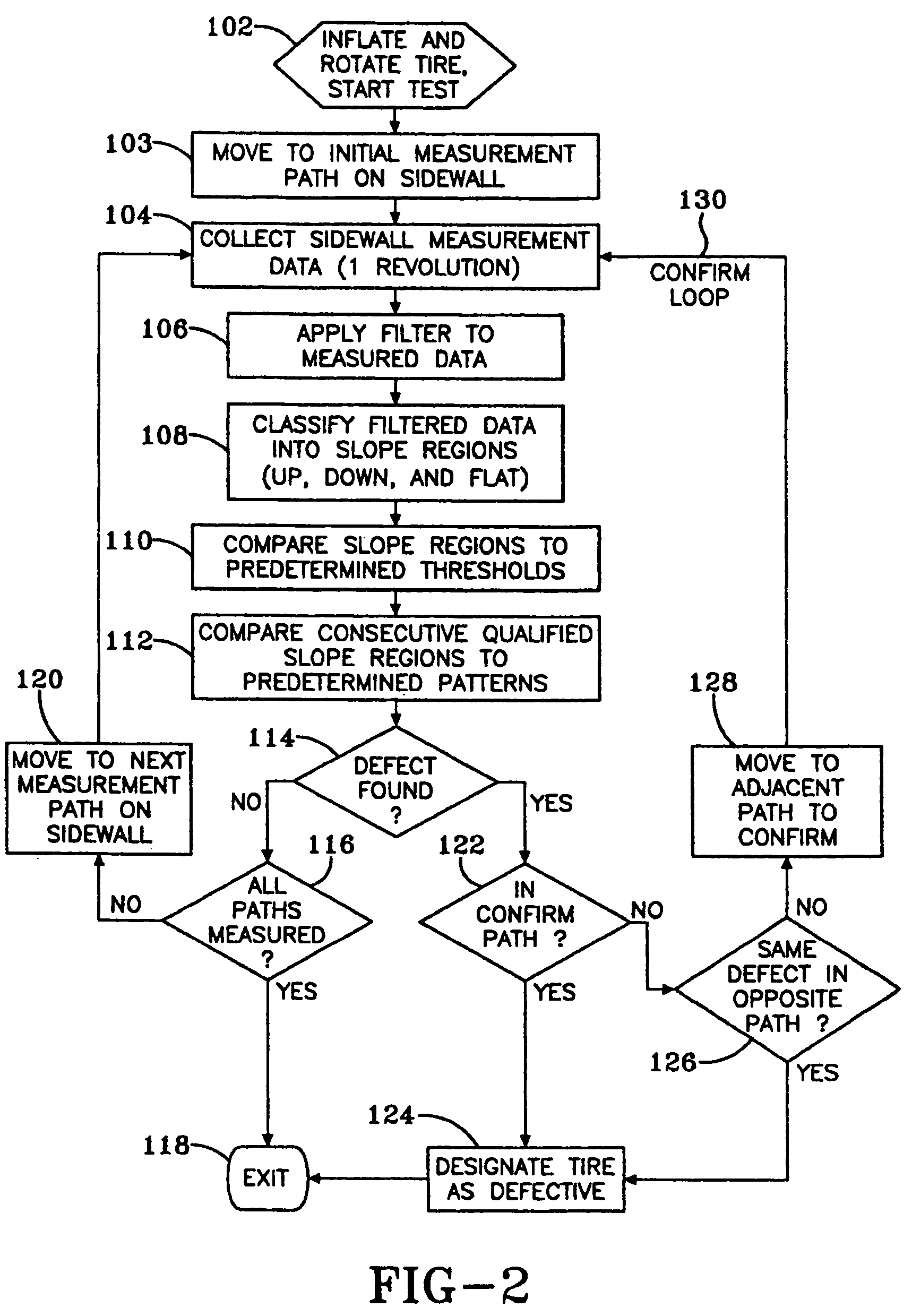

System for testing tire sidewall irregularities and related methods

Owner:COMML TIME SHARING

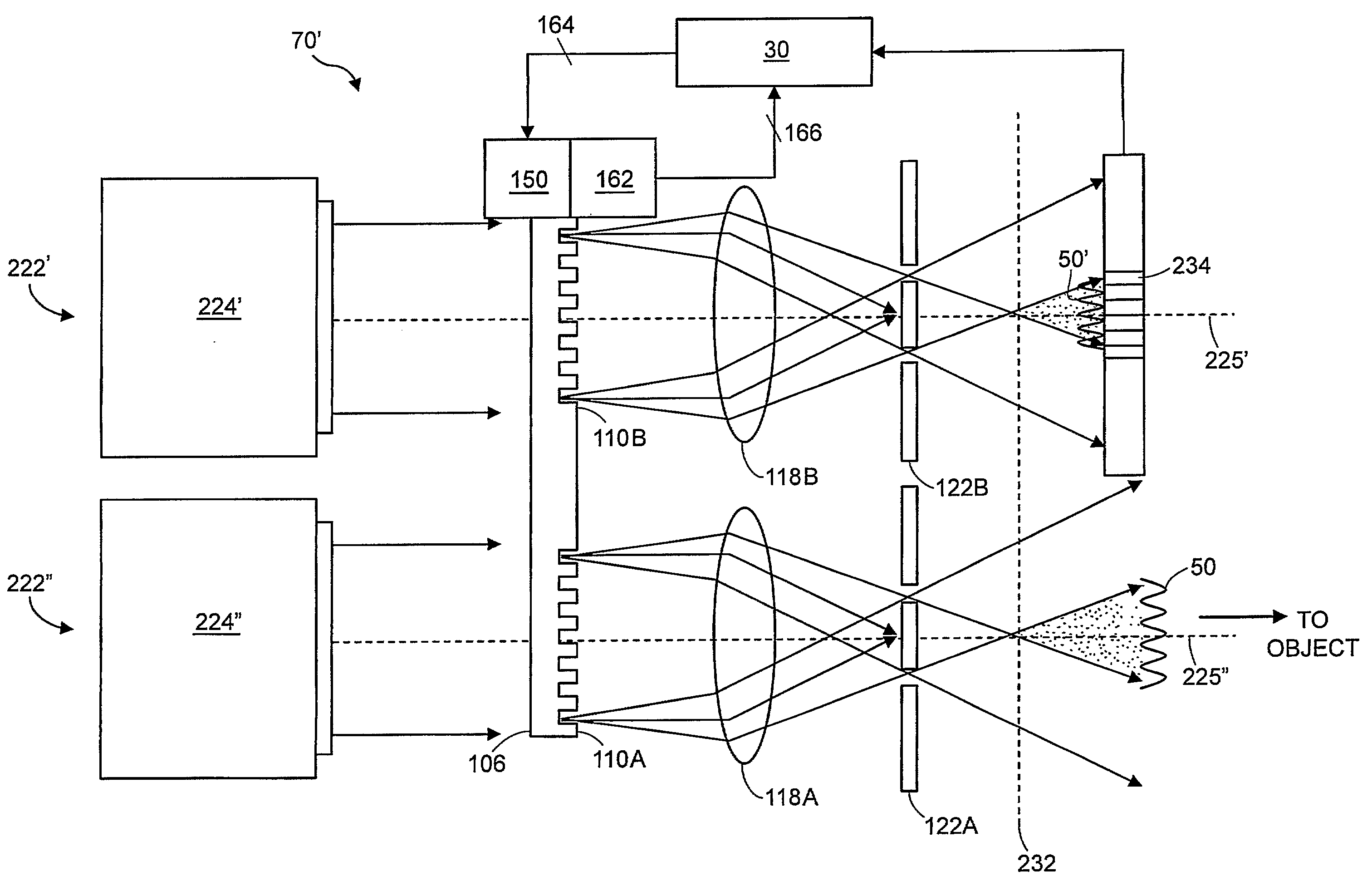

Multiple Channel Interferometric Surface Contour Measurement System

ActiveUS20080165341A1Improved directional stabilitySlow changeMaterial analysis by optical meansUsing optical meansMeasurement precisionImaging data

Described is a multiple channel interferometric surface contour measurement system. The measurement system includes a multiple channel interferometer projector, a digital camera and a processor. The projector includes two or more interferometer channels. Each channel has an optical axis spatially separate from the optical axes of the other channels. Each channel projects a fringe pattern onto the surface of an object to be measured. Image data for the fringe patterns projected on the object surface are acquired by the digital camera. The processor controls the projection of the fringe patterns of different spatial frequencies, adjusts the phase of each fringe pattern and generates surface contour data in response to the camera image data. The multiple channel interferometric surface contour measurement system provides numerous advantages over conventional single channel interferometric systems, including reduced sensitivity to optical noise, improved stability and increased measurement accuracy.

Owner:DIMENSIONAL PHOTONICS INT

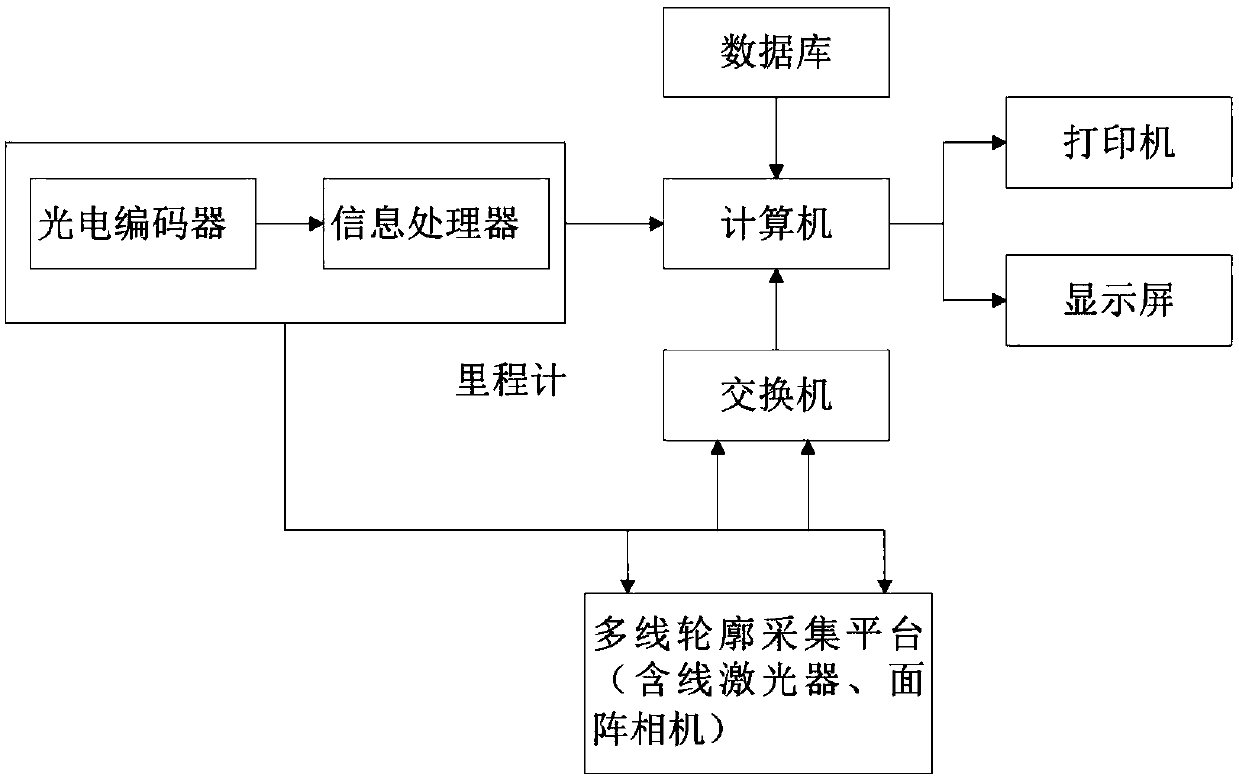

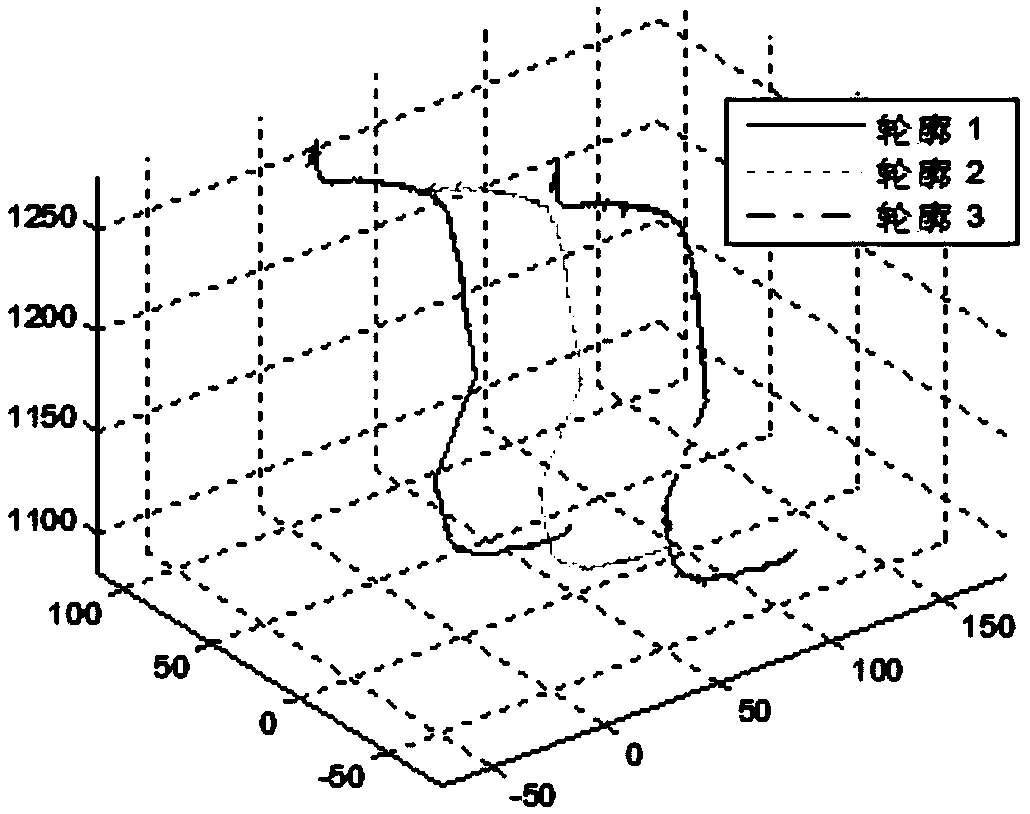

Dynamic measurement method of rail corrugation

ActiveCN109017867AInhibition effectHas engineering application valueUsing optical meansRailway auxillary equipmentEngineeringDistortion

The invention discloses a dynamic measurement method of rail corrugation, which comprises the following steps: (1) constructing an auxiliary plane perpendicular to the rail longitudinal direction by utilizing the characteristics that the connecting lines of the rail jaw points of a plurality of measurement profiles are parallel to the rail longitudinal direction, and projecting the measurement profiles onto the auxiliary plane for distortion calibration. (2) Progressively and accurately align the reference contour with the stratified contour registration. (3) Using the characteristic that thedistance between the center of the circular arc of the rail waist and the measuring point of the wave grinding is fixed in the direction of the track gauge, the measuring point is precisely positioned, and the distance in the vertical direction of the two points is taken as the wave grinding value of the section. This method can effectively solve the problem of low precision of the dynamic detection method of rail corrugation.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com