High-precision free-form surface profiling measurement device and method based on three-dimensional measurement frame

A technology of three-dimensional measurement and measuring device, which is applied in the field of precision measurement, can solve problems such as inability to realize component surface shape detection, failure to meet measurement requirements, detection problems, etc., and achieve the effects of fast measurement speed, good versatility, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

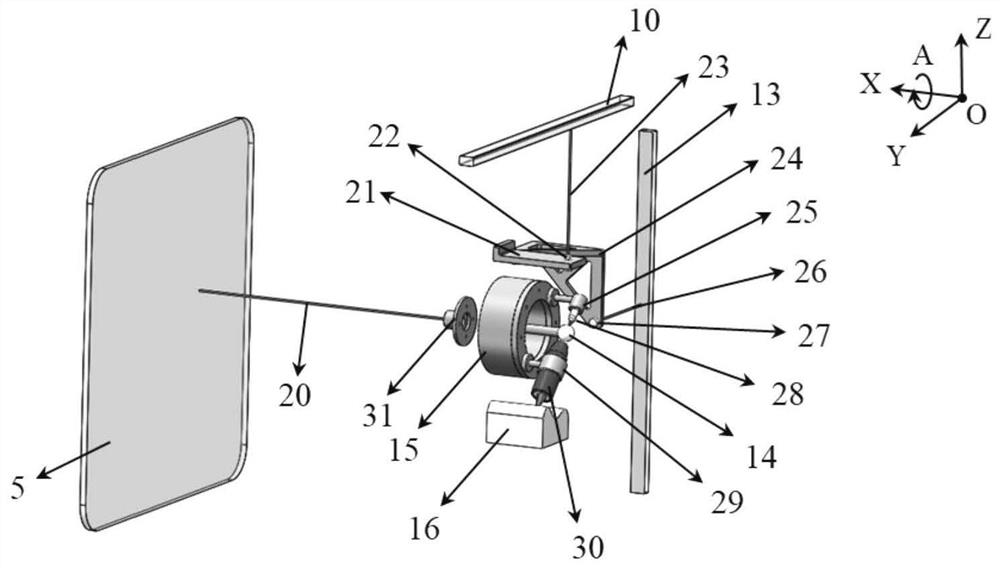

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as figure 1 As shown, the vibration isolation base (1) is placed on the ground, the marble base (2) is horizontally installed on the vibration isolation base, and the X-axis motion platform (3) in the form of double drive and the flat crystal base (4) are installed on it. with C-axis turntable (18). Wherein the plane flat crystal (5) is installed above the plane flat crystal support (4). A B-axis pitch table (18) and a workpiece table (17) are stacked above the C-axis turntable (18), and the workpiece to be measured (16) is fixed on the workpiece table (17). A Y-axis motion table (8) and a Z-axis motion table (9) are stacked on the Y-axis gantry (6). The A-axis turntable (15) is installed at the bottom of the Z-axis motion table (9), and the Z-direction compensation probe bracket (21) and the Y-direction compensation probe bracket (24) are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com