Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1282 results about "Liquid–liquid extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid–liquid extraction (LLE), also known as solvent extraction and partitioning, is a method to separate compounds or metal complexes, based on their relative solubilities in two different immiscible liquids, usually water (polar) and an organic solvent (non-polar). There is a net transfer of one or more species from one liquid into another liquid phase, generally from aqueous to organic. The transfer is driven by chemical potential, i.e. once the transfer is complete, the overall system of chemical components that make up the solutes and the solvents are in a more stable configuration (lower free energy). The solvent that is enriched in solute(s) is called extract. The feed solution that is depleted in solute(s) is called the raffinate. LLE is a basic technique in chemical laboratories, where it is performed using a variety of apparatus, from separatory funnels to countercurrent distribution equipment called as mixer settlers. This type of process is commonly performed after a chemical reaction as part of the work-up, often including an acidic work-up.

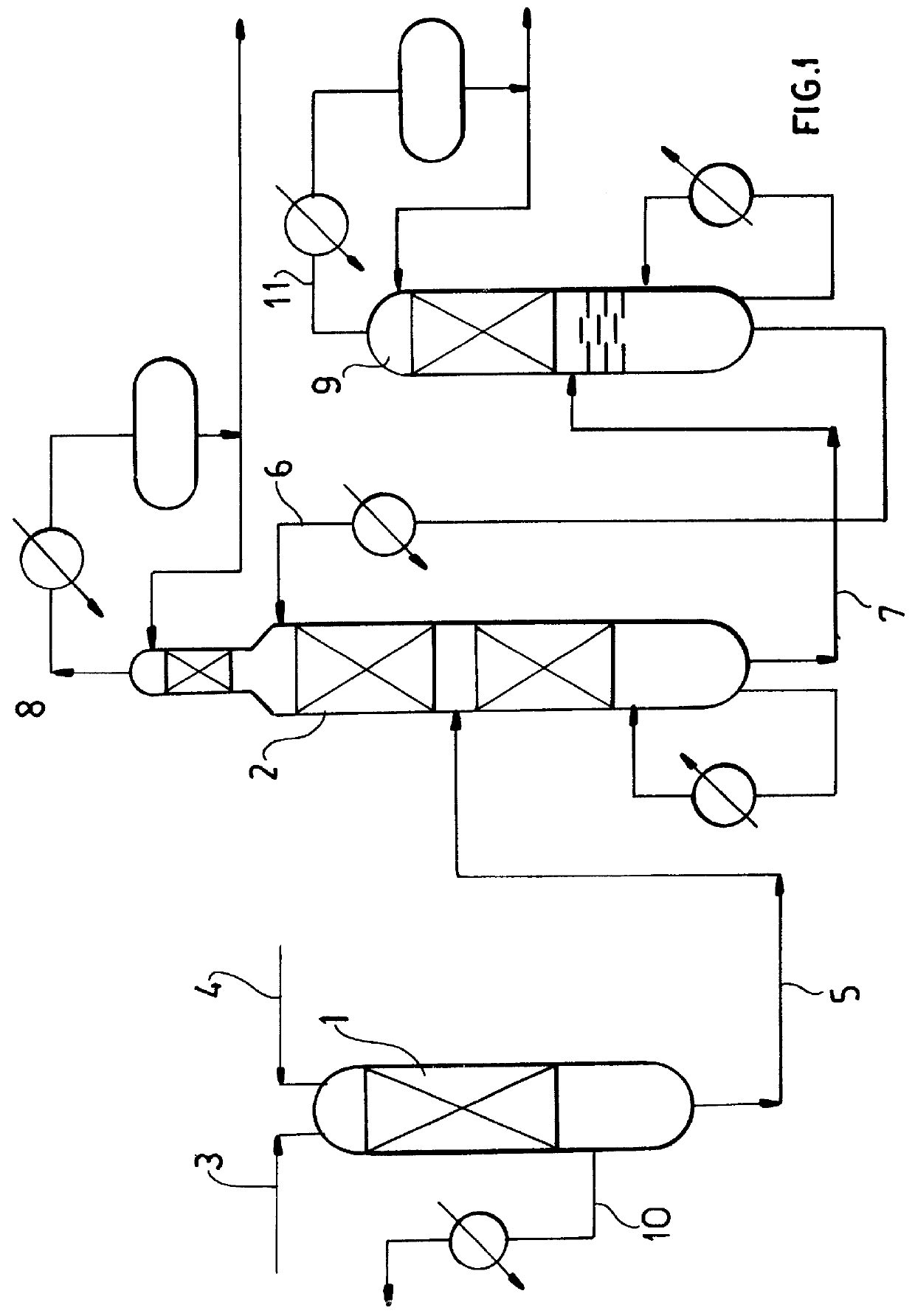

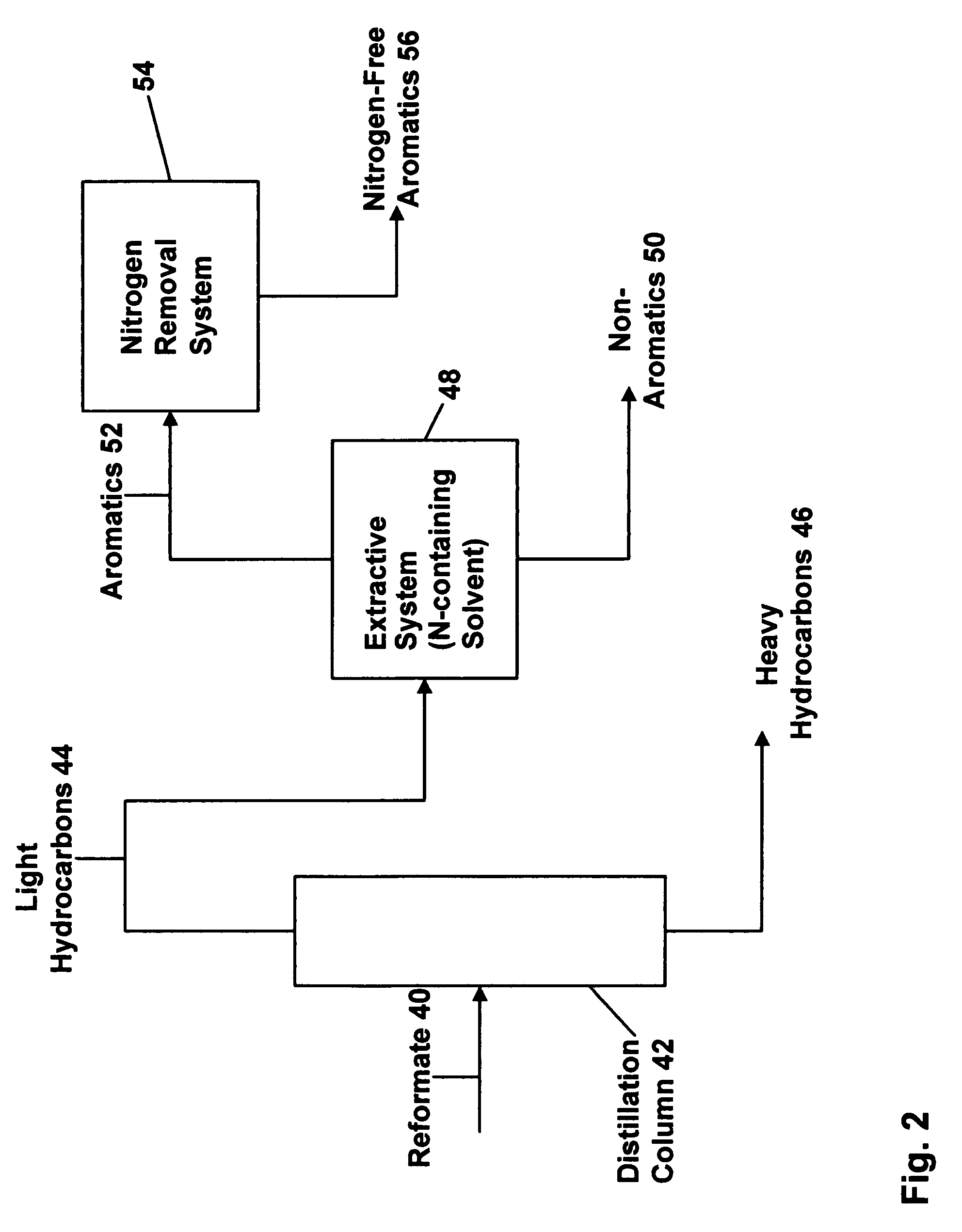

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

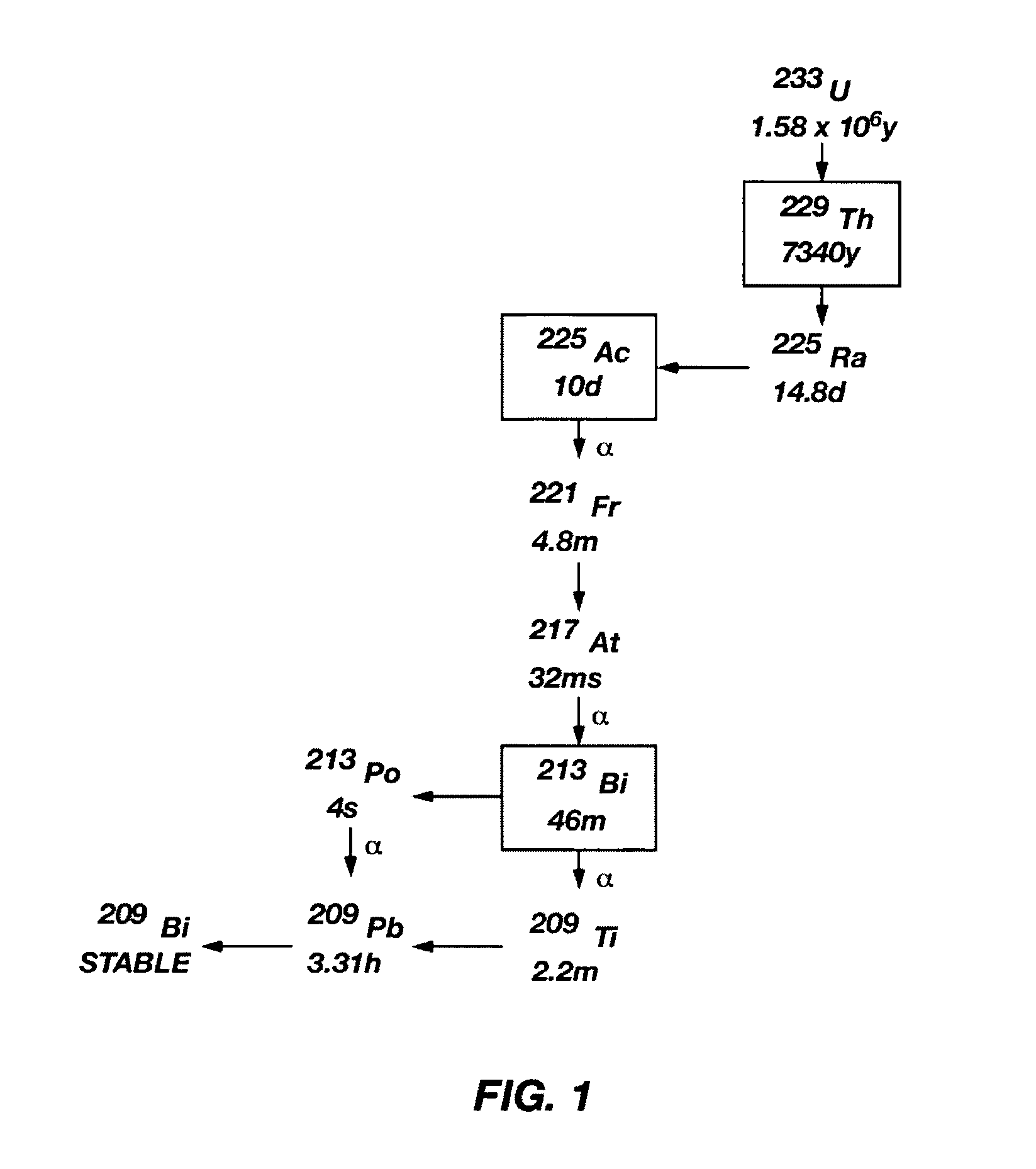

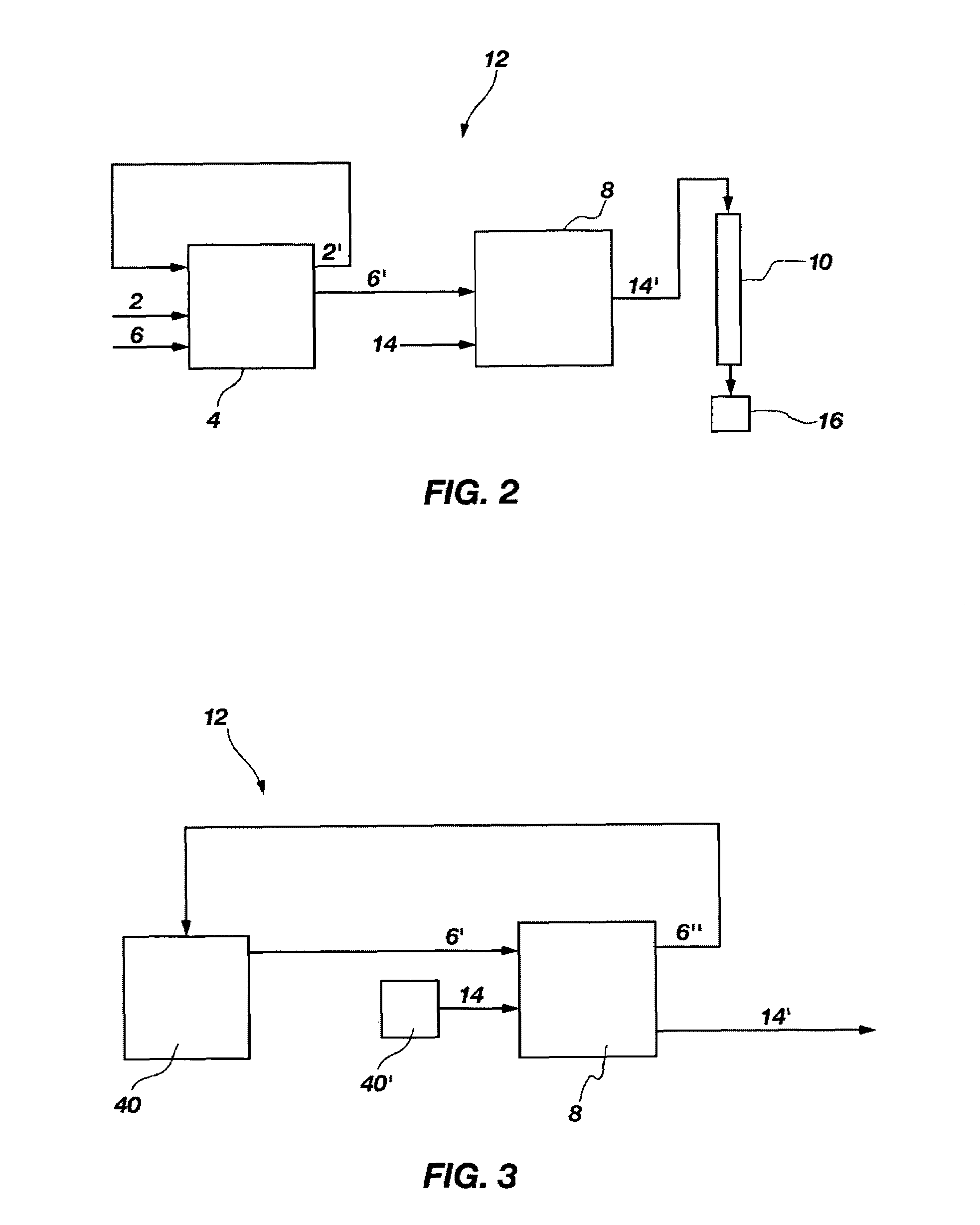

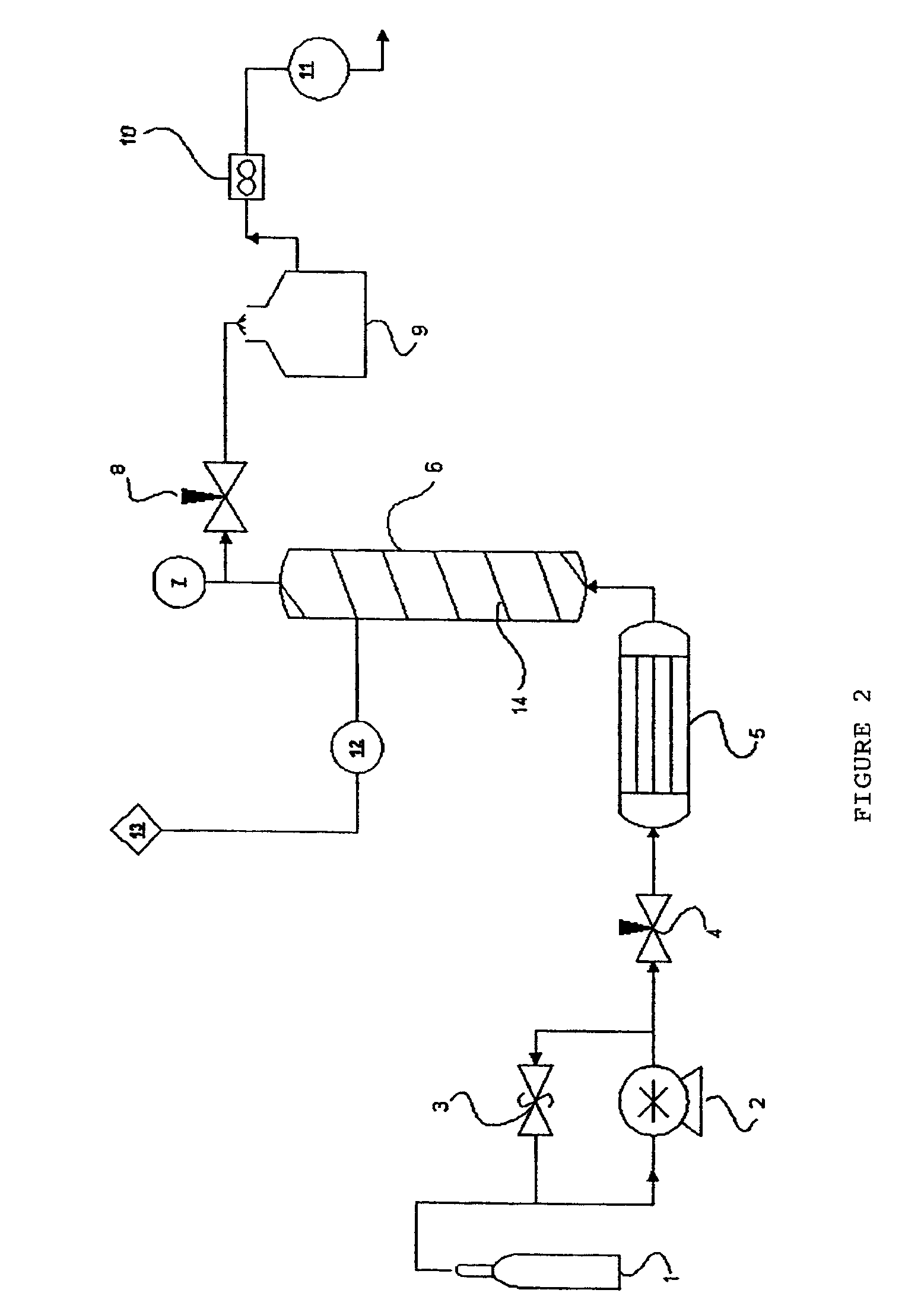

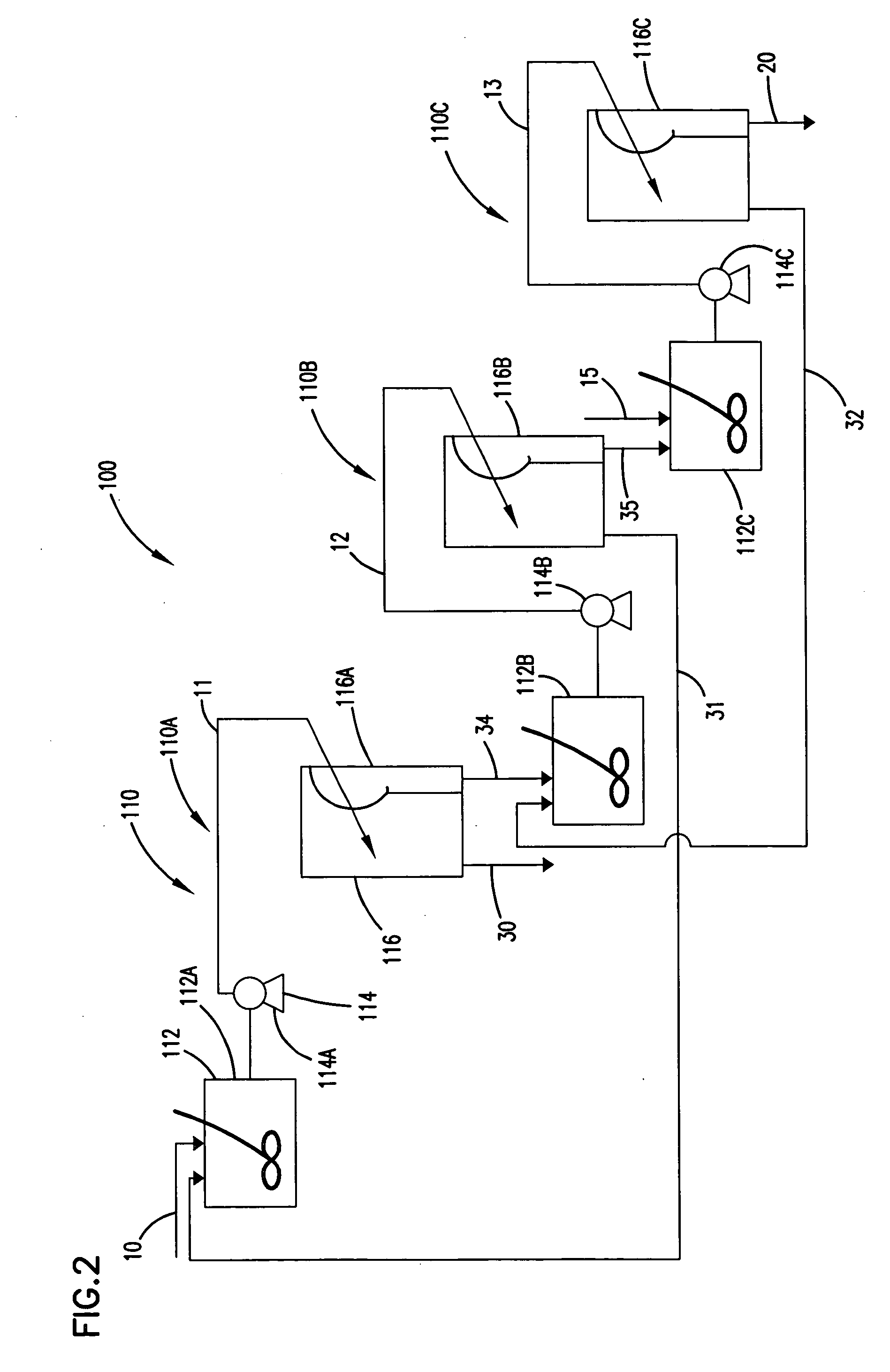

Process for radioisotope recovery and system for implementing same

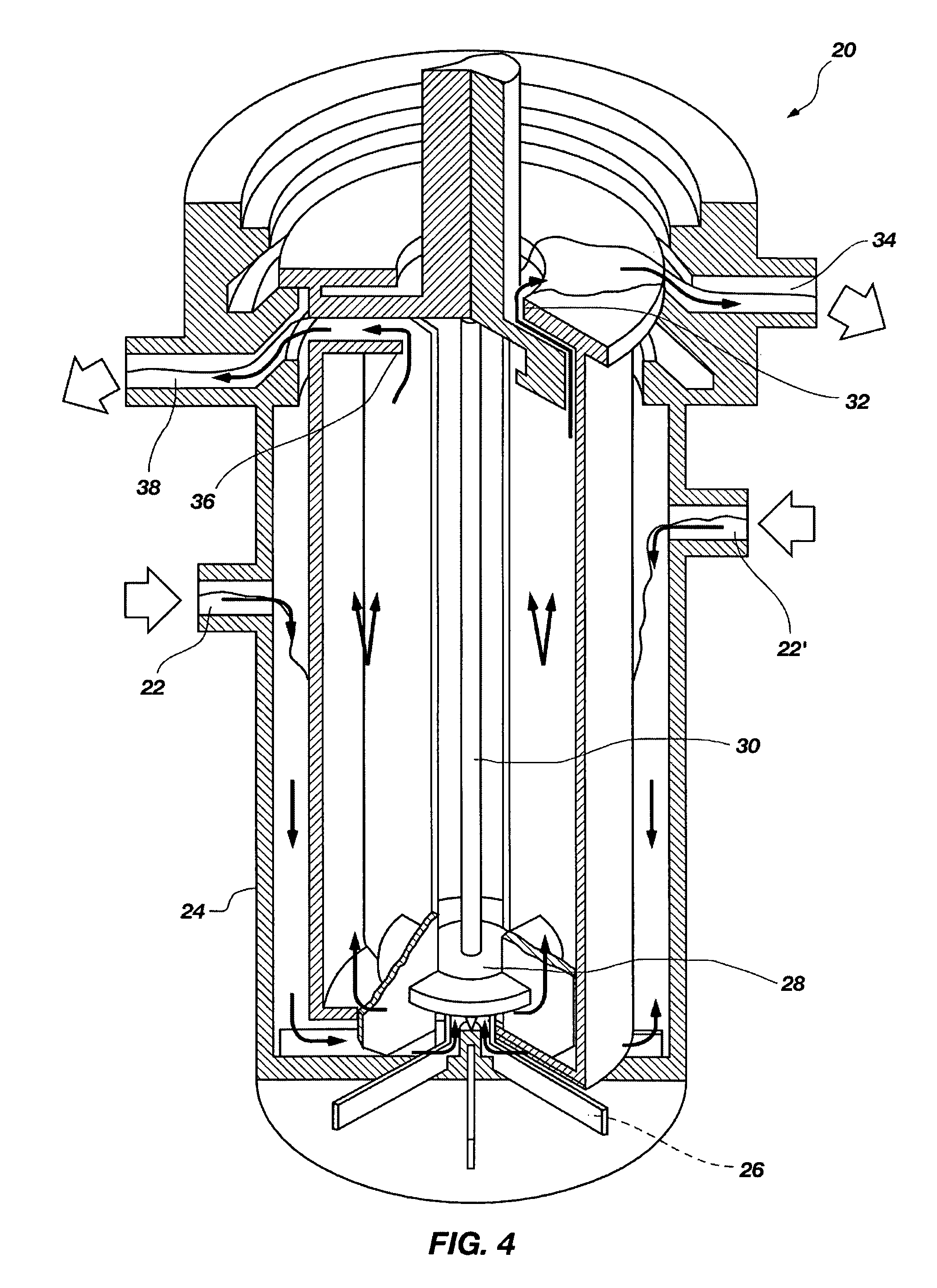

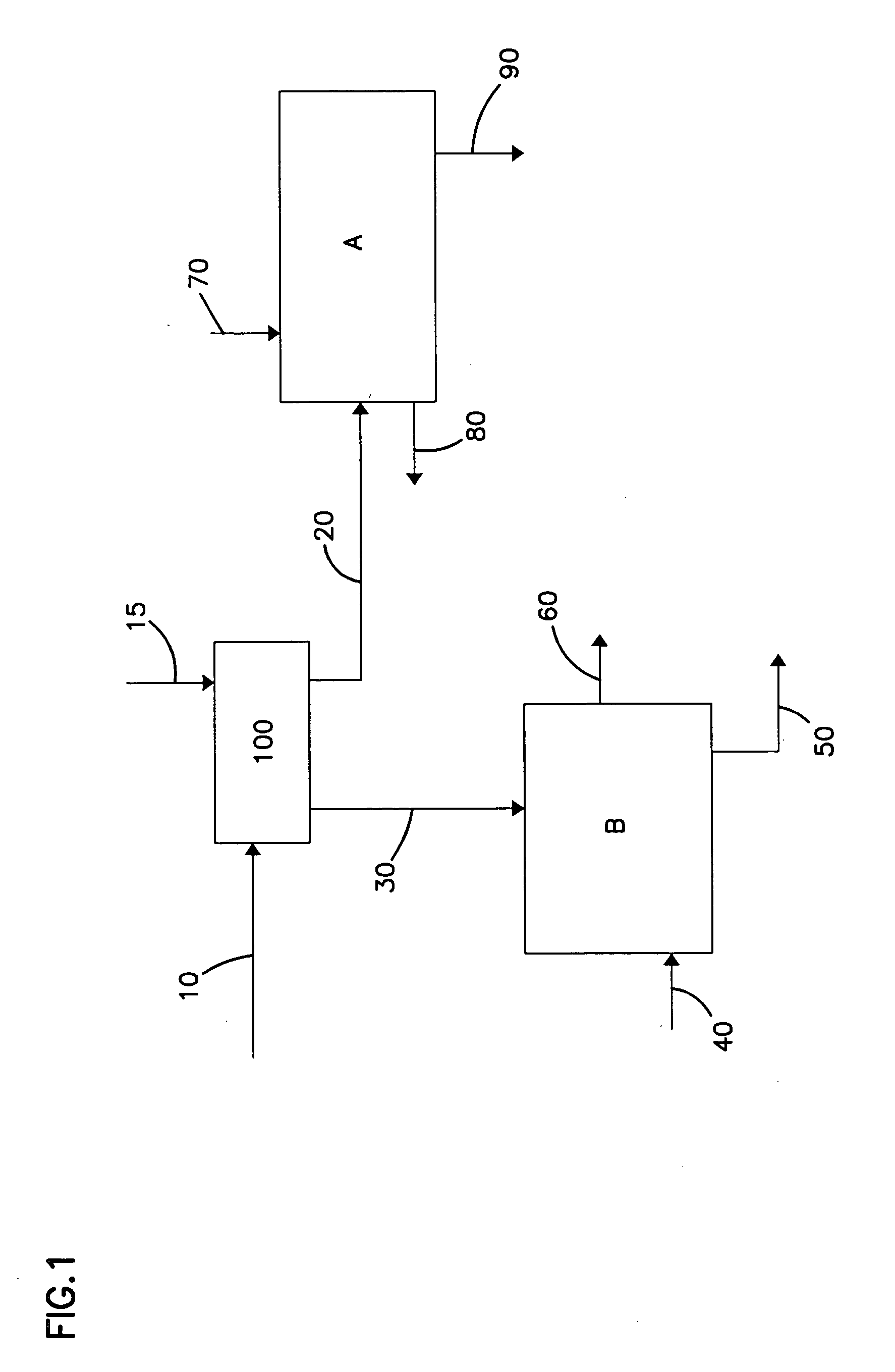

A method of recovering daughter isotopes from a radioisotope mixture. The method comprises providing a radioisotope mixture solution comprising at least one parent isotope. The at least one parent isotope is extracted into an organic phase, which comprises an extractant and a solvent. The organic phase is substantially continuously contacted with an aqueous phase to extract at least one daughter isotope into the aqueous phase. The aqueous phase is separated from the organic phase, such as by using an annular centrifugal contactor. The at least one daughter isotope is purified from the aqueous phase, such as by ion exchange chromatography or extraction chromatography. The at least one daughter isotope may include actinium-225, radium-225, bismuth-213, or mixtures thereof. A liquid-liquid extraction system for recovering at least one daughter isotope from a source material is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

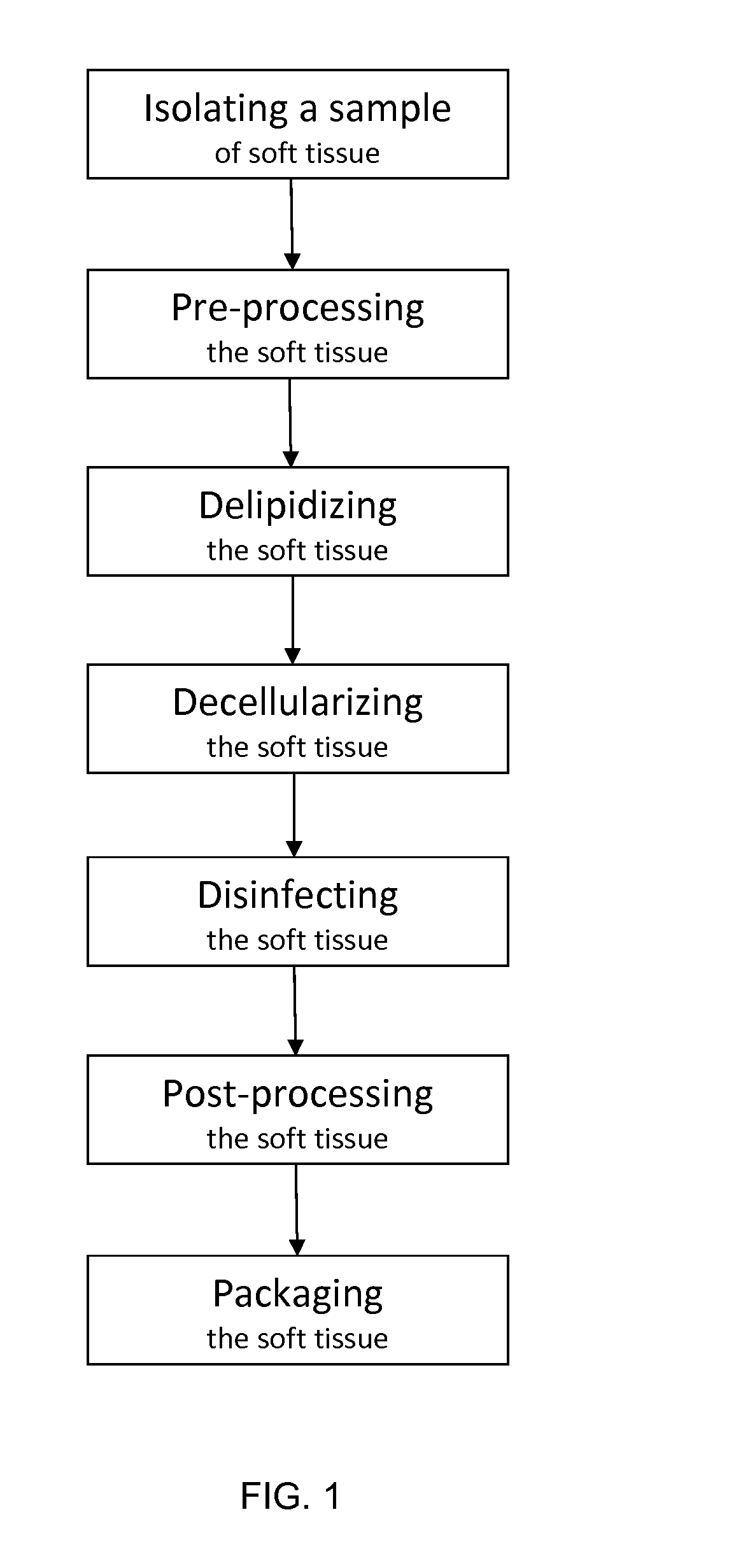

Acellular soft tissue-derived matrices and methods for preparing same

InactiveUS20150037436A1Mammal material medical ingredientsTissue regenerationTissue repairAcellular matrix

An acellular soft tissue-derived matrix includes a collagenous tissue that has been delipidated and decellularized. Adipose tissue is among the soft tissues suitable for manufacturing an acellular soft tissue-derived matrix. Exogenous tissuegenic cells and other biologically-active factors may be added to the acellular matrix. The acellular matrix may be provided as particles, a slurry, a paste, a gel, or in some other form. The acellular matrix may be provided as a three-dimensional scaffold that has been reconstituted from particles of the three-dimensional tissue. The three-dimensional scaffold may have the shape of an anatomical feature and serve as a template for tissue repair or replacement. A method of making an acellular soft tissue-derived matrix includes steps of removing lipid from the soft tissue by solvent extraction and chemical decellularization of the soft tissue.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

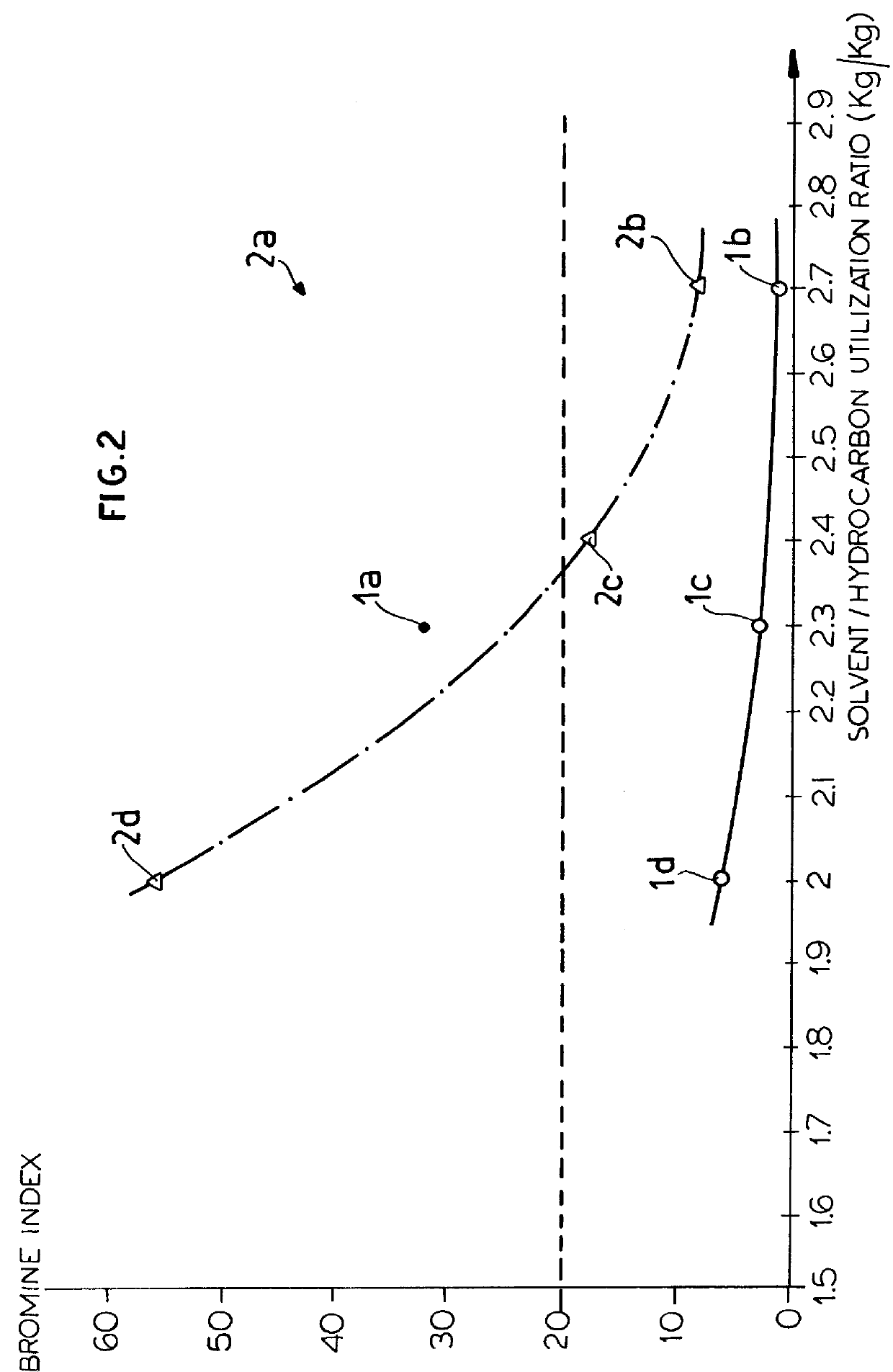

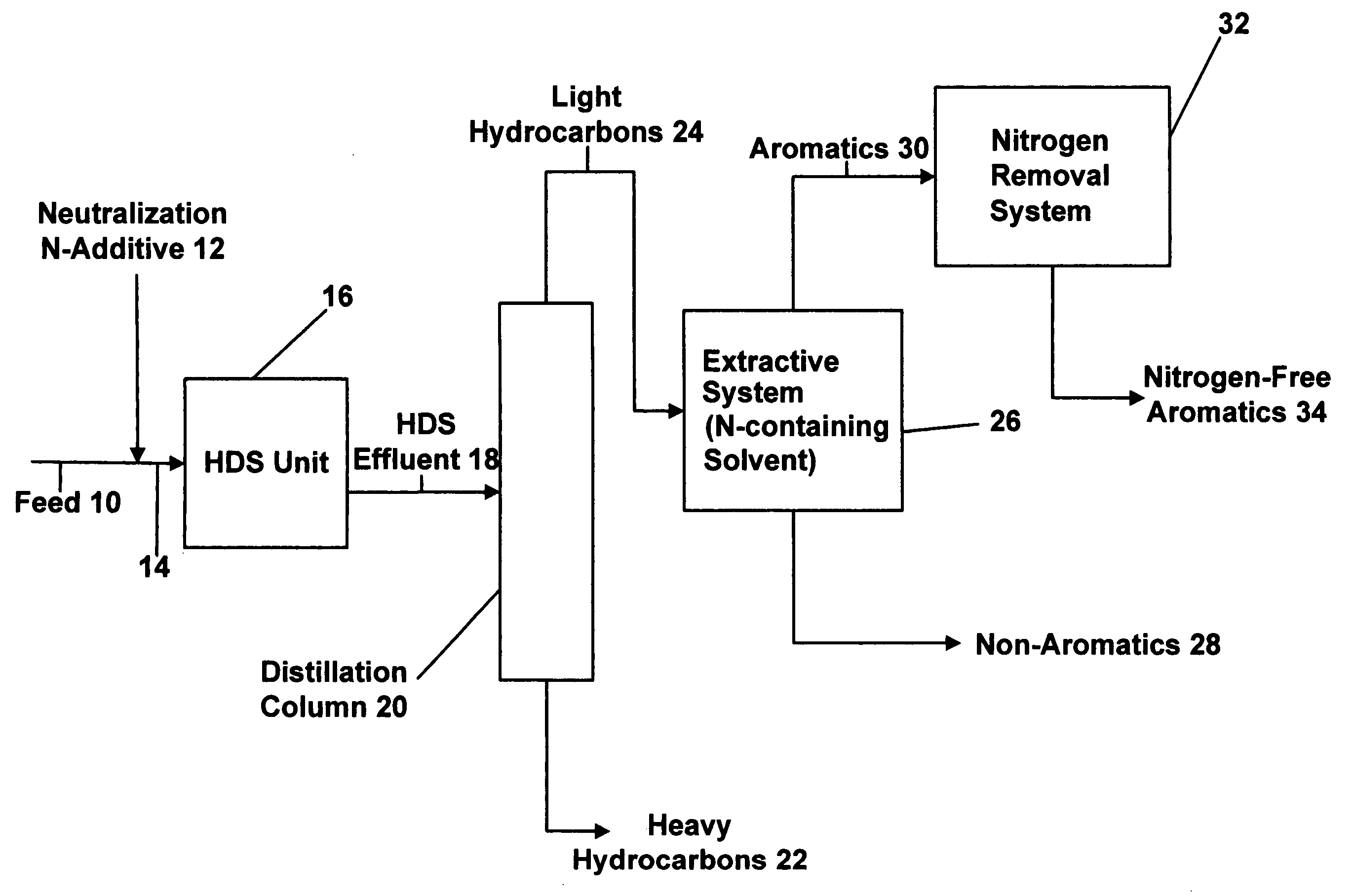

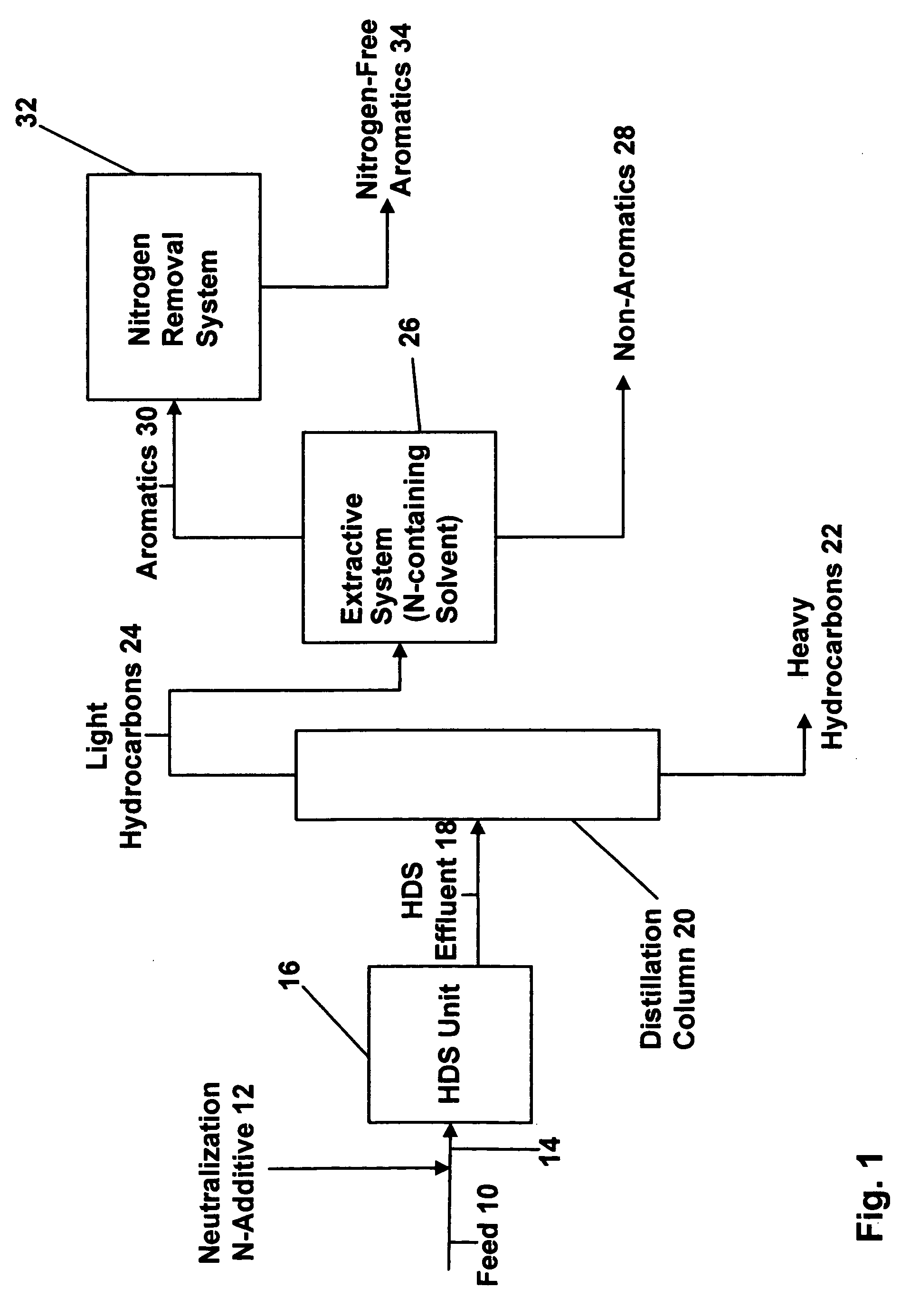

Process for producing petroleum oils with ultra-low nitrogen content

ActiveUS20070000809A1Highly effectiveSpeed up the extraction processHydrocarbon distillationTreatment with plural serial refining stagesLow nitrogenSolvent

A highly effective liquid-liquid extraction process to remove nitrogen compounds and especially basic nitrogen compounds from aromatic light petroleum oils with excellent recovery employs de-ionized water, which can be acidified, as the extractive solvent. The product is an aromatic hydrocarbon with ultra-low amounts of nitrogen poisons that can deactivate acidic catalysts. The extracted oils are suitable feedstock for the subsequent catalytic processes that are promoted with the high performance solid catalysts, which are extremely sensitive to nitrogen poison.

Owner:CPC CORPORATION +1

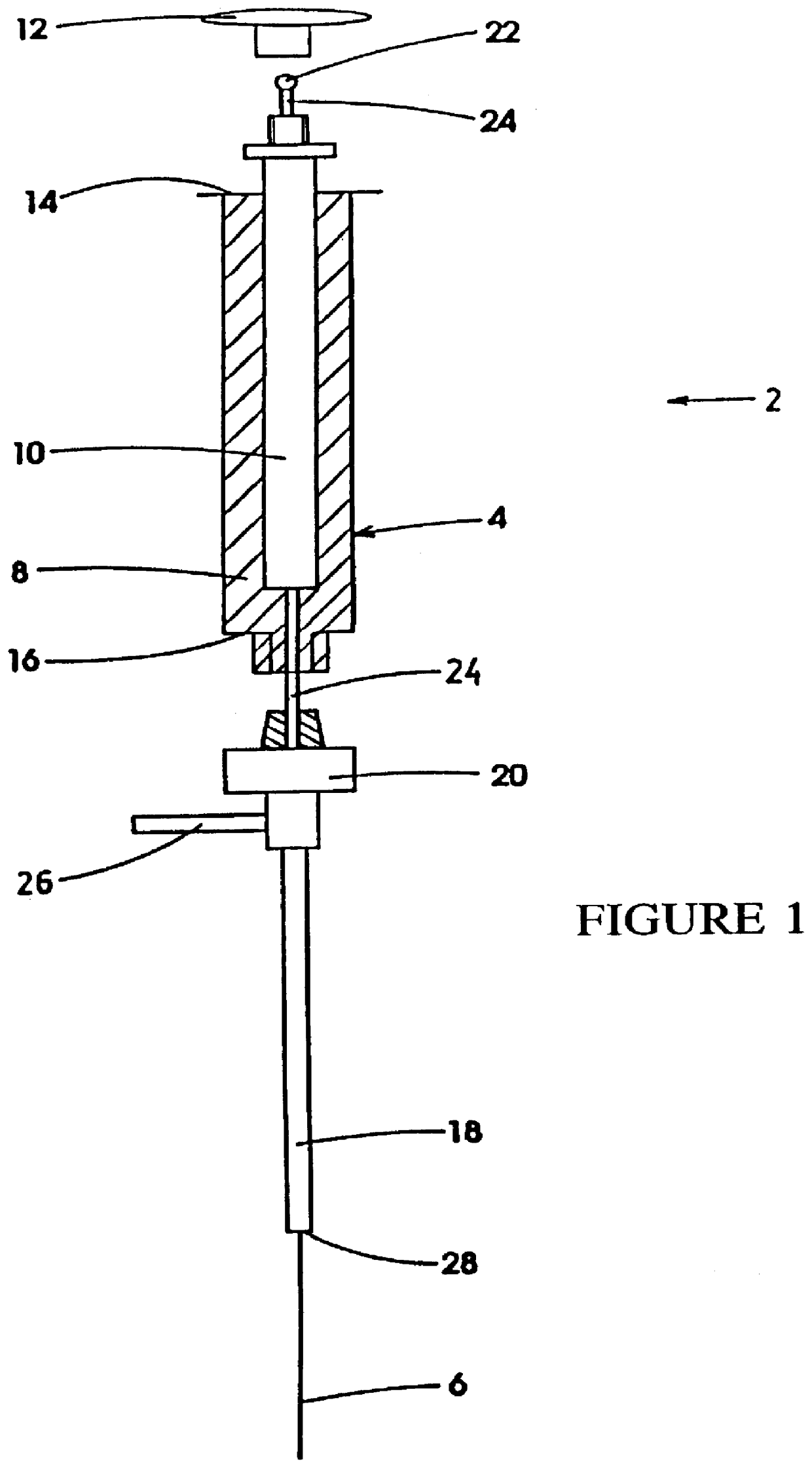

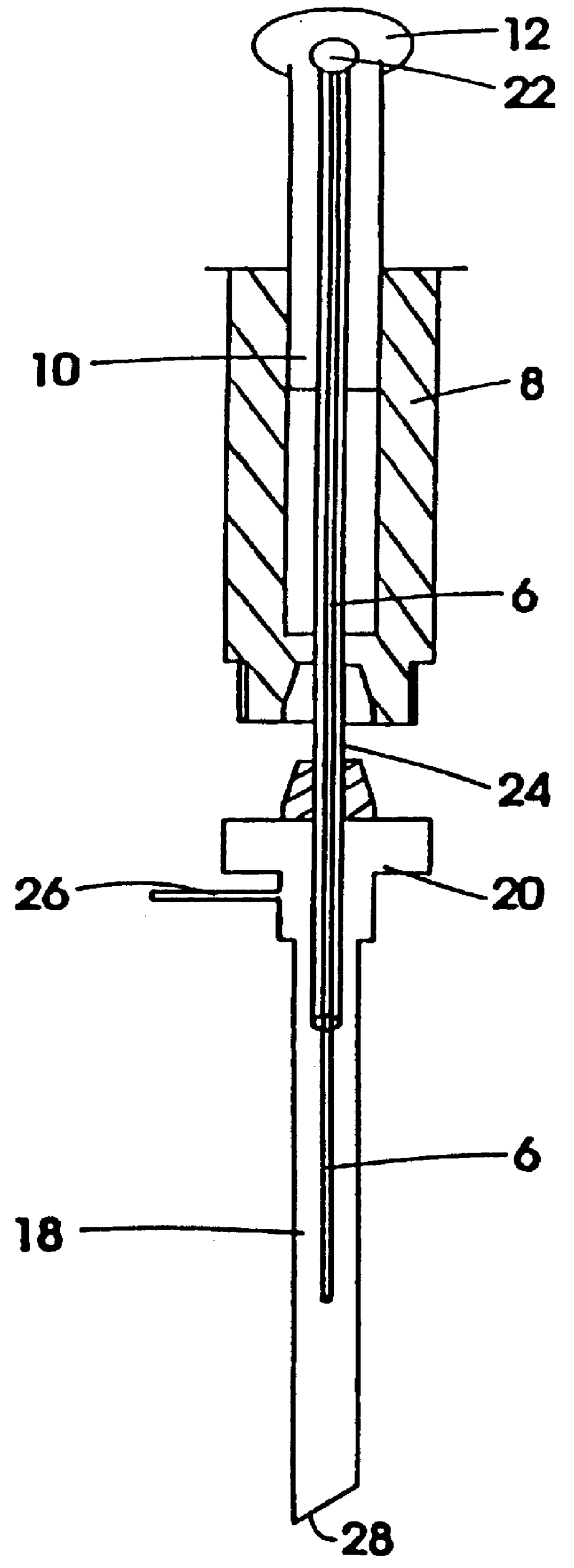

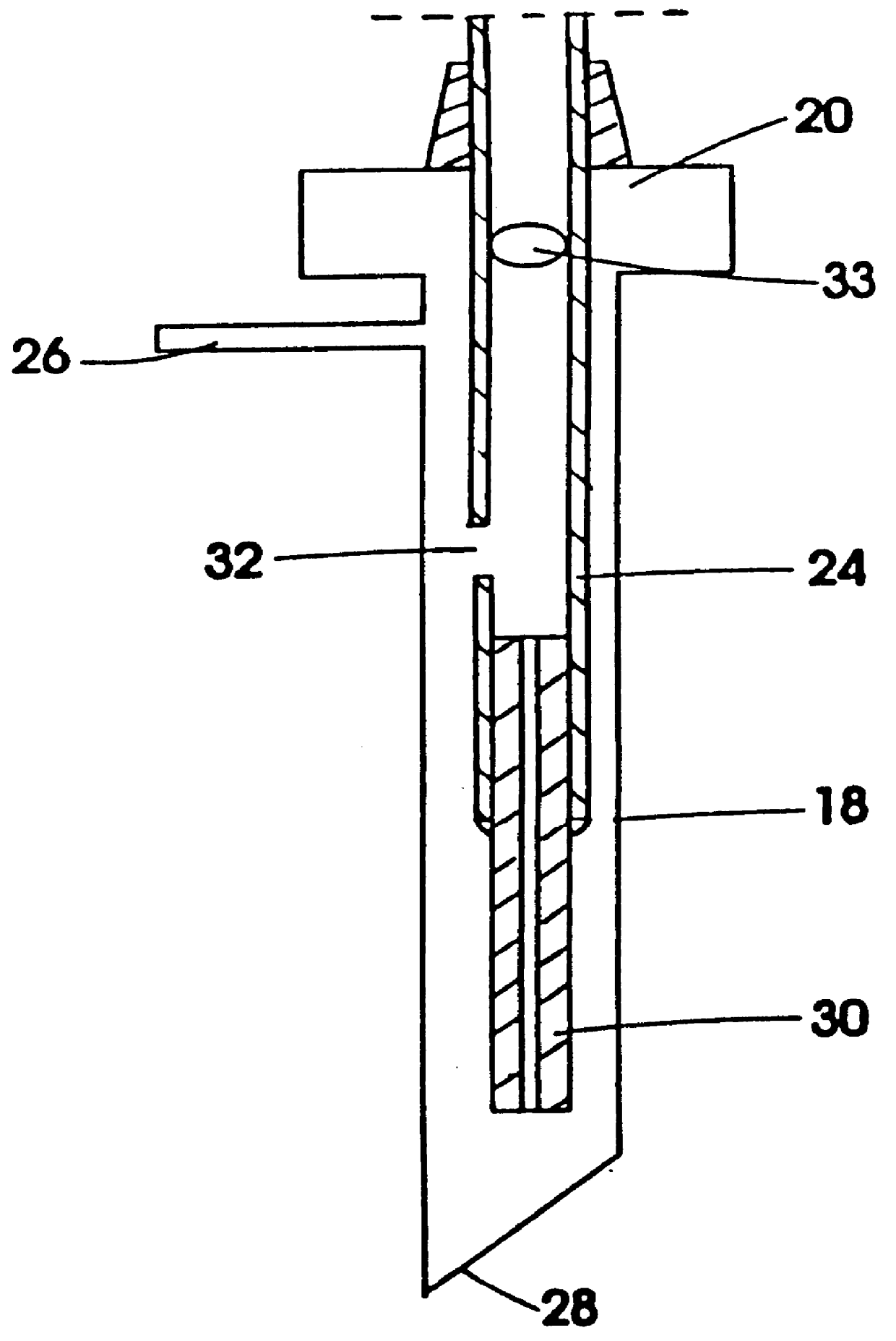

Device for solid phase microextraction and desorption

InactiveUS6042787AMaterial nanotechnologyAnalysis using chemical indicatorsAnalyteSolid-phase microextraction

A device for carrying out solid phase microextraction is a tubular member having one closed end and one open end with an extracting surface within said tubular member. The extracting surface can be an extracting phase coating extending over a zone within the tubular member. The tubular member has a heater that can be used for either or both drawing fluid carrier into the tubular member or assisting in desorbing analytes into an injector of an analysis instrument. The tubular member can also be mounted in a housing with an airtight cavity and a plunger. A method of operation of the device is also provided. Previously, samples were analyzed using liquid-liquid extraction or using cartridges. Both of these methods are relatively expensive and time consuming. Both of these methods also require the use of solvents which can be difficult and expensive to dispose of.

Owner:PAWLISZYN JANUSZ B

Desulfurization process

This invention is a method of purifying fuels containing organosulfur impurities. The fuel is oxidized with an organic hydroperoxide in the presence of an oxidation catalyst to form a sulfone product, followed by extraction of the sulfone product by solid-liquid or liquid-liquid extraction. The fuel is then contacted with a decomposition catalyst to remove the residual organic hydroperoxide from the fuel.

Owner:LYONDELL CHEM TECH LP

Method for preparing lithium carbonate by using salt lake brine with high magnesium-to-lithium ratio

InactiveCN101698488AReduce energy consumptionNo way outLithium carbonates/bicarbonatesEvaporationCalcination

The invention provides a method for preparing industrial lithium carbonate by using salt lake brine with a high magnesium-to-lithium ratio. In the method, a TBP-CON-KS+FeCl3 is used as an extraction system to extract and back-extract impurity-free salt lake brine with a high magnesium-to-lithium ratio, the residual liquid obtained after back-extraction is converted by alkaline liquor for precipitation, the precipitate is washed to form an industrial lithium carbonate product and the lithium carbonate content is more than or equal to 99.0 percent and is in accordance with the requirements of GB / T 11 075-2003 standards. The method has the advantages that: liquid-liquid extraction with an organic solvent is adopted to realize the separation of lithium from magnesium, the lithium carbonate is precipitated by inorganic slats, the lithium carbonate is extracted from the salt lake brine with a high magnesium-to-lithium ratio, the process is simple, the control is easy, the operational reliability is high and the application range is wide; a process of calcination and diluted lithium solution evaporation and concentration is saved, the energy consumption is only 30 to 50 percent of that of the conventional process for producing lithium carbonate by using lithium-containing brine; initial raw material consumption comparison show that the production cost of the method is only about 8 percent of that of the prior art; and the raw material brine can return to a storage pool after the extraction of the lithium carbonate, so no by production disposal problem is involved, environmental pollution is relatively low and lithium yield in the whole process is more than or equal to 70 percent.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

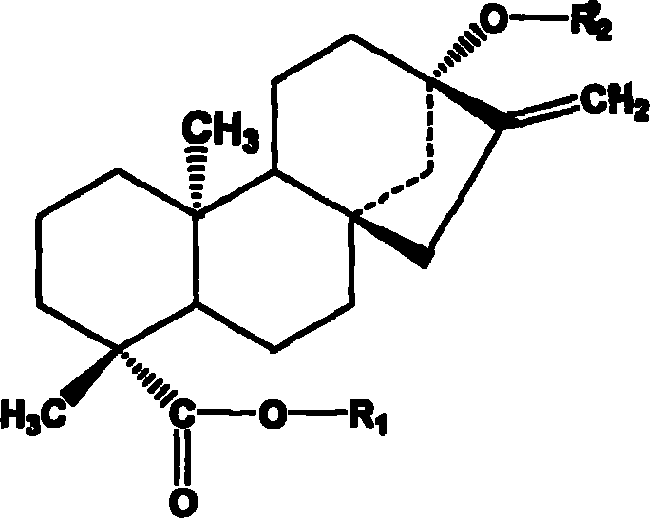

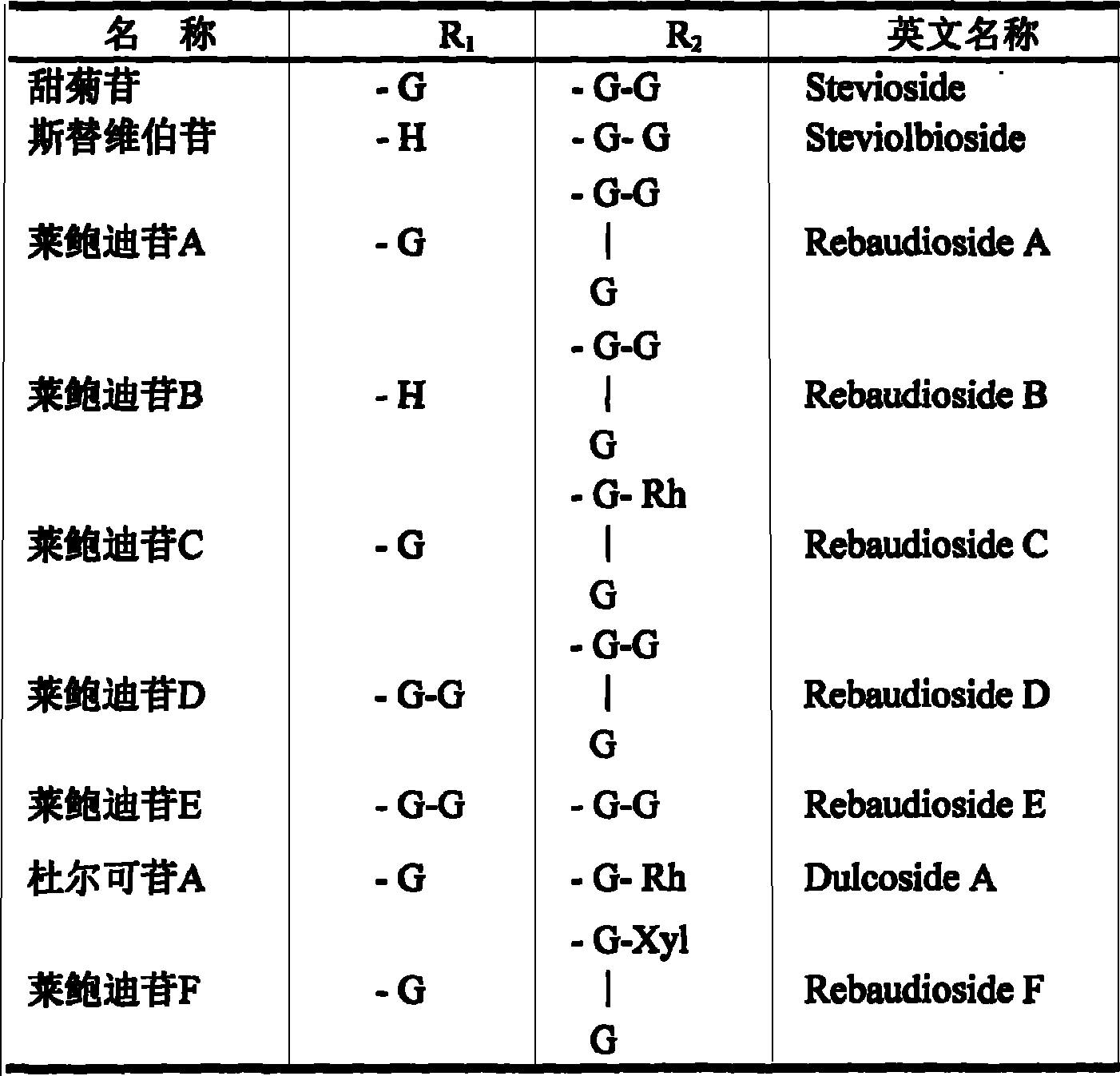

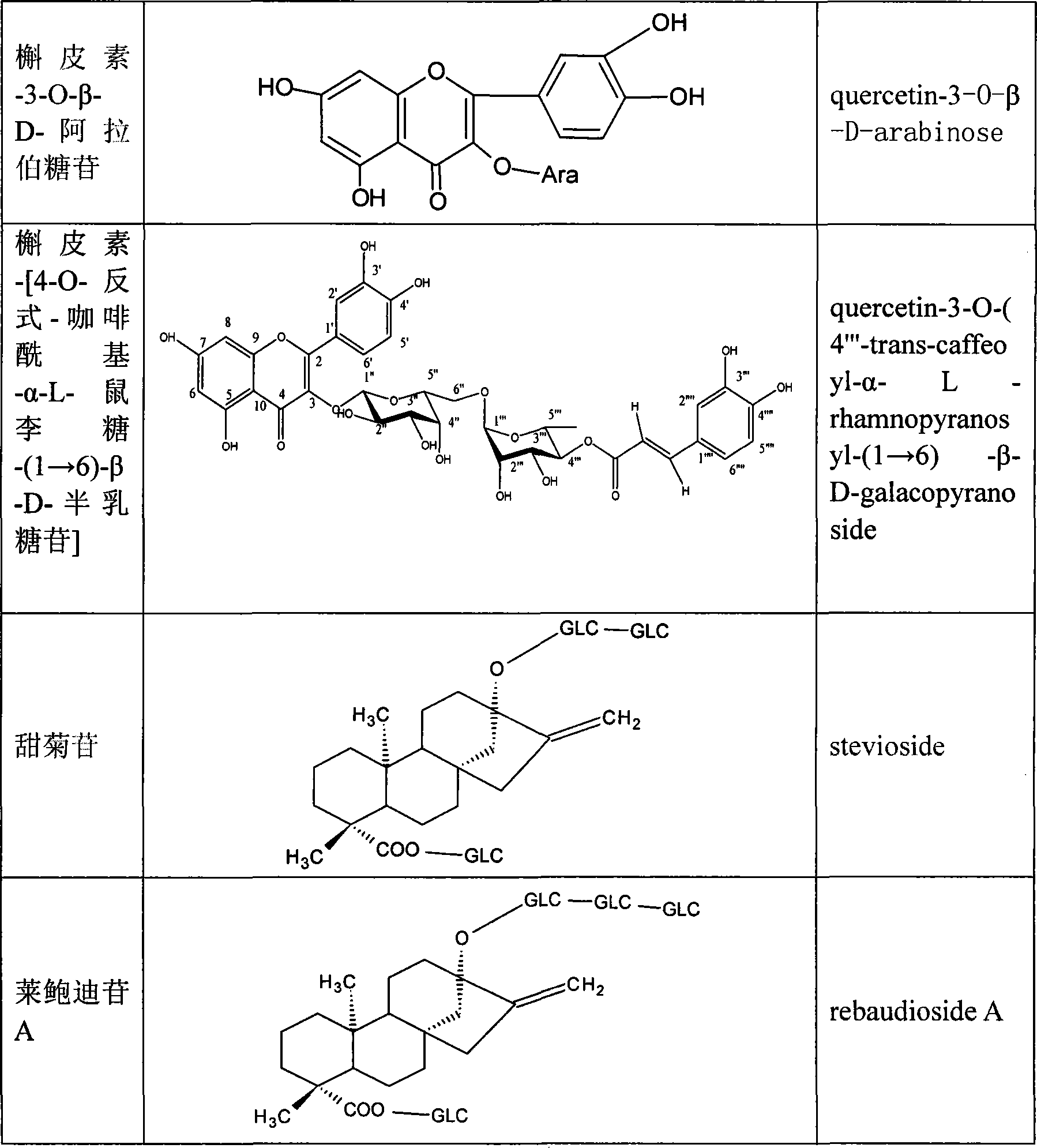

Method for preparing stevia whole stevioside and stevia whole flavone at the same time

ActiveCN101062077AImprove mildew resistanceConducive to food preservationSugar derivativesMetabolism disorderLuteolinGlucoside

The invention discloses a preparing method of total sweet chrysanthemum glycosides and total chromocor in sweet leaf chrysanthemum, which is characterized by the following: comprising sweet chrysanthemum glycosides, stevi primary glycosides, labroid glycosides A, B, C, D, E, F, duacl glycosides A and so on in total sweet chrysanthemum glycosides; comprising cyanidenon, meletin, cyanidenon-7-0-beta-D glycosides, celery element-7-0-beta-D-glycosides, quercetin, meletin-3-0-beta-D-arabinoside, meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside] and so on; choosing one or several methods from solvent extraction, solvent extraction process, macroreticular absorption resin method, column chromatography, supercritical fluid chromatography, liquid-liquid counter-current partition chromatography and so on; extracting the total chromocor; setting content of sweet chrysanthemum glycosides element in total sweet chrysanthemum glycosides at 5-100%; counting 5-100% of all sweet chrysanthemum glycosides content with sweet chrysanthemum glycosides and labroid glycosides; counting 5-100% of chromocor element in sweet leaf chrysanthemum total chromocor; counting 5-100% of all total chromocor content with cyanidenon-7-0-beta-D glycosides, quercetin and meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside].

Owner:石任兵 +1

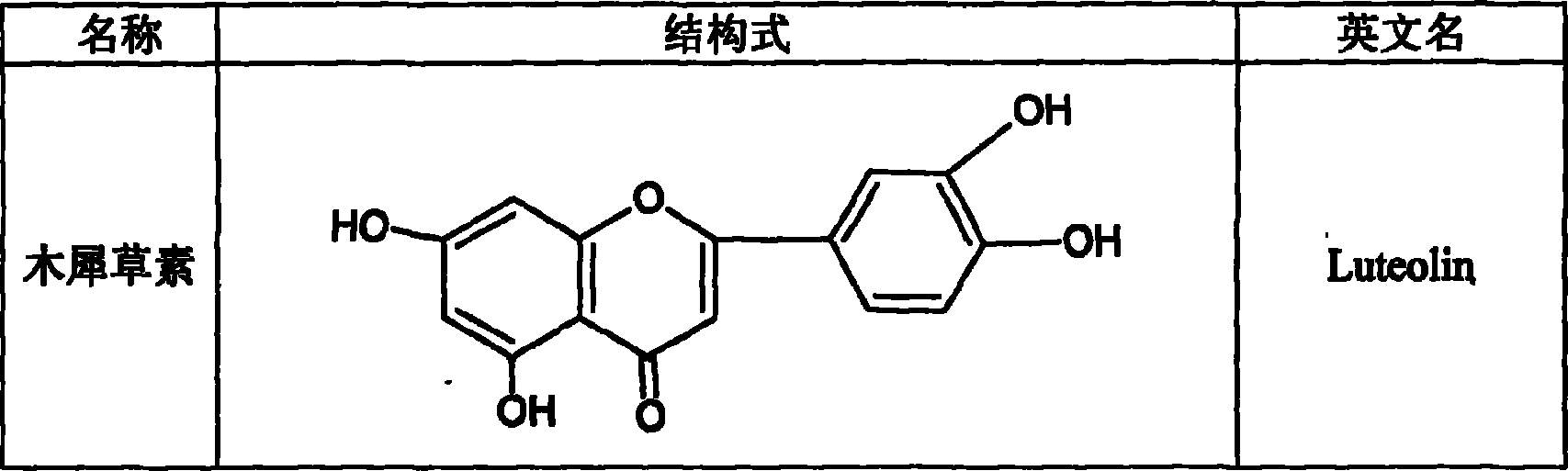

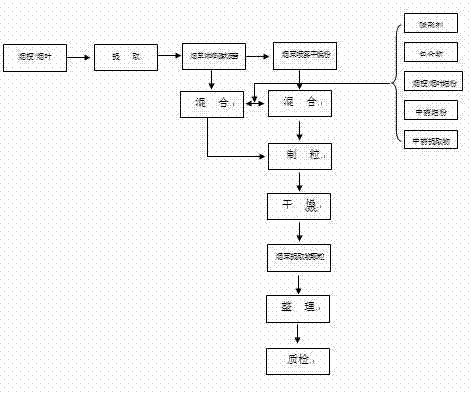

Preparation method of tobacco extract granules

The invention relates to a preparation method of tobacco extract granules, which comprises the following steps: firstly taking and cutting up tobacco leaves and / or tobacco stalks, taking water or ethanol or ethyl ether as a solvent for extraction, settling and filtering to obtain tobacco extract, then concentrating to the relative density of 1.00-1.30, and controlling the temperature to 20-40 DEGC to obtain tobacco extract concentrate or tobacco extractum; and including beta-cyclodextrin and flavouring essence for tobacco according to the mass ratio of 1-3:1 with the inclusion time of 1 / 5-3 hours to obtain a flavouring essence and beta-cyclodextrin inclusion compound, and then spray drying the flavouring essence for tobacco and beta-cyclodextrin inclusion compound and the tobacco extractconcentrate together to obtain tobacco spray dried powder; or directly spray drying the tobacco extractum to obtain the tobacco spray dried powder; and then adding excipient material to the tobacco spray dried powder for dry method or wet method granulation to obtain the tobacco extract granules. The tobacco extract granules obtained in the method disclosed by the invention are applied to cigarettes to improve the tar and harm reduction effect of the cigarettes, and can be used for aroma compensation, the utilization rate of waste tobacco leaf raw material is improved, and the cost of the cigarettes is reduced.

Owner:云南拓宝科技有限公司

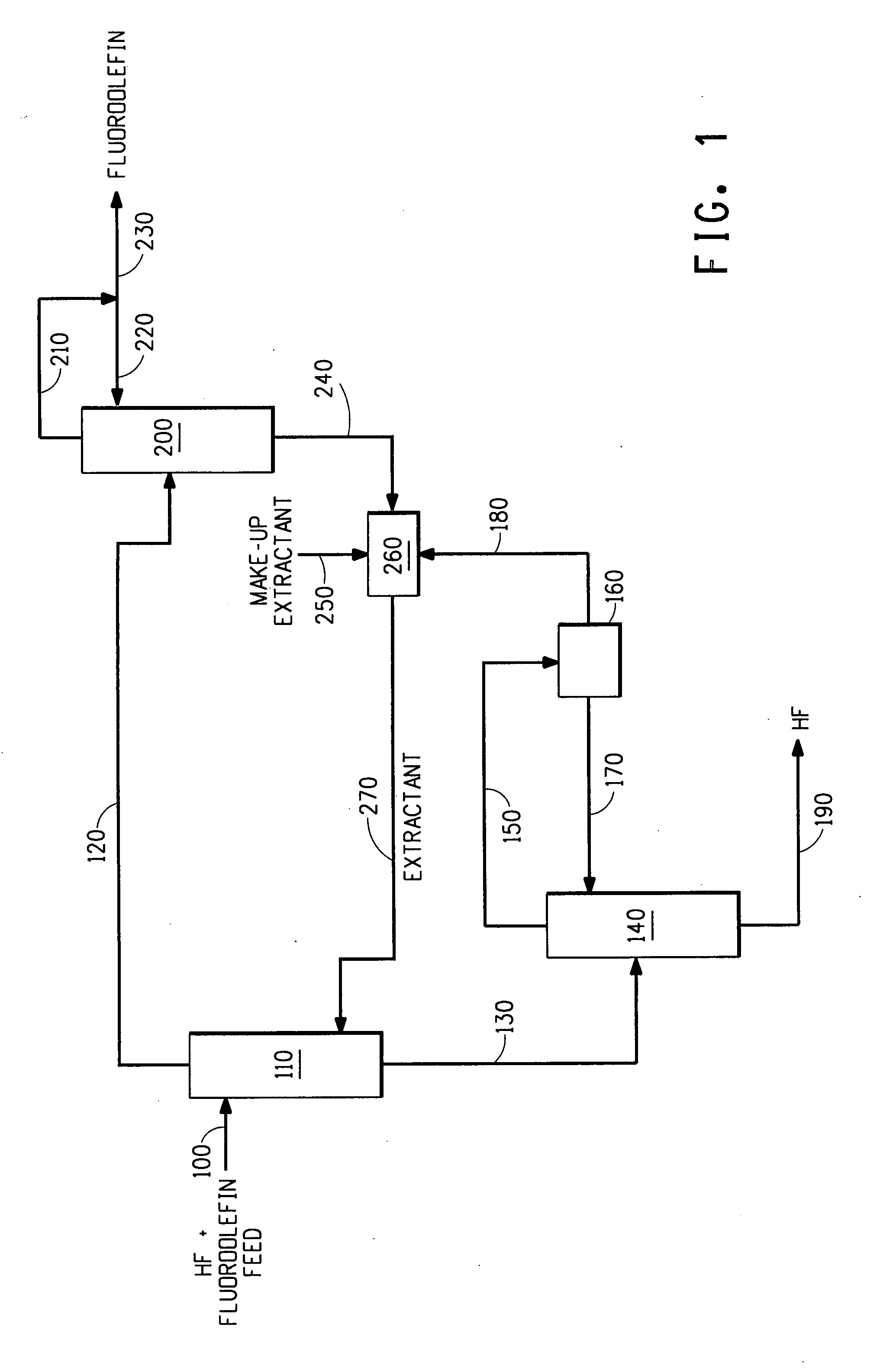

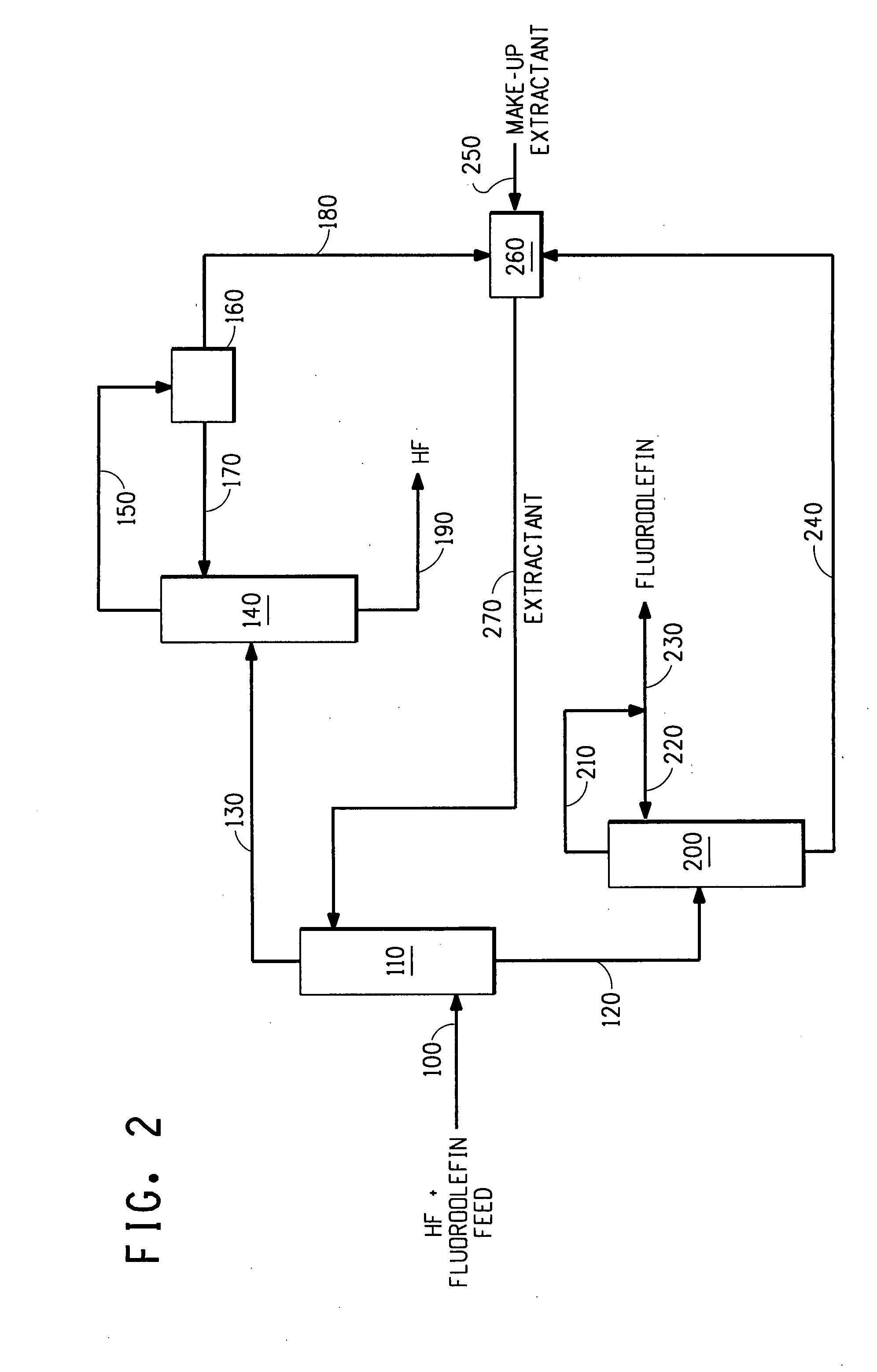

Process for separating a fluoroolefin from HF by liquid-liquid extraction

ActiveUS20080011678A1Water/sewage treatment bu osmosis/dialysisHalogenated hydrocarbon separation/purificationChemistryLiquid–liquid extraction

Owner:THE CHEMOURS CO FC LLC

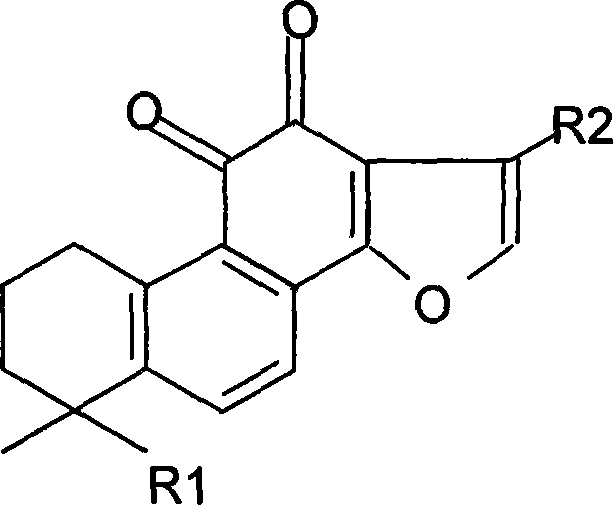

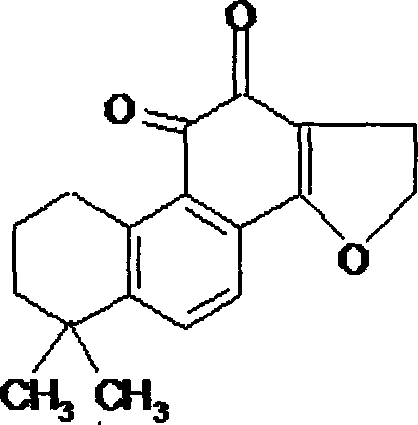

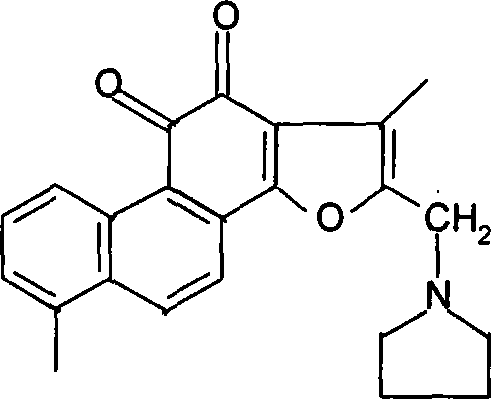

Total tanshinone and total phenolic acid extract in red-rooted salvia root and its production

The invention is concerned with a kind of extract of total ketone of salviae miltiorrhizae and total phenolic acid and its produce method form radix Salviae Miltiorrhizae. The extract of total ketone of salviae miltiorrhizae has cryptotanshinone, tanshinone I, tanshinone IIA, methyl Tanshinon, dihydrotanshinon I and ramification. The extract of total phenolic acid has salvianolic acid A, salvianolic acid B, protocatechuic aldehyde and ramification. The extract can be got form one or arbitrary compound of extraction with solvent method, macroporous resin method, column chromatography and liquid-liquid counter-current chromatography. The summation of the content to each total ketone of salviae miltiorrhizae is 20 to 100 percnte (w / w) of the extract of total ketone of salviae miltiorrhizae, the contene of cryptotanshinone, tanshinone I and tanshinone IIA is 5 to 100 percent (w / w) of whole content of total ketone of salviae miltiorrhizae. The summation of the content to each total phenolic acid is 5 to 100 percent (w / w) of the extract of the radix salviae miltiorrhizae total phenolic acid. The content of salvianolic acid B is the 5 to 100 percent (w / w) of the whole salvianolic acid.

Owner:石任兵 +1

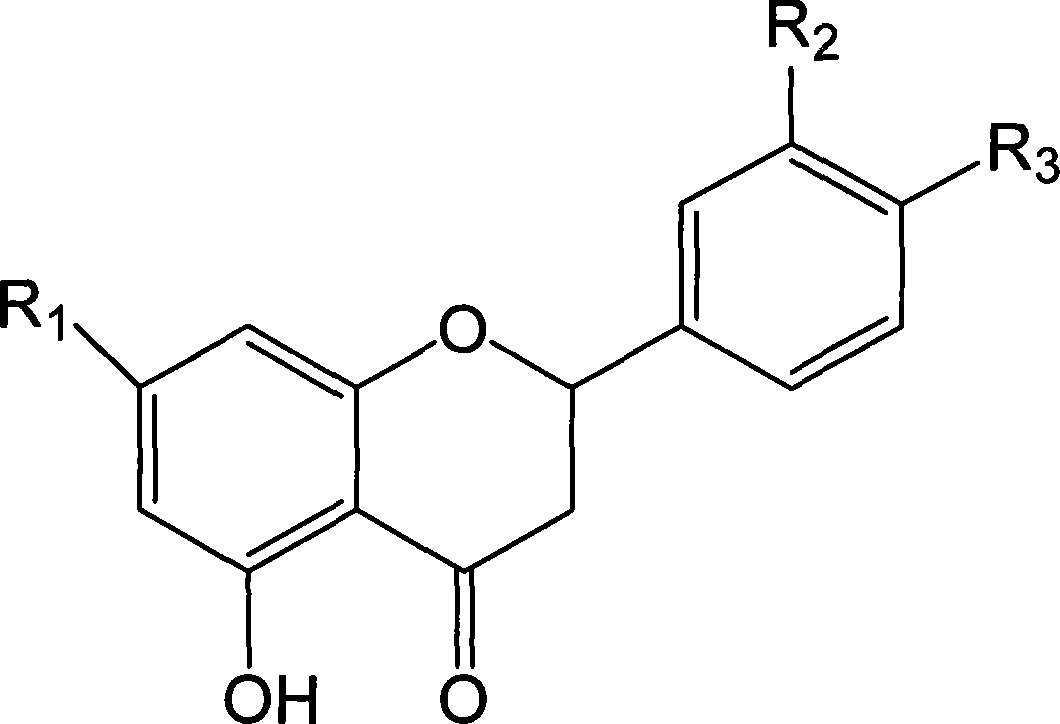

Citrus aurantium total flavone extract and the preparing method thereof

The invention discloses a total chromocor extract from traditional medicine citrus fruit and preparing method, which is characterized by the following: comprising pomelo ped glycosides, new orange peel glycosides, orange peel glycosides, pomelo ped rutin, derivant and so on; choosing one or several methods from solvent extraction, solvent extraction process, macroreticular absorption resin method, lead salt precipitation method, column chromatography, supercritical fluid chromatography, liquid-liquid counter-current partition chromatography and so on; producing extract; setting percentage content of various chromocor element at 5-100%(w / w) in the extract; counting 5-100%(w / w) of pomelo ped glycosides, new orange peel glycosides, orange peel glycosides in total chromocor content.

Owner:石任兵 +1

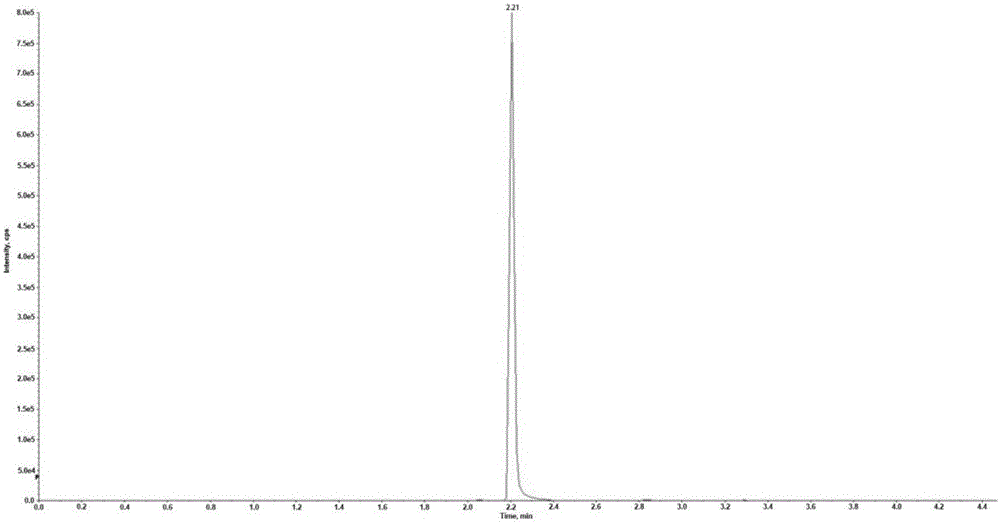

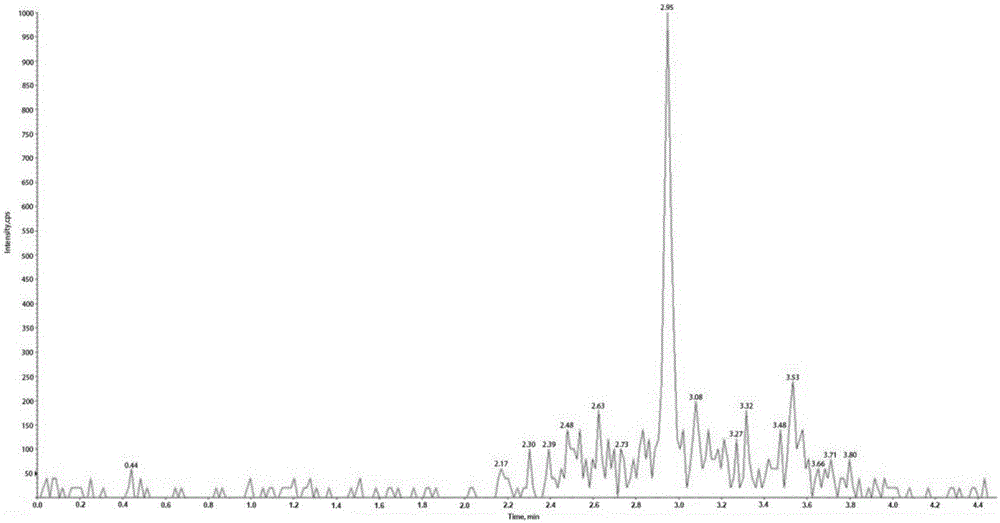

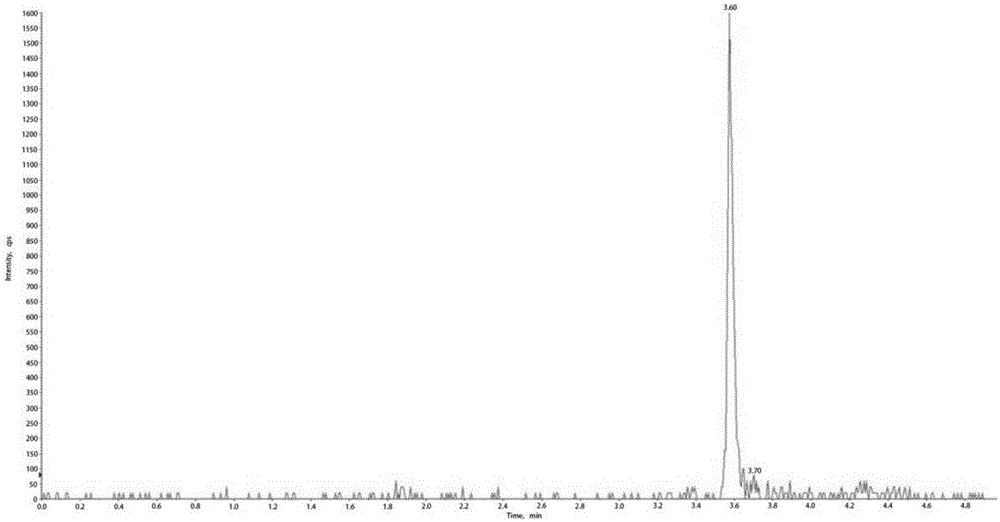

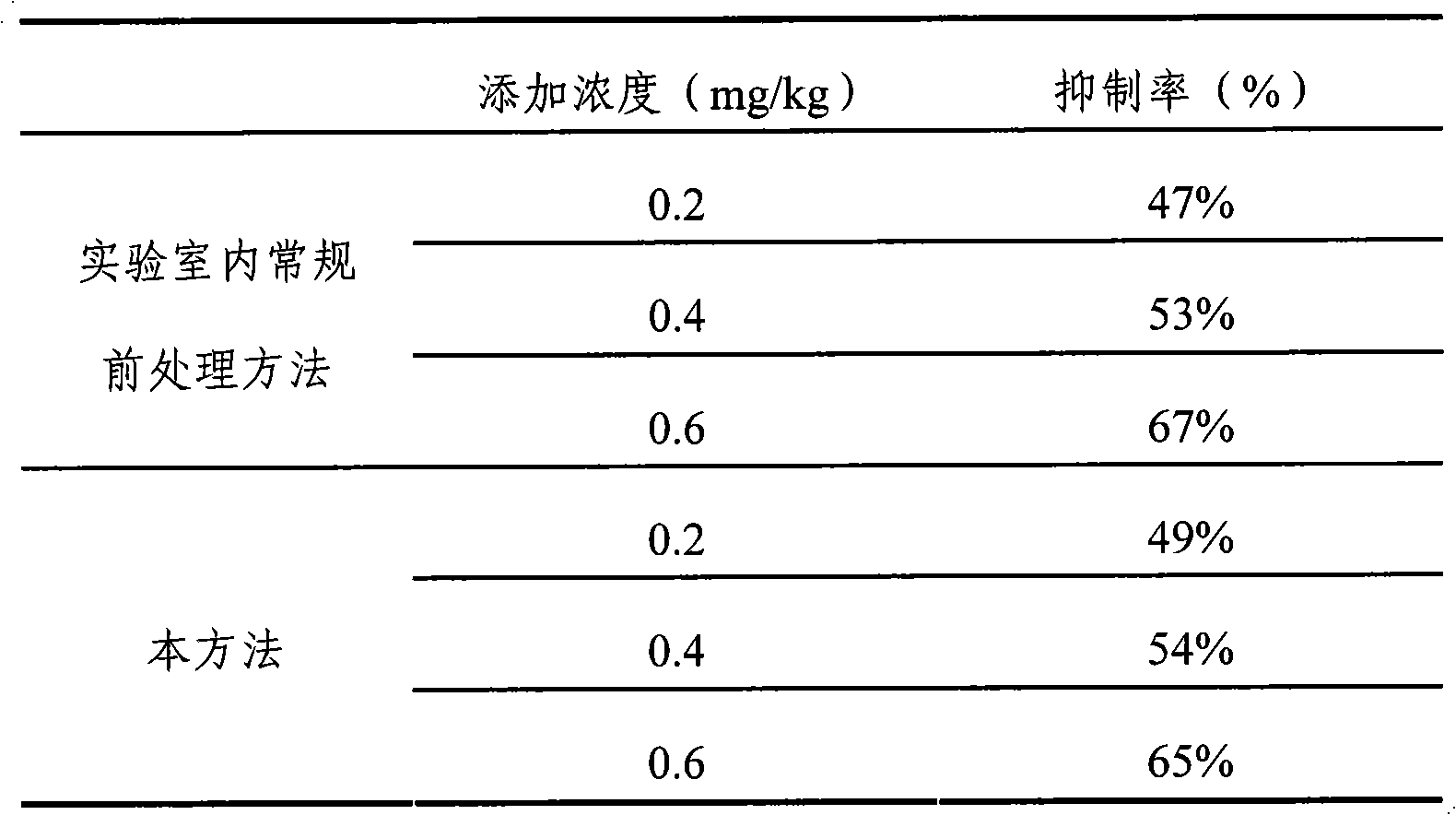

Method for detecting multiple lipid-soluble vitamins in blood sample simultaneously

ActiveCN105158394AEasy to handleImprove throughputComponent separationChromatographic separationThree level

The invention discloses a method for detecting multiple lipid-soluble vitamins in a blood sample simultaneously. The method comprises the steps of preprocessing a biological sample by a simple liquid-liquid extraction method, then carrying out chromatographic separation and mass spectrometric detection, respectively selecting a pair of qualitative ions and a pair of quantitative ions according to each vitamin, wherein the relative retention time and qualitative ion pairs of the various vitamins are taken as qualitative basis, and a standard curve for quantitation is formed by standard substances. Meanwhile, according to the method, three levels of quality control substances are used for inspecting the accuracy and effectiveness of the method, and the distortion of the detection result is avoided. According to the method, the purpose that six lipid-soluble vitamins in one serum sample can be simultaneously detected can be realized for the first time by applying an LC-MS technology, the influence caused by interferents can be alleviated, the operation is simple, convenient and rapid, the analysis time is only 4.8min, the throughput is high, the cost is low, the levels of lipid-soluble vitamins in a human body are effectively monitored, and the method has guiding significance on the reasonable and safe supplementation of vitamins, and is liable to clinical promotion and popularization.

Owner:JINAN YING SHENG BIOTECH

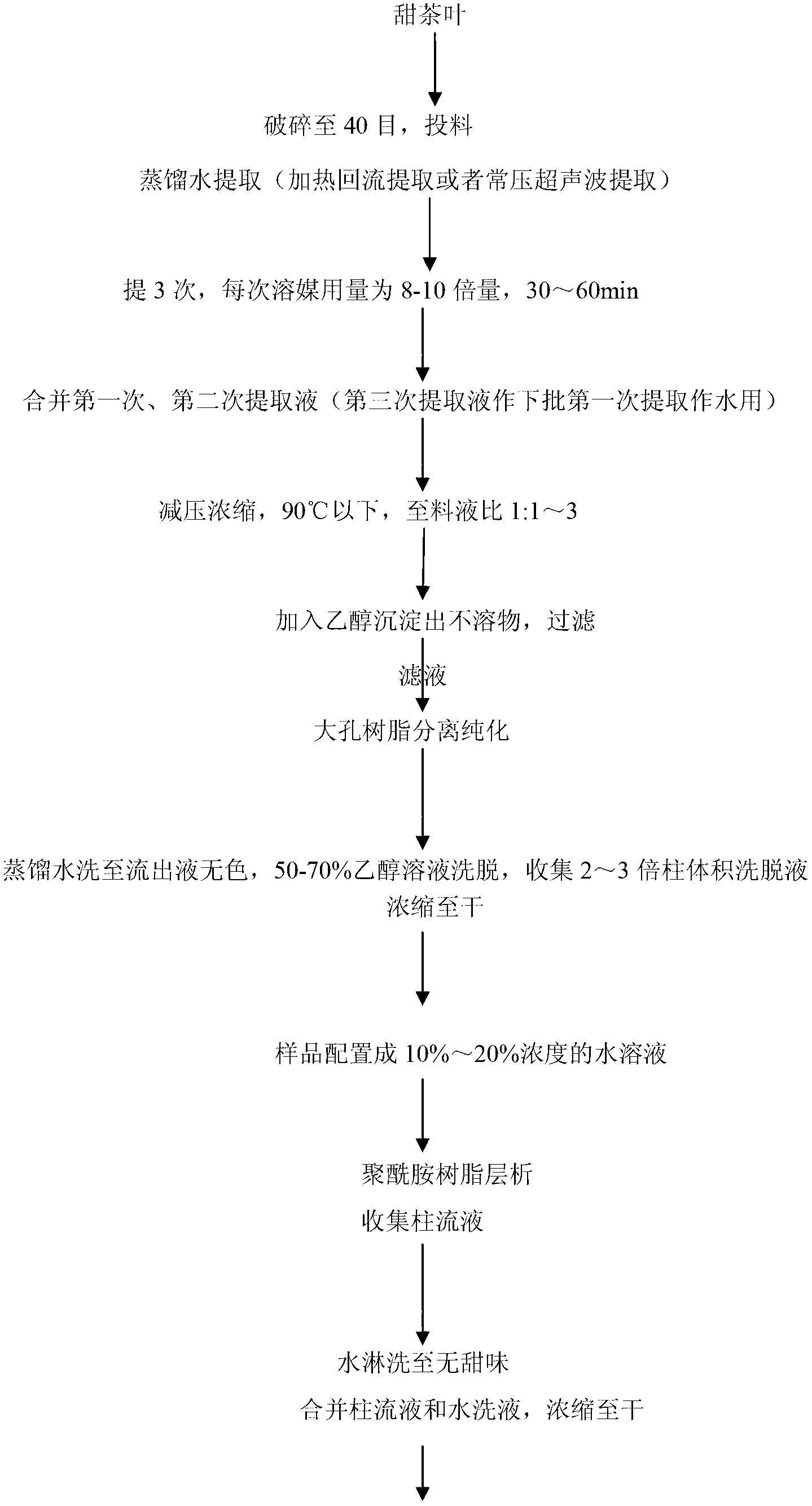

Production method for extracting sweet tea glucoside from sweet tea leaves

ActiveCN102838644AAvoid dependenceReduce manufacturing costSugar derivativesSugar derivatives preparationAlcoholSolvent

The invention provides a production method for extracting sweet tea glucoside from sweet tea leaves. The method comprises the following process flows of: smashing a sweet tea crude drug; extracting a solvent; concentrating; precipitating with alcohol; purifying with macroporous resin; concentrating; carrying out chromatography with polyamide resin; concentrating; crystallizing and recrystallizing; drying; and obtaining a finished product. By using the method, a high-quality sweet tea glucoside product can be produced, and the method also has the advantages of reducing the material loss, shortening the production period, improving the product yield and reducing the production cost and is suitable for the industrial production; the purity of the sweet tea glucoside produced by utilizing the method is higher than 98 percent, so that the product purity is high, and the component is single; the color of the sweet tea glucoside is white and good; and meanwhile, the technical difficulty of industrially producing a high-content and high-quality sweet tea glucoside extractive is overcome, so that large-scale production is smoothly produced.

Owner:HUNAN NUSTREETCARAX

High pressure liquid-liquid extraction method

InactiveCN102179063AReduce labor intensitySimple and fast operationLiquid solutions solvent extractionOrganic solventZone melting

The invention discloses a high pressure liquid-liquid extraction method, which comprises the step of sealing and refrigerating solution requiring extraction and organic extraction solvent in a pressure resistant container, the volume of water increases below 4 DEG C and in the solidification process of water to ice, so the pressure in the pressure resistant container increases to improve the dissolubility of organic impurities in organic solvent during extraction, and simultaneously, based on the principal of zone melting, the organic impurities are squeezed out of ice in the solidification process of water to ice, thereby further enhancing the extraction efficiency. The liquid-liquid extraction method has the advantages of being low in labor intensity, simple and convenient in operation and short in extraction time, and can improve the extraction effect remarkably.

Owner:SOOCHOW HIGH TECH CHROMATOGRAPHY

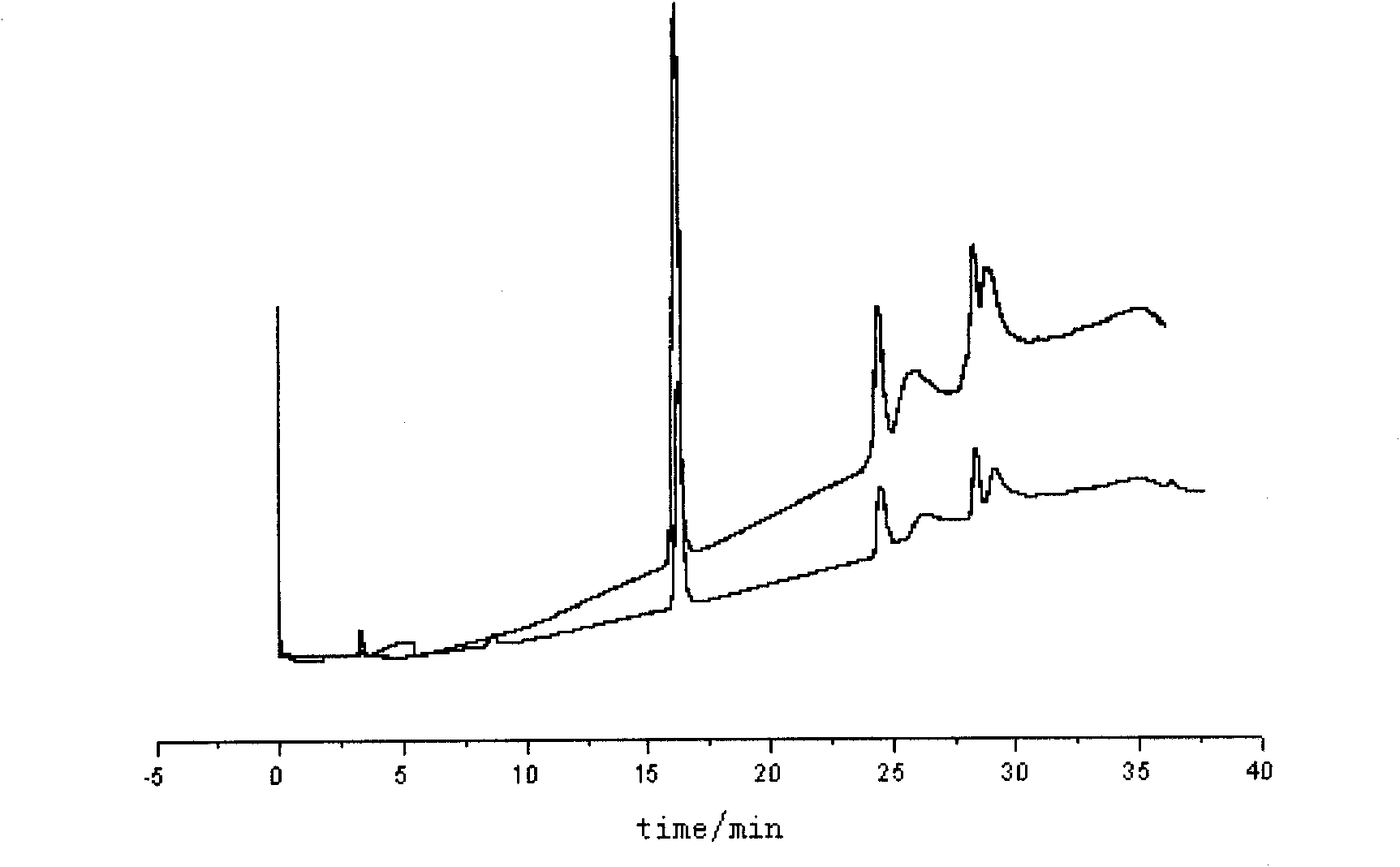

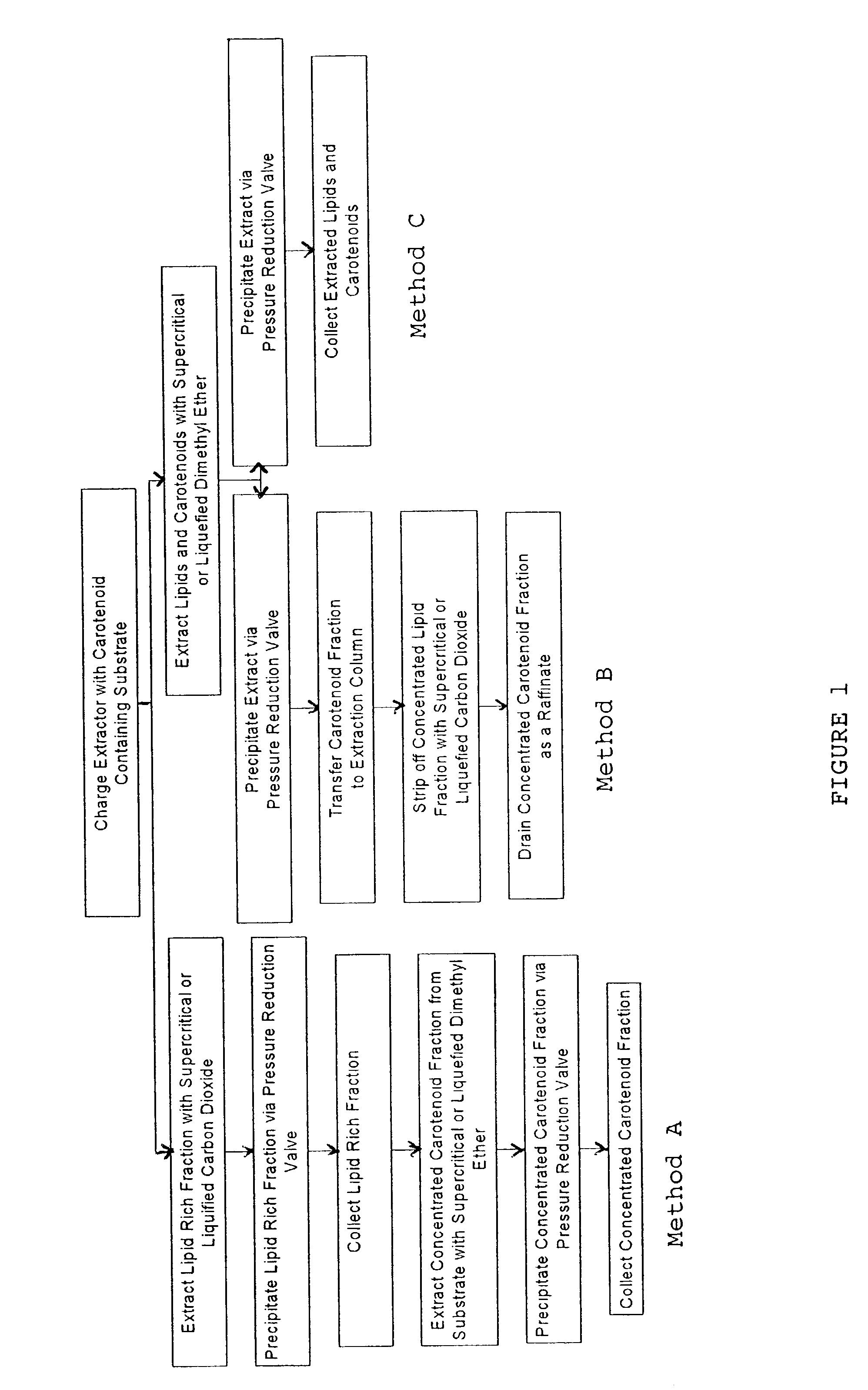

Method for extraction and concentration of carotenoids using supercritical fluids

ActiveUS7329789B1Hydrocarbon purification/separationWater/sewage treatment bu osmosis/dialysisLipid formationOrganic solvent

Carotenoids are extracted and / or enriched from a mixture containing such compounds. The extraction / enrichment process involves the use of liquefied or supercritical solvents to extract lipids and carotenoids from carotenoid-containing substrates. The extraction process can also be performed in two steps in which lipids and carotenoids are first removed from a carotenoid-containing substrate with a liquefied or supercritical solvent, and subsequently a liquefied or supercritical gas is used to separate the lipids from the carotenoids. The two step process can be reversed to first extract lipids with the liquefied or supercritical gas, and subsequently use the solvent to extract the carotenoids. The process is also applicable to yield an organic solvent-free product from a carotenoid-containing source that was first extracted using an organic solvent.

Owner:GREEN RECOVERY TECH

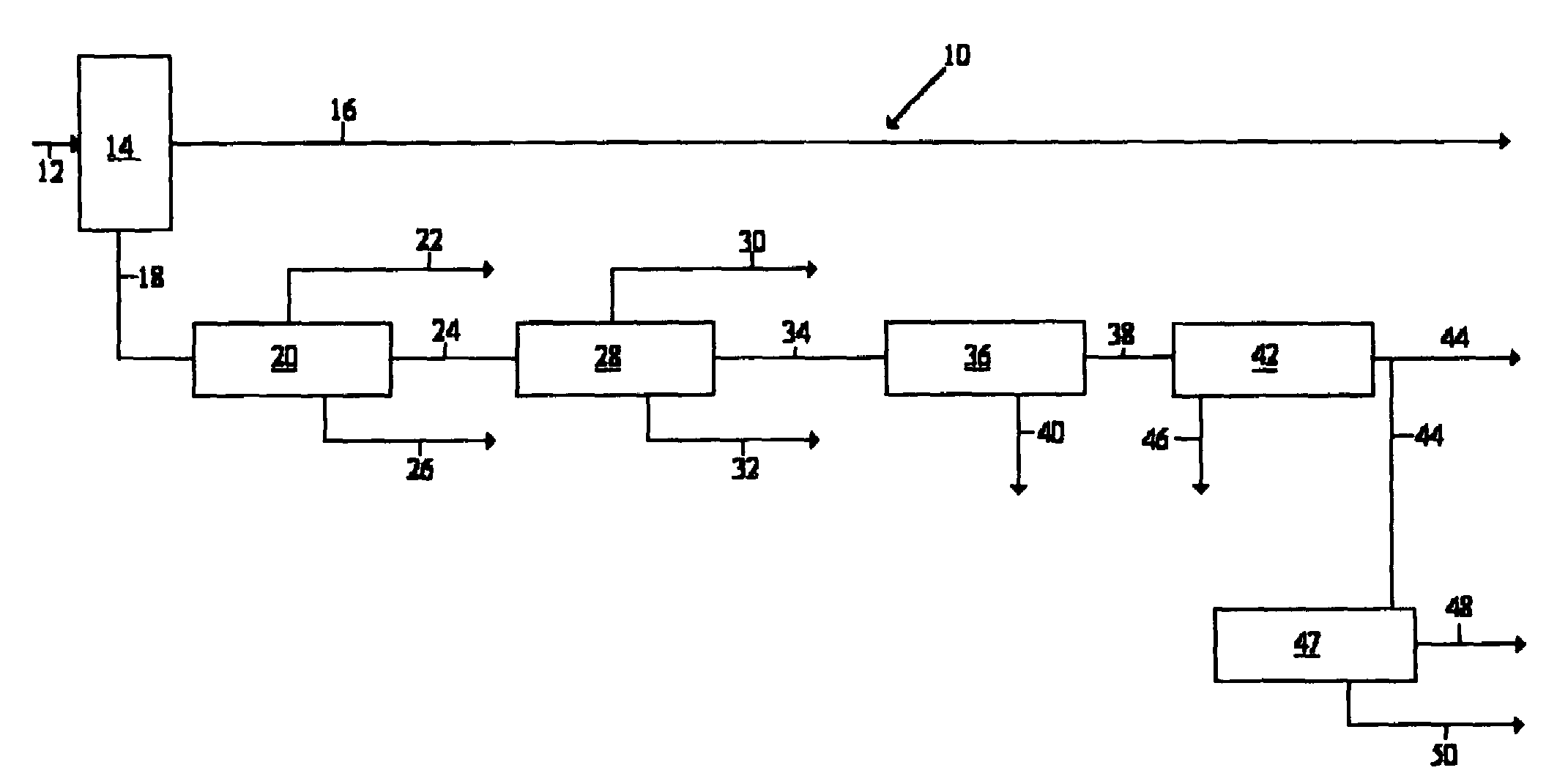

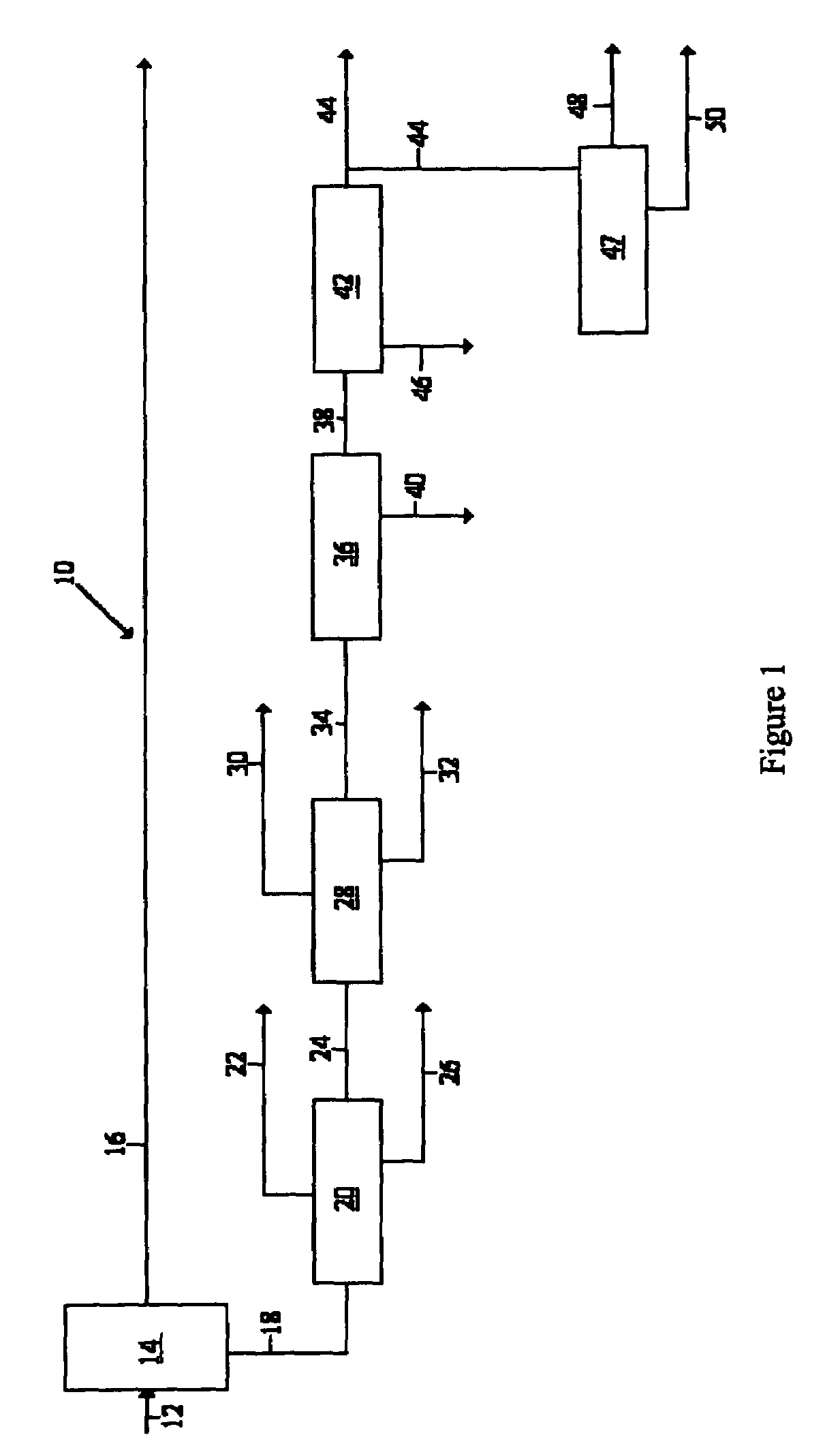

Method of purifying fischer-tropsch derived water

InactiveUS7150831B2Simplify and reduce costsTreatment using aerobic processesUltrafiltrationOrganic acidTotal dissolved solids

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

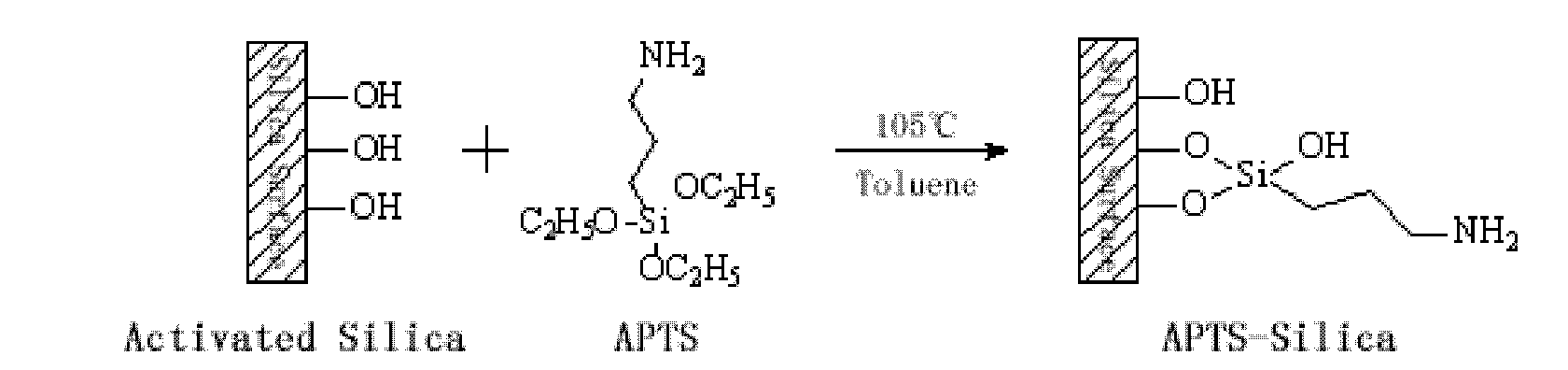

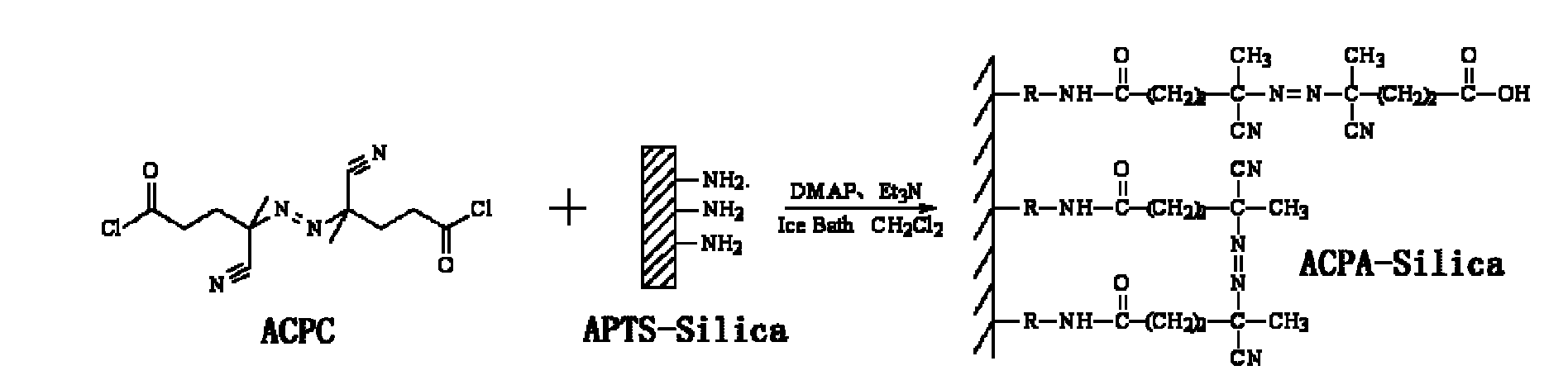

Preparation method and application of molecular imprinted polymer on silica surface for specifically adsorbing patulin

A preparation method and application of a molecular imprinted polymer on the silica surface for specifically adsorbing patulin belong to the technical field of bioassay. The method comprises the following steps: firstly pretreating the silica surface; siliconizing the silica surface to prepare APTS-silica and introducing amino groups; preparing ACPA-silica by dewatering and esterifying or an acyl chloride intermediate method and grafting an azo initiator on the silica surface; and finally taking the patulin analog 2-hydroxynicotinic acid as a template to replace molecules, taking acrylamide, methylacrylic acid, 4-vinyl pyridine and trifluoromethyl acrylic acid as the functional monomers and taking ethylene glycol dimethacrylate (EDMA) as a cross-linking agent to obtain the molecular imprinted polymer on the silica surface in acetonitrile and pyridine solvents by thermal initiation. The invention has the following advantages: as the pretreatment method for liquid chromatography of trace patulin in apple juice and related products, the polymer prepared by the invention can specifically adsorb the enriched patulin, the sample is simply and quickly treated and can be reused multiple times, and the polymer is resistant to acid and alkali treatment and is preserved under normal temperature, at the same time, the invention avoids the recovery loss caused by the traditional steps of removing impurities by alkaline washing by liquid-liquid extraction and removing organic solvents by rotary evaporation and reduces the usage amount of the organic solvents.

Owner:SHANGHAI JIAO TONG UNIV

Extract of stevia whole stevioside and stevia whole flavone and the preparing method thereof

The invention discloses a preparing method of sweet chrysanthemum glycosides and chromocor extract from sweet leaf chrysanthemum, which is characterized by the following: comprising sweet chrysanthemum glycosides, labroid glycosides A, cyanidenon, meletin, cyanidenon-7-0-beta-D glycosides, celery element-7-0-beta-D-glycosides, quercetin, meletin-3-0-beta-D-arabinoside, meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside], derivant and so on; choosing one or several methods from solvent extraction, solvent extraction process, macroreticular absorption resin method, column chromatography, supercritical fluid chromatography, liquid-liquid counter-current partition chromatography and so on; producing extract; counting 5-100%(w / w) of each sweet chrysanthemum glycosides element and chromocor element content in sweet chrysanthemum glycosides and chromocor extract; setting the chromocor element sum in sweet chrysanthemum glycosides, labroid glycosides A, cyanidenon-7-0-beta-D glycosides, quercetin, meletin-3-0-[4-0-trans-coffe acyl-alpha-L-isodulcitol-(1-6)-beta-D-arabinoside] at 5-100%(w / w).

Owner:石任兵 +1

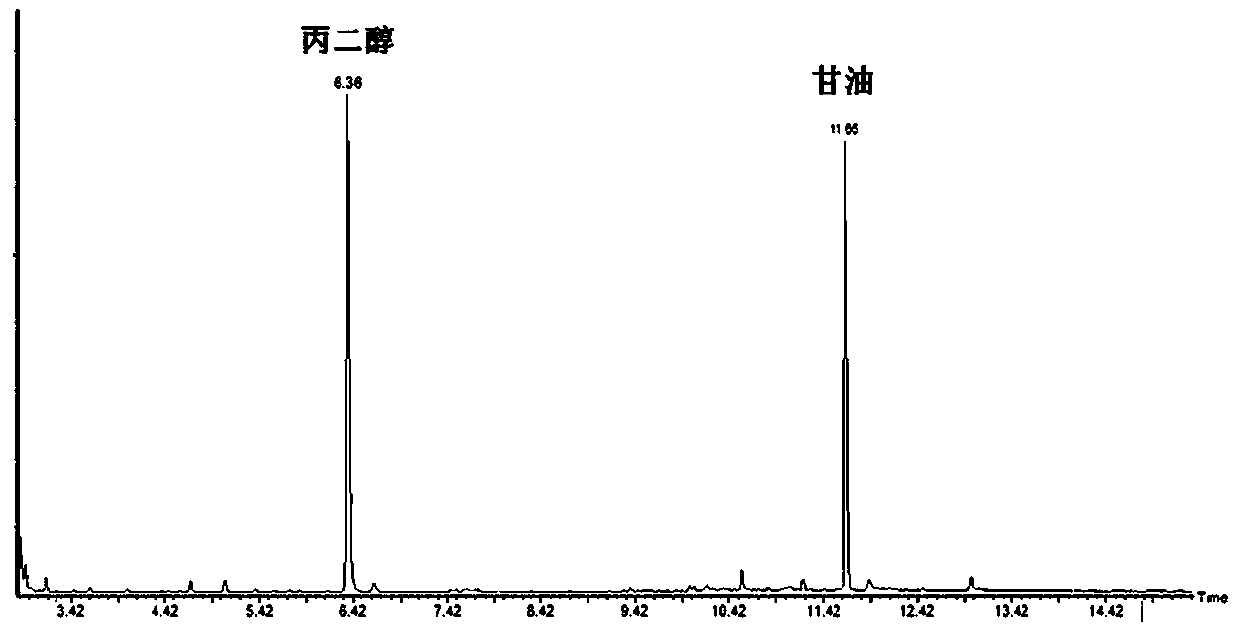

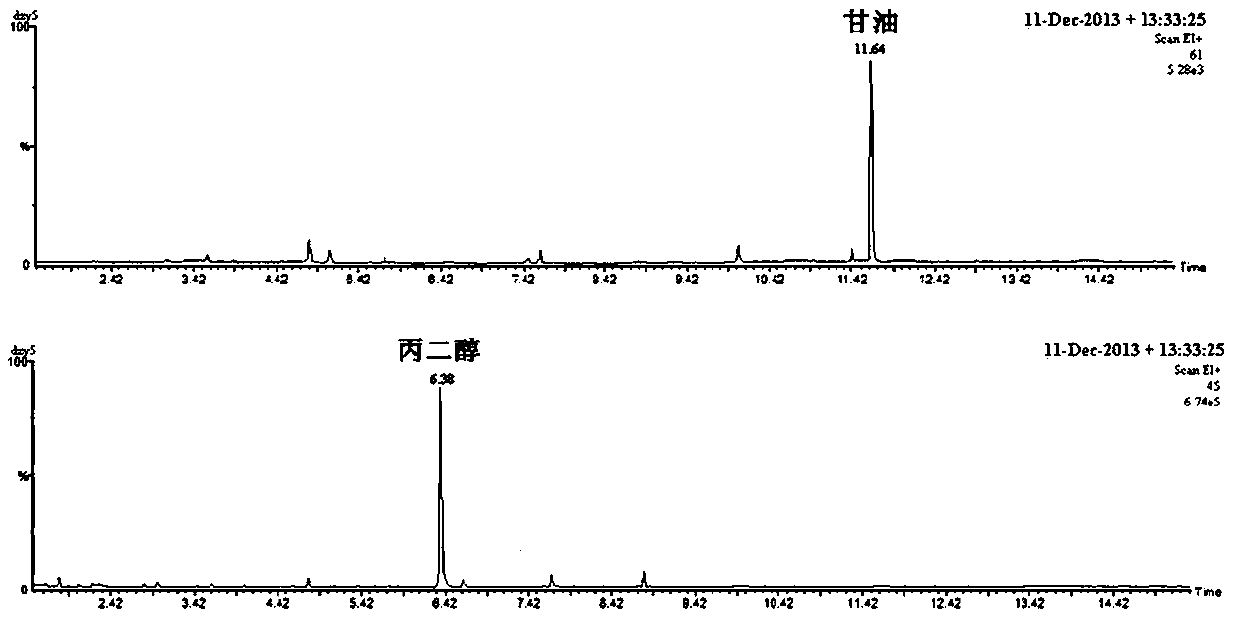

Method for measuring glycerinum and 1,2-propylene glycol in cigarettes, electronic cigarettes and low-temperature cigarettes

InactiveCN103698431AQuality improvementIndustry standard for perfect monitoringComponent separationGlycerolBottle

The invention discloses a method for measuring glycerinum and 1,2-propylene glycol in cigarettes, electronic cigarettes and low-temperature cigarettes. The method comprises cigarette suction, smoke capturing, sample extraction and instrumental analysis and specifically comprises the steps: (1) sucking the cigarettes, the electronic cigarettes and the low-temperature cigarettes through a range hood; (2) capturing components to be measured in mainstream smoke through a Cambridge filtering disk or an absorption bottle; (3) adding a solvent into the Cambridge filtering disk with the components to be measured for extraction; (4) filtering an extracting solution or an absorption solution in the absorption bottle for analysis and determination through an instrument. The method is high in reproducibility and high in analysis sensitivity and can be used for accurately and quantitatively analyzing the glycerinum and the 1,2-propylene glycol in the cigarettes, the electronic cigarettes and the low-temperature cigarettes. The method is easy to operate, and a measurement result is accurate; therefore, the industrial standard for evaluation and monitoring of the quality of a cigarette product is further perfected.

Owner:YUNNAN RES INST OF TOBACCO SCI

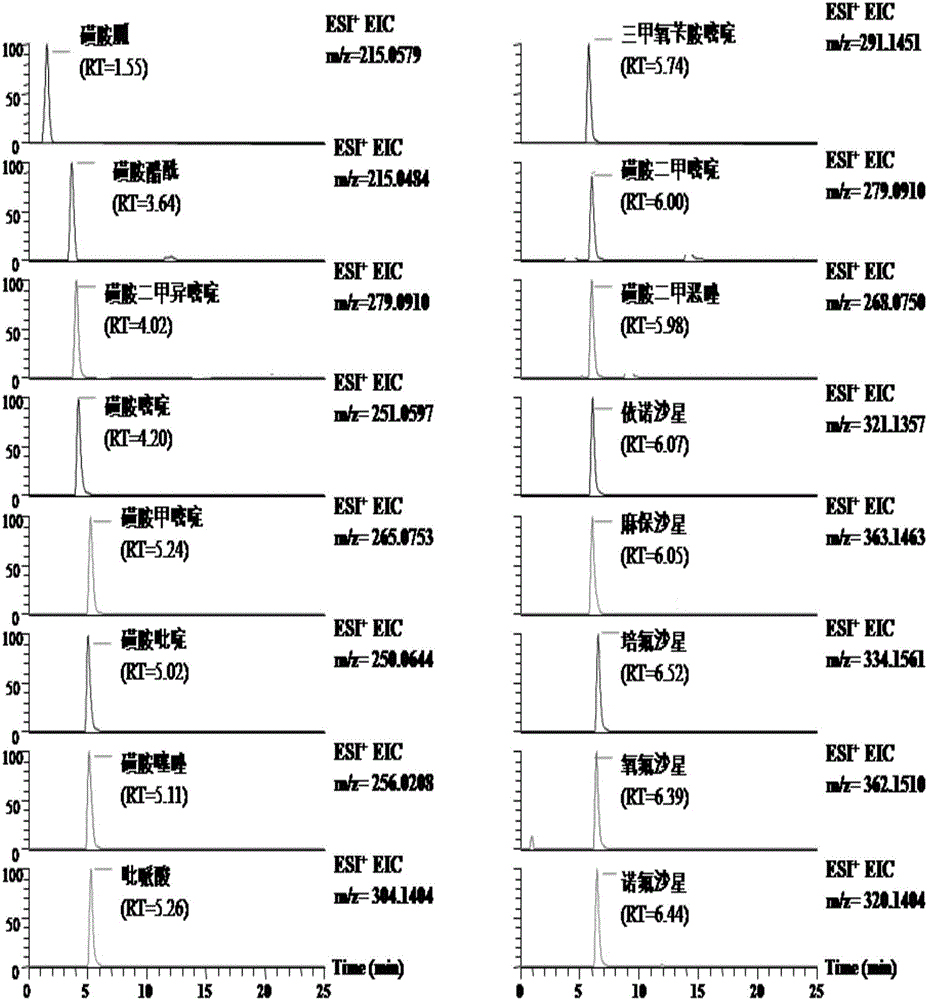

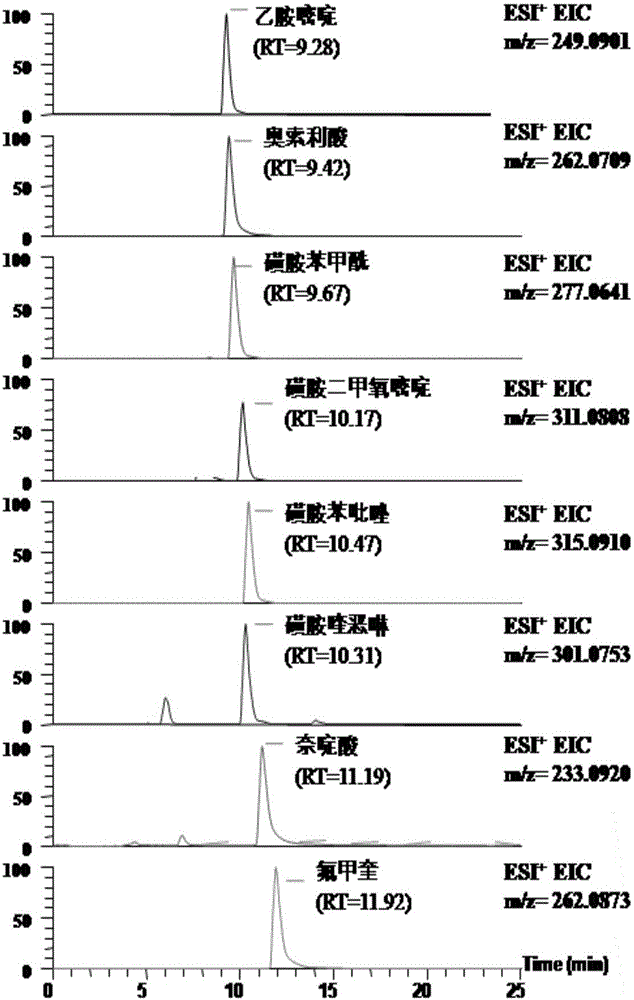

High-throughput detection method for 99 residual veterinary drugs in animal-derived food

The invention discloses a high-throughput detection method for 99 residual veterinary drugs in animal-derived food. The detection method is characterized by comprising the following concrete steps: (1) carrying out extraction and purification on 99 residual veterinary drugs having substantially different physicochemical properties and belonging to eight kinds of common veterinary drugs through one-step pretreatment based on carrier-assisted liquid-liquid extraction technology; (2) preparation of a mixed standard solution and a matrix standard curve; and (3) determining the concentrations of 99 residual veterinary drugs in a to-be-detected solution by using ultrahigh performance liquid chromatography-triple quadrupole tandem mass spectrometry. According to the invention, the pretreatment and instrumental analysis process of the method is directed at compounds with different physicochemical properties, so the method has the advantages of good compatibility, high detection efficiency, good operability and low detection cost, and the detection limit of the method can meet requirements of all the test objects.

Owner:INSPECTION & QUARANTINE TECH CENT OF NINGBO ENTRY EXIT INSPECTION & QUARANTINE BUREAU

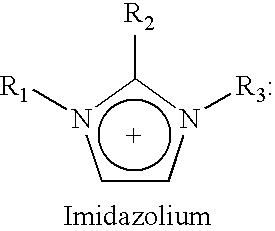

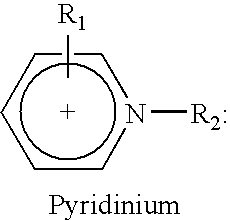

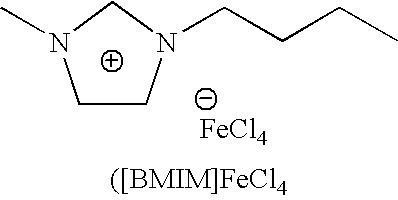

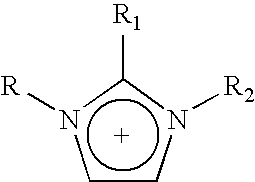

Desulfurization of hydrocarbons by ionic liquids and preparation of ionic liquids

ActiveUS20090288992A1Improve efficiencyShort timeOrganic chemistryOther chemical processesHydrocarbon mixturesPyridinium

The present invention relates to an ionic liquid compound of general formula C+A−, where C+ represents an organic cation such as alkyl-pyridinium, di-alkyl imidazolium and tri-alkyl imidazolium; and A− is an anion of halides of iron (III), such as, for example, FeCl4− and to a method of producing the ionic liquid compound by heating the reactants using microwave energy. The ionic liquids can be used to desulfurize hydrocarbon mixtures by a liquid-liquid extraction.

Owner:INST MEXICANO DEL GASOLINEEO

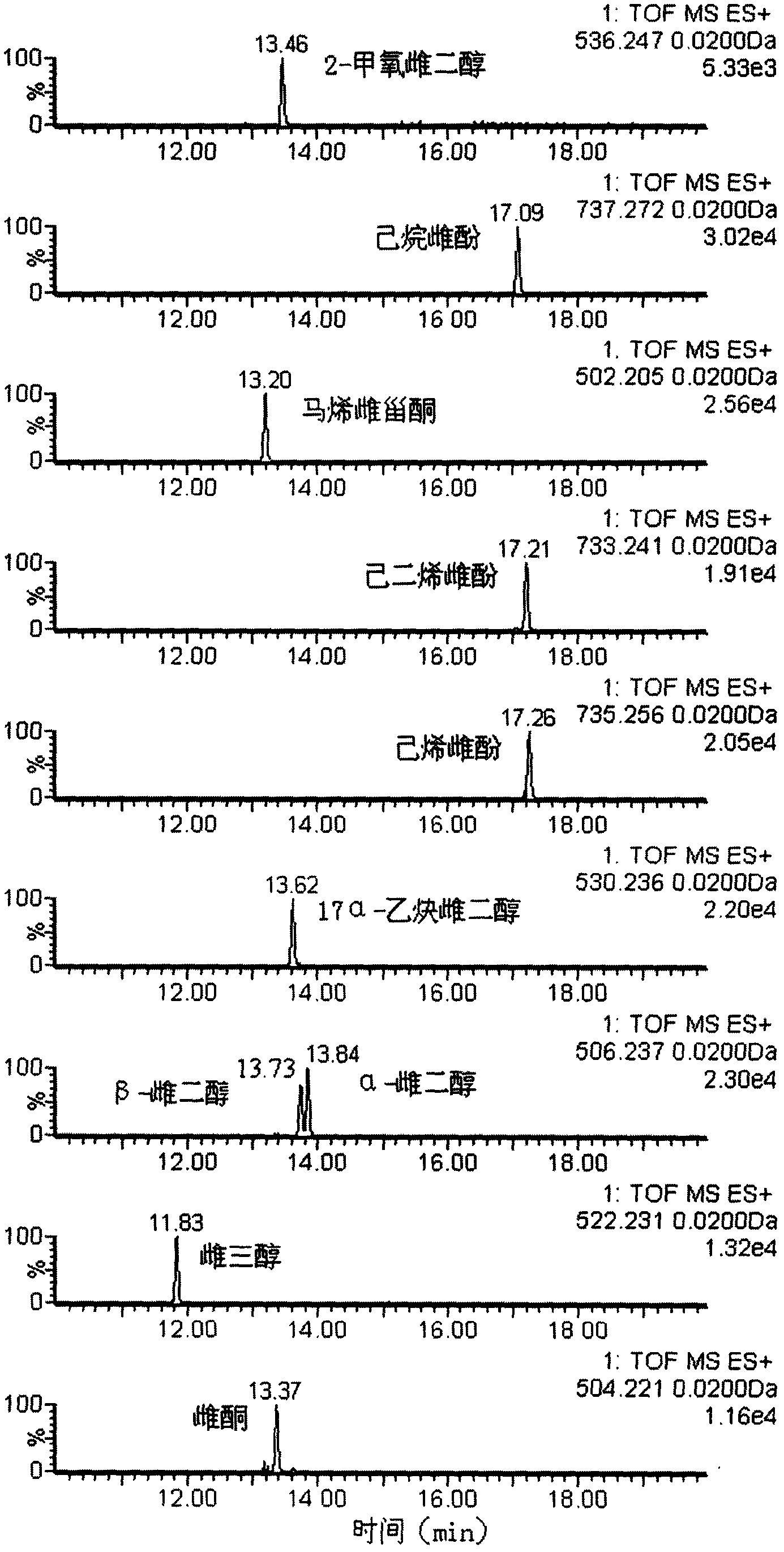

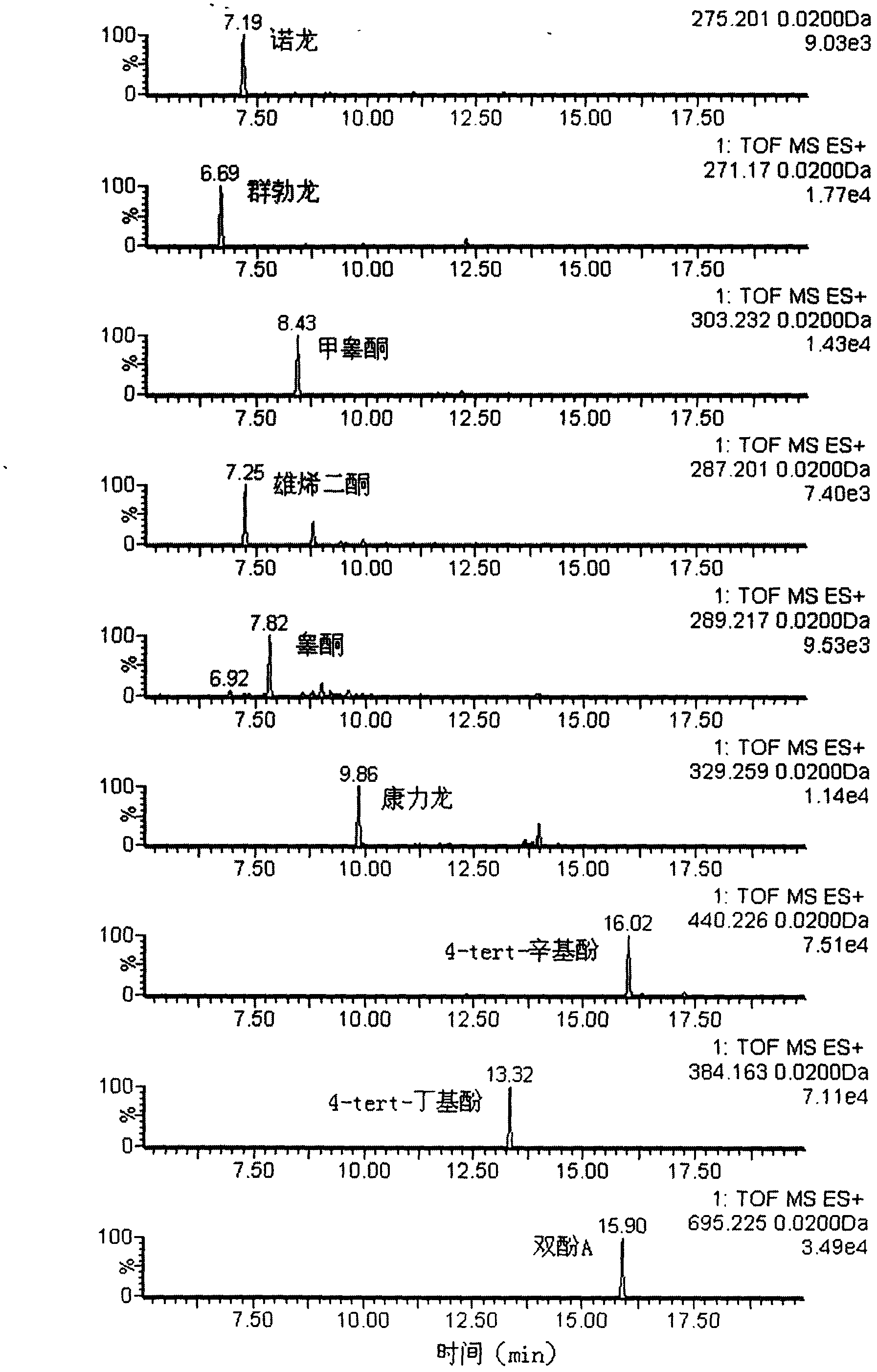

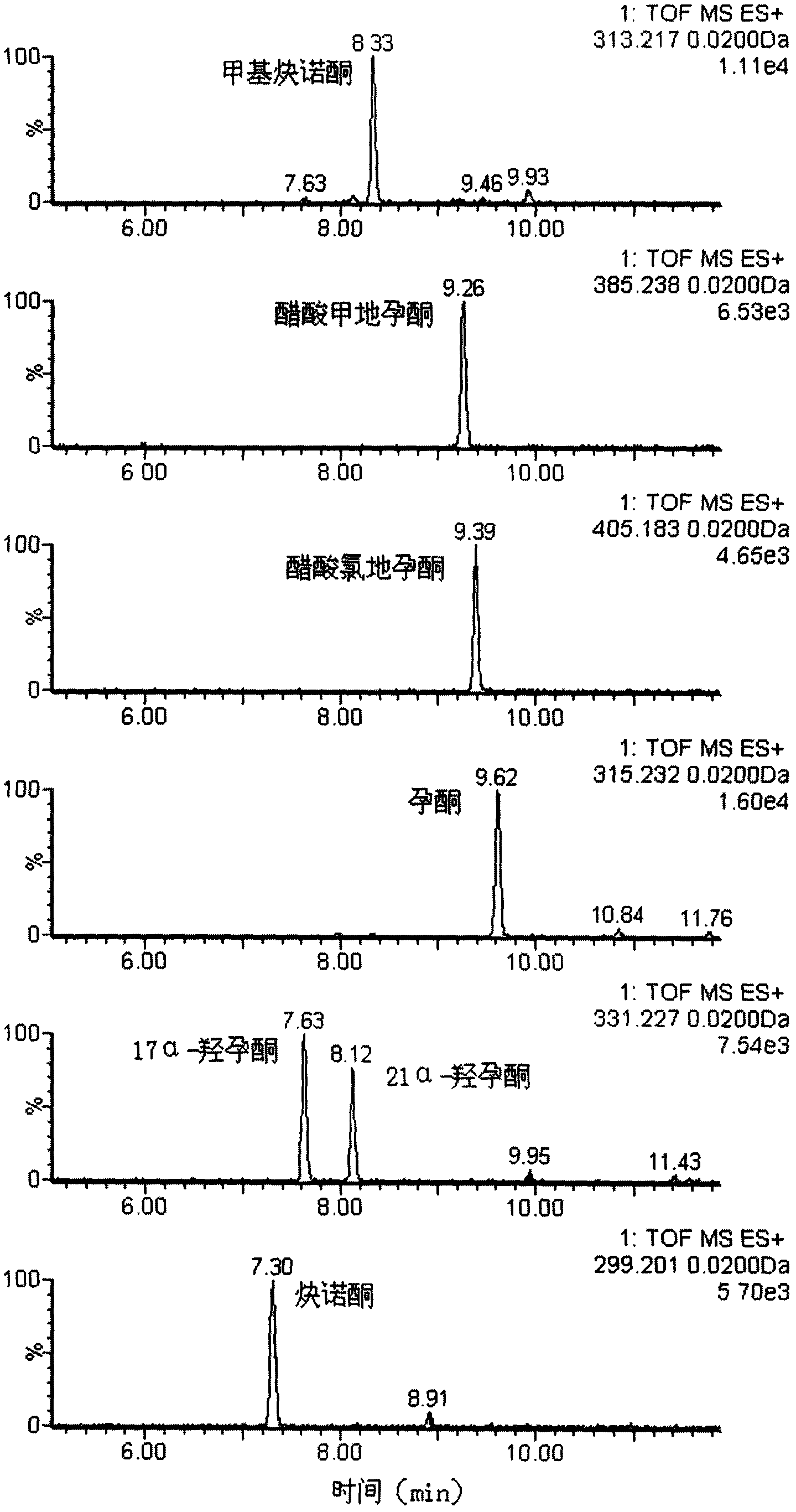

Method for analyzing and detecting a plurality of endocrine disruptors in food

ActiveCN103185762AHigh sensitivityAccurate analysisComponent separationPerturbateurs endocriniensLiquid milk

The invention belongs to the field of food inspection, relates to an assay determination method for endocrine disruptors in food, and particularly relates to a method for analyzing and determining a plurality of endocrine disruptors in milk powder and liquid milk. The method comprises the steps of dissolving a sample with water, adding an organic solvent mixable with water, extracting a to-be-detected material by ultrasonic, adding a sodium salt to make the organic solvent separated from a water phase to realize liquid-liquid extraction, taking an organic solvent containing quantitative to-be-detected material, purifying by extraction with a solid phase filled with C 18 materials, deriving by dansyl chloride, and analyzing and detecting four types of 26 endocrine disruptors in the food by using ultra-high performance liquid chromatography-quadrupole-time of flight-mass spectrometry at the same time. The method can overcome the disadvantages that a conventional technology cannot realize simultaneous analysis of the plurality of the endocrine disruptors in the food by once chromatographic sample injection, can increase sensitivity of the quadrupole-time of the flight-mass spectrometry, and realize accurate analysis of the endocrine disruptors in the food by using the quadrupole-time of the flight-mass spectrometry.

Owner:FUDAN UNIV

Halogen-free ionic liquids in naphtha desulfurization and their recovery

InactiveUS20100051509A1Organic compound preparationLiquid solutions solvent extractionPyridiniumNaphtha

Ionic liquids of the general formula C+A− where C+ represents an organic cation, specifically, but not limited to the imidazolium, pyridinium, isoquinolinium, ammonium types, which have aliphatic and aromatic substituents, while A− represents a carboxylate, aromatic and aliphatic anion. The ionic liquids are synthesized under conventional heating or microwave irradiation This invention is also related to the application of ionic liquids to remove sulfur compounds of naphthas through a liquid-liquid extraction and the recovery and reuse of ionic liquids by the application of heat, reduced pressure and washing with solvents.

Owner:INST MEXICANO DEL GASOLINEEO

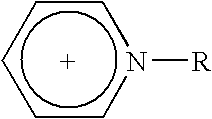

Isolation and purification of sterols from neutrals fraction of tall oil pitch by single decantation crystallization

Sterols from the solvent-extracted or distilled neutrals of saponified tall oil pitch are disclosed to be isolated and purified by a process of a liquid-liquid extraction where the hydrocarbon extraction stream is washed with an aqueous methanol solution to remove methanol-soluble impurities by adding the methanol and water, sequentially or as a blend. The resulting hydrocarbon / neutrals / methanol / water solution separates into an upper organic phase and a lower methanol / water phase, which lower phase is removed. The remaining organic phase is allowed to cool to from about 20-30 DEG C., with agitation, to facilitate crystallization of sterols, which crystals are recovered by filtering.

Owner:MEADWESTVACO CORP

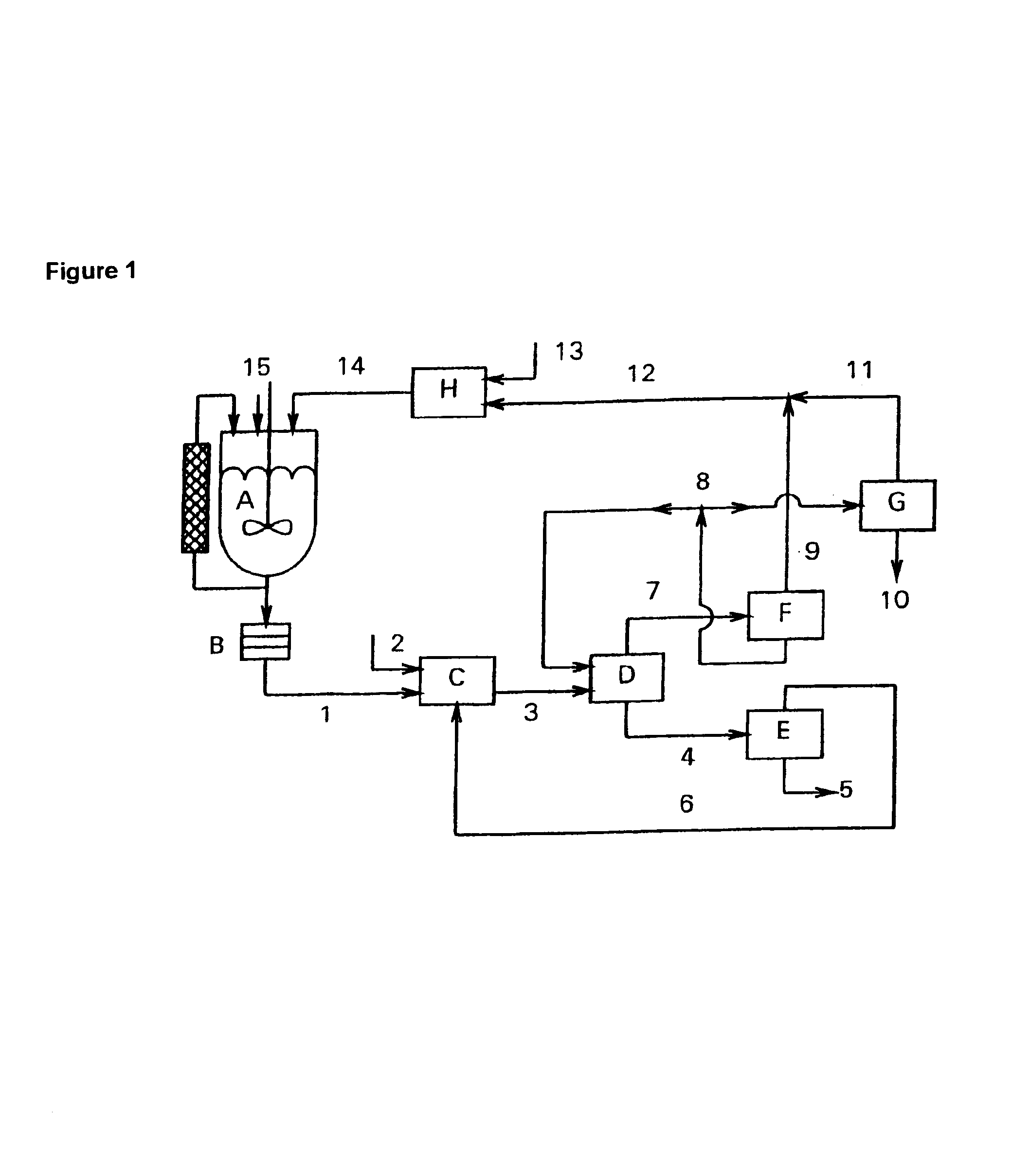

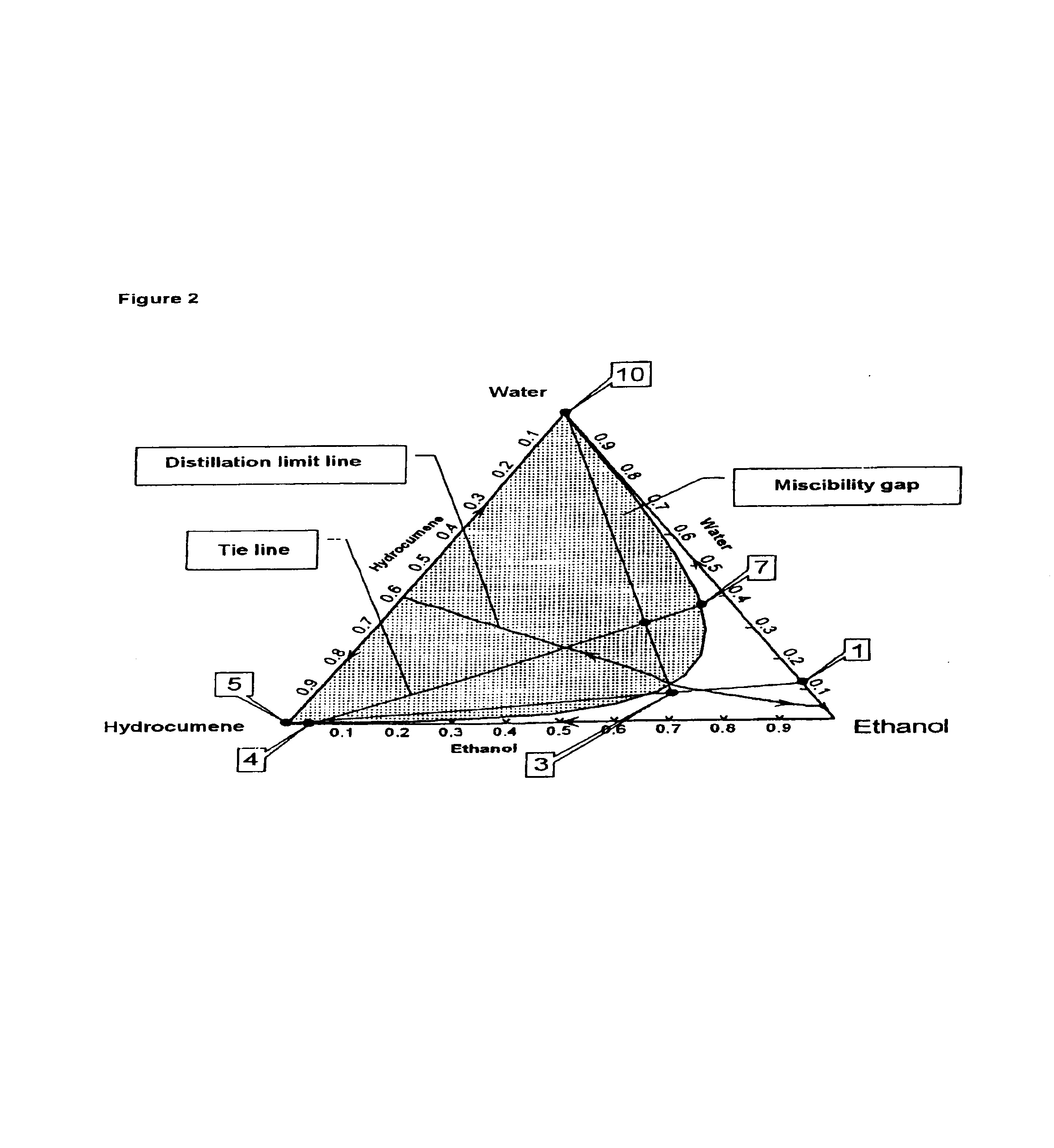

Work-up of the ammoximation products of ketones by liquid-liquid extraction in a ternary solvent system

The present invention relates to a process for working up an ammoximation reaction mixture, by separating a catalyst from the reaction mixture, removing the ketone oxime product, discharging the water of the reaction, and recirculating a solvent, where the ketone oxime formed is removed in a liquid phase with at least one liquid-liquid extraction in a ternary solvent system.

Owner:EVONIK DEGUSSA GMBH

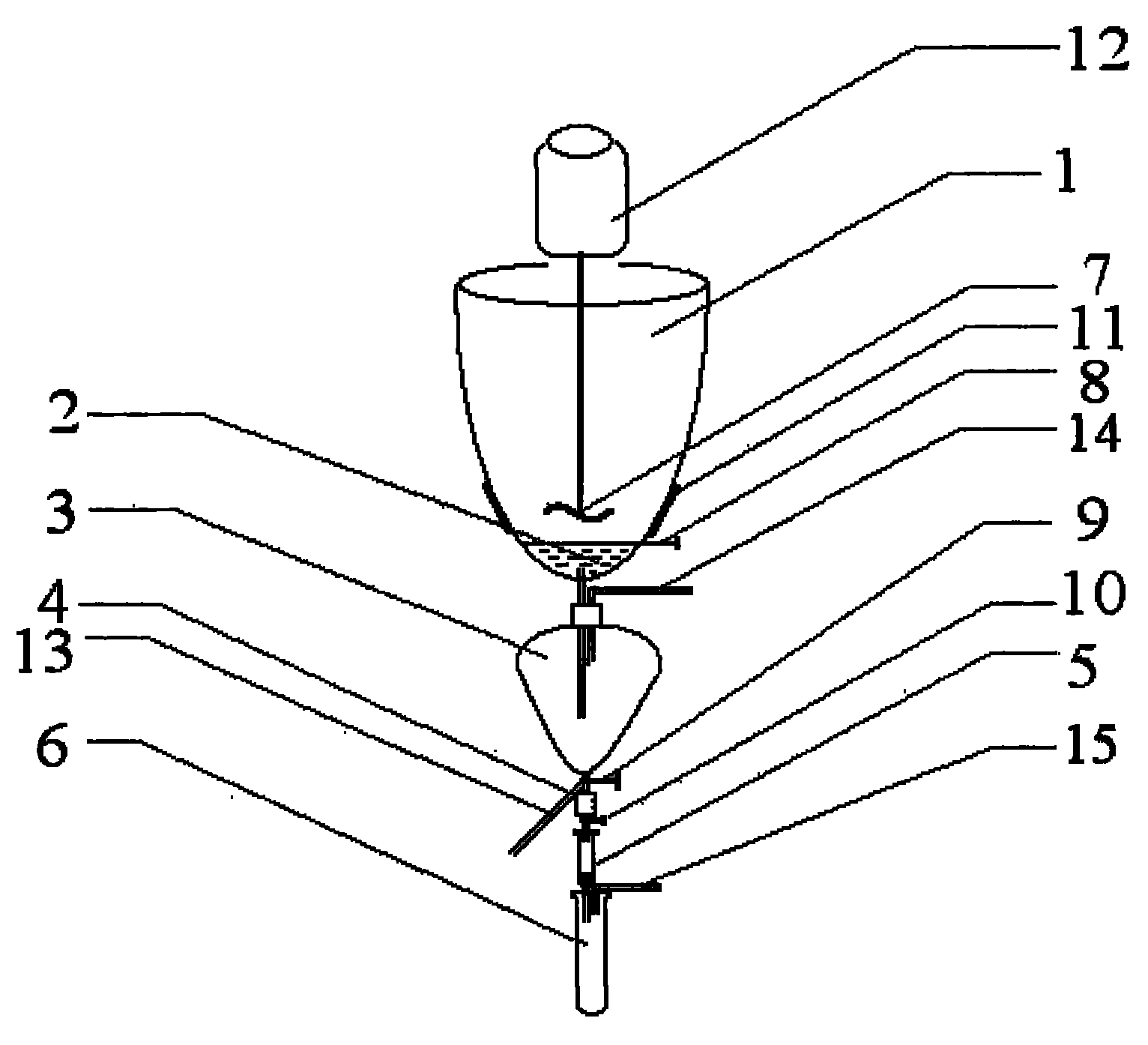

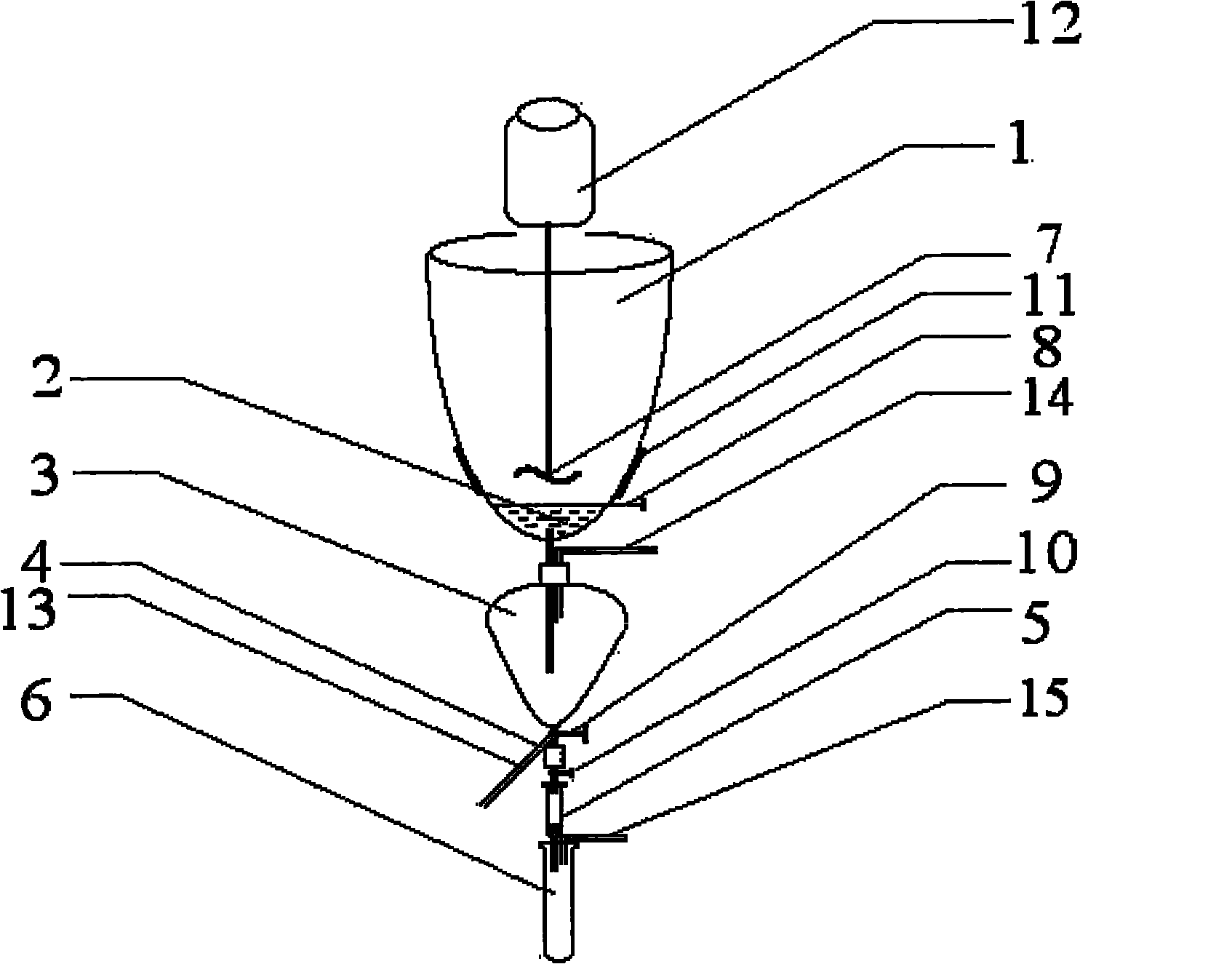

Integrated pesticide residue detection pretreatment device and pretreatment method

InactiveCN101813582AQuick checkQuick preprocessingPreparing sample for investigationPretreatment methodFiltration

The invention provides an integrated pesticide residue detection pretreatment device and a pretreatment method. The device comprises a cup body, a filter, a liquid divider, a jigger, a solid phase extraction column and a test tube, wherein a crushing homogenizer is arranged in the cup body, and the bottom of the cup body is connected with the filter; the liquid divider is arranged on the bottom of the filter to be used for carrying out standing stratification on filter liquid flowing out of the filter, and the bottom of the liquid divider is connected with a three-way valve; the jigger is connected with one opening of the three-way valve to be used for quantitatively collecting a target compound, and the bottom end of the jigger is provided with a second graduating valve; the solid phase extraction column is connected on the bottom of the jigger to be used for eluting the target compound; and the test tube is used for collecting eluent and is also connected with a nitrogen flow system used for concentrating the eluent. The device and the method integrate the processes of crushing, homogenizing, ultrasonic vibrating, suction filtration, liquid-liquid extraction, solid phase extraction, concentrating constant volume and the like; the treatment method is simple and has high efficiency, and the treatment device is convenient and simple, practical and portable and can be used for on-site operation.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

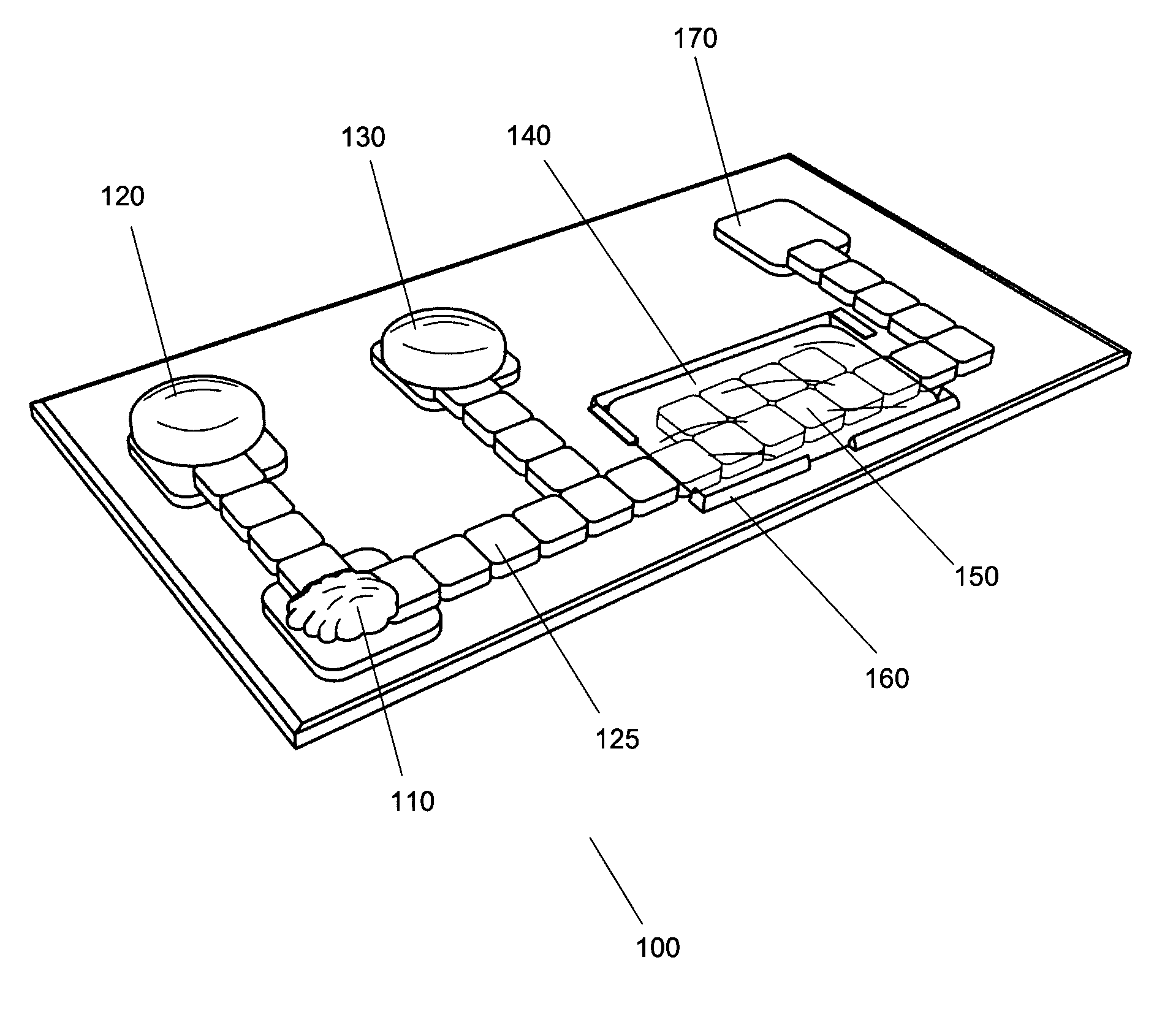

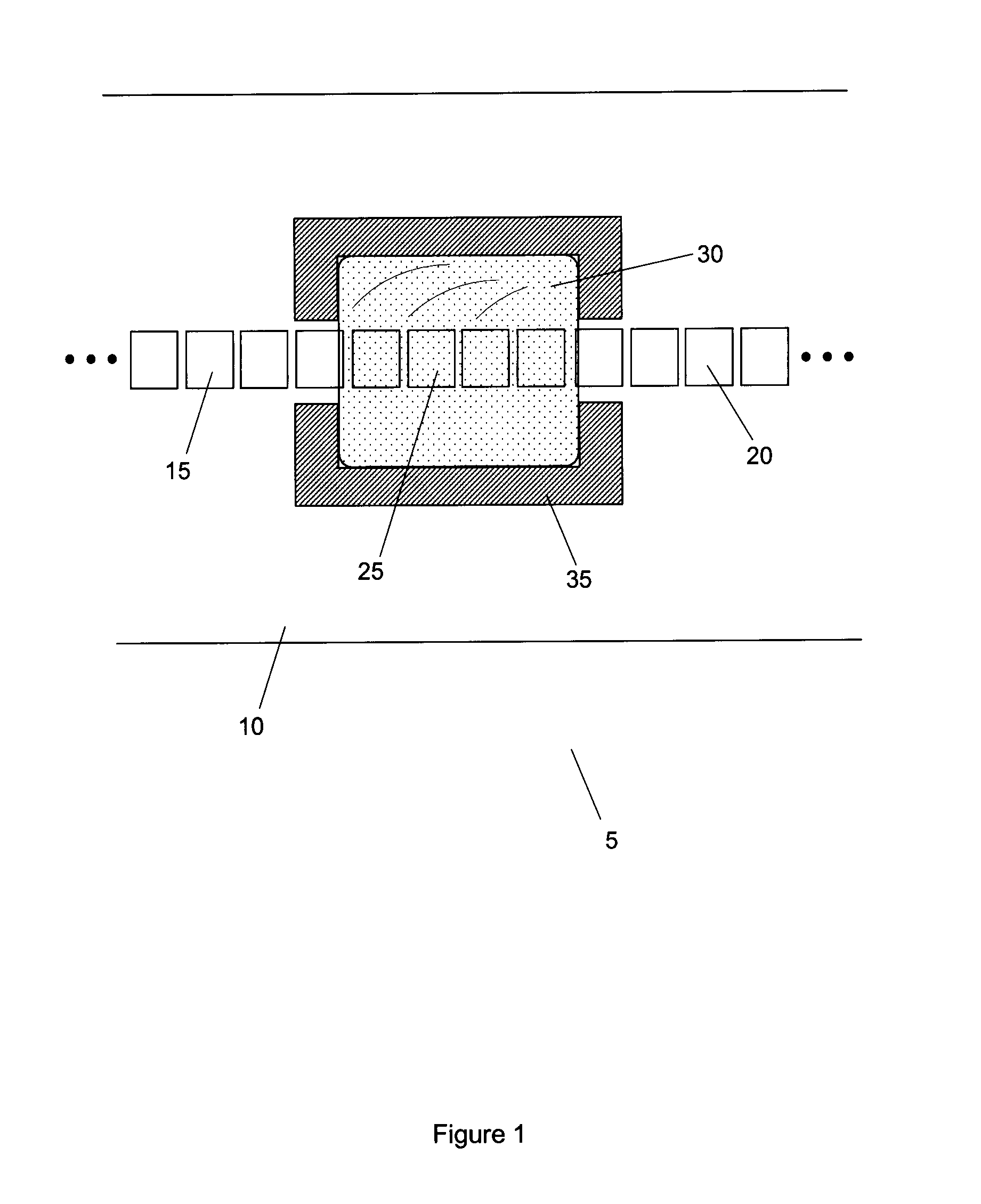

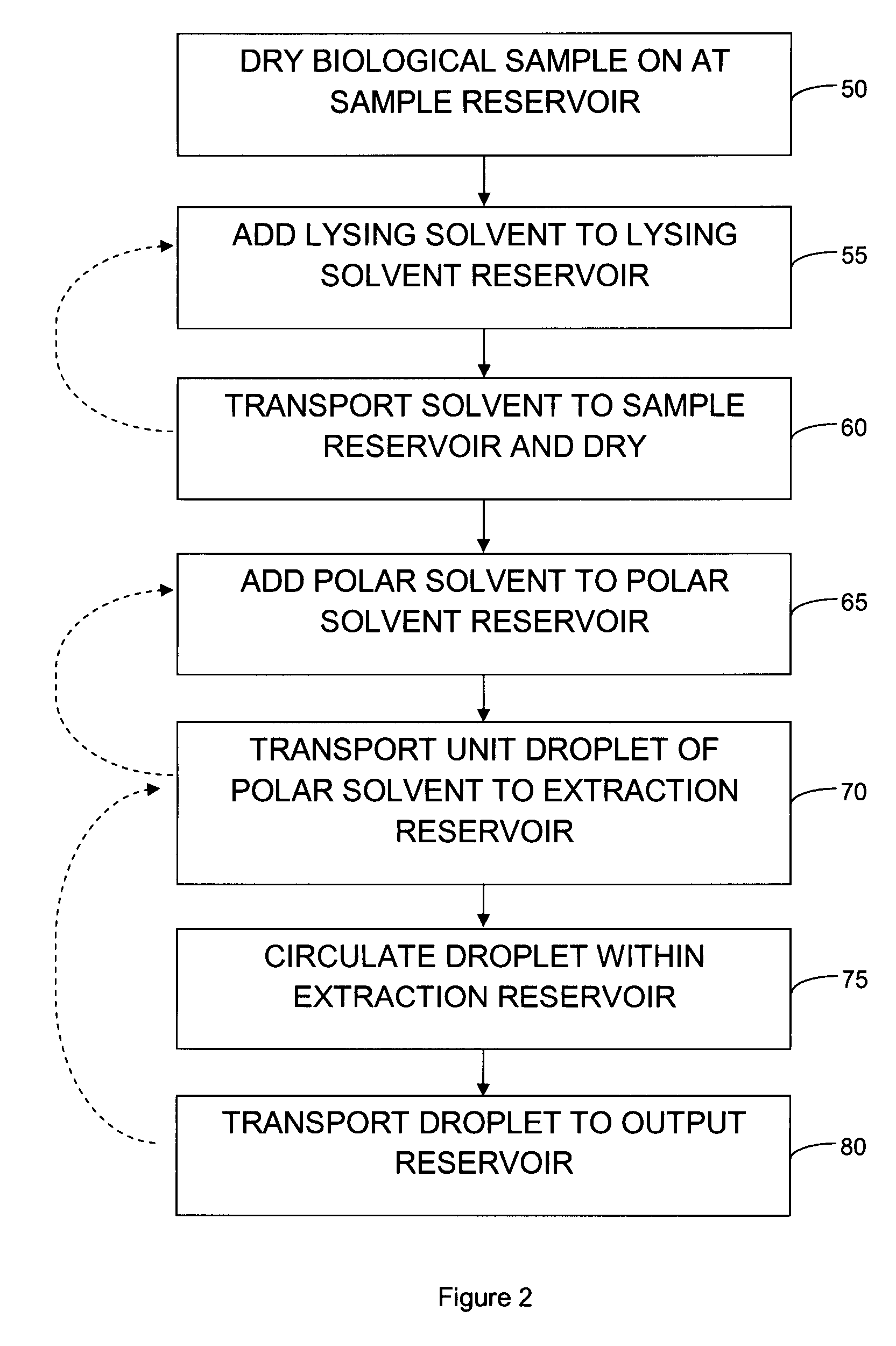

Digital microfluidic liquid-liquid extraction device and method of use thereof

ActiveUS20120085645A1Need be addressSludge treatmentFixed microstructural devicesElectrical polaritySolvent

Methods and devices for liquid-liquid extraction using digital microfluidic arrays are provided. A polar droplet is transported to a separation region containing a substantially non-polar solvent, where non-polar impurities may be extracted from the polar droplet while maintaining a distinct phase separation. In a preferred embodiment, biological samples containing hormones are dried on a digital microfluidic array, lysed by a lysing solvent, dried, subsequently dissolved in a polar solvent, and further purified in a separation step in which droplets are transported through a volume of non-polar solvent. The method disclosed herein provides the distinct advantage of an automated sample preparation method that is capable of extracting hormones from low sample volumes with high precision and recovery.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

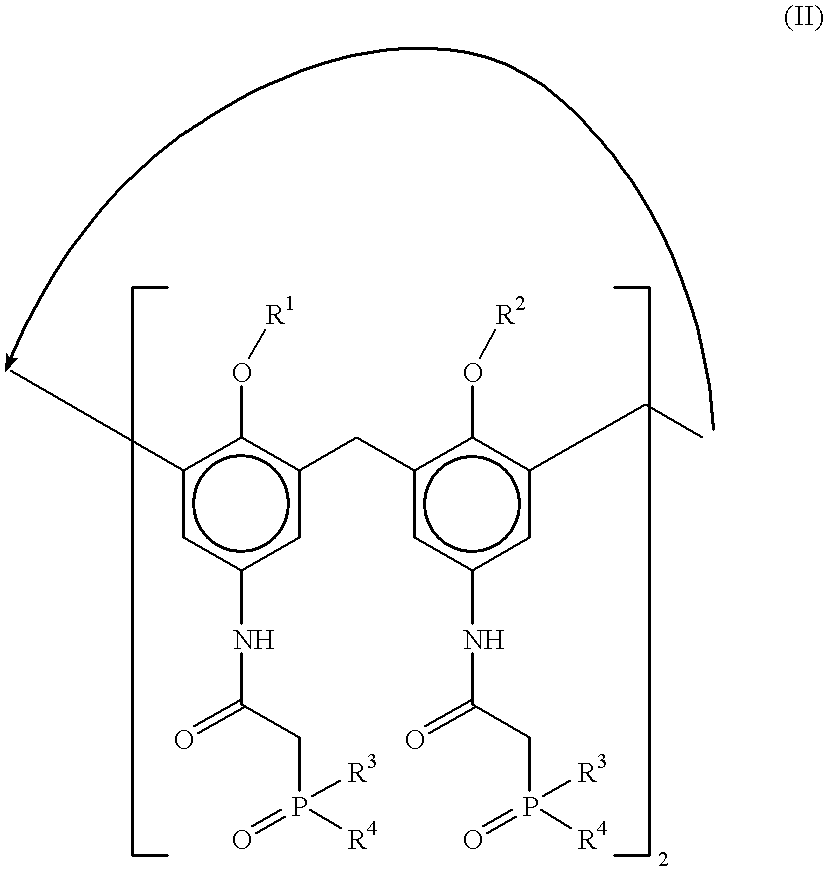

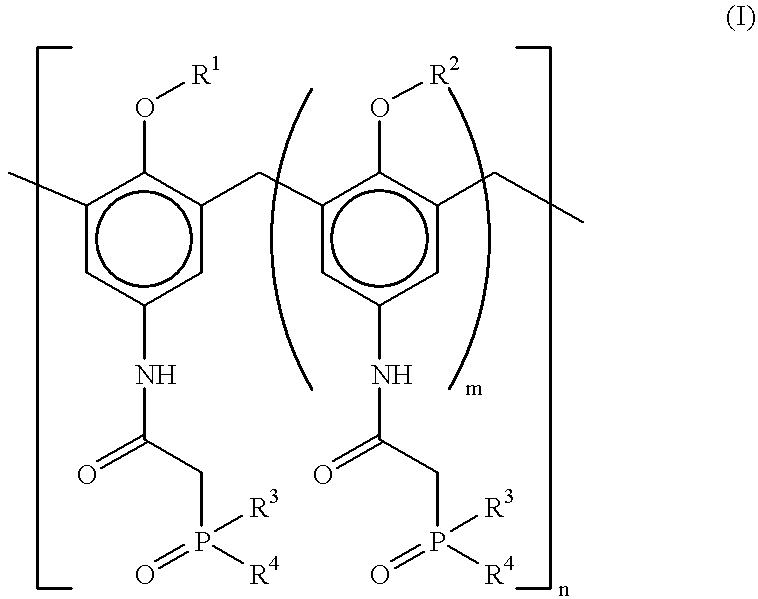

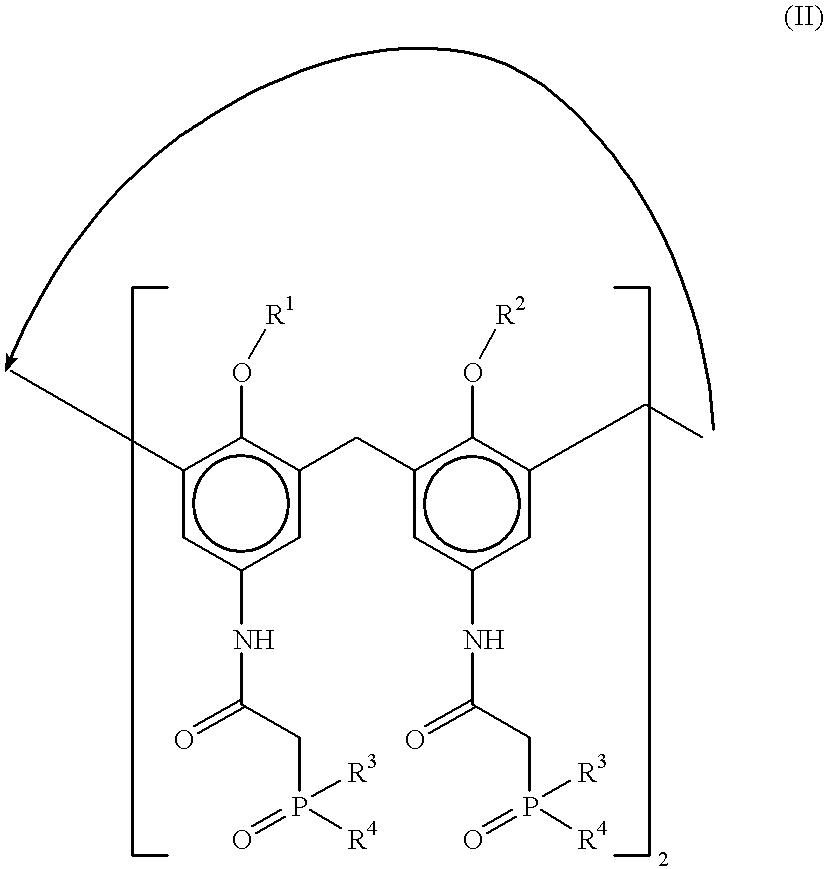

Method for separating actinides and lanthanides by liquid-liquid extraction using calixarenes

The invention involves a process for separating actinides and lanthanides by liquid-liquid extraction by means of calixarenes.These calixarenes have the formula:with R1 and R2 being alkyl groups or o-nitrophenoxy alkyl groups and R3 and R4 being aryl groups,and they are used in an organic liquid phase containing an organic diluent. The diluent and the calixarene concentration of the organic phase are chosen so as to ensure an enrichment of the organic phase with the actinide(s) and / or lanthanide(s) to be separated from an aqueous acid or saline solution.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

System for liquid extraction, and methods

ActiveUS20060086664A1Accelerates the removal of moistureFacilitates separation of waterDrying solid materials with heatDrying solid materials without heatThermal energyBoiling point

A process for removing water from solid material using liquid-solid extraction and liquid-liquid extraction. In most embodiments, multiple solvents are used to remove the water from the solids and obtain dry solids. Multiple solvents facilitate the removal of the water from the solids, by replacing the water with a solvent, replacing that solvent with a different solvent, and then eventually removing the second solvent from the solids. The process utilizes a lesser amount of thermal energy to dry the solids and separate the solvents than conventionally used in drying processes. The first solvent selected has a lower heat of vaporization, enthalphy of vaporization, boiling point, or other such physical property, than water. Each additional solvent can have a still lower heat of vaporization, enthalphy of vaporization, boiling point, or other such physical property.

Owner:KFI INTPROP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com