Preparation method of tobacco extract granules

A tobacco extract and tobacco extraction technology, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problem that the compensation function of cigarette aroma is not obvious, and achieve the effects of reducing the harm of cigarettes, being easy to store, and reducing the amount of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

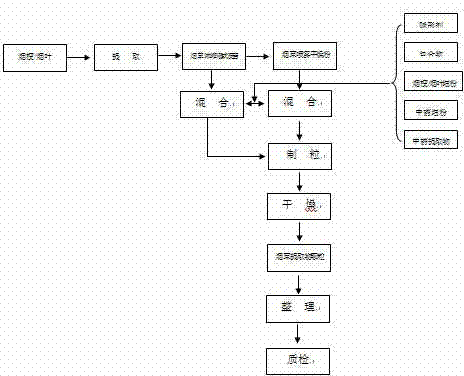

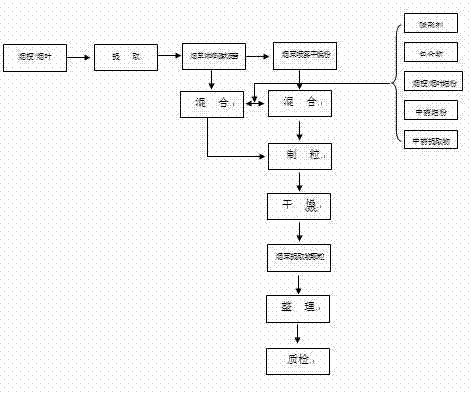

[0013] A preparation method of tobacco extract particles, such as figure 1 As shown, the preparation method is as follows:

[0014] (1) Take tobacco leaves and / or tobacco stems and chop them up, extract with water or ethanol or ether as a solvent, settle and filter to obtain tobacco extract, then concentrate to a relative density of 1.00-1.30 and control the temperature at 20-40°C , to obtain the tobacco extract concentrate;

[0015] (2) According to the mass ratio of β-cyclodextrin: tobacco flavor is 1 to 3:1, and the inclusion time of tobacco flavor and β-cyclodextrin is 1 / 5 to 3 hours to obtain flavor and β-cyclodextrin inclusion compound, and then spray-dry spices, β-cyclodextrin inclusion compound and tobacco extract concentrate to obtain tobacco spray-dried powder; or directly spray-dry tobacco extract to obtain tobacco spray-dried powder;

[0016] (3) Tobacco spray-dried powder is dry or wet granulated by adding excipient materials to obtain tobacco extract granules. ...

Embodiment 5

[0028]The tobacco stems were chopped and extracted with 10 times aqueous solution under reflux for 1.5 hours, filtered, and the filtrate was concentrated under reduced pressure at a vacuum degree of 0.05 MPa to a relative density of 1.2 at a temperature of 25-30°C to obtain a tobacco extract concentrate. β-cyclodextrin and cinnamaldehyde were clathrated at a mass ratio of 2.5:1 for 1.5 hours to obtain the clathrate of cinnamaldehyde and β-cyclodextrin. The cinnamaldehyde is spray-dried together with the β-cyclodextrin inclusion compound and the tobacco extract concentrate to obtain the spray-dried powder. Glycyrrhiza licorice was crushed and sieved to 120 mesh, mixed evenly with spray-dried powder, lactose, microcrystalline cellulose, and talcum powder, and the mixed powder was made into 40-80 mesh granules by dry method. The total amount of lactose, microcrystalline cellulose, and talcum powder added is twice the mass of the spray-dried powder, and the added amount of the lic...

Embodiment 6

[0030] The tobacco stems were chopped and extracted with 10-fold aqueous solution under reflux for 1.5 hours, filtered, and the filtrate was concentrated under reduced pressure at a vacuum of 0.05 MPa to a relative density of 1.1 at a temperature of 20-30°C to obtain a tobacco extract concentrate. The β-cyclodextrin and cinnamaldehyde were clathrated at a mass ratio of 2:1 for 1.5 hours to obtain the clathrate of cinnamaldehyde and β-cyclodextrin. The cinnamaldehyde is spray-dried together with the β-cyclodextrin inclusion compound and the tobacco extract concentrate to obtain the spray-dried powder. In addition, rice was crushed and sieved to 80 meshes, mixed evenly with spray-dried powder, microcrystalline cellulose, soluble starch, and liquid paraffin, and made into granules. The total amount of microcrystalline cellulose, soluble starch, and liquid paraffin is 0.5 times the mass of the spray-dried powder, and the amount of added rice flour is 1 / 10 of the mass of the spray-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com