Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Intermediate Fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A type of striated skeletal muscle fiber that contracts quicker than a red fiber but slower than a white fiber and contains only a moderate amount of mitochondria, myoglobin and sarcoplasm.

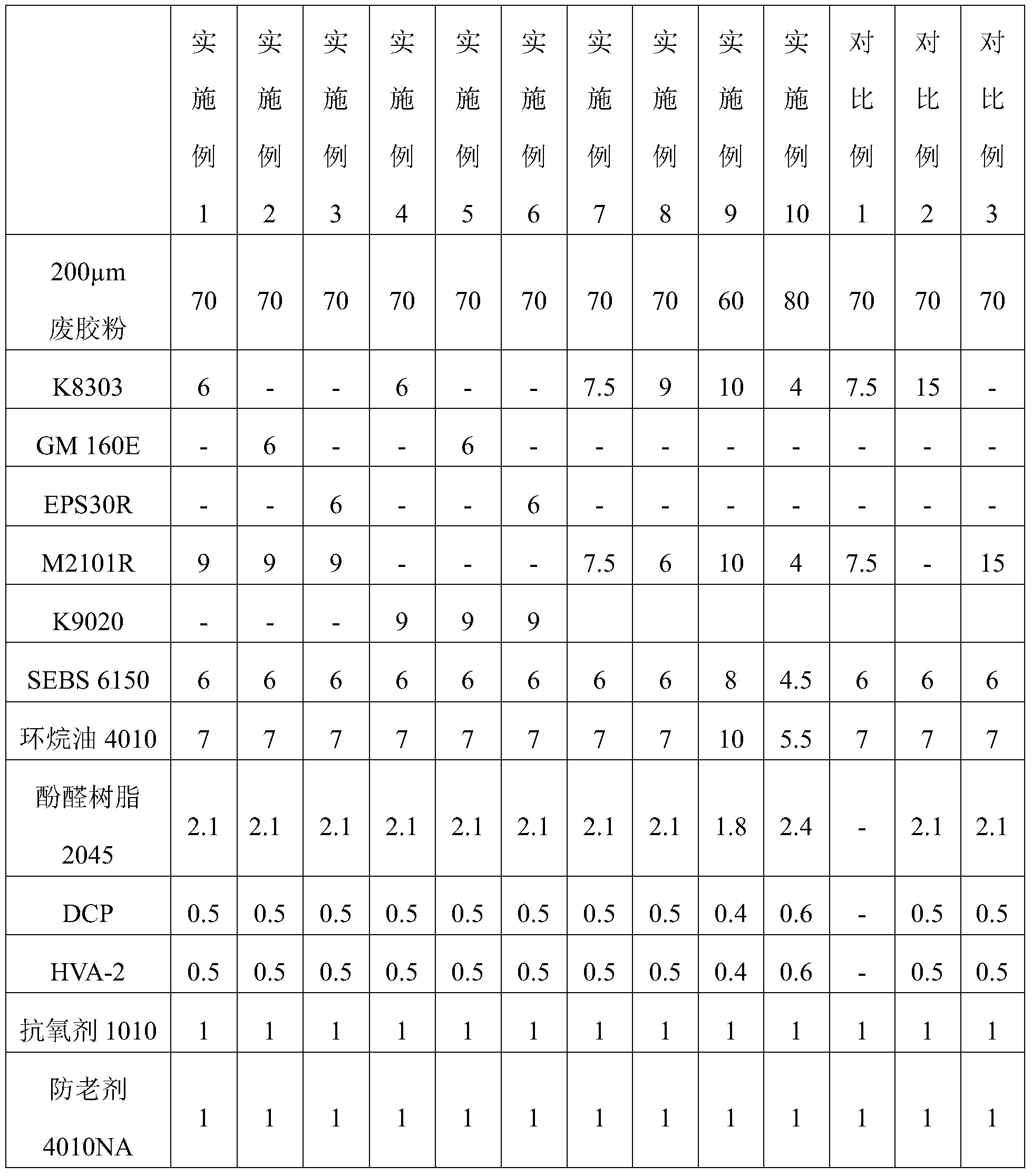

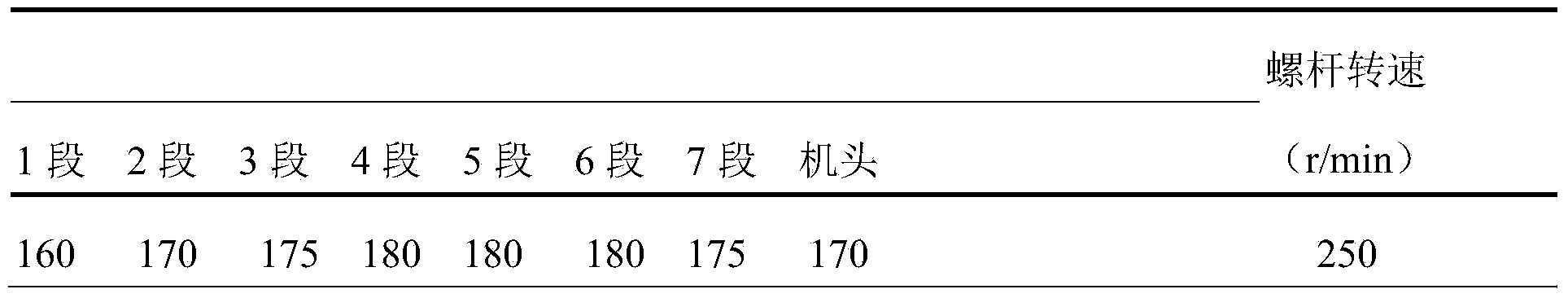

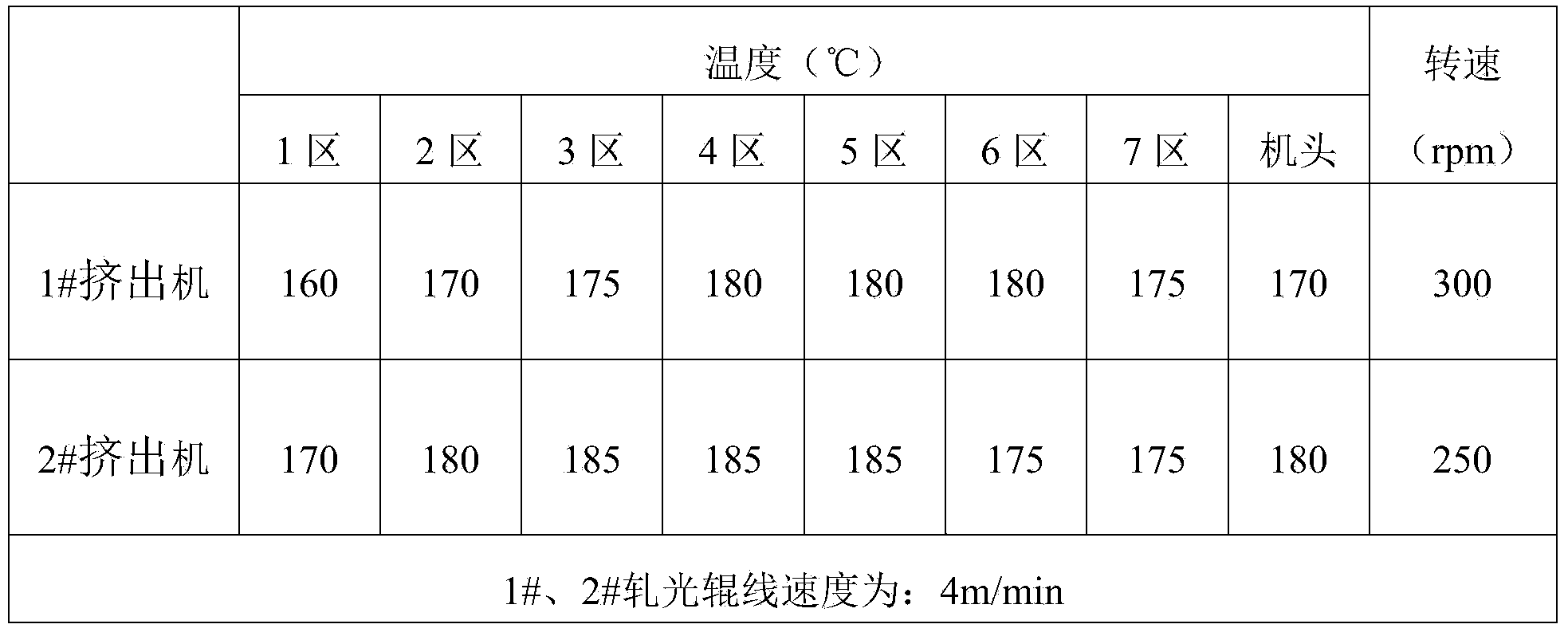

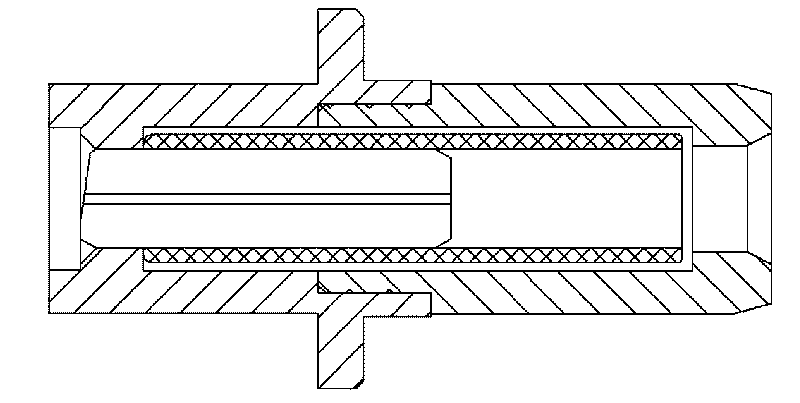

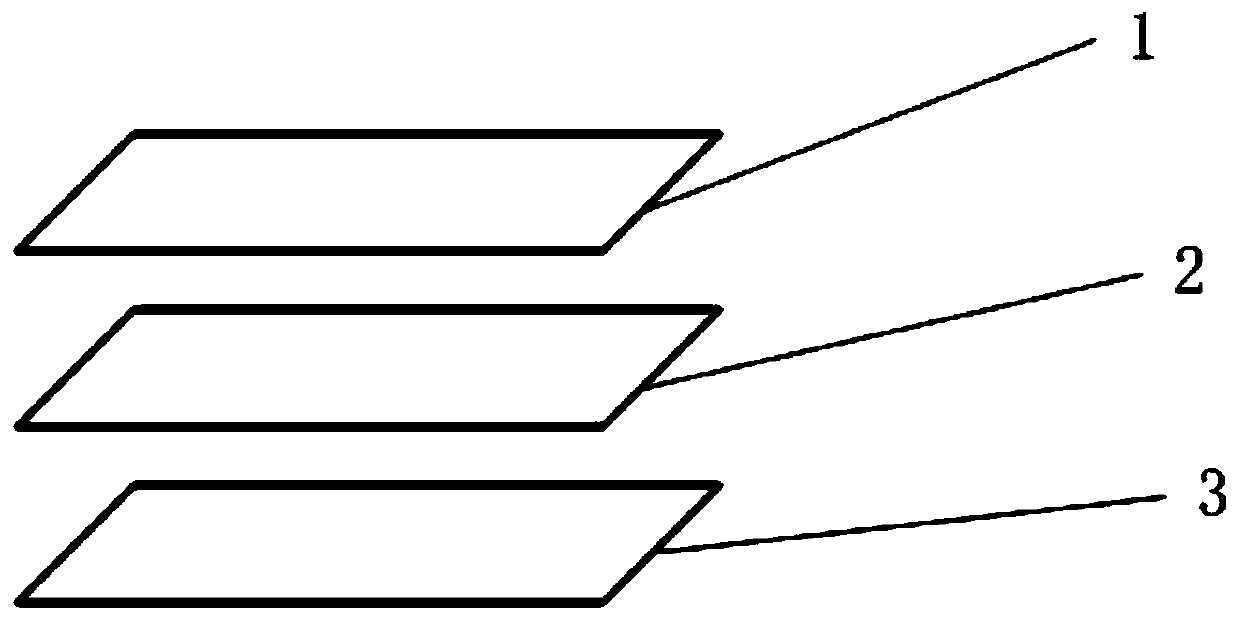

High-performance thermoplastic polyolefin waterproof coiled material with high scrap rubber powder doping amount

ActiveCN104260504AWide variety of sourcesLow priceSynthetic resin layered productsConstructions elementsThermoplasticPolymer science

The invention relates to a high-performance thermoplastic polyolefin waterproof coiled material with a high scrap rubber powder doping amount. The high-performance thermoplastic polyolefin waterproof coiled material is formed by compounding an upper surface thermoplastic polyolefin (TPO) coiled material layer, an intermediate fiber fabric enhancement layer and a lower surface scarp rubber powder-based thermoplastic elastomer (WRTPE) coiled material layer. The composite waterproof coiled material disclosed by the invention is high in tensile strength and high in breakage ductility; all the coiled material layers are tightly combined, and all properties are higher than the indexes of enhancement coiled materials in a fabric GB 27789-2011; the composite coiled material is convenient to construct, and the cost of the composite coiled material is lowered by 20-30 percent when compared with the cost of a TPO enhanced coiled material with the same thickness; the high-performance thermoplastic polyolefin waterproof coiled material has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Method for inhibiting chromatic dispersion in process of optical fiber conduction, special adapter and installation method

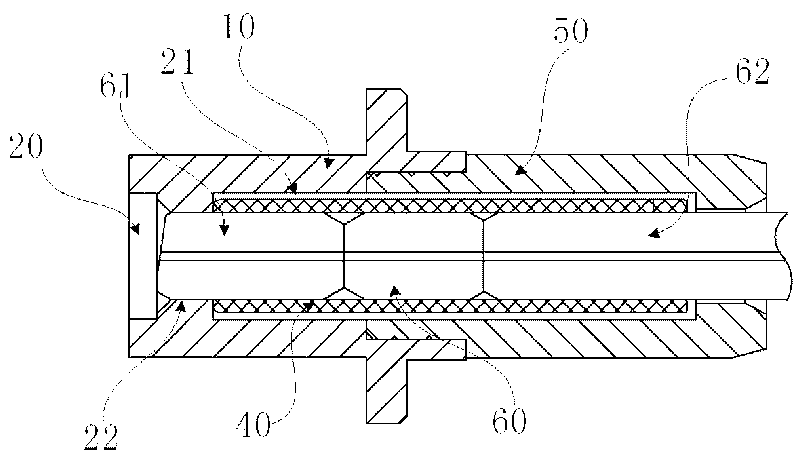

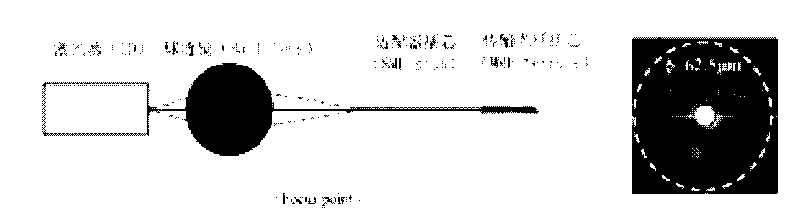

ActiveCN101713849ALow costEasy to transformCoupling light guidesConcentration ratioIntermediate muscle fiber

The invention relates to a ferrule adapter for inhibiting chromatic dispersion in the process of optical fiber conduction, comprising a tail jacket (10), a ceramic sleeve (40) and an incident single-mode ceramic ferrule (61). An intermediate single-mode ceramic ferrule (60) is embedded into the ceramic sleeve (40); both ends of the intermediate single-mode ceramic ferrule (60), the incident single-mode ceramic ferrule and the inserting end of an emergent single-mode ceramic ferrule are all ground into a regular spherical shape with raised intermediate fiber cores; the three optical fibers keep the state of fiber core contact and air isolation of peripheral coverings; and a covering film is consumed by air isolation. The invention can well ensure the concentration ratio of luminous flux in multimode optical fibers, the incident angle of light coupled into the multimode optical fibers is single and basically a low-order mode and a basic mode, the harm of the chromatic dispersion between modes can be basically minimized, and the cost is lower. In addition, the invention can be realized based on the traditional ferrule adapter, facilitate the modification and avoid the waste.

Owner:深圳市惠富康光通信有限公司

Dispersion spinning core-shell fluoropolymers

InactiveUS20050143494A1Increase chanceAvoid huge wasteSynthetic resin layered productsCork mechanical workingTetrafluoroethylenePolymer science

A process is disclosed for dispersion spinning non-melt-processible fluoropolymer fiber in which a mixture of an aqueous dispersion of non-melt-processible fluoropolymer particles and an aqueous solution of a matrix polymer is formed. The non-melt-processible fluoropolymer particles have an SSG of less than about 2.40 and comprise a core of high molecular weight polytetrafluoroethylene and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The mixture is extruded into a coagulation bath containing a concentration of ions which coagulate the matrix polymer to form an intermediate fiber structure. The intermediate fiber structure is sintered to decompose the matrix polymer and coalesce the non-melt-processible fluoropolymer particles to form the fiber. The present invention also provides for spinning composition useful for the dispersion spinning of non-melt-processible fluoropolymer fiber.

Owner:THE CHEMOURS CO FC LLC

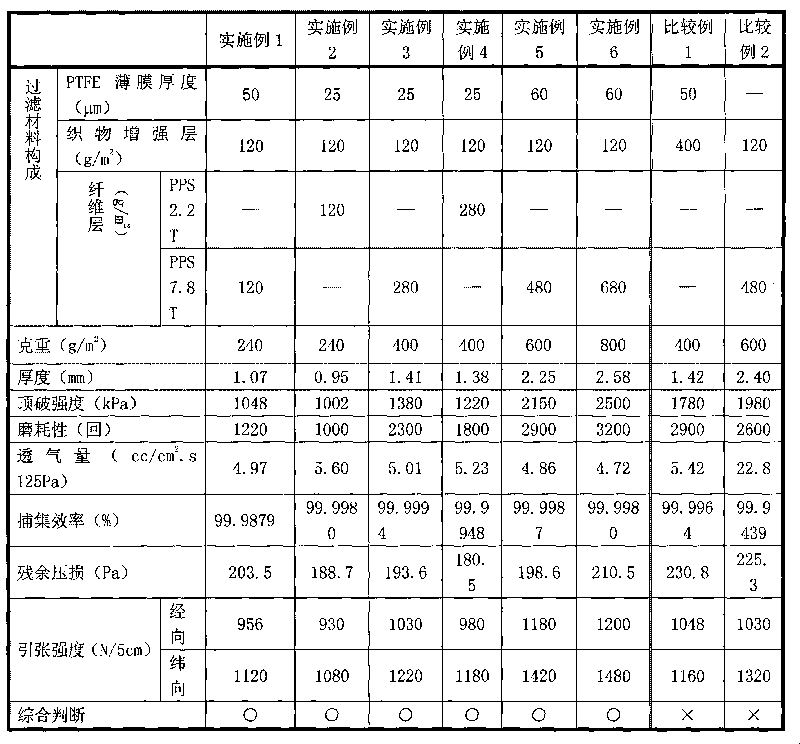

Filter material and use thereof

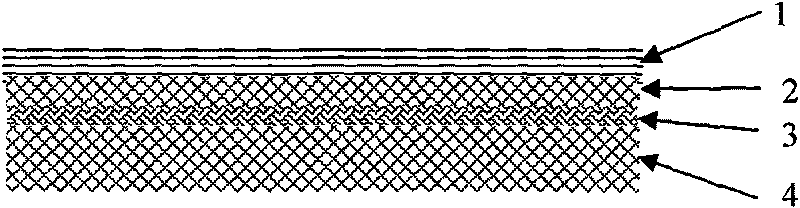

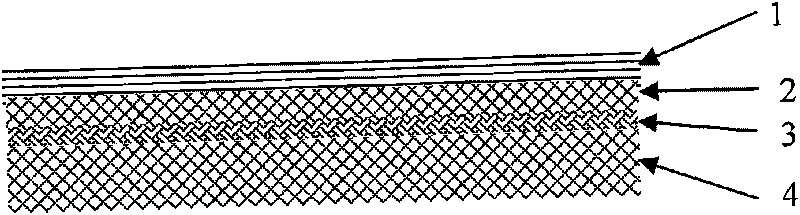

InactiveCN101745270AImprove capture efficiencyImprove wear resistanceDispersed particle filtrationLayered productsKeelMaterials science

The invention discloses a filter material and use thereof. The filter material adopts a structure having a first polytetrafluoroethylene membrane layer, a second fabric reinforcing layer and a third fiber layer, wherein a intermediate fiber layer, which is a fiber needling combination through layer formed by part of fibers, passing through the second layer, of the third layer when the second layer and the third layer are combined by needling, is arranged between the first and second layers. The filter material of the invention has the advantages that: the efficiency of the capture of the dust in exhausted gases is high; the keel has excellent mechanical strength properties such as wear resistance or fracture strength, high stiffness and stable size; and the service life is long. Thus, the filter material is particularly suitable to be used as dedusting filter cloth for filtering high-temperature gases exhausted from garbage incinerators, coal-fired boilers, metal smelting furnaces and the like and used in filter bags formed by the filter cloth.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

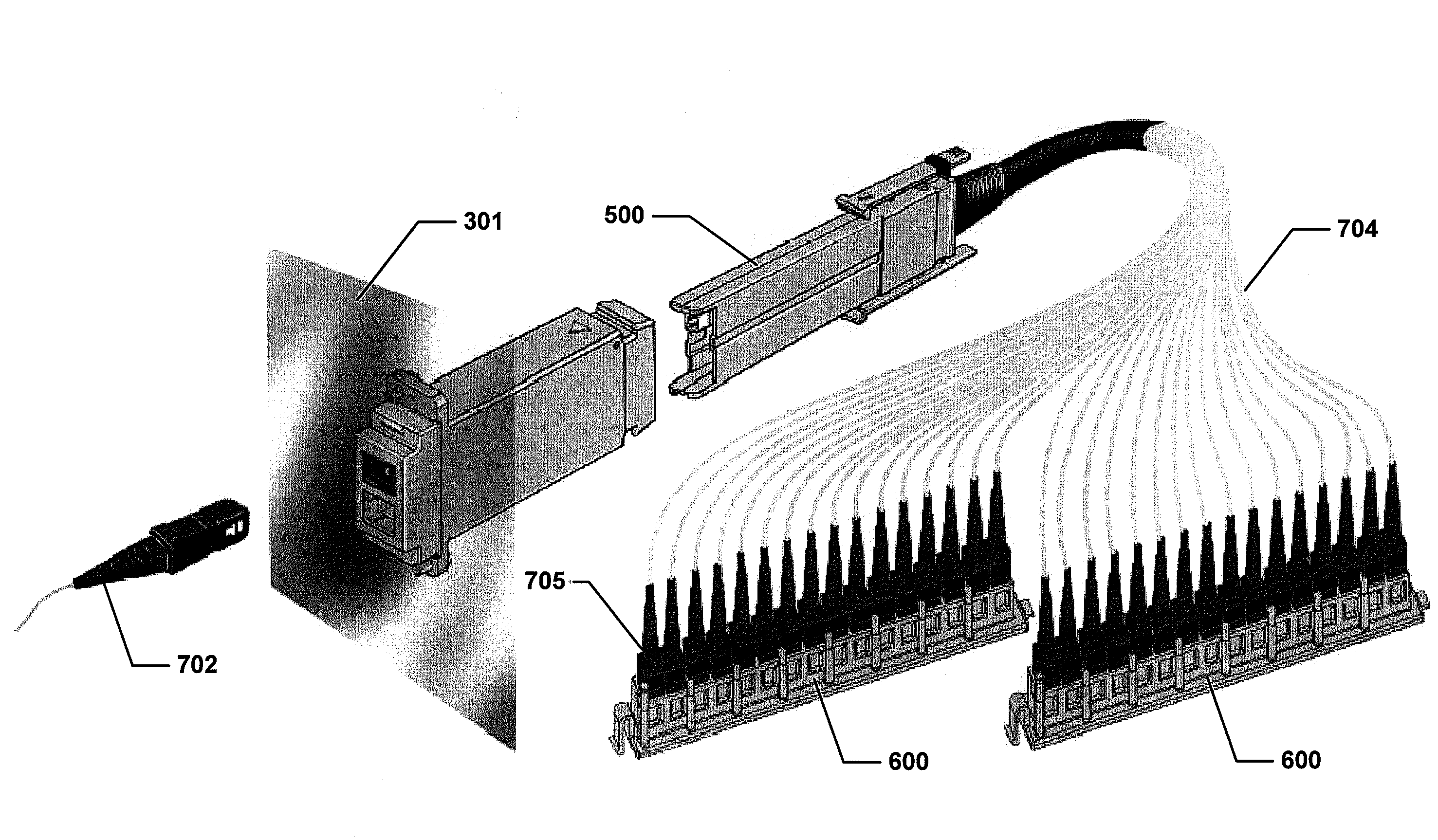

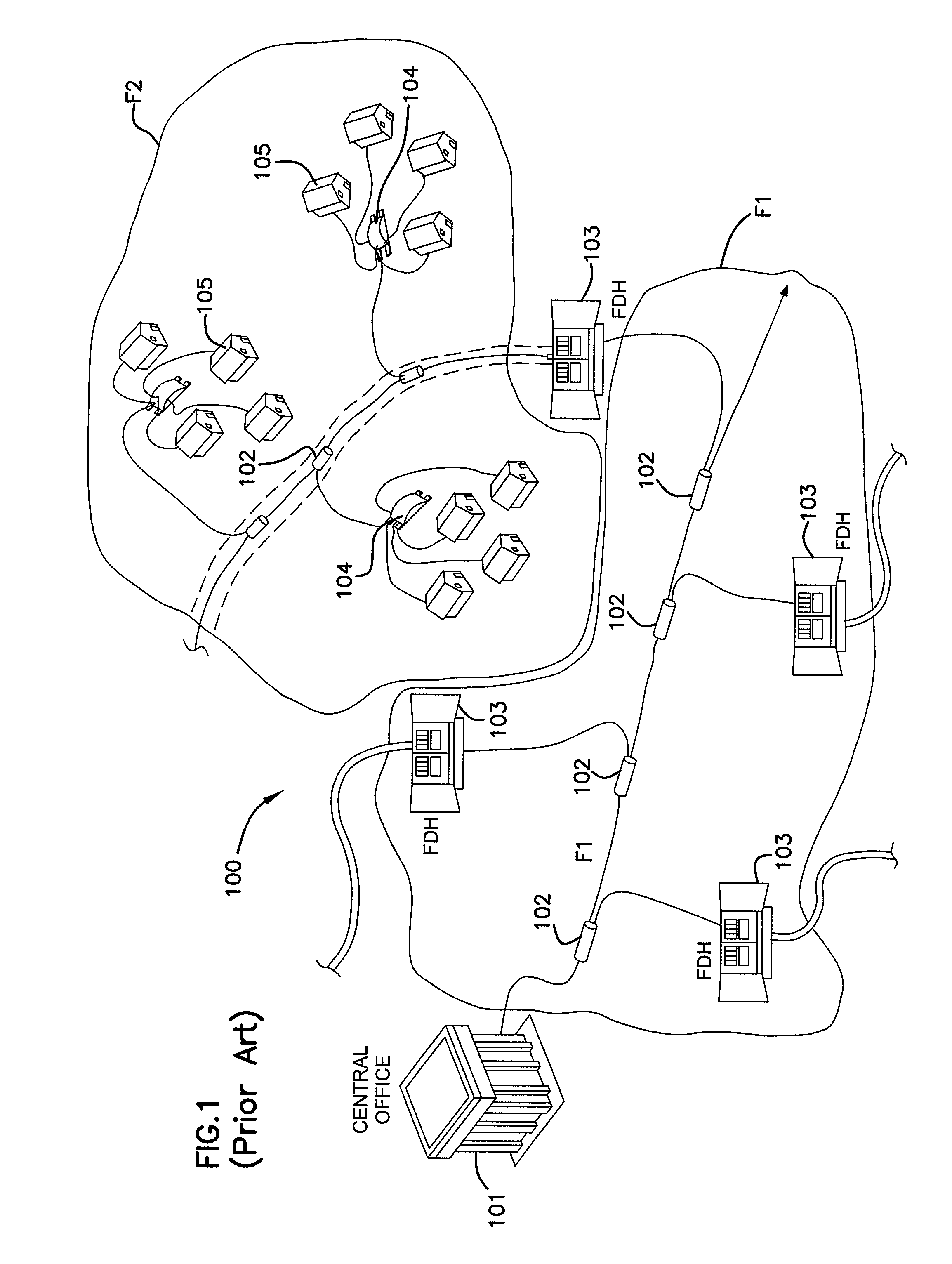

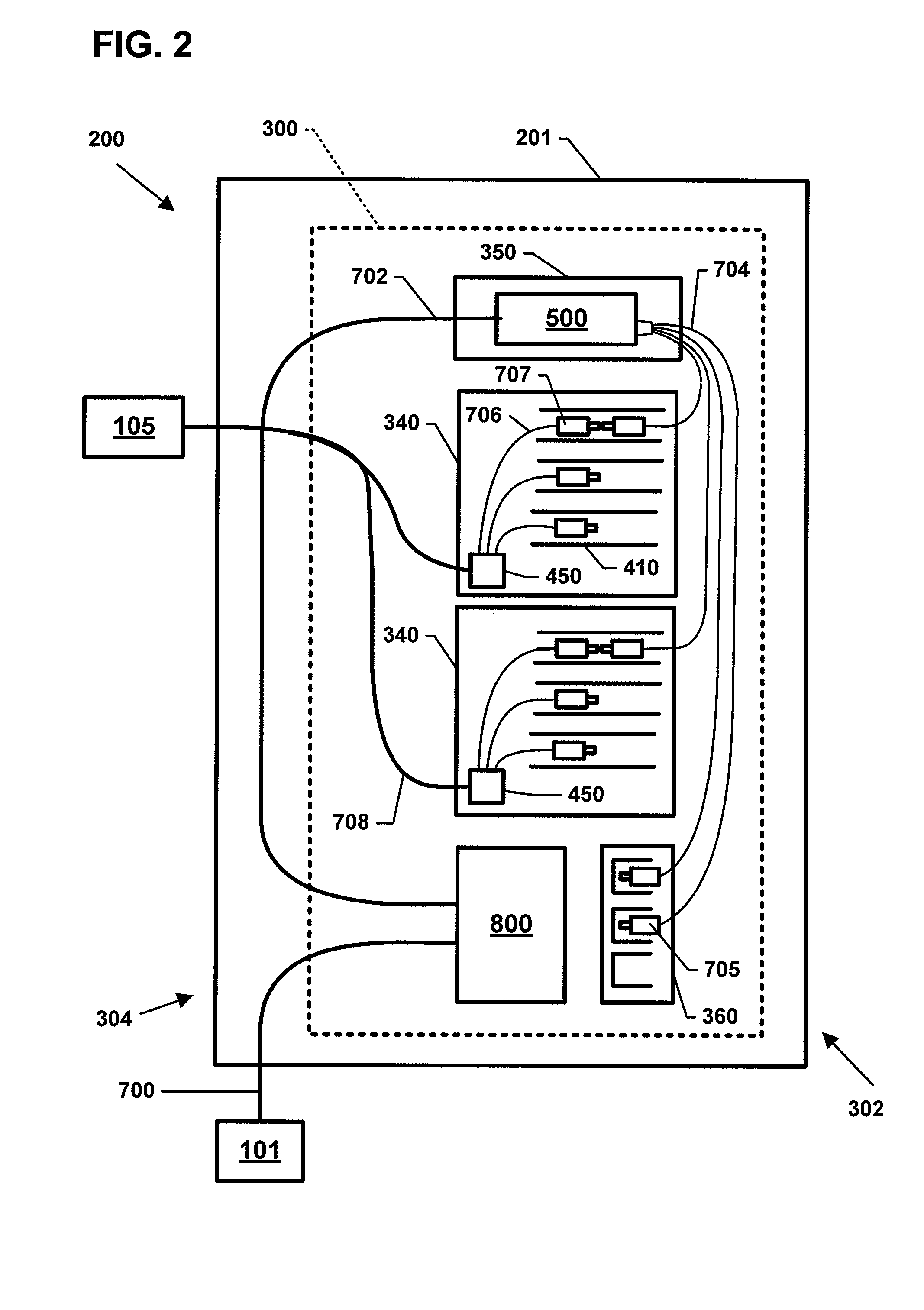

Fiber distribution hub

ActiveUS8068712B2Easy accessImprove scalabilityOptical light guidesIntermediate muscle fiberEngineering

A fiber distribution hub includes a cabinet; a termination region positioned within the interior of the cabinet; at least one termination module mounted in at least one opening defined at the termination region; fiber optic connectors coupled to termination adapters of the termination module; intermediate fibers extending rearwardly of the fiber optic connectors; and a multi-fiber connector terminating the intermediate fibers. The termination module includes a housing enclosing the termination adapters. One or more termination modules can be incrementally added to the fiber distribution hub.

Owner:COMMSCOPE TECH LLC

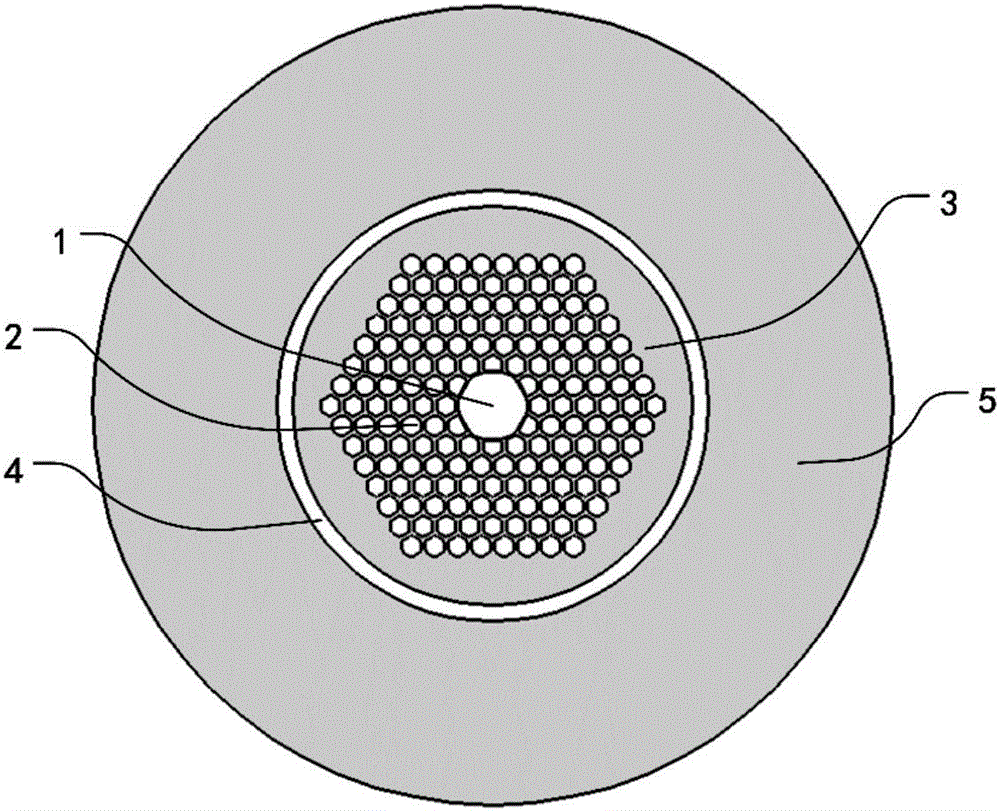

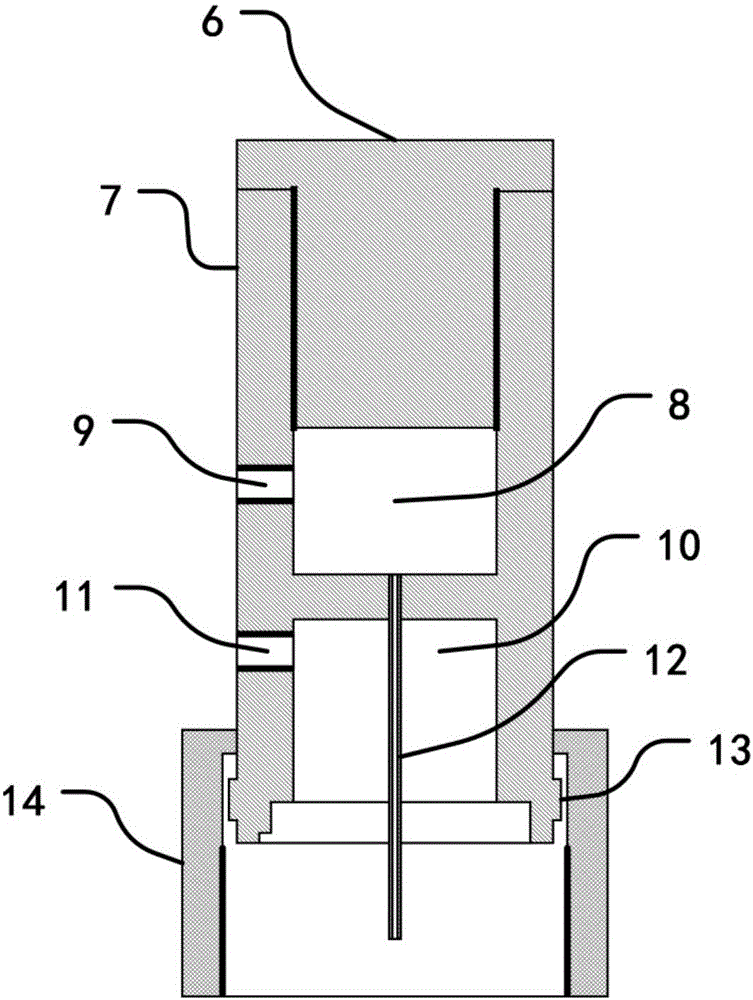

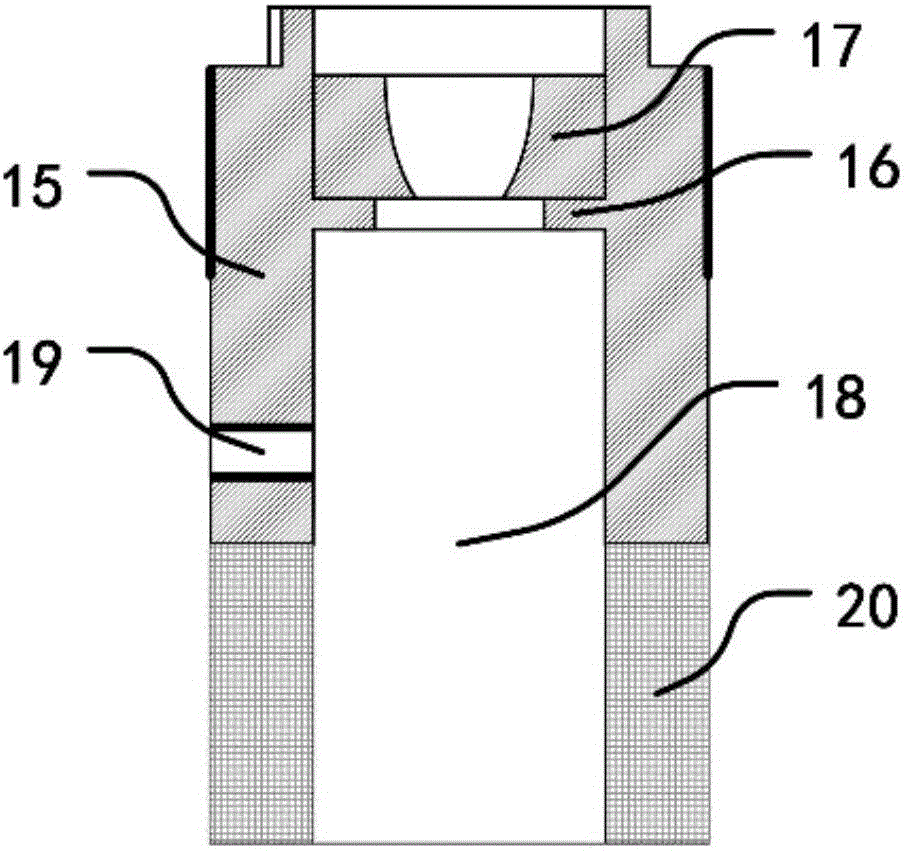

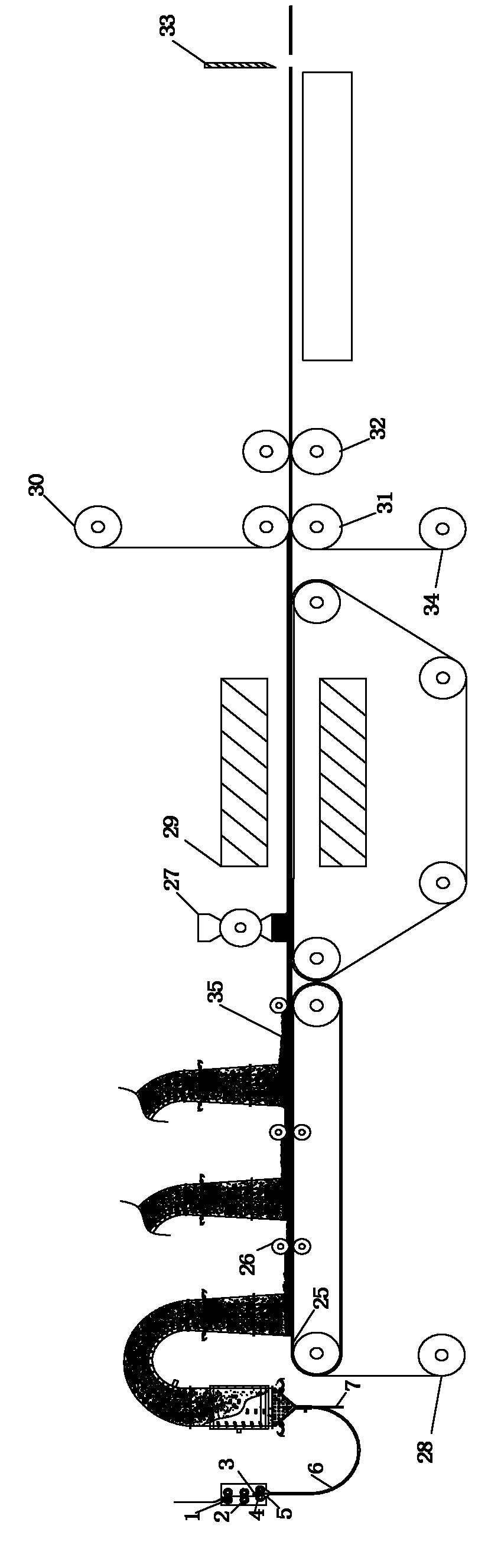

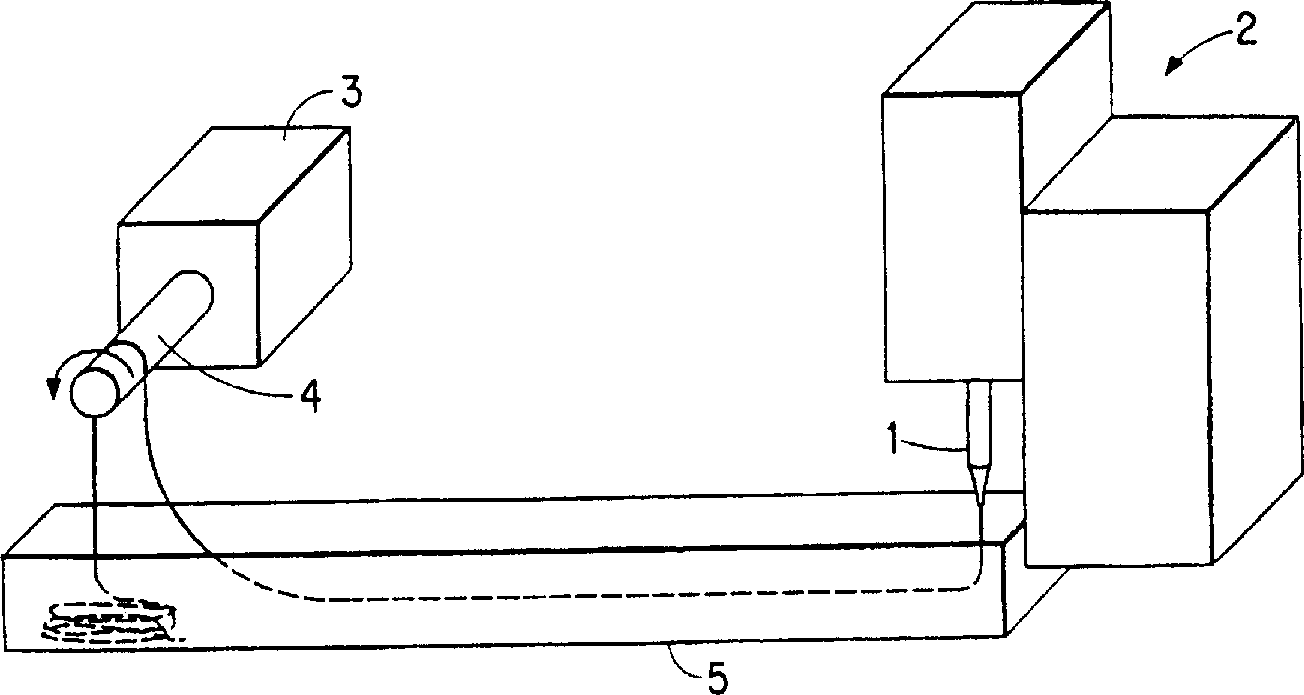

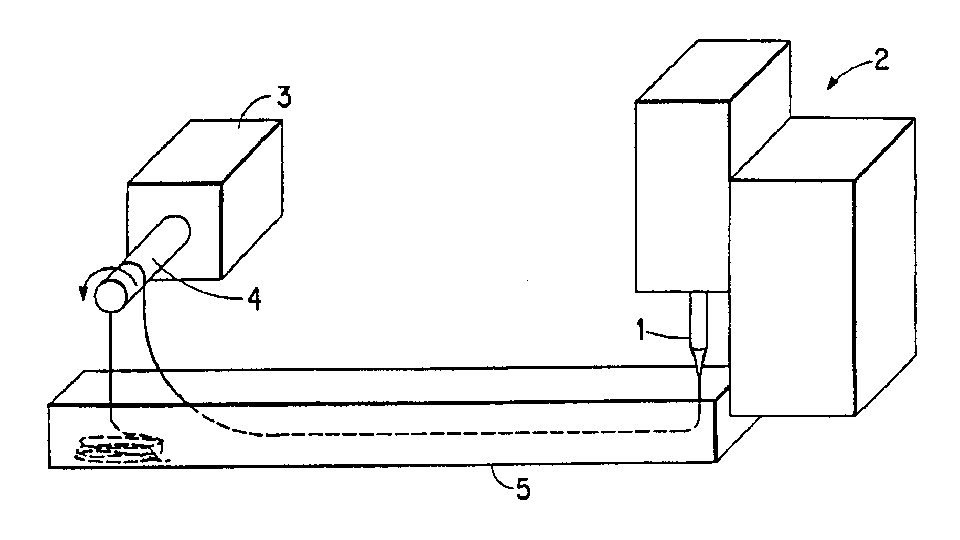

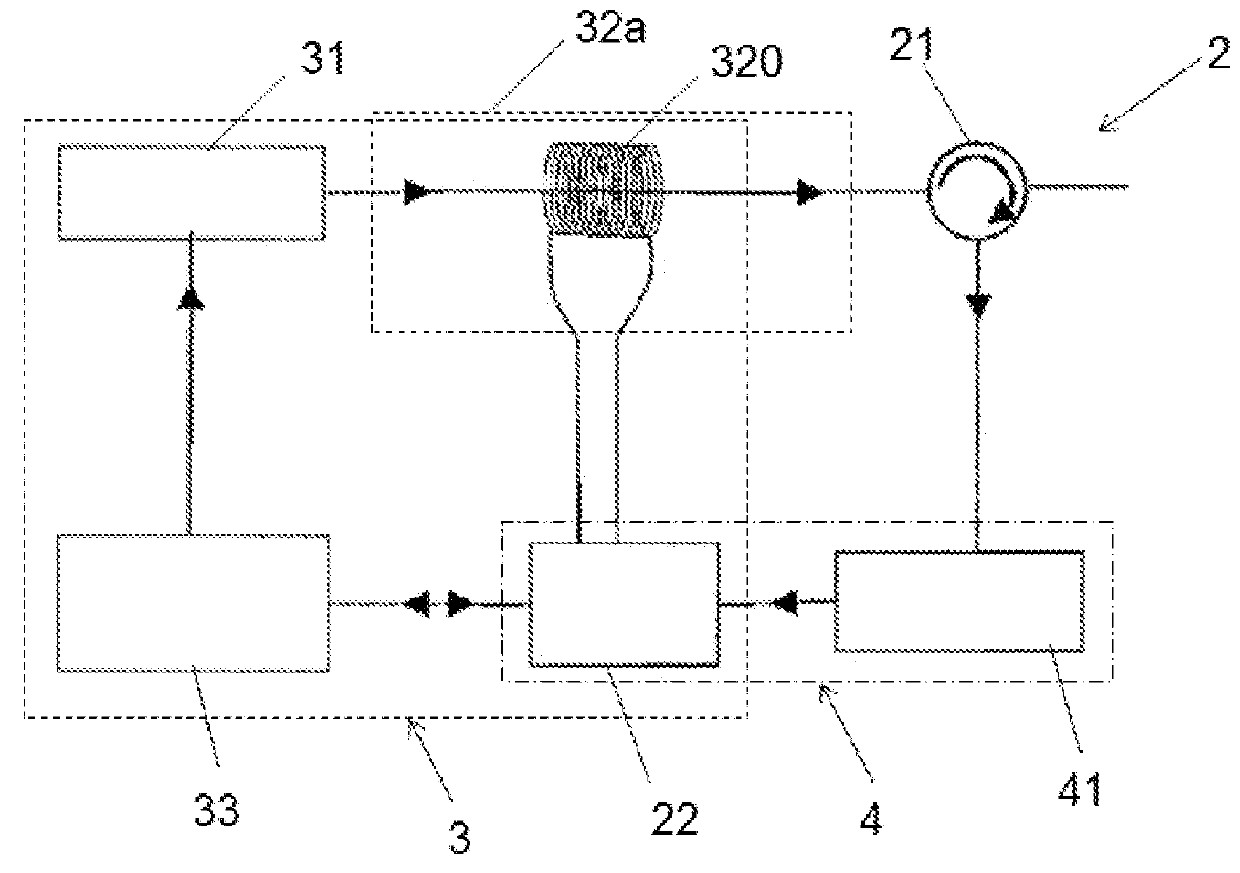

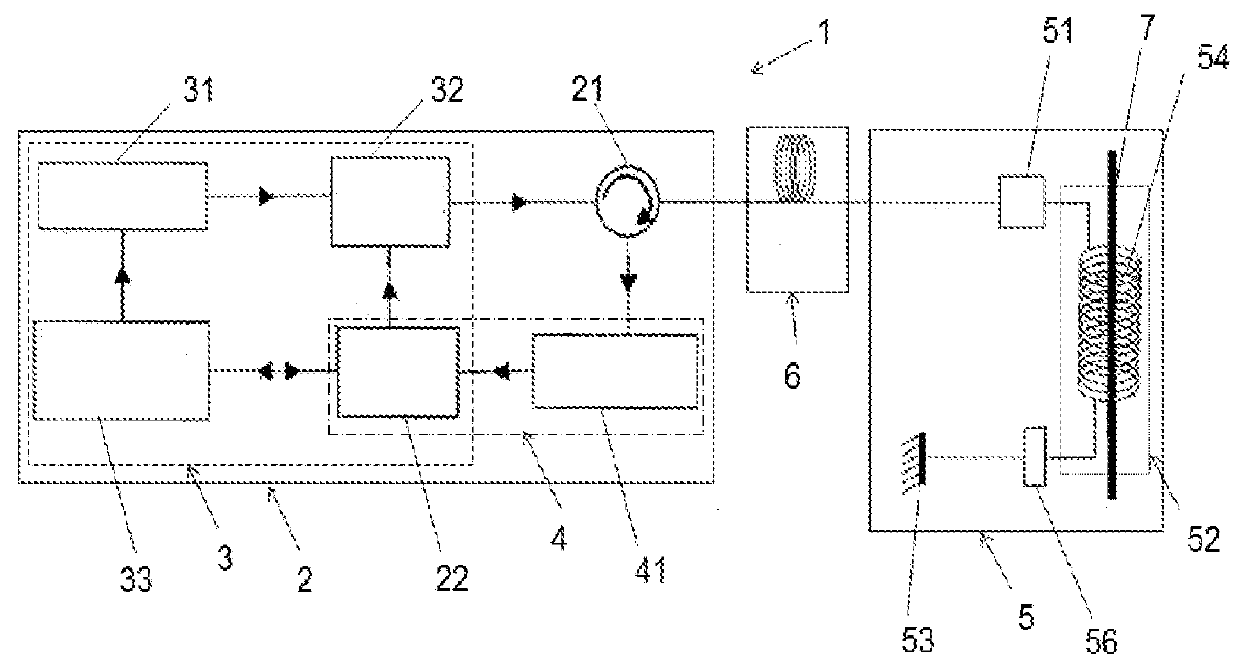

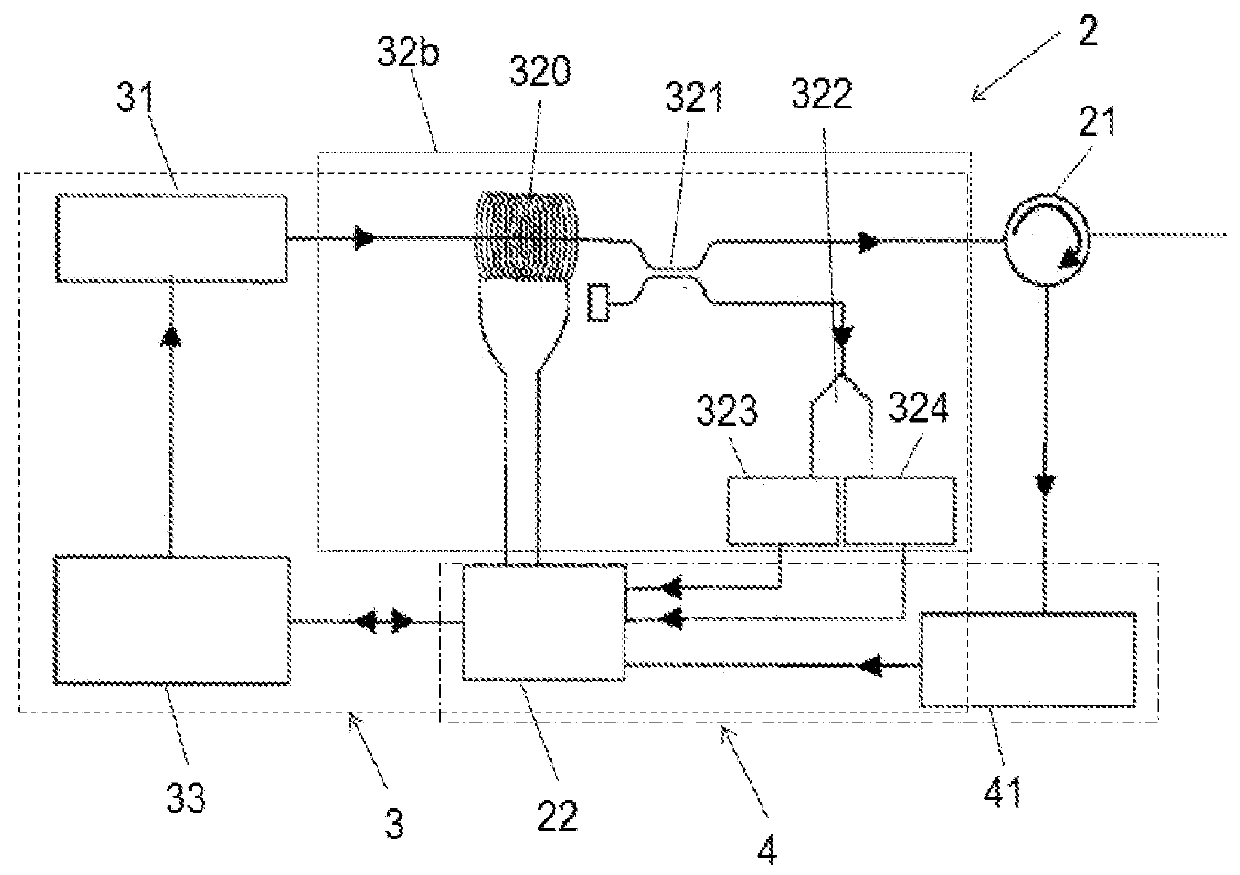

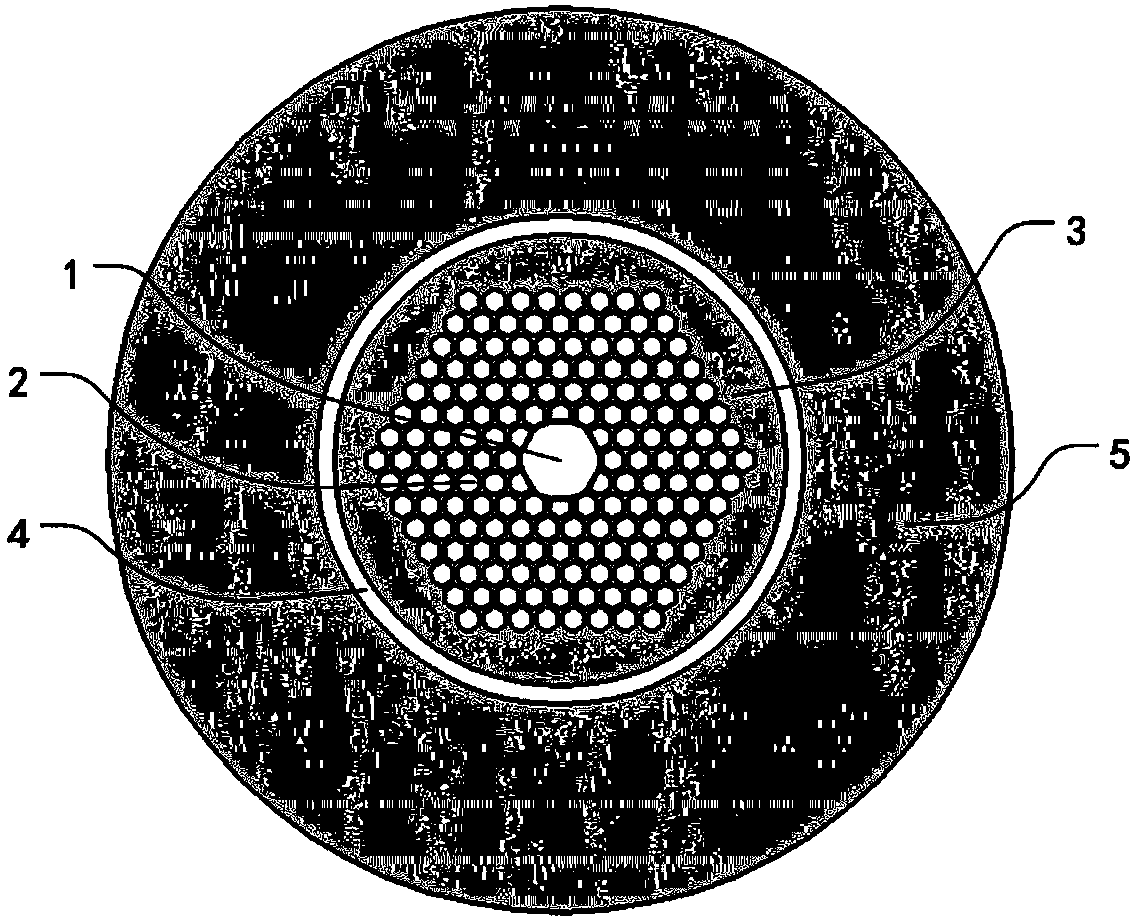

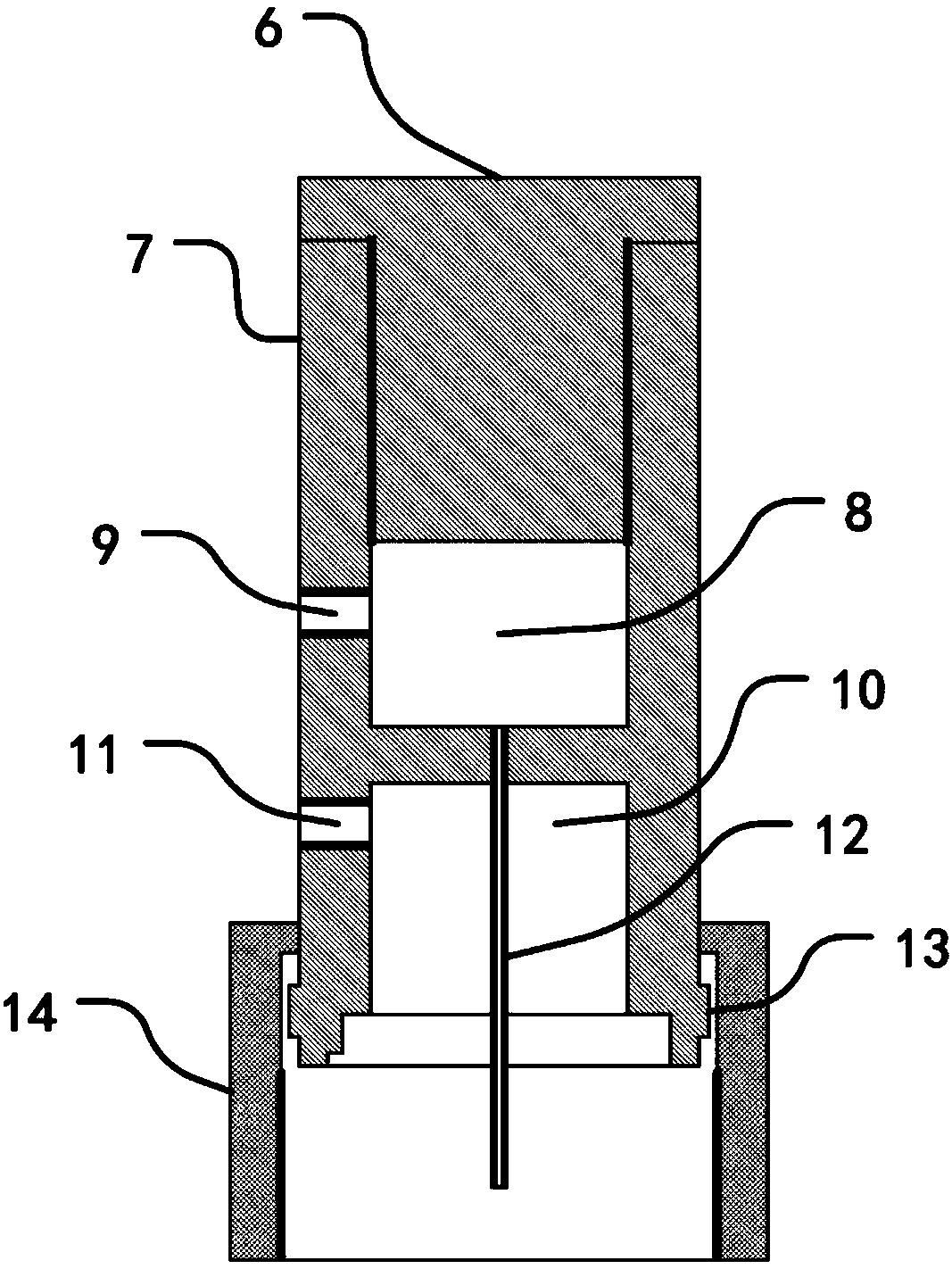

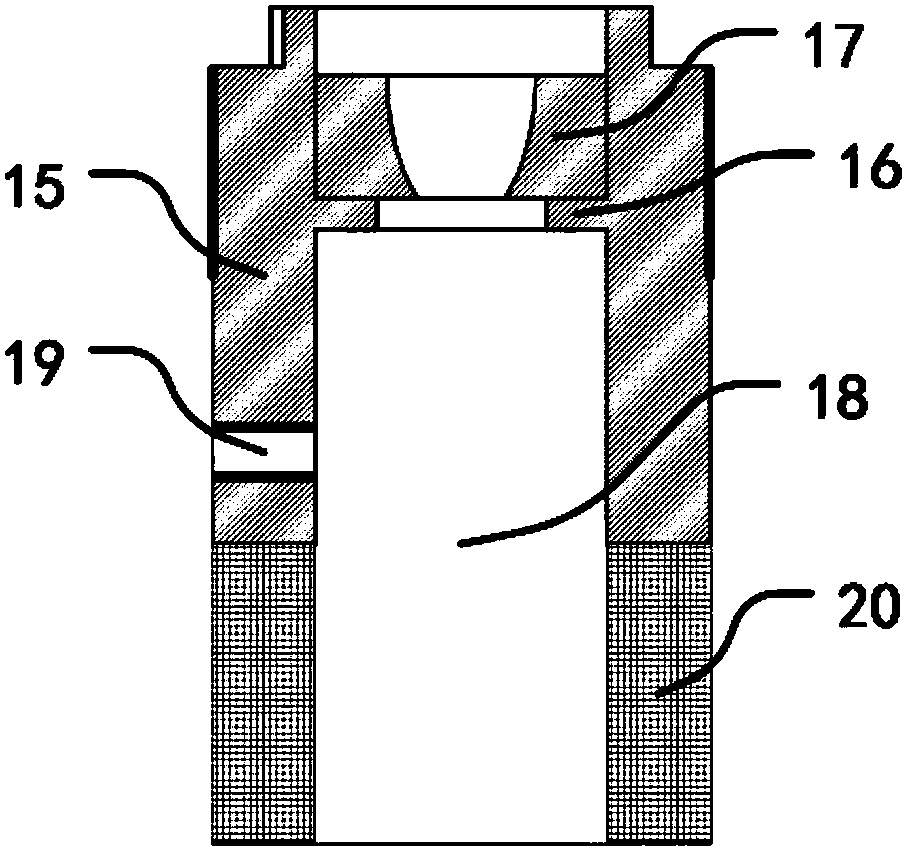

An air pressure control method and device used for photonic band gap optical fiber drawing

ActiveCN106495464AStable air pressureSolve the problem of independent and precise control of regional air pressureGlass making apparatusEngineeringIntermediate Fiber

The invention discloses an air pressure control method and device used for photonic band gap optical fiber drawing, and belongs to the technical field of optical fiber manufacturing. The method includes firstly inserting an intermediate into an intermediate fixing table, sealing the intermediate and the intermediate fixing table with sealing glue, connecting a single-cavity body and a double-cavity body in a threaded manner, with a fiber core duct being inserted into an intermediate fiber core during connection, and after assembling is finished, communicating a fiber-core-cavity gas pipe port, a cladding-cavity gas pipe port and an outer-cavity gas pipe port to a gas chamber of an air pressure control electric part through gas guiding pipes separately to achieve independent air pressure control of three regions which are a fiber core cavity, a cladding cavity and an outer cavity. The method and the device overcome a problem of independent precise air pressure control of the three regions during a photonic band gap optical fiber drawing process. The method and the device have universality and are suitable for porous micro-structured optical fiber drawing requiring independent air pressure control for separated regions. A pressure difference is adopted to determine on-off control time of an electromagnetic valve, thus controlling a gas flux through the pressure difference and increasing air pressure control precision.

Owner:BEIHANG UNIV

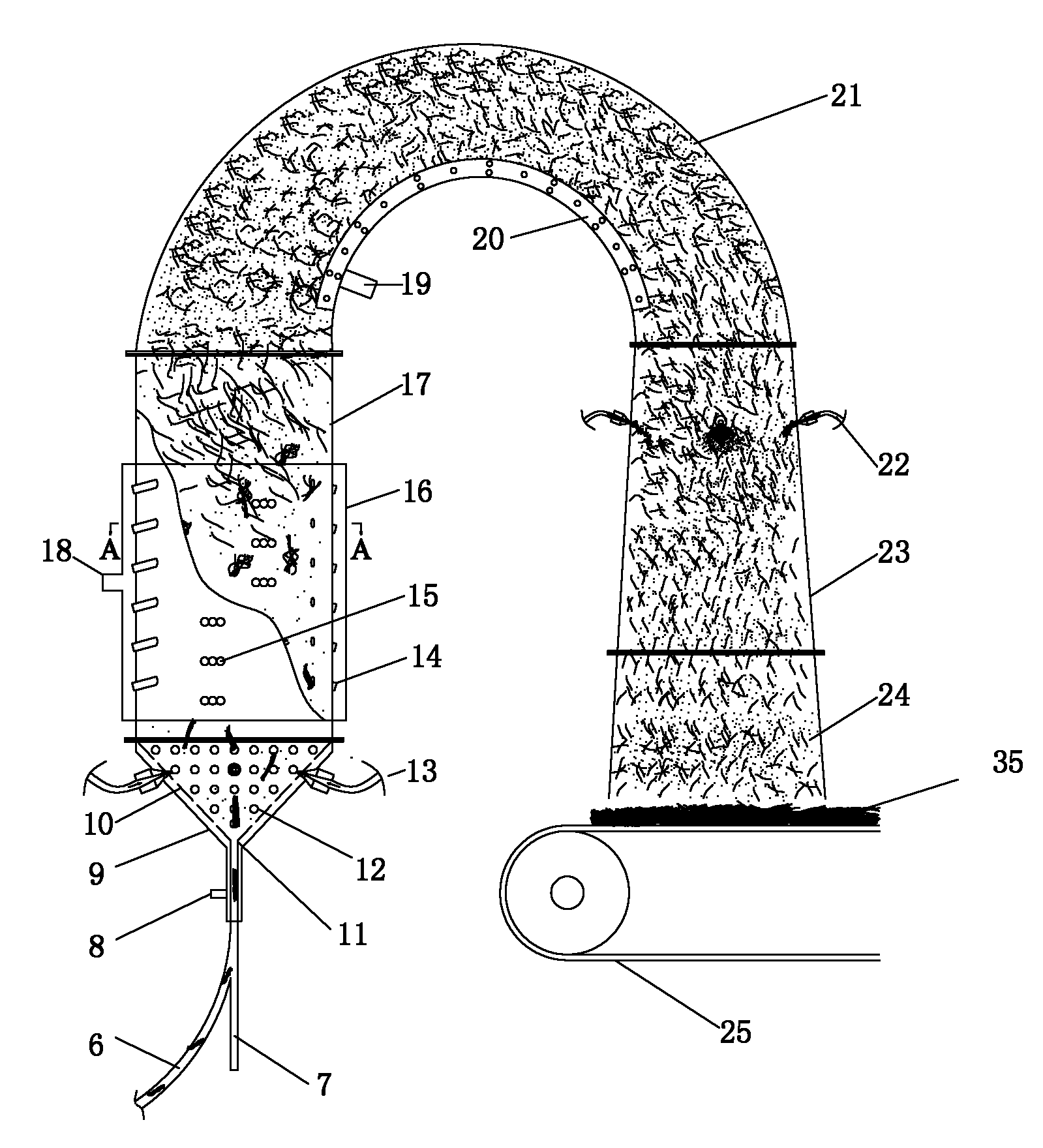

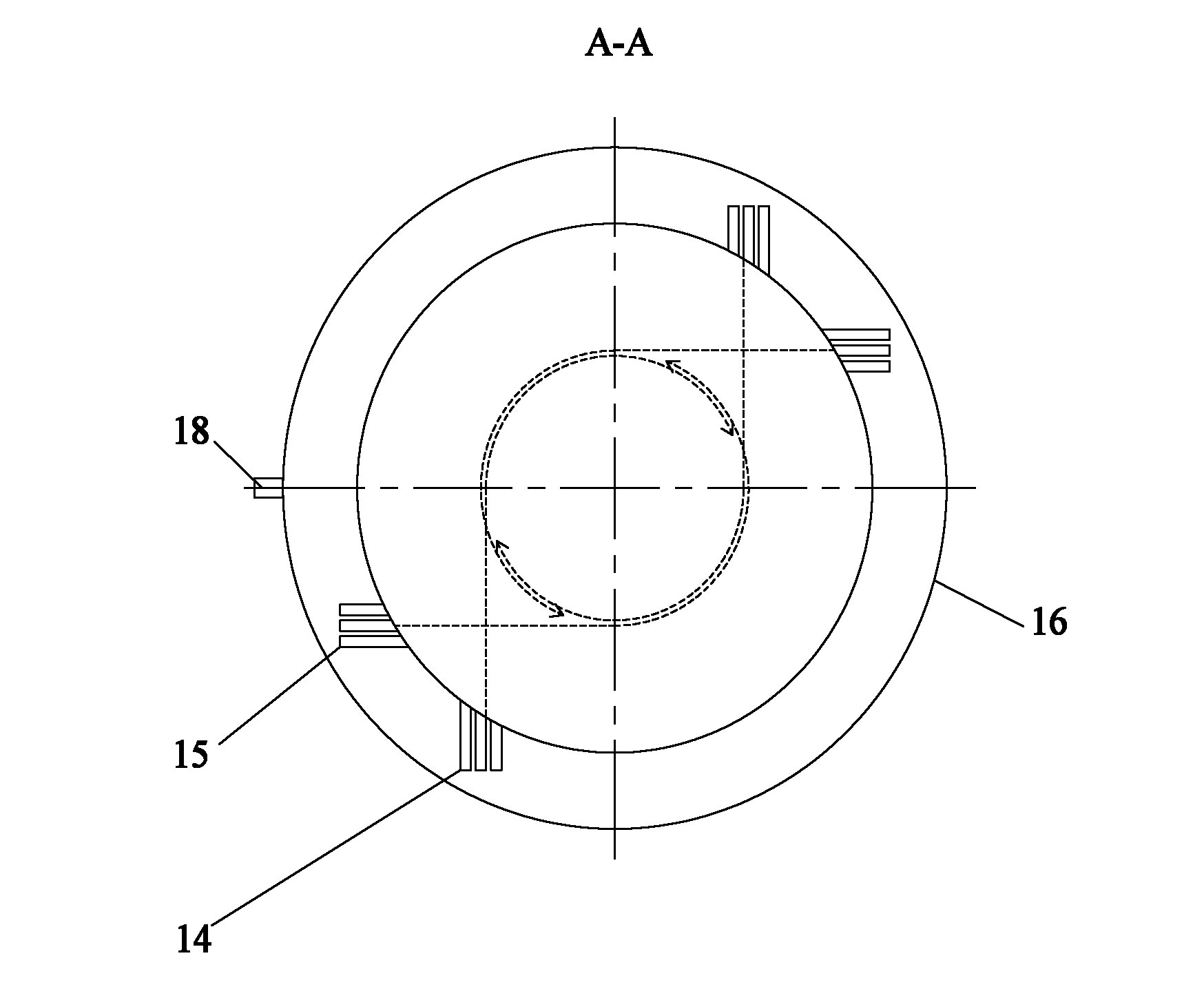

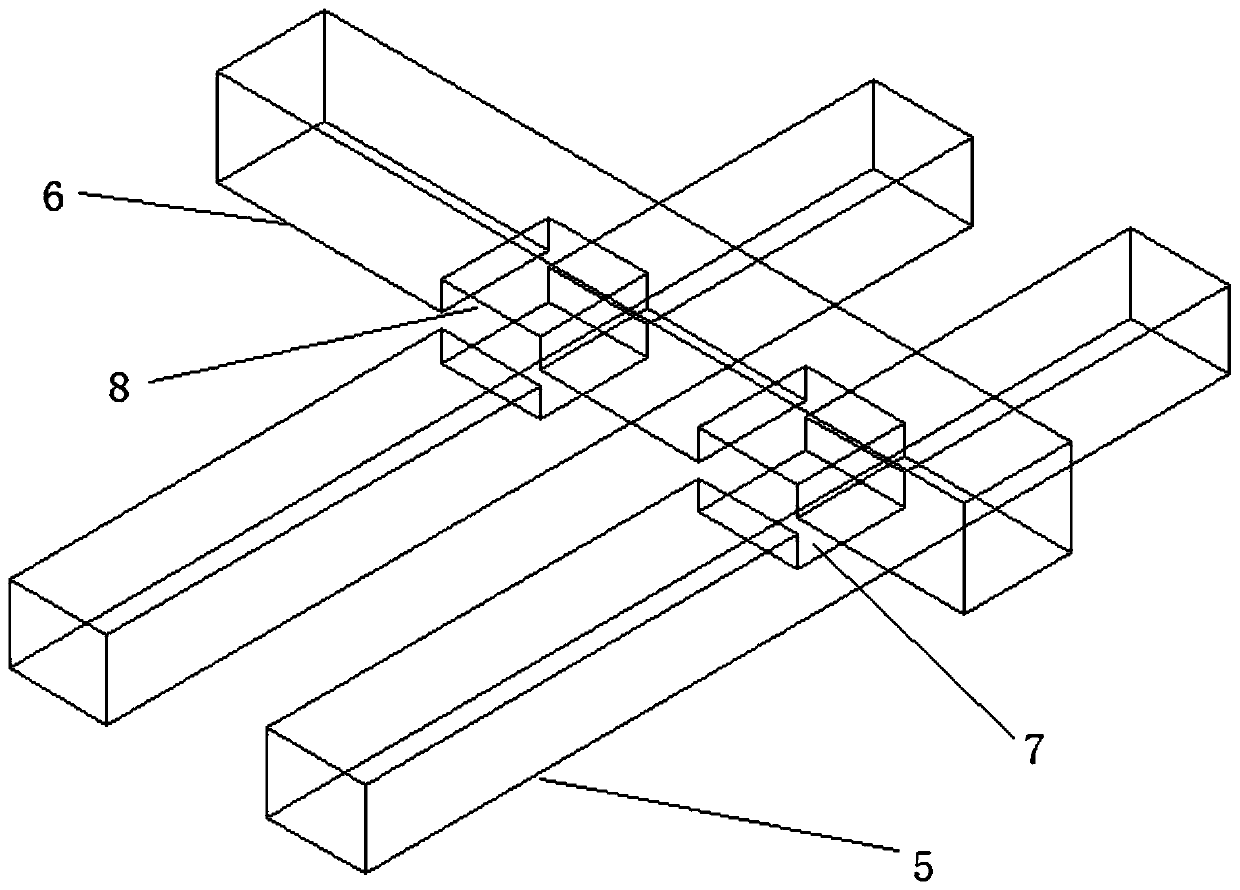

Cluster fiber thermoplastic composite sheet material

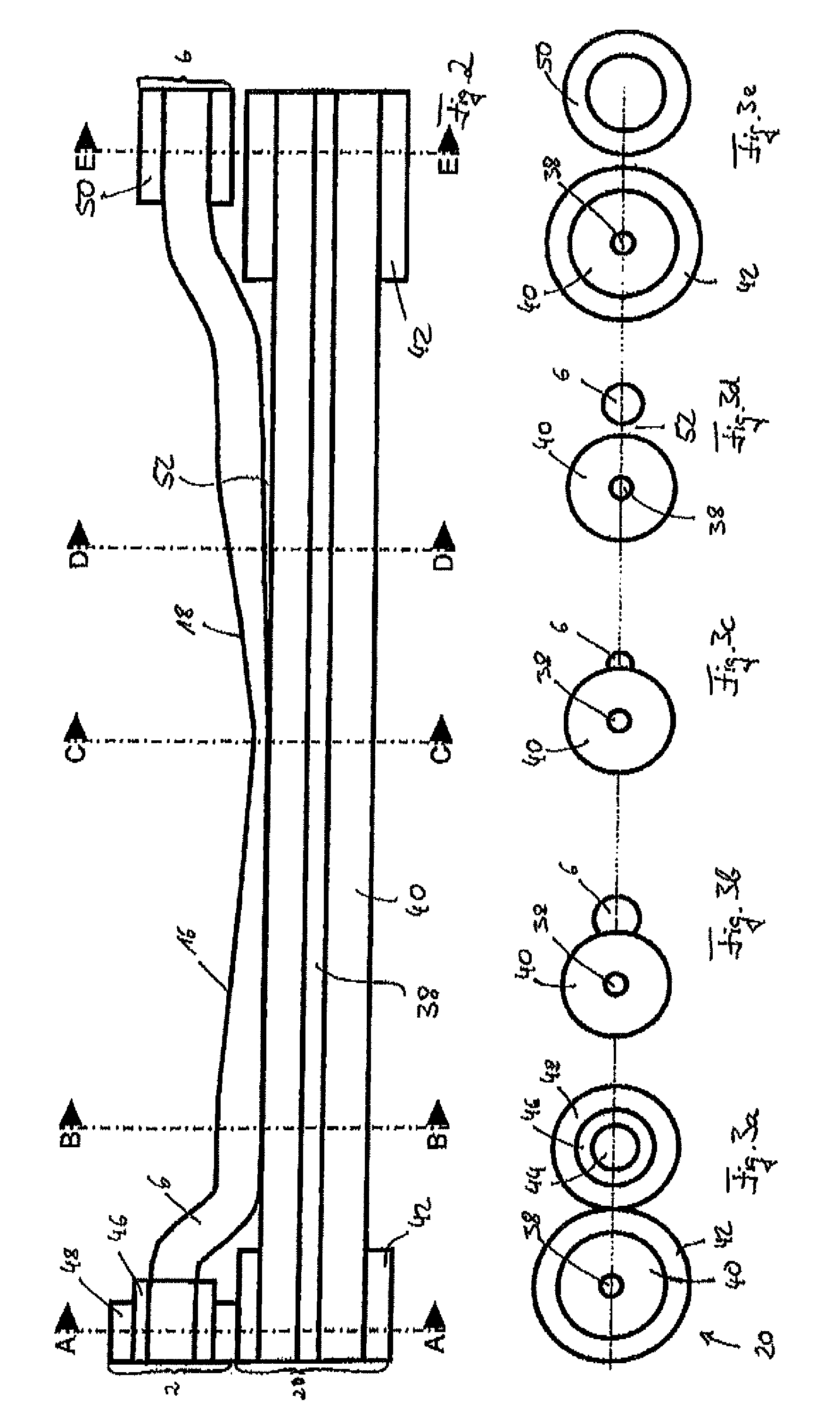

ActiveCN102416718AMeet feature requirementsHigh mechanical strengthLayered productsNon-woven fabricsIntermediate muscle fiberVolumetric Mass Density

The invention discloses a cluster fiber thermoplastic composite sheet material, comprising a sheet material upper superficial layer (37), an intermediate fiber and mixed powder matrix layer (35) and a sheet material lower superficial layer (36). The intermediate fiber and mixed powder matrix layer (35) is produced by the following steps: (1) fiber shearing; (2) pneumatic disperse-mixing-adherence; (3) mixing settlement to form net. The cluster fiber thermoplastic composite sheet material of the invention has enhanced shear behavior, strong tension and bending resistance mechanical properties at each direction, high puffed rate, low density, and high quality intensity, and is lightweight, humidity resistant, nontoxic and harmless.

Owner:湖南亚太实业有限公司

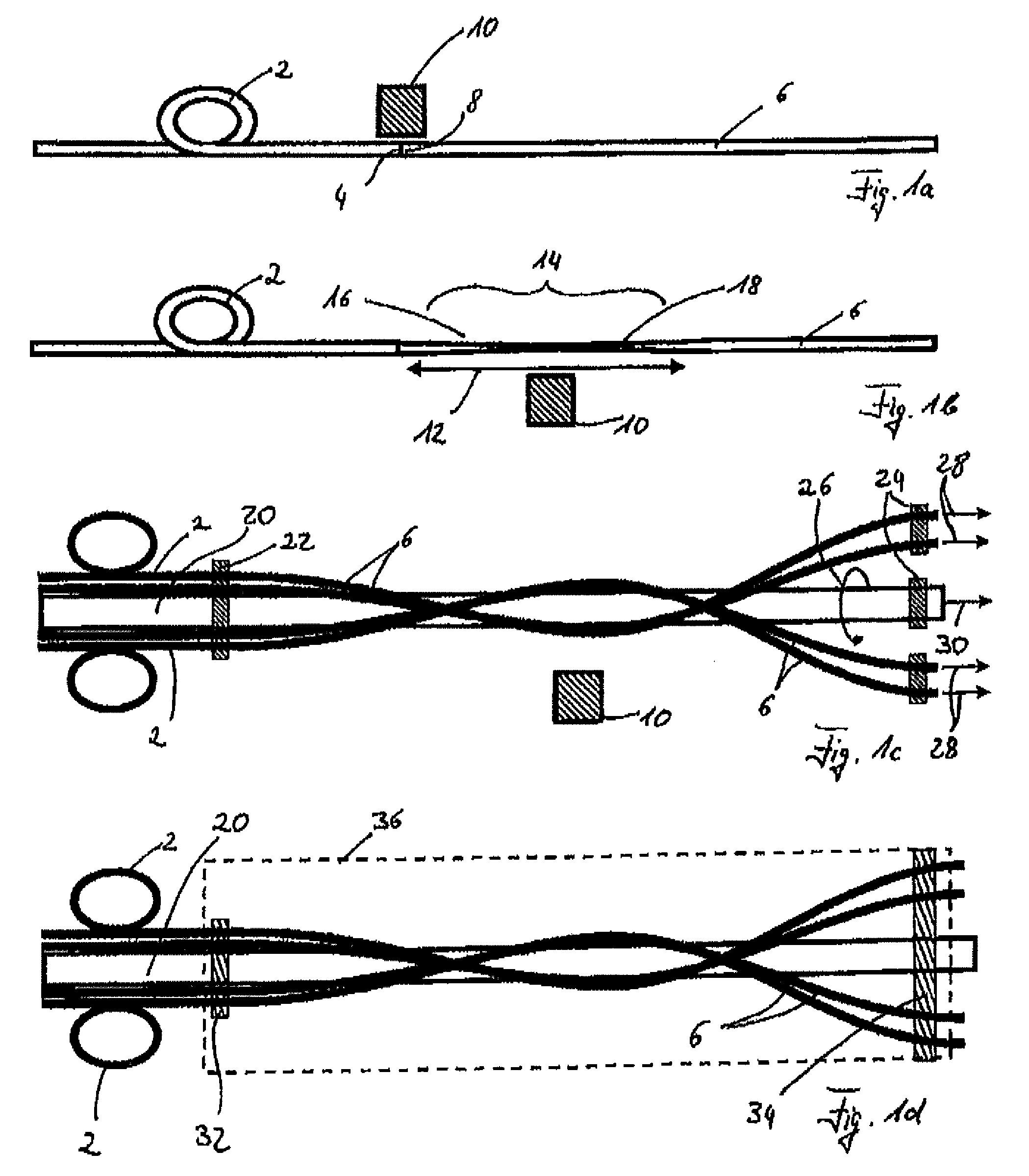

Dispersion spinning process for poly(tetrafluoroethylene) and related polymers

InactiveCN1241224AViscose forming methodAvoid serious disadvantagesArtificial filaments from cellulose derivativesWet spinning methodsTetrafluoroethylenePolymer science

A process for spinning a fully water washed fluorinated olefinic polymer intermediate fiber structure from a mixture of an aqueous dispersion of particles of the fluorinated olefinic polymer and a solution of a cellulosic ether.

Owner:TORAY IND INC

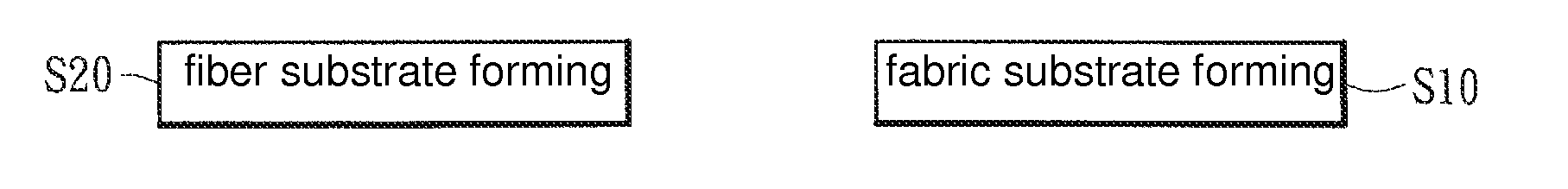

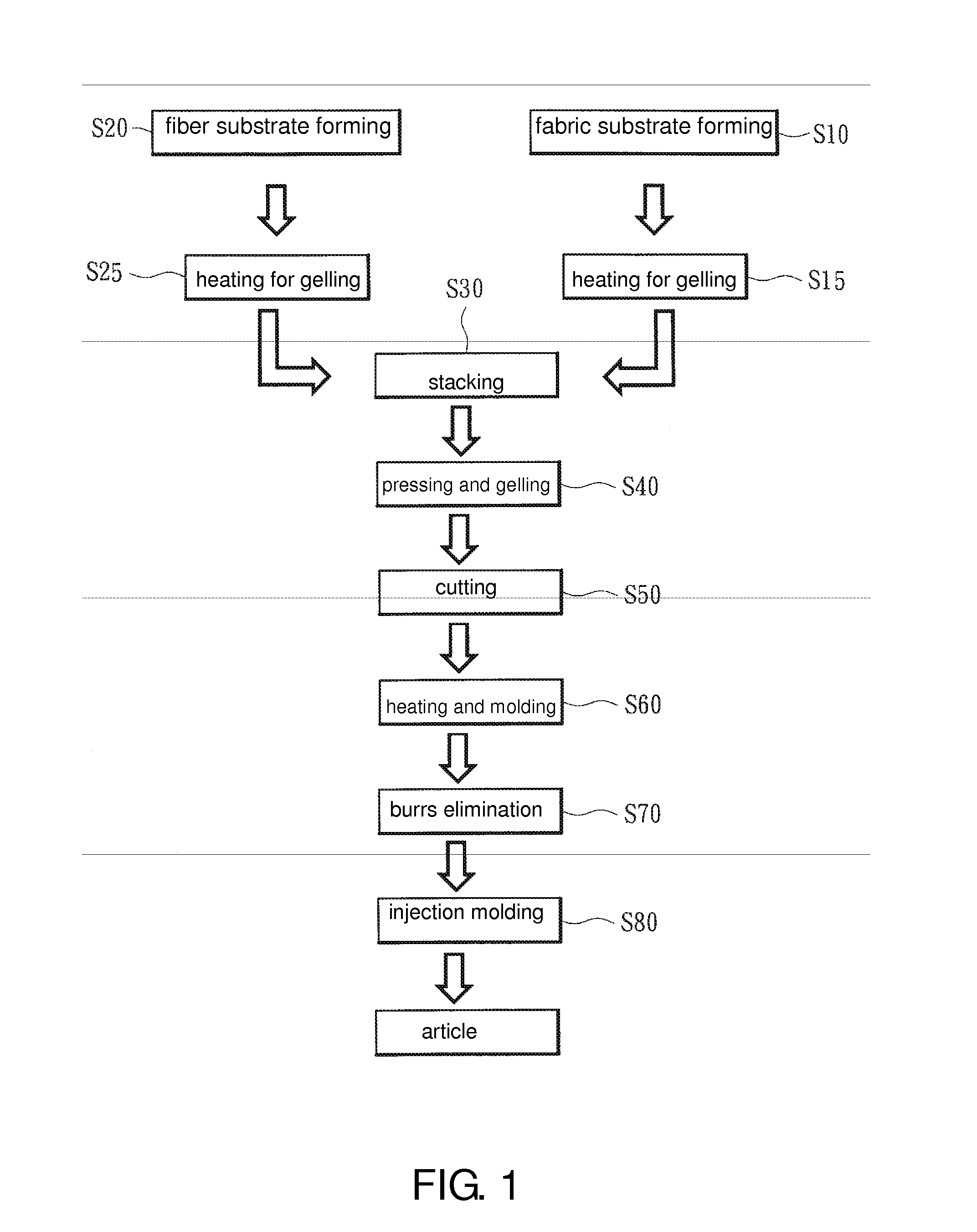

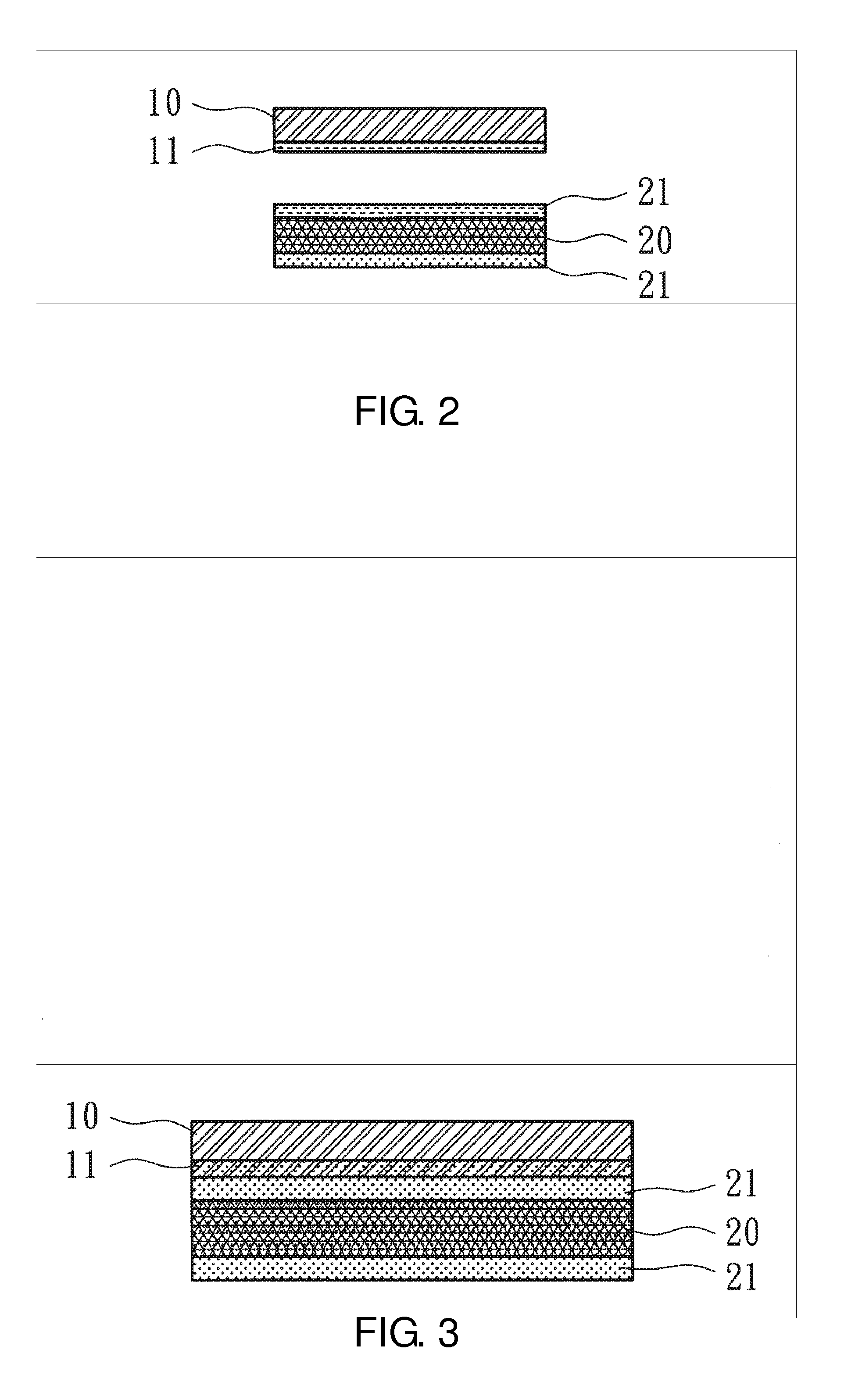

Fibrous article with fabric-like surface and process of manufacturing same

InactiveUS20110104971A1Lamination ancillary operationsLayered product treatmentIntermediate muscle fiberIntermediate Fiber

A fibrous article having a fabric-like surface and process of manufacturing same are provided. The fibrous article includes an outer fabric substrate; an intermediate fiber substrate; and an inner thermoplastic resin layer. A first thermoplastic resin is formed between the fabric substrate and the fiber substrate. The first thermoplastic resin is further formed between the fiber substrate and the thermoplastic resin layer. The thermoplastic resin layer is formed by injection molding by causing a second thermoplastic resin to react with the first thermoplastic resin. A person may have the feeling of touching fabric when touches the fibrous article.

Owner:MA SHUI YUAN +1

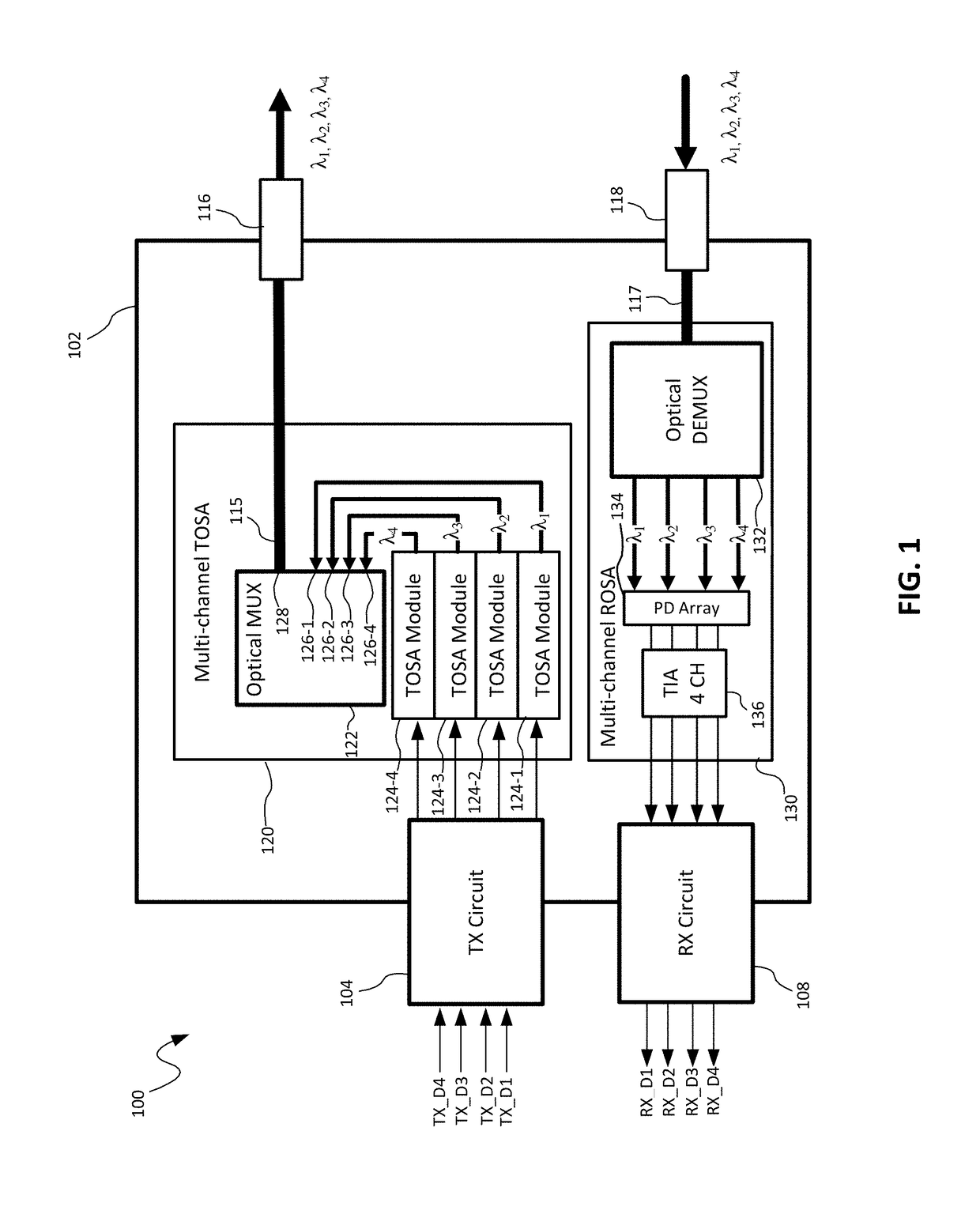

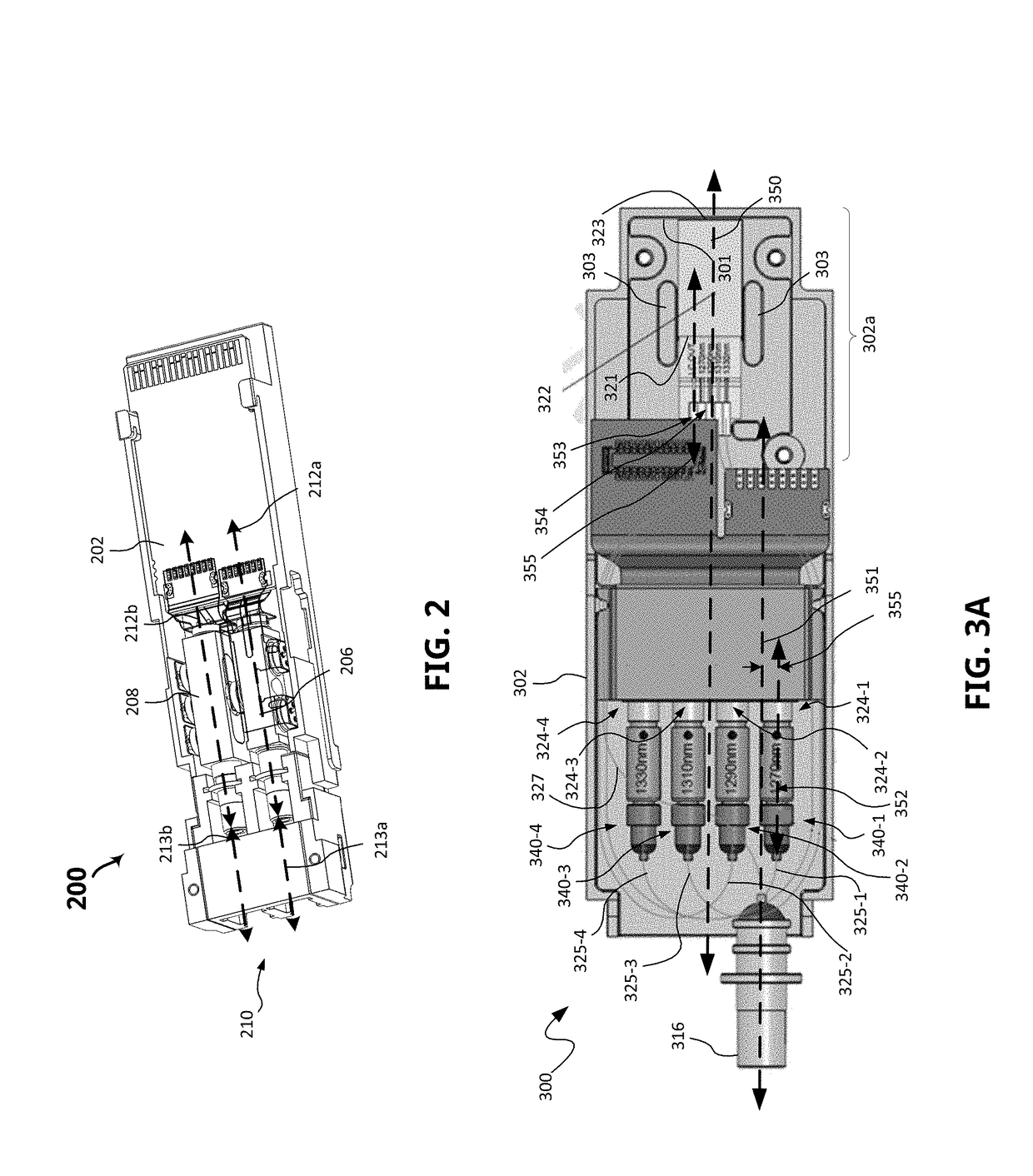

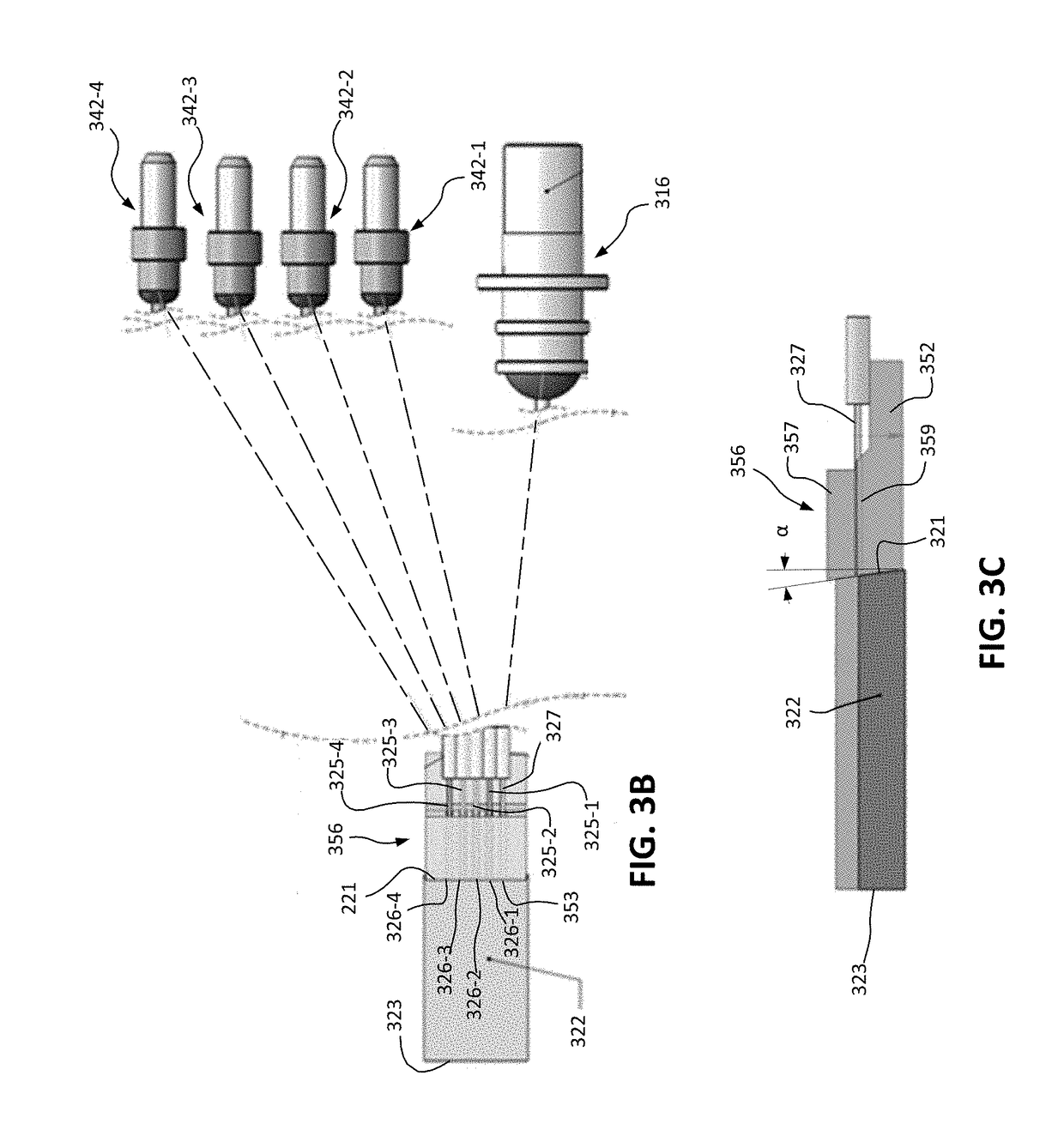

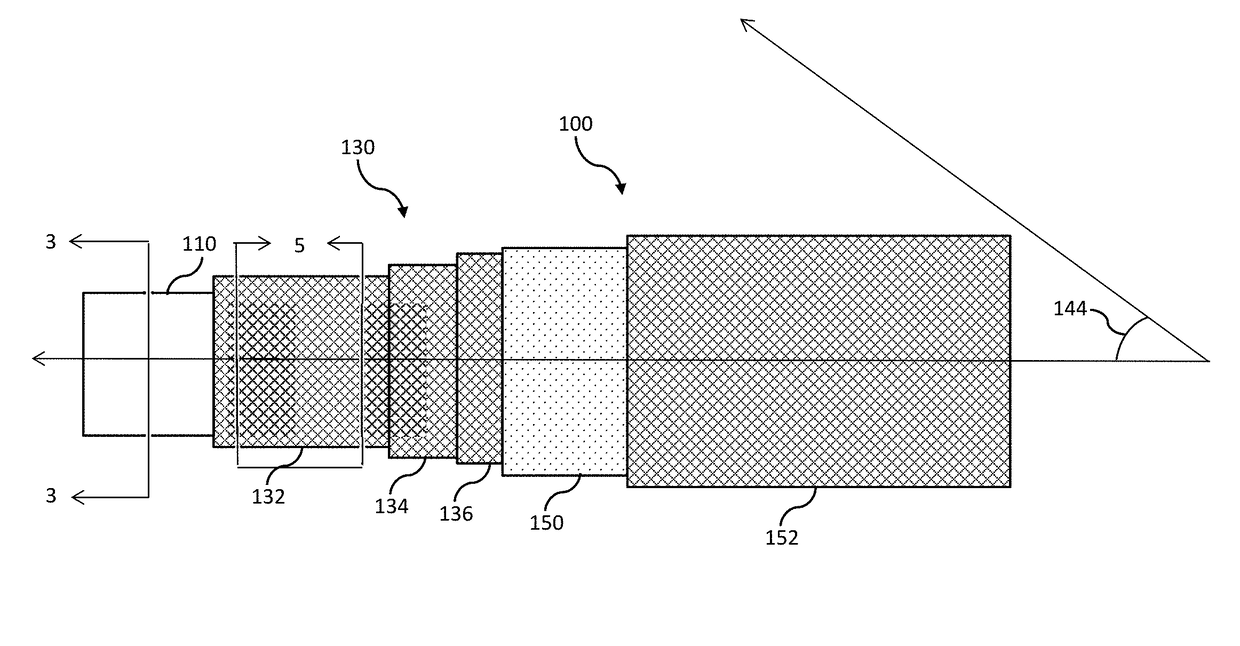

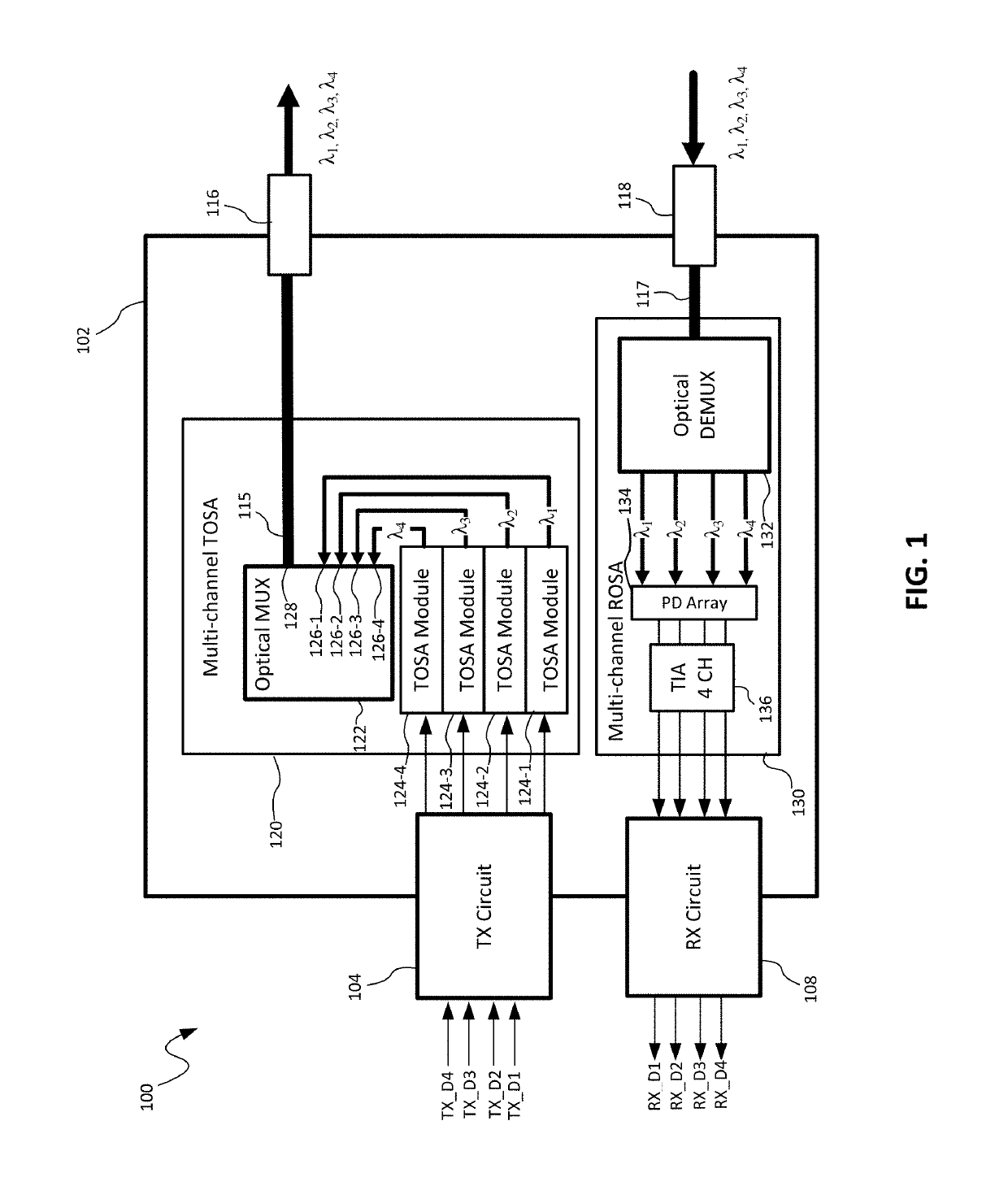

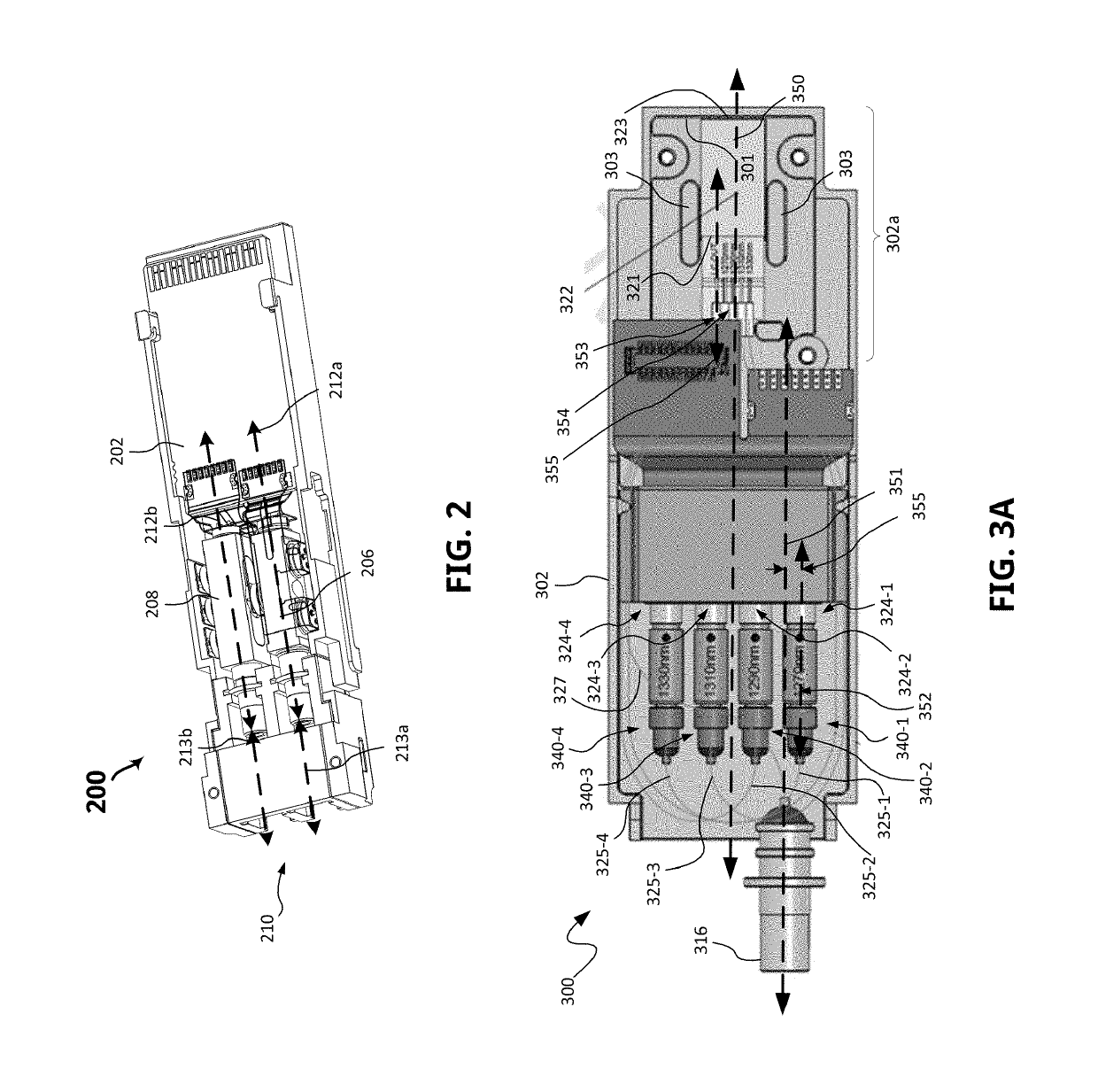

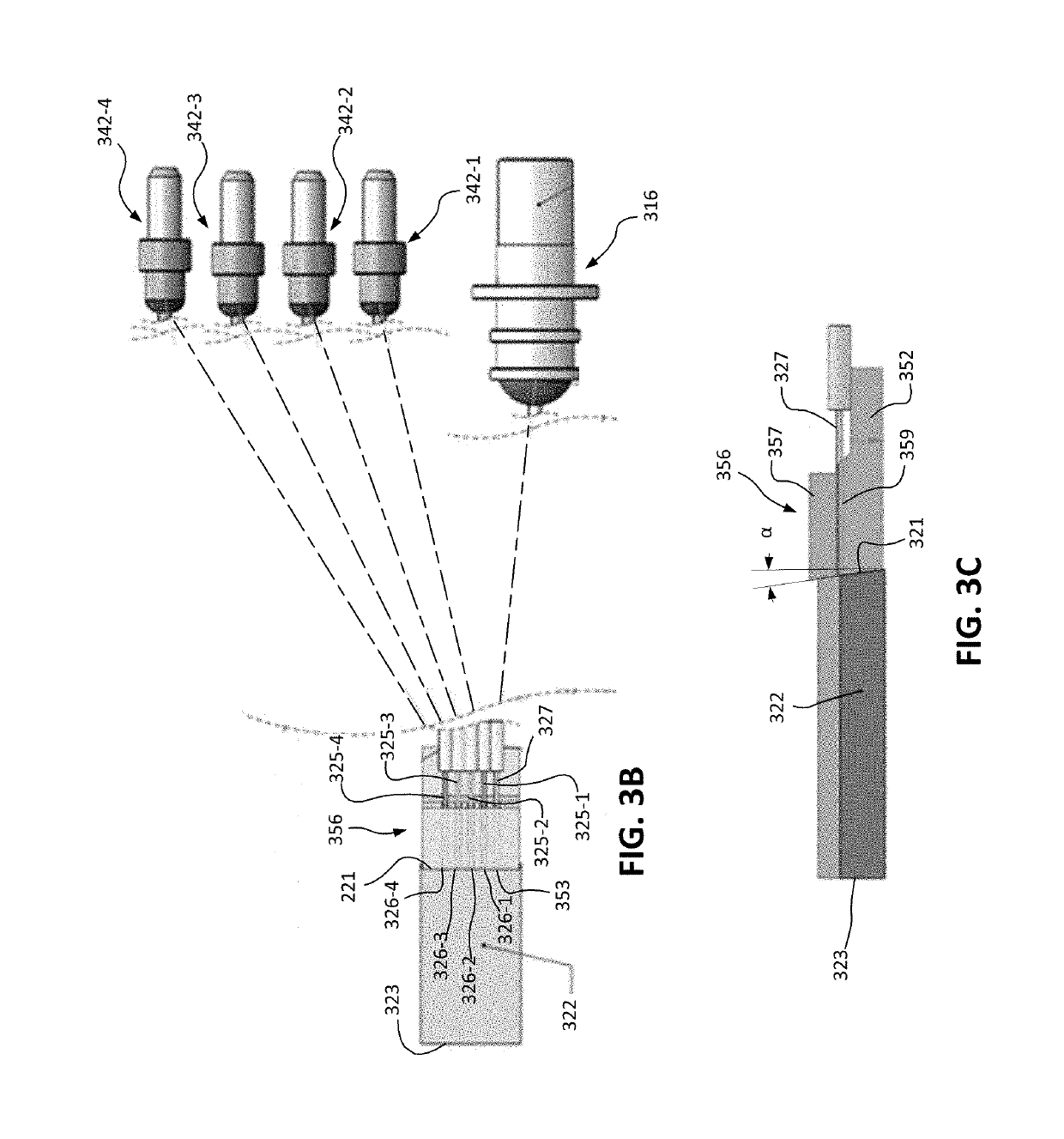

Techniques for indirect optical coupling between an optical input/output port of a subassembly housing and an arrayed waveguide grating (AWG) device disposed within the same

Techniques for flexible coupling between an optical coupling receptacle / port of an optical transceiver housing and optical components within the same are disposed. In an embodiment, an optical transceiver housing includes an intermediate fiber with a first end optically coupled to an optical coupling port and a second end optically coupled to a multiplexer / de-multiplexer device, e.g., an arrayed waveguide grating (AWG) device, PLC splitter, and so on. The intermediate fiber may be routed in the transceiver housing in a manner that and the radius of the bends may be optimized to reduce fiber bending losses. The techniques herein are equally applicable to both ROSA and TOSA modules and may be utilized to achieve flexible coupling for multi-channel transceiver devices.

Owner:APPLIED OPTOELECTRONICS

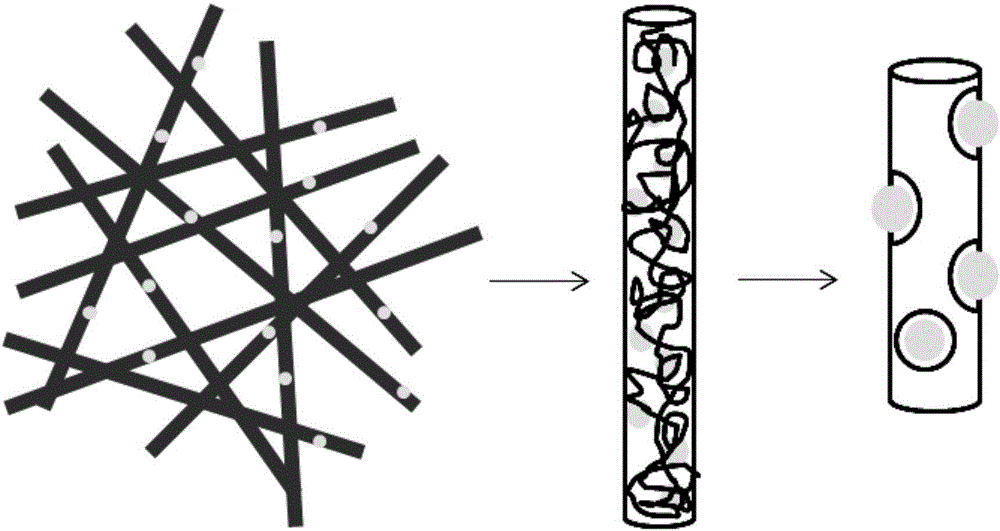

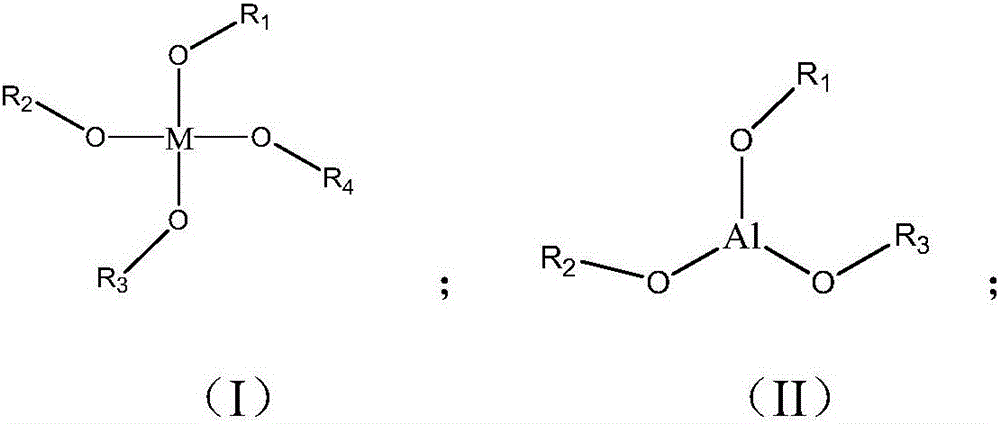

Preparation method for fiber film and production of fiber film

ActiveCN106654116ANo sheddingClose mosaic bondingFinal product manufactureCell component detailsOrganic polymerOrganic inorganic

The invention relates to the field of a fiber film, in particular to a preparation method of a fiber film and a product of the fiber film. The preparation method comprises the steps of mixing an inorganic particle precursor, an organic polymer and an organic solvent to prepare a spinning solution, and preparing to obtain a fiber film intermediate body by an electrostatic spinning process; and enabling the intermediate fiber film to react with an alkali to form an organic-inorganic particle composite fiber film. According to the preparation method, the inorganic particle precursor is selected to form a homogeneous-phase spinning solution, the inorganic particle formed after reaction is nanocrystallized, and the nanometer inorganic particle is tightly embedded and combined with the polymer and is uniformly combined and distributed in a polymer fiber substrate. With the preparation method disclosed by the invention, the mechanical strength of the fiber film is improved, a porous structure in the fiber film is improved, and the dynamic performance of a lithium battery can be improved.

Owner:NINGDE AMPEREX TECH

Spinning low fluorosurfactant fluoropolymer dispersions

ActiveUS20070029697A1Low total surfactant contentSynthetic resin layered productsCork mechanical workingPolymer scienceFluoropolymer

A process for dispersion spinning non-melt-processible fluoropolymer fiber in which a mixture of an aqueous dispersion of non-melt-processible polytetrafluoroethylene or modified polytetrafluoroethylene fluoropolymer particles and an aqueous solution of matrix polymer is formed. The non melt-processible particles have an SSG of less than about 2.40. The aqueous dispersion contains an aliphatic alcohol ethoxylate nonionic surfactant having a 20% residuals temperature determined by thermogravimetric analysis (TGA) of less than about 290° C. and is essentially free of surfactants containing aromatic groups. The dispersion has a fluorinated surfactant content of less than about 300 ppm. The mixture is extruded into a coagulation bath containing a concentration of ions which coagulate the matrix polymer to form an intermediate fiber structure. The intermediate fiber structure is sintered to decompose the matrix polymer and coalesce. The present invention also provides a spinning composition useful for the dispersion spinning of non-melt-processible fluoropolymer fiber.

Owner:THE CHEMOURS CO FC LLC

Current Measuring Equipment and Methods

ActiveUS20180095113A1Magnetic measurementsCurrent measurements onlyElectrical conductorIntermediate muscle fiber

Optical fiber based current measuring equipment for measuring the current circulating through a conductor. The equipment includes an interrogator having a light emitter and a light receiver, and a sensing portion close to the conductor, the interrogator and the sensing portion being connected through at least one standard single-mode intermediate fiber. The light emitter of the interrogator is configured to emit sets of at least two polarized light pulses to the sensing portion, the pulses being polarized with a specific degree difference, and the light receiver (4) is configured to determine the current circulating through the conductor depending on the pulses it receives in return from the sensing portion. A method for measuring the current circulating through a conductor with the use of an optical fiber based current measuring equipment is also provided.

Owner:LUMIKER APLICACIONES TECHCAS SL

Dispersion spinning core-shell fluoropolymers

InactiveUS7347960B2Increase chanceAvoid huge wasteSynthetic resin layered productsCork mechanical workingPolymer scienceFluoropolymer

A process is disclosed for dispersion spinning non-melt-processible fluoropolymer fiber in which a mixture of an aqueous dispersion of non-melt-processible fluoropolymer particles and an aqueous solution of a matrix polymer is formed. The non-melt-processible fluoropolymer particles have an SSG of less than about 2.40 and comprise a core of high molecular weight polytetrafluoroethylene and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The mixture is extruded into a coagulation bath containing a concentration of ions which coagulate the matrix polymer to form an intermediate fiber structure. The intermediate fiber structure is sintered to decompose the matrix polymer and coalesce the non-melt-processible fluoropolymer particles to form the fiber. The present invention also provides for spinning composition useful for the dispersion spinning of non-melt-processible fluoropolymer fiber.

Owner:THE CHEMOURS CO FC LLC

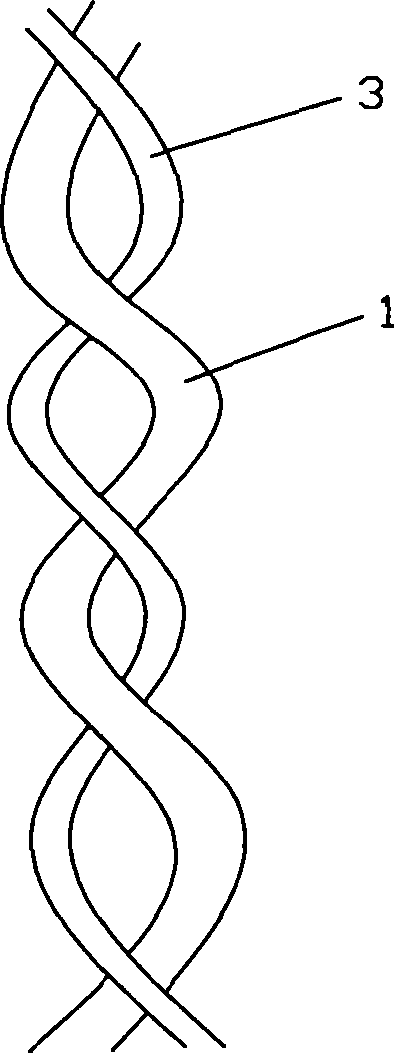

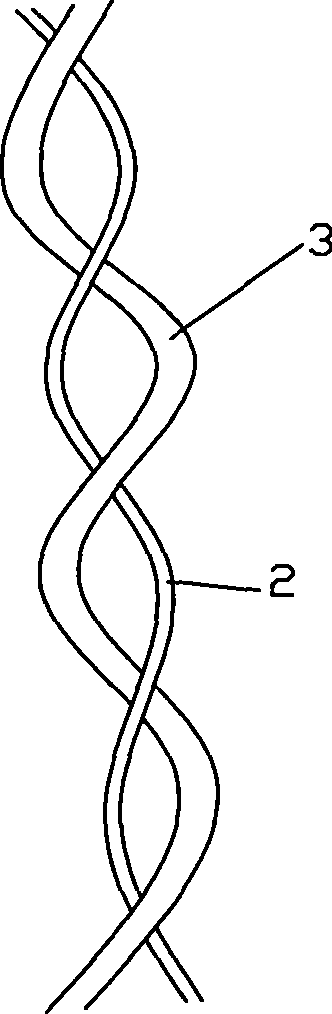

Crude fiber and fine fiber blended yarn

A rough fiber / fine fiber blended yarn comprises two types of fiber of rough fiber and fine fiber, as well as at least another one type of intermediate fiber with the fineness which is between the fineness of the rough fiber and the fine fiber, and any two types of fiber with the similar fineness in a variety of fibers can be mutually cohered. As at least another one type of intermediate fiber with the fineness which is between the fineness of the rough fiber and the fine fiber is added in the fiber mixture of the rough fiber / fine fiber blended yarn, the breaking strength of the blended yarn is improved. If the intermediate fiber with one fineness is added, the intermediate fiber can be cohered with the rough fiber and can also be cohered with the fine fiber; if various types of intermediate fiber with different finenesses are added, the various types of the intermediate fibers can also be well cohered together, so that the various types of fibers can be cohered and wound together in blending and the breaking strength of the blended yarn can be further well enhanced.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

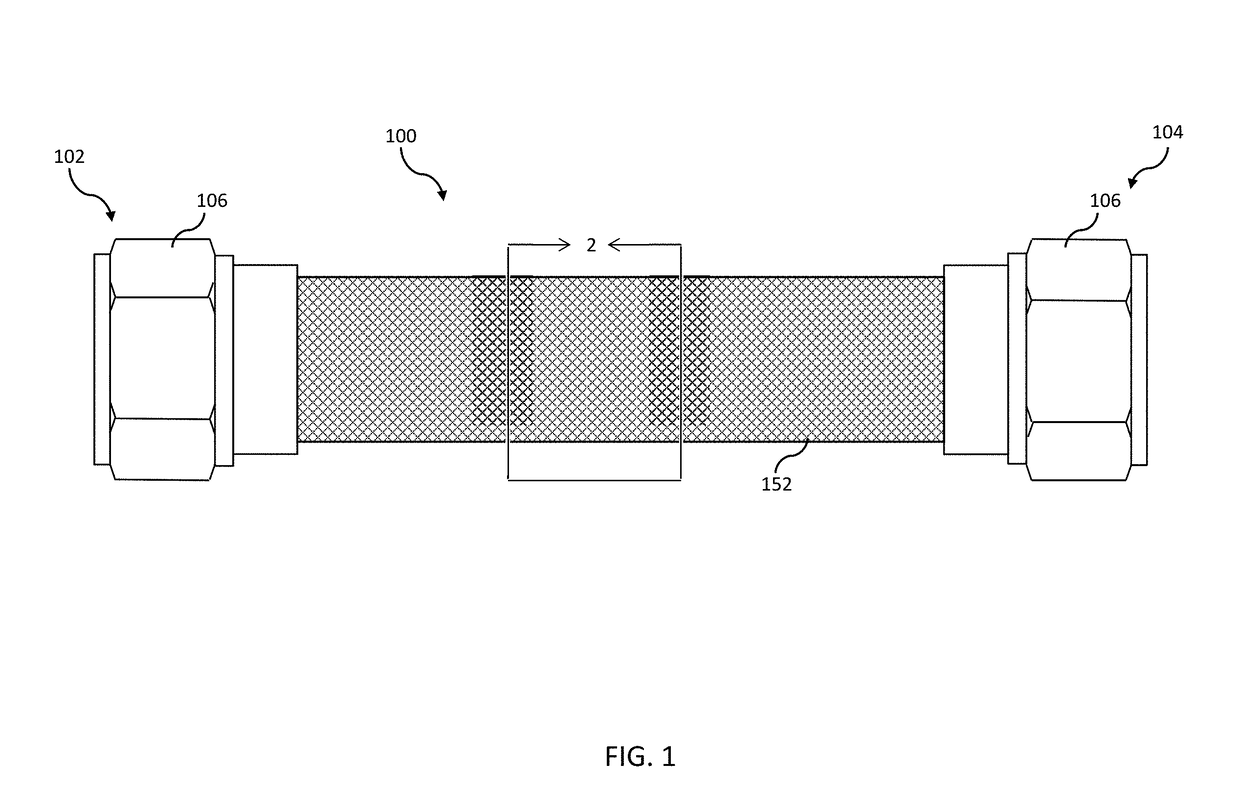

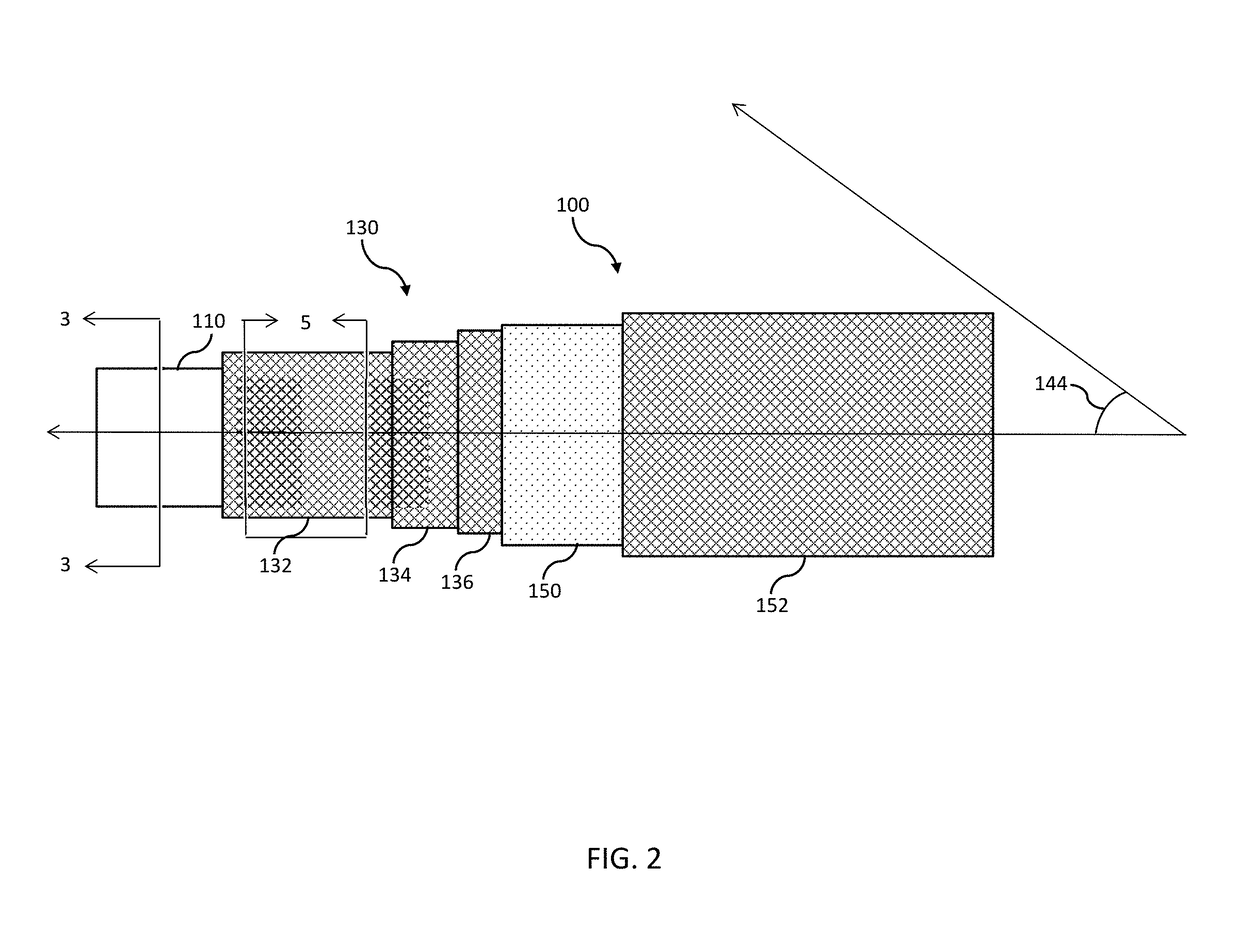

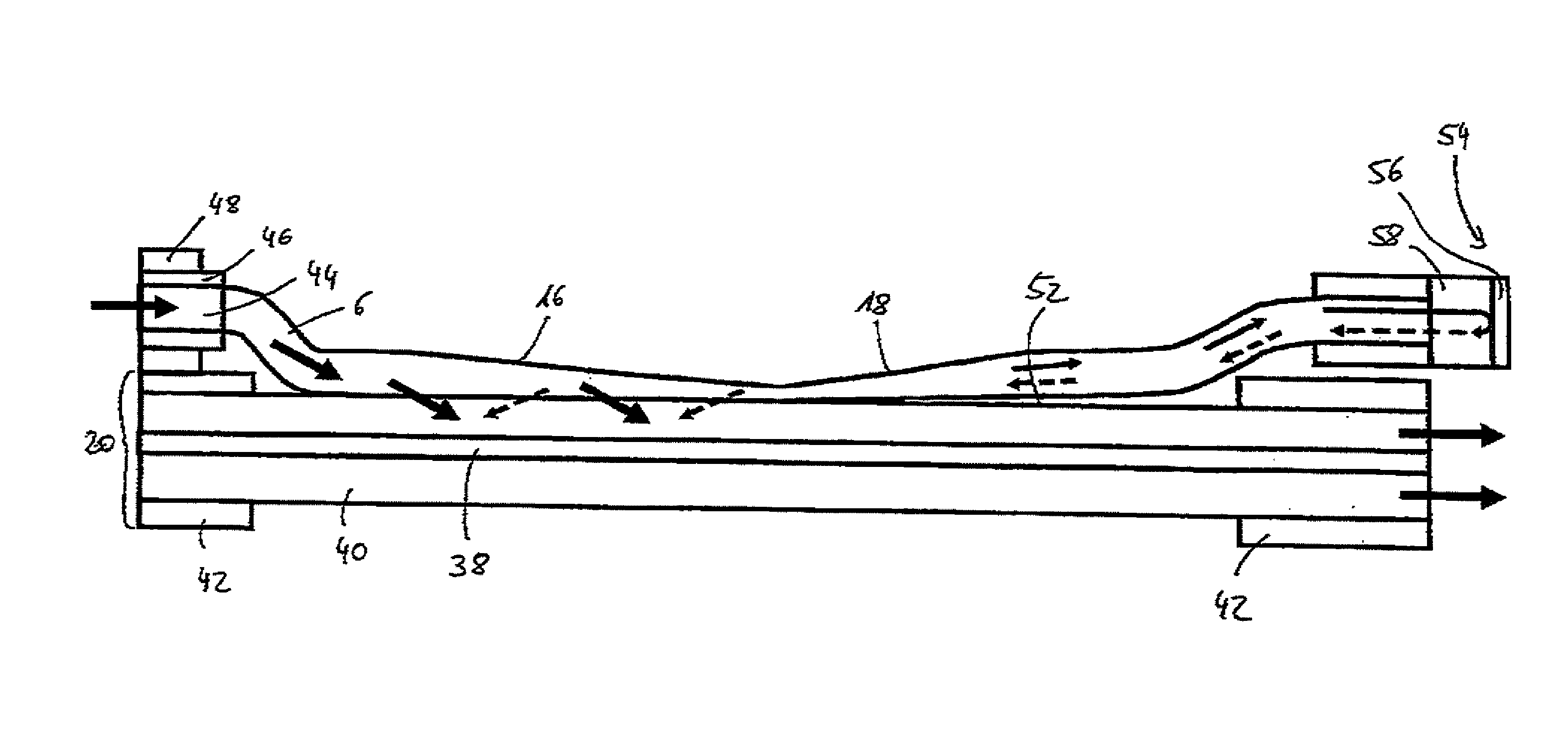

Fiber reinforced thermoplastic hoses and methods for forming the same

ActiveUS20180073667A1Synthetic resin layered productsFlexible pipesIntermediate muscle fiberAramides

A hose can include an inner tube that can form a flow path and an inner fiber layer that can be formed around an outer surface of the inner tube. The hose can further include an intermediate fiber layer that can be formed around the inner fiber layer, and an intermediate fiber layer that can be formed around the inner fiber layer. An outer layer can be formed around the intermediate fiber layer. The inner fiber layer, the intermediate fiber layer, and the outer fiber layer can be formed from support thread applied with greater than about 10 pounds (lbs) of tension. The support thread of the inner fiber layer, the support thread of the intermediate fiber layer, and the support thread of the outer fiber layer can include aramid fibers.

Owner:EATON INTELLIGENT POWER LIMITED

Techniques for indirect optical coupling between an optical input/output port of a subassembly housing and an arrayed waveguide grating (AWG) device disposed within the same

ActiveUS10295763B2Coupling light guidesOptical waveguide light guideTransceiverIntermediate muscle fiber

Techniques for flexible coupling between an optical coupling receptacle / port of an optical transceiver housing and optical components within the same are disposed. In an embodiment, an optical transceiver housing includes an intermediate fiber with a first end optically coupled to an optical coupling port and a second end optically coupled to a multiplexer / de-multiplexer device, e.g., an arrayed waveguide grating (AWG) device, PLC splitter, and so on. The intermediate fiber may be routed in the transceiver housing in a manner that and the radius of the bends may be optimized to reduce fiber bending losses. The techniques herein are equally applicable to both ROSA and TOSA modules and may be utilized to achieve flexible coupling for multi-channel transceiver devices.

Owner:APPLIED OPTOELECTRONICS

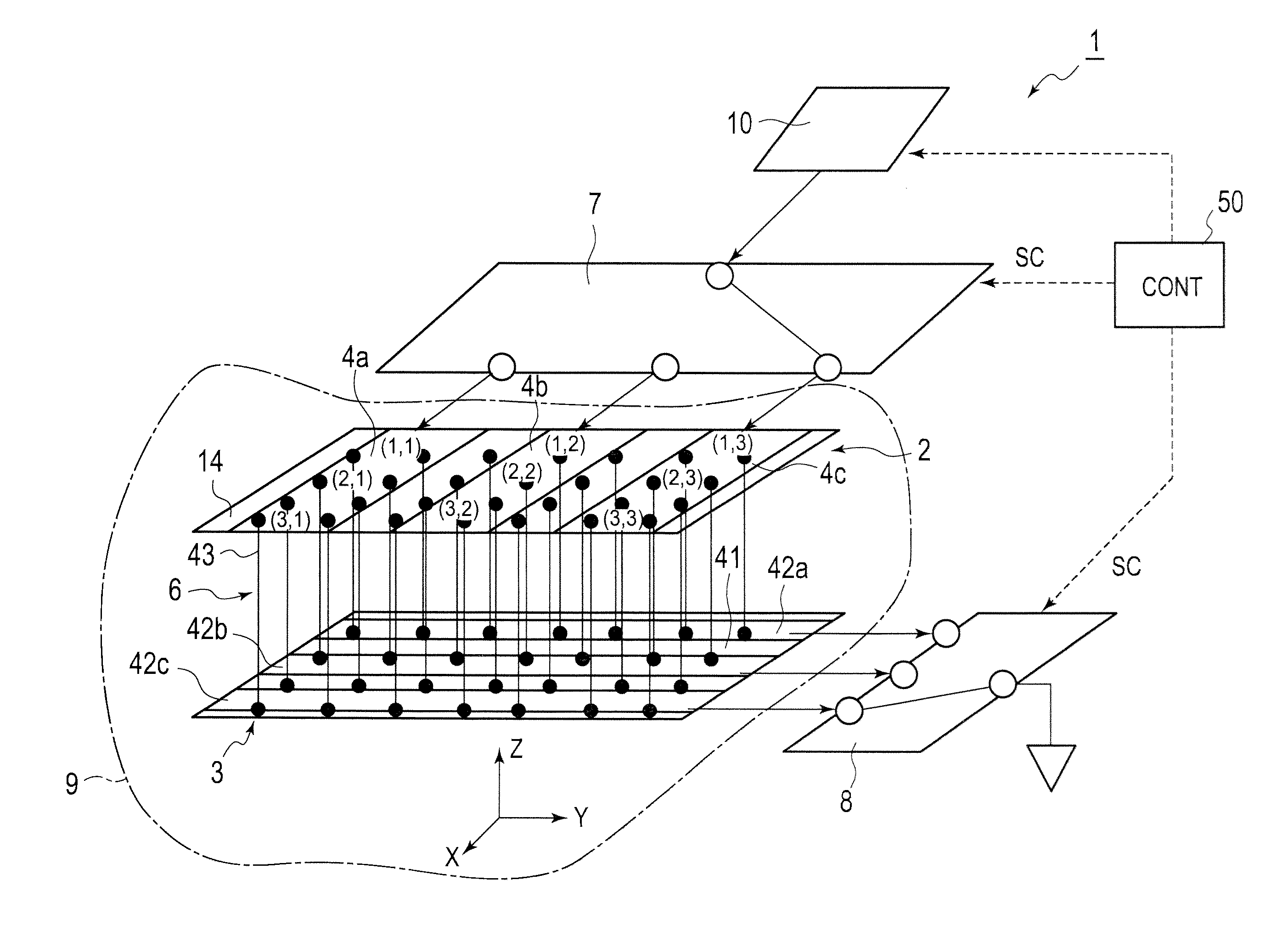

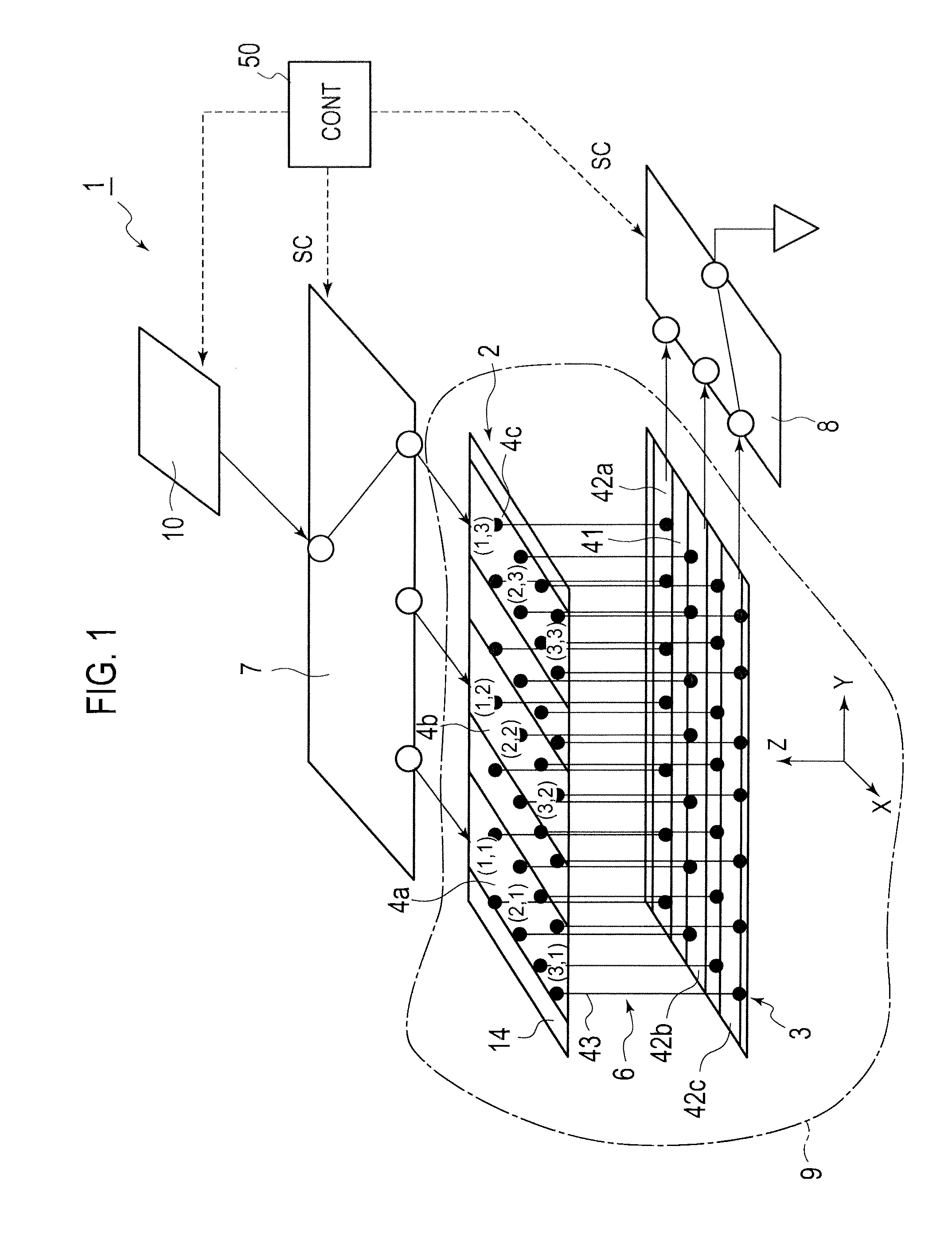

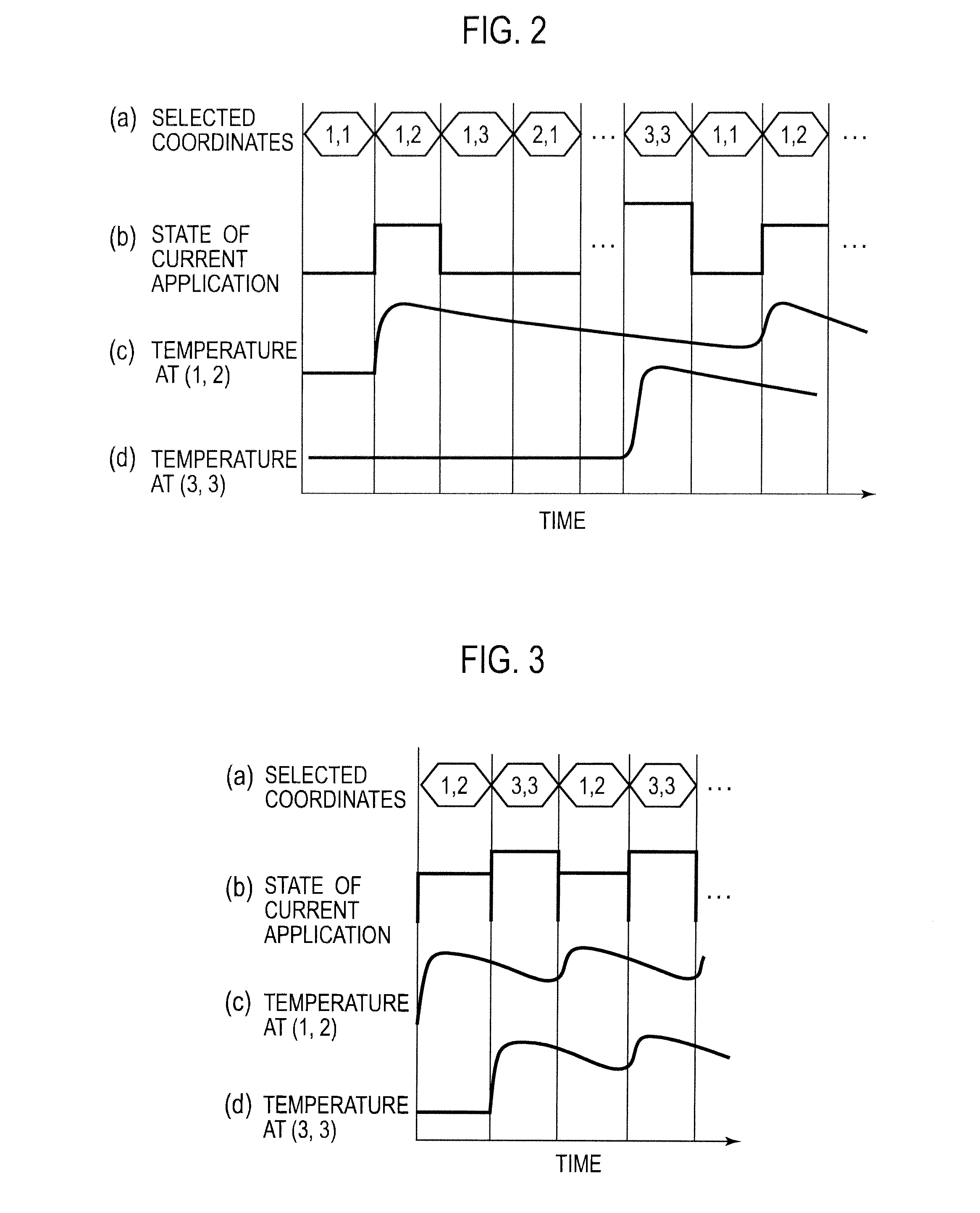

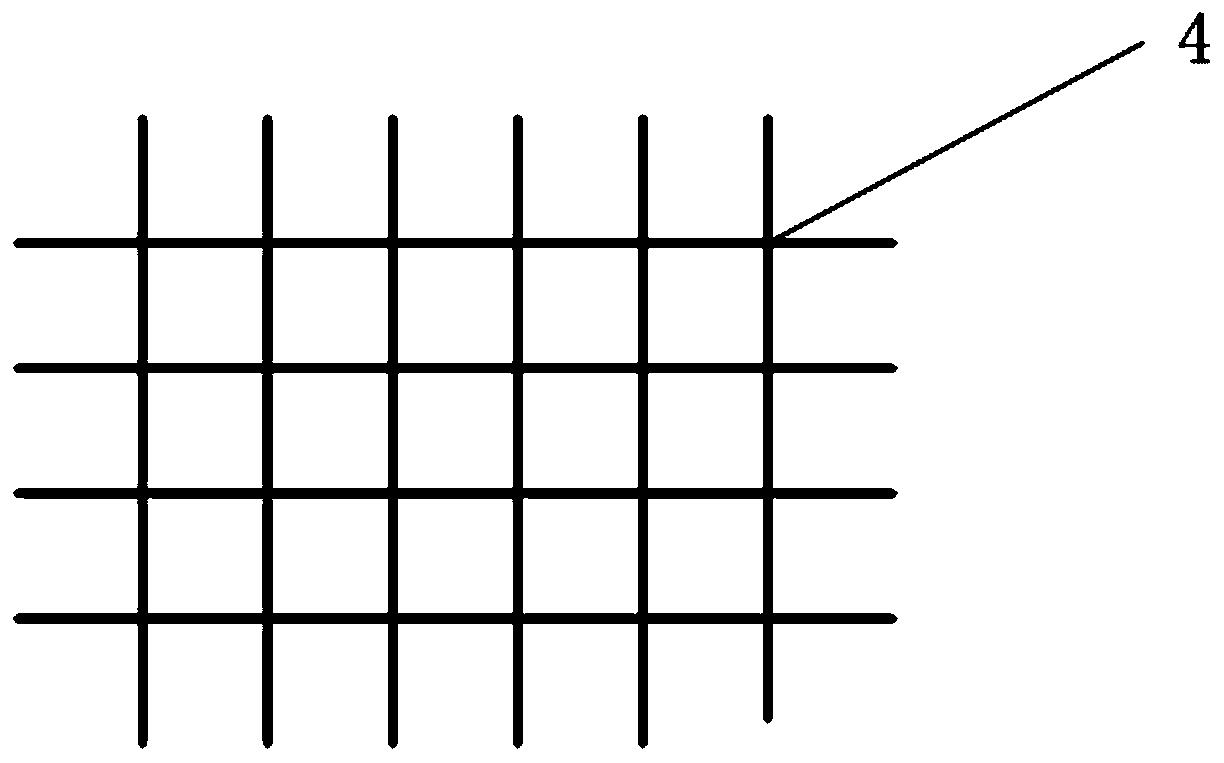

Matrix-patterned cloth

A matrix-patterned cloth includes: first and second fiber layers including mutually isolated first and second conductors, respectively; an intermediate fiber layer between the first and second fiber layers; conductive connecting yarns connecting one of the first conductors and one of the second conductors, wherein, when a pressure is applied to the matrix-patterned cloth, each connecting yarn bends so that a position of contact between the connecting yarn and the first or second conductor changes depending on how large the pressure is; a selector; and a heating controller or a resistance measuring unit. The selector scans and sequentially selects one of the first conductors and one of the second conductors. The heating controller applies voltage to intersecting areas where the selected first and second conductors intersect each other via the first and second conductors. The resistance measuring unit measures electric resistances of the intersecting areas via the first and second conductors.

Owner:NISSAN MOTOR CO LTD

Dispersion spinning process for poly(tetrafluoroethylene) and related polymers

InactiveCN1241223AMonocomponent synthetic polymer artificial filamentWet spinning methodsTetrafluoroethylenePolymer science

A process for preparing a dispersion spun fluorinated polymer fiber wherein the intermediate fiber structure, immediately before sintering, contains primarily ions characterized as fugitive ions.

Owner:EI DU PONT DE NEMOURS & CO

Spinning low fluorosurfactant fluoropolymer dispersions

ActiveUS7390448B2Synthetic resin layered productsCork mechanical workingPolymer scienceFluoropolymer

A process for dispersion spinning non-melt-processible fluoropolymer fiber in which a mixture of an aqueous dispersion of non-melt-processible polytetrafluoroethylene or modified polytetrafluoroethylene fluoropolymer particles and an aqueous solution of matrix polymer is formed. The non melt-processible particles have an SSG of less than about 2.40. The aqueous dispersion contains an aliphatic alcohol ethoxylate nonionic surfactant having a 20% residuals temperature determined by thermogravimetric analysis (TGA) of less than about 290° C. and is essentially free of surfactants containing aromatic groups. The dispersion has a fluorinated surfactant content of less than about 300 ppm. The mixture is extruded into a coagulation bath containing a concentration of ions which coagulate the matrix polymer to form an intermediate fiber structure. The intermediate fiber structure is sintered to decompose the matrix polymer and coalesce. The present invention also provides a spinning composition useful for the dispersion spinning of non-melt-processible fluoropolymer fiber.

Owner:THE CHEMOURS CO FC LLC

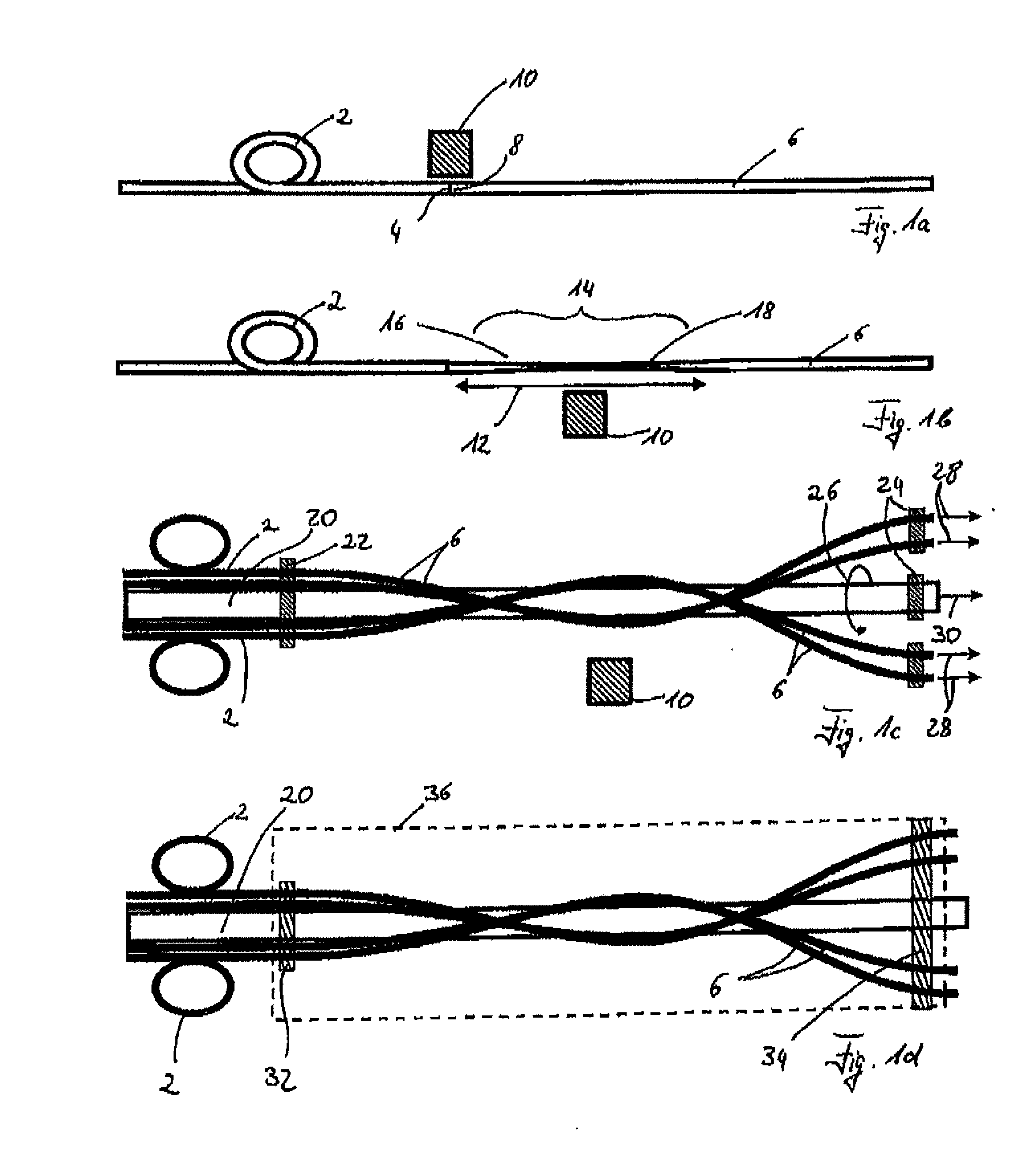

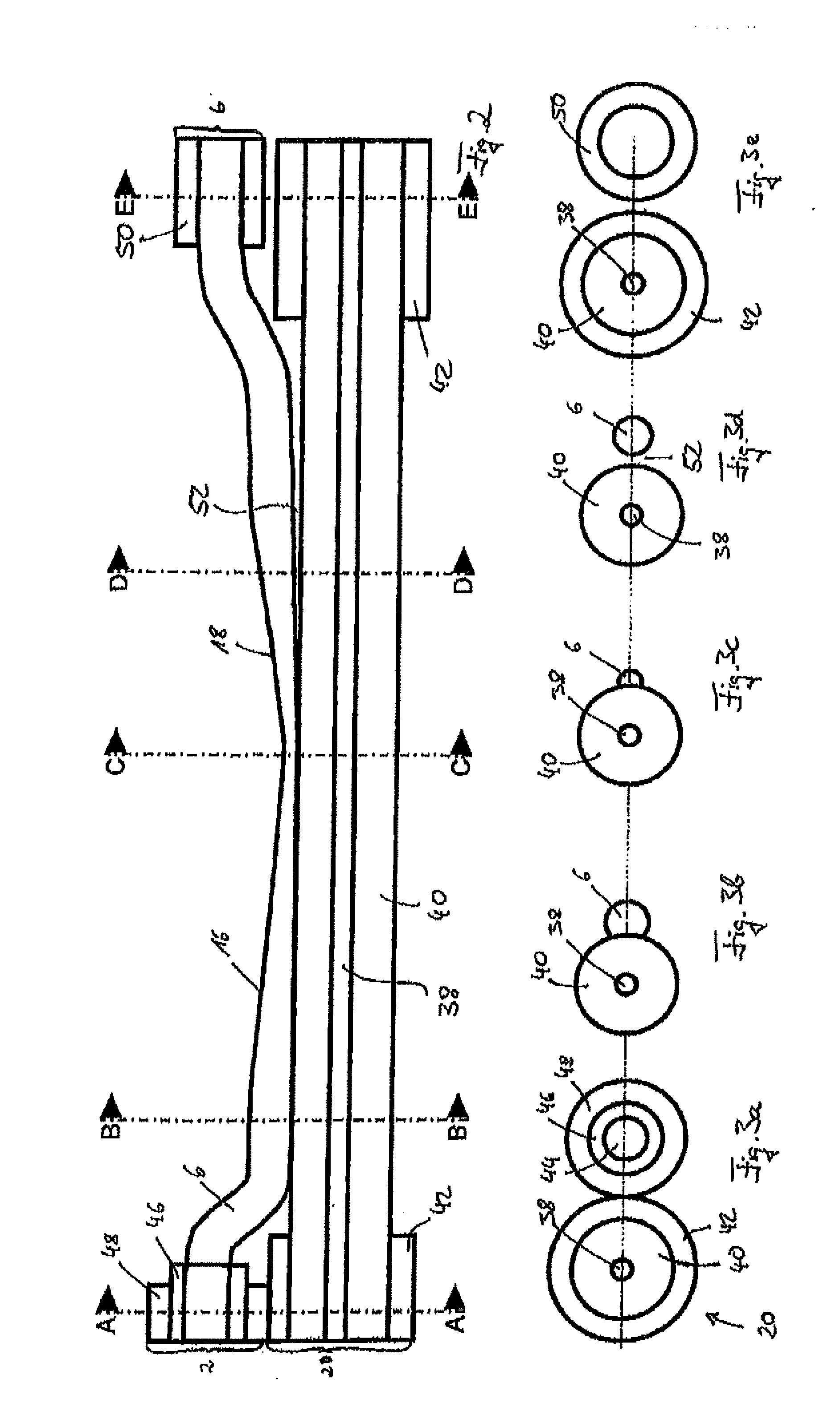

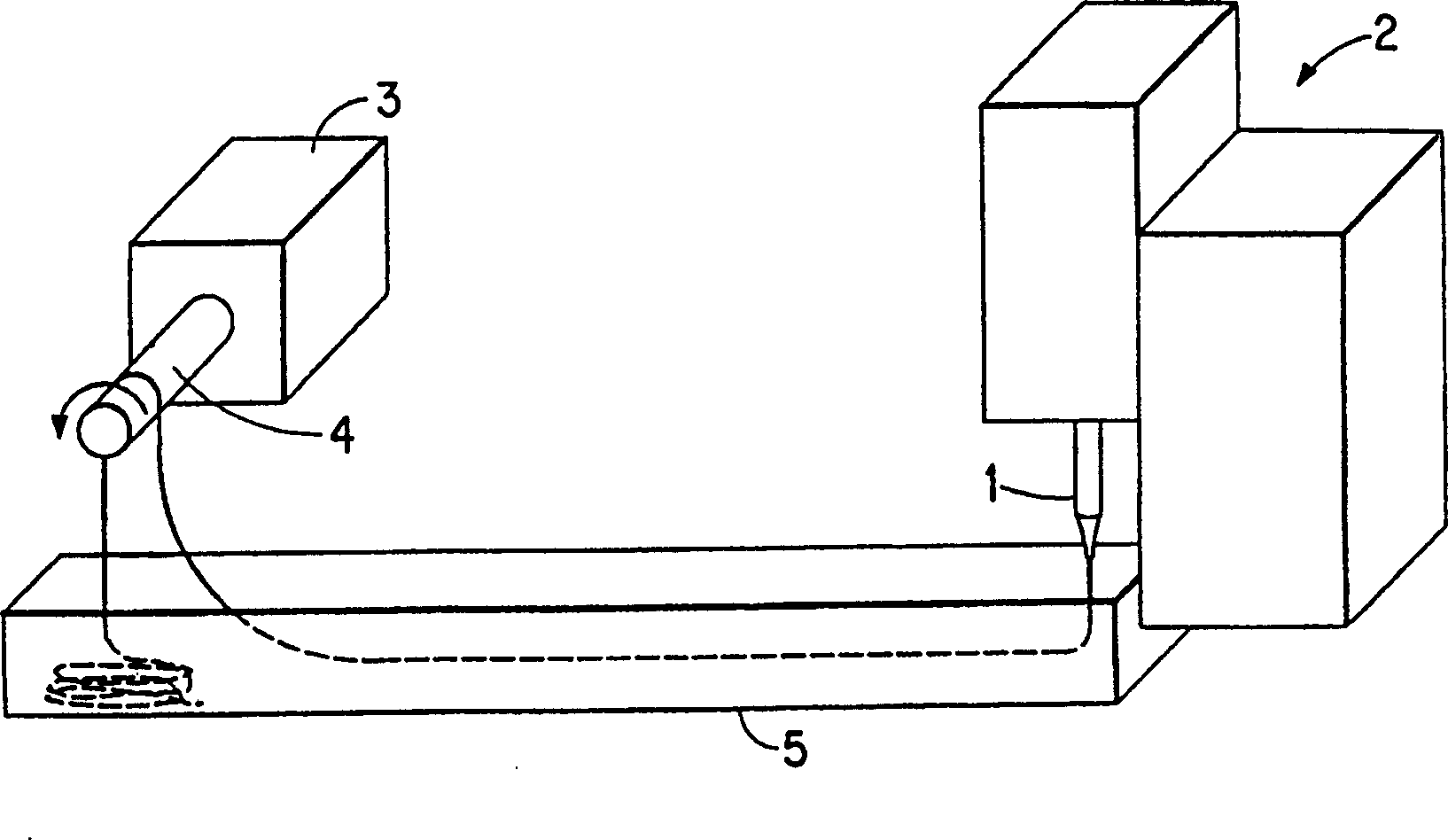

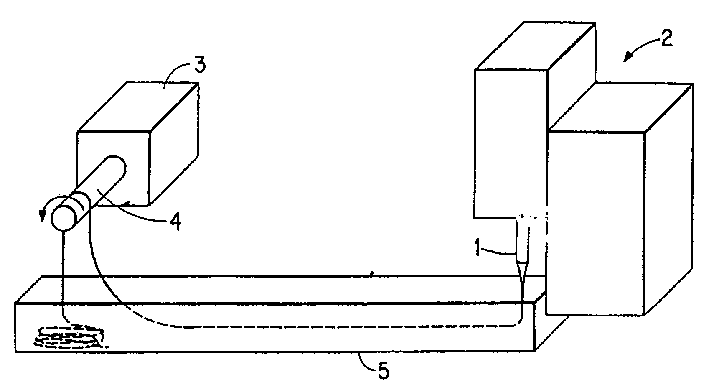

Coupling Arrangement for Non-Axial Transfer of Electromagnetic Radiation

ActiveUS20130188911A1Coupling efficiency is improvedLess negative effects on the optical characteristics of the target fiberLine/current collector detailsOptical fibre/cable installationCouplingIntermediate muscle fiber

A coupling arrangement according to the present invention comprises a target fiber, at least one feeding fiber and an intermediate fiber. The intermediate fiber comprises an input end and a converging taper portion, wherein the input end of the intermediate fiber is spliced to an output end of the feeding fiber in an axial way. Due to this coupling electromagnetic radiation being fed through the feeding fiber enters the intermediate fiber through its input end surface. The converging taper portion of the intermediate fiber is fused to the target fiber in the transfer region in a non-axial way. This leads to a non-axial coupling such that electromagnetic radiation, which entered the intermediate fiber through the input end surface thereof, is coupled into the target fiber.

Owner:LASER ZENT HANNOVER

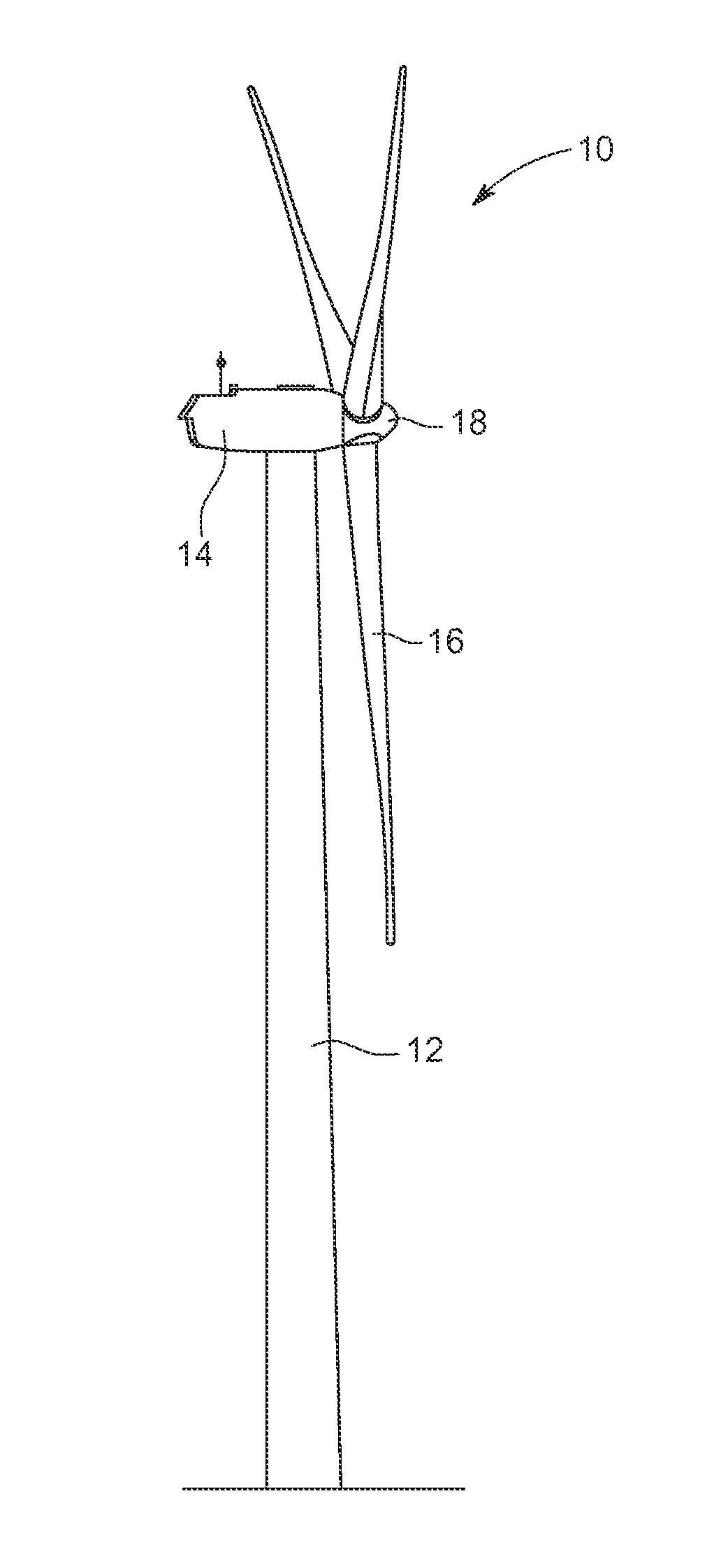

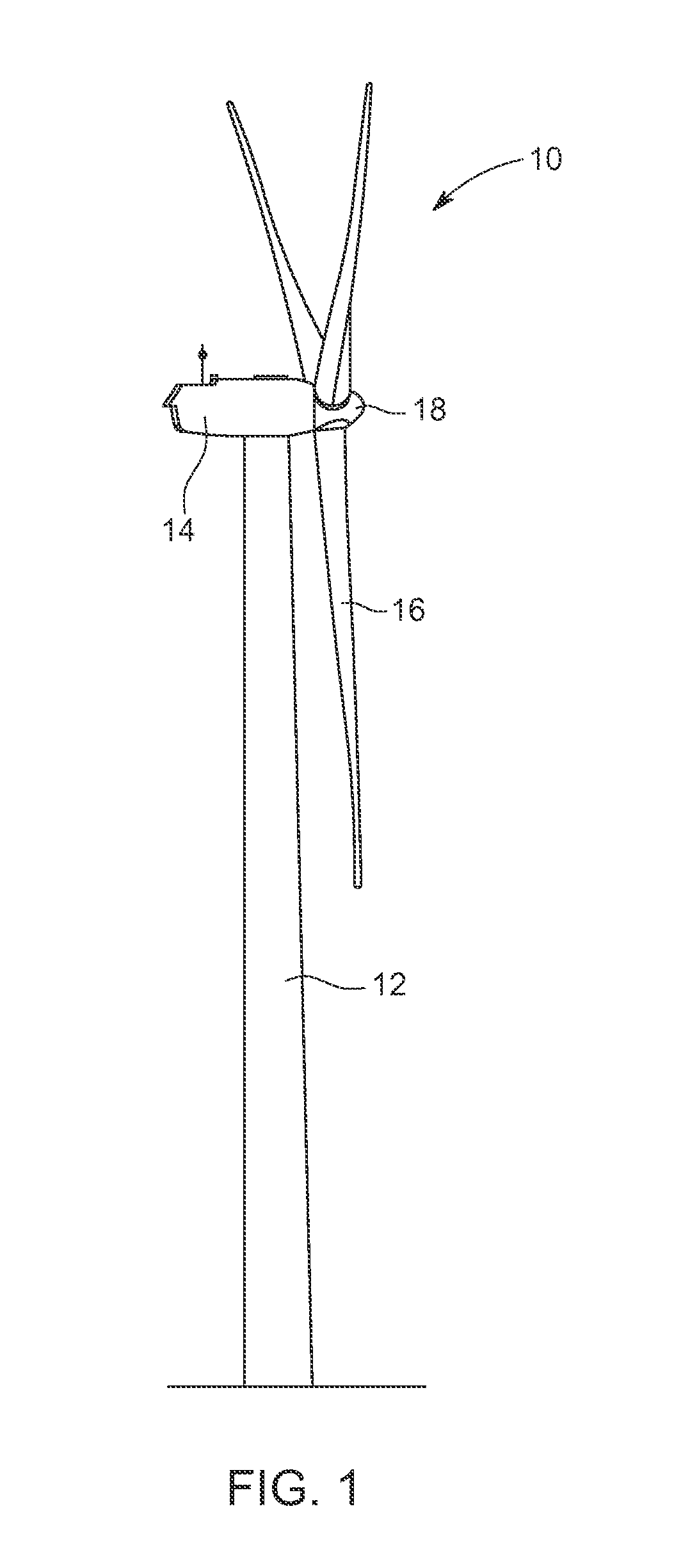

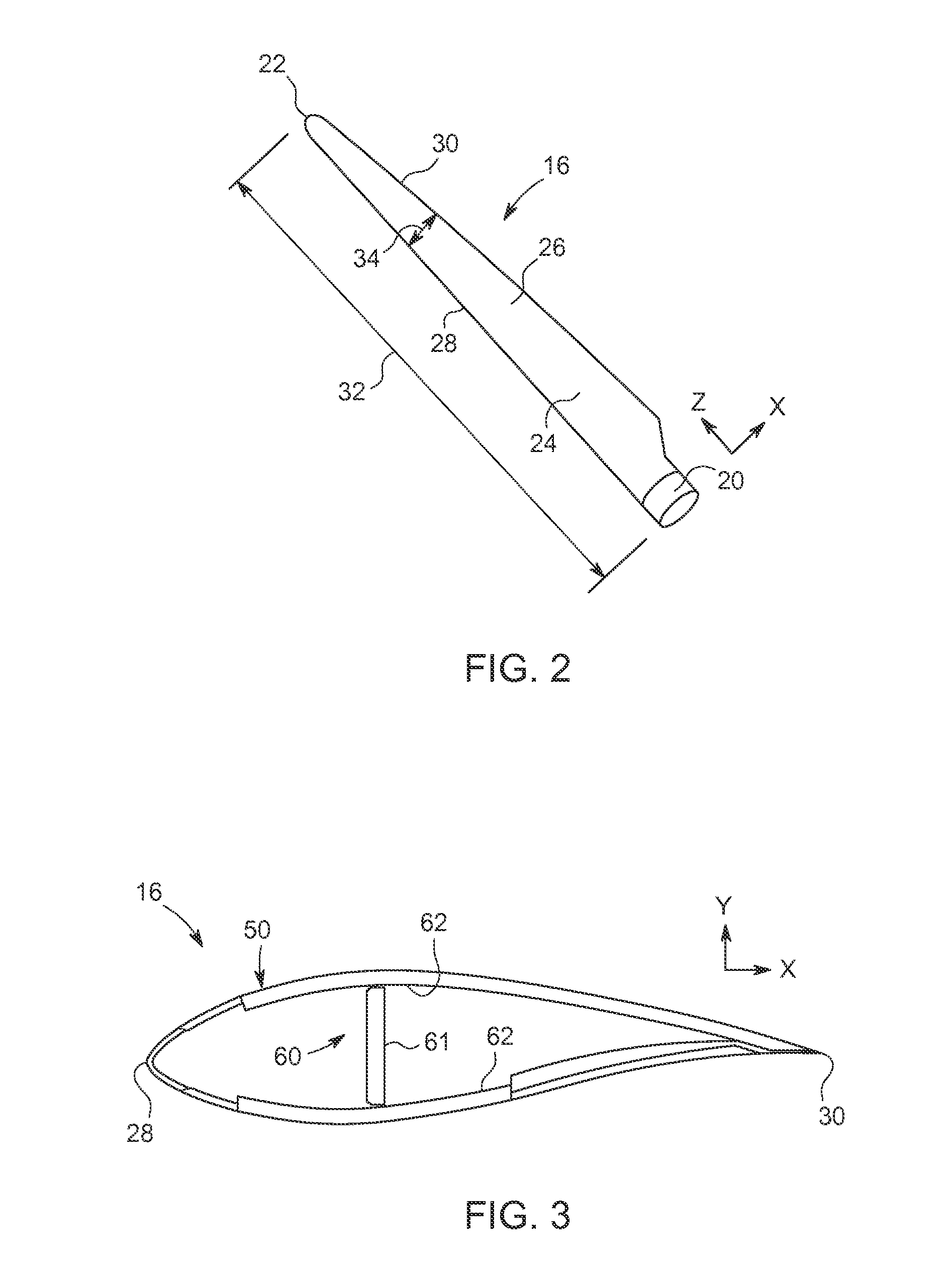

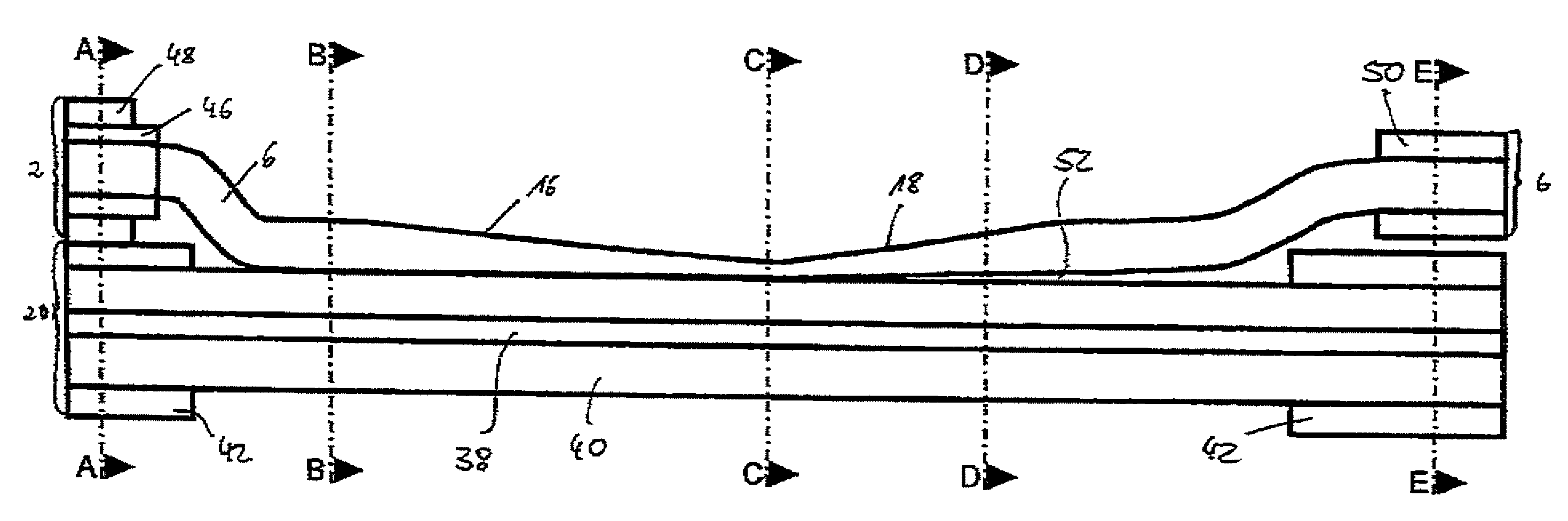

Structural support members with different areal weight fiber reinforcing layers for wind turbine rotor blades

Structural support members includes a plurality of fiber reinforcing layers positioned on top of one another, wherein a plurality of intermediate fiber reinforcing layers are disposed between a top fiber reinforcing layer and a bottom fiber reinforcing layer, and wherein at least one of said fiber reinforcing layers comprises a first areal weight, and wherein at least one of said fiber reinforcing layers comprises a second areal weight different than the first areal weight. The structural support members further include a resin infused throughout the plurality of fiber reinforcing layers.

Owner:GENERAL ELECTRIC CO

Coupling arrangement for non-axial transfer of electromagnetic radiation

ActiveUS9097853B2Coupling efficiency is improvedLess negative effects on the optical characteristics of the target fiberLine/current collector detailsCoupling light guidesCouplingIntermediate muscle fiber

A coupling arrangement according to the present invention comprises a target fiber, at least one feeding fiber and an intermediate fiber. The intermediate fiber comprises an input end and a converging taper portion, wherein the input end of the intermediate fiber is spliced to an output end of the feeding fiber in an axial way. Due to this coupling electromagnetic radiation being fed through the feeding fiber enters the intermediate fiber through its input end surface. The converging taper portion of the intermediate fiber is fused to the target fiber in the transfer region in a non-axial way. This leads to a non-axial coupling such that electromagnetic radiation, which entered the intermediate fiber through the input end surface thereof, is coupled into the target fiber.

Owner:LASER ZENT HANNOVER

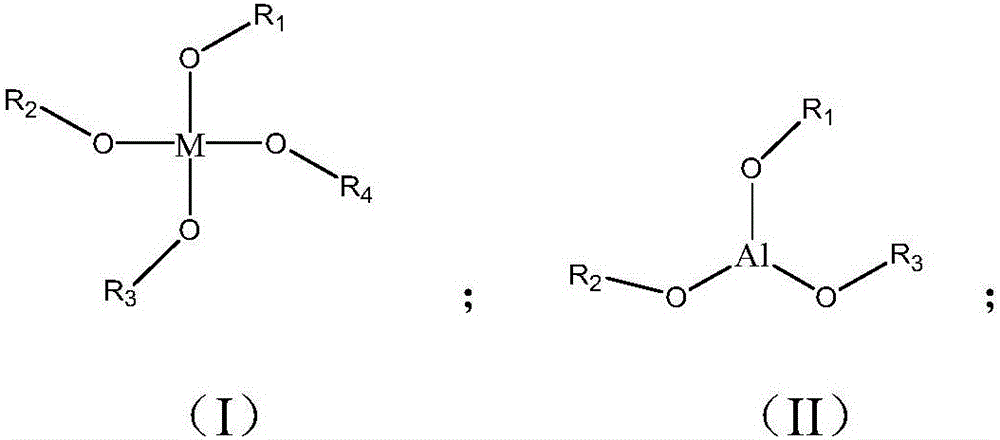

Preparation method of antifouling and antibacterial glove with low surface energy

InactiveCN111363176AWith waterproof functionImprove the protective effectCarbon fibresGlovesAnti bacteriaChemical protection

The invention discloses a preparation method of an antifouling and antibacterial gloves with low surface energy, and belongs to the technical field of high polymer materials. The preparation method issimple, convenient and feasible. Low-surface-energy antifouling latex is adopted as an outer layer and an inner layer of the anti-poison glove, and a phenolic aldehyde-based active carbon fiber composite fabric is used as an adsorption intermediate fiber layer to prepare the antibacterial protective glove with functions of mechanical hazard prevention and high-performance poison prevention. The glove has the advantages of being waterproof, excellent in mechanical protection and chemical protection performance, high in strength, high in rebound resilience, capable of being rapidly processed and produced, wide in application range, environmentally friendly, non-toxic and safe, the inner surface and the outer surface have low surface energy, attachment of microorganism germs and the like canbe effectively prevented, sweat stains can be effectively prevented, and the antifouling and antibacterial capacity is further improved.

Owner:安徽攀望科技有限公司

Low-ink paper sludge and preparation method thereof

The invention discloses low-ink paper sludge and a preparation method thereof. First, waste paper is smashed to obtain shredded paper material slices, the shredded paper material slices are washed, residues are settled, and impurities are removed. Second, additives are added, and micro-fermentation treatment is performed within the controlled acid range of pH (potential of hydrogen) values. High-pressure digestion and sterilization are performed, and materials are extruded and kneaded to obtain intermediate fiber stuff. Deinking agents, glycerol and Chinese honey locust extracts are added into the intermediate fiber stuff, the materials are uniformly stirred, and ink is removed by normal temperature flotation. Latency, fiber separation and disintegration and concentration are performed to obtain paper pulp. Bentonite, blending agents, antioxidants and auxiliaries are sequentially added, and the materials are stirred while black light irradiation to prepare a target product. The obtained paper sludge is prepared by recycling the waste paper, precious resources are recycled, the paper sludge is green, economical, environmentally friendly, low in ink content, uniform in texture and free from irregular pores and undesirable odor.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

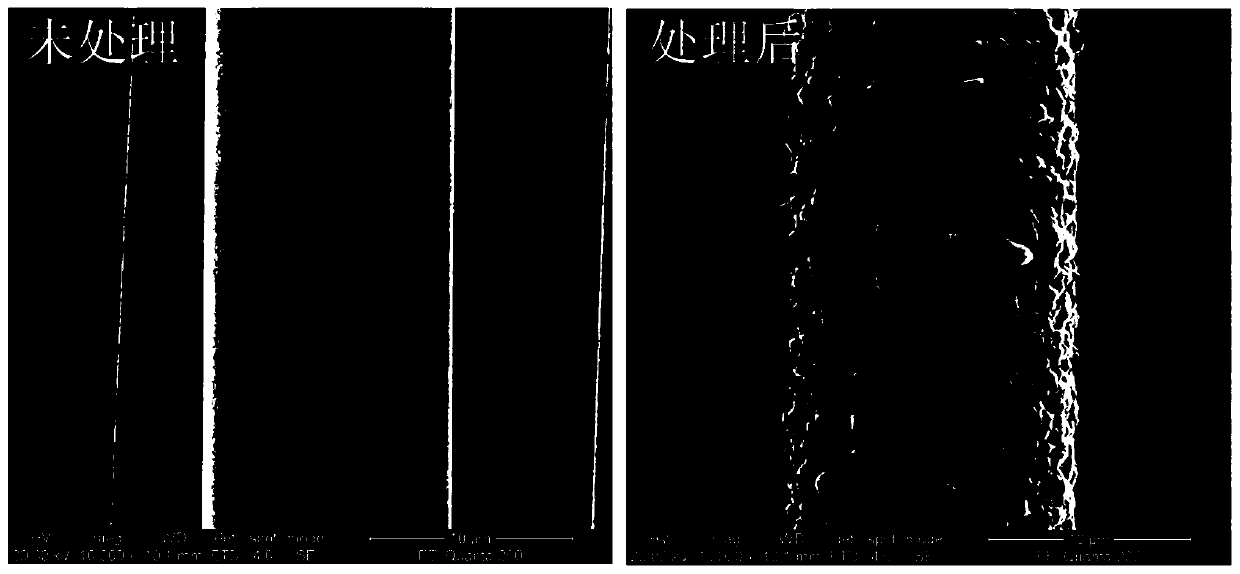

Continuous firing method of boron-containing SiC fiber

The invention discloses a continuous firing method of boron-containing SiC fiber. According to the method, SiC fiber is taken as a raw material and is firstly subjected to surface activation treatment, and pretreated fiber with high reaction activity is obtained; the activated fiber is wetted in a solution of a boron-containing compound and dried, and an intermediate fiber is obtained; finally, the intermediate fiber is fired at the high temperature, and the boron-containing SiC fiber is obtained. By means of the provided method, boron can be introduced into a firing furnace in a dynamic quantitative manner, the concentration of boron-containing atmosphere in the firing furnace is kept relatively constant, the boron-containing compound and high-activity SiC fiber subjected to surface activation treatment are subjected to an in-situ reaction, introduction of boron is realized, and the method adopts a simple process and is low in cost and suitable for industrial production. The preparedboron-containing SiC fiber has excellent high-temperature resistance and has good application prospects in aerospace, aviation and high-performance weapons.

Owner:NAT UNIV OF DEFENSE TECH

High-strength composite plywood

ActiveCN110027061AAvoid deformationAvoid bubblingWood veneer joiningIntermediate muscle fiberSingle plate

The invention discloses high-strength composite plywood which comprises an intermediate fiber board, upper-layer veneer and lower-layer veneer, wherein the upper-layer veneer is fixedly connected withthe upper side of the intermediate fiber board; and the lower-layer veneer is fixedly connected with the lower side of the intermediate fiber board. A preparation method of the high-strength composite plywood comprises the following steps: a bonding agent is uniformly sprayed onto the upper side and the lower side of the intermediate fiber board; the upper-layer veneer and the lower-layer veneerare correspondingly bonded to the upper side and the lower side of the intermediate fiber plate; and the high-strength composite plywood is obtained through hot-press forming. The high-strength composite plywood disclosed by the invention has the characteristics of being high in bonding strength as well as resistant to acid and alkali.

Owner:夏邑县金展木业有限责任公司

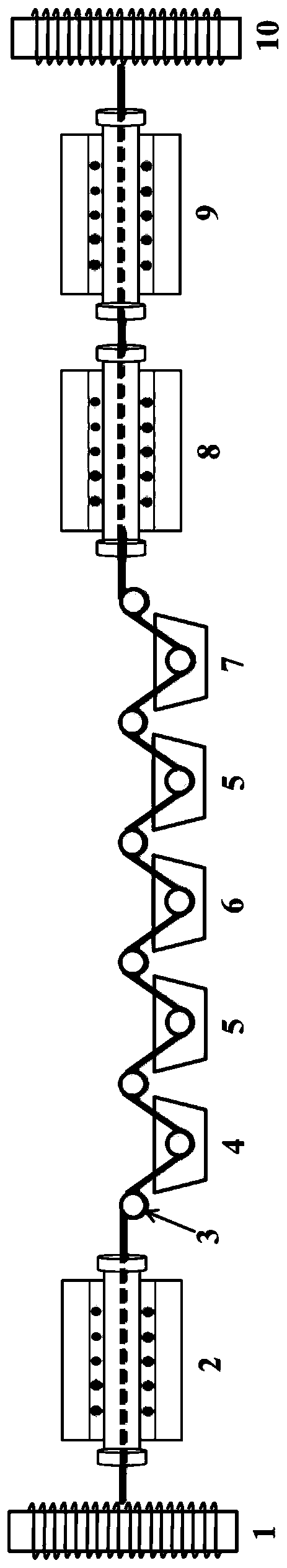

Air pressure control method and device for drawing photonic bandgap fiber

ActiveCN106495464BStable air pressureSolve the problem of independent and precise control of regional air pressureGlass making apparatusDifferential pressurePhotonics

The invention discloses an air pressure control method and device used for photonic band gap optical fiber drawing, and belongs to the technical field of optical fiber manufacturing. The method includes firstly inserting an intermediate into an intermediate fixing table, sealing the intermediate and the intermediate fixing table with sealing glue, connecting a single-cavity body and a double-cavity body in a threaded manner, with a fiber core duct being inserted into an intermediate fiber core during connection, and after assembling is finished, communicating a fiber-core-cavity gas pipe port, a cladding-cavity gas pipe port and an outer-cavity gas pipe port to a gas chamber of an air pressure control electric part through gas guiding pipes separately to achieve independent air pressure control of three regions which are a fiber core cavity, a cladding cavity and an outer cavity. The method and the device overcome a problem of independent precise air pressure control of the three regions during a photonic band gap optical fiber drawing process. The method and the device have universality and are suitable for porous micro-structured optical fiber drawing requiring independent air pressure control for separated regions. A pressure difference is adopted to determine on-off control time of an electromagnetic valve, thus controlling a gas flux through the pressure difference and increasing air pressure control precision.

Owner:BEIHANG UNIV

Dispersion spinning process for poly (tetrafluoroethylene) and related polymers and improved midbody fibre structure

InactiveCN1106462CViscose forming methodAvoid serious disadvantagesArtificial filaments from cellulose derivativesWet spinning methodsTetrafluoroethylenePolymer science

A process for spinning a fully water washed fluorinated olefinic polymer intermediate fiber structure from a mixture of an aqueous dispersion of particles of the fluorinated olefinic polymer and a solution of a cellulosic ether.

Owner:TORAY IND INC

Polyimide film and preparation method thereof

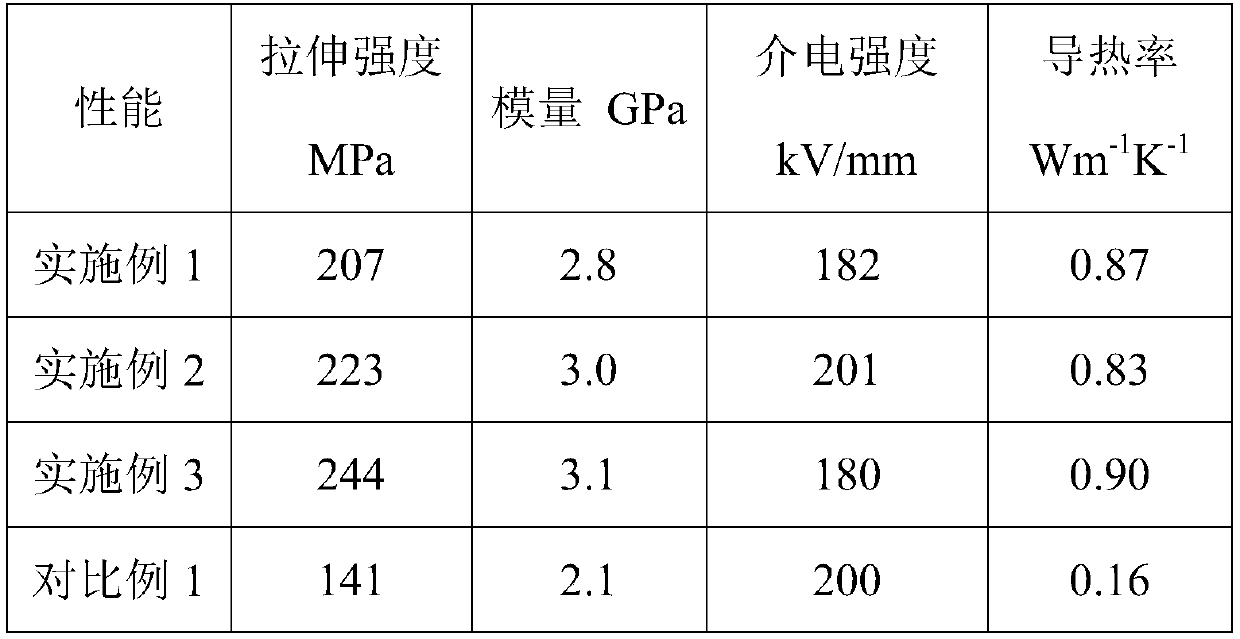

The invention discloses a polyimide film. The polyimide film comprises the following raw materials: polyimide and modified carbon fibers. In the preparation process of the modified carbon fibers, carbon fibers are weighed and subjected to acid pickling to obtain intermediate fibers; the intermediate fibers are uniformly dispersed in ethanol water, then a pH value is adjusted to 9.5-10 by using ammonia water, tetraethoxysilane is added, a reaction is conducted, then centrifuging is carried out, and a precipitate is taken, washed and dried to obtain silicon dioxide coated carbon fibers; and thesilicon dioxide coated carbon fibers are ultrasonically dispersed in a 3-aminopropyltriethoxysilane solution, ultrasonic stirring and filtering are carried out, and a filter cake is washed and dried to obtain the modified carbon fibers. The invention also discloses a preparation method of the polyimide film. The polyimide film has good thermal conductivity, good insulativity and high mechanical properties.

Owner:太湖方舟新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com