Preparation method for fiber film and production of fiber film

A fiber membrane and composite fiber membrane technology, applied in the field of fiber membranes, can solve the problems of weakened mechanical properties, poor adhesion between inorganic coatings and porous membranes, uneven thickness, etc., achieve high mechanical properties and safety, and improve kinetics Performance, Ease of Diffusion and Penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

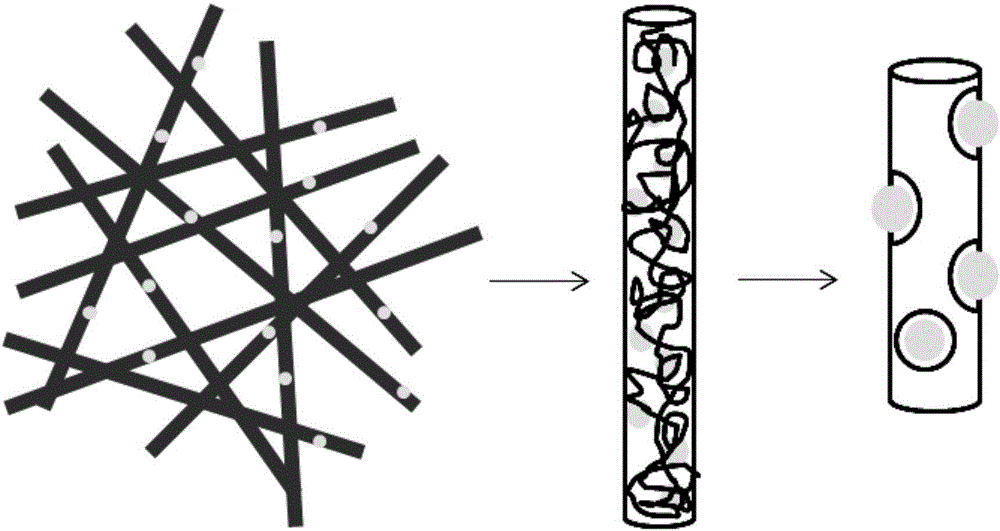

[0032] The application relates to a method for preparing a fiber membrane, at least including the following steps:

[0033] (1) Mixing inorganic particle precursors, organic polymers and organic solvents to make spinning liquid, and preparing fiber membrane intermediates by electrospinning process;

[0034] (2) reacting the intermediate fiber membrane with an alkali to form an organic-inorganic particle composite fiber membrane to obtain the fiber membrane.

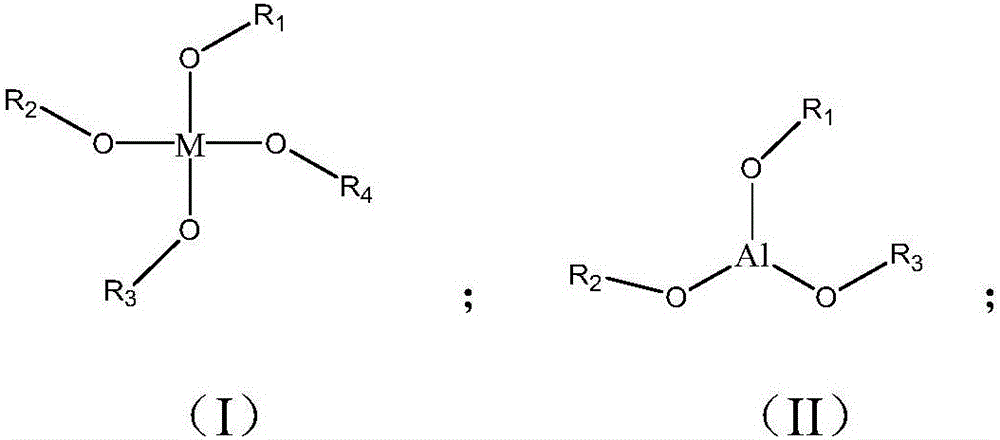

[0035] In this application, the inorganic particle precursor refers to the existing form of the inorganic particle before reacting with the base, which includes all material forms that can be reacted with the base to obtain the inorganic particle compound, such as acids, salts or ester compounds. As an improvement of the preparation method of the present application, the inorganic particle precursor can be selected from liquid soluble organic ester compounds; preferably, the structural formula of the inorganic particle pr...

Embodiment 1

[0057] 1. Mix the inorganic particle precursor, organic polymer and organic solvent in proportion, stir for 30 minutes to obtain a homogeneous solution as a spinning solution, prepare the intermediate nanofiber membrane by electrospinning, and control the diameter of the fiber in the nanofiber membrane 200~600nm;

[0058] 2. The intermediate nanofiber membrane is soaked in an alkaline solution, taken out, washed with water, and then dried in an oven to obtain an organic-inorganic composite nanofiber membrane. The specific parameters are described in Table 1.

[0059] Table 1

[0060]

experiment example

[0068] The performance of the organic-inorganic composite nanofibrous membrane prepared by the above-mentioned examples and comparative examples is detected, wherein:

[0069] 1. Gas permeability (s / 100cc): Gas permeability tester is used to test with reference to the standard "GB / T1038-2000 Plastic Film and Sheet Gas Permeability Test Method Pressure Difference Method".

[0070] 2. Porosity (%): A mercury porosimeter is used for detection, specifically: the sample is dried and weighed, and the pore size distribution curve and pore volume parameters are obtained according to the volume of mercury pressed into the pores under different pressures.

[0071] 3. Longitudinal tensile strength (N): Use a multifunctional electronic tensile machine to test with reference to the standard "GB / T16491-1996 Electronic Universal Testing Machine". For the sample, install the corresponding tension fixture, input the length, width and thickness of the sample, measure the maximum plastic deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com