Dispersion spinning process for poly (tetrafluoroethylene) and related polymers and improved midbody fibre structure

A technology of tetrafluoroethylene and structure, applied in the direction of single-component synthetic polymer rayon, wet spinning method, fiber chemical characteristics, etc., can solve problems such as hindering sintering fibers and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

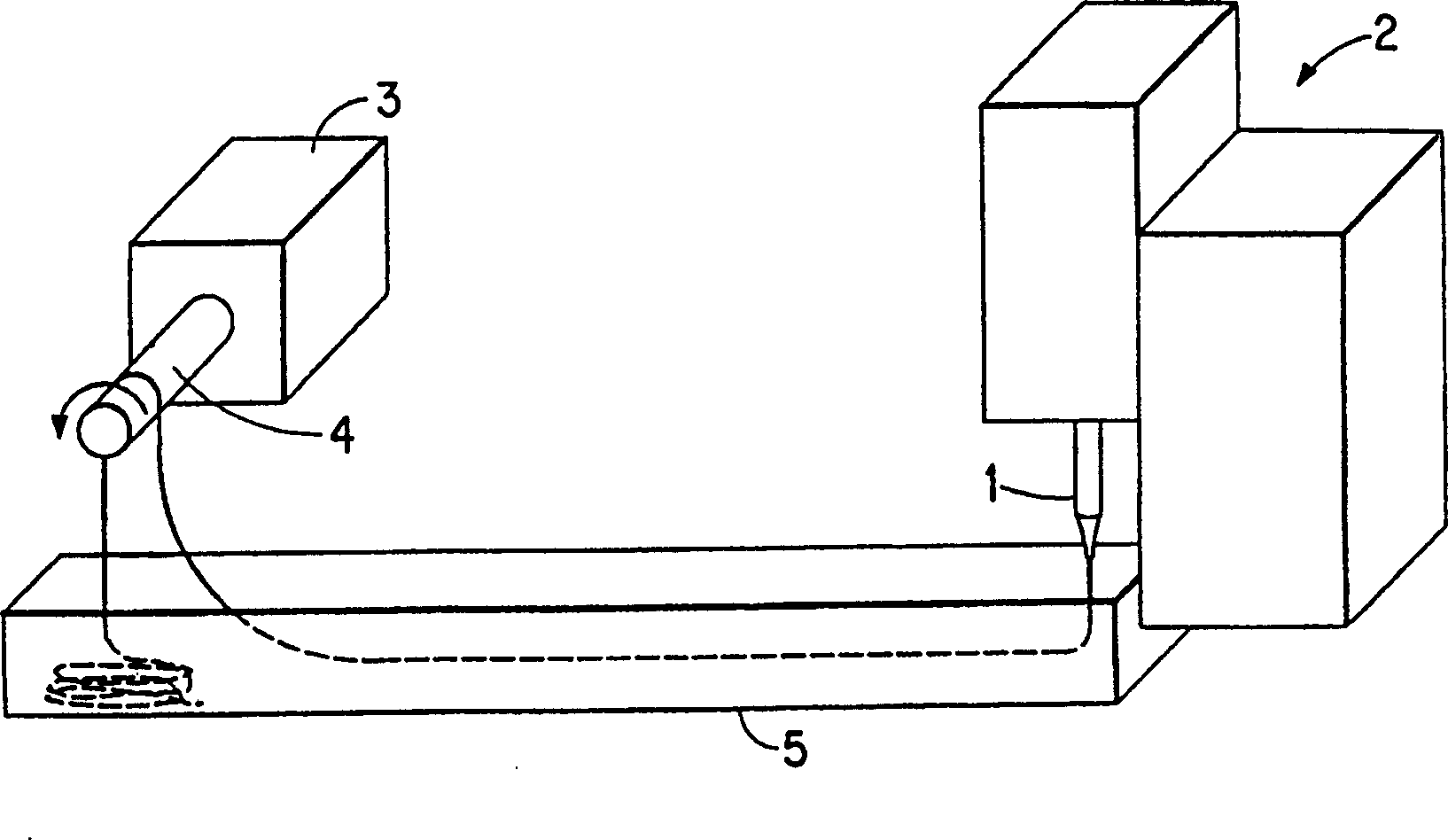

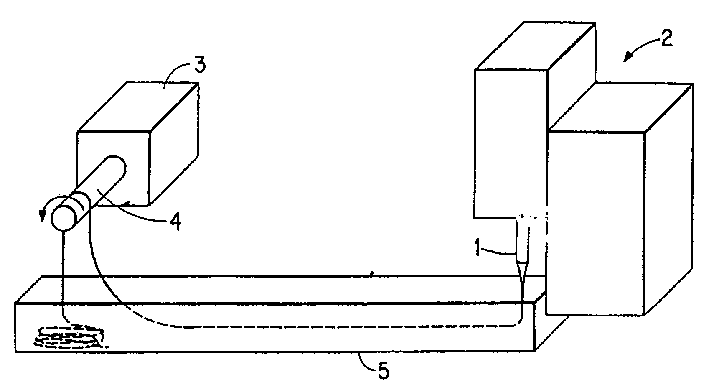

Image

Examples

Embodiment

[0067] The following Examples 1-15 were tested using the intermediate fiber strength determination method described above.

[0068] Table 1 shows the name of the matrix polymer tested, DS, the weight percent concentration of the matrix polymer in the polymer solution, the viscosity of the matrix polymer solution at 25°C, the weight ratio of PTFE to matrix polymer solids in the intermediate fiber, The composition of the coagulation liquid and the measured value of the strength of the intermediate fiber structure.

[0069] matrix

Sample No.

D.S.

%

matrix

Viscosity, MPa

.s, 25°C

PTFH:

matrix ratio

coagulant

Washing fiber strength, mg / denier

(washed with deionized water to pH7,

25℃)

Methylcellulose 1

1

1.4to

1.95

3.9

only in water

4480

9∶1

18%Na 2 SO 4 5%

h 2 SO 4 @35℃

0, not st...

example 16~20

[0084] The solution was prepared as follows: 1.9 kg of the hydroxypropyl cellulose (HPC) of Examples 11, 12 and 13 above were slurried in 15.8 liters of soft water at about 25°C. After the HPC was wetted, 12.3 kg of 23% sodium hydroxide solution was added to the water / HPC mixture. The resulting mixture was stirred under vacuum (approximately 29 mm Hg) for 1 h and then filtered through a 50 μm polypropylene felt bag filter into a membrane degasser operating at approximately 29 mm Hg vacuum. The viscosity of the obtained solution at 25°C was 4,800 mP·s. The above solution stream was combined with a stream of TEF 3311 poly(tetrafluoroethylene) (PTFE) dispersion (supplied by DuPont, Wilmington, DE) with relative flows controlled so that the weight ratio of PTFE solids to HPC solids was 8.2, and the in-line static Mix in a mixer. The resulting mixture was then pumped through a spinneret with 180 holes (6 mil diameter) submerged below the level of the coagulation bath. The coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com