EPM-g-MAN toughener and preparation method thereof as well as engineering plastics AEMS

A technology of engineering plastics and toughening agents, applied in the field of engineering plastics AEMS, can solve the problems of low monomer conversion rate, grafting rate and grafting efficiency, difficulty in recycling residual monomers, AES yellowing and brown, etc., and achieves weather resistance. Excellent aging yellowing performance, improved monomer conversion rate and less solvent dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

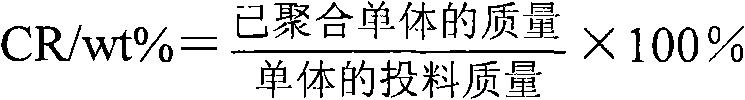

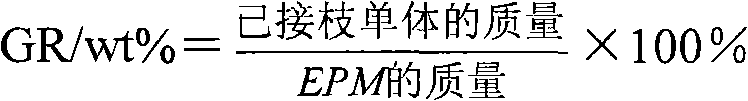

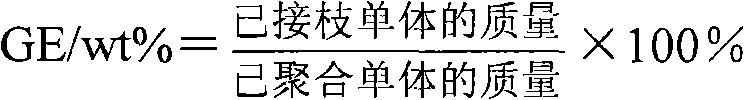

Method used

Image

Examples

Embodiment 1

[0028] The basic formula and implementation formula of embodiment 1 are as shown in table 1. The synthesis operation process of EPM-g-MAN when the mass ratio of AN / MMA is 15 / 85 is as follows:

[0029] Add 60g of EPM and 150g of toluene to a 1000ml three-necked round-bottomed flask equipped with a condensing reflux tube, a stirrer, and an oil bath heating temperature controller, fully dissolve at 60°C for 16 hours, add 34g of methyl methacrylate and 6g of propylene Nitrile mixed monomer. Control the stirring speed to 200 rev / min, add 0.6gBPO and 0.132gSDS after stirring for 30 minutes, stir for 15 minutes to make them evenly mixed. 72g of polyvinyl alcohol-224 (PVA-224) aqueous solution with a concentration of 2% was added dropwise to the reaction system, and the addition was completed within 30 minutes, while adjusting the stirring speed to gradually increase to 1000 rpm. Slowly add 385 g of deionized water into the flask, pass nitrogen gas for 15 minutes, and raise the reac...

Embodiment 2

[0049] Table 2 (b) The relationship between the EPM / MMA-AN mass ratio of Example 2 and the CR, GR, GE and AEMS notched impact strength of the graft system

[0050]

[0051] *EPM content of AEMS: EPM / AEMS percentage is 25wt%.

Embodiment 3

[0054] Table 3 (b) The relationship between the amount of BPO in Example 3 and the CR, GR, GE and AEMS notched impact strength of the graft system

[0055]

[0056] *EPM content of AEMS: EPM / AEMS percentage is 25wt%.

[0057] Table 4 (a) embodiment 4 formula and reaction condition

[0058]

[0059] Table 4 (b) the relationship between the amount of solvent in Example 4 and the CR and AEMS notched impact strength of the graft system

[0060]

[0061] *EPM content of AEMS: EPM / AEMS percentage is 25wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com