Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221 results about "Cascade refrigeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cascade refrigeration system with fluoroolefin refrigerant

InactiveUS20120216551A1Lower global warming potentialIncrease capacityCompression machines with cascade operationHeat-exchange elementsEngineeringRefrigeration

The present invention relates to a cascade refrigeration system which circulates a refrigerant comprising a fluoroolefin therethrough. The cascade refrigeration system includes a low temperature refrigeration loop and a medium temperature refrigeration loop. The fluoroolefin circulates through either loop, or both. In a particular embodiment, the fluoroolefin circulates through the medium temperature loop. In a particular embodiment, where the cascade refrigeration system includes a first and a second cascade heat exchanger, and a secondary heat transfer loop which extends between the first and second cascade heat exchangers, either the first and / or second refrigerant may be, but need not necessarily be, a fluoroolefin.

Owner:THE CHEMOURS CO FC LLC

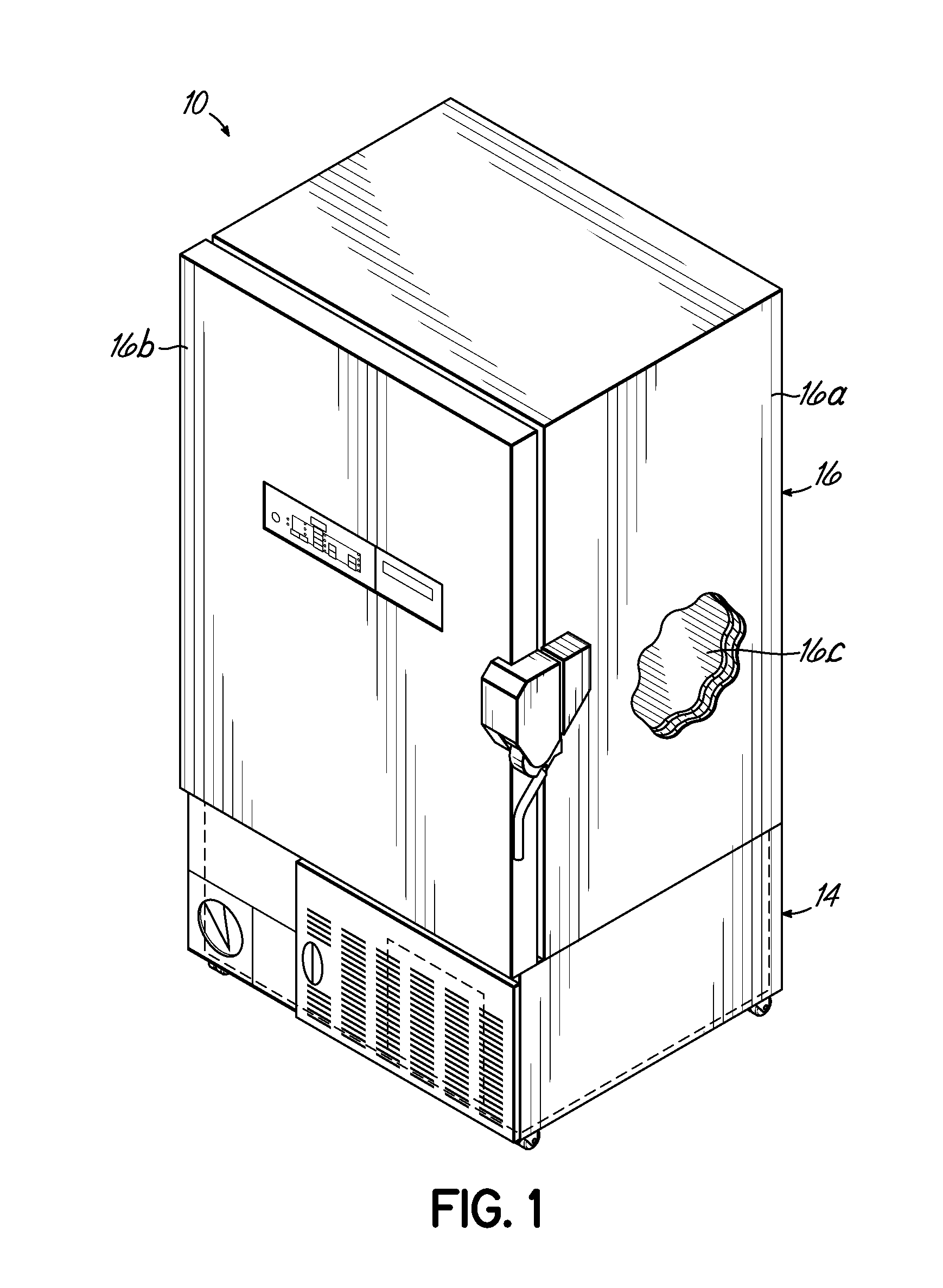

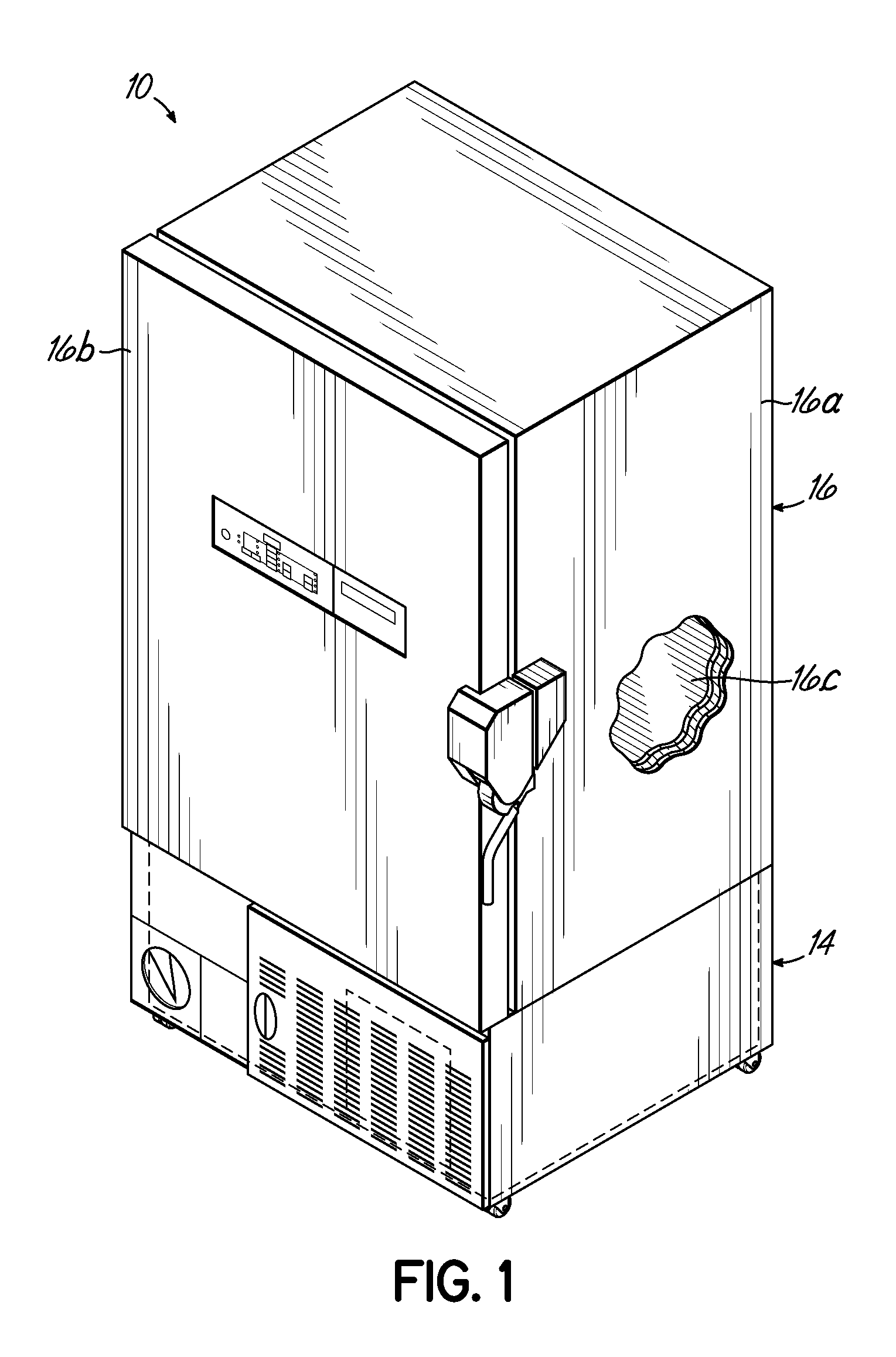

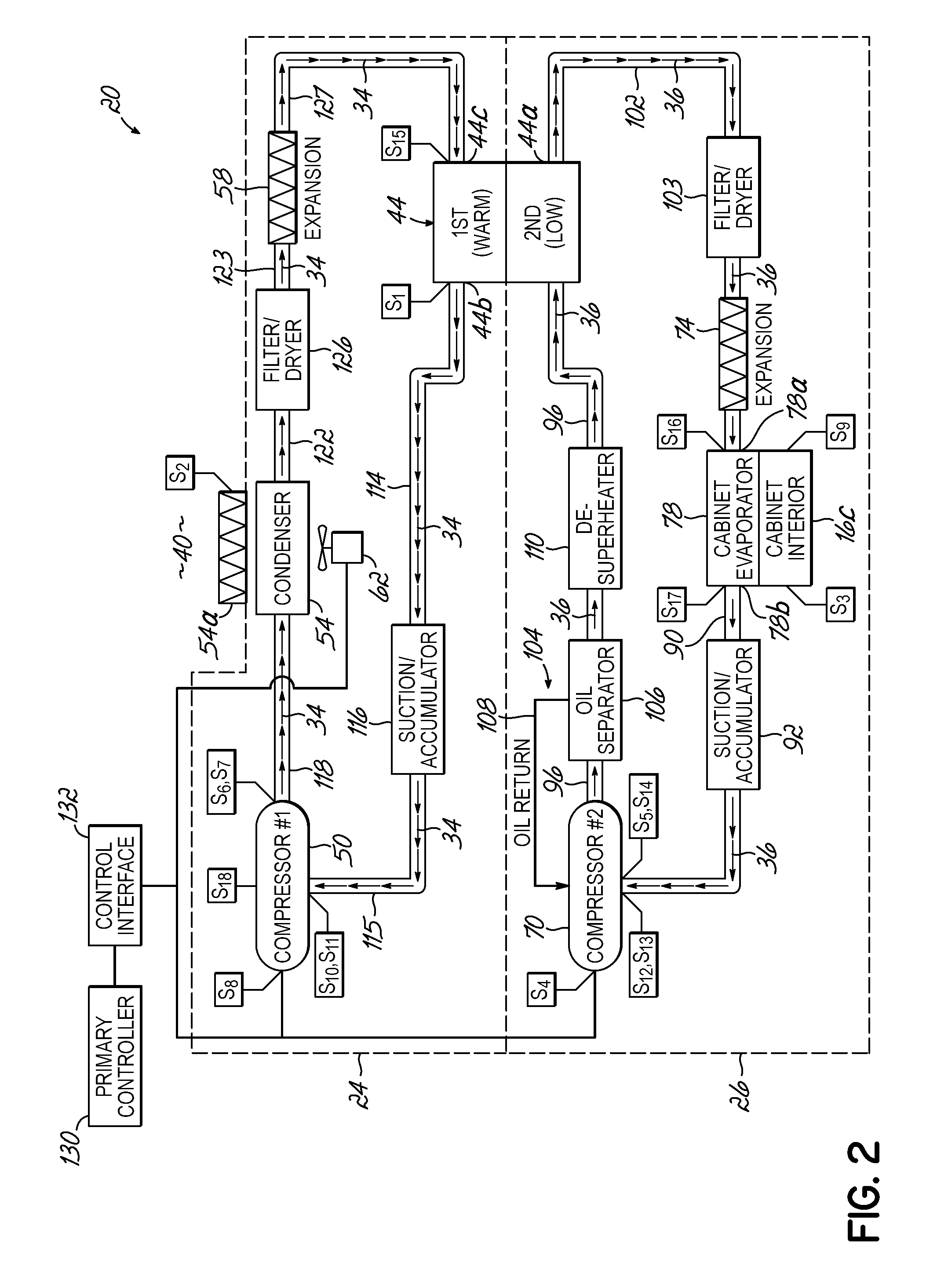

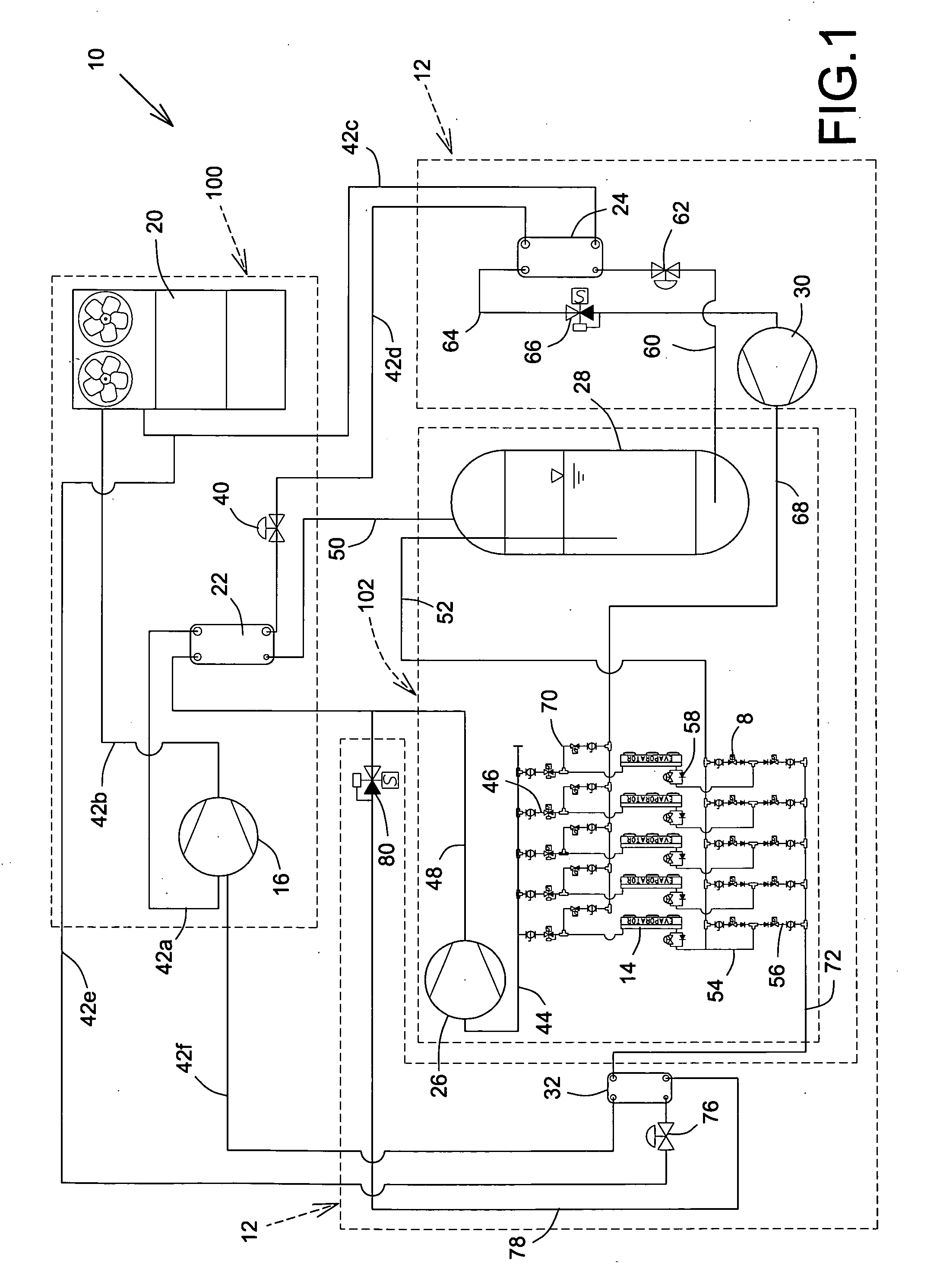

Refrigeration system having a variable speed compressor

ActiveUS20110072836A1Uniform temperature distributionImprove life expectancyCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigeration

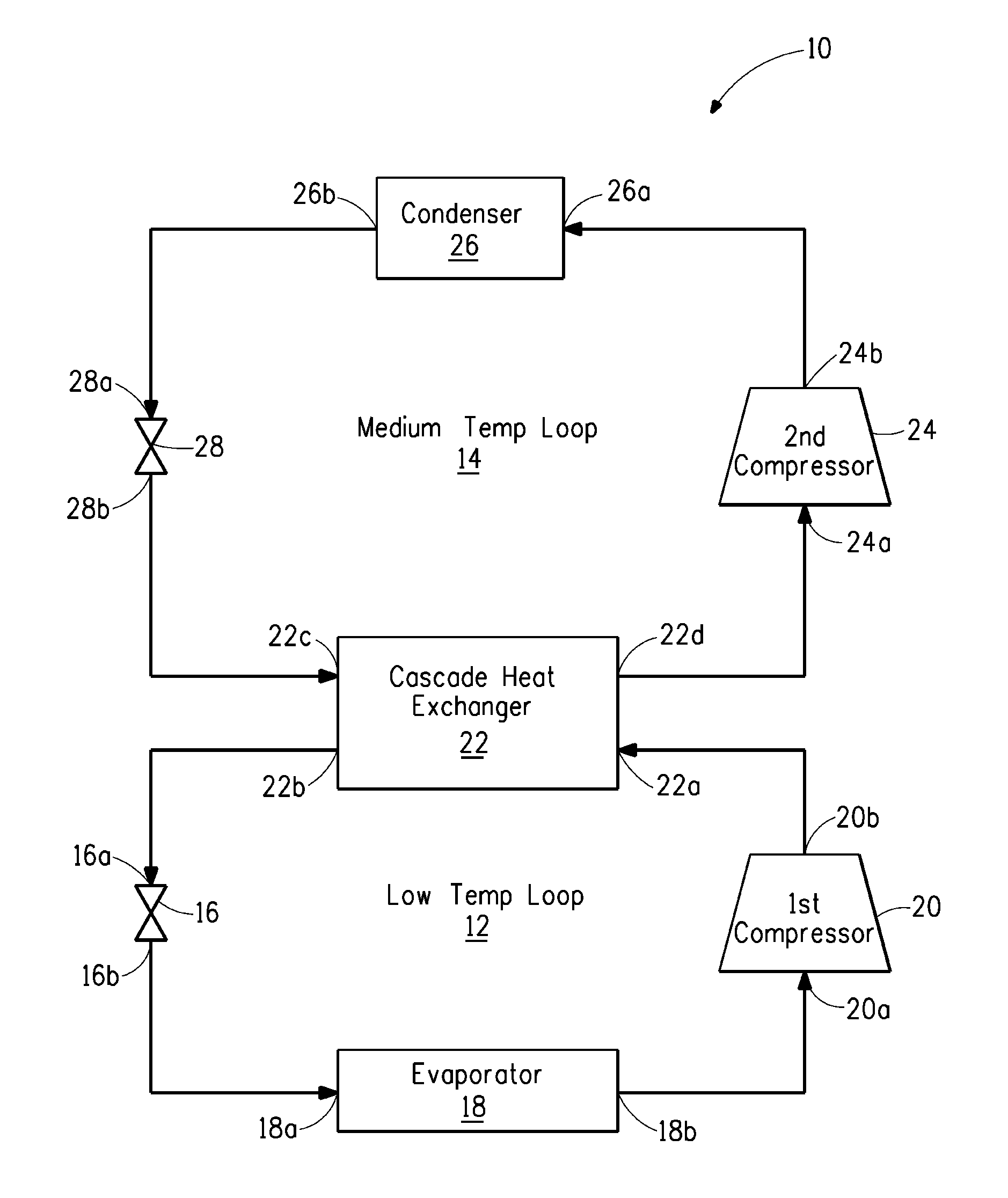

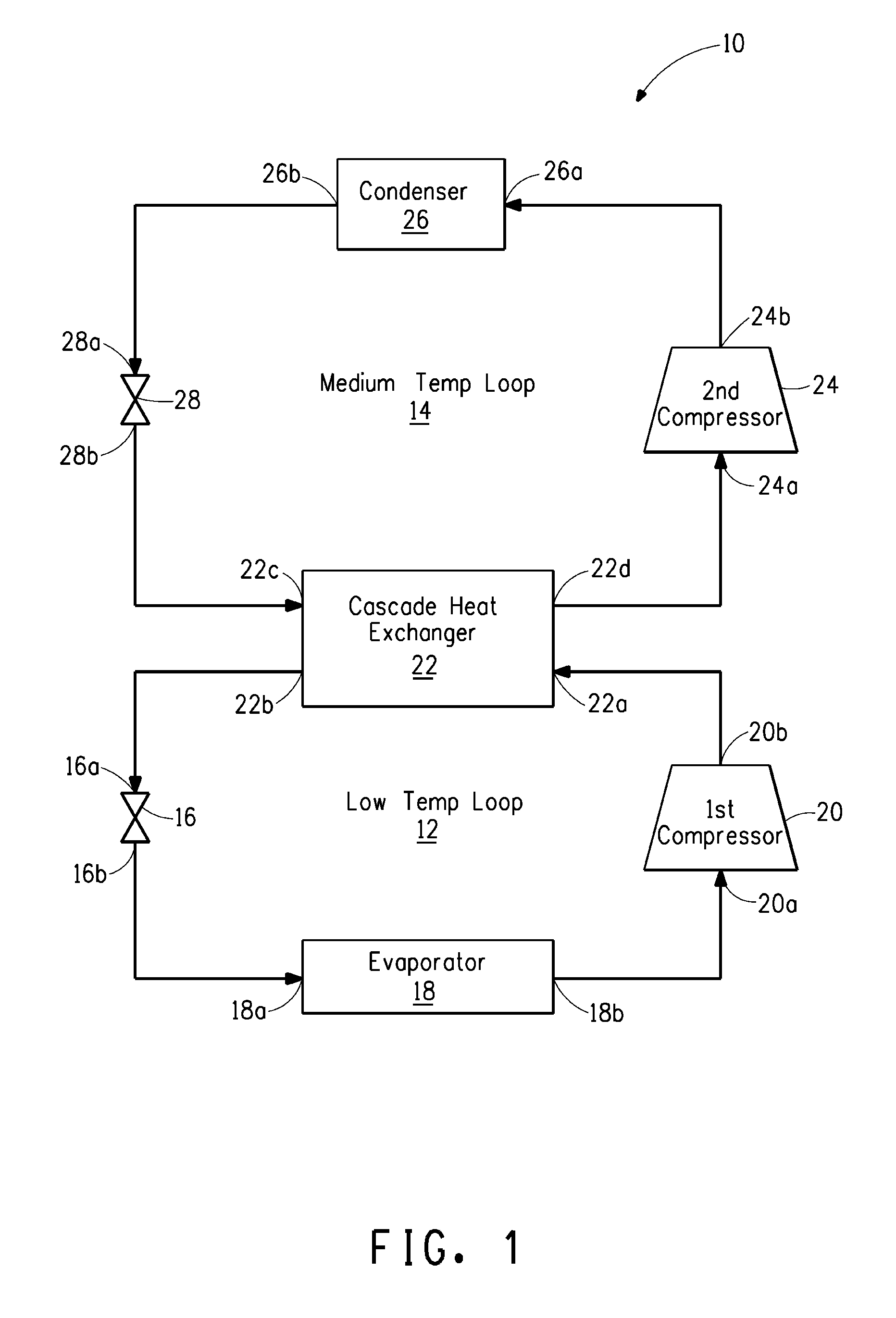

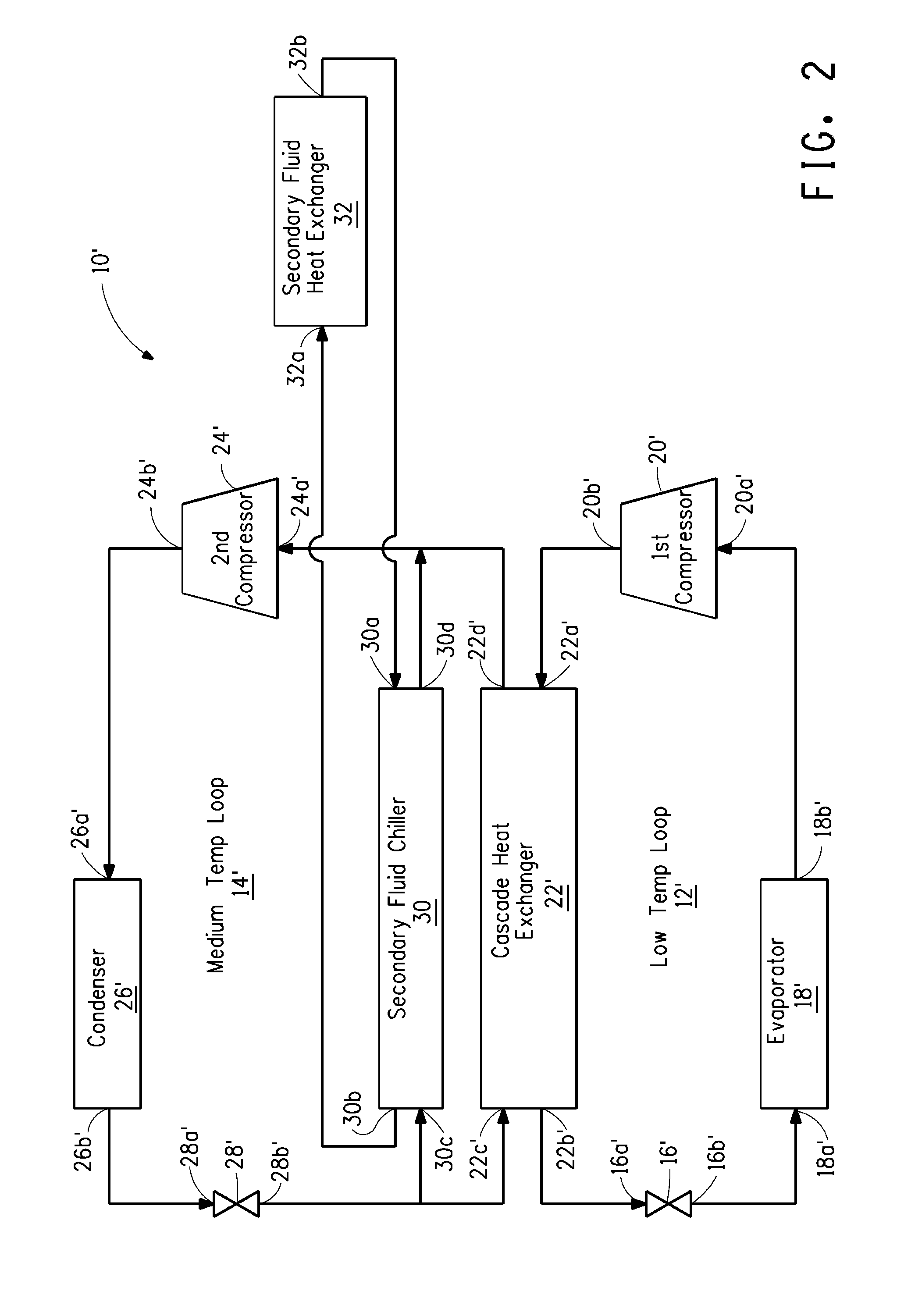

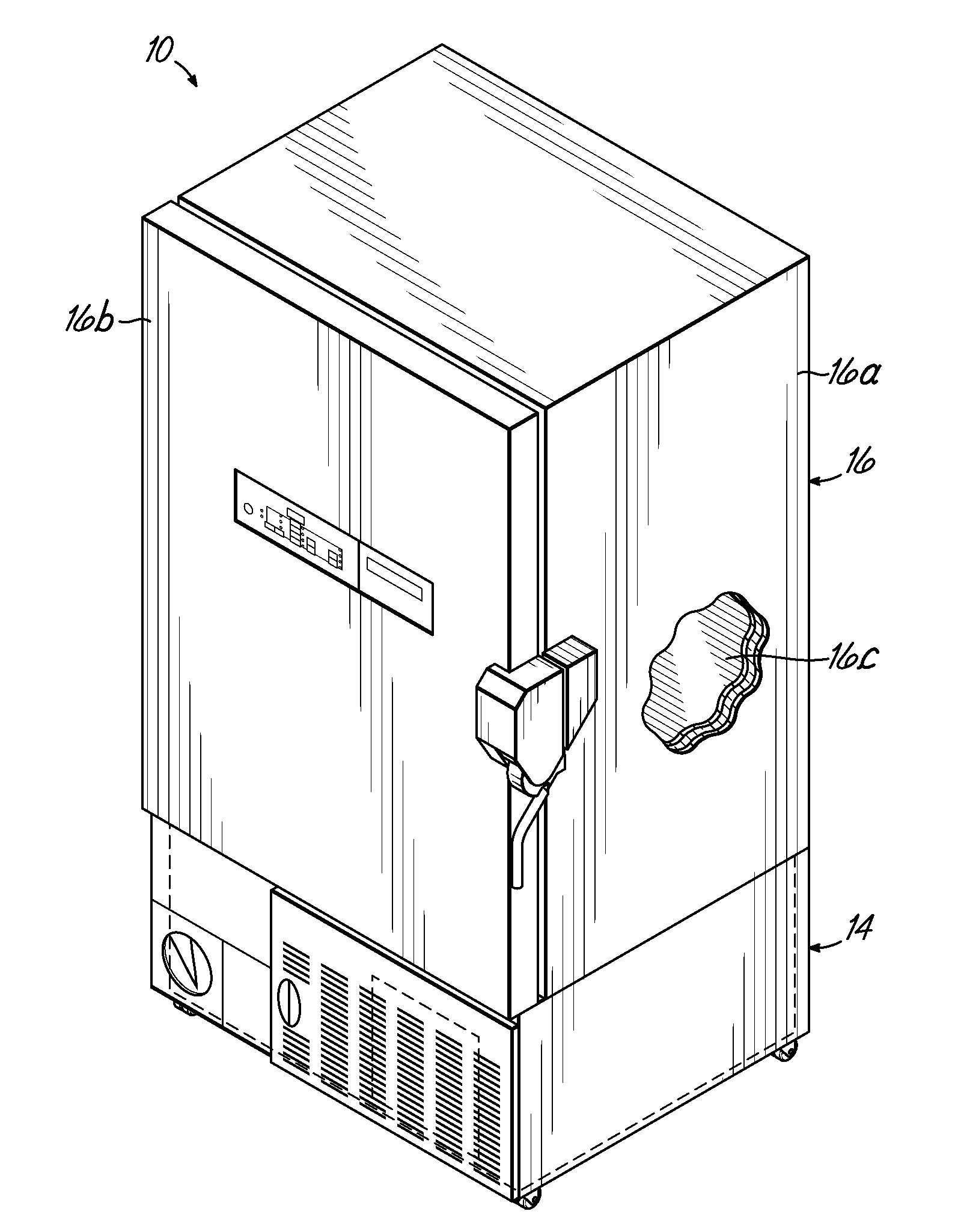

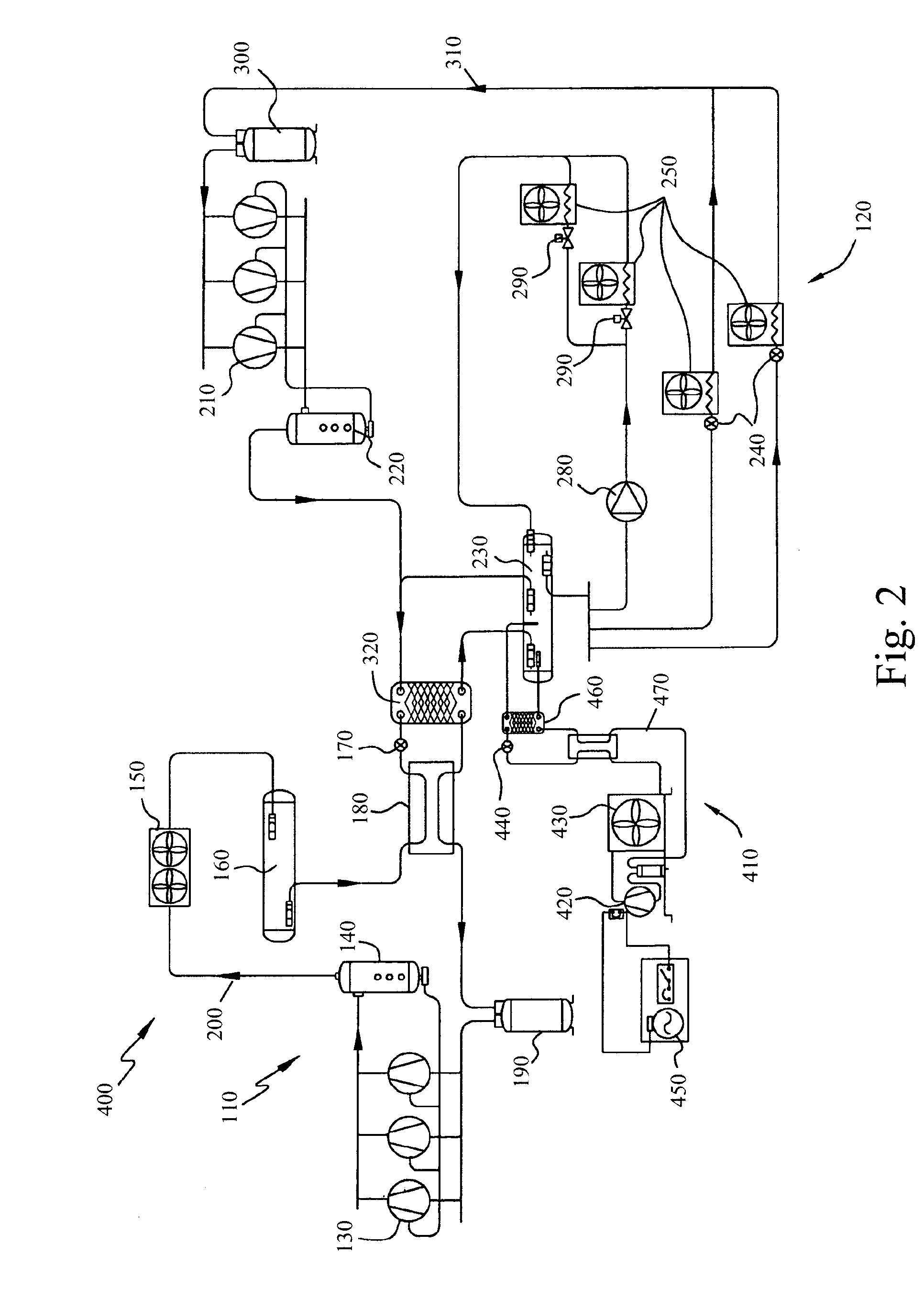

A two-stage cascade refrigeration system is provided having a first refrigeration stage and a second refrigeration stage. The first refrigeration stage defines a first fluid circuit for circulating a first refrigerant, and has a first compressor, a condenser, and a first expansion device that is in fluid communication with the first fluid circuit. The second refrigeration stage defines a second fluid circuit for circulating a second refrigerant, with the second refrigeration stage having a second compressor, a second expansion device, and an evaporator that is in fluid communication with the second fluid circuit. A heat exchanger is in fluid communication with the first and second fluid circuits to exchange heat between the first and second refrigerants. At least one of the first or second compressors is a variable speed compressor.

Owner:THERMO FISHER SCI ASHEVILLE

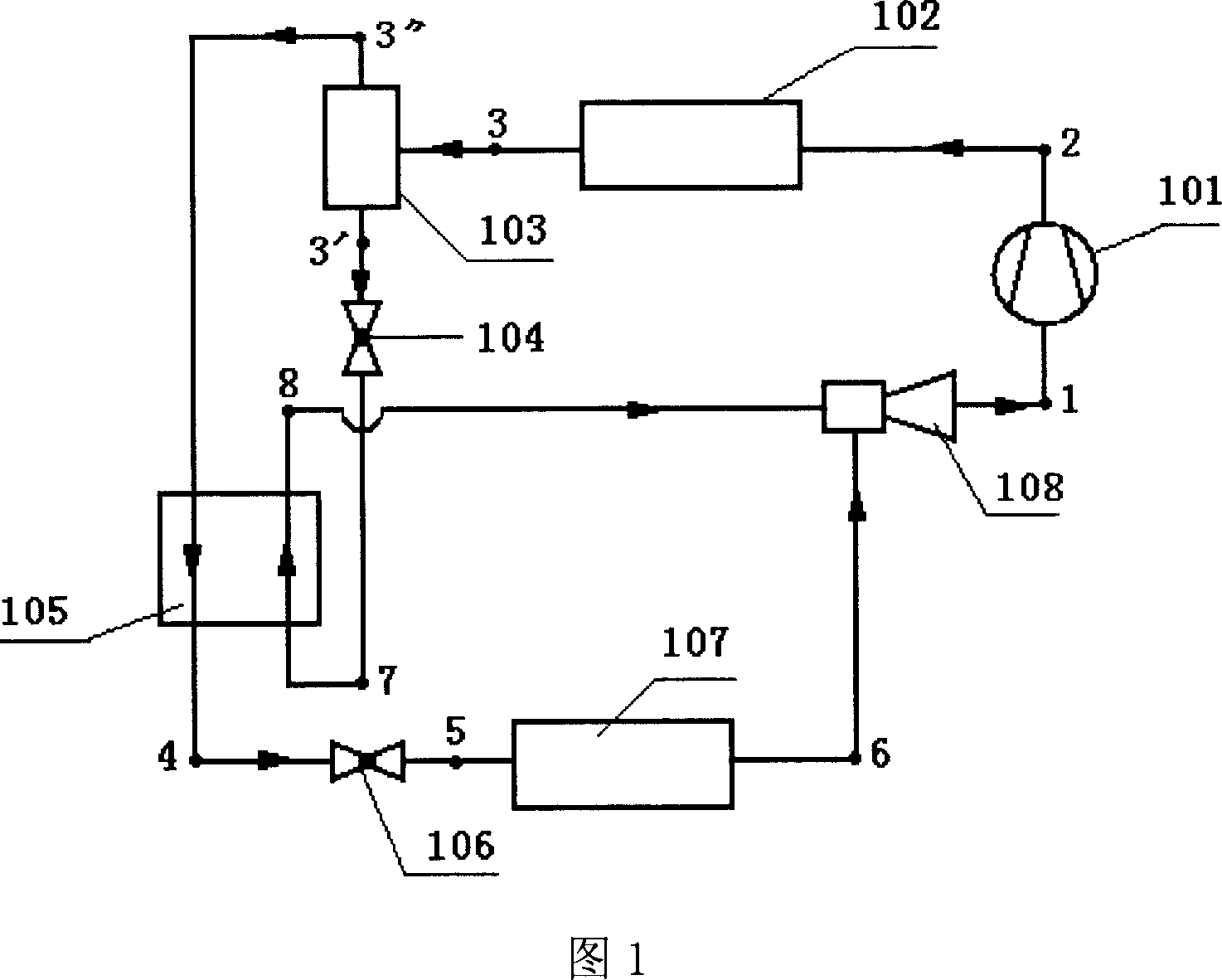

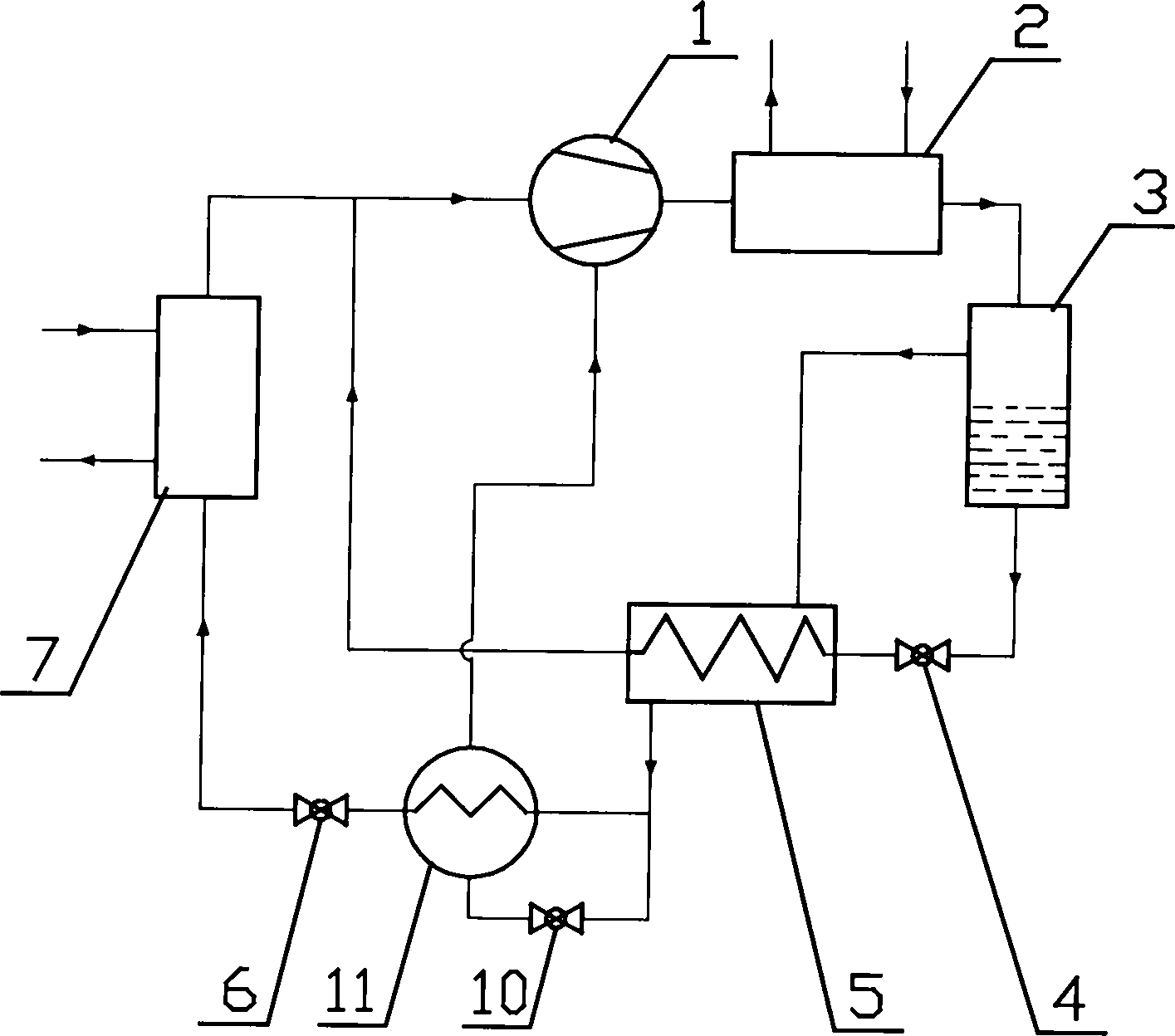

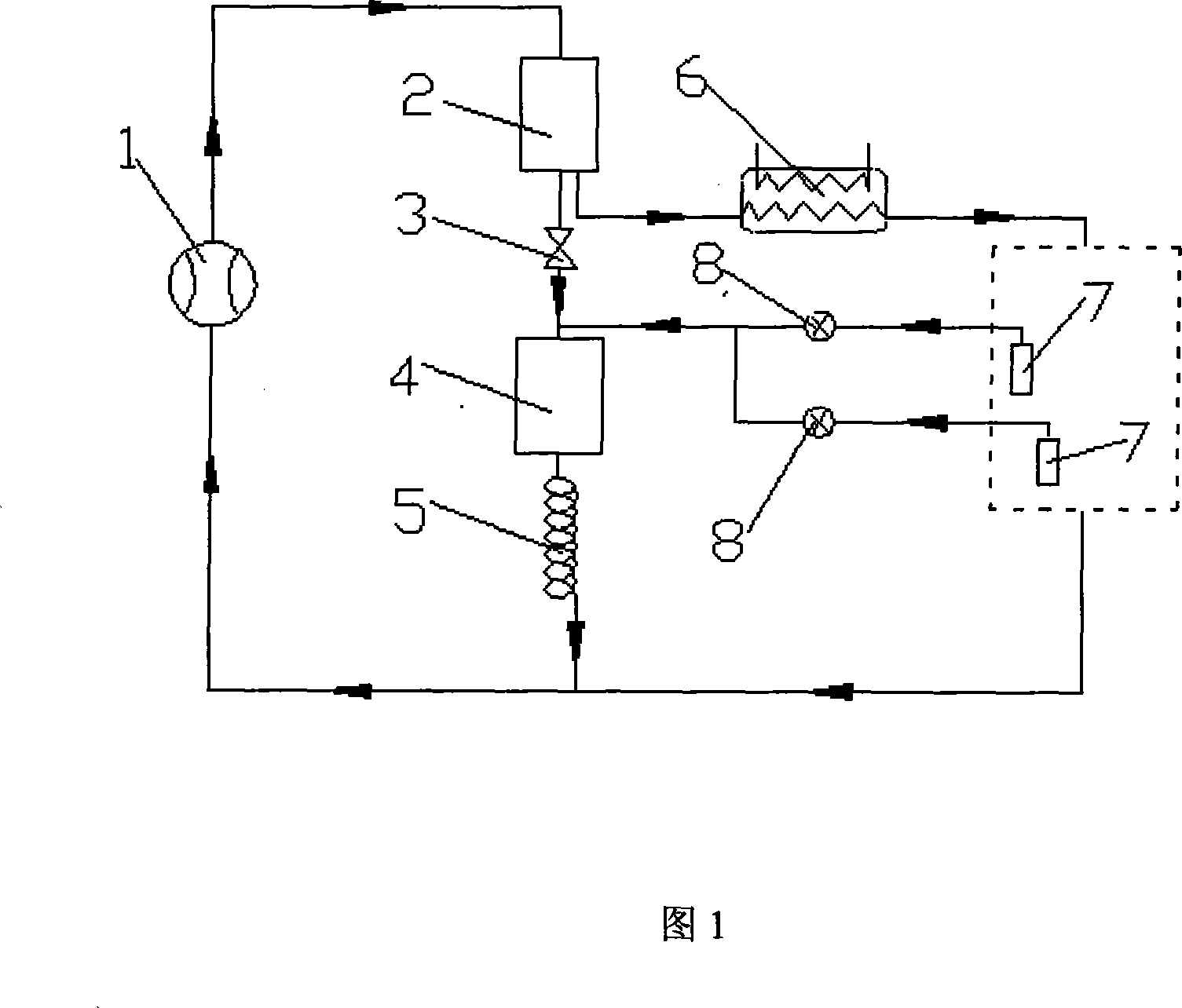

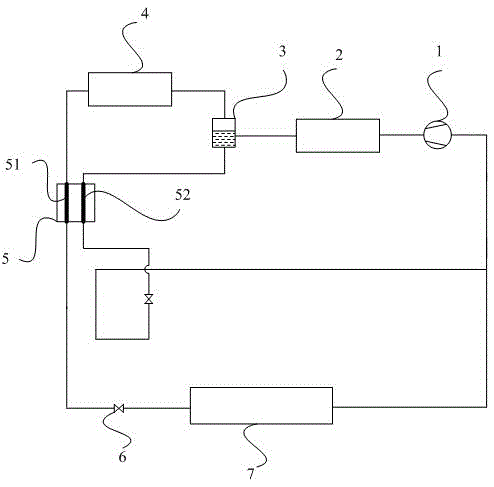

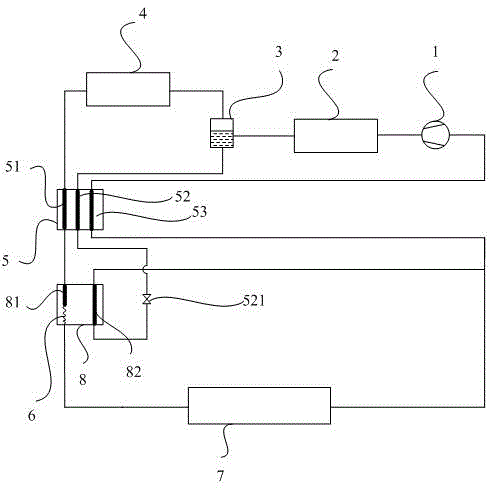

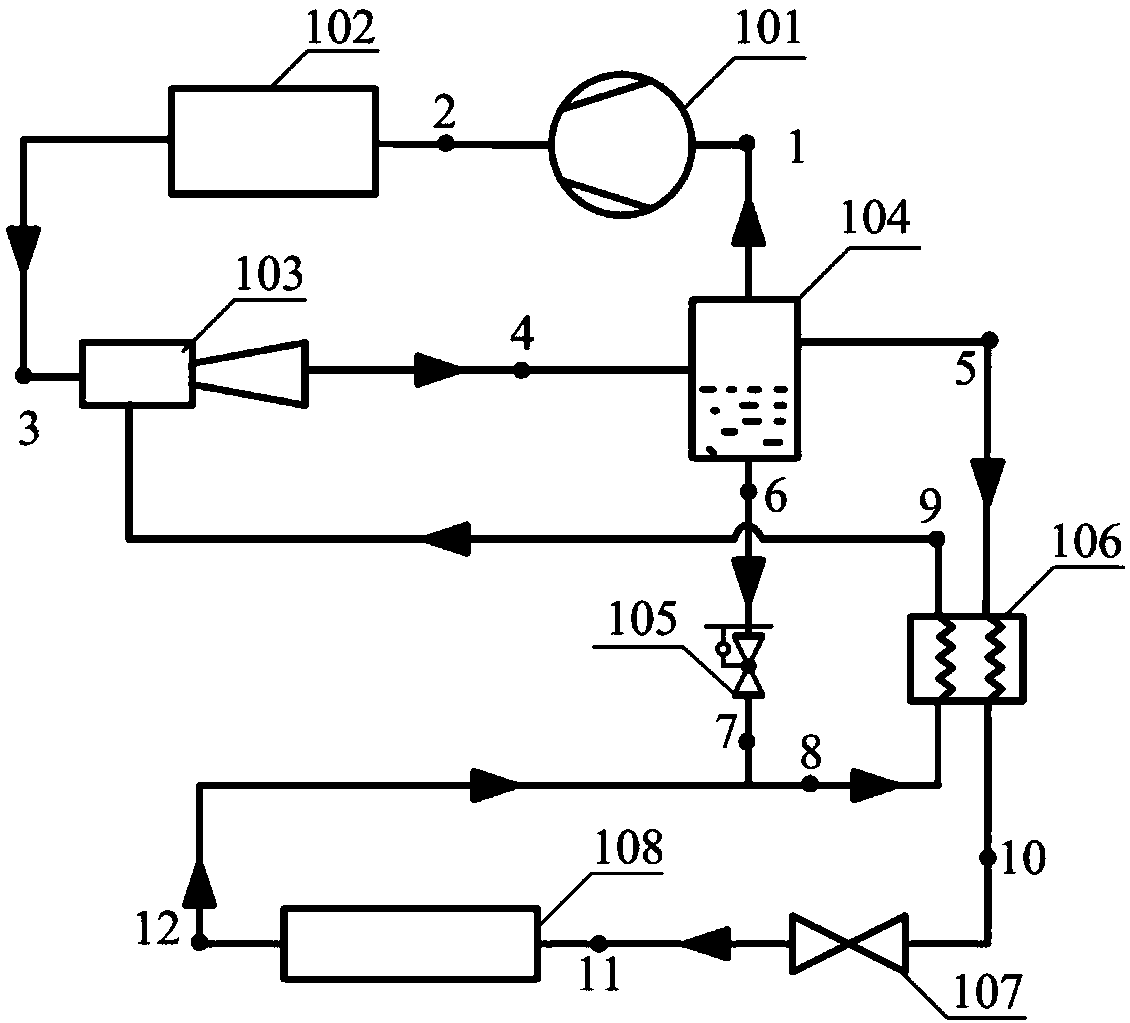

Self-overlapping refrigerating cycle system with injector

InactiveCN1963341ASimple structureHas a supercharging effectCompression machines with cascade operationFluid circulation arrangementVapor–liquid separatorWorking fluid

The ejector attached self cascade refrigeration circulating system comprises a pipes connected compressor, a condenser, a gas and liquid separator, an evaporation condenser, an evaporator, and an inflated valve with ejectors between the evaporating condenser and the evaporator. The outlet of the compressor connects with the inlet of the condenser whose outlet connects with the inlet of the gas and liquid separator and the gaseous coolants of the outlet of the gas and liquid separator connecting with the inlet of the evaporating condenser, the other liquidized coolant connecting with the evaporating condenser through the inflated valve. One of the branches of the outlet of the evaporating condenser enters into the evaporator through the inflated valve; the other branch of coolant vapor enters into the ejector as the working vapor, with the outlet of the ejector connecting with the inlet of the compressor.

Owner:XI AN JIAOTONG UNIV

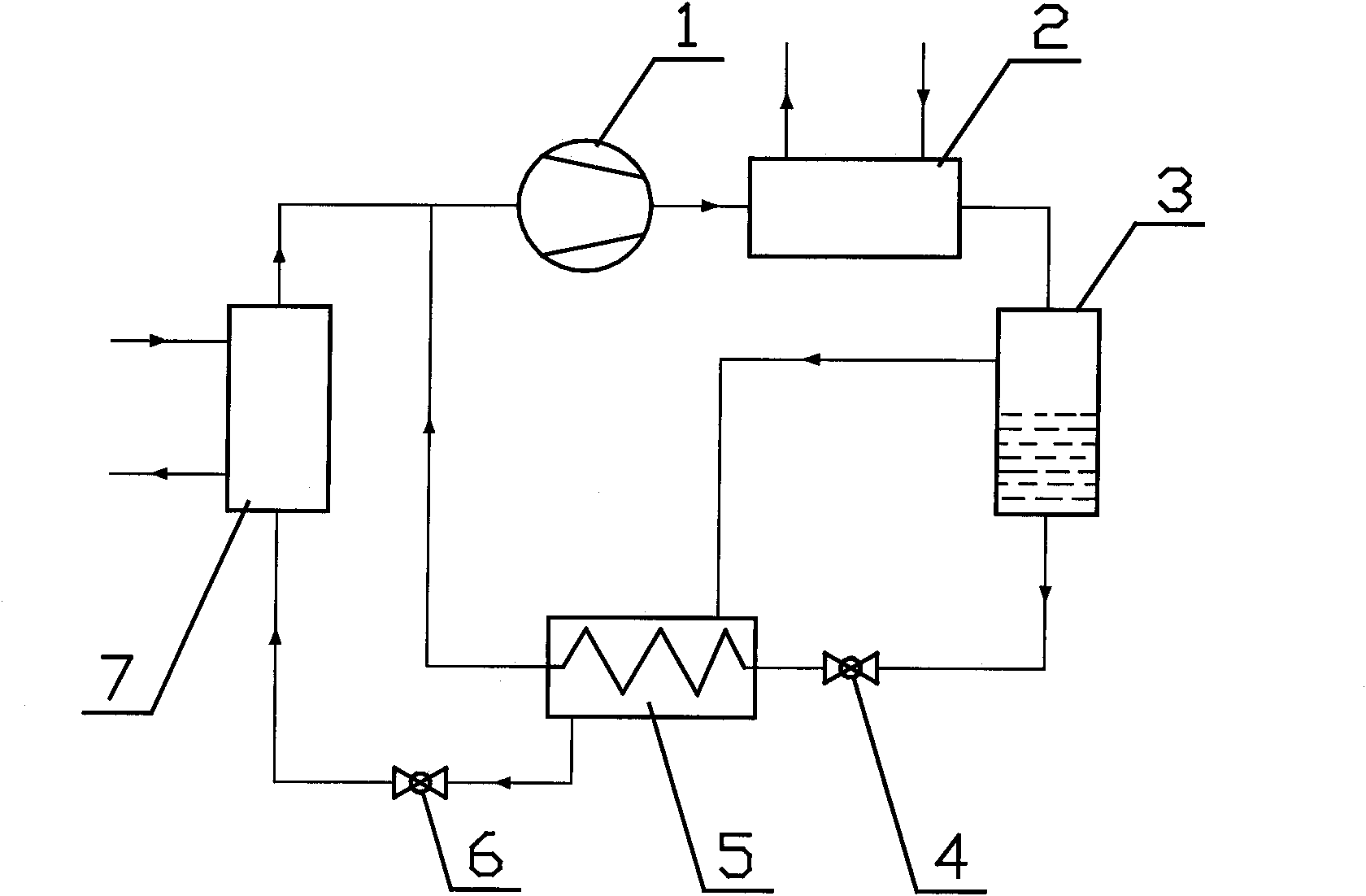

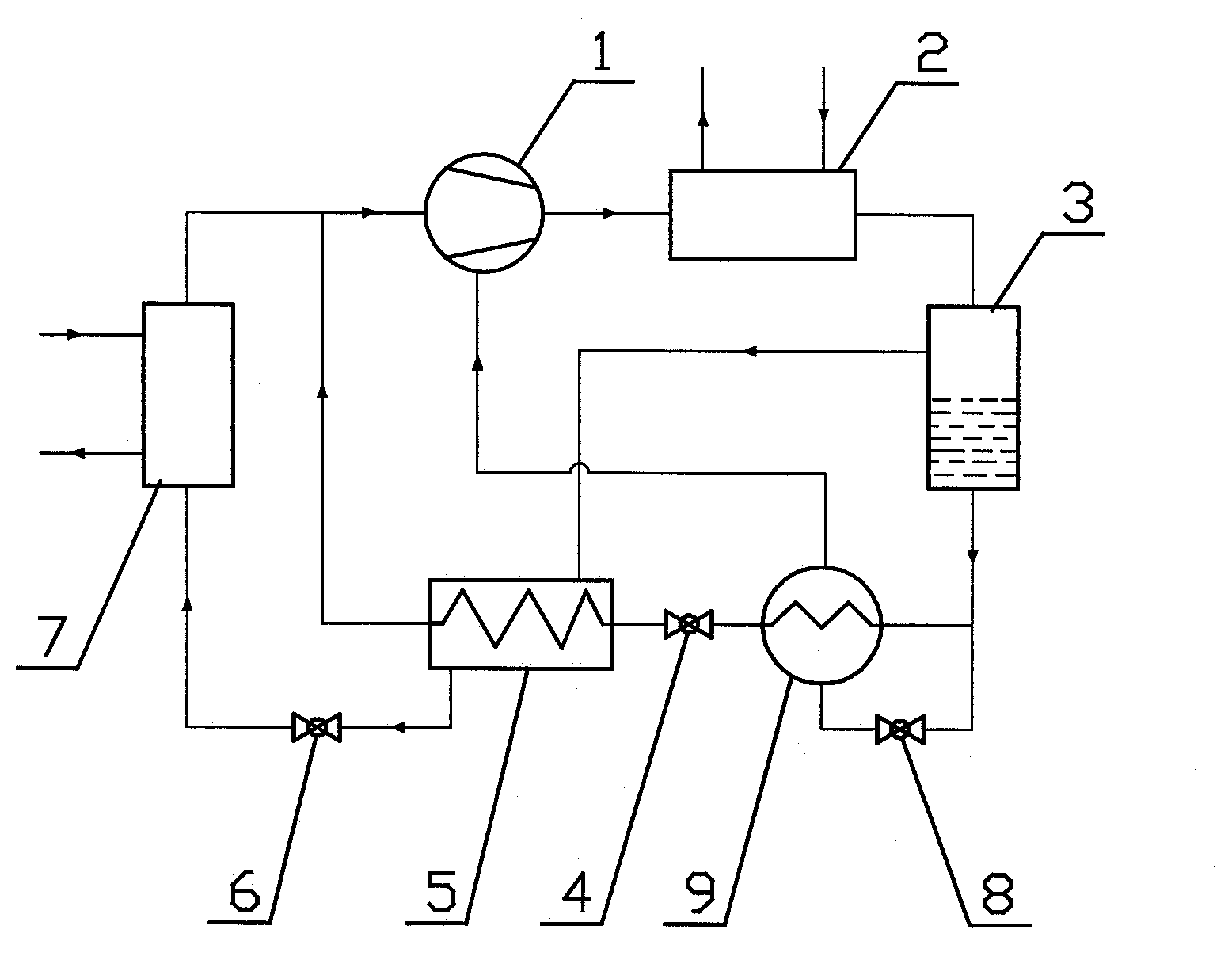

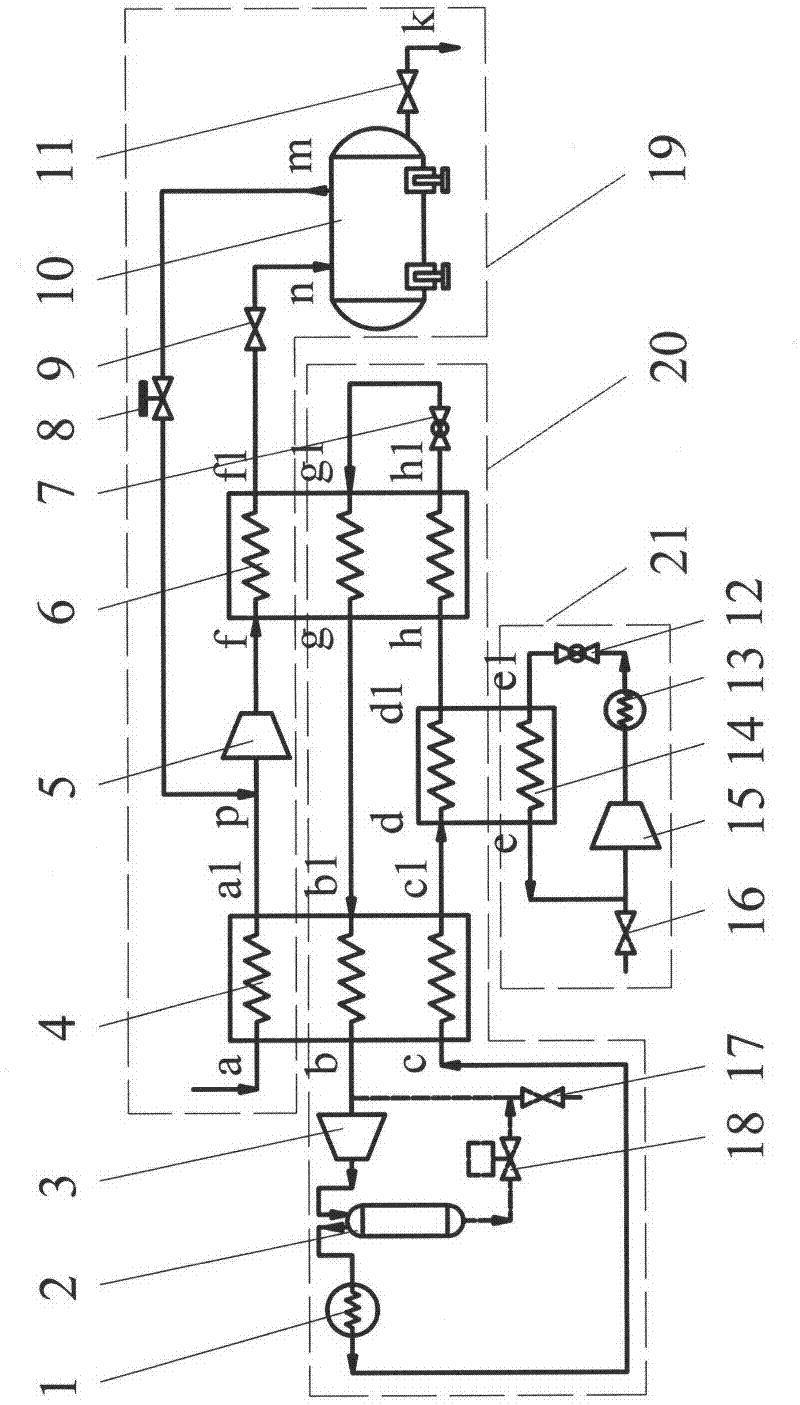

High-efficiency screw-type auto-cascading refrigeration system

ActiveCN101782289AReduce the temperatureImprove cooling effectCompression machines with non-reversible cycleRefrigeration compressorVapor–liquid separator

The invention discloses a high-efficiency screw-type auto-cascading refrigeration system which comprises a screw-type refrigeration compressor for the cycle operation of a binary mixed refrigerant, a condenser, a gas-liquid separator, a first throttle element, a condensing evaporator, a second throttle element and an evaporator. The high-efficiency screw-type auto-cascading refrigeration system is characterized in that an economizer gas-supplementing hole is arranged on the screw-type refrigeration compressor; and an economizer component is arranged between the liquid outlet of the gas-liquid separator and the first throttle element or / and between the high-pressure liquid outlet of the condensing evaporator and the second throttle element, mainly comprises an auxiliary throttle element and an economizer and utilizes the economizer gas-supplementing hole of the screw-type refrigeration compressor to recycle a small part of gas evaporated by solely throttling the recycled refrigerant in the economizer. The liquid temperature of the refrigerant with a low boiling point is directly or indirectly reduced to remarkably improve the refrigeration amount and the refrigeration coefficient of the whole refrigeration system under a low-temperature condition. The invention is extremely suitable for the low-cost upgrading and regenerating modification of the traditional screw-type auto-cascading refrigeration system.

Owner:武汉新世界制冷工业有限公司

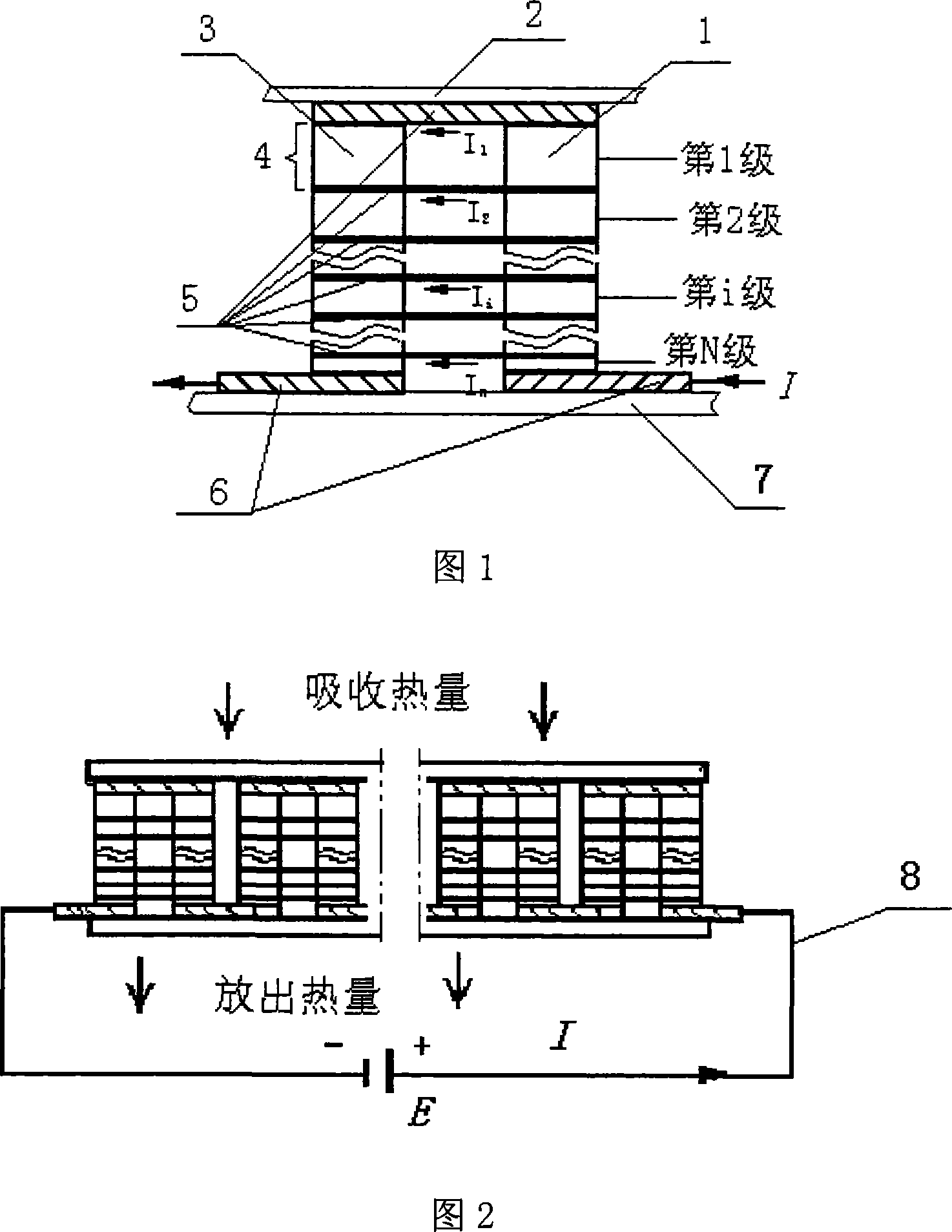

Multilevel semiconductor cascade refrigeration element and refrigeration thermopile

InactiveCN101246947ASimple structureIncrease manufacturing costThermoelectric device with peltier/seeback effectElectricityInsulation layer

The present invention discloses a multilevel semiconductor cascade refrigeration element and refrigeration thermopile. Multilevel semiconductor cascade refrigeration element is cascaded from the first level to the nth level refrigeration galvanic, each level of refrigeration galvanic comprises of p type semiconductor and n type semiconductor in paired, the cold end on the top of the first refrigeration galvanic has connection tablet to connect heat-conducting plate of cold end, the hot end on the bottom of Nth level refrigeration galvanic has hot end connection tablet to connect heat-conducting plate of hot end. Wherein, the section of each of level refrigeration galvanic is identical, and the length of galvanic arm becomes shorter and shorter from the first level to the Nth. Connection tablet are set among all refrigeration galvanic cascade surfaces, and levels of refrigeration galvanic connected by electrical connection in parallel and hot connection in series. Because in the refrigeration galvanic employing non-isolength galvanic arm multilevel cascade structure type, insulation layer isn't between levels, additional heat transfer thermal resistance and thermal leak loss between levels are reduced, so the refrigeration capability of multilevel refrigeration element and thermopile are enhanced efficiently.

Owner:XI AN JIAOTONG UNIV

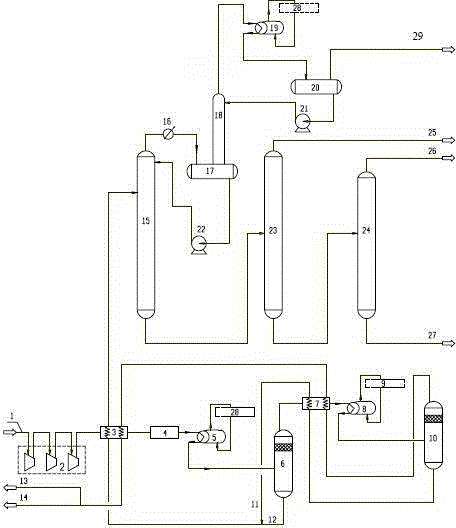

Separation method for reaction product of propane dehydrogenated propylene preparation

InactiveCN106316760AEasy to operateReduce contentDistillation purification/separationHigh energyPetrochemical

The invention discloses a separation method for a reaction product of propane dehydrogenated propylene preparation and belongs to the field of petrochemical industry. The method comprises the following steps: (1) the reaction product of propane dehydrogenated propylene preparation is pretreated, then, the pretreated reaction product enters a propylene and ethylene cascaded refrigeration system with an expander, and then, a liquid phase is fed to a deethanizer; (2) top oil gas of the deethanizer is condensed and then enters a reflux tank of the deethanizer, tank bottom liquid of the reflux tank of the deethanizer totally returns to the deethanizer, tank top gas of the reflux tank of the deethanizer enters a top condensation section of the deethanizer and is fractionated by the condensation section, and top gas of the condensation section is condensed by a refrigerator of the top condensation section of the deethanizer under the action of a propylene refrigerating system and then enters a deep freezing tank of the deethanizer; (3) tank top gas of the deep freezing tank of the deethanizer is delivered out of a device as fuel gas, and bottom liquid of the deethanizer enters a propylene refiner; and (4) a refined propylene product is fractionated from the top of the propylene refiner, a bottom liquid phase of the propylene refiner enters a depropanizer, and a bottom product C4+ cut of the depropanizer is delivered out of the device. By adopting the separation method, the problems, i.e., large absorbent circulating rate and high energy consumption in the prior art can be solved.

Owner:SINOPEC GUANGZHOU ENG +1

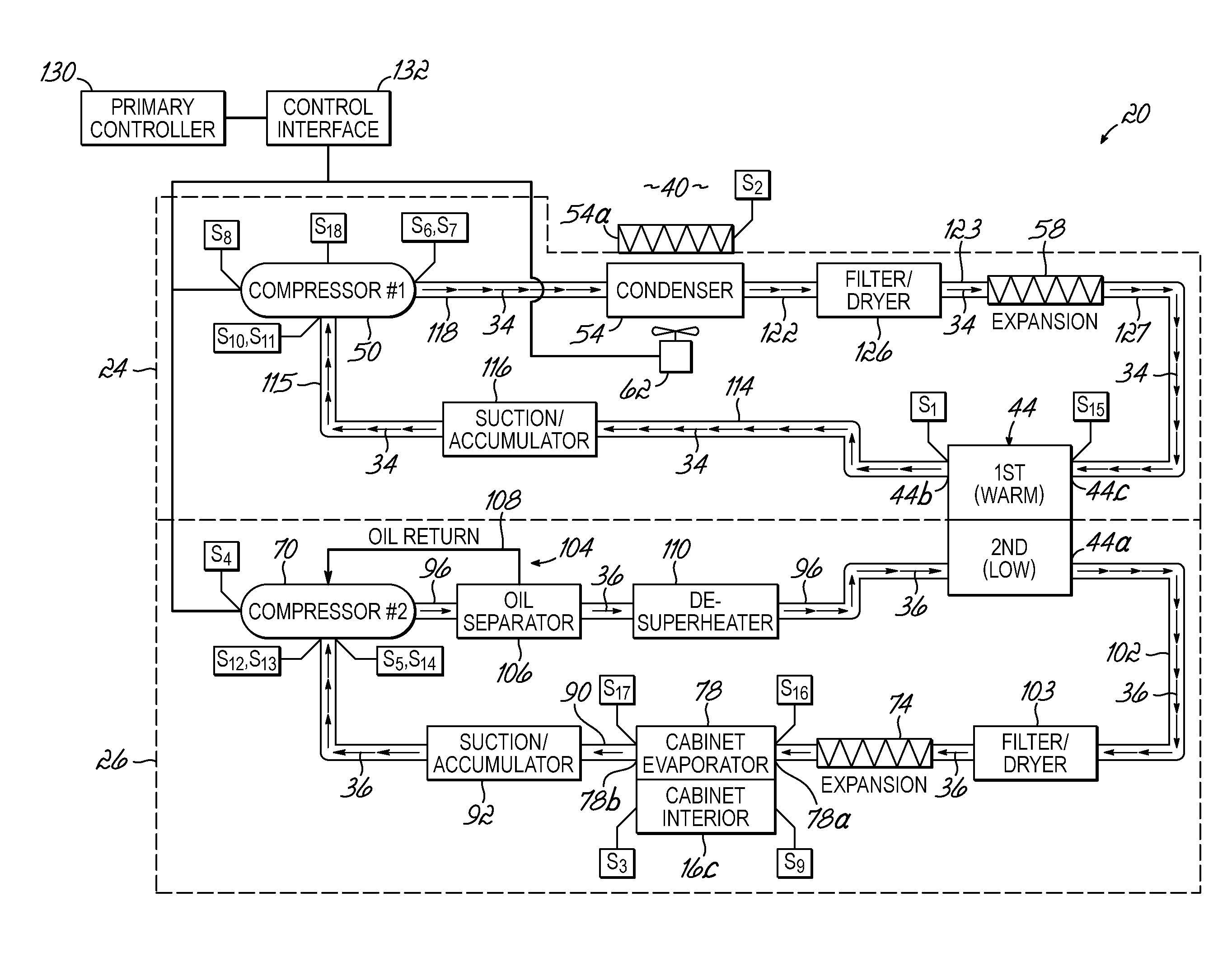

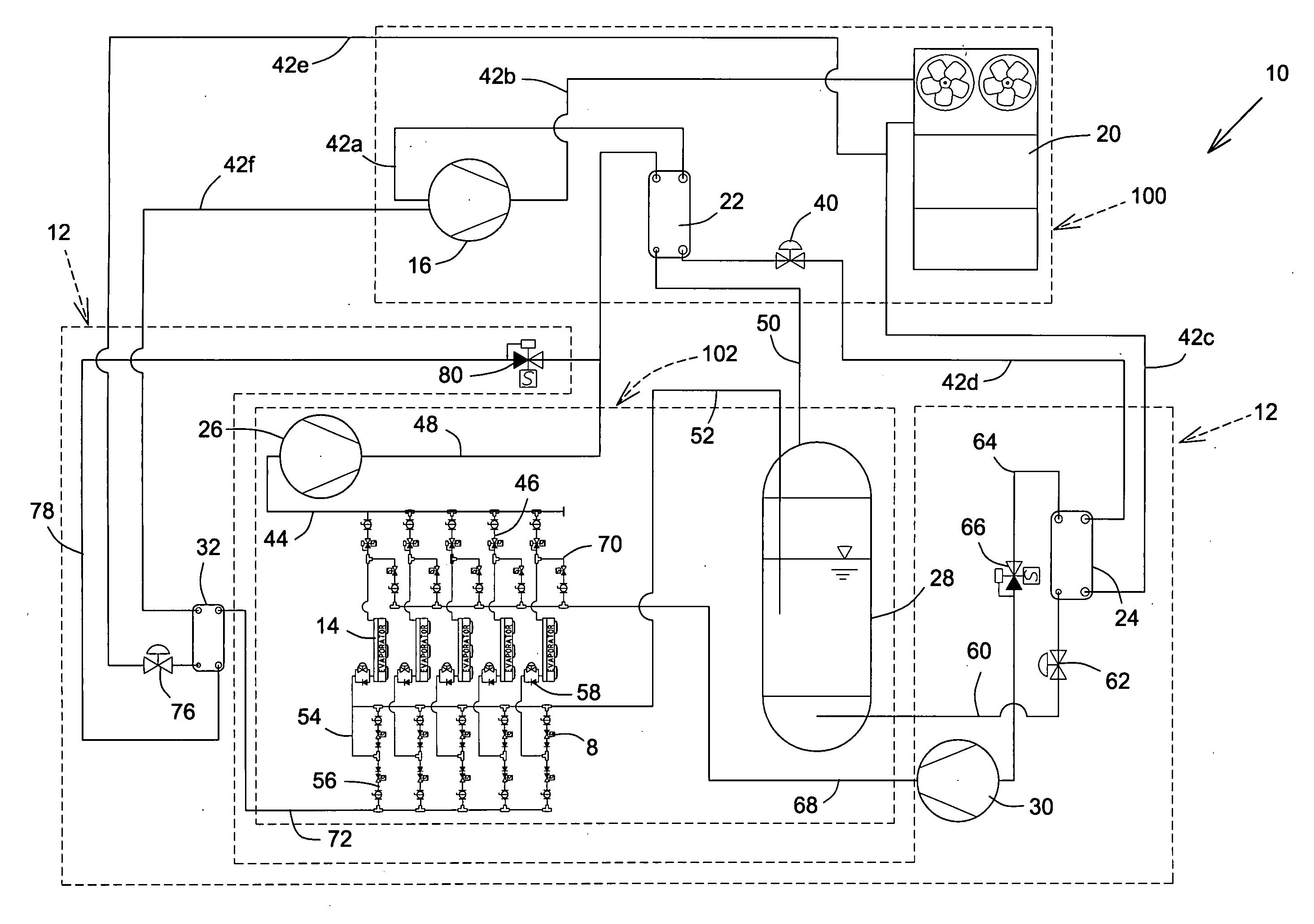

Refrigeration system having a variable speed compressor

ActiveUS8011191B2Uniform temperature distributionImprove life expectancyCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringRefrigeration

A two-stage cascade refrigeration system is provided having a first refrigeration stage and a second refrigeration stage. The first refrigeration stage defines a first fluid circuit for circulating a first refrigerant, and has a first compressor, a condenser, and a first expansion device that is in fluid communication with the first fluid circuit. The second refrigeration stage defines a second fluid circuit for circulating a second refrigerant, with the second refrigeration stage having a second compressor, a second expansion device, and an evaporator that is in fluid communication with the second fluid circuit. A heat exchanger is in fluid communication with the first and second fluid circuits to exchange heat between the first and second refrigerants. At least one of the first or second compressors is a variable speed compressor.

Owner:THERMO FISHER SCI ASHEVILLE

Carbon Dioxide Based Auxiliary Cooling System

InactiveUS20160178244A1Compression machines with several evaporatorsCompression machines with cascade operationEngineeringCarbon dioxide

The present application provides a cascade refrigeration system. The cascade refrigeration system may include a first side cycle, a second side cycle with a second side cycle carbon dioxide refrigerant, and an auxiliary cooling system to cool the second side cycle carbon dioxide refrigerant in the event of a power outage. The auxiliary cooling system may include an auxiliary carbon dioxide refrigerant.

Owner:HEATCRAFT REFRIGERATION PRODS

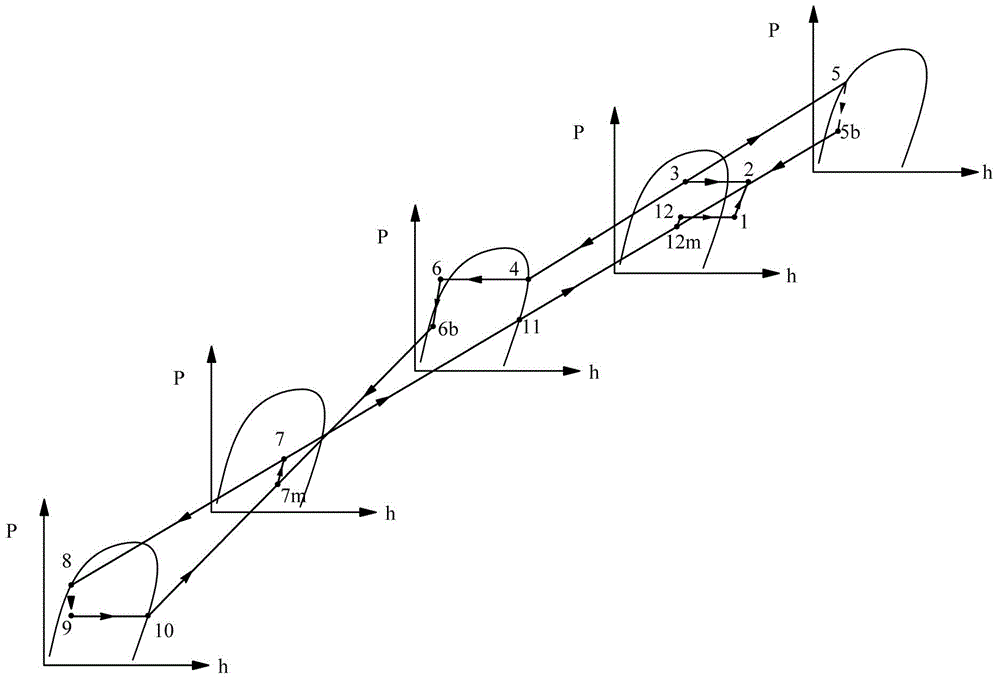

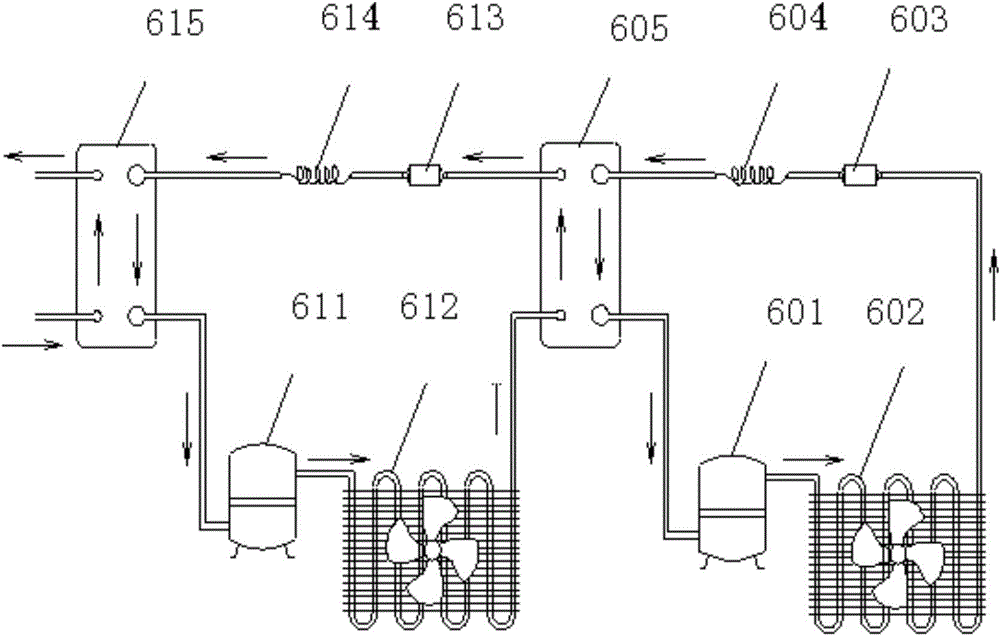

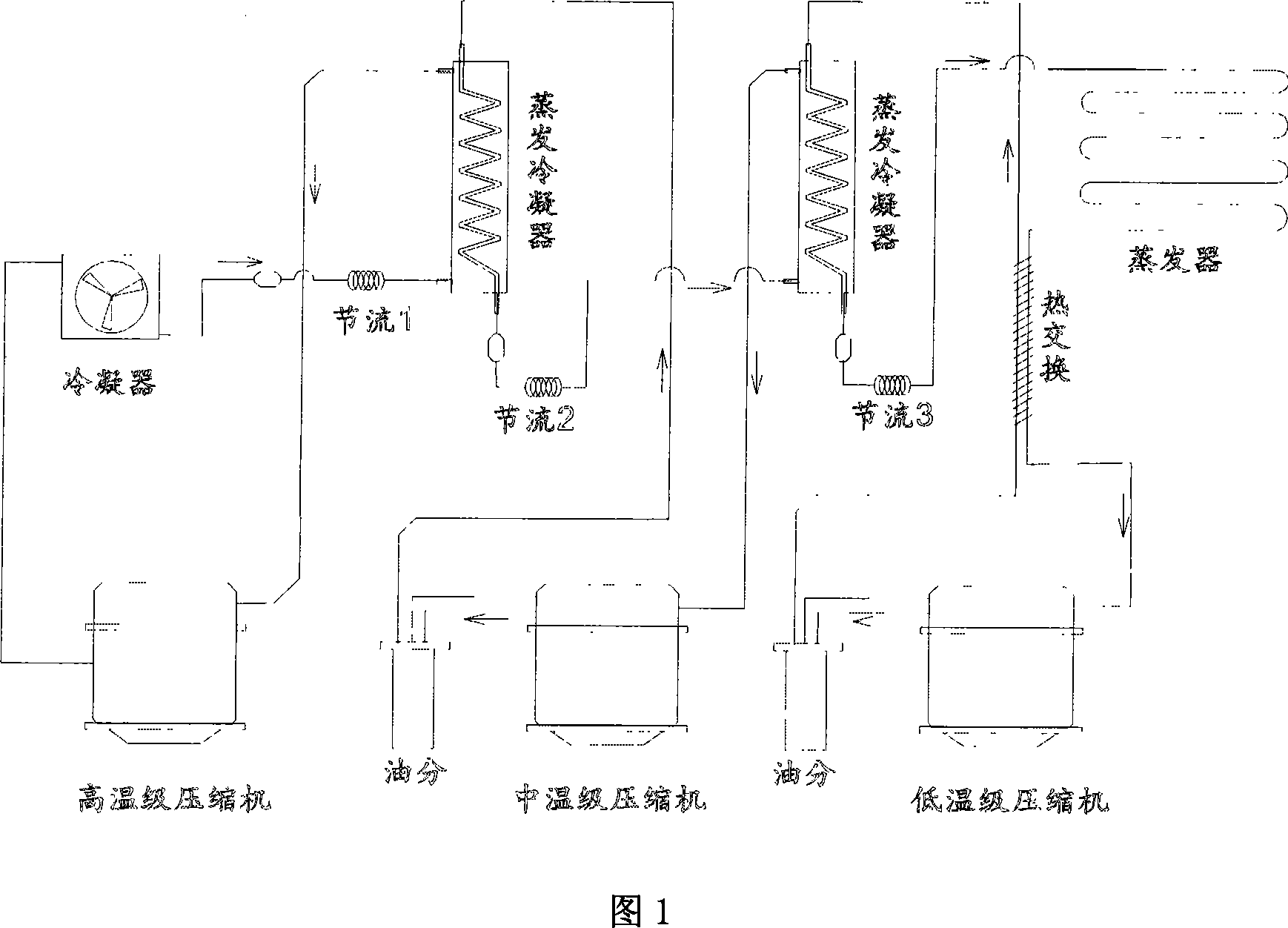

Double-stage cascade refrigeration method used for oil-gas recovery

InactiveCN101852504ASimplify condensate recovery systemReduce manufacturing costCompression machines with cascade operationProcess engineeringRefrigeration

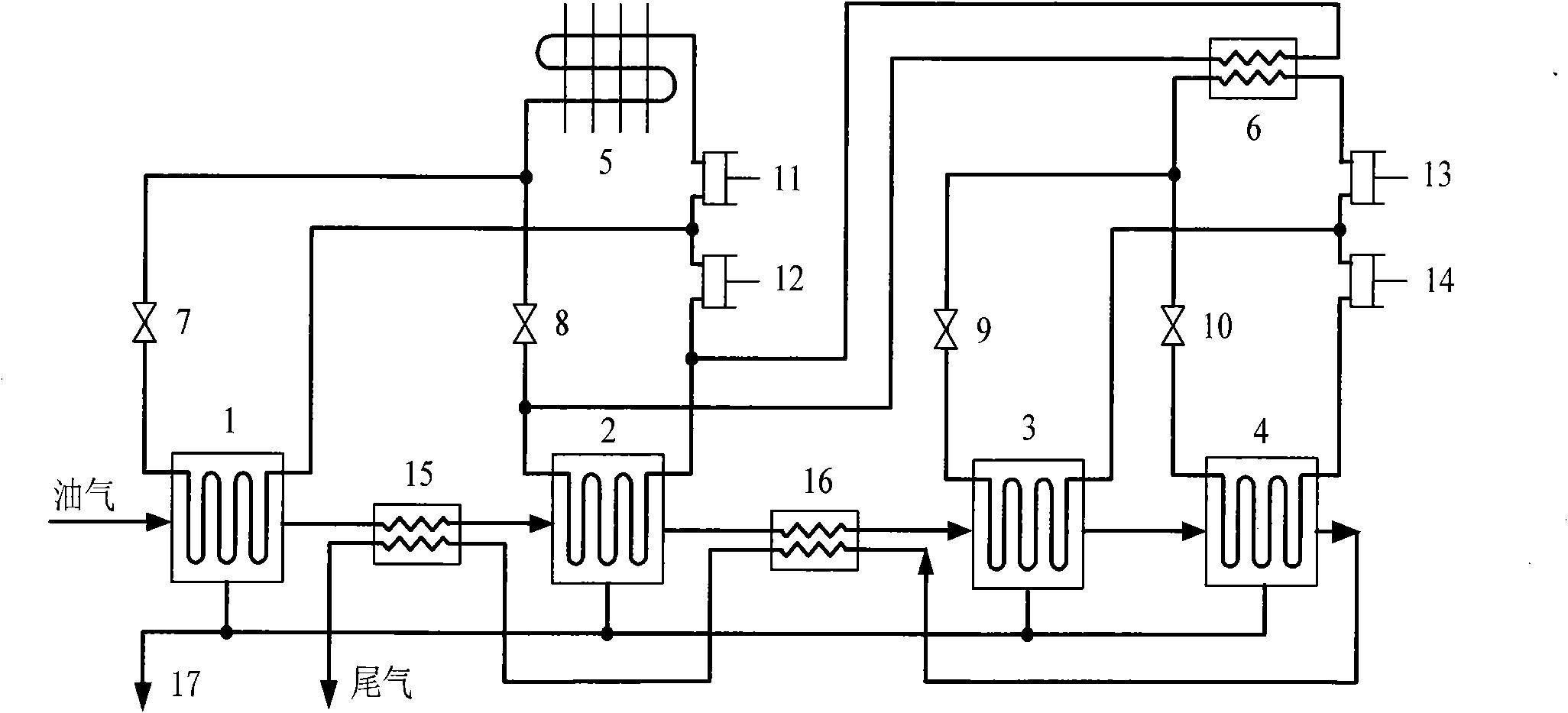

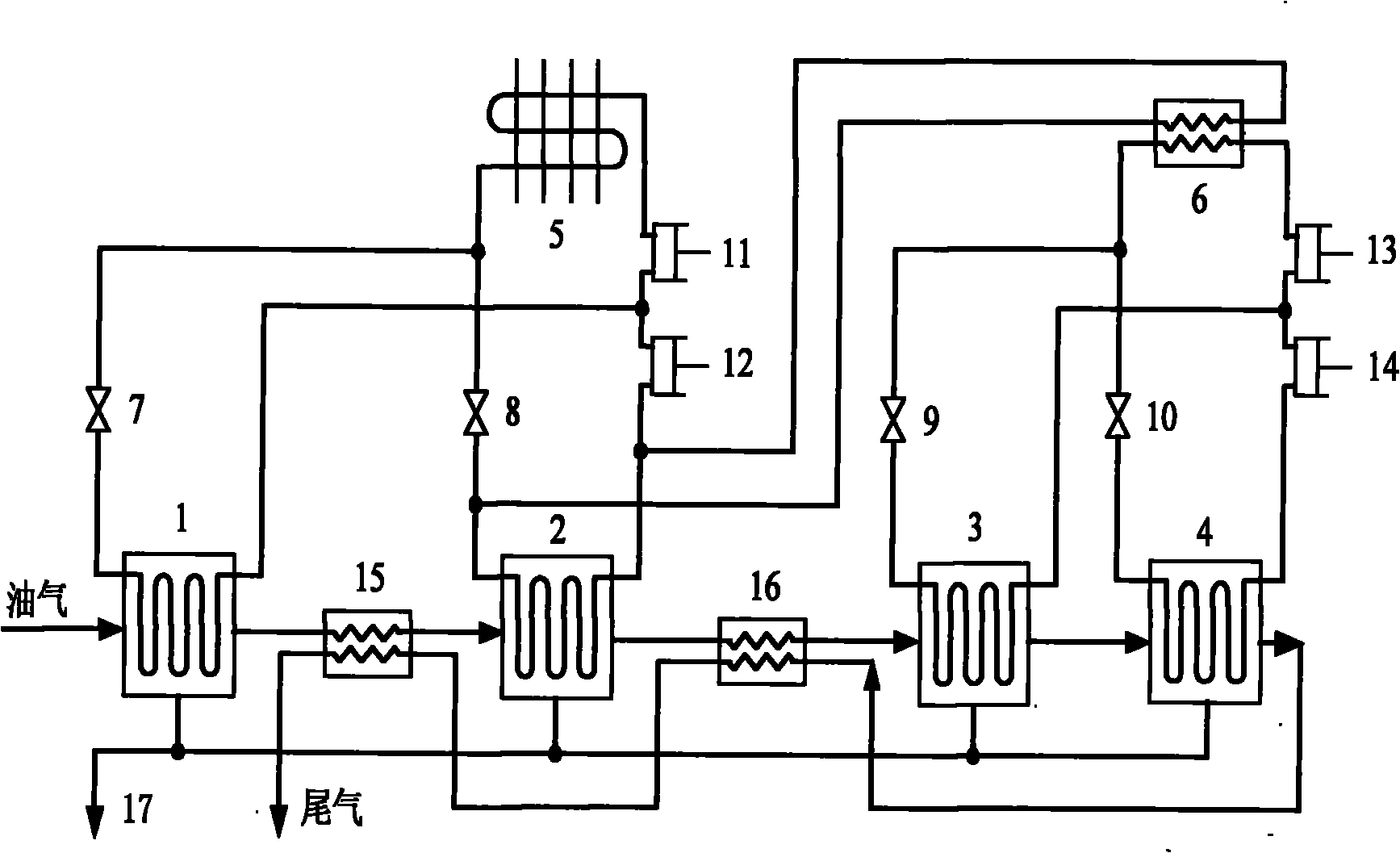

The invention discloses a double-stage cascade refrigeration method used for oil-gas recovery. The method adopts a double-stage cascade refrigeration system to provide cold energy for an oil-gas condenser step by step, wherein the cascade refrigeration system consists of two double-stage compression refrigeration cycles; and an oil-gas condenser with a higher level evaporating temperature is arranged on the cascade refrigeration system under an intermediate pressure of the double-stage compression refrigeration cycles to ensure that the oil gas is condensed step by step according to the temperature level. The double-stage cascade refrigeration method used for the oil-gas recovery has the advantages of not only being beneficial for reducing the manufacturing cost of equipment and the system energy consumption, but also providing convenience for adjusting condensation loads at each different temperature segment according to the different component distribution of the oil gas.

Owner:SOUTHEAST UNIV

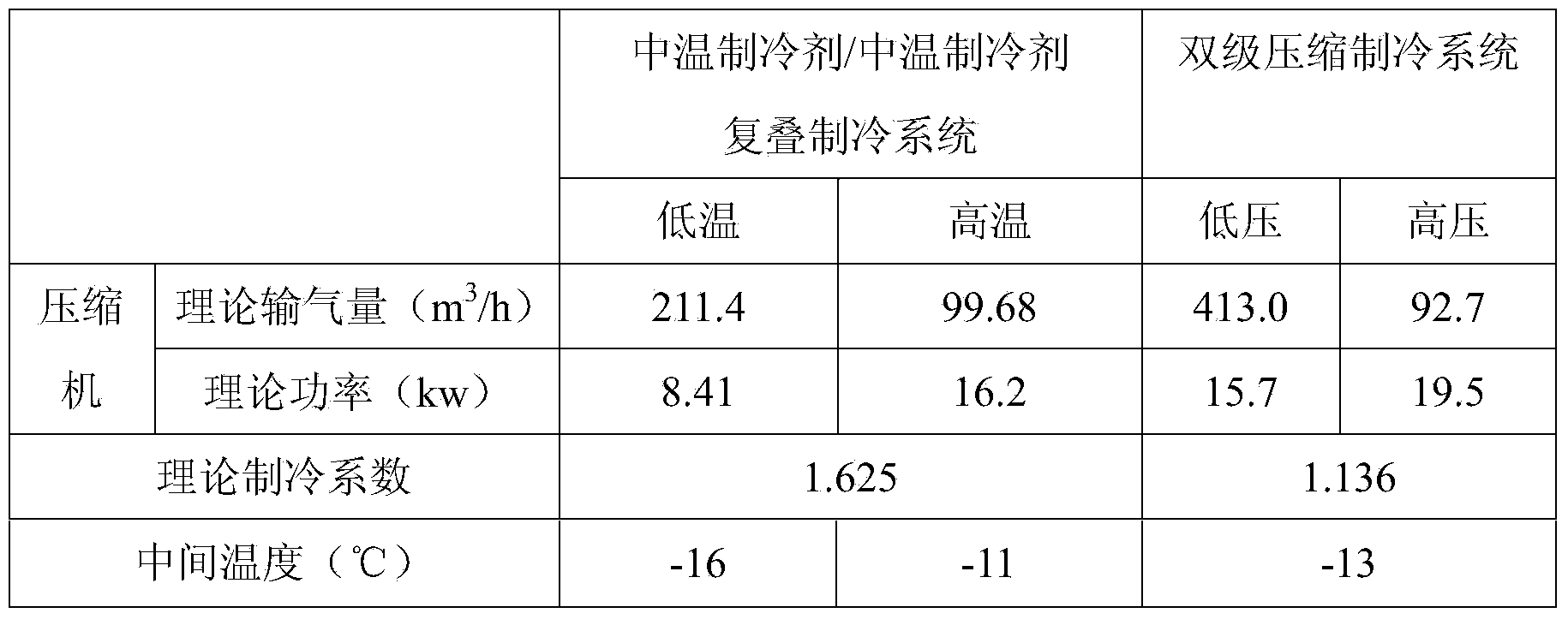

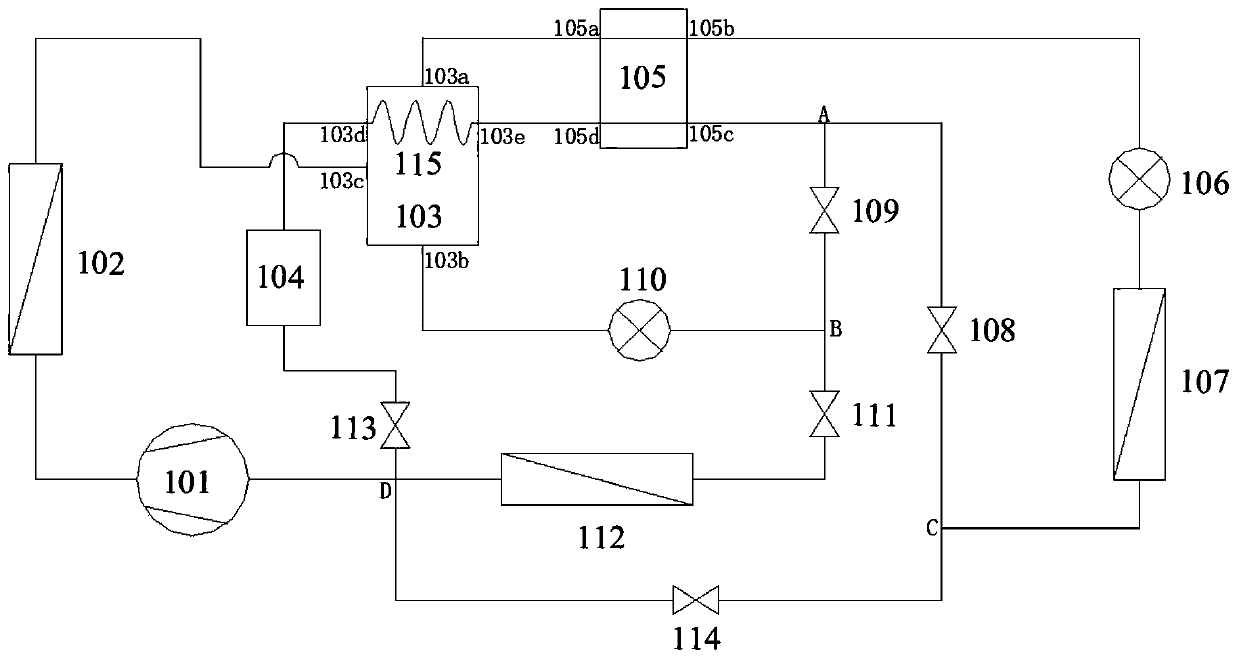

Energy-saving middle temperature refrigerant/middle temperature refrigerant cascade refrigeration system

InactiveCN103486754AImprove the cooling factorReduce consumptionCompression machines with cascade operationEngineeringRefrigeration

The invention discloses an energy-saving middle temperature refrigerant / middle temperature refrigerant cascade refrigeration system, which comprises a high-temperature level refrigeration cycle and a low-temperature level refrigeration cycle, wherein heat exchange is carried out by virtue of a condensation evaporator. The high-temperature level refrigeration cycle is additionally provided with a high-temperature level refrigeration branch. The high-temperature level refrigeration cycle and the low-temperature level refrigeration cycle adopt the same middle temperature refrigerant, and share the same evaporator, and switching is realized through the opening and closing of an electromagnetic valve. The cascade refrigeration system disclosed by the invention has the remarkable effects that the refrigeration coefficient is high, cold supply can be realized respectively under the high-temperature level working condition and the low-temperature level working condition, energy can be saved, the operating cost can be lowered, and the use ratio of equipment can be improved.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

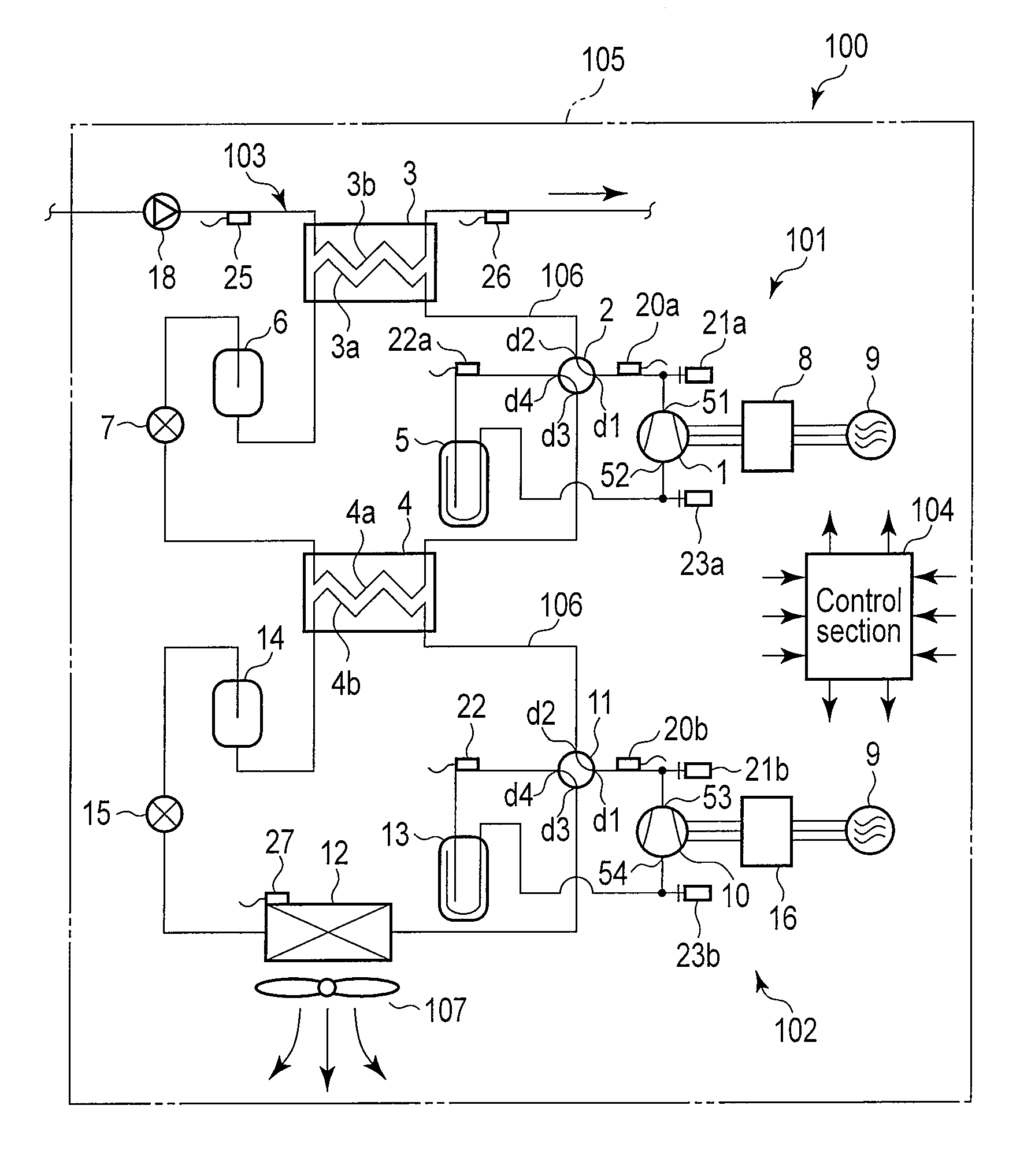

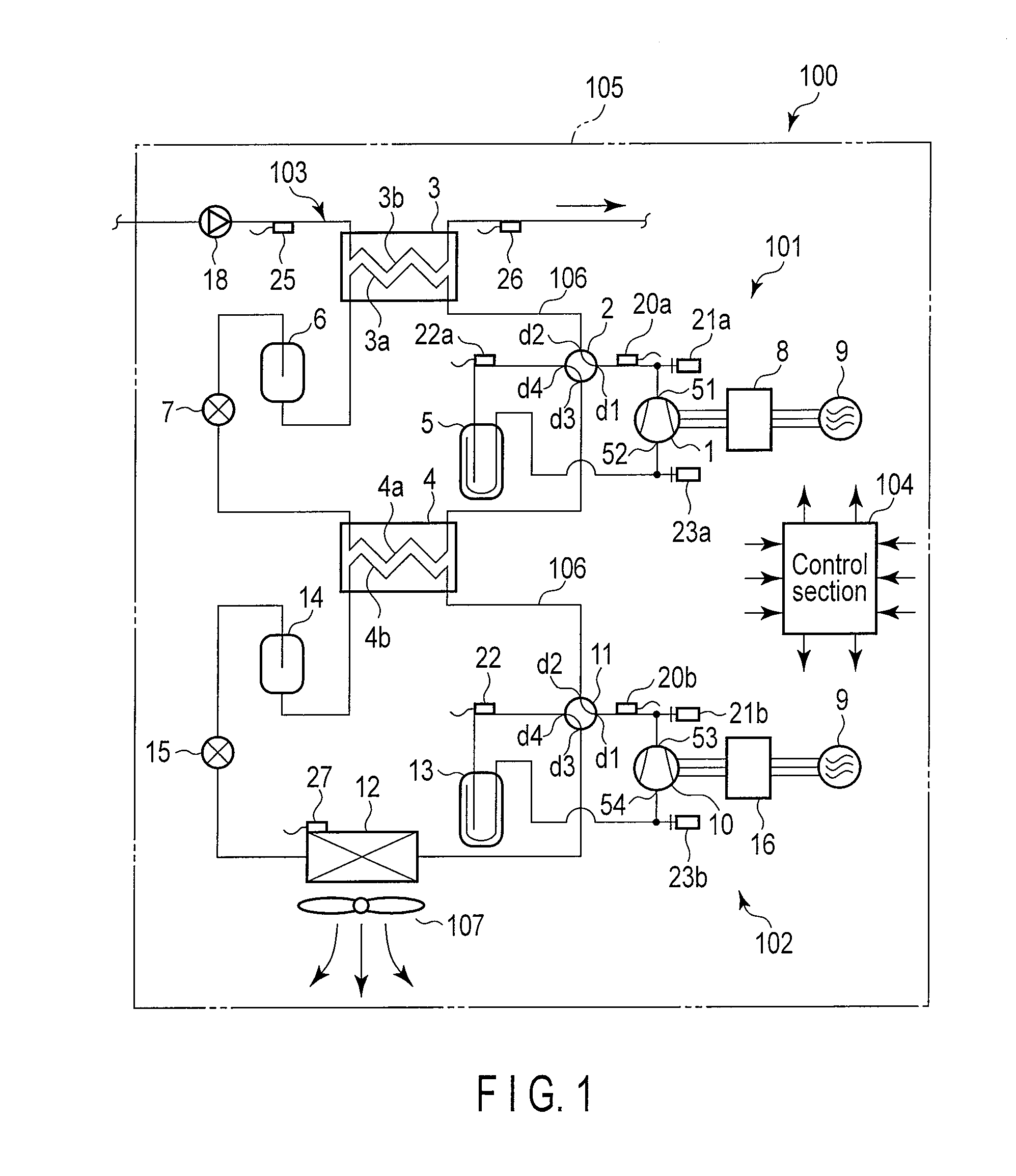

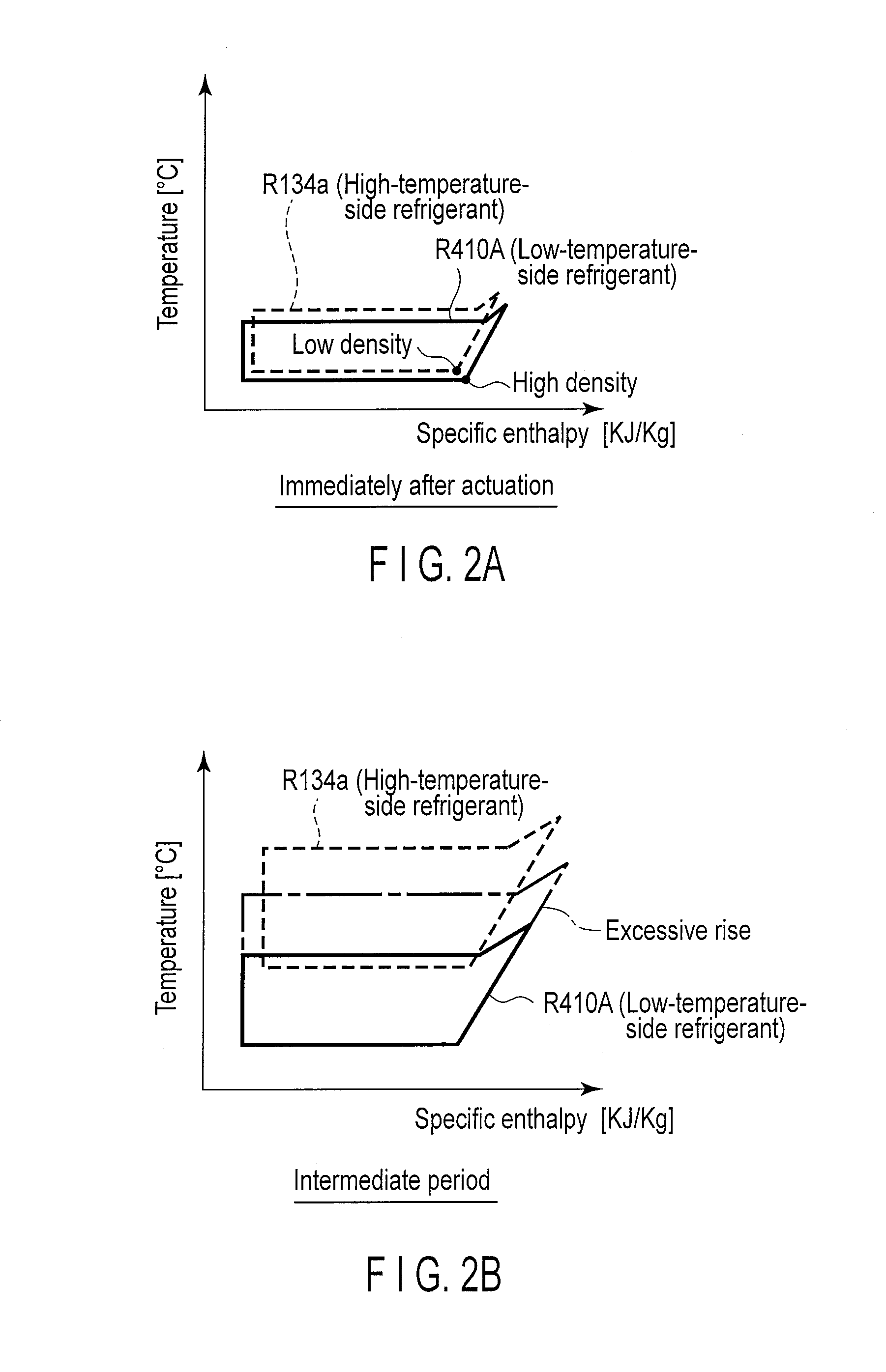

Cascade refrigeration cycle apparatus

ActiveUS20140013790A1Compression machines with non-reversible cycleCorrosion preventionProcess engineeringEngineering

According to one embodiment, a cascade refrigeration cycle apparatus according to the present embodiment includes a high-temperature-side and a low-temperature-side refrigeration circuits, an inverter and a control section. The high-temperature-side refrigeration circuit includes a first compressor and a cascade heat exchanger. The low-temperature-side refrigeration circuit includes a second compressor and the cascade heat exchanger. The inverter connected to at least one of the compressors. The control section controls the inverter so that a set operating frequency for the first compressor is higher than a set operating frequency for the second compressor when an operation of the apparatus is started.

Owner:TOSHIBA CARRIER CORP

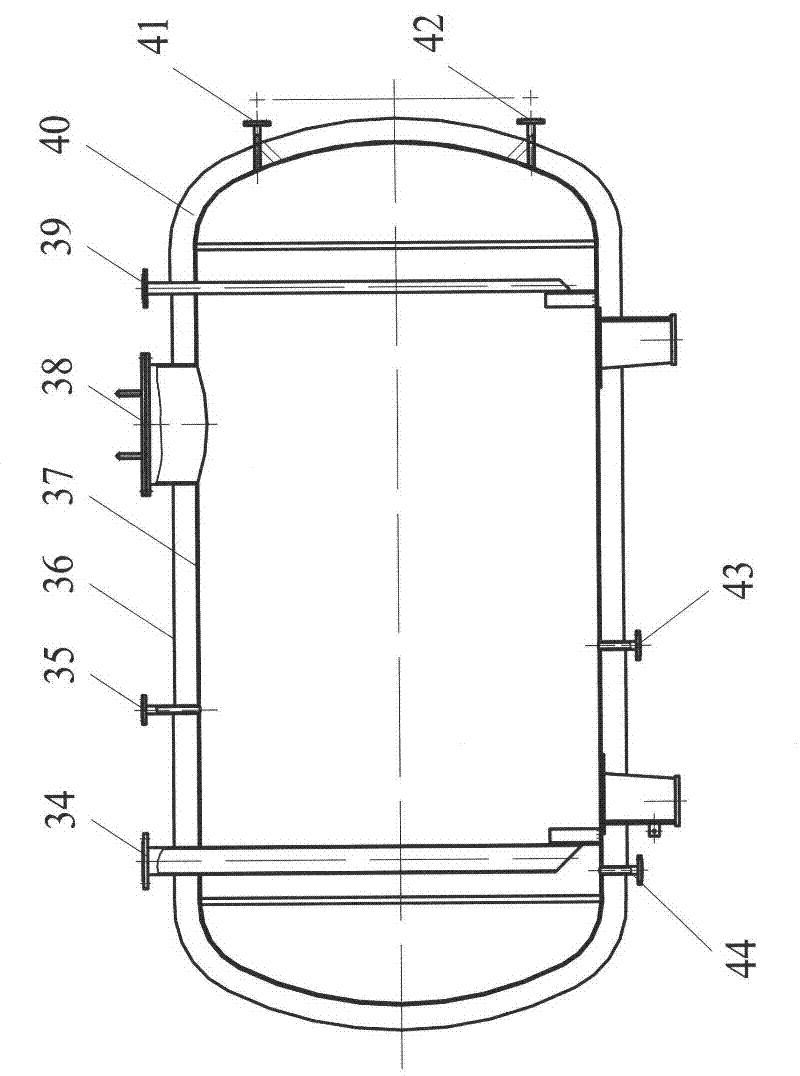

Automatic cascade refrigeration system exhaust pressure regulating device

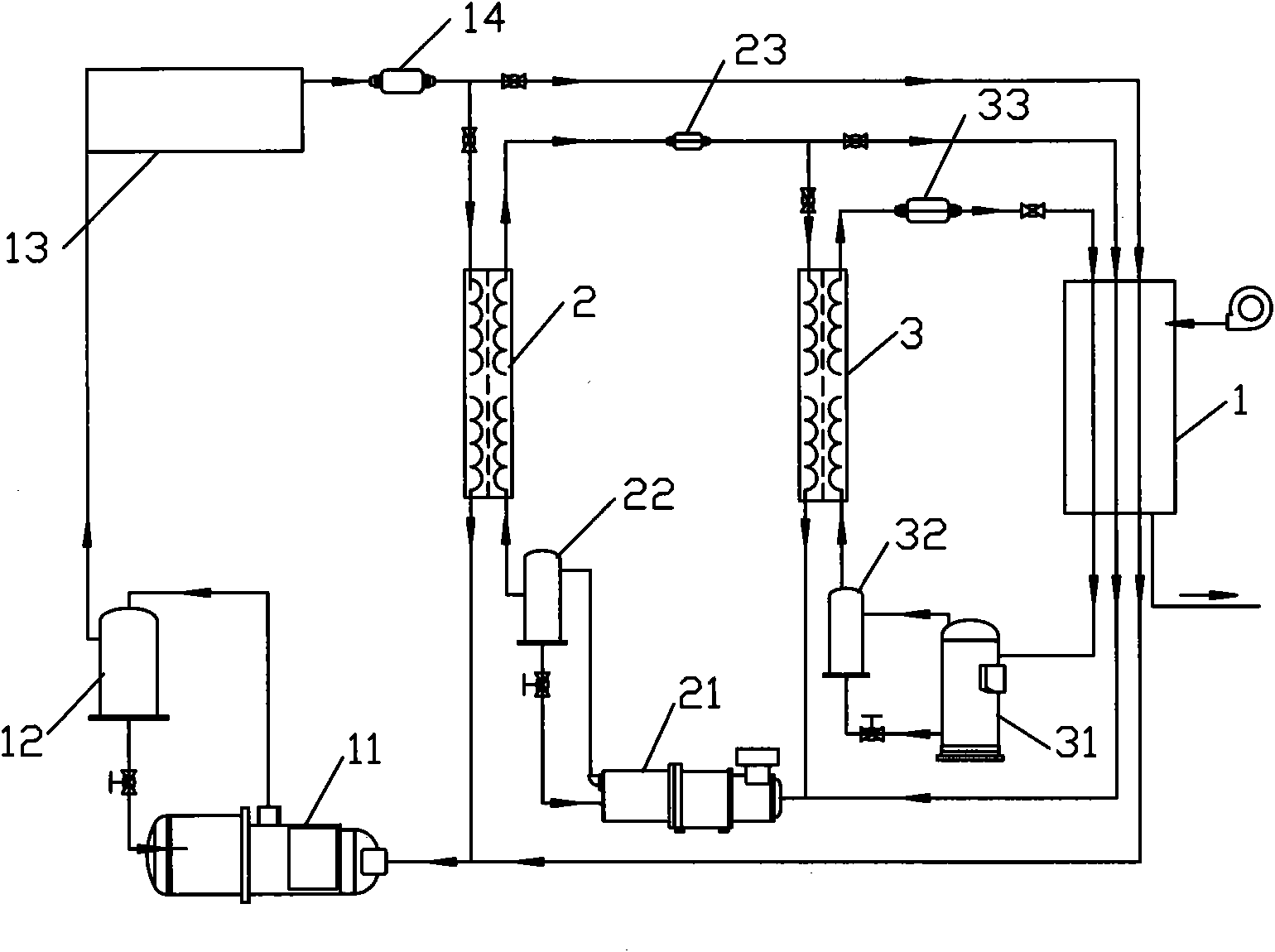

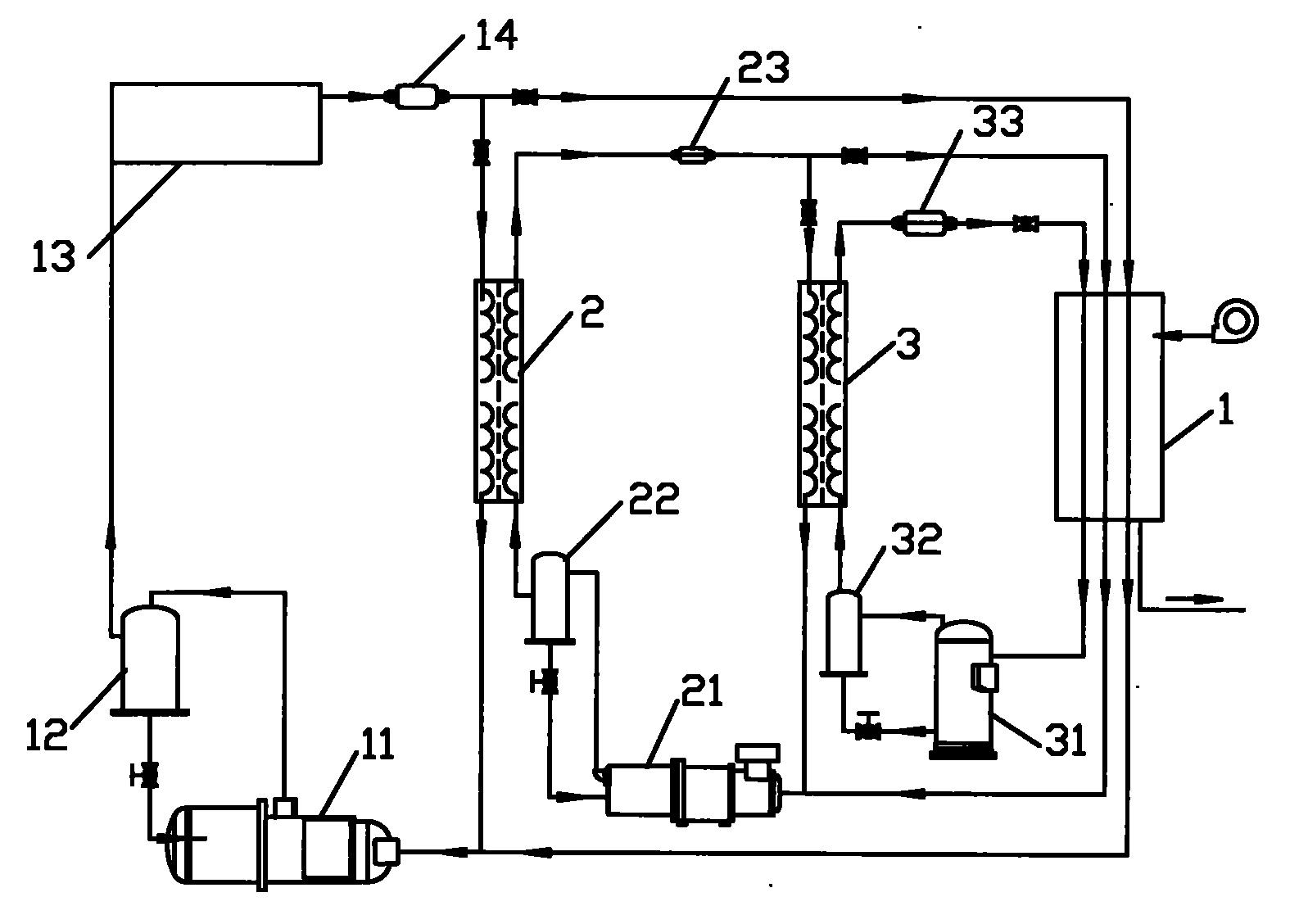

InactiveCN101126566AEasily damagedFast coolingCompression machinesFluid circulation arrangementVapor–liquid separatorEngineering

The utility model relates to a controlling device used to regulate the discharge pressure of an automatic cascaded refrigeration system, wherein a buffer is positioned between the outlet of a compressor and the inlet of a condenser, the buffer vessel is connected with a by-pass valve, an expanding vessel and a capillary tube in sequence, and the capillary tube is connected with the return duct to form a by-pass branch; the upper outlet of each gas-liquid separator in the middle of and downstream the automatic cascaded system is connected with a pressure control valve, the press control valves are connected with each other in parallel and connected with the expanding vessel by the pipeline. The utility model redesigns the arrangement of the tube so that the low temperature refrigerator based on automatic cascaded circulation can reduce operation pressure and equalizing pressure effectively and protect the compressor and pipeline of the system well; meanwhile, the air branch designed at the upper part of the gas-liquid separator increases the cooling speed of the system and shortens the cooling time of the refrigerator considerably.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Biogas liquefaction process and device for scattered gas source point

InactiveCN102445052AReduce energy costsReduce processing costsSolidificationLiquefactionPlate heat exchangerSolenoid valve

The invention relates to a biogas liquefaction process and a device for a scattered gas source point. The device comprises a multi-component mixed refrigerant pre-cooling unit, a multi-component mixed refrigerant circulating unit and a liquefaction and storage unit, and is characterized in that: the multi-component mixed refrigerant pre-cooling unit and the multi-component mixed refrigerant circulating unit form cascade refrigeration circulation to obtain low temperature to cool and condensate a raw material biogas flowing in the liquefaction and storage unit into a liquid, and the liquefaction and storage unit consists of a regenerator, a raw material biogas compressor, a cold box, a storage inlet cut-off valve and a storage tank; and the multi-component mixed refrigerant circulating unit consists of a main compressor, an oil separator, a main condenser, the regenerator, a pre-cooling heat exchanger, the cold box, a main throttle valve and an oil return solenoid valve, and the multi-component mixed refrigerant pre-cooling unit consists of an auxiliary compressor, an auxiliary condenser, the pre-cooling heat exchanger and an auxiliary throttle valve. The regenerators and the multi-stream plate heat exchangers are used, so that the efficiency of the device is greatly improved; and the throttle valves are used for one-time throttling, so that the flow process is simple, the control and adjustment are convenient, the investment is less, and the device is convenient to move and skid.

Owner:NANJING FORESTRY UNIV

Defrost system and method for a subcritical cascade R-744 refrigeration system

ActiveUS20110011104A1Less spaceLess energyCompression machines with non-reversible cycleEvaporators/condensersProcess engineeringHigh pressure

A cascade refrigeration system using a first refrigerant or a high stage and a second, R-744, refrigerant for low stage refrigeration has a defrost system including a defrost compressor, a defrost inlet heat exchanger and defrost outlet heat exchanger. The defrost inlet heat exchanger receives a defrost portion of second refrigerant and adds an additional defrost heat load thereto from first refrigerant, thus evaporating defrost portion. Defrost portion is then compressed into high pressure defrost vapor potion in the defrost compressor. The defrost vapor portion is then circulated through a selected evaporator, where a defrost heat, augmented by additional defrost heat load, defrosts selected evaporator, defrost vapor being at least partially condensed into defrost condensed portion which is liquefied in defrost outlet heat exchanger.

Owner:SYST LMP INC +1

Intermediate fractional-condensation type auto-cascade refrigeration cycle system and refrigeration equipment

ActiveCN106196681AImprove heat transfer efficiencyImprove energy efficiencyCompression machines with several condensersSuperheatersVapor–liquid separatorEngineering

The invention provides an intermediate fractional-condensation type auto-cascade refrigeration cycle system and refrigeration equipment. The intermediate fractional-condensation type auto-cascade refrigeration cycle system comprises a compressor, a first condenser, a gas-liquid separator, a first regenerator, a second condenser, a first throttle device and an evaporator. The first regenerator is provided with a first heat exchange channel and a second heat exchange channel. An outlet of the compressor is connected with an inlet of the first condenser. An outlet of the first condenser is connected with an inlet of the gas-liquid separator. A gas outlet of the gas-liquid separator is connected with an inlet of the second condenser, and an outlet of the second condenser is connected with an inlet of the evaporator sequentially through the first heat exchange channel and the first throttling device. A saturated liquid outlet of the gas-liquid separator is connected with an inlet of the compressor through the second heat exchange channel. An outlet of the evaporator is further connected with the inlet of the compressor. By the adoption of the intermediate fractional-condensation type auto-cascade refrigeration cycle system and the refrigeration equipment, the uniformity of temperature distribution in the refrigeration space is improved, the temperature variation is reduced, and thus the refrigeration effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

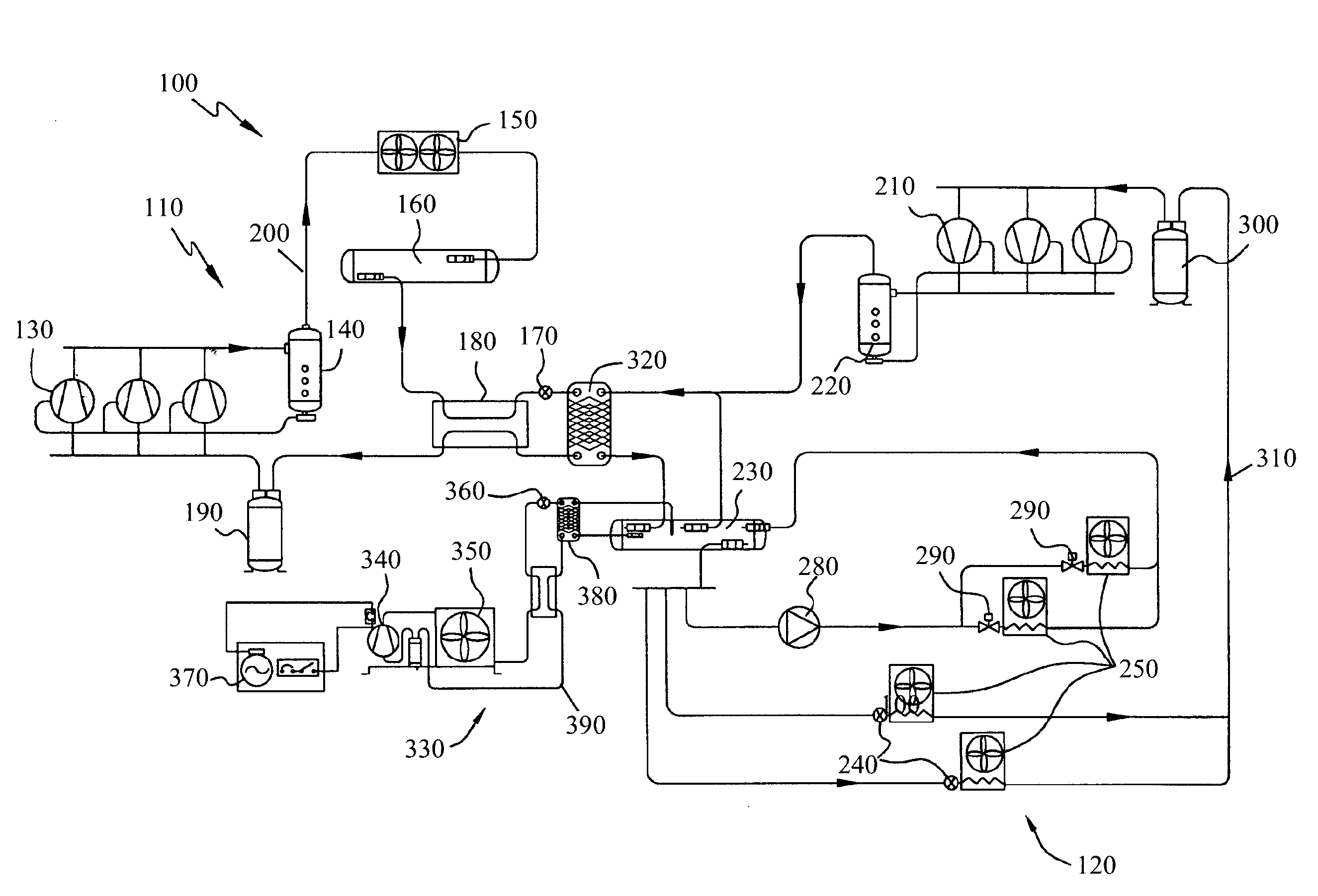

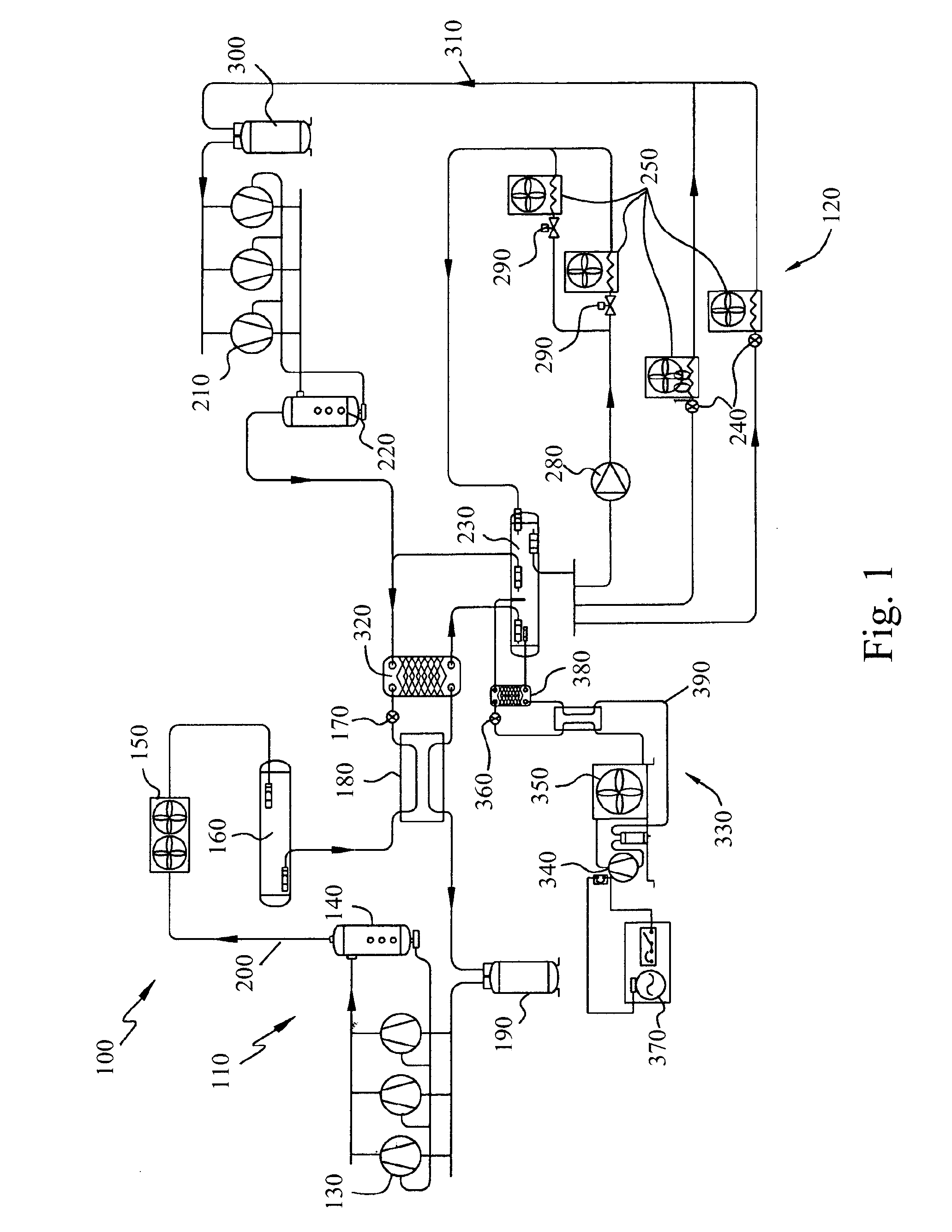

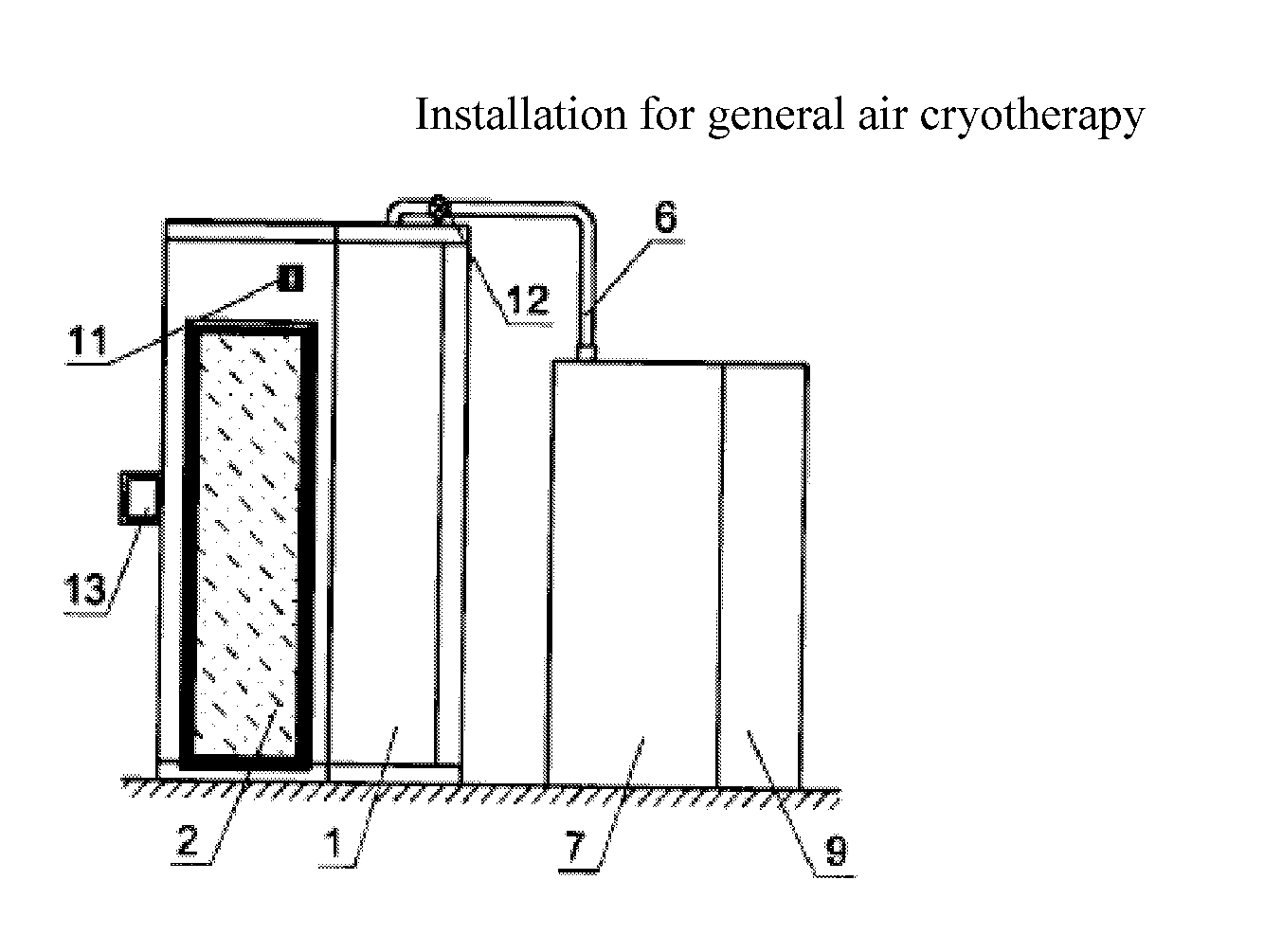

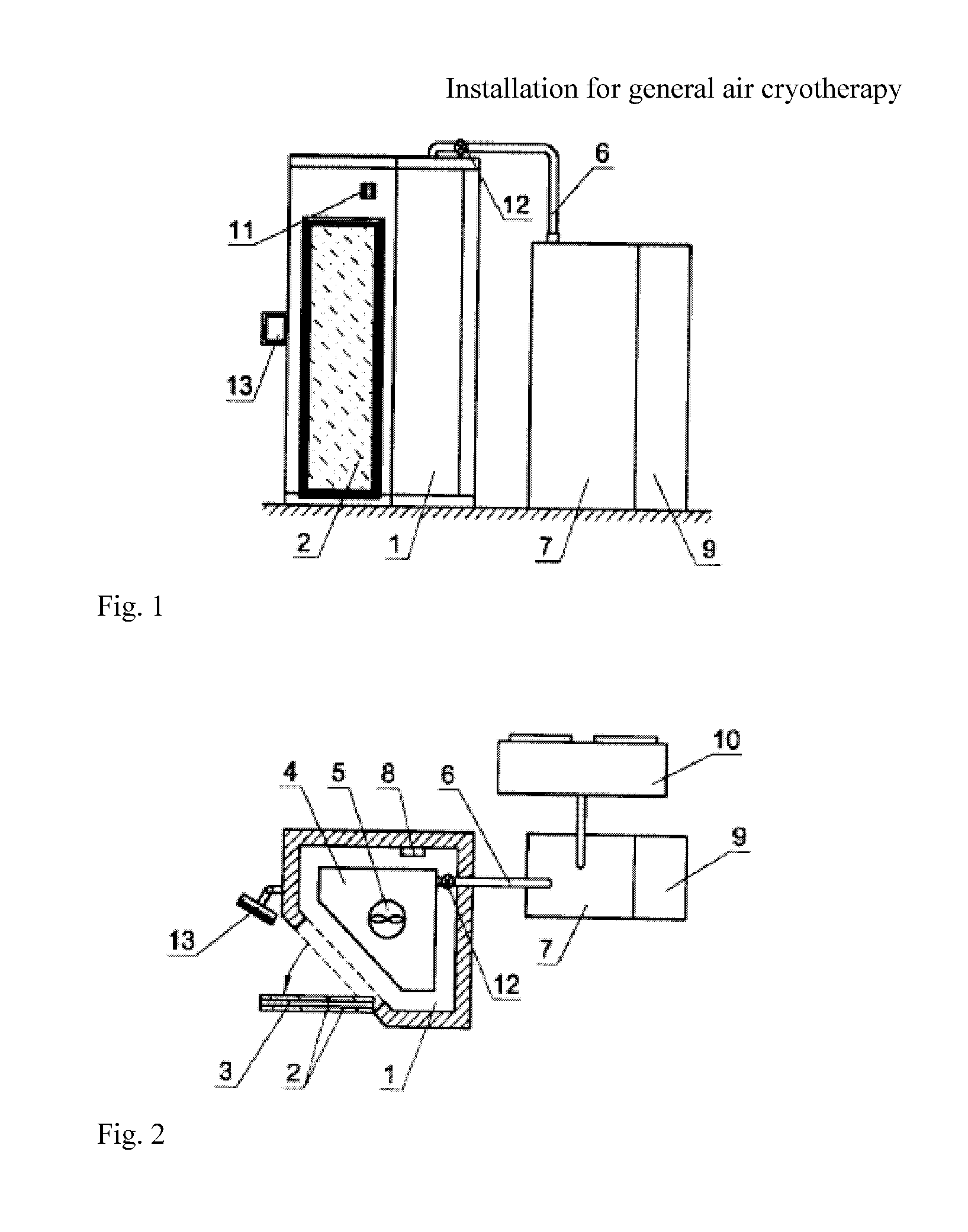

Installation for general air cryotherapy

InactiveUS20150265460A1Reduced footprintImprove reliabilityDomestic cooling apparatusLighting and heating apparatusDiseaseTreatment field

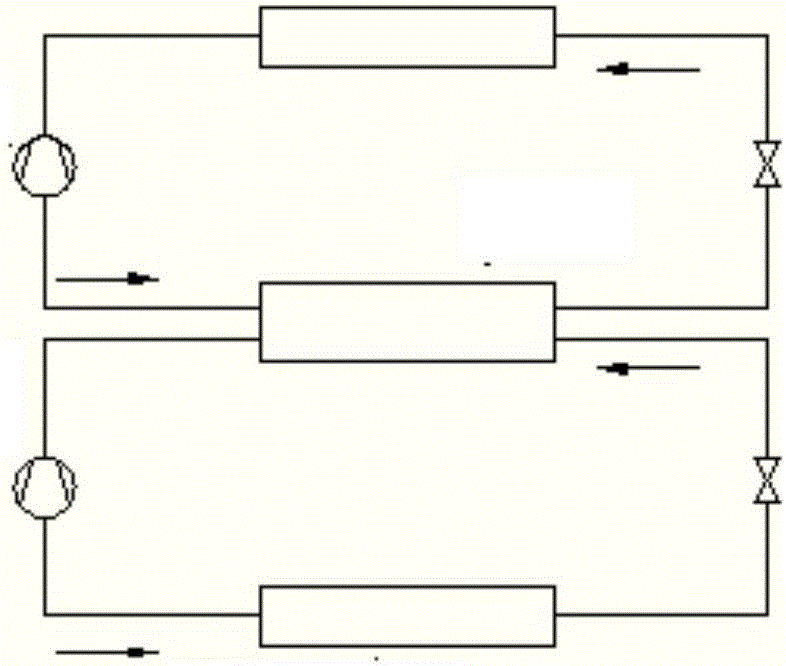

The proposed invention relates to the field of physical therapy and can be used for the treatment and prophylaxis of a number of diseases, and also for health-improving purposes, including improving the stamina, for instance, of athletes. The installation for conducting general air cryotherapy comprises a closed-type cryogenic chamber (1) with a door (2) with heat insulation (3) and a heat sensor (8), a refrigeration machine (7) with a condenser and a power and control unit (9), and a coolant supply line (6), wherein the refrigeration machine (7) has two cascades, and an evaporator (4) with a ventilator (5) is installed into the ceiling or wall of the cryogenic chamber (1) and is connected by means of the coolant supply line (6) to the double-cascade refrigeration machine (7), and wherein a heat control valve (12) is installed at the inlet to the evaporator (4), and the cryogenic chamber (1) is equipped with a valve for equalizing pressure with the outside environment (11), and wherein said valve (11) has an electric heater, the door (2) of the cryogenic chamber (1) is made entirely transparent and is equipped, as is the frame thereof, with an electric heater, and a control console with a sensor panel (13) is installed on the external surface of the cryogenic chamber (1). The proposed installation is more reliable than the prototype and the dimensions and cost of the installation are significantly decreased. The proposed installation can be used for the purposes of treatment and prophylaxis in the fields of rheumatoid arthritis, neurology, dermatology, traumatology and orthopedics, states of depression and stress, and in sports medicine.

Owner:ERGANOKOV KHASANBI KHABIEVICH

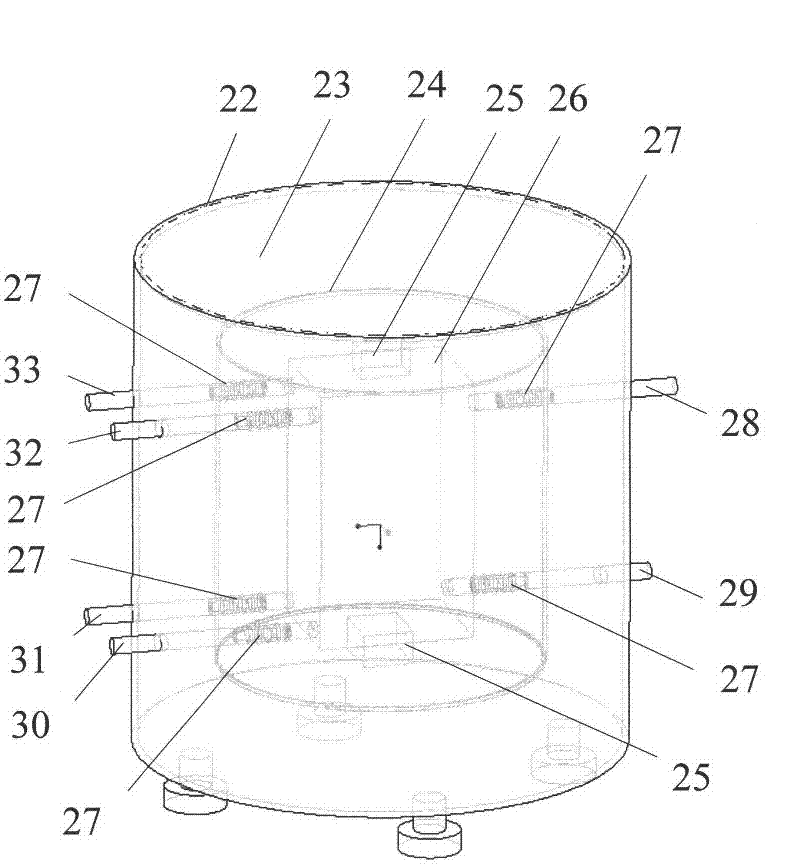

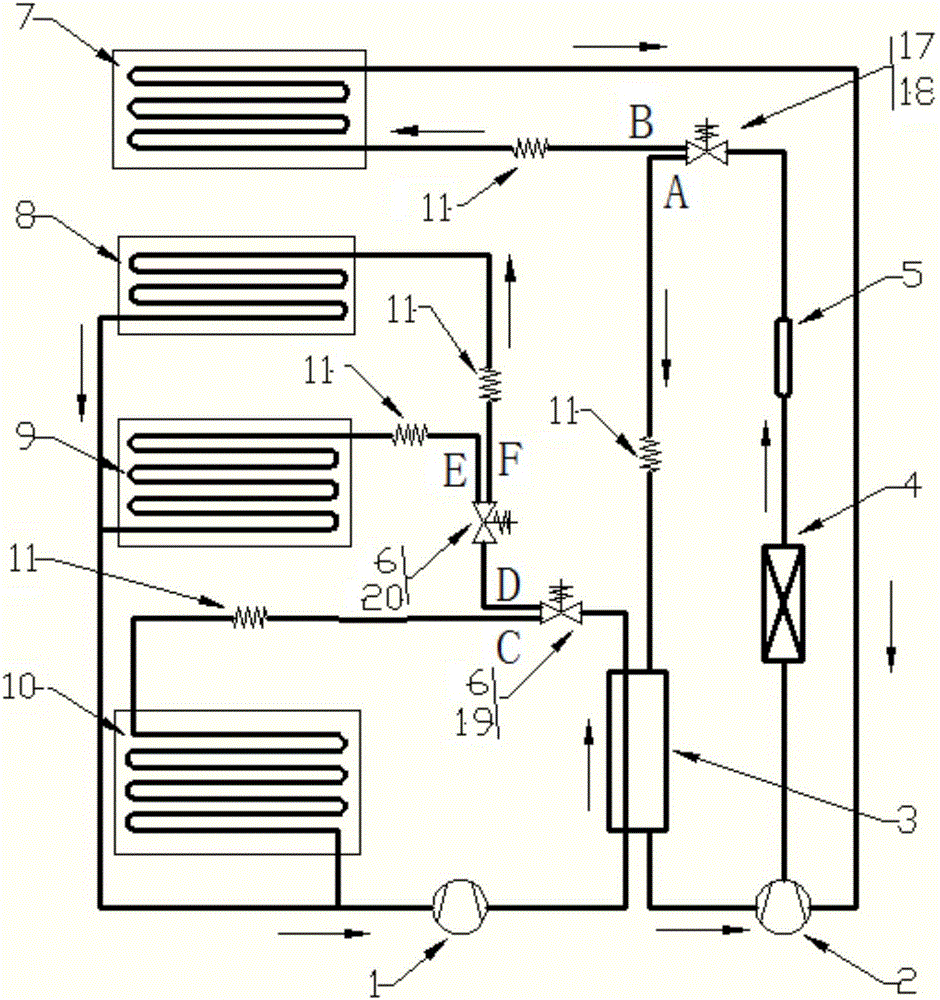

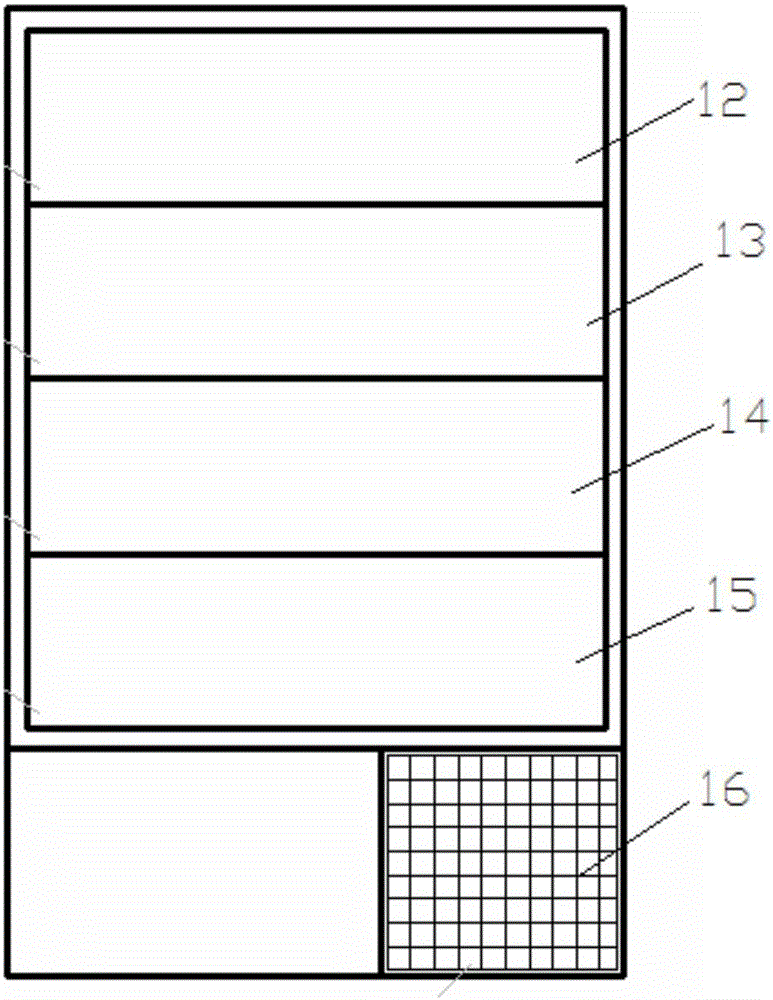

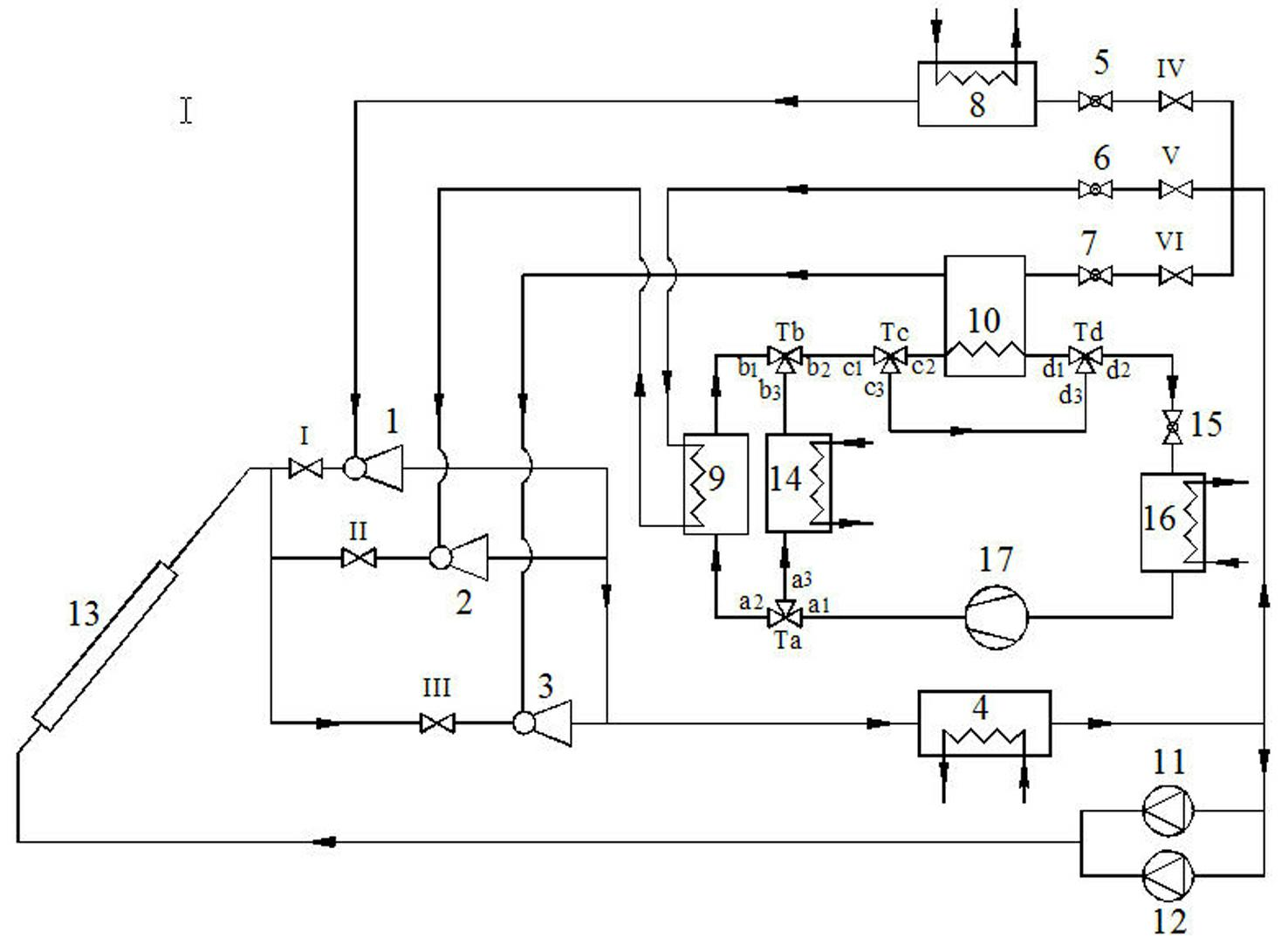

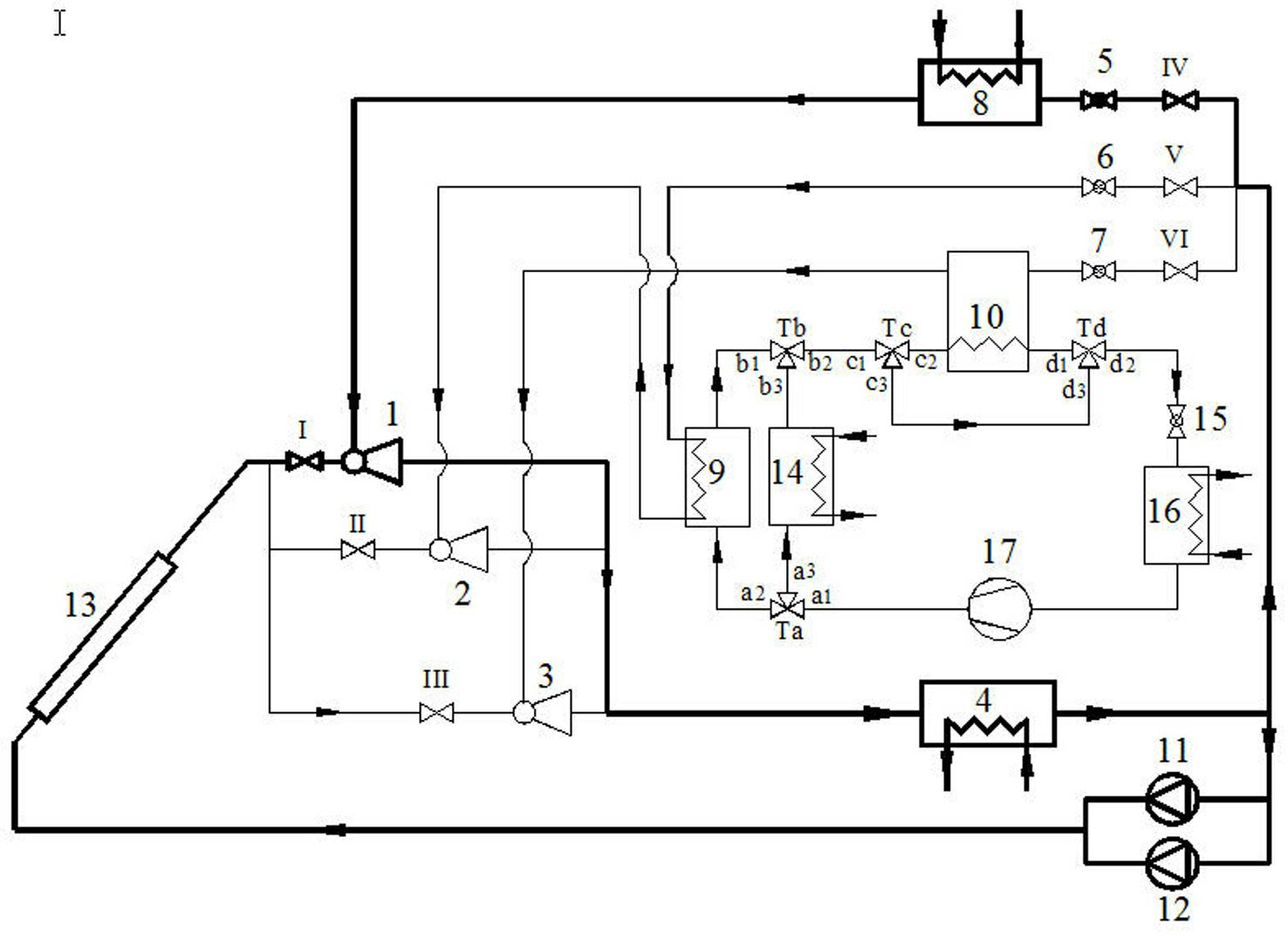

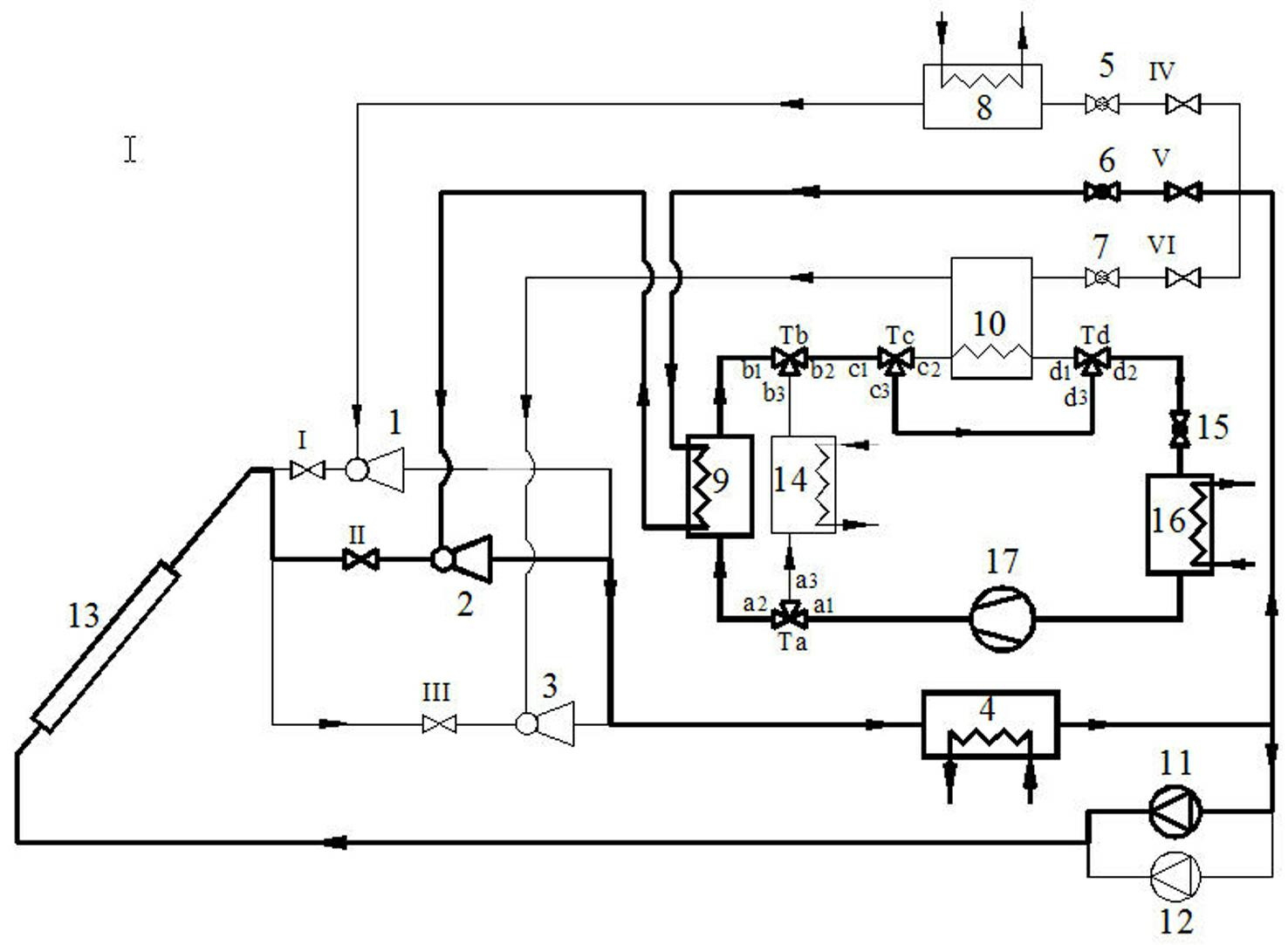

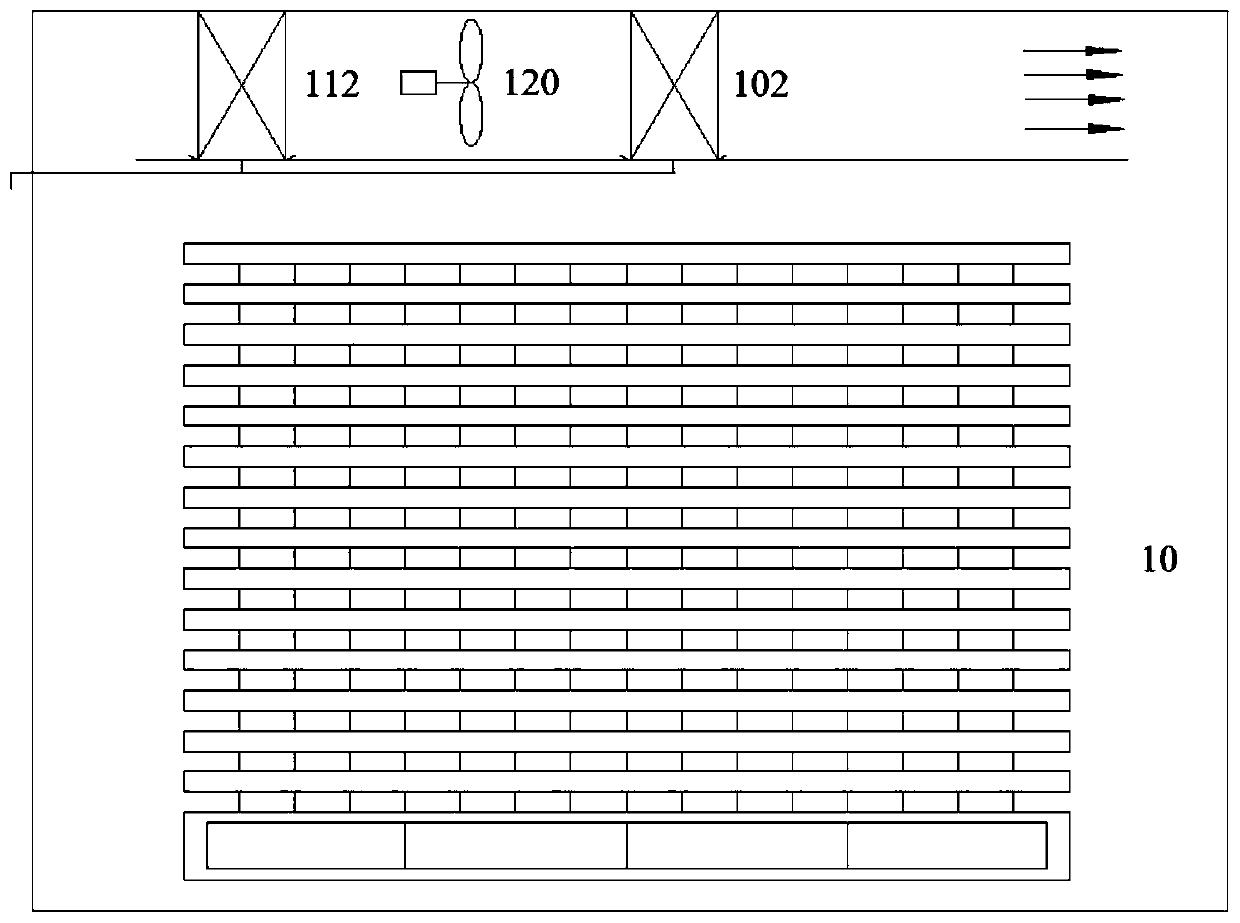

Multi-temperature-zone cascade refrigeration system and low-temperature refrigerated storage box

InactiveCN106403341ARefined temperature zone divisionMeet different needsMechanical apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention discloses a multi-temperature-zone cascade refrigeration system and a low-temperature refrigerated storage box. The multi-temperature-zone cascade refrigeration system comprises a low-temperature refrigeration system and a high-temperature refrigeration system which are connected with a condensing evaporator, wherein the outlet of a low-temperature compressor of the low-temperature refrigeration system is connected to a condensing pipe through the condensing evaporator, and then connected to evaporators in all temperature zones in a branched manner through low-temperature regulating valves; and the outlets of all the evaporators are connected to the inlet the low-temperature compressor. According to the multi-temperature-zone cascade refrigeration system, a plurality of the evaporators correspond to the different temperature zones, thereby achieving a single refrigeration system with various temperature zones and meeting the different requirements of various objects for the refrigerated storage temperature; and the high-temperature refrigeration system and the low-temperature refrigeration system are connected through the condensing evaporator, so that cold energy can be supplied by the high-temperature refrigeration system to both the objects and a low-temperature refrigerant.

Owner:GREE ELECTRIC APPLIANCES INC

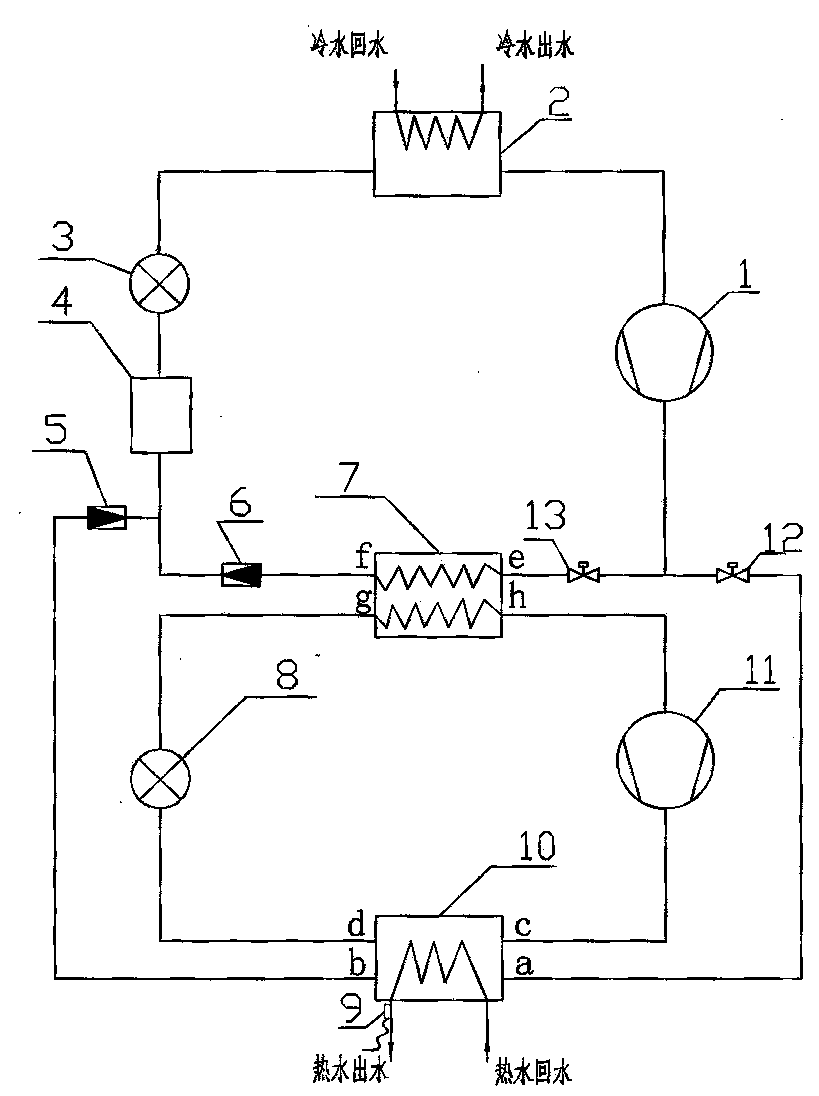

High-temperature water source heat pump unit

InactiveCN103697613AReduce shipping costsSave the cost of coal storage siteFluid heatersCompression machines with cascade operationEnvironmental resistanceSlag

Disclosed is a high-temperature water source heat pump unit. Single-step compression refrigeration cycle and cascaded refrigeration cycle combined linkage technology is adopted, temperature of outgoing water of the unit can be increased to be higher than 85 DEG C by utilizing a low-temperature heat source to lower a compression ratio of the unit under a high-temperature working condition, efficiency of the unit is improved, working conditions of compressors are improved, and running reliability of the unit under the high-temperature working condition is guaranteed. The high-temperature water source heat pump unit is composed of a first compressor, a first heat exchanger, a first throttling element, a liquid storage device, a first one-way valve, a second one-way valve, an intermediate heat exchanger, a first electromagnetic valve, a second electromagnetic valve, a second compressor, a second throttling element, a second heat exchanger and a connecting pipeline. By the high-temperature water source heat pump unit, high environmental-protection benefit and economic benefit can be achieved, waste gas and waste residues of a coal fired boiler are avoided from polluting surrounding environment, and coal transporting cost, coal storage site cost, dedusting cost, coal slag transporting and processing cost and the like are omitted; investment in building a heating system is saved, and the high-temperature water source heat pump unit is especially suitable for being used for building a central air conditioning heating system in northern cold areas.

Owner:JINGUODA TECH HUNAN

Auto-cascade vapor compression type refrigeration cycle system with evaporation subcooler

ActiveCN105546864AImprove performanceIncrease subcoolingMechanical apparatusCompression machines with cascade operationVapor–liquid separatorEvaporation

Owner:XI AN JIAOTONG UNIV

Auto-cascade steam compression type refrigeration cycle system

InactiveCN104864622AImprove performanceIncrease inspiratory pressureMechanical apparatusCompression machines with cascade operationVapor–liquid separatorEvaporation

The invention discloses an auto-cascade steam compression type refrigeration cycle system which comprises a first gas and liquid separator, an evaporation condenser, an evaporator and an expansion valve. A first ejector is connected between a saturated refrigerant liquid outlet of the first gas and liquid separator and an evaporation side inlet of the steam condenser, a second gas and liquid separator is connected between a condensation side outlet of the evaporation condenser and an inlet of the evaporator, and a second ejector is connected between an inlet of the second gas and liquid separator and a condensation side outlet of the evaporation condenser. The system has the advantages that compared with a conventional auto-cascade refrigeration cycle system, the two ejectors are adopted in the system to take the place of an expansion valve or a capillary tube, so that expansion work in the throttling process is fully recycled, gas suction pressure of a compressor is improved, power consumption of the compressor in a cycle is reduced, gas conveying amount of the compressor is also improved, and performance of the cycle system is effectively improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX +1

N2O-containing low temperature mixing working substance for cascade refrigeration system

InactiveCN101434831ADestruction will notSmall slip temperatureHeat-exchange elementsHexafluoroethaneBoiling point

The invention relates to a cascade refrigeration system low-temperature mixed refrigerant which is applicable to the temperature area of 180-220K and contains N2O, and a preparation method thereof; the low-temperature mixed refrigerant comprises one or two components of low-boiling point refrigerant N2O(R744A), ethane (R170), fluoromethane (R23), hexafluoroethane (R116), fluoromethane (R41), and CO2 (R744) and is formed by physical mixing at normal temperature. The low-temperature mixed refrigerant damages no ozonosphere, has low greenhouse effect potential, meets the requirement of environmental protection, has suitable thermal parameters and excellent circulation performance, and can optimize and design the new refrigerant system by the existing cascade low-temperature compressor. The mixed refrigerant can be used for replacing the refrigerant in the existing cascade refrigeration low-temperature system.

Owner:XI AN JIAOTONG UNIV

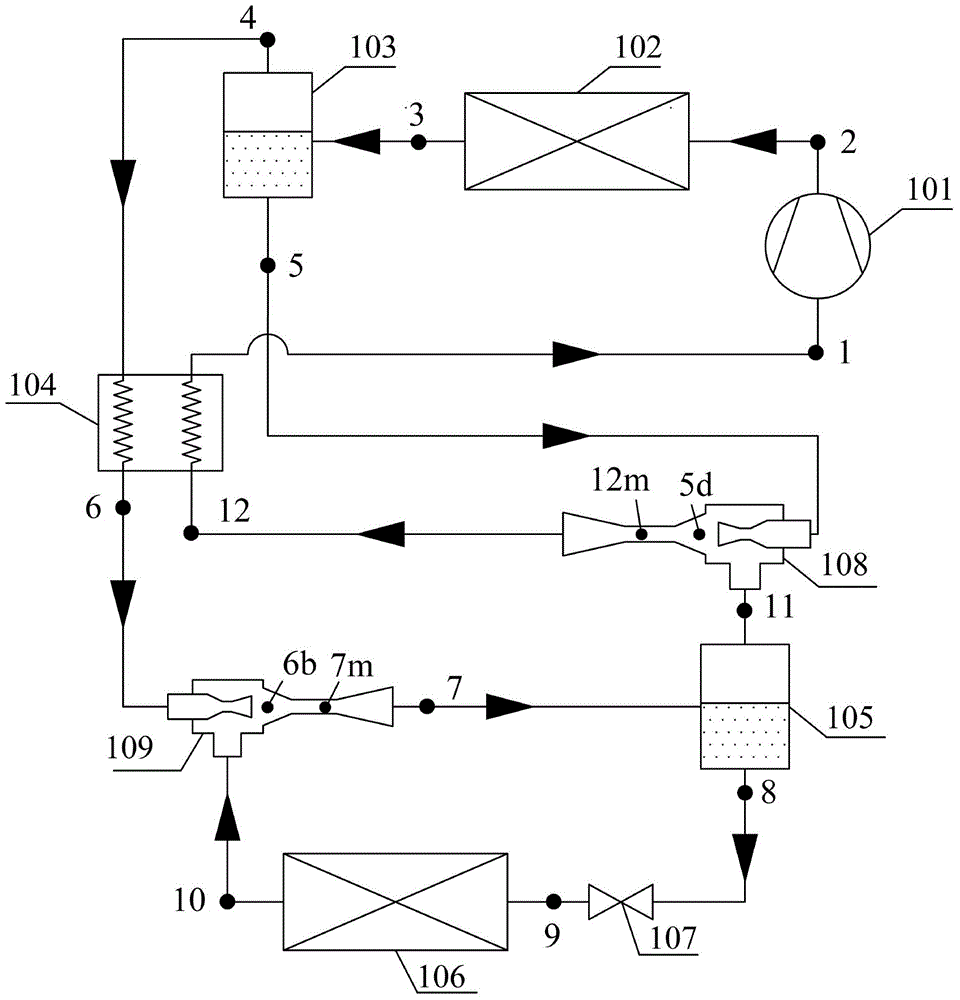

Ejector expansion auto-cascade refrigeration circulation system and work process

ActiveCN108106048AImprove performanceImprove the coefficient of performanceMechanical apparatusEfficient regulation technologiesPressure riseWorking fluid

The invention discloses an ejector expansion auto-cascade refrigeration circulation system and a work process. The system comprises a compressor, a condenser, an ejector, a gas and liquid separator, athrottling valve, an evaporator, a backpressure valve and an evaporation cooler which are connected on a pipeline; the ejector takes condenser outlet high-pressure non-azeotropy mixture refrigerationagent gas and liquid two-phase fluid as work fluid, an evaporator outlet low-pressure refrigeration agent is ejected, a two-phase refrigerant obtained after mixed pressure rise enters the gas and liquid separator through an ejector outlet to be separated into the liquid state and the gas state, a gas outlet of the gas and liquid separator is divided into two paths, one path is connected with an air suction pipeline of the compressor, and the other path is connected with a condensation channel inlet of the evaporation condenser; a liquid outlet of the gas and liquid separator is connected withthe backpressure valve, and the backpressure valve adjusts the flow and the pressure of the refrigeration agent of the evaporation condenser by sensing the liquid outlet pressure of the gas and liquid separator. The ejector and the backpressure valve are effectively arranged in the auto-cascade refrigeration circulation system, the ejector expansion power recycling effect and the system dynamic adjusting effect can be sufficiently improved, and the refrigeration efficiency of the auto-cascade refrigeration circulation system can be efficiently improved.

Owner:XI AN JIAOTONG UNIV

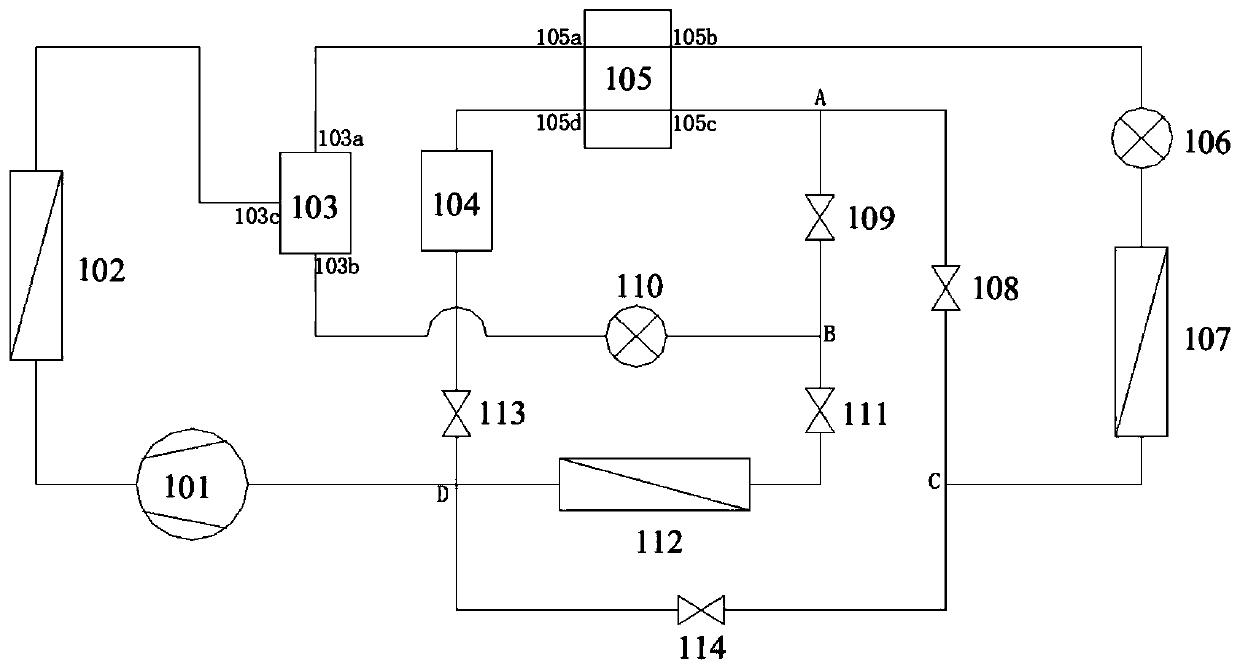

Cascade refrigeration system

InactiveCN104567068ASmall temperature differenceImprove performanceCompression machines with cascade operationThermodynamicsHeat losses

A cascade refrigeration system comprises a high-temperature-class circulation loop, a low-temperature-class circulation loop and an evaporative condenser for connecting the high-temperature-class circulation loop with the low-temperature-class circulation loop, wherein the evaporative condenser comprises a low-temperature condenser located on one side and a high-temperature condenser located on the other side, the low-temperature condenser is connected in the low-temperature-class circulation loop, the high-temperature condenser is connected in the high-temperature-class circulation loop, and a pre-cooler is connected in the low-temperature-class circulation loop and is located in front of the evaporative condenser. The pre-cooler is arranged in a low-temperature-class circulation system and is located in front of the evaporative condenser, so that a low-temperature-class refrigerant can be cooled to be at certain temperature before flowing into the low-temperature condenser of the evaporative condenser, the temperature difference between a high-temperature evaporator and the low-temperature condenser is reduced, the reliability is improved, the service life is prolonged, the lower the temperature difference is, irreversible heat loss is lower, heat exchange efficiency can be also improved, and the performance of the unit can be improved.

Owner:JIANGSU SUJING GROUP +1

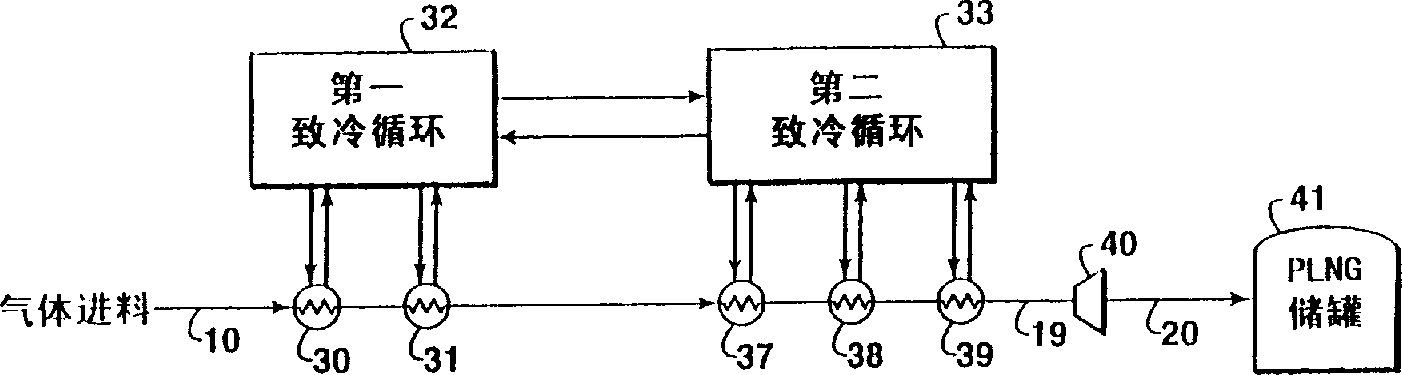

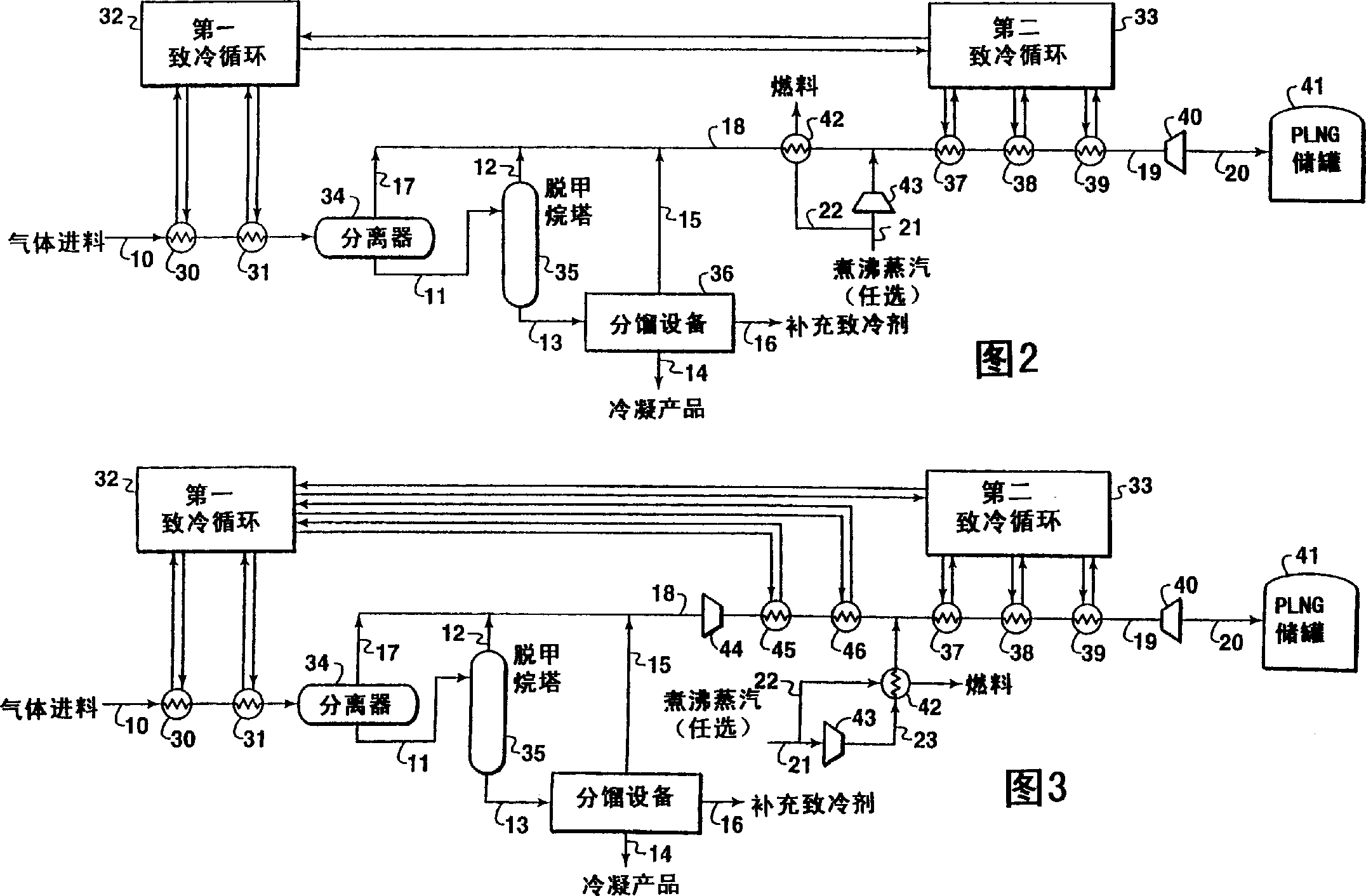

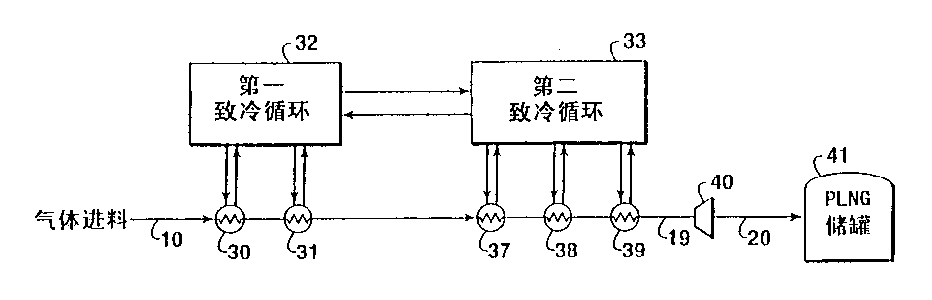

Improved cascade refrigeration process for liquefaction of natural gas

InactiveCN1261430AEconomical and efficient to operateIncreased fractionation processSolidificationLiquefactionLiquid productProcess engineering

This invention relates to a process for liquefying a pressurized gas stream (10) rich in methane with a heat exchanger being cooled by a cascade refrigeration system to produce a methane-rich liquid product (20) having a temperature above about -112 DEG C. (-170 DEG F.). In this process, a pressurized gas stream (10) is introduced into heat exchange contact with a first refrigerant cycle (32) comprising at least one refrigeration stage (30-31) whereby the gas stream is cooled against a first portion of a first refrigerant to produce a cooled gas stream. The cooled gas stream is then introduced into heat exchange contact with a second refrigerant cycle (33) comprising at least one refrigeration stage (37-39) whereby the temperature of the cooled gas stream is cooled to produce a liquefied methane-rich stream (20) having a temperature above about -112 DEG C. (-170 DEG F.) and a pressure sufficient for the liquefied stream to be at or below its bubble point.

Owner:EXXONMOBIL UPSTREAM RES CO

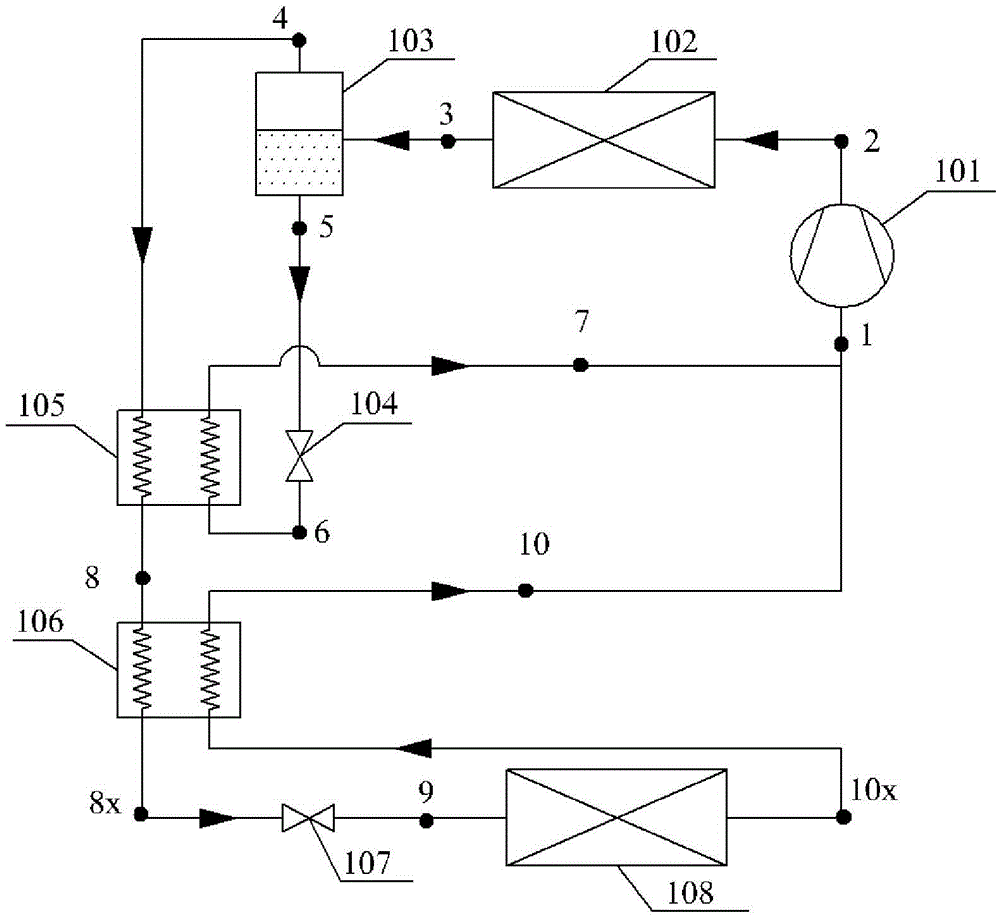

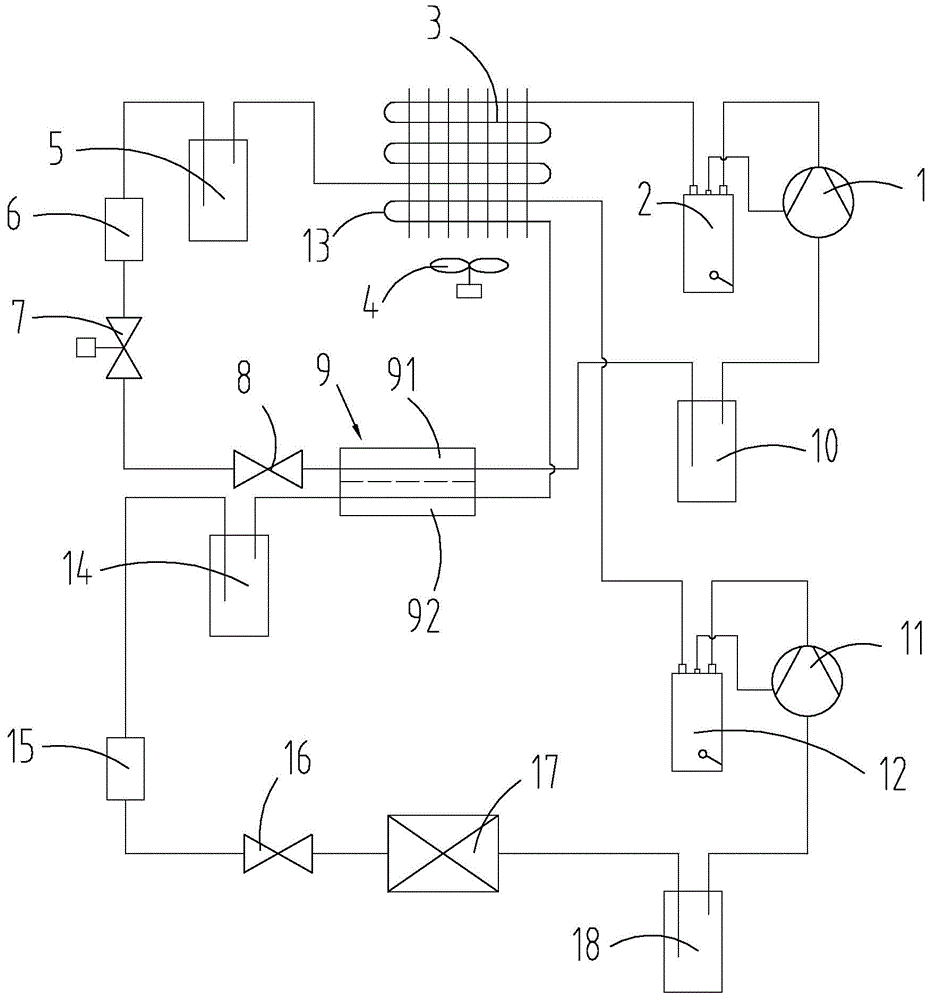

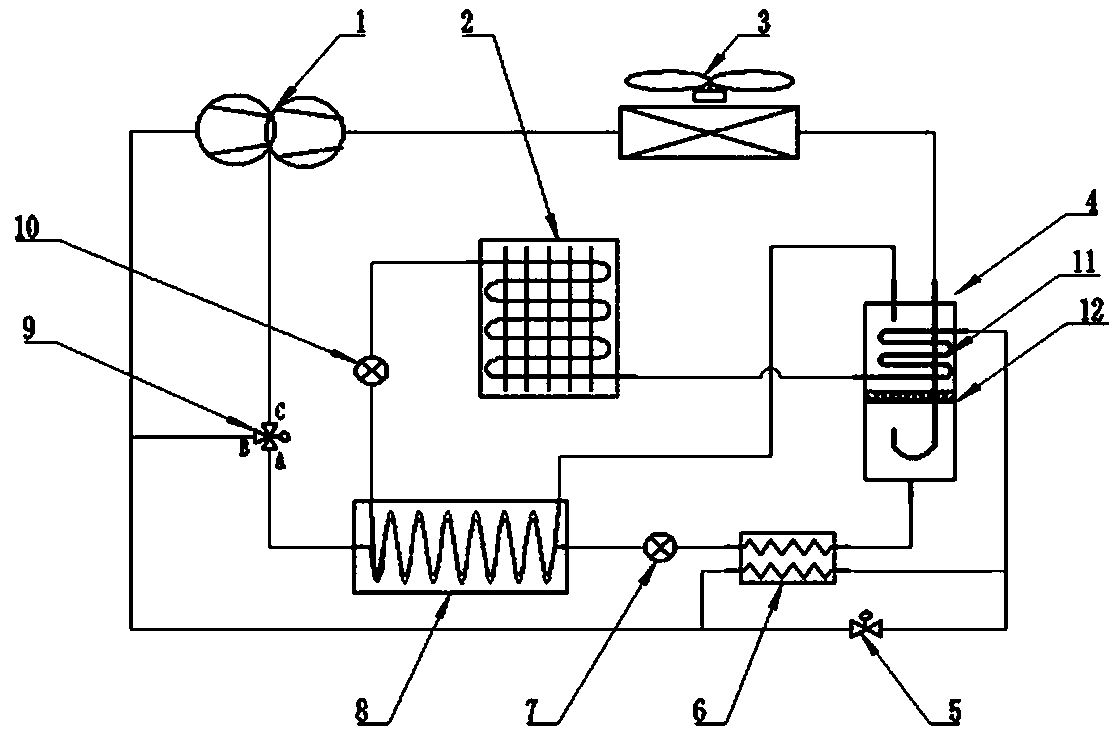

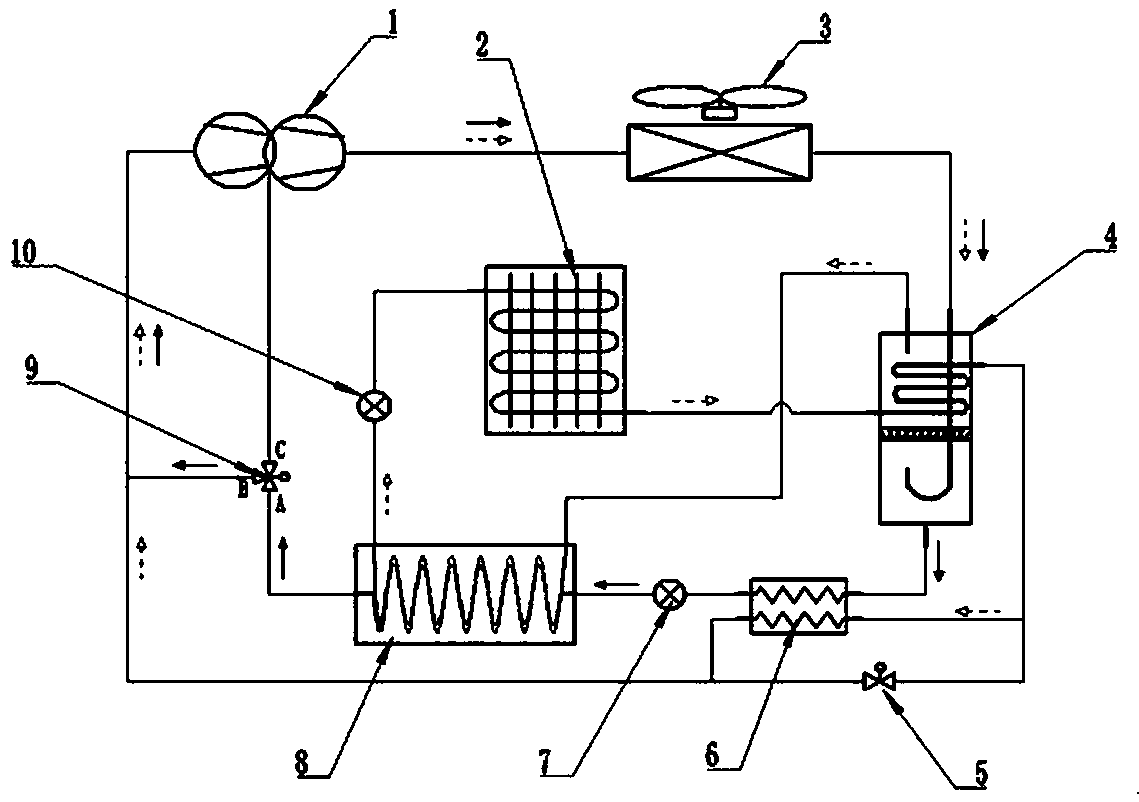

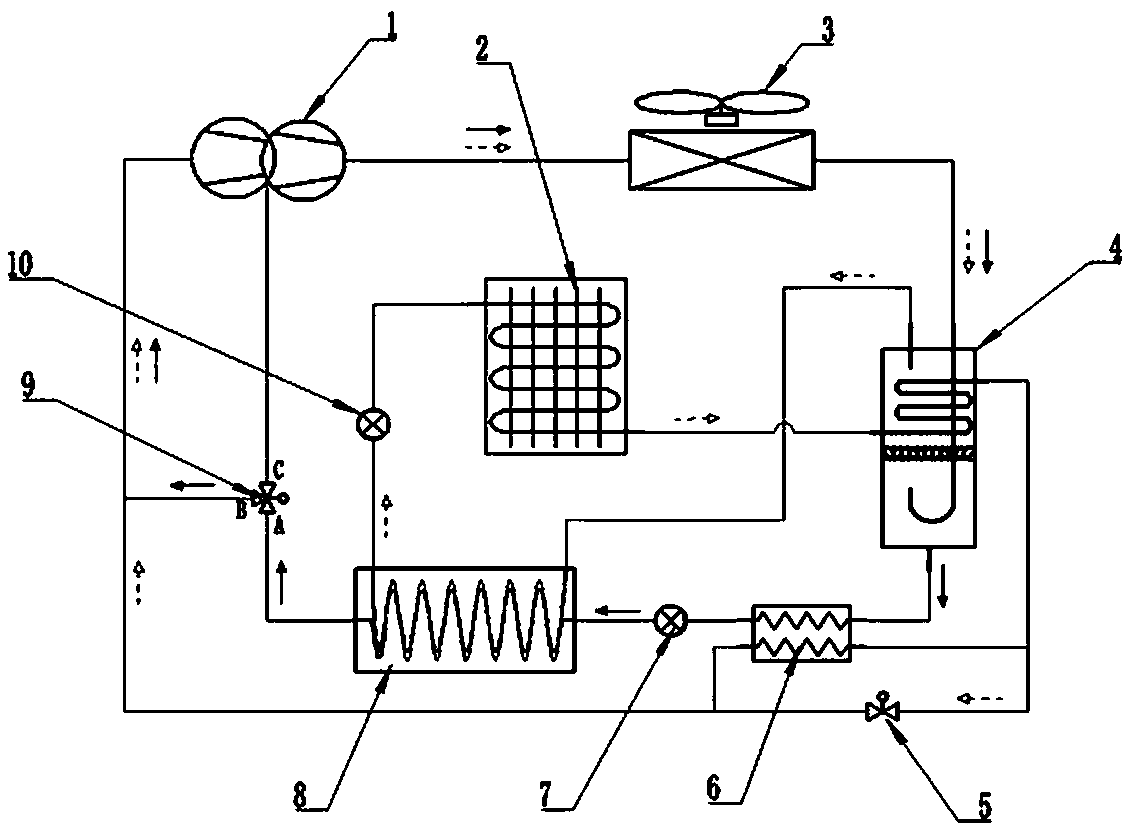

Self-cascade refrigeration system with double-stage compression function

ActiveCN108413638AImprove cooling effectReduce the temperatureCompressorMechanical apparatusVapor–liquid separatorBoiling point

The invention discloses a self-cascade refrigeration system with a double-stage compression function. The self-cascade refrigeration system is characterized in that a compressor (1) is provided with an intermediate air supplement port, refrigerants adopt two non-azeotropic refrigerants, an exhaust port of the compressor is sequentially connected with a condenser (3) and a gas-liquid separator (4),the high-boiling-point refrigerant discharged from the lower part of the gas-liquid separator sequentially flows through a heat regenerator (6), a first throttling component (7), a condensation evaporator (8) to a port A of a three-way valve (9), the low-boiling-point refrigerant discharged from the upper part of the gas-liquid separator sequentially flows through the condensation evaporator (8),a second throttling component (10), an evaporator (2), a rectifying pipe (11) arranged in the gas-liquid separator and the heat regenerator (6) and then is mixed with the refrigerant discharged froma port B of the three-way valve and then is returned to an air suction port of the compressor, and a port C of the three-way valve is connected with the air supplement port of the compressor. According to the system, the structure is simple, the power consumption can be effectively reduced, the refrigerating capacity can be improved, the lower temperature can be prepared, and the efficiency can beimproved.

Owner:GREE ELECTRIC APPLIANCES INC

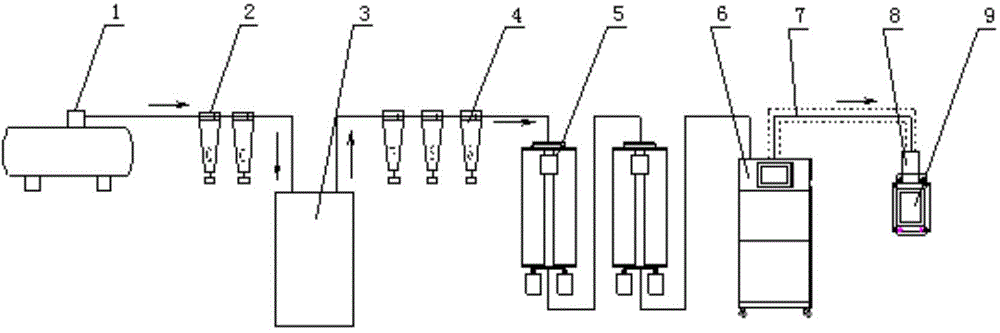

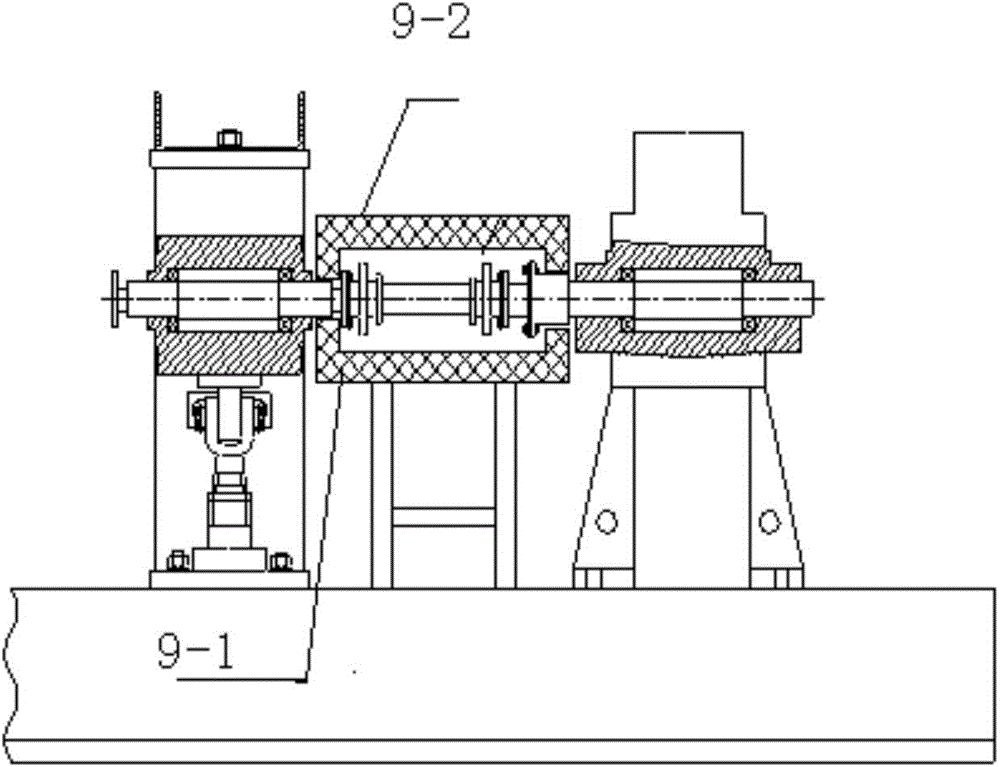

High and low temperature environment simulation test device

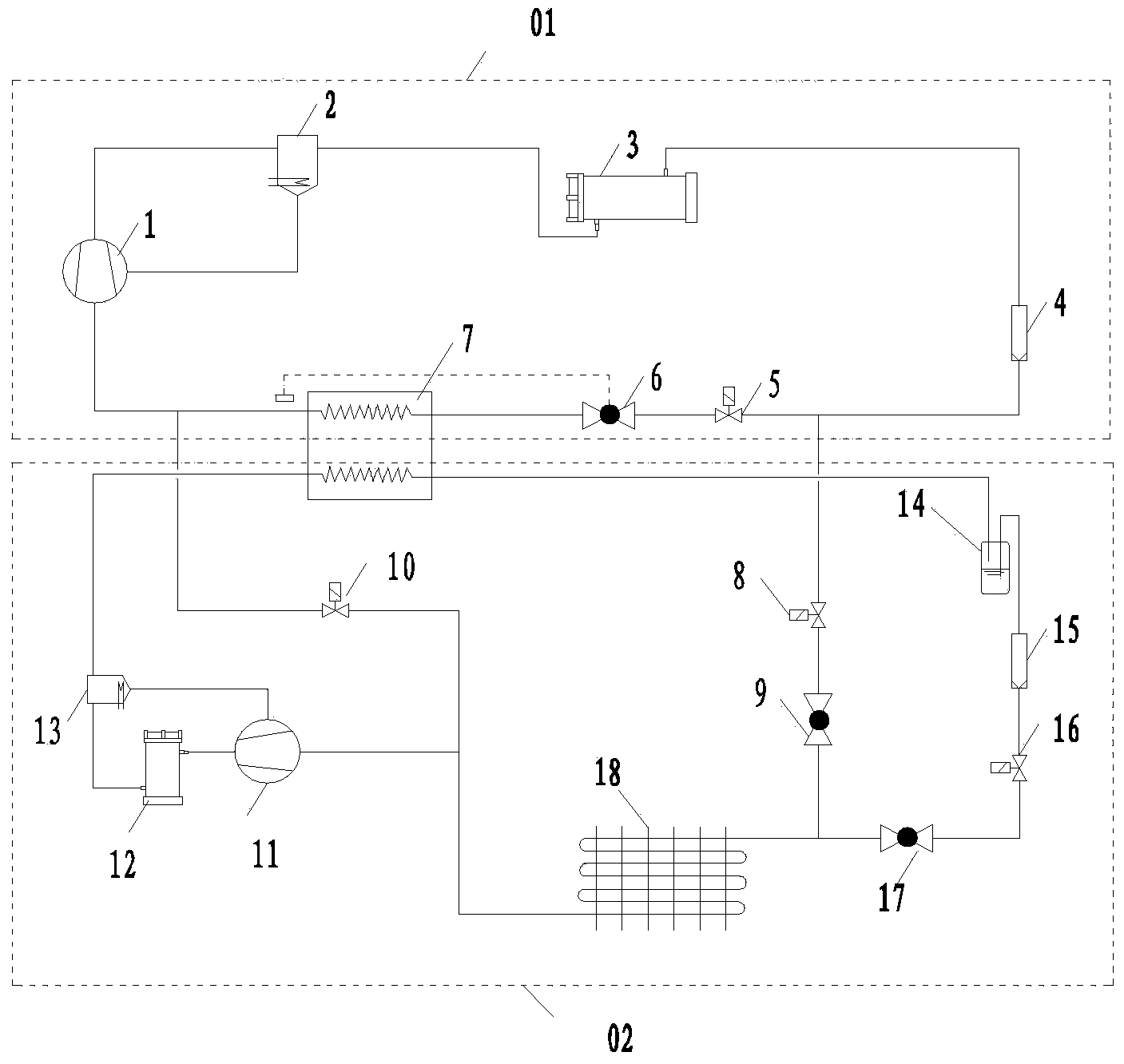

InactiveCN104670523ARapid hot and cold testAvoid enteringCosmonautic condition simulationsThermal insulationAir filter

The invention provides a high and low temperature environment simulation test device, wherein the high and low temperature environment simulation test device comprises an air compressor, a refrigerated dryer, an air filter, a cascade refrigeration system, a high and low temperature air delivery pipe and a thermal insulation box connected in sequence; the thermal insulation box packages the transmission product, the compressed air is cooled by the cascade refrigeration system after processed by the refrigerated dryer and filtered by the air filter, and transmitted to the thermal insulation box through the high and low temperature air delivery pipe.

Owner:中国航空工业集团公司航空动力控制系统研究所

Solar jet-variable compression hybrid refrigeration system

InactiveCN102620468ATake advantage ofUse part of the solar energy to make full use of itFluid circulation arrangementEngineeringRefrigeration

A solar jet-variable compression hybrid refrigeration system comprises a solar jet refrigeration system, a solar jet-variable compression cascade refrigeration system, a solar jet-variable compression coupling refrigeration system and a variable compression refrigeration system which are integrated; when solar radiation is intense, the solar jet refrigeration system operates; when solar radiationis higher than the medium level, the solar jet-variable compression cascade refrigeration system operates; when solar radiation is weak, the solar jet-variable compression coupling refrigeration system operates to sufficiently utilize part of the solar energy not utilized by the prior art, and when solar energy is extremely low or solar radiation does not exist, the variable compression refrigeration system in the system operates. The system can efficiently utilize solar energy at different levels according to the intensity of solar radiation, and sufficiently and effectively utilizes the solar energy resource.

Owner:TAIYUAN UNIV OF TECH

Auto-cascade refrigeration system, drying device with same and operation method

The invention relates to an auto-cascade refrigeration system, in particular to an auto-cascade refrigeration system for a drying device and an operation method. The refrigeration system comprises a compressor, a condenser, a separation device, a first throttling device, an evaporation condenser, a liquid storage device, a second throttling device, a low-temperature evaporator, a high-temperatureevaporator and other refrigeration equipment as well as a valve assembly. Through the control of the valve assembly, the characteristics and setting of the auto-cascade system can be simplified, and the auto-cascade refrigeration system is capable of realizing component separation, storage, capacity adjustment and high-efficiency operation at different operating temperature stages.

Owner:GREE ELECTRIC APPLIANCES INC

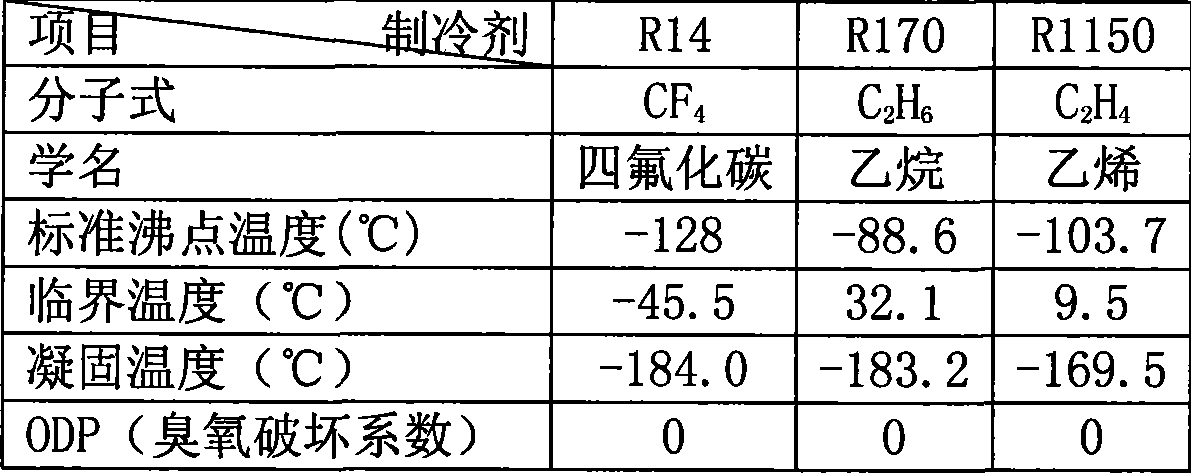

Mixed refrigerant adapted for refrigerating temperature range of minus 105 degree centigrade to minus 125 degree centigrade

InactiveCN101225292AMeet environmental protection requirementsImprove liquidityCompression machines with cascade operationHeat-exchange elementsWaxRoom temperature

The invention provides a mixed refrigerant suitable for the freezing zone at 105 to 125 DEG C below zero. The carbon tetrafluoride (R14) is mixed with one or two of the ethane (R170) and the ethylene (R1150) and then the mixed refrigerant can be obtained after physically mixing. The above components are physically mixed according to a set matching at normal temperature and the corresponding mixedworking substance can be obtained. The ODP is zero, greenly and environment-friendlily, and the mineral lubricating oil of compressor can be well inter-dissolved with the mixed refrigerant. The mixedrefrigerant suitable for the freezing zone at 90 to 100 below zero DEG C can flow the capillary and the expansion valve throttling gear well without oil solidification and wax plugging, and is suitable for the low temperature third grade of three-grade cascade refrigeration system and can form 105 to 125 DEG Cbelow zero low temperature.

Owner:龙志刚

Condensed explosion-proof oil gas reclaiming device

InactiveCN101874936AImprove energy efficiency ratioNo secondary pollutionLarge containersVapor condensationBusiness efficiencyThree stage

The invention discloses a condensed explosion-proof oil gas reclaiming device, which comprises an oil gas heat exchange separator, a first condensation evaporator, a second condensation evaporator and three-stage refrigerating parts, wherein the cold energy of the first-stage refrigerating part is divided into two paths, one path of cold energy enters the first condensation evaporator, and the other path of cold energy enters the oil gas heat exchange separator; the cold energy of the second-stage refrigerating part is divided into two paths, one path of cold energy enters the second condensation evaporator, and the other path of cold energy enters the oil gas heat exchange separator; and the cold energy of the third-stage refrigerating part directly enters the oil gas heat exchange separator. The condensed explosion-proof oil gas reclaiming device reclaims oil gas by adopting a pure condensation method, and the oil gas after condensation and liquefaction directly becomes gasoline for recycle; meanwhile, fractional condensation is performed at a higher evaporation temperature by adopting compressor double-parallel cascade refrigeration technology, and the preceding stage refrigerating part provides a heat displacement low-temperature environment for the refrigeration and oil gas cooling fractional condensation of the post stage, so the energy efficiency ratio can be improved; and the device has the advantages of energy conservation, environmental protection, low cost and convenient operation and maintenance.

Owner:NANJING DOULE REFRIGERATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com