Double-stage cascade refrigeration method used for oil-gas recovery

A cascading refrigeration and oil-gas technology, which is applied in refrigerators, refrigeration and liquefaction, and compressors with cascading work, can solve the problems of large systems, high manufacturing and operating costs, and high energy consumption, and reduce manufacturing costs. , Simplify the effect of oil and gas condensation recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

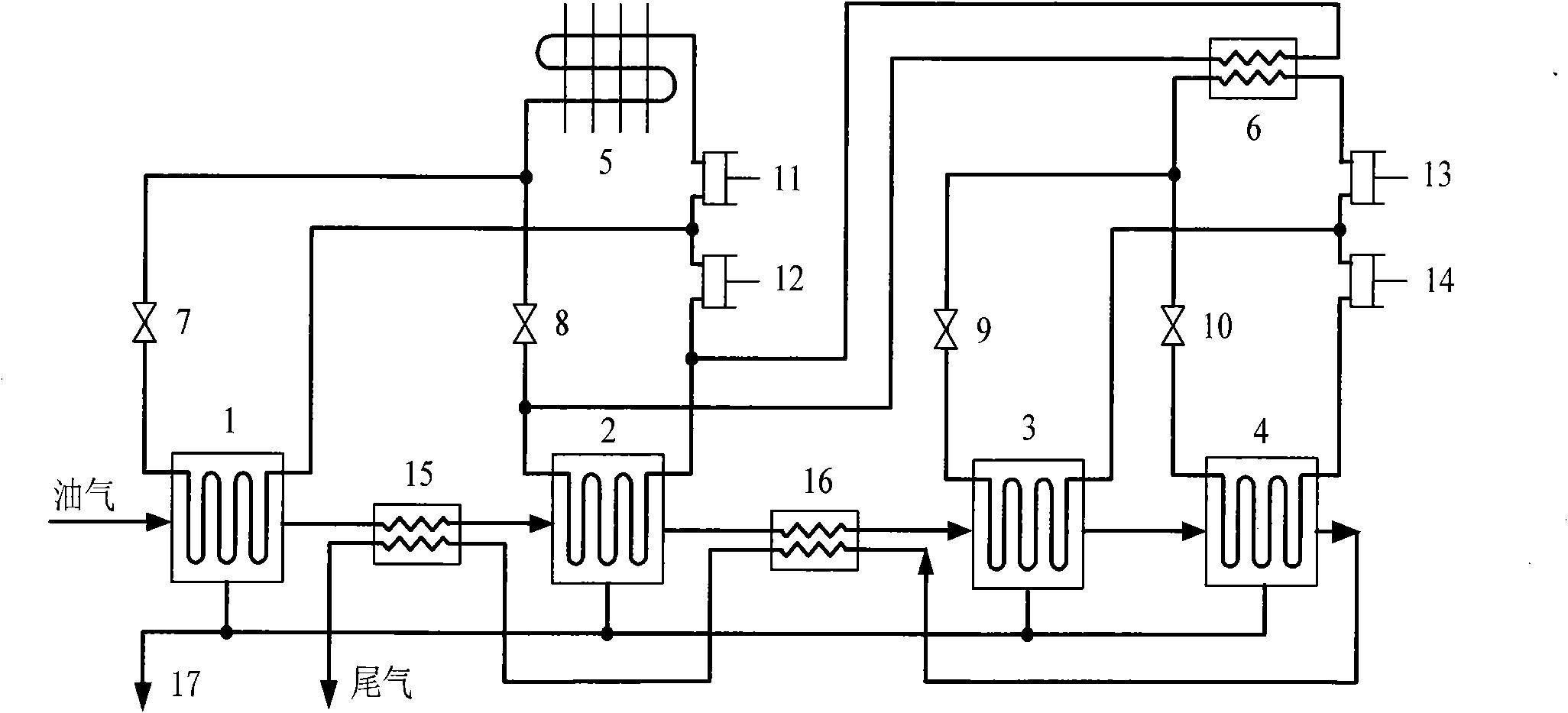

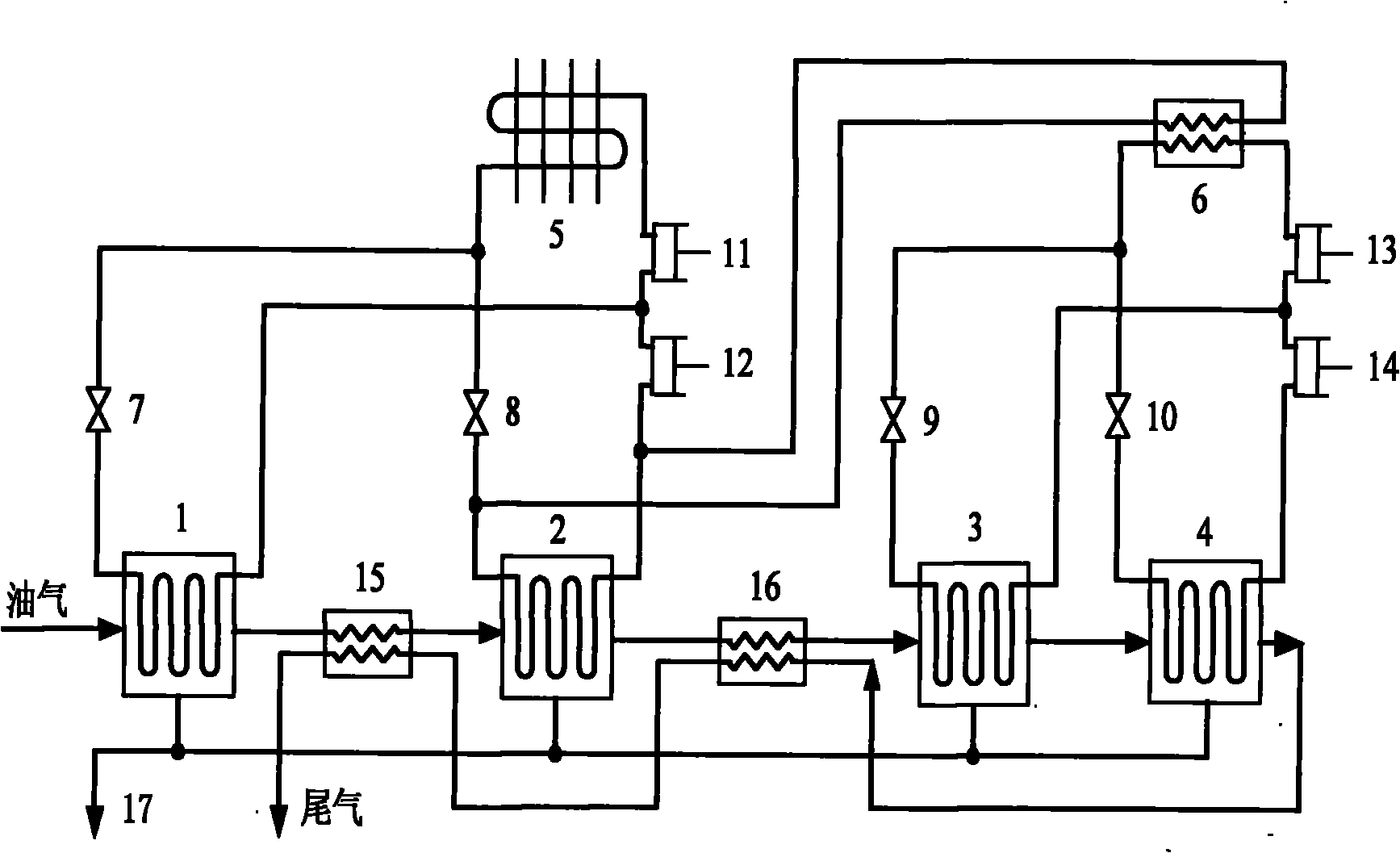

[0014] like figure 1 As shown in , the cascade refrigeration system is composed of a two-stage compression refrigeration cycle in the high temperature part and a two-stage compression refrigeration system in the low temperature part. 1, the second-stage oil-gas condenser 2, the third-stage oil-gas condenser 3, and the fourth-stage oil-gas condenser 4 are condensed into liquids step by step and recovered, and the oil-gas and non-condensable gas that meet the discharge standard at the end of the fourth-stage oil-gas condenser The mixture passes through the gas-gas heat exchanger 16 and the gas-gas heat exchanger 15 in turn to recover the cooling capacity of the exhaust gas and then discharge it.

[0015] The two-stage compression refrigeration cycle of the high-temperature part of the cascade refrigeration system at least includes a refrigerant condenser 5, an expansion valve 7, a primary oil-gas condenser 1, an expansion valve 8, a secondary oil-gas condenser 2, and the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com