High and low temperature environment simulation test device

An environmental simulation test, high and low temperature technology, applied in the field of aviation environmental test, can solve the problems of test termination, easy frosting of evaporator, slow cooling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

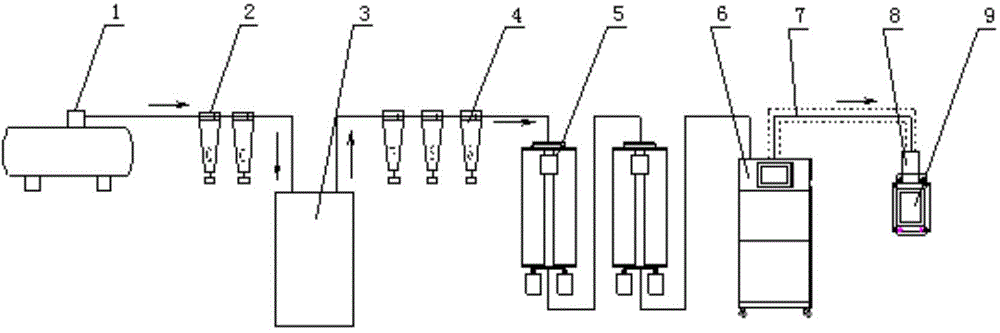

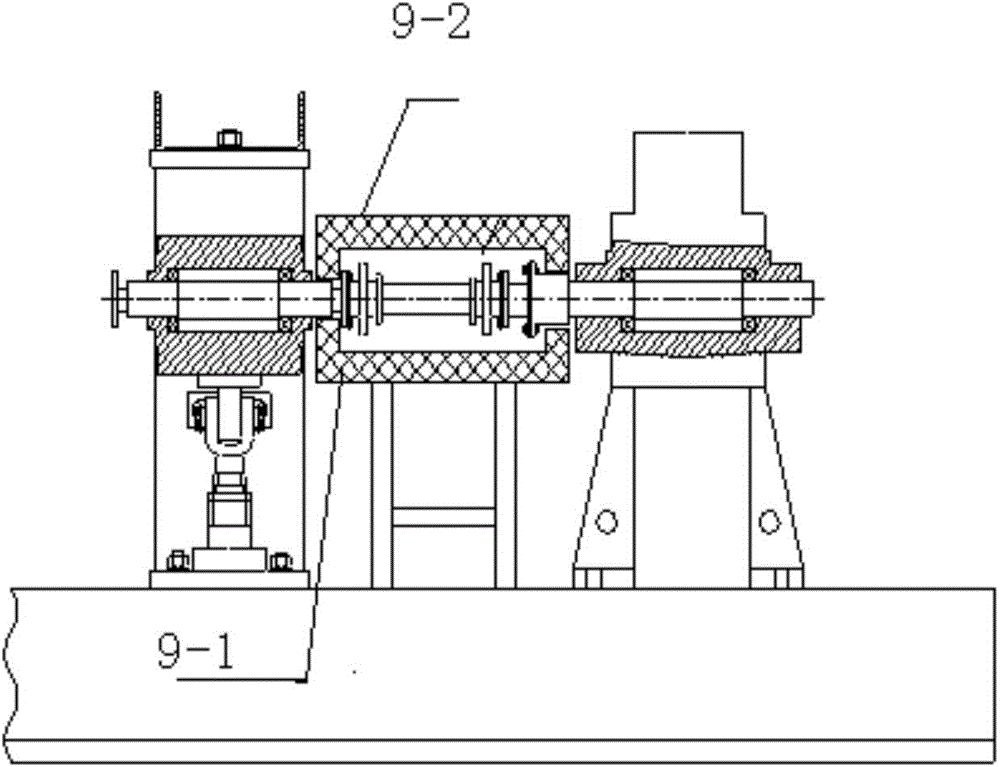

[0020] like figure 1 The sequence shown is air compressor 1, pre-oil and water-removing air filters 2 (2), refrigerated dryer 3, rear oil-removing, water-removing air filters 4 (3), no heat The regenerative dry air filter 5 (2 pieces) and the cascade refrigeration system 6 are connected by air pipes. One end of the high and low temperature gas transmission pipe 7 is connected to the cascade refrigeration system, and the other end is connected to the heater 8. The air outlet of the heater 8 is inserted into the insulation box. 9 and fixed with the insulation box 9.

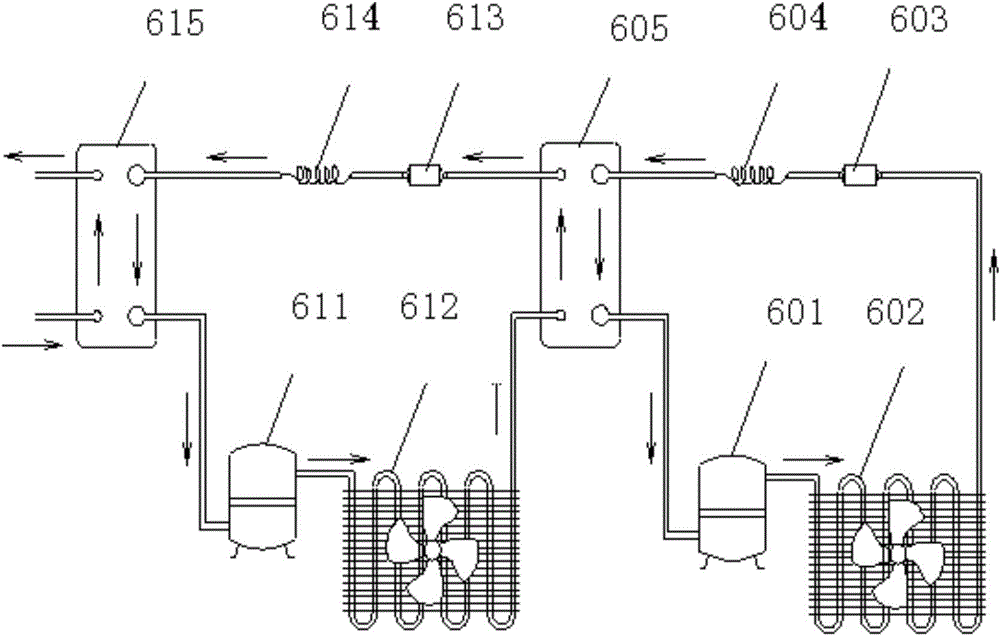

[0021] like figure 2 As shown, the stacked refrigeration system consists of two separate refrigeration cycles, referred to as a high temperature stage refrigeration cycle and a low temperature stage refrigeration cycle. The compressor 601, the air-cooled radiator 602, the dryer 603, the capillary tube 604, and the plate heat exchanger 605 are connected in series to form a high-temperature refrigeration cycle. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com