Automatic cascade refrigeration system exhaust pressure regulating device

A technology of cascade refrigeration and exhaust pressure, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reducing the operating pressure of the refrigeration system, shortening the cooling time of the refrigerator, and reducing the balance pressure of the system, so as to speed up the cooling. Speed, shortening the cooling time, the effect of increasing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

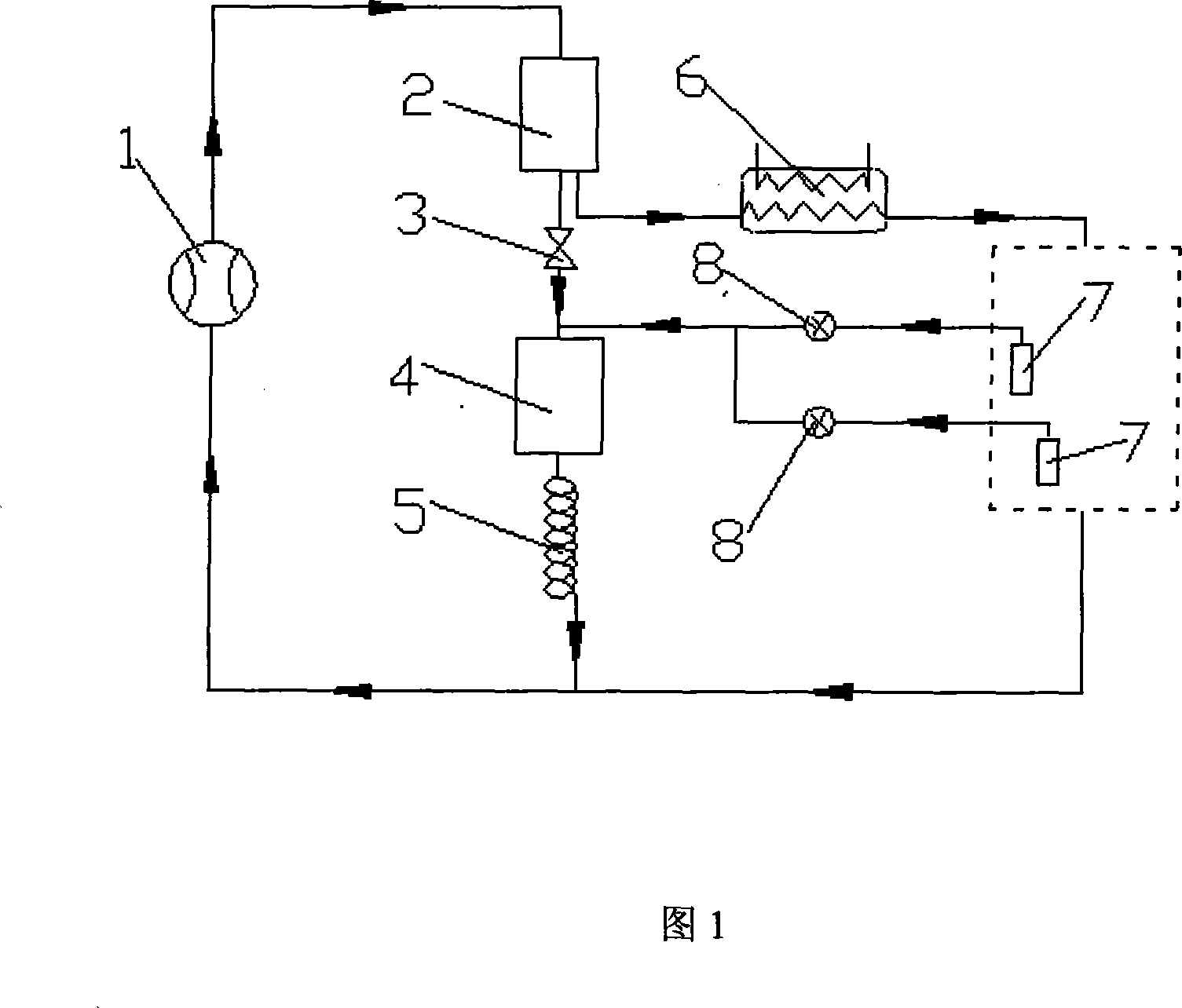

[0009] A device for adjusting the exhaust pressure of an automatic cascade refrigeration system, as shown in Figure 1. first:

[0010] ①A buffer 2 is connected between the exhaust port of the compressor 1 and the inlet of the condenser 6, the buffer is connected with the bypass valve 3, the expansion vessel 4, and the capillary 5 in turn, and the capillary is connected with the return air line of the system to form a bypass through branch road.

[0011] The high-temperature and high-pressure mixed refrigerant gas coming out of the exhaust port of compressor 1 is firstly buffered by buffer 2, which can reduce the exhaust pressure. If no buffer is installed, a large amount of continuously discharged working fluid will be in the form of gas Accumulated in the condenser 6, causing the pressure to be too high, the high pressure exceeding the allowable value will also damage the diaphragm and cause the compressor to be paralyzed. If the pressure of the mixed gas coming out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com