Self-cascade refrigeration system with double-stage compression function

A refrigeration system and two-stage compression technology, which is applied in the direction of compressors, refrigerators, compressors, etc., can solve the problems of multiplied system components, increased production costs, complex refrigeration systems, etc., to achieve improved efficiency, improved effect, and reliability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

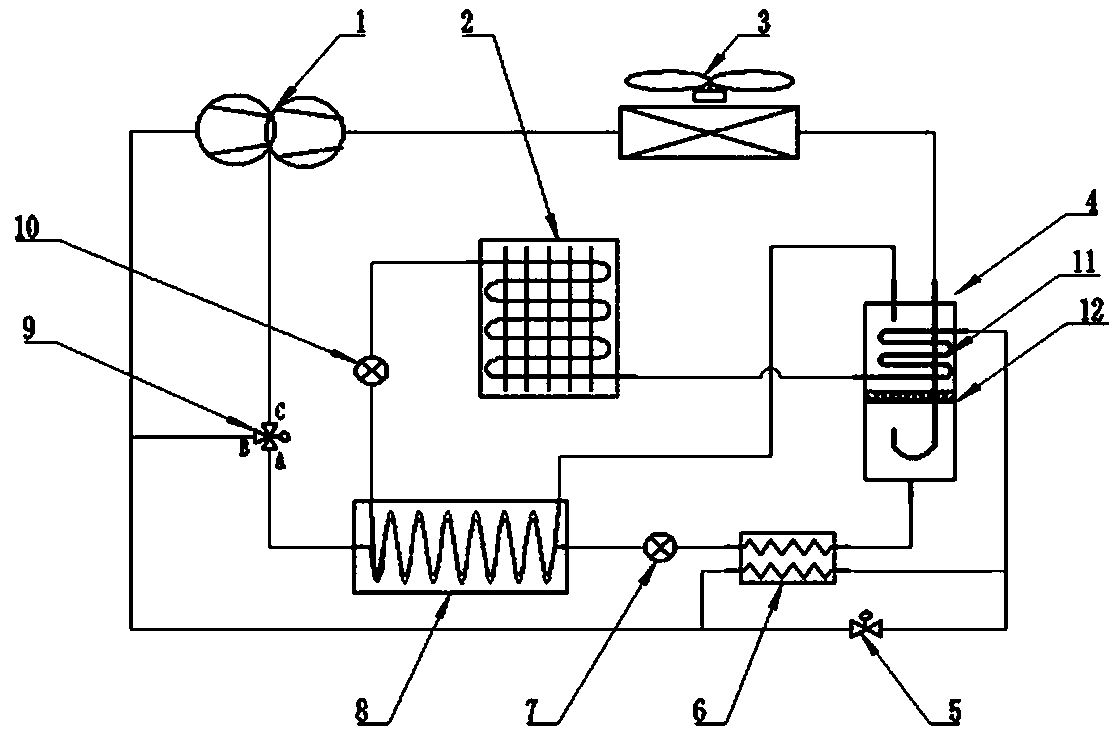

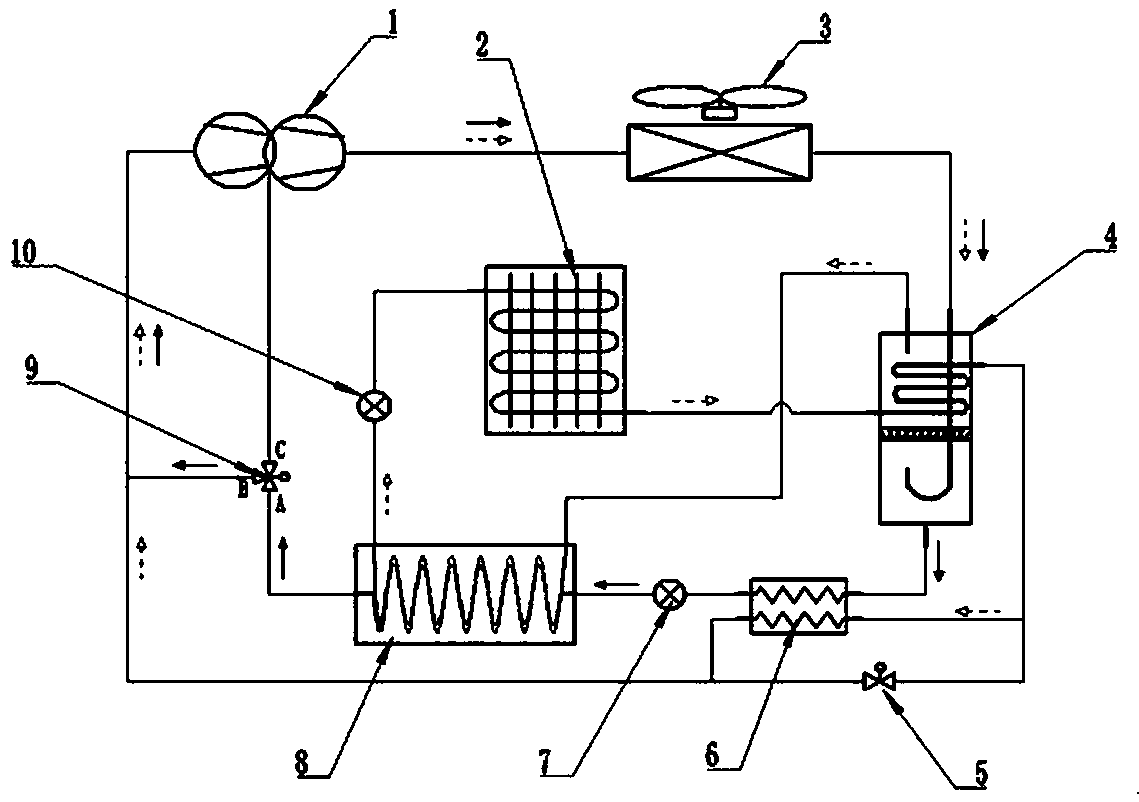

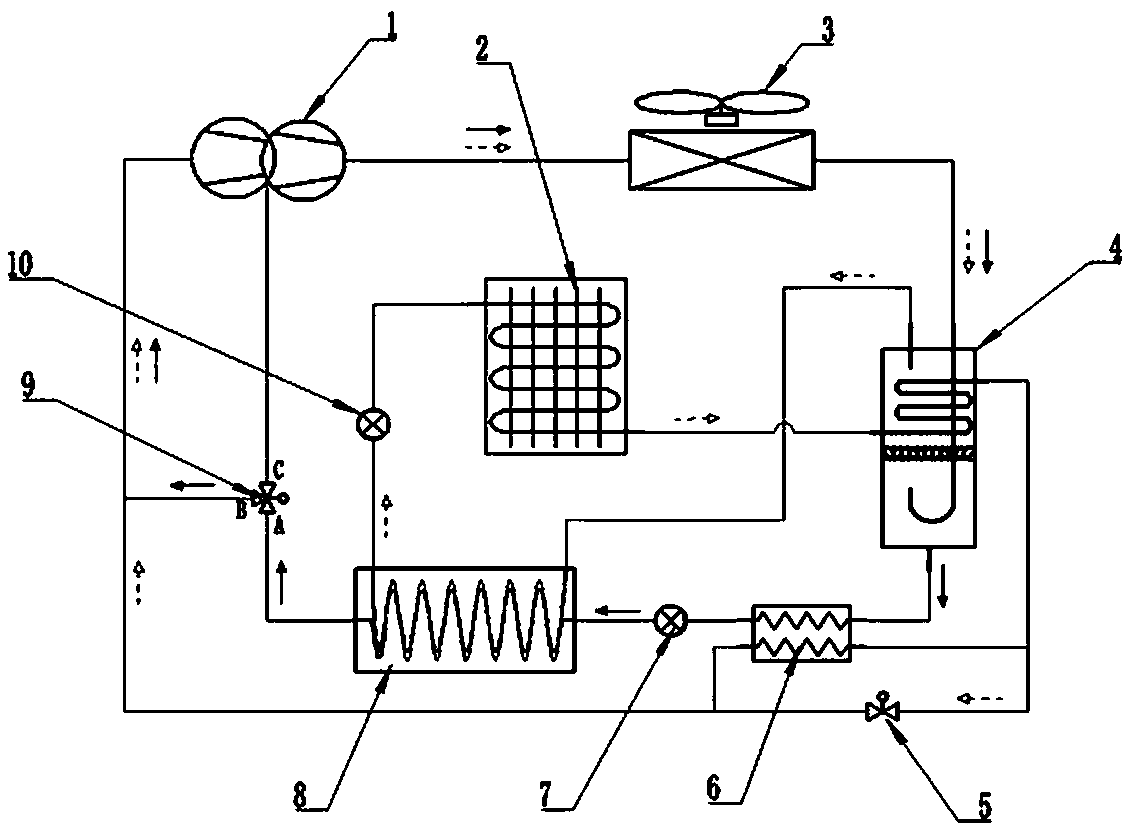

[0019] like figure 1 As shown, the main components of the self-cascading refrigeration system proposed by the present invention include a compressor 1, an evaporator 2, a condensation heat exchanger 3, a gas-liquid separator 4, a two-way valve 5, a regenerator 6, and a first throttling component 7. Condensing evaporator 8 , three-way valve 9 and second throttling component 10 .

[0020] like figure 1 As shown, the compressor 1 adopts a two-stage compressor, which has a suction port, an exhaust port and an intermediate gas supply port. The refrigerant adopts two non-azeotropic refrigerants, among which the high boiling point refrigerant can be selected but not limited to R600a, R134a, R22 or R32, and the low boiling point refrigerant can be selected but not limited to R23 or R14. The exhaust port of the compressor 1 is connected to the condenser 3 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com