Multilevel semiconductor cascade refrigeration element and refrigeration thermopile

A cascade refrigeration, semiconductor technology, applied in the direction of thermoelectric devices that only use the Peltier or Seebeck effect, can solve the limitation of substantially improving the refrigeration performance of the pagoda-type multi-stage semiconductor refrigeration components, increase the additional heat transfer resistance, and the pagoda-type structure. Large leakage heat loss and other problems, to achieve the effect of reducing heat transfer resistance and heat leakage loss, increasing manufacturing cost, and improving refrigeration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

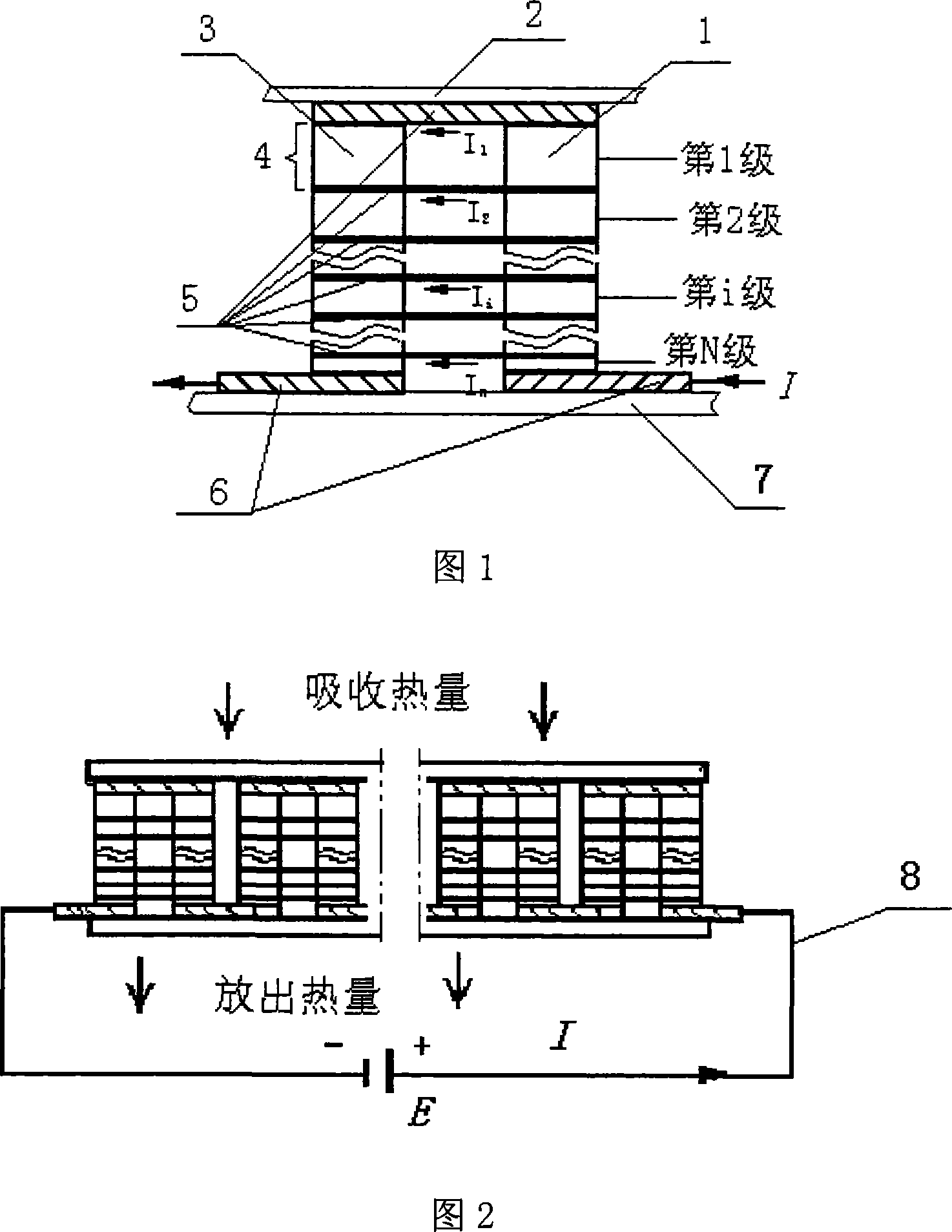

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] As shown in Figure 1, the multi-stage semiconductor cascade refrigeration element is formed by cascading the first to Nth refrigeration couples, N can be selected from 2 to 8 according to the refrigeration temperature requirements, and each refrigeration couple is composed of p Type semiconductor 3 and n-type semiconductor 1 are formed in pairs, and the cross-section of the cooling galvanic couple between adjacent two stages is the same, and thermal connection and electrical connection are all realized through the same galvanic couple connecting sheet (copper sheet or silver sheet) 5; The p-type and n-type semiconductors 3 and 1 at the upper cold end of the first-stage refrigeration couple are welded together in series with the couple connecting piece 5, and the couple arm 4 is set to a certain length h1; The connecting piece 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com