Biogas liquefaction process and device for scattered gas source point

A liquefaction device and biogas technology, applied in liquefaction, refrigeration and liquefaction, compressors, etc., can solve the problems of biogas liquefaction without scattered gas sources, large initial investment in equipment, complex process equipment, etc., to achieve convenient and stable control and adjustment The effect of liquefaction rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

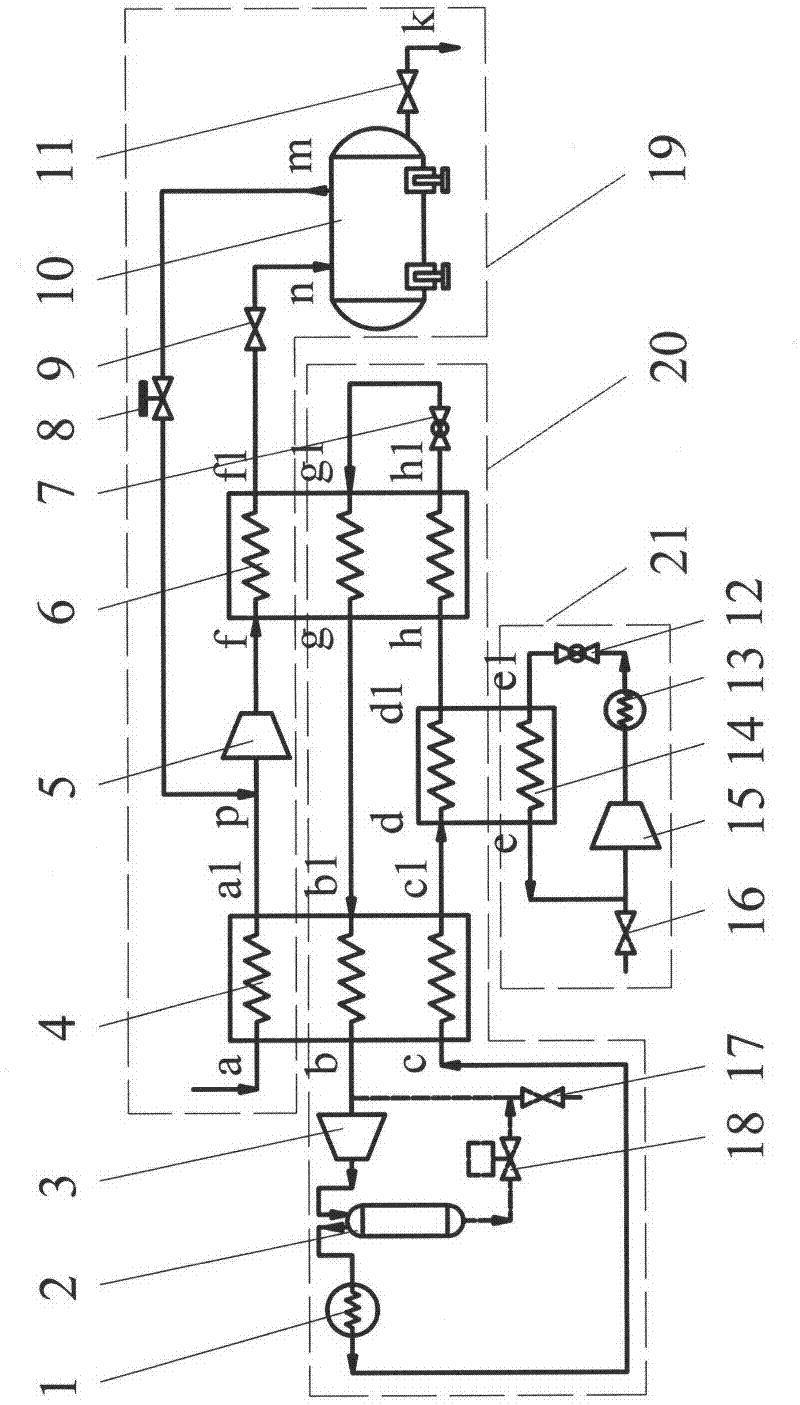

[0033] Such as figure 1 As shown, the biogas liquefaction process and device of the present invention is a cascade refrigeration cycle system composed of a multi-component mixed refrigerant circulation unit 20 and a multi-component mixed refrigerant pre-cooling unit 21, forming a low temperature in the cold box 6, condensing and liquefying raw material biogas. The single refrigerant is propane, and the multi-component mixed refrigerant is a mixture of propane, ethane, methane and nitrogen in a certain mass ratio. The multi-component mixed refrigerant cycle unit 20 is connected in turn by pipelines from the main compressor 3, the oil separator 2, the main condenser 1, the regenerator 4, the pre-cooling heat exchanger 14, the cold box 6, and the main th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com