Separation method for reaction product of propane dehydrogenated propylene preparation

A technology of propane dehydrogenation and reaction products, applied in distillation purification/separation, organic chemistry and other directions, can solve the problems of high energy consumption and large circulation of absorbent, and achieve the effects of low energy consumption, convenient operation and guaranteed yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

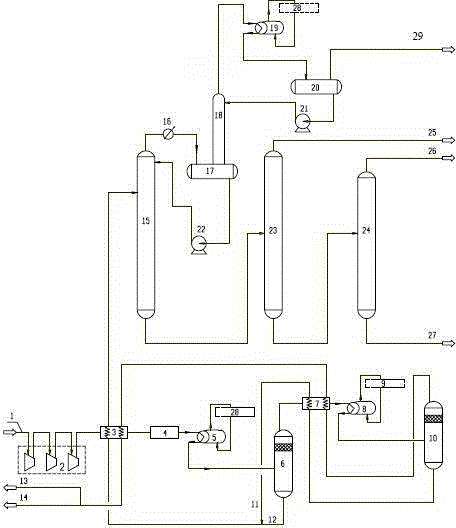

[0027] Such as figure 1 As shown, the reaction product 1 of propane dehydrogenation to propylene is compressed to 1.2-2.0 MPa (gauge pressure) through the three-stage compression system 2, cooled to 5-10°C through the compression outlet cooling unit 3, and enters the drying system 4, and the reaction product is The water content in the water drops below 1ppm. Under the action of the propylene refrigeration system 28, it is cooled to -35~-20°C by the first-stage refrigerator 5 and then enters the first-stage cryogenic tank 6 for gas-liquid separation. Under the action of the ethylene refrigeration system 9, it is cooled to -95~-85°C by the second-stage refrigerator 8, and enters the second-stage cryogenic tank 10 for gas-liquid separation. After the tank top gas is exchanged, most of it is returned to the reaction as circulating hydrogen 14 Part, the remaining gas is sent out to the device as propane hydrogen 13. The first-stage cryogenic tank liquid phase 12 and the second-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com