Carbon Dioxide Based Auxiliary Cooling System

a technology of auxiliary cooling and carbon dioxide, which is applied in the field of refrigeration systems, can solve the problems of carbon dioxide based systems losing refrigerant during power outages, dioxide based systems starting to gain heat, and increasing refrigerant pressure and exceeding the effect of pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

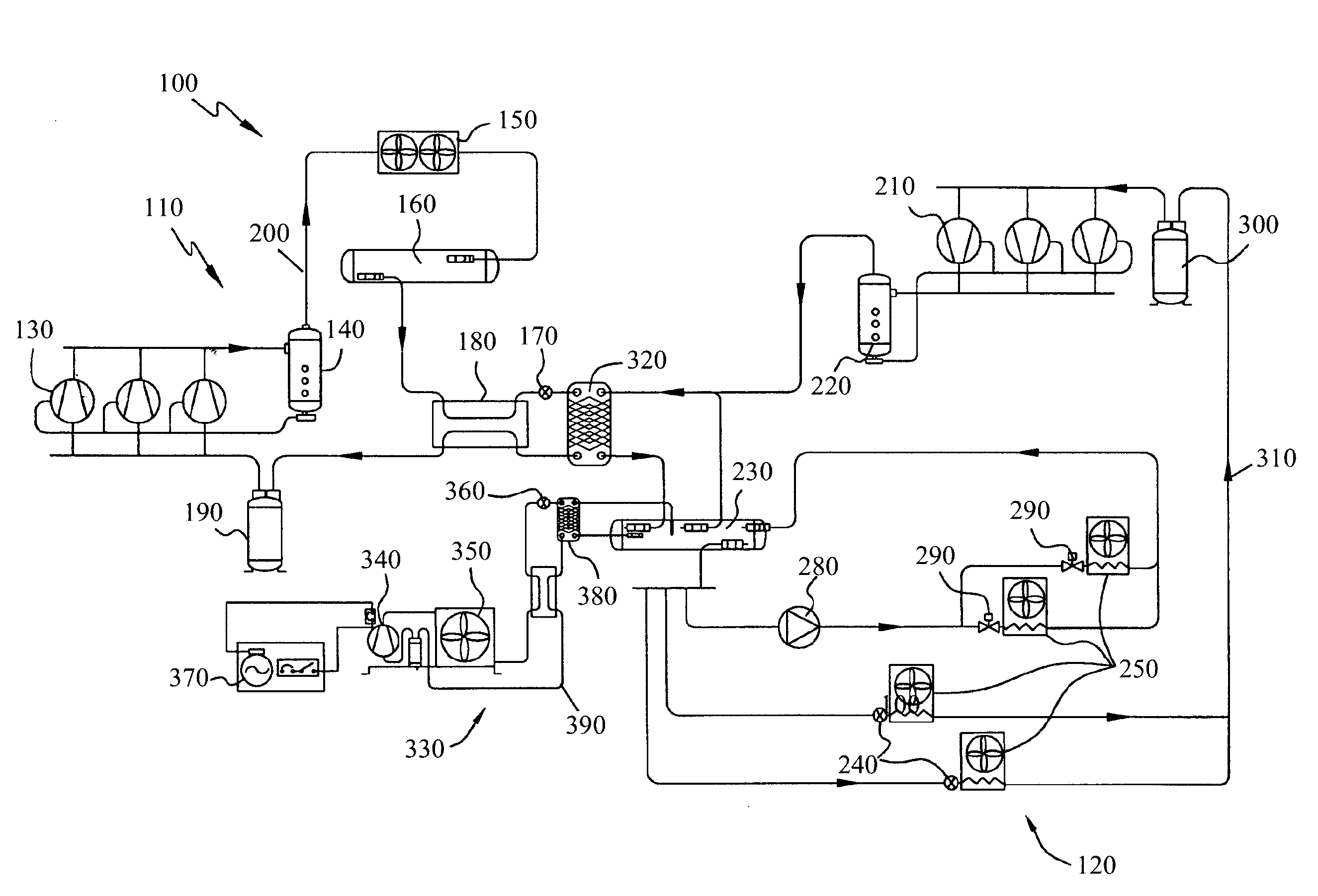

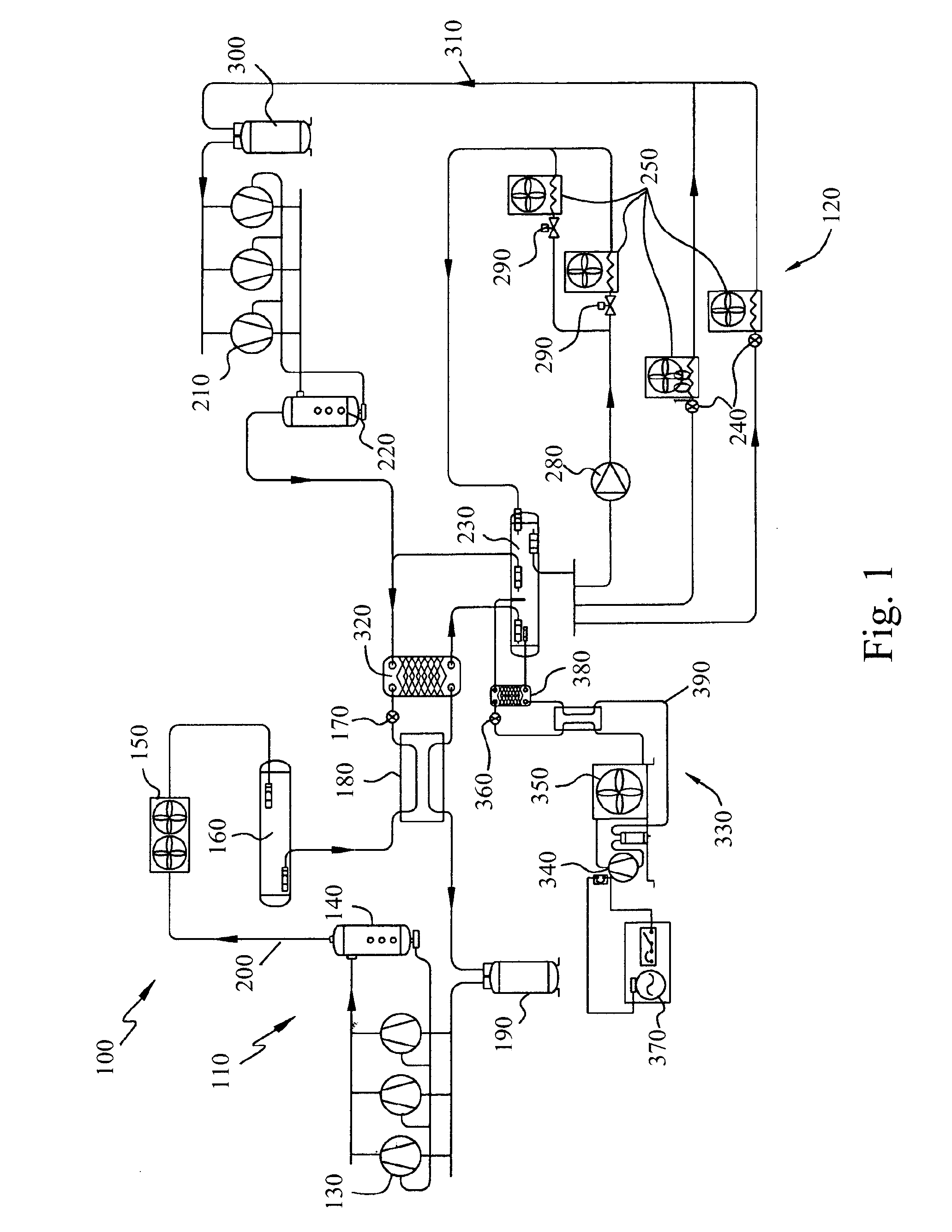

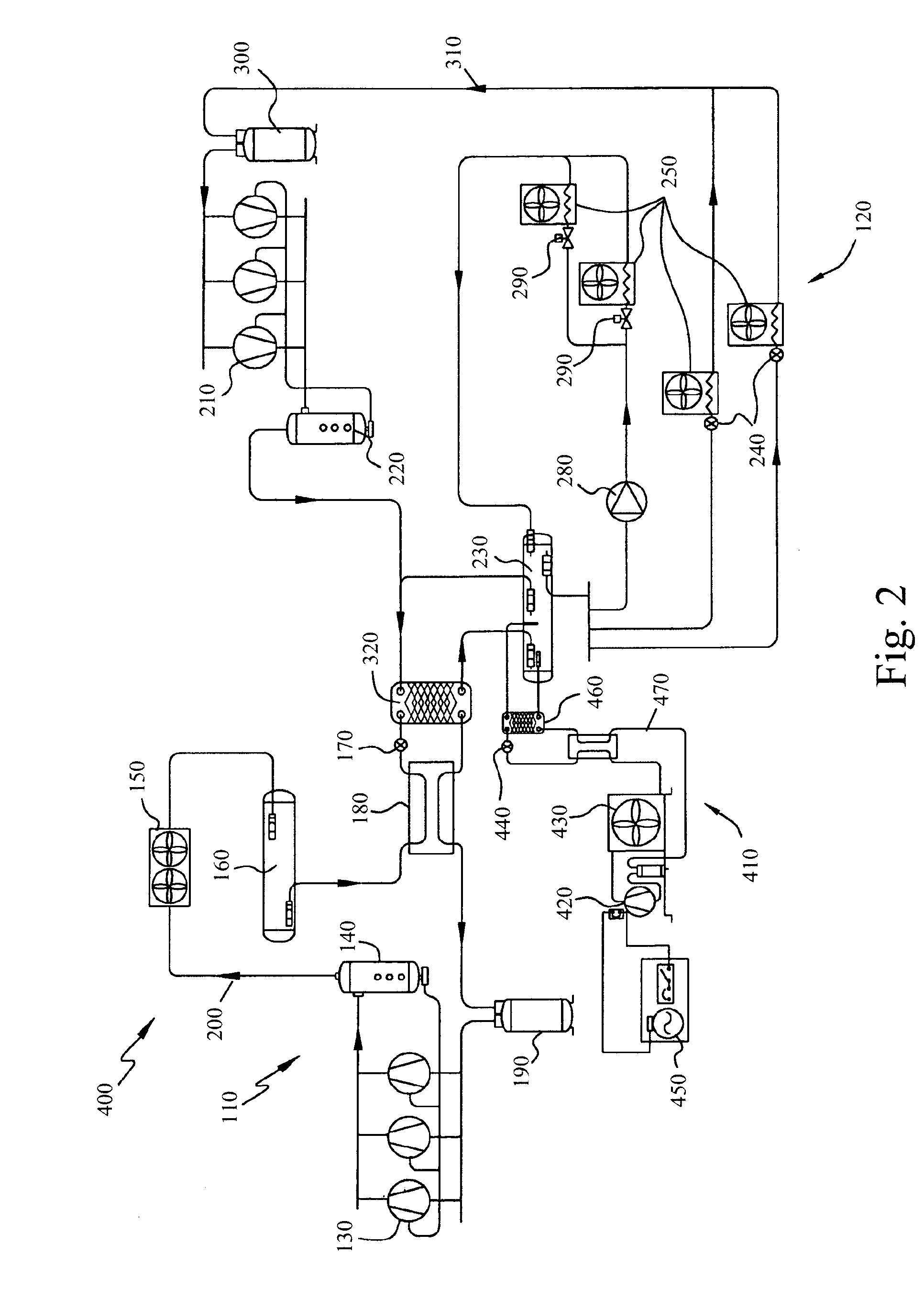

[0013]Referring now to the drawings, in which like numerals refer to like elements throughout the several views, FIG. 1 shows an example of a cascade refrigeration system 100. The cascade refrigeration system 100 may be used to cool any type of enclosure for use in, for example, supermarkets, cold storage, and the like. The cascade refrigeration system 100 also may be applicable to heating, ventilation, and air conditioning and / or different types of industrial applications. The overall cascade refrigeration system 100 may have any suitable size or capacity.

[0014]Generally described, the cascade refrigeration system 100 may include a first or a high side cycle 110 and a second or a low side cycle 120. The high side cycle 110 may include a high side compressor 130, a high side oil separator 140, a high side condenser 150, a high side receiver 160, and a high side expansion device 170. The high side cycle 110 also may include a suction / liquid heat exchanger 180 and a suction accumulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com