Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "With UV protection function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet resistant functional fabric

The invention discloses an anti-ultraviolet functional fabric. The fabric contains polyester fibre with anti-ultraviolet nanoparticles; the anti-ultraviolet nanoparticle is one or more of TiO2, ZnO, CeO2, SiO2, Al2O3, Fe2O3, CaCO3, PbO, kaoline, talcum powder and argil nanoparticles; the nanoparticle accounts for 0.1 to 30 weight percent of the total weight of the fabric; the UPF value of the fabric is 50 plus; and T(UVA)AV is less than 5. The fabric can be used for manufacturing clothes, a cap, a sun shading article, a parasol, a tent, work clothes and various touring articles.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Monomer composition for manufacturing chameleon glass blocks and method for preparing chameleon glass blocks

InactiveCN101838369AHigh refractive indexWith UV protection functionOptical elementsMonomer compositionAcrylic resin

The invention provides a monomer composition for manufacturing chameleon glass blocks and a method for preparing chameleon glass blocks. The composition comprises the following components in percentage by weight: 1, a monomer mixture: 40 to 70 percent of (methyl) acrylic resin, 20 to 40 percent of ethenyl monomer and 10 to 20 percent of crosslinker; and 2, auxiliary material and assistant for 1,000 grams of monomer mixture: 0.1 to 1 gram of chromotropic dye, 0.05 to 0.2 gram of ultraviolet absorber, 2 to 6 grams of antioxidant, 2 to 6 grams of stabilizer, 1 to 5 grams of polymerization additive and 0.8 to 5 grams of polymerization initiator. The reflection index of the obtained chameleon glass blocks is 1.60 to 1.63 and the transmittance after color change is 20 percent. Therefore, the effect that one pair of glasses can be used for multiple purposes is achieved.

Owner:SHANGHAI WEIXING OPTICAL

Production technology of nano-self cleaning architechtural aluminium curtain wall board

InactiveCN1824394ALess investmentReduce manufacturing costWallsPretreated surfacesProduction lineSpray coating

The present invention discloses a production process of nano self-cleaning building aluminium curtain wall plate. Said production process includes the following steps: (1). spray-coating face paint; (2). leveling; (3). spray-coating nano self-cleaning solution; (4). heating and curing; and (5) photocuring.

Owner:蒋建新

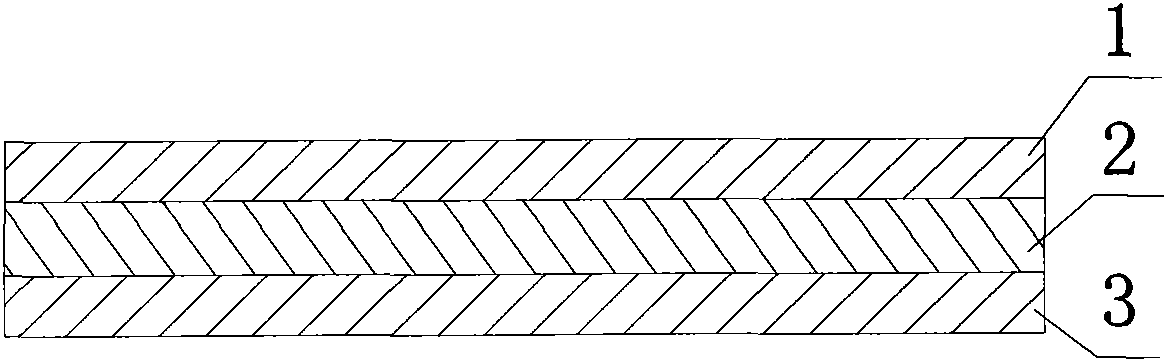

Precoated films with UV protection

InactiveCN102277095AWith UV protection functionEasy to useMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesUv protectionUltraviolet

The present invention relates to a film for packaging. A pre-coated film with anti-ultraviolet function is characterized in that it consists of a secondary functional layer, a core layer, and a coating functional layer, and the core layer is located between the secondary functional layer and the coating functional layer; the material of the secondary functional layer includes poly Composed of propylene and anti-ultraviolet agent, the addition of anti-ultraviolet agent is 0.1-3% of the mass of polypropylene; the material of the core layer is modified polyethylene, and the material for coating the functional layer is an adhesive; the sub-functional layer, core layer, The coated functional layer is thermally synthesized into one body. The invention has the characteristics of anti-ultraviolet function and convenient and simple use.

Owner:YUNMENG COUNTY DEBANG IND

Anti-ultraviolet polyester fine-denier ATY (air-jet texturing yarn) fiber

InactiveCN102766985AWith UV protection functionFilament/thread formingMonocomponent polyesters artificial filamentPolyesterYarn

The invention relates to a polyester fine-denier ATY (air-jet texturing yarn) fiber. The polyester fine-denier ATY fiber is made by steps of using polyester chips and additives as raw materials, preparing a PDY (partially drawn yarn) fine-denier filament by a process route of a screw extruder, a pre-filter, a static mixer, a metering pump, a spinning component, trickling, side blowing, oiling, a passage, a first fiber guide roll, a second fiber guide roll, a third fiber guide roll and winding, and using an air jet nozzle for air jet to prepare the ATY fiber. A polyester melt structure is modified by means of metal salt catalysts to prepare the fine-denier ATY fiber with an anti-ultraviolet function.

Owner:WUJIANG YATAI CHEM TEXTILE

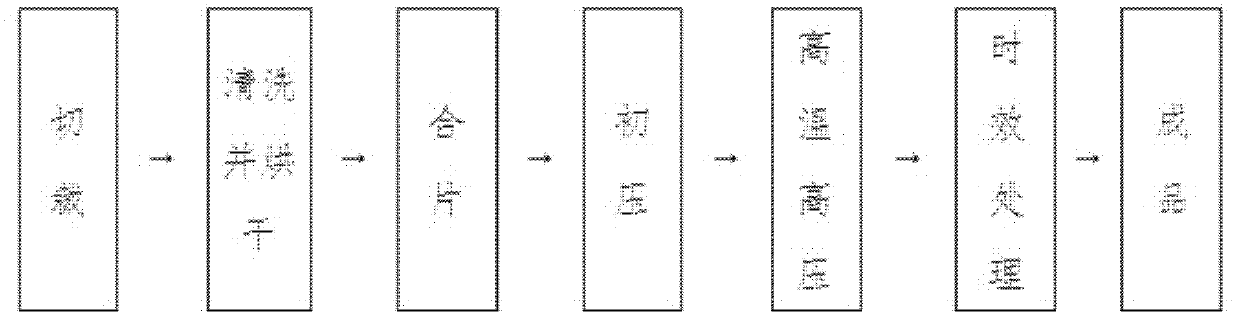

Bulletproof and smash-proof composite glass and manufacturing method thereof

ActiveCN103373024AResist shootingShock resistanceSynthetic resin layered productsLaminationPolyvinyl butyralInter layer

The invention relates to a bulletproof and smash-proof composite glass. High-quality float glass with low iron content and high flexibility is used as an original film; an imported high-quality polyvinyl butyral (PVB) anti-tearing rubber sheet (Dupont and Solutia) is used as a middle layer; by a series of processing technologies of cleaning, preliminary pressing, high-temperature and high-pressure operation, aging treatment and the like, external bullets can be resisted, and impact of external violence such as stones and hammers can be effectively resisted.

Owner:HENGSHUI JINGMEI GLASS PROD CO LTD

Antibacterial shrink-proof ultravioresistant finishing method for polyester/cotton fabric

InactiveCN103774430AImprove bindingImprove waterproof performanceLiquid/gas/vapor removalVegetal fibresPolyesterAcetic acid

The invention provides an antibacterial shrink-proof ultravioresistant finishing method for a polyester / cotton fabric. The antibacterial shrink-proof ultravioresistant finishing method comprises the following steps: performing padding, predrying and baking treatment on the polyester / cotton fabric by use of a finishing bath fluid; then performing padding, predrying and baking treatment on the polyester / cotton fabric by use of a 20-30g / L nano ultravioresistant finishing agent, wherein the finishing bath fluid consists of a finishing agent, a catalyst, a softener, a penetrating agent and a pH regulator; the finishing agent consists of 30-50g / L teflon CO and 10-20g / L etherified resin; the catalyst is 6-15g / L magnesium chloride or iron chloride; the softener is 11-30g / L low-xanthochromia amido-modified organosilicon; the penetrating agent is 2g / L natrium alkylsulfate; the pH regulator is 0.5-5g / L acetic acid. The low-xanthochromia amido-modified organosilicon and natrium alkylsulfate are added into the finishing bath fluid, so that the combination property of the fabric and teflon CO is improved.

Owner:JIANGSU YUHAO TEXTILE

Glass and making method thereof

The invention relates to a glass which comprises the following components in parts by weight: 1-10 parts of silicon dioxide, 1-2 parts of aluminium oxide, 0.2-0.8 part of sodium hydroxide, 1-2 parts of bismuth oxide, 3-5 parts of ethyl orthosilicate and 3-7 parts of hydroxybenzophenone. The making method of the glass comprises the following steps of: 1, mixing the silicon dioxide, the aluminium oxide, the sodium hydroxide, the bismuth oxide and the hydroxybenzophenone; 2, smelting the mixture obtained in the step 1 in a smelting furnace at the pressure of 100-200Mpa and the temperature of 500-1000 DEG C for 1-2 hours, and then adding 3-5 parts by weight of the ethyl orthosilicate and 3-7 parts by weight of the hydroxybenzophenone; 3, pouring glass water obtained in the step 2 into a mould, naturally annealing to normal temperature, and opening the mould and demoulding to obtain the glass. Due to addition of hydroxybenzophenone serving as an additive, the glass made by using the method has an ultraviolet resistant function, thereby protecting the health of human bodies.

Owner:刘岩玉

Antifouling paint

InactiveCN102746788ANot easy to solidifyLong storage timeAntifouling/underwater paintsPaints with biocidesAcetic acidPolyol

The invention discloses an antifouling paint, which comprises the following components: 90-150 parts of polyols, 8-16 parts of organic silicone resin, 11-20 parts of a crosslinking agent, 2-9 parts of glacial acetic acid, 10-20 parts of methyl ethyl ketone, 15-35 parts of anti-ultraviolet organic silicone oil, 50-90 parts of copper oxide, and the balance a solvent as well as a filling material. The antifouling paint disclosed in the invention has the advantages of difficult solidification, long preservation time, as well as good antifouling performance, and has an anti-ultraviolet function.

Owner:南通永源服饰有限公司

Polymer antibacterial and anticorrosive anti-fouling coating

InactiveCN107177251AWon't releaseStrong water resistanceAntifouling/underwater paintsPaints with biocidesUltravioletAntimicrobial peptides

The invention discloses a polymer antibacterial and anticorrosive anti-fouling coating and belongs to the technical field of building materials. The polymer antibacterial and anticorrosive anti-fouling coating is prepared from the following components in parts by weight: 18 to 29 parts of titanium dioxide, 15 to 30 parts of acrylate copolymer emulsion, 5 to 10 parts of polyethylene wax emulsion, 16 to 28 parts of deionized water, 10 to 20 parts of antimicrobial peptides-inorganic metal ion complex, 3 to 6 parts of asbestos, 3 to 5 parts of dispersing agent, 2 to 4 parts of defoaming agent, 90 to 150 parts of polyhydric alcohols, 8 to 16 parts of organosilicon resin, 11 to 20 parts of cross-linking agent, 2 to 9 parts of glacial acetic acid, 10 to 20 parts of methyl ethyl ketone, 15 to 35 parts of anti-ultraviolet agent, 50 to 90 parts of copper oxide and the balance of solvent and filler. The polymer antibacterial and anticorrosive anti-fouling coating disclosed by the invention has the beneficial effects of low possibility of solidification, long preservation time, good anti-fouling property, ultraviolet resisting function, higher adhesion of the coating and radiating fins, better water resistance, higher corrosion resistance and facilitation for environmental protection.

Owner:李壮

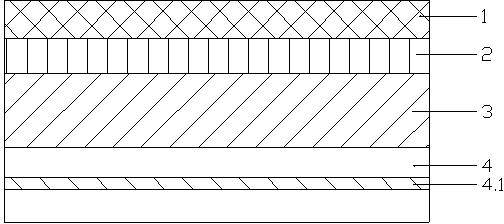

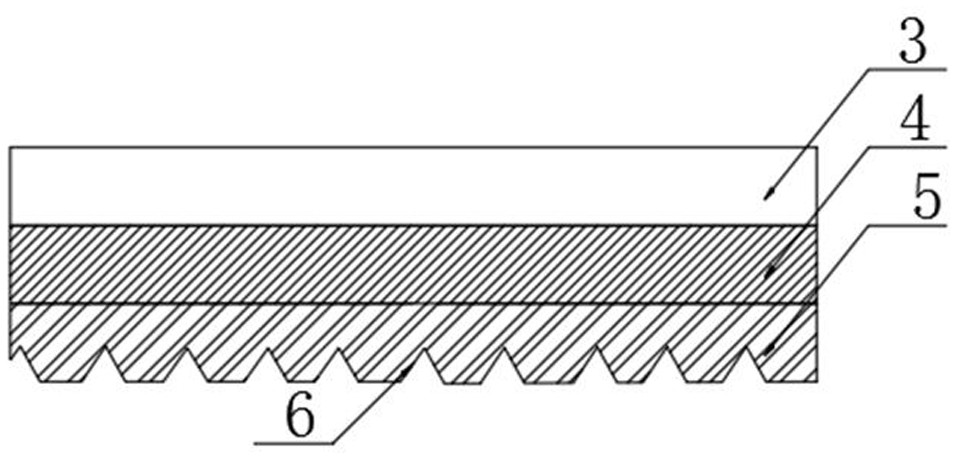

Artificial leather with ultraviolet resistance, colorful effect and flash effect

InactiveCN104342988AWith UV protection functionRich textureTextile decorationMetal layered productsSurface layerUltraviolet

The invention relates to an artificial leather with ultraviolet resistance, colorful effect and flash effect. The artificial leather comprises a surface layer (3) and a base layer (4) which are bonded to each other, a silver colloid coating (4.1) with an ultraviolet resistance function is embedded in the base layer (4), a pearl essence layer (2) is bonded to the surface layer (3), a transparent film (1) is bonded to the pearl essence layer (2), the base layer (4) is made of a fabric, the fabric comprises a netted layer, the netted layer is provided with a plurality of laser reflectors, the laser reflectors are rhombic, and the laser reflectors are arranged in a rhombic array manner with one of the rhombic laser reflectors as a base. The artificial leather has an ultraviolet resistance function. The fabric adopted in the invention has the advantages of abundant texture, layered sensation and flash effect.

Owner:JIANGYIN CHUANGJIA ELECTRICAL APPLIANCE

ES fiber containing olive and preparation method thereof

InactiveCN112410906AImprove processing stabilityImprove distributionMelt spinning methodsConjugated synthetic polymer artificial filamentsBiotechnologyFiber

The invention provides ES fiber containing olive and a preparation method of the ES fiber. The preparation method comprises the following steps: preparing an olive extracting solution, preparing molecular nest particles, preparing the molecular nest particles containing an olive extract, preparing a skin layer material, preparing a core layer material, spinning and post-treating. The ES fiber containing the olive has the beneficial effects that the antibacterial rate of the ES fiber containing the olive to staphylococcus aureus is greater than or equal to 99.3%, the antibacterial rate of the ES fiber containing the olive to escherichia coli is greater than or equal to 96.8%, the antibacterial rate of the ES fiber containing the olive to candida albicans is greater than or equal to 95.2%; after 1.2*10<-2> w / in2 ultraviolet irradiation for 50 hours, the physical properties of the fiber can still be maintained at 96.1% or above; and the modulus of the fiber is 163-170 N / tex.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

Linden-containing polyamide fiber and preparation method thereof

ActiveCN112127001AReduce lossesGood compatibilityTextile/flexible product manufactureArtifical filament manufacturePolymer scienceCompatibilization

The invention provides a linden-containing polyamide fiber and a preparation method thereof. The preparation method comprises the following steps of preparing a molecular nest, preparing a linden-extract-containing molecular nest, preparing functional master batch, spinning and post-treating. The preparation of the molecular nest comprises the following steps of preparing a precursor, volatilizinga solvent, forming the molecular nest and modifying; and the preparation of the linden-extract-containing molecular nest comprises the following steps of preparing a linden extracting solution, preparing a molecular nest dispersion solution and loading. According to the linden-containing polyamide fiber, the compatibility of the active ingredients of the linden extract and the polyamide fiber isgood, the loss of the active ingredients in the preparation process is low, and the modification effect is good; and the active ingredients of the linden extract can be stably distributed in the polyamide fiber, and the immobilization degree is good.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Colourless transparent glass possessing ultraviolet radiation preventing function

A colorless transparent glass with the function of shielding ultraviolet radiation features use of SiO2 as main raw material, CeO2 as ultraviolet shielding material (0.3-0.6 wt.%), and ErO as decoloring agent (0.02-0.07 wt.%). Its advantages are low cost and high radiation shielding power.

Owner:上海高雅玻璃有限公司

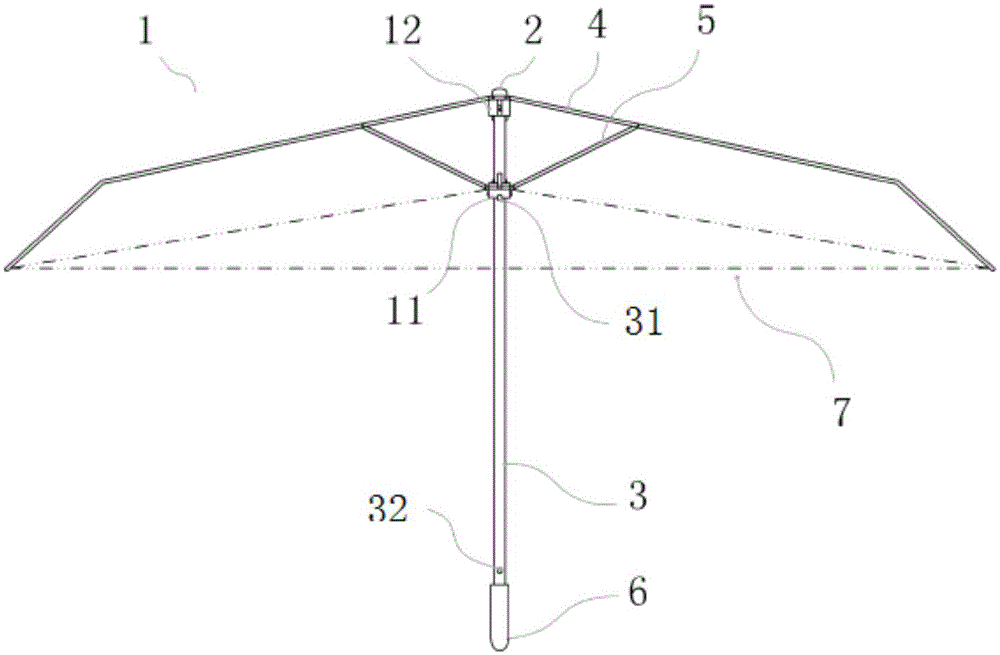

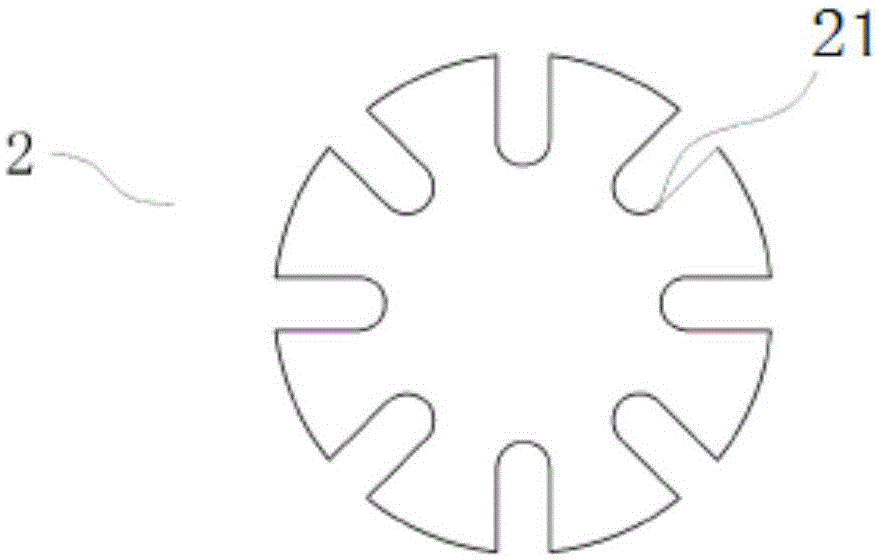

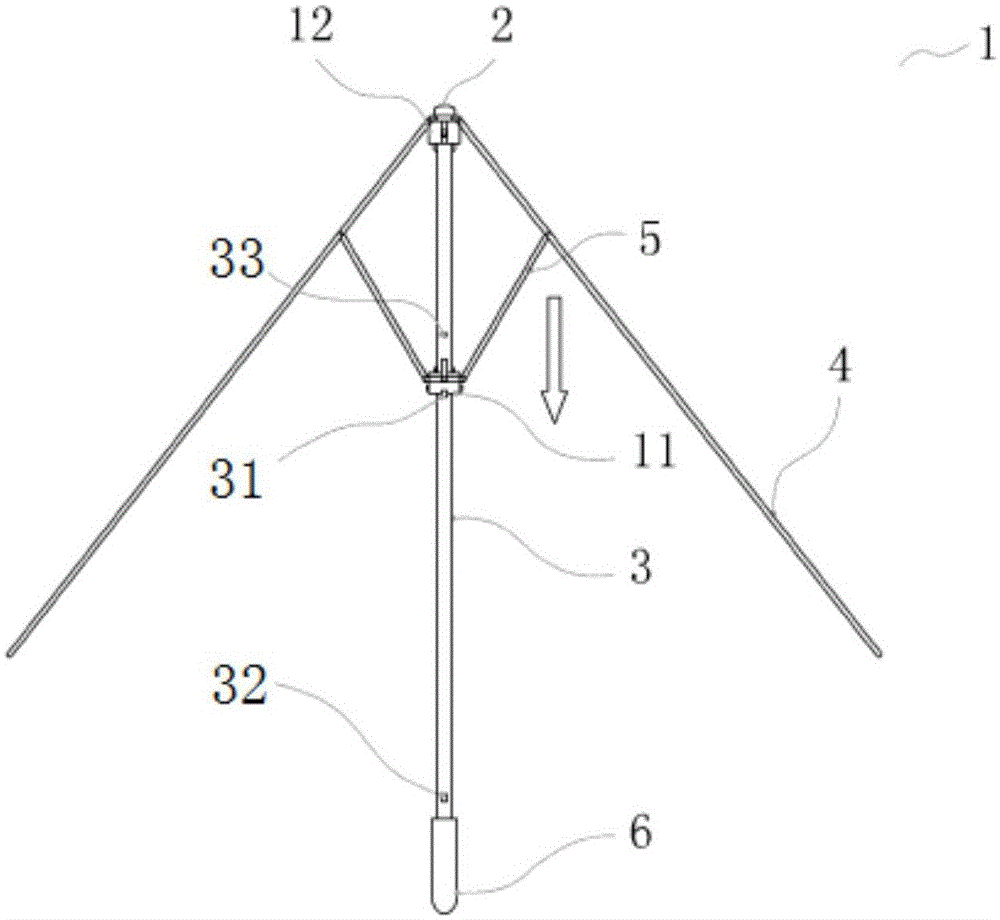

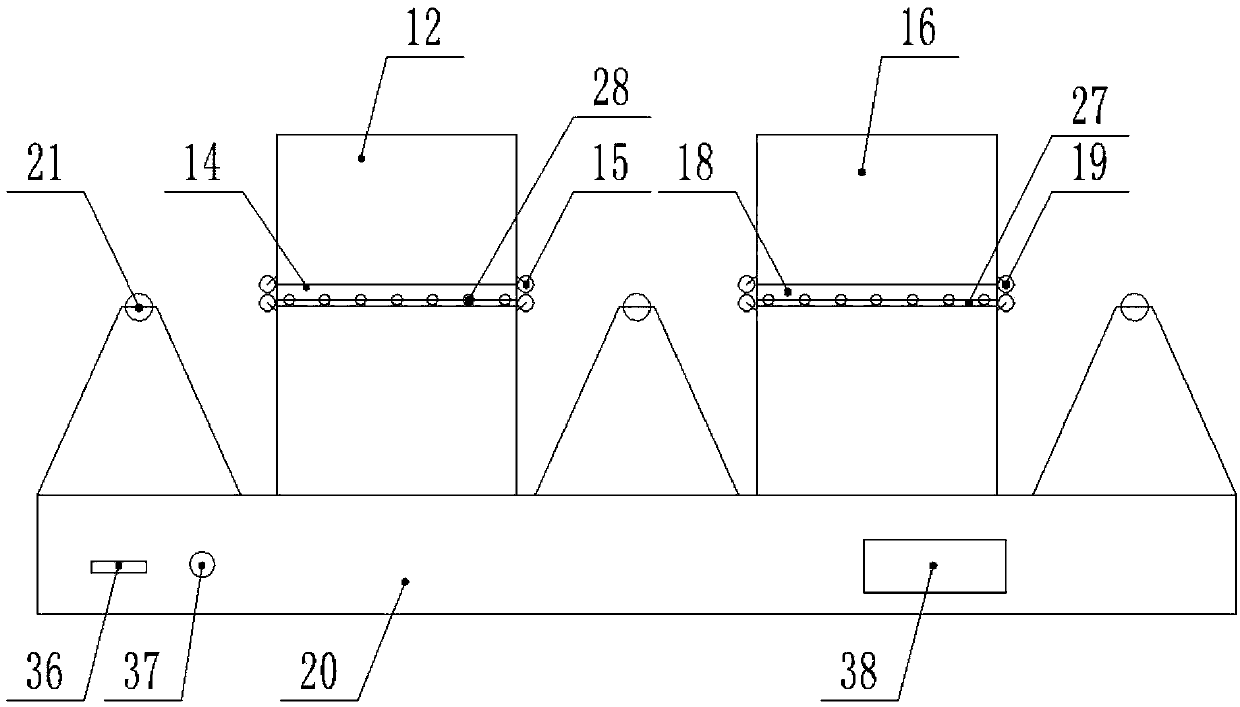

Umbrella equipment

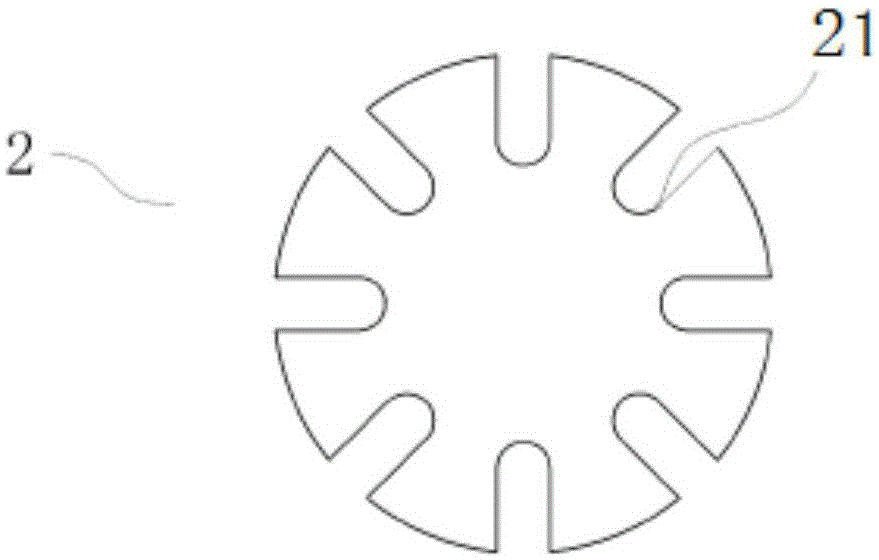

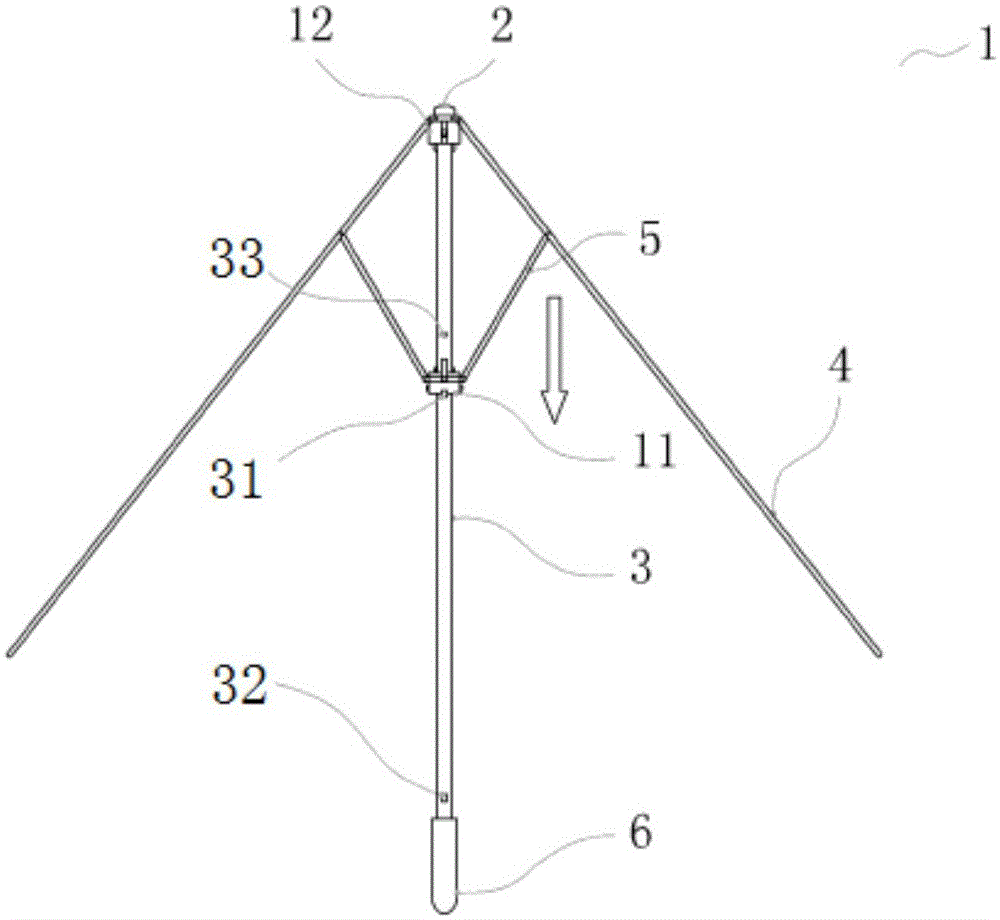

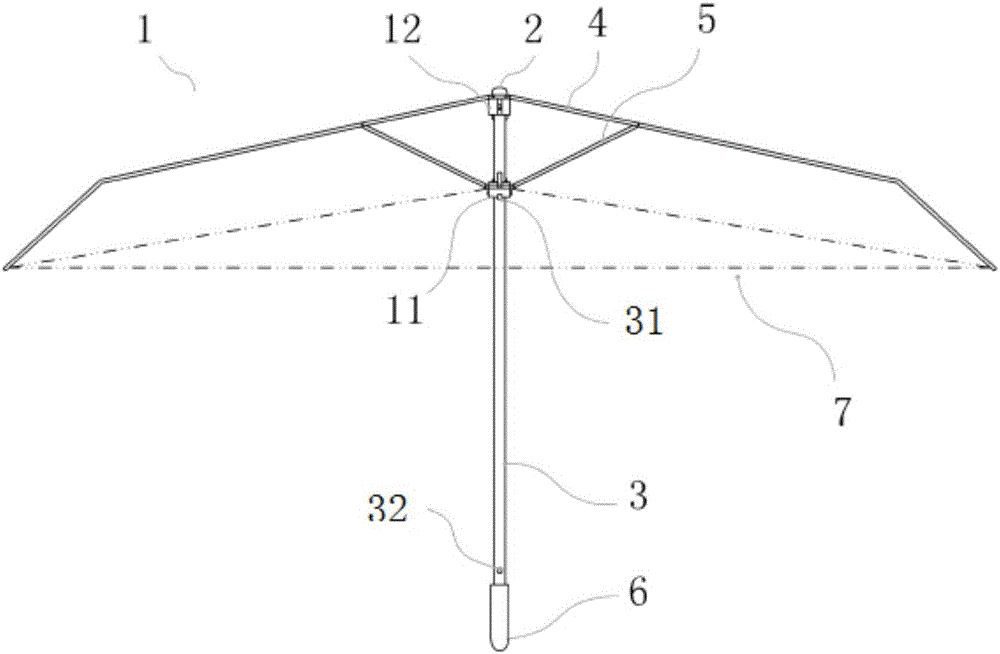

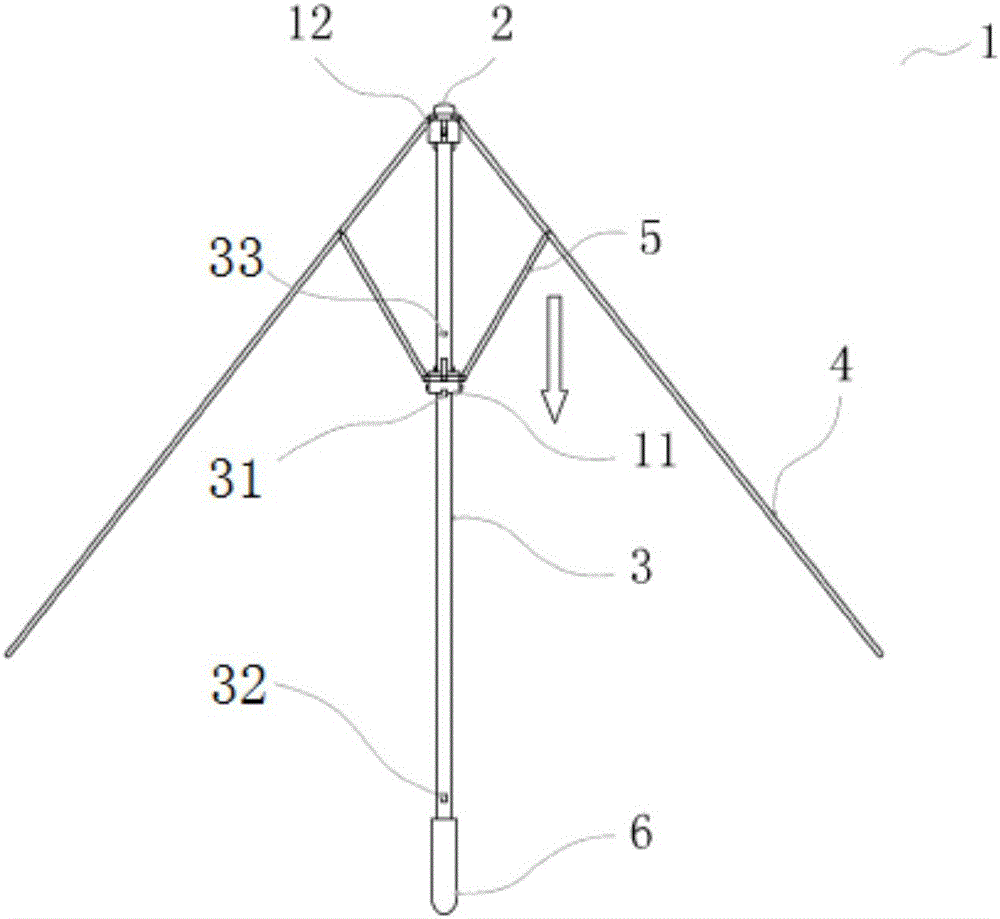

InactiveCN105011494AGood antibacterial effectExtend your lifeWalking sticksUmbrellasEngineeringFiber

The invention provides umbrella equipment comprising an umbrella rod, an umbrella cap, a first slide block, a second slide block, an umbrella cloth, ribs and stretchers, wherein the external surface of the umbrella cloth is coated with coating made from a mixture of nano-silver and fluorescent powder. The umbrella rod is made from carbon fiber. The ribs and the stretchers are respectively made from glass fibre. A bracket is movably connected to the umbrella cap. Compared with the prior art, theumbrella equipment is UV resistant and has a function of a selfie rod.

Owner:赖玉春

Polyamide fiber containing olive and preparation method of polyamide fiber

InactiveCN112251835AGive full play to the modification effectImprove distributionArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceCandida albicans

The invention provides polyamide fiber containing olive and a preparation method of the polyamide fiber. The preparation method comprises the following steps: preparation of an olive extracting solution, preparation of porous nanoparticles, preparation of porous nanoparticles containing an olive extract and preparation of functional master batch. The preparation method disclosed by the invention has the beneficial effects that the prepared porous nanoparticles containing the olive extract are good in distribution in the fiber, the antibacterial rate of the polyamide fiber to staphylococcus aureus is greater than or equal to 99.8%, the antibacterial rate of the polyamide fiber to escherichia coli is greater than or equal to 95.4%, and the antibacterial rate of the polyamide fiber to candidaalbicans is greater than or equal to 92.7%; the breaking strength of the polyamide fiber is greater than or equal to 6.2 cN / dtex, the elongation at break of the polyamide fiber is greater than or equal to 39%, and the yellowing resistance class of the polyamide fiber is 5.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

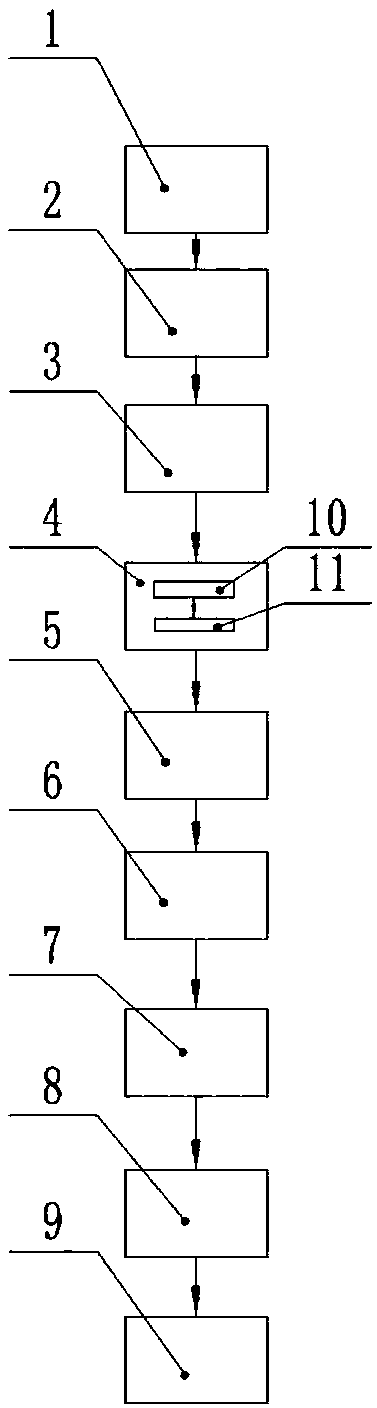

Curtain fabric production and processing technology

InactiveCN107802170AWith heat insulationWaterproofLamination ancillary operationsLaminationCold airWork in process

The invention discloses a curtain fabric production and processing technology. The curtain fabric production and processing technology comprises the following steps of raw spinning silk selection, looming alignment, grey cloth weaving, low-temperature cold-batch finishing, dyeing and finishing, drying and setting, heat-insulated layer compounding, ultraviolet-proof layer compounding and water-proof layer compounding. The technology is characterized in that the step of raw spinning silk selection is completed through a two-for-one twister; the steps of looming alignment and grey cloth weaving are completed through a loom; the step of low-temperature cold-batch finishing comprises the substeps of low-temperature processing and drying, a low-temperature unit is composed of a low-temperature processing box, a cold air vent pipe, a cooling through groove, cooling through groove rollers and a cooling device, and a drying unit is composed of a low-temperature processing box, a hot air vent pipe, a drying through groove, drying through groove rollers and a heating device; afterwards, dyeing is conducted, then drying and setting are conducted, and finally, a heat-insulated layer, an ultraviolet-proof layer and a water-proof layer are compounded on a semi-finished fabric through a compound device. The curtain fabric production and processing technology has the advantages that the structure is simple, and the practicability is high.

Owner:张志海

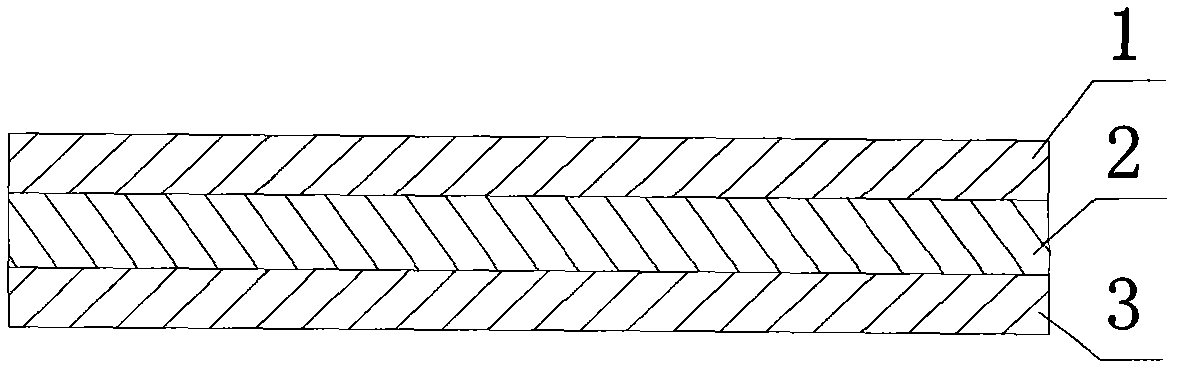

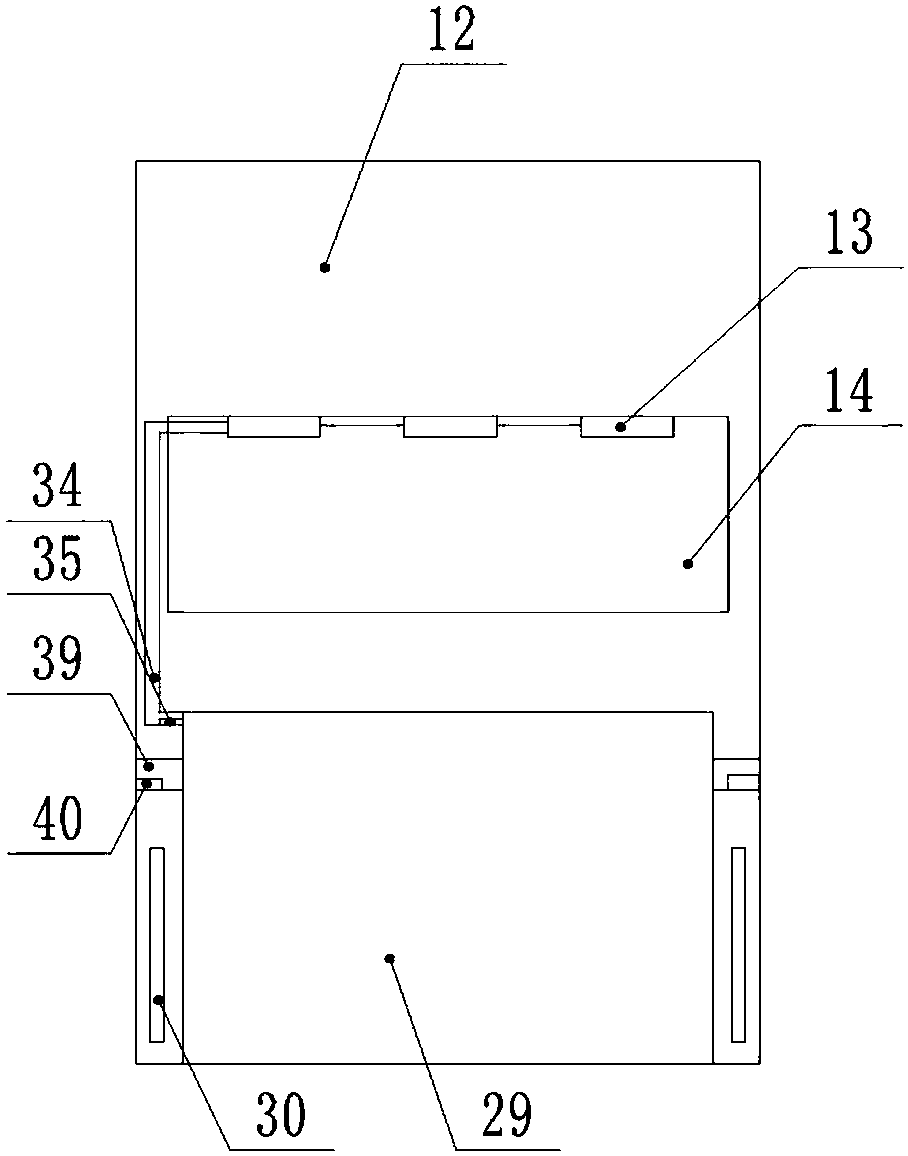

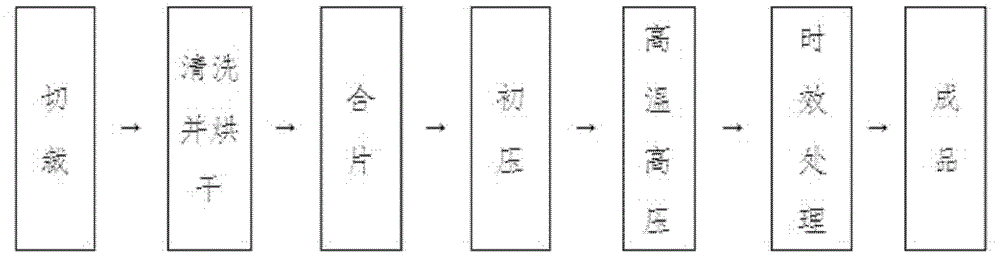

Production method of laminated tempered glass

InactiveCN108909093AWith UV protection functionHigh strengthNon-macromolecular adhesive additivesSynthetic resin layered productsEpoxyPolyvinyl alcohol

The invention discloses a production method of laminated tempered glass. The production method comprises the following steps: preparing specially-made PVB rubber, wherein the specially-made PVB rubbercomprises the following raw materials in parts by weight: 80-110 parts of polyvinyl butyral, 8-12 parts of polyvinyl formal, 2-5 parts of metallic silver powder, 4-6 parts of polyvinylpyrrolidone, 2-5 parts of tetraepoxypropyl methylene diphenylamine, 3-5 parts of hydroxyl-terminated nitrile rubber epoxy prepolymer, 3-6 parts of polyethylene naphthalate prepolymer, 1-3 parts of polyvinyl alcohol,2-5 parts of plasticizer, 3-8 parts of antioxidant and 2-5 parts of ultraviolet light absorber; and slightly hammering the top surface of tempered glass on an upper layer by using a small wooden hammer, uniformly hammering the tempered glass, and continuously detecting the thickness of the laminated tempered glass by using a thickness detector. The production method is artful in design, reasonable, good in ultraviolet prevention effect, high in strength and suitable for popularization.

Owner:HUAIAN RUNCHENG BUILDING ENERGY SAVING MATERIAL CO LTD

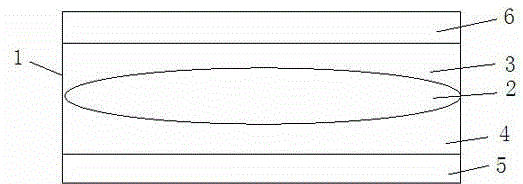

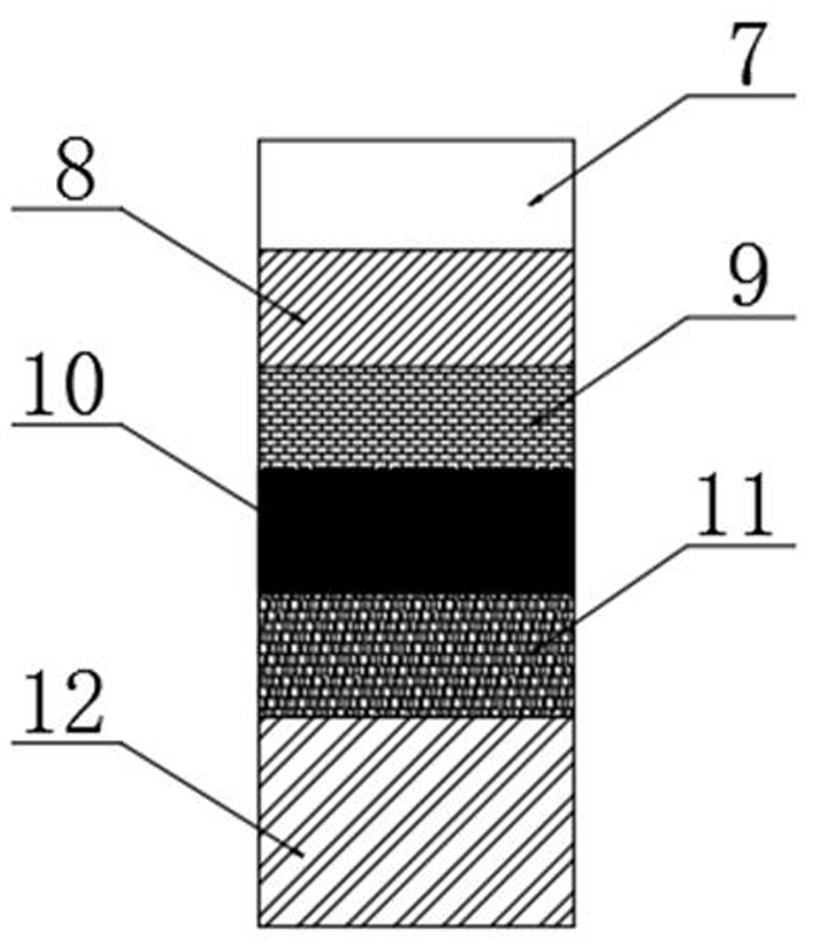

Anti-radiation anti-ultraviolet spectacle lens with high hardness

InactiveCN105700188AReduce weightWith radiation protection functionOptical partsOptical elementsSurface layerUltraviolet

The invention discloses an anti-radiation anti-ultraviolet spectacle lens with high hardness. The anti-radiation anti-ultraviolet spectacle lens comprises a lens body and is characterized by further comprising an ultraviolet ray absorption layer and an anti-radiation film, wherein the lens body is of a layered structure which comprises a middle layer, an upper surface layer and a lower surface layer; the middle layer is made of a glass material; the upper surface layer and the lower surface layer are made of a resin layer; a layer of the anti-radiation film is bonded with the outer side of the upper surface layer; a layer of the ultraviolet ray absorption layer is bonded with the outer side of the lower surface layer; the thickness of the lens body is 0.3 to 0.4 mm; and the thickness of the anti-radiation film is 0.002 mm. The anti-radiation anti-ultraviolet spectacle lens with high hardness provided by the invention has the advantages of simple structure, convenience in usage, high hardness, good wear resistance, more diversified functions and longer service life.

Owner:DANYANG HUAFENGXIANG OPTICS GLASSES CO LTD

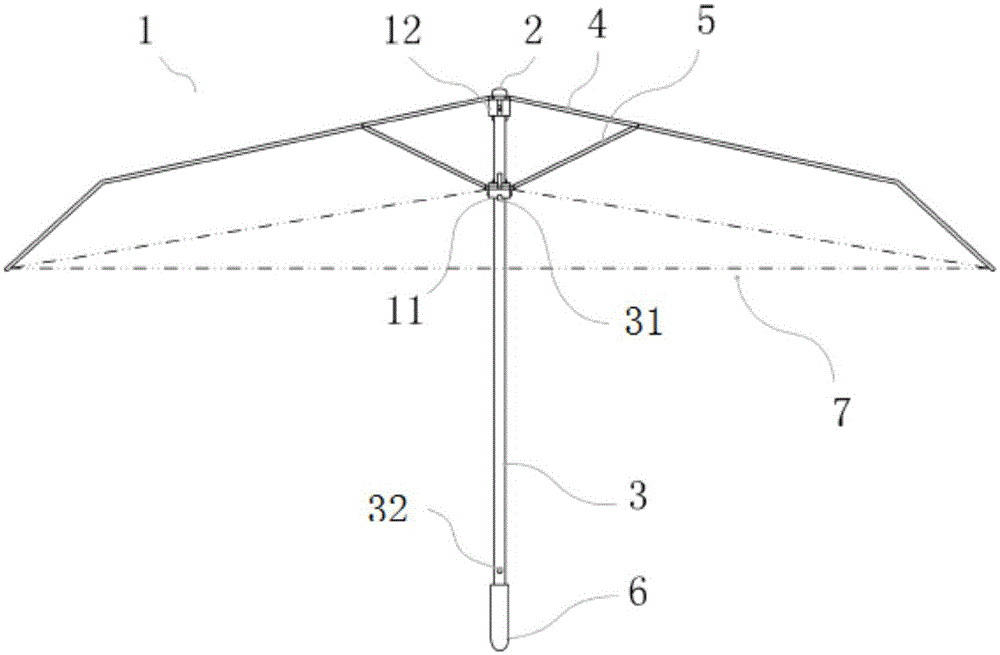

Umbrella equipment

InactiveCN105124881AWith UV protection functionImprove antibacterial propertiesWalking sticksFiberWater storage

The invention provides umbrella equipment, which comprises an umbrella rod, an umbrella cap, a first slide block, a second slide block, umbrella cloth, a long rib and supporting ribs, wherein a coating layer coats the outer surface of the umbrella cloth; a material of the coating layer is a mixture of nanometer silver and fluorescent powder; the umbrella rod is made of carbon fiber materials; the long rib and the support ribs are made of glass fiber materials; one end of an umbrella handle is provided with a groove; and the groove is formed through extending in a direction from one end of the umbrella handle to the umbrella cap along the umbrella rod. A fixing ring is also arranged on the umbrella rod in a sleeving way; the fixing ring is connected with a groove cover through a connecting part; and the groove can be sealed through covering the groove cover on the umbrella rod. Compared with the prior art, the umbrella equipment provided by the invention has the ultraviolet-ray-resistant function, the anti-bacterium function and the water storage function.

Owner:蔡桂钧

Making method of light-shading curtain cloth

InactiveCN108283427AImproves UV protectionWith UV protection functionCurtainsDraperiesUltravioletUv absorber

The invention discloses a making method of light-shading curtain cloth. The making method comprises the following steps: S1, selecting materials: selecting linen yarns as a weaving raw material; S2, implementing weaving: splitting the linen yarns, making warp yarns of the split linen yarns vertically spaced and staggered so that weft yarns can run through the warp yarns conveniently in a later period, and implementing weaving via a loom, so that gray cloth is obtained; and S3, implementing ultraviolet-protecting treatment: placing the woven and shaped gray cloth in a soaking jar containing anultraviolet absorbent and a reflecting agent, and rapidly implementing extruding-rolling via two rollers through a one-soaking and one-rolling treatment technique, wherein in a soaking-rolling process, a sewing speed of the gray cloth is 24-30m / min; implementing the ultraviolet-protecting treatment; and drying the gray cloth, which is taken out, in a drying device. In comparison with other extraction techniques, by soaking the gray cloth via the ultraviolet absorbent and the reflecting agent and by plating the soaked gray cloth with a metal film, the curtain cloth undergoes good ultraviolet-protecting treatment; and by conducting formaldehyde removal treatment in various processes, the shaped light-shading curtain cloth is free from toxins and harm.

Owner:海宁市金雅特纺织有限公司

Preparation method of anti-ultraviolet hydrophobic fabric

The invention discloses a preparation method of an anti-ultraviolet hydrophobic fabric. The preparation method comprises the steps of preparing nano ZnO loaded base cloth and performing hydrophobic treatment on the nano ZnO loaded base cloth. By adopting the preparation method disclosed by the invention to prepare the anti-ultraviolet hydrophobic fabric, materials are saved, and the production efficiency is improved.

Owner:SHANGHAI YANGFAN INDAL CO LTD

Umbrella equipment

InactiveCN105011493AWith UV protection functionImprove antibacterial propertiesWalking sticksUmbrellasGlass fiberFiber

The invention provides umbrella equipment comprising an umbrella rod, an umbrella cap, a first slide block, a second slide block, an umbrella cloth, ribs and stretchers, wherein the external surface of the umbrella cloth is coated with coating made from a mixture of nano-silver and fluorescent powder. The umbrella rod is made from carbon fiber. The ribs and the stretchers are respectively made from glass fibre. Compared with the prior art, the umbrella equipment is UV resistant, environmentally-friendly and energy-saving.

Owner:蔡桂钧

Bulletproof and anti-smashing composite glass and its manufacturing method

ActiveCN103373024BResist shootingShock resistanceSynthetic resin layered productsLaminationPliabilityHigh pressure

Owner:HENGSHUI JINGMEI GLASS PROD CO LTD

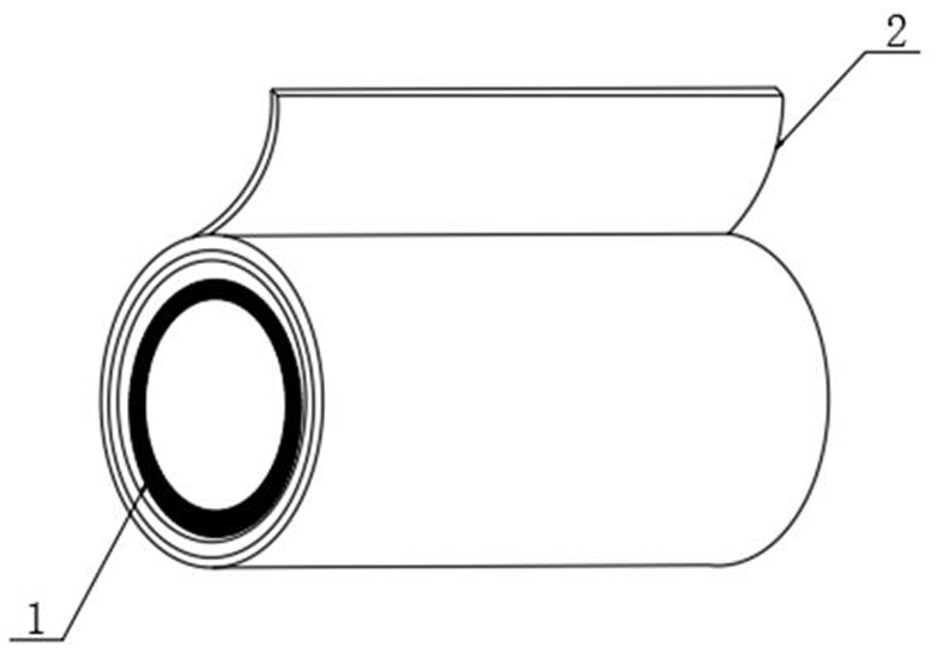

Polymer silica gel protective film

PendingCN114507485AImprove stabilityExtend the anti-static timeFilm/foil adhesivesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a polymer silica gel protective film, and particularly relates to the field of protective films, the polymer silica gel protective film comprises a roll core, and a PET protective film is arranged outside the roll core; the PET protective film is composed of a protective film body, a release film and oiled paper, the release film is arranged at the bottom of the protective film body, and the oiled paper is arranged outside the protective film body; the protective film body consists of a UV (ultraviolet) adhesive layer, a polymer layer, a PU (polyurethane) adhesive layer, a PET (polyethylene terephthalate) base material and an organic silicon pressure-sensitive adhesive layer, and the PU adhesive layer is arranged at the top of the PET base material. The surface of the PU adhesive is subjected to special macromolecule treatment, the effective period of macromolecules can reach 12 months or above, the antistatic effect of the PU protective film is greatly improved, the obtained macromolecule protective film is long in antistatic lasting time and stable in effect, the quality guarantee period can reach one year or above, the resistance value can reach 106-11 omega, and the service life of the macromolecule protective film is prolonged. And the antistatic effect cannot be transferred to the surface of an object to be protected to cause pollution.

Owner:湖南神舟中药饮片有限公司

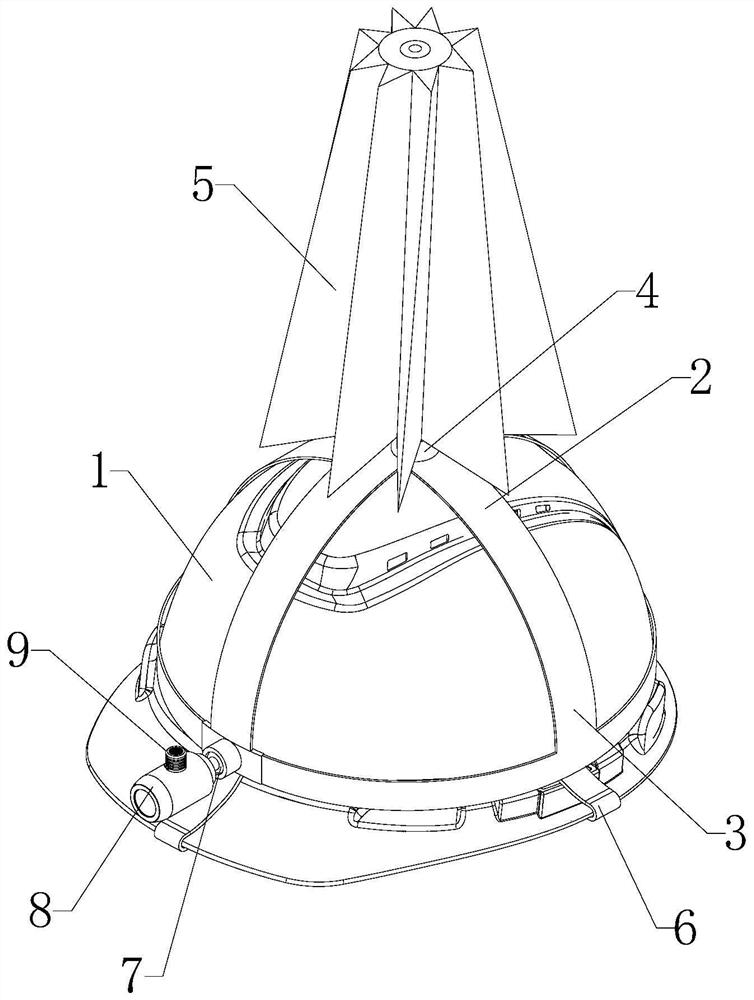

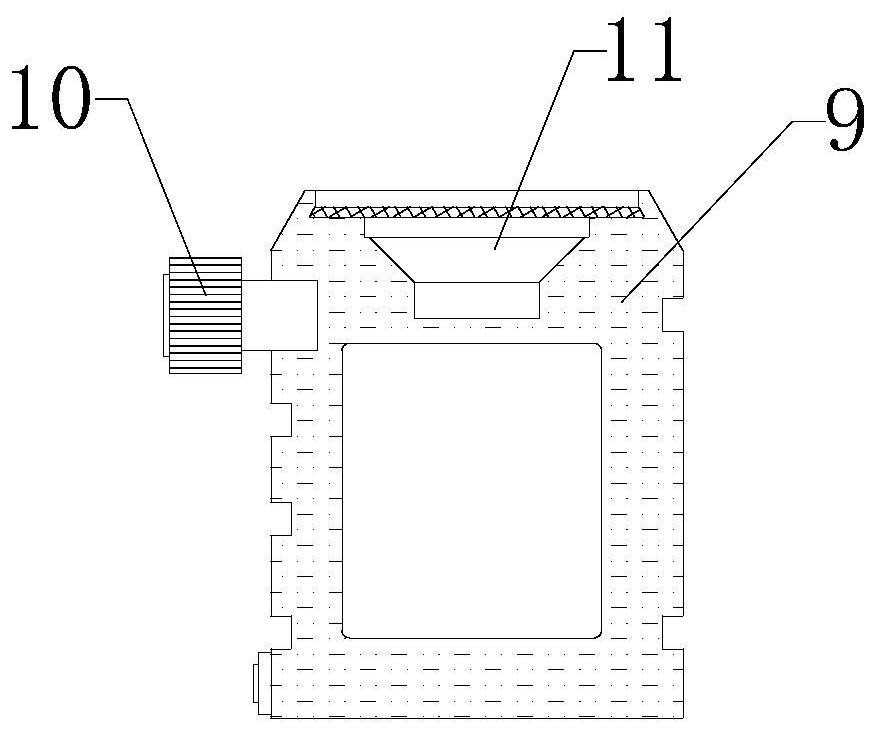

Safety helmet with auxiliary tool

InactiveCN113826980AAvoid getting wetWith UV protection functionHelmetsHelmet coversElectric field sensorStructural engineering

The invention relates to a safety helmet with the auxiliary tool; the helmet comprises a safety helmet body, the auxiliary tool is installed on the upper side of the safety helmet body, and the auxiliary tool comprises an installation limiting belt, a top connecting base, a folding protection umbrella, a limiting hook, a lamp body adjusting base, an illuminating lamp and a warning box. The top connecting base is installed in the middle of the base face of the installation limiting belt, the installation limiting belt is provided with the folding protection umbrella through the top connecting base, limiting hooks distributed in the circumferential direction are installed on the lower side of the installation limiting belt, and the lamp body adjusting base is installed in the middle of the lower side of the front face of the installation limiting belt. The illuminating lamp is installed at the end of the lamp body adjusting base, the warning box is installed in the middle of the upper side of the illuminating lamp, an electric field sensor is installed in the middle of the warning box, a buzzer alarm is installed on the upper side of the warning box, and the whole structure is simple, convenient to use and high in stability and practicability.

Owner:GUIZHOU POWER GRID CO LTD

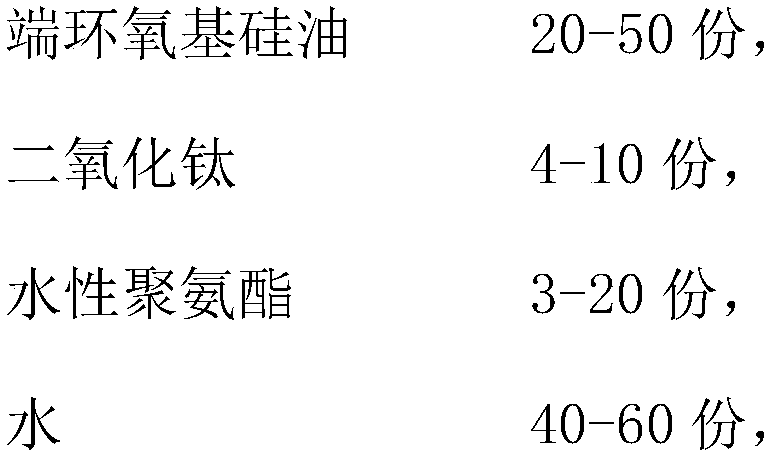

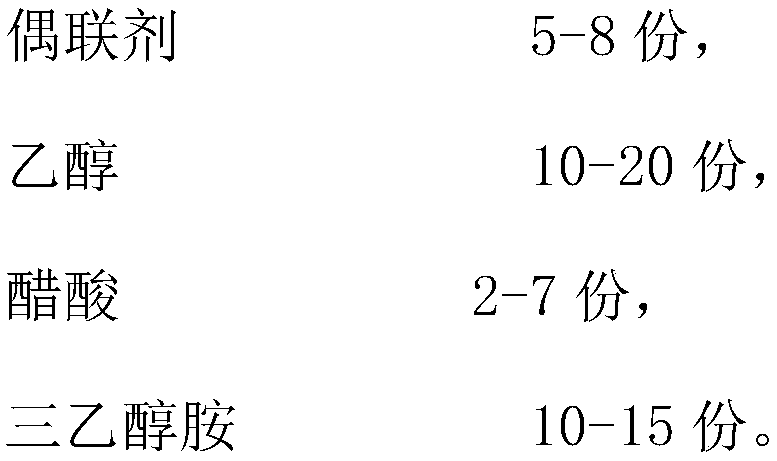

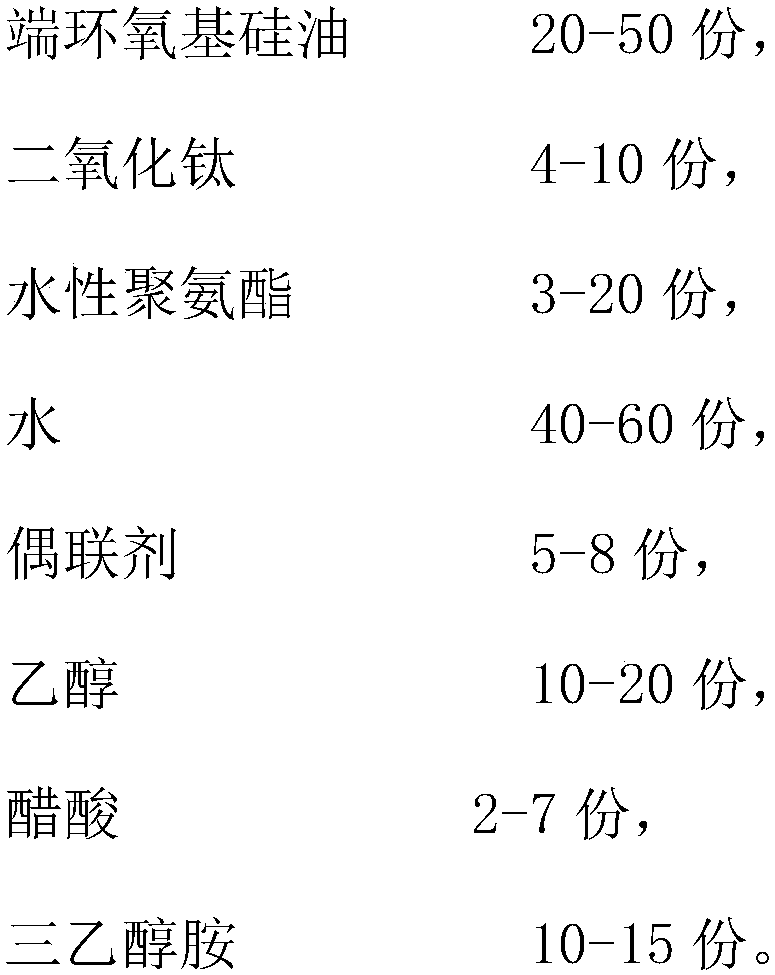

Anti-ultraviolet softening agent for wool fabric and preparation method of anti-ultraviolet softening agent

InactiveCN109183424AGood solvent resistanceImprove water resistanceLight resistant fibresGrip property fibresFiberEmulsion

The invention discloses an anti-ultraviolet softening agent for a wool fabric and a preparation method of the anti-ultraviolet softening agent. The anti-ultraviolet softening agent comprises the following steps: (1) preparing a titanium dioxide emulsion; (2) loading titanium dioxide; and (3) preparing a softening agent. A titanium dioxide loaded softening agent is adopted in the preparation method, and the surface of the fabric is covered with a layer of epoxy silicon oil modified waterborne polyamine film coupled with titanium dioxide, so that air gaps among parts of fibers are filled, the surface friction coefficient is reduced, the softening performance of the fabric is further improved, meanwhile, the wool fabric is enabled to have an anti-ultraviolet function, the heat conductivity ofthe wool fabric is improved, the damage of sun radiation to the wool fabric is reduced, and the service life of the wool fabric is prolonged.

Owner:阜南华翔羊毛衫有限公司

Antibacterial, anti-wrinkle, and anti-ultraviolet finishing method for all polyester/cotton fabrics

InactiveCN103774430BImprove bindingImprove finishing efficiencyLiquid/gas/vapor removalVegetal fibresPolyesterAcetic acid

The invention provides an antibacterial shrink-proof ultravioresistant finishing method for a polyester / cotton fabric. The antibacterial shrink-proof ultravioresistant finishing method comprises the following steps: performing padding, predrying and baking treatment on the polyester / cotton fabric by use of a finishing bath fluid; then performing padding, predrying and baking treatment on the polyester / cotton fabric by use of a 20-30g / L nano ultravioresistant finishing agent, wherein the finishing bath fluid consists of a finishing agent, a catalyst, a softener, a penetrating agent and a pH regulator; the finishing agent consists of 30-50g / L teflon CO and 10-20g / L etherified resin; the catalyst is 6-15g / L magnesium chloride or iron chloride; the softener is 11-30g / L low-xanthochromia amido-modified organosilicon; the penetrating agent is 2g / L natrium alkylsulfate; the pH regulator is 0.5-5g / L acetic acid. The low-xanthochromia amido-modified organosilicon and natrium alkylsulfate are added into the finishing bath fluid, so that the combination property of the fabric and teflon CO is improved.

Owner:JIANGSU YUHAO TEXTILE

Manufacturing method of real silk scarf with ultraviolet-proof function

PendingCN112376298ARemove green and astringent tasteGood removal effectDyeing processWoven fabricsLavandulaMegasonic cleaning

The invention discloses a method for manufacturing a real silk scarf with an ultraviolet-proof function. The method comprises the following specific steps: step 1, organizing technicians by a technical production director to review scarf technical production parameters, asking for questions and answering, compiling a production process flow by the technicians, and performing technical disclosure to the technicians; step 2, weighing lavender flowers, impatiens balsamina petals and feltwort petals, putting the weighed lavender flowers, impatiens balsamina petals and feltwort petals into an ultrasonic cleaning machine, adding clear water and a sodium carbonate solution, carrying out ultrasonic cleaning, quickly blow-drying the cleaned lavender flowers, impatiens balsamina petals and feltwortpetals in warm air, removing dirt impurities on substrate surfaces, and soaking in a citric acid solution for 5-6 h. The manufacturing method of the real silk scarf with the ultraviolet-proof functionhas good economic benefits, is simple in step, convenient to operate, high in practicability and wide in application prospect, and is suitable for wide application and popularization.

Owner:义乌市大丰花边有限公司

Artificial leather with ultraviolet resistance, colorful effect and reasonable structure

InactiveCN104342954AWith UV protection functionReasonable structureSynthetic resin layered productsWoven fabricsSurface layerPolyamide

The invention relates to an artificial leather with ultraviolet resistance, colorful effect and reasonable structure. The artificial leather comprises a surface layer (3) and a base layer (4) which are bonded to each other, a silver colloid coating (4.1) with ultraviolet resistance is embedded in the base layer (4), a pearl essence layer (2) is bonded to the surface layer (3), a transparent film (1) is bonded to the pearl essence layer (2), the base layer (4) is made by using a fabric, the warps and the wefts of the fabric respectively adopt polyamide 6 fibers and tussah silk fibers, the diameter and the fineness of the polyamide 6 fibers are 9[mu]m and 398dtex respectively, the diameter and the fineness of the tussah silk fibers are 4[mu]m and 356dtex respectively, the warp density and the weft density of the fabric are 22.3 / cm and 20.2 / cm respectively, and the silver colloid coating is placed in the fabric. The artificial leather has an ultraviolet resistance function. The fabric adopted in the invention has a reasonable structure and good use performances.

Owner:WUXI HENGTONG LIGHT IND PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com