Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "The signal output is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

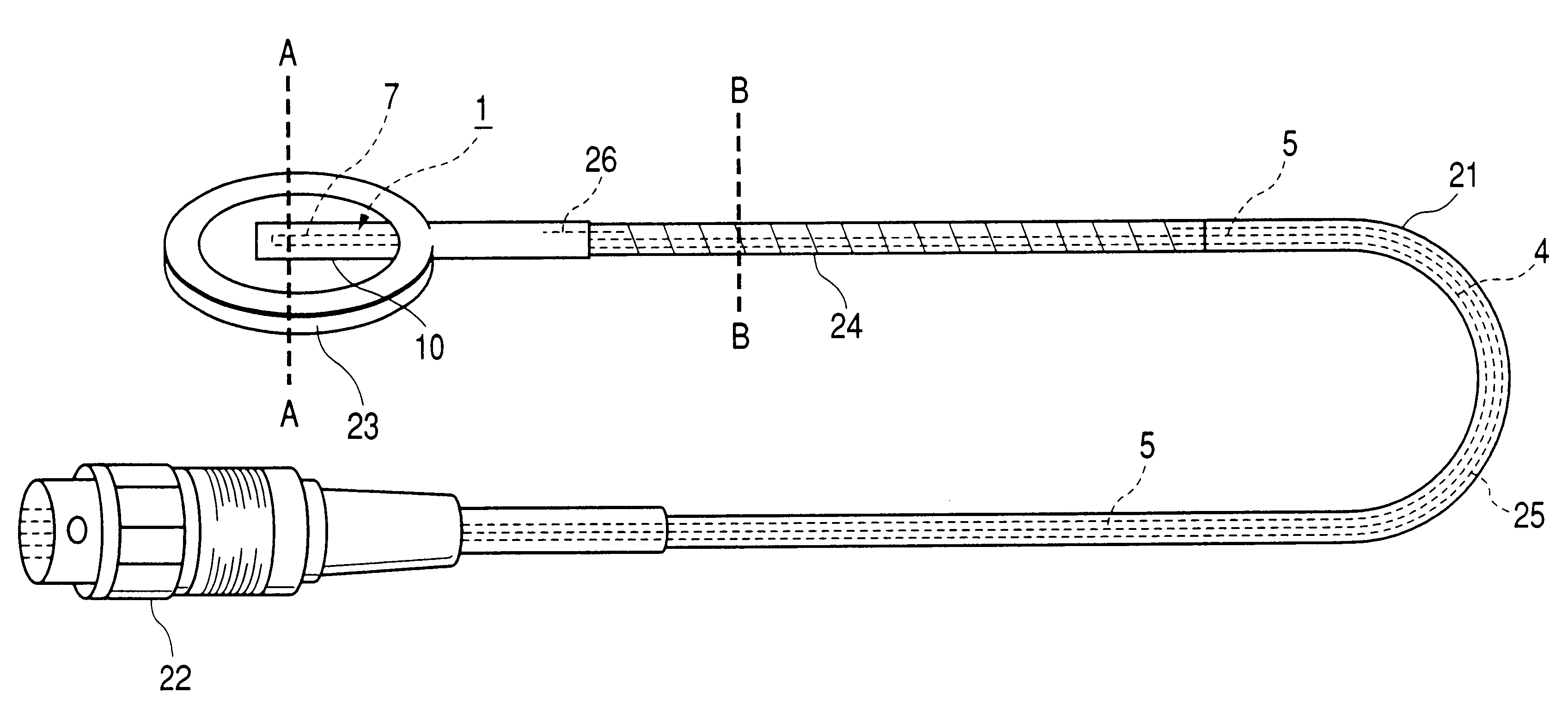

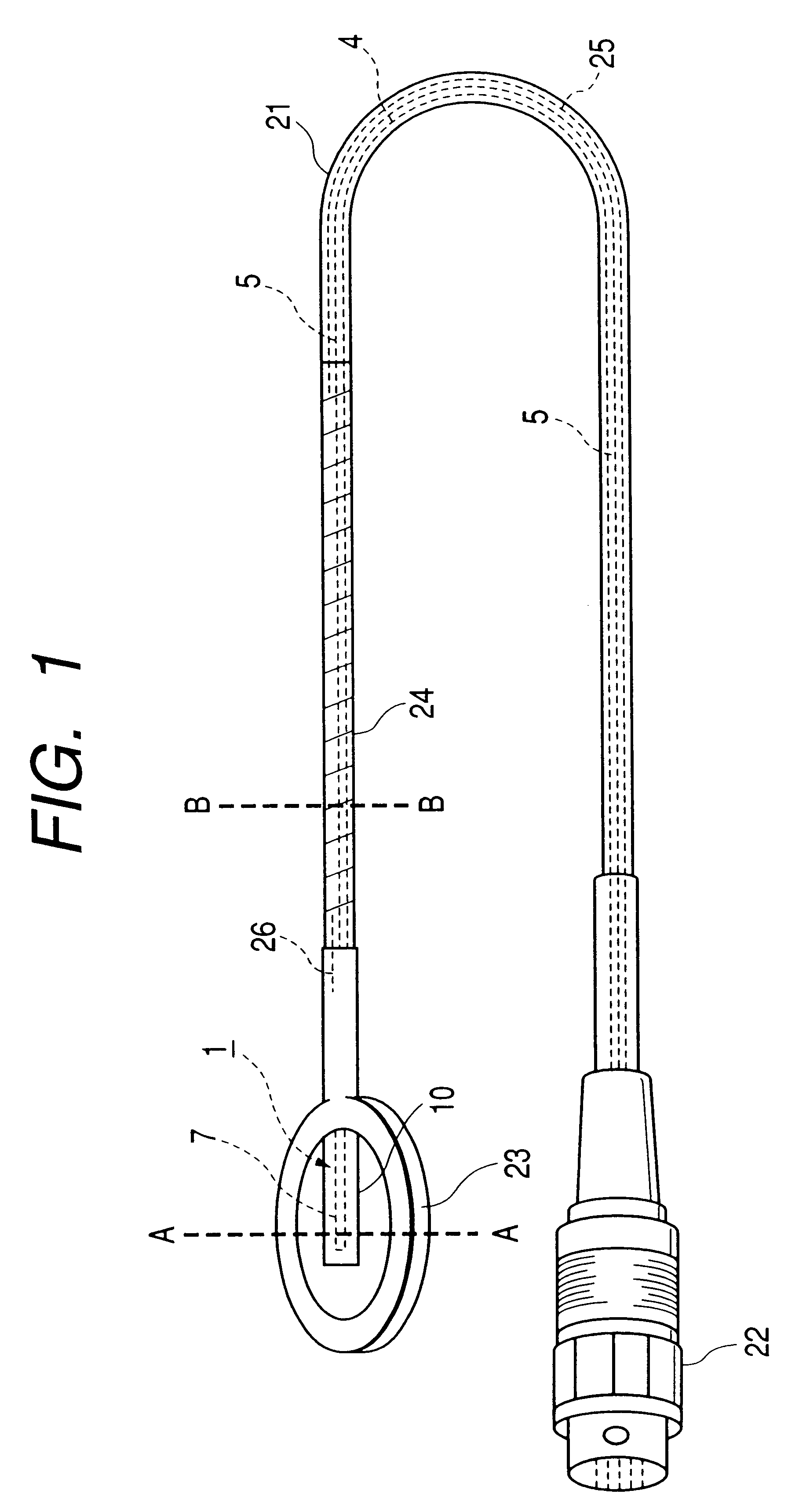

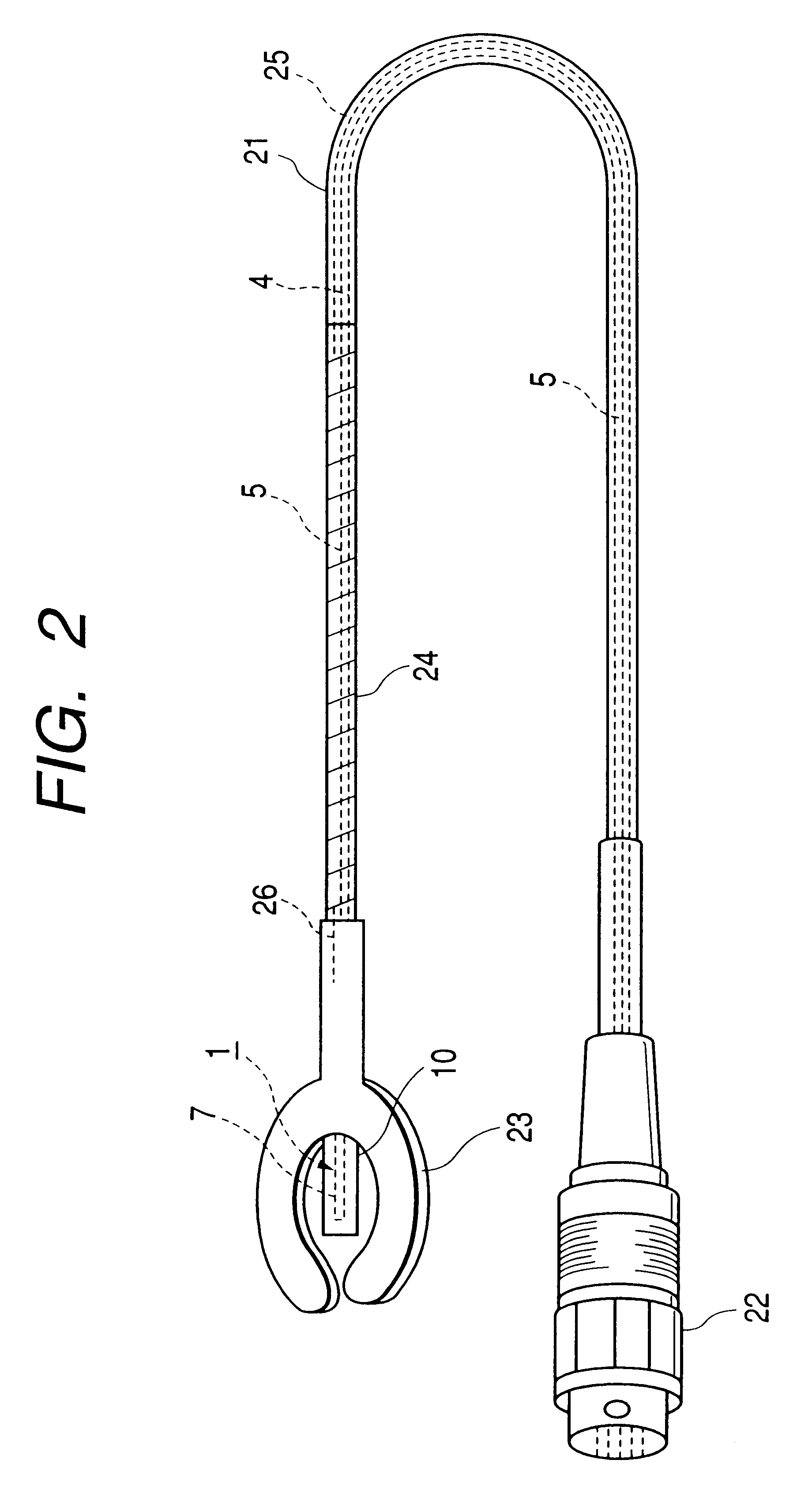

Biological sensor

InactiveUS6411834B1Measurement stabilityEasy to fixCatheterRespiratory organ evaluationBiological tissueEngineering

An annul protecting portion 23 having a thickness larger than the thickness of a sensor sensitive portion 1 is provided in such a manner as to surround the sensor sensitive portion 1, the sensor sensitive portion 1 together with the protecting portion 23 is placed between living tissues, so as to ensure that the gate portion 7 is not subjected to an external pressure by coming into contact with the living tissues. Further, outer peripheries of lead wires 4 on the sensor sensitive portion 1 side are covered with a plasticity material 24 woven into a tubular shape by a metal wire such as a stainless steel wire, and is grounded together with the metallic protecting portion, so as not to be subjected to induction noise. Further, the metal wire is bent to hold the sensor sensitive portion 1 at a suitable angle.

Owner:NIHON KOHDEN CORP

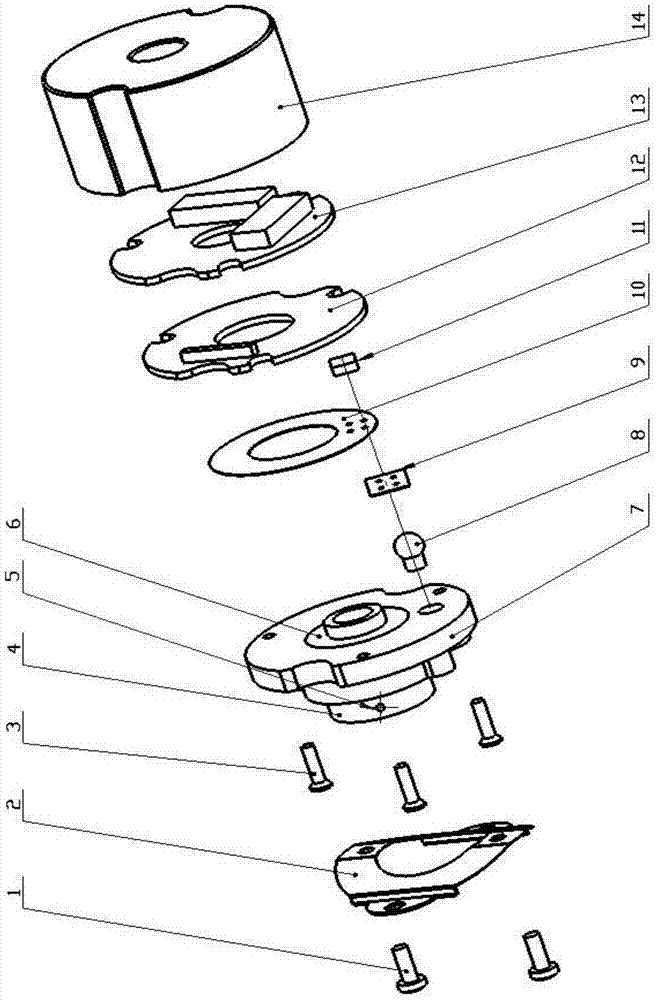

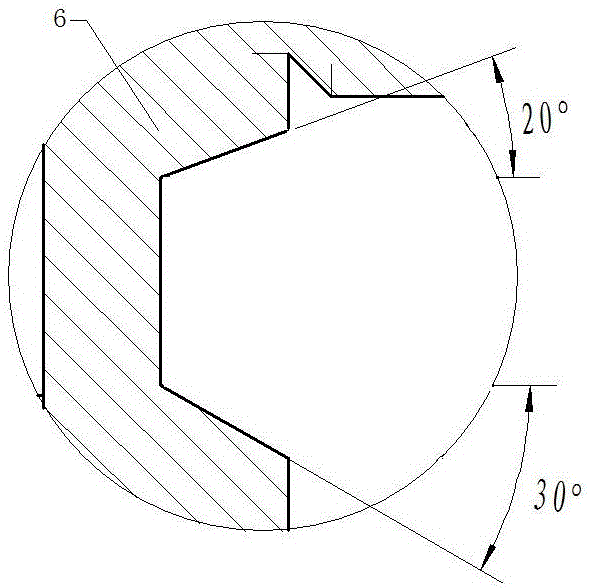

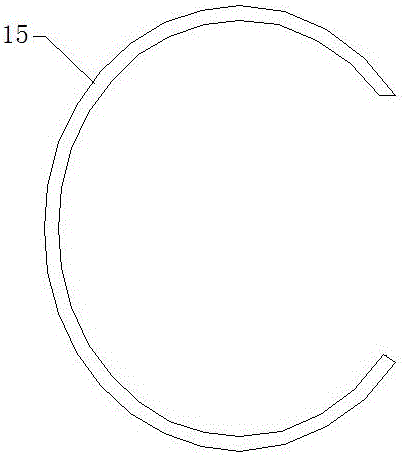

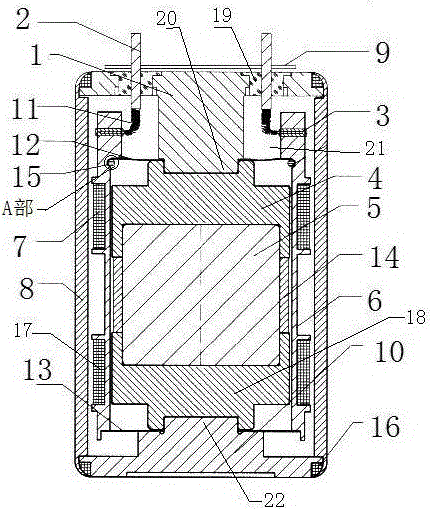

Combined type optical-electricity encoder with copper code disc

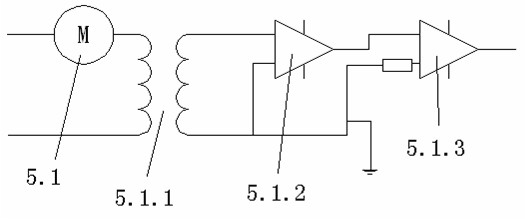

InactiveCN103616040AEasy to getSimple structureConverting sensor output opticallySignal conditioning circuitsElectricity

The invention relates to a combined type optical-electricity encoder with a copper code disc, and belongs to the technical field of electrified transmission detection. The combined type optical-electricity encoder with the copper code disc comprises a fixing elastic piece clamp, a fastening screw, a connecting shaft sleeve, a bearing, a base, an LED light source, a grating ruler, the copper code disc, an optical-electricity receiving component, a signal conditioning circuit board, a signal amplification circuit board, a shell and locating screws. A permanent magnet synchronous motor shaft and the connecting shaft sleeve are tightly connected through the fastening screw, the copper code disc is fixed at one end, far away from the motor shaft, of the connecting shaft sleeve, the LED light source is fixed in a light source hole of the base, and the grating ruler is arranged and fixed on the outer portion of the light source hole of the base. The optical-electricity receiving component is welded to the signal conditioning circuit board, and the signal conditioning circuit board, the signal amplification circuit board and the shell are arranged on the base in a matched mode through the locating screws. The base is fastened with the outer ring of the bearing, and the inner ring of the bearing is fastened with the outer ring of the connecting shaft sleeve. The combined type optical-electricity encoder with the copper code disc has the advantages of being simple and compact in structure, low in cost and easy to mount and use. A rotor magnetic pole position signal 'U' or 'V' or 'W' and a rotor displacement signal 'A' or 'B' and a correction signal 'Z' in an alternating current servo system can be provided simultaneously, wherein the rotor magnetic pole position signal 'U' or 'V' or 'W' and the rotor displacement signal 'A' or 'B' are needed for controlling a permanent magnet synchronous motor, and the correction signal 'Z' is used for eliminating accumulated errors.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

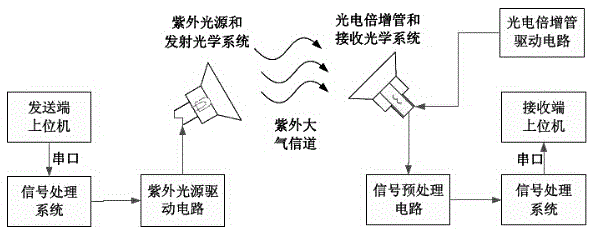

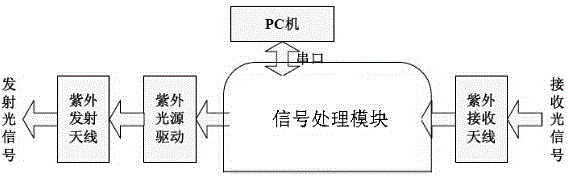

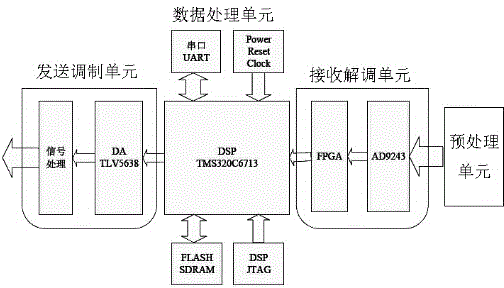

Ultraviolet light communication system based on SR digital signal processing technology

InactiveCN104917565AImprove response rateFast responseClose-range type systemsDigital signal processingControl signal

The invention discloses an ultraviolet light communication system based on a SR digital signal processing technology. A signal processing module is developed, wherein a high speed floating point type DSP chip is taken as a core and a FPGA is a coprocessor. A DSP main processor mainly carries out modulation and demodulation on a signal. The FPGA coprocessor is responsible for digital filtering and data buffering after the data is collected. The system comprises an ultraviolet light transmitting antenna, an ultraviolet light source driving module, a signal processing module, an upper computer and an ultraviolet receiving antenna. The signal processing module is communicated with the upper computer through a serial port. The ultraviolet receiving antenna receives an ultraviolet light signal. The module converts the light signal into a voltage signal and transmits to the signal processing module. The ultraviolet light source driving module receives a control signal of a signal processing unit and drives the ultraviolet receiving antenna to emit an ultraviolet signal. The design in the invention satisfies requirements of industrialization, a practical ability and miniaturization. High-efficient transmission of a long distance and a large amount of data can be realized.

Owner:徐云鹏

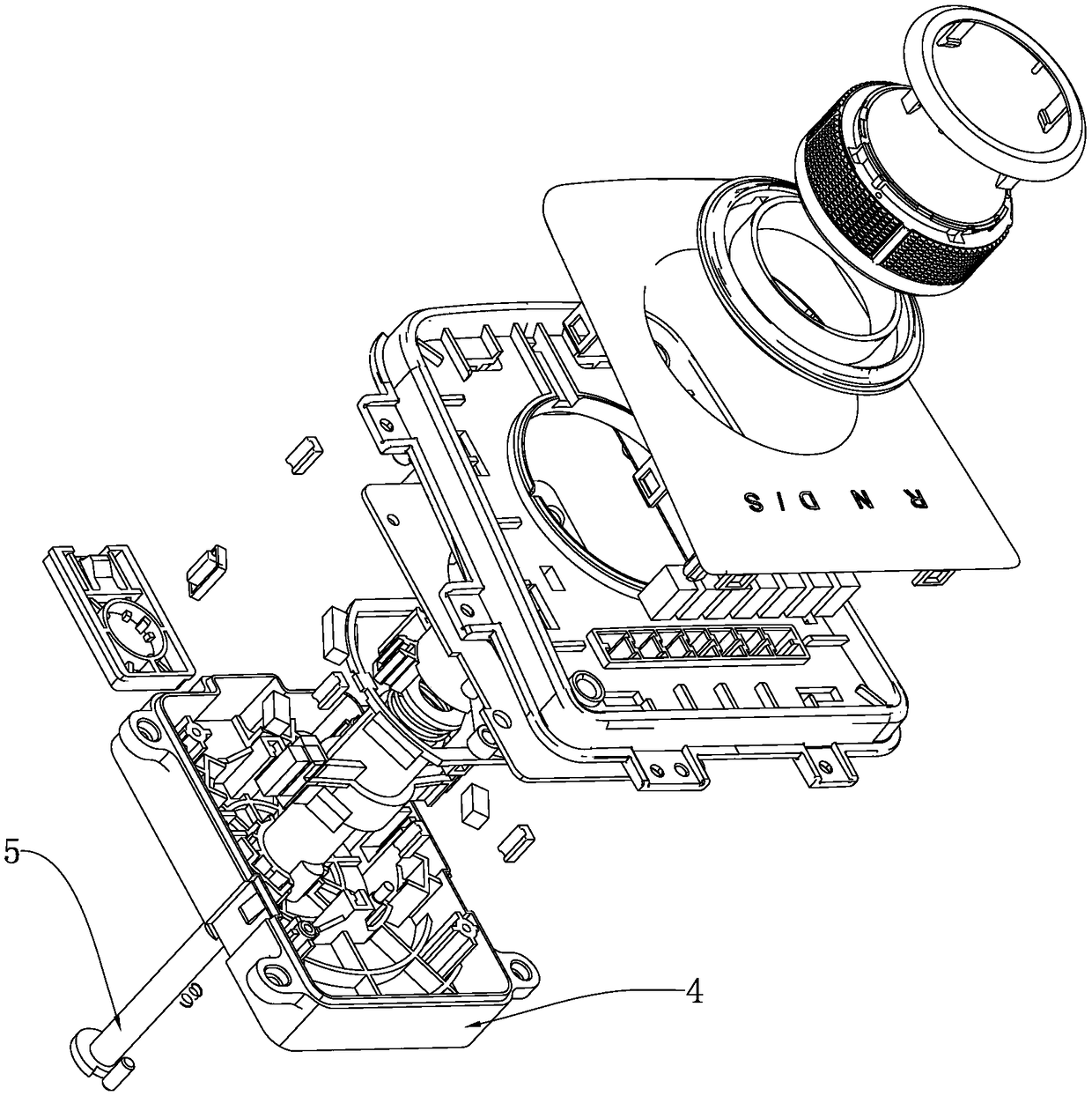

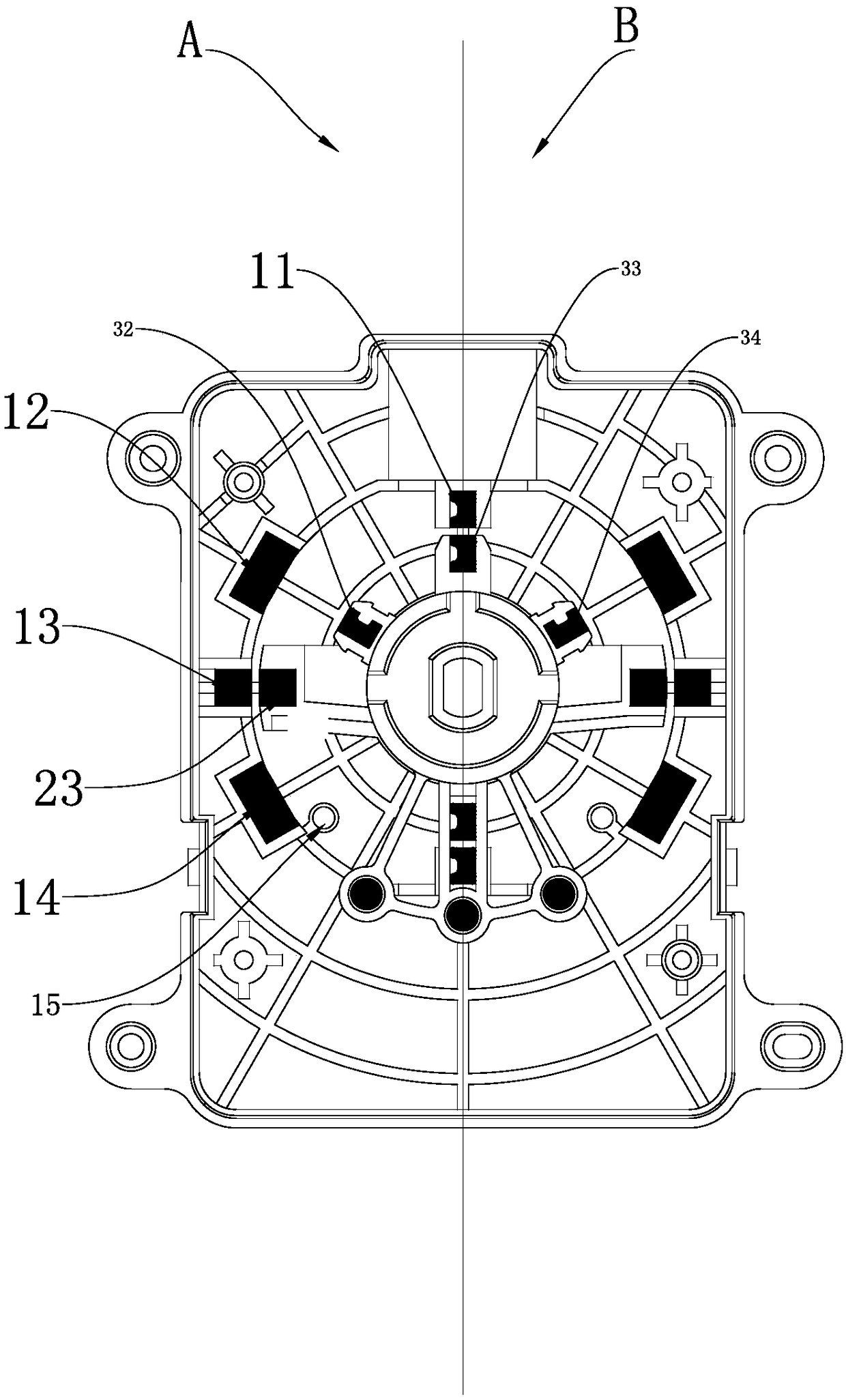

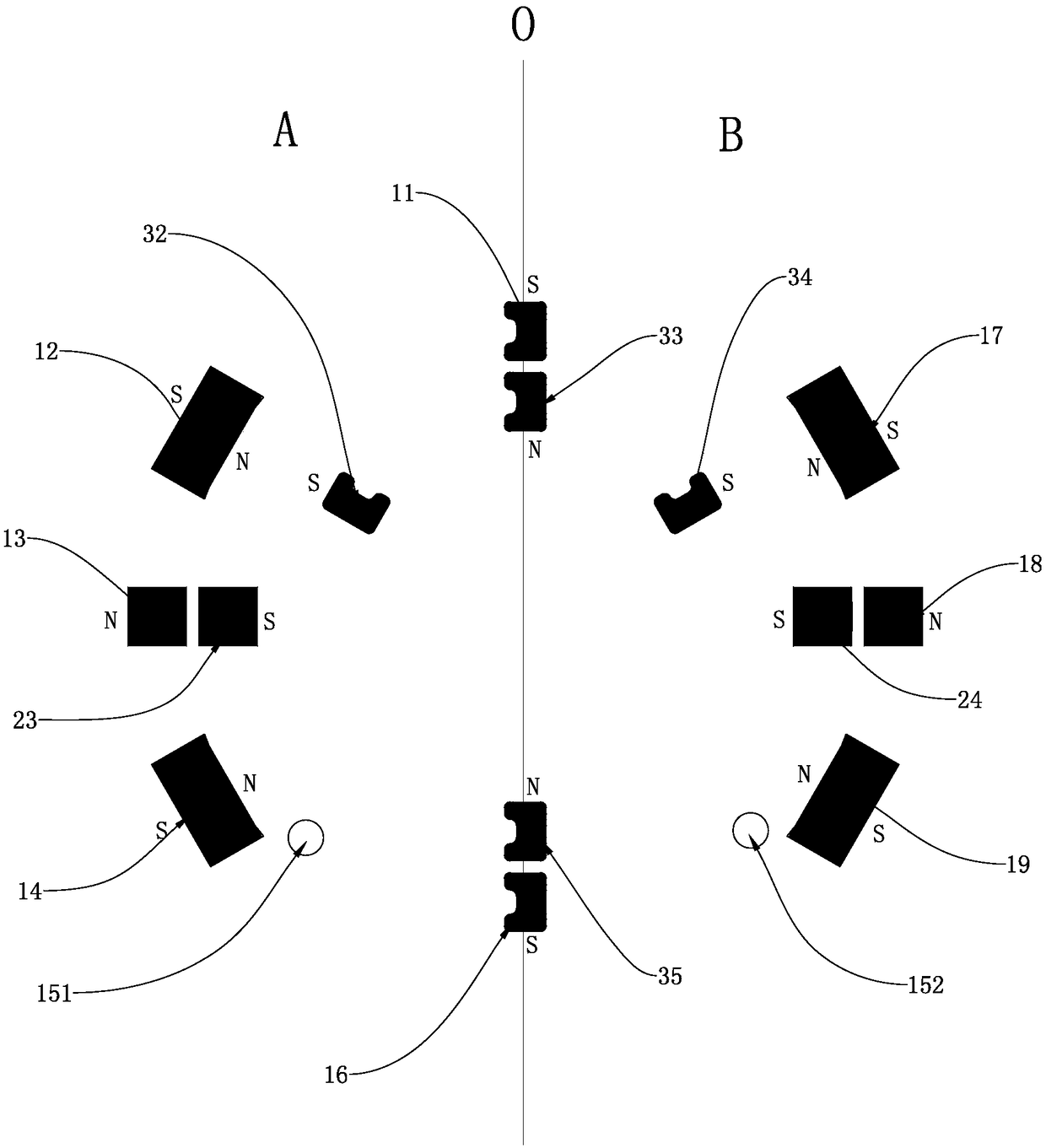

Rotary electronic gear shifting device

PendingCN109505966ARealize rotation positioningSimple structureGearing controlEngineeringElectrical and Electronics engineering

The invention discloses a rotary electronic gear shifting device. The rotary electronic gear shifting device comprises a shell, a rotary knob mechanism and a rotating shaft, wherein the rotary knob mechanism comprises a first magnetic assembly, a third magnetic assembly, a second magnetic assembly and a blocking part; when the rotary knob mechanism is in an initial state, the first magnetic assembly sucks and fixes the second magnetic assembly and the third magnetic assembly, external force F1 is applied, the rotary knob mechanism is circumferentially rotated, the third magnetic assembly is separated from the first magnetic assembly and rotates along with the rotating shaft, and when rotating to touch the second magnetic assembly, the third magnetic assembly automatically resets; and whenexternal force F2 larger than F1 is applied, the rotary knob mechanism is circumferentially rotated, the third magnetic assembly can drive the second magnetic assembly to circumferentially rotate to the blocking part, and the third magnetic assembly and the second magnetic assembly automatically reset. According to the rotary electronic gear shifting device, the structure is simple, friction noiseis not generated, the hand feeling is good, utilization experience of users is good, the service life is long, and operation is effort-saving.

Owner:金华斯迈尔电子科技有限公司

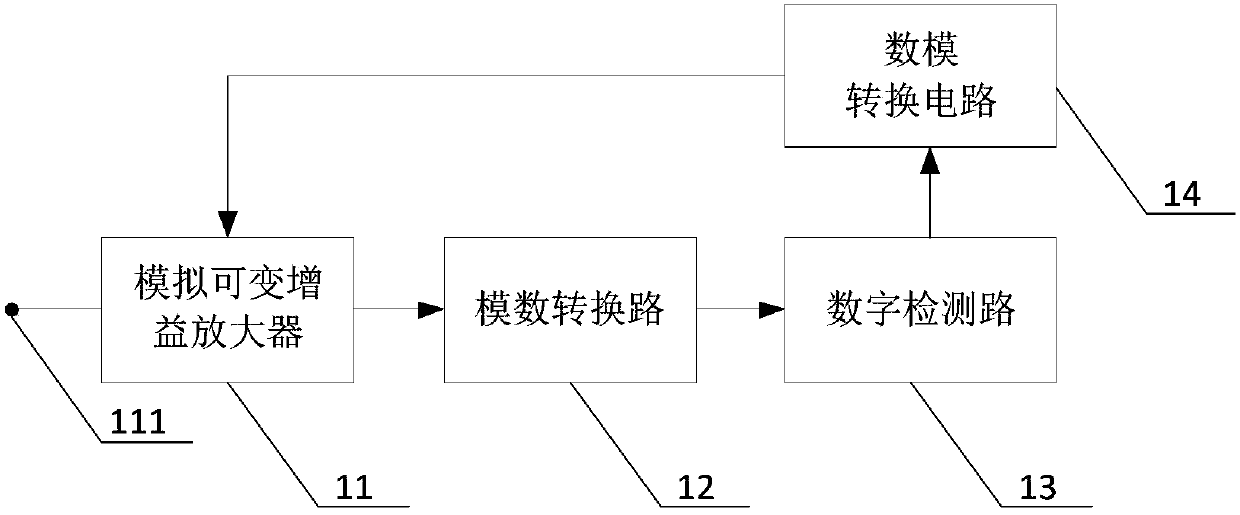

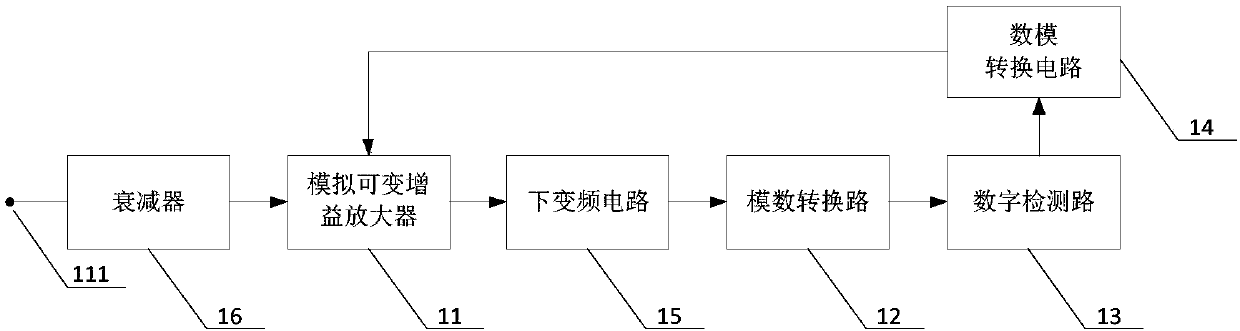

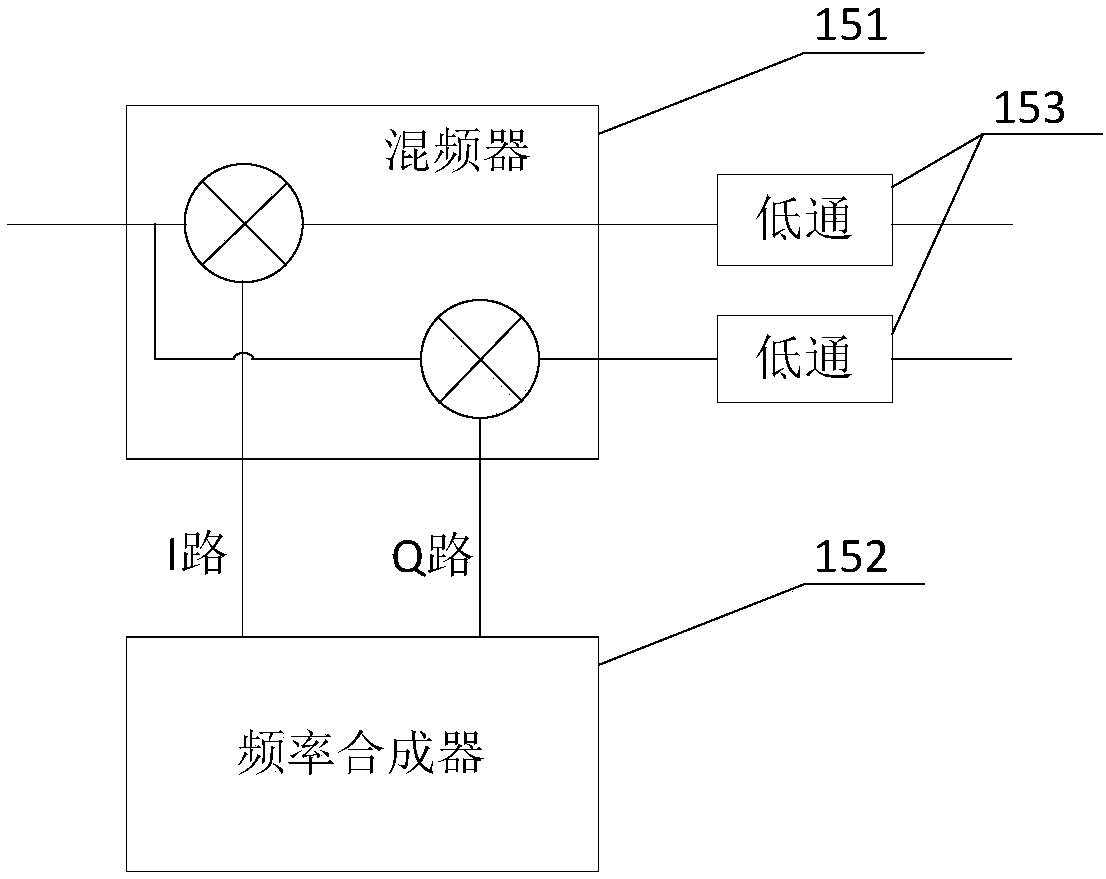

Automatic gain control receiver

ActiveCN107919881AThe signal output is stableFast and accurate detection of signal powerTransmissionAutomatic controlAudio power amplifier

The invention relates to an automatic gain control receiver. The receiver consists of an analog variable gain amplifier, an analog to digital conversion circuit, a digital detection circuit and a digital to analog conversion circuit, which are electrically connected with each other in sequence, an output end of the digital to analog conversion circuit is electrically connected with a gain controlend of the analog variable gain amplifier, so that an output signal of the digital detection circuit performs automatic adjustment and control on the gain of the analog variable gain amplifier. By adoption of the automatic gain control receiver, the automatic gain control can be performed on the input analog radio frequency signal, so that the analog radio frequency signal can have signal output of stable power within a greater dynamic range, and the signal power can be quickly and accurately detected through the digital detection circuit so as to feed back and control the gain of the analog variable gain amplifier, and the automatic gain control receiver has the technical advantages of wide dynamic range of controlling the radio frequency signal, high control precision, fast control speedand little interference from the outside.

Owner:ARMY ENG UNIV OF PLA

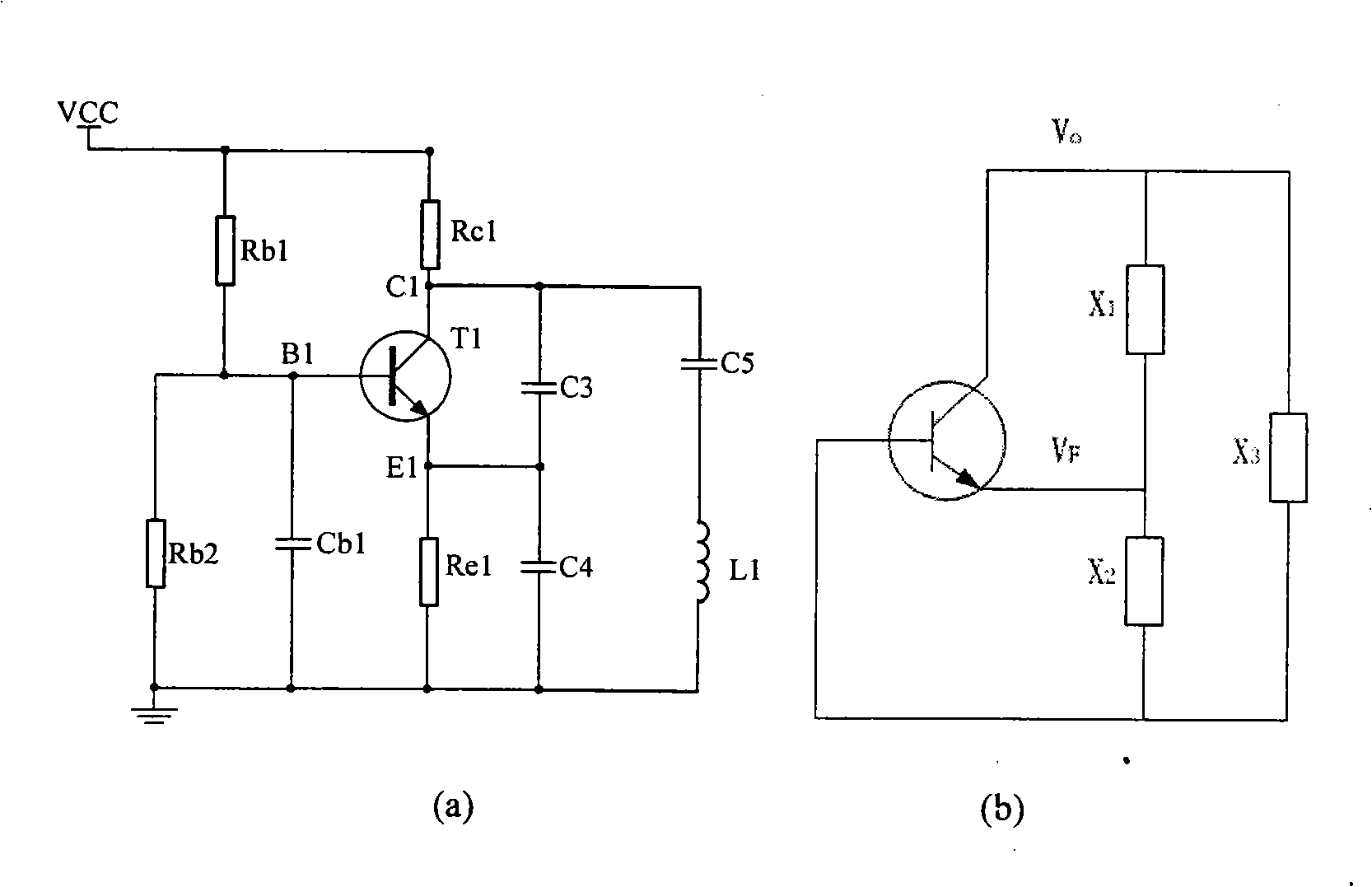

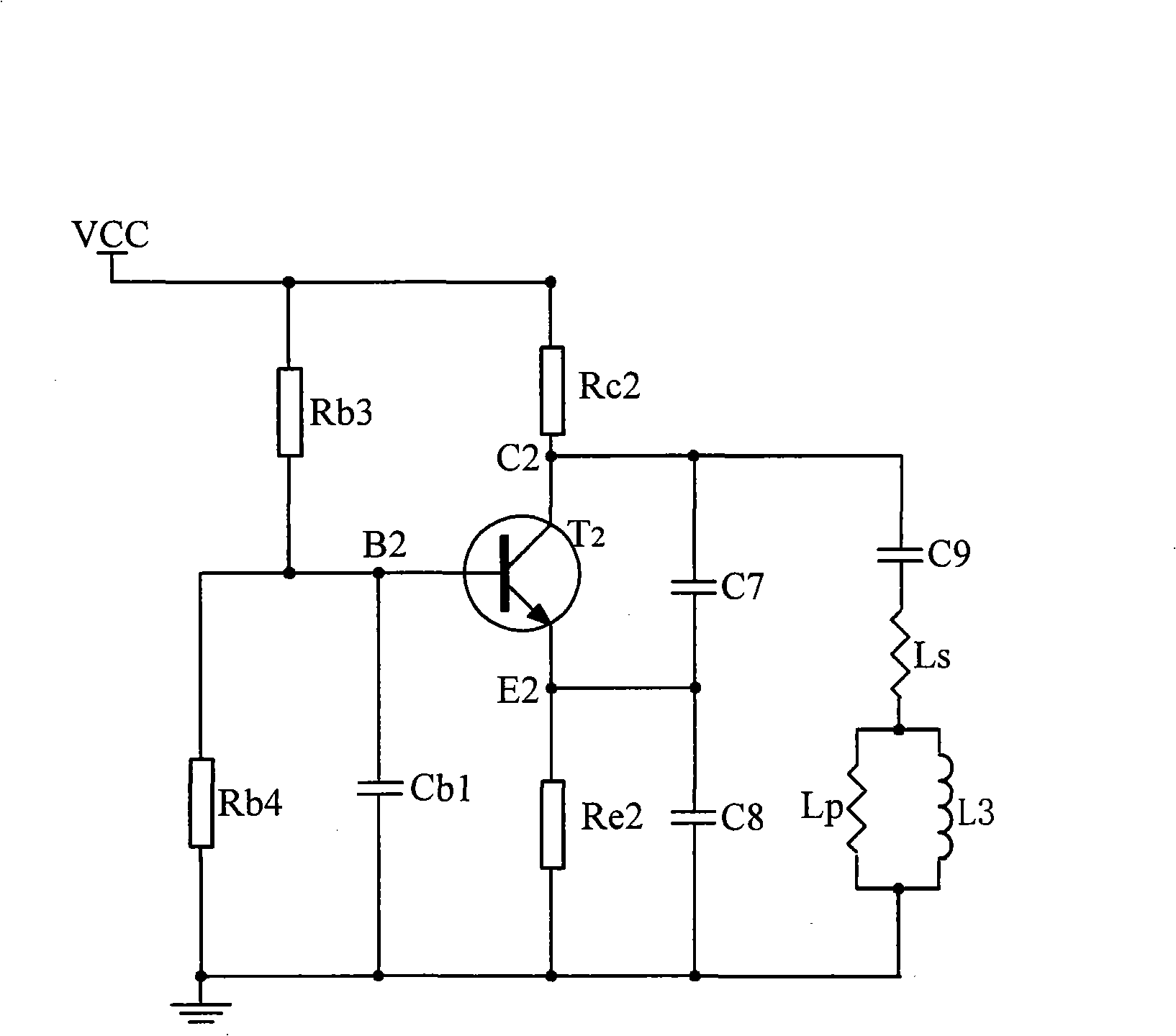

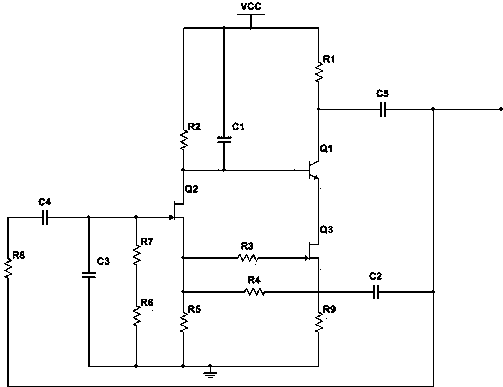

Oscillating circuit for detecting tiny plane coil inductance

InactiveCN101408569AHigh quality factorThe signal output is stableResistance/reactance/impedencePlanar coilInductor

The invention relates to an oscillatory circuit used for detecting the coil inductance of a miniature plane, belonging to the technical field of electronics detection. A resistance Rc2 is connected with a power supply and a collector of a triode, a capacitor C7 is connected with an emitter of the triode, the emitter is connected with a resistance Re2 and the capacitor, the Re2 and a capacitor C8 are respectively ground, a resistance Rb3 is connected with the power supply and the base of the triode, the base is connected both with a resistance Rb4 and with a Cb2, the two of which are respectively ground, the collector and one end of a capacitor C9 are connected, the capacitor C9 is connected with an inductor Ls, and the inductor Ls is connected with an inductor Lp and the coil L3 of the detected plane, the three of which are respectively ground.In the oscillatory circuit, a sensor coil is connected with the inductor Lp in parallel and then connected to a capacitance connecting three point type oscillator, thus effectively improving the quality factor of the circuit system and leading to stable signal output of current vortex coil.

Owner:TSINGHUA UNIV

Blade type level gage

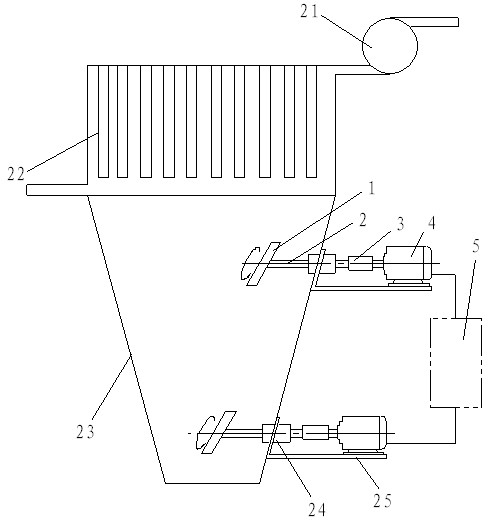

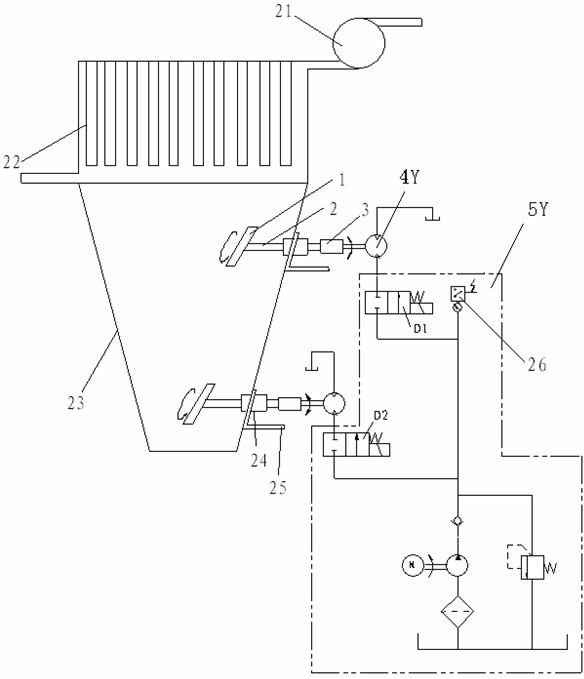

ActiveCN102331287AMeet the needs of material level measurementMeet the needs of different use environmentsLevel indicators by physical variable measurementDrive shaftBaghouse

The invention relates to a blade type level gage which is mainly used for measuring the level of a hopper (23) in a bag type dust collector (23). The blade type level gage comprises a blade (1), a transmission shaft (2), a power device (4) and a signal acquisition control device (5), wherein an output shaft of the power device (4) is connected with the transmission shaft (2); the blade (1) is fixed on the transmission shaft (2); and the signal acquisition control device (5) is connected with the power device (4). The requirement of different kinds of dust and different use environments can besatisfied, the blade type level gage has strong universality, wide applicability, simple structure, stable performance, long service life, high reliability, stable signal output, small error and goodenvironmental suitability and is convenient to install and use, and the requirement of level measurement in scattered material containers such as bag type dust collector and the like can be satisfied.

Owner:张元杰

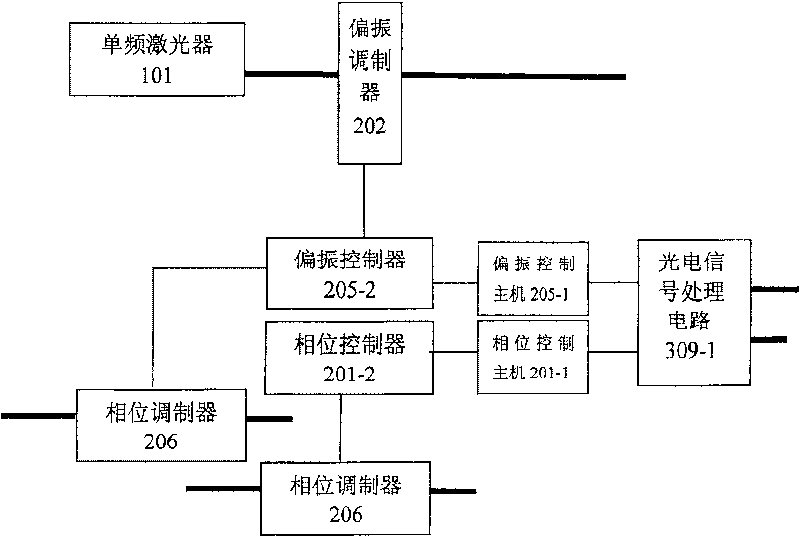

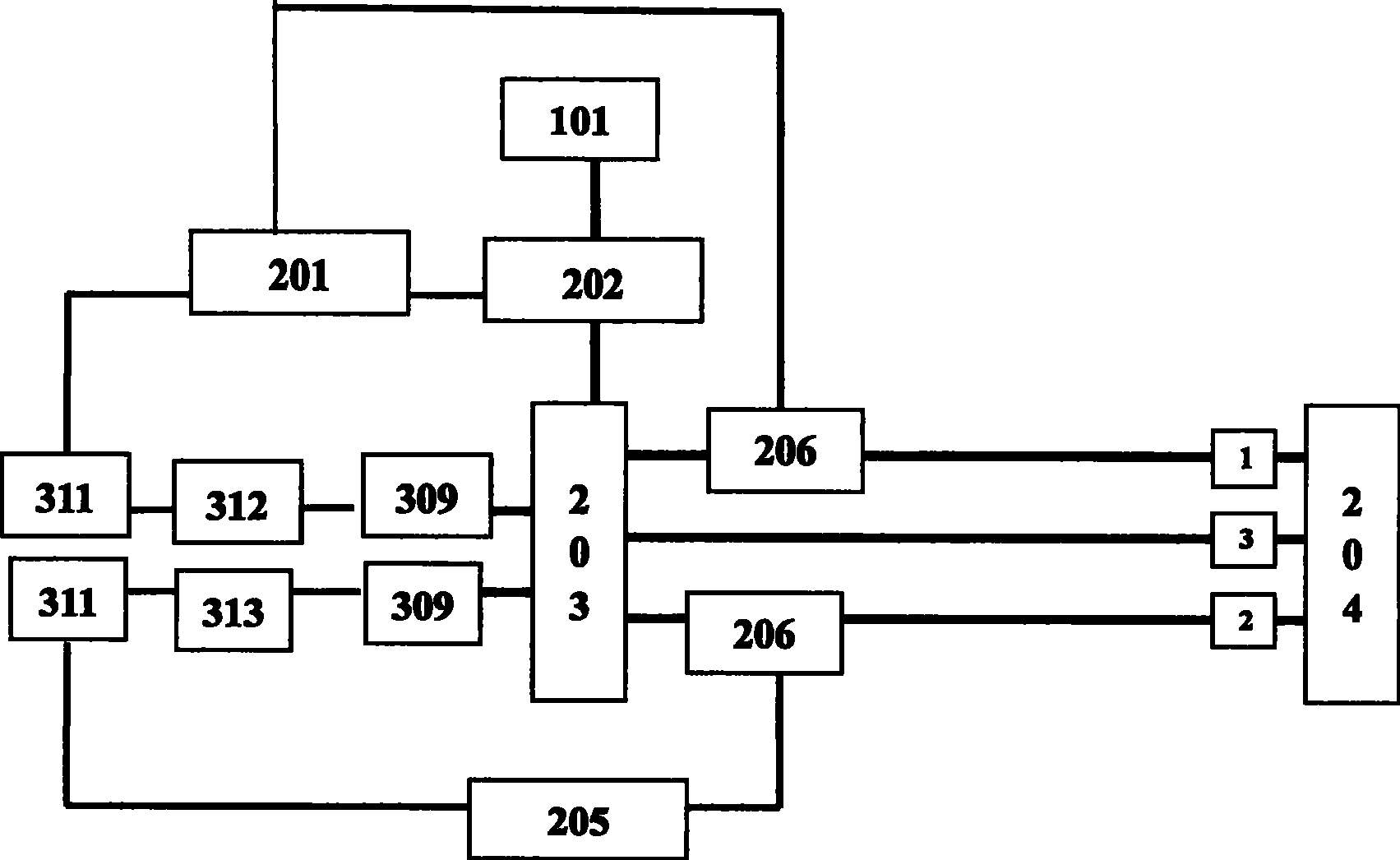

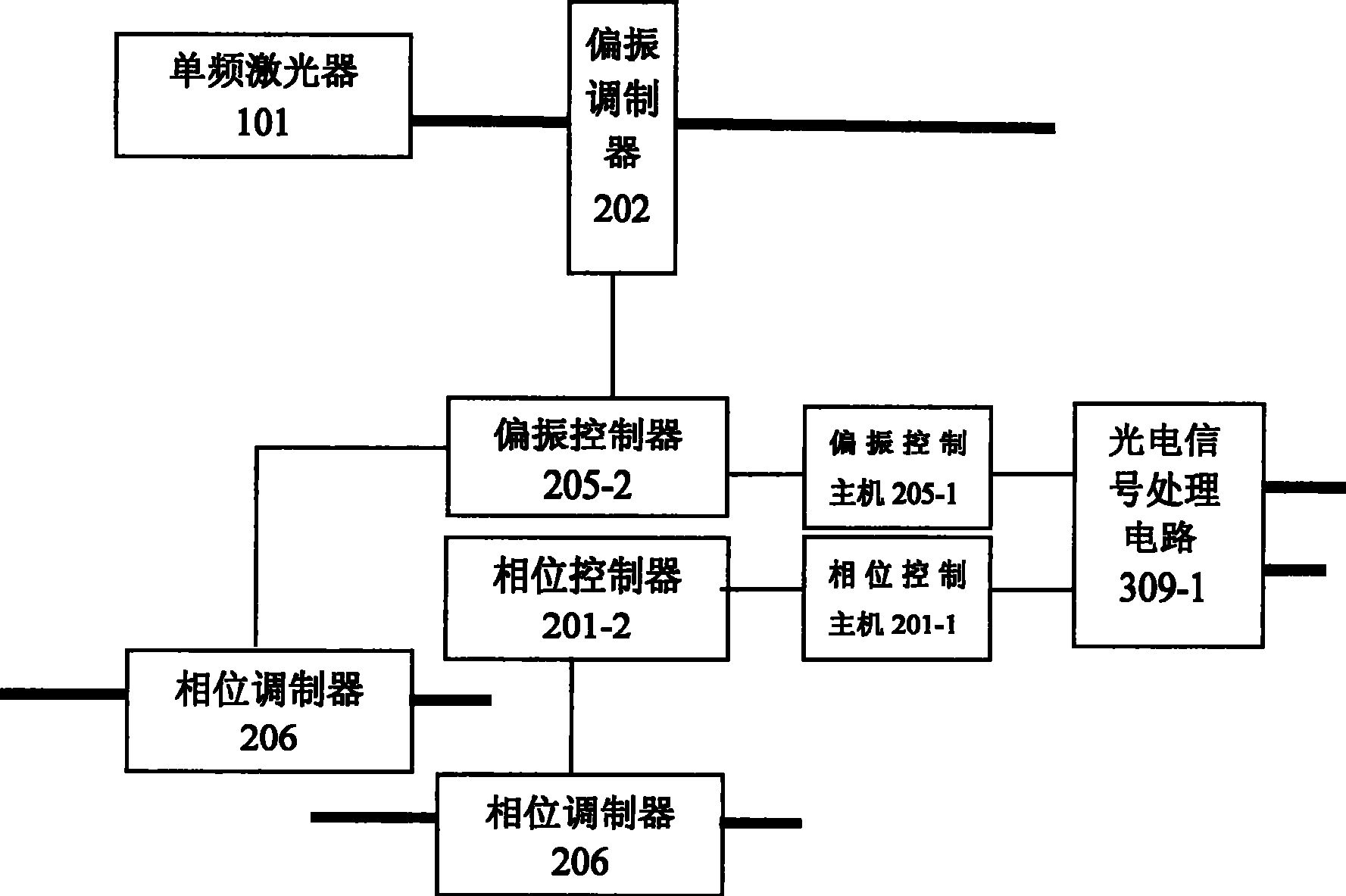

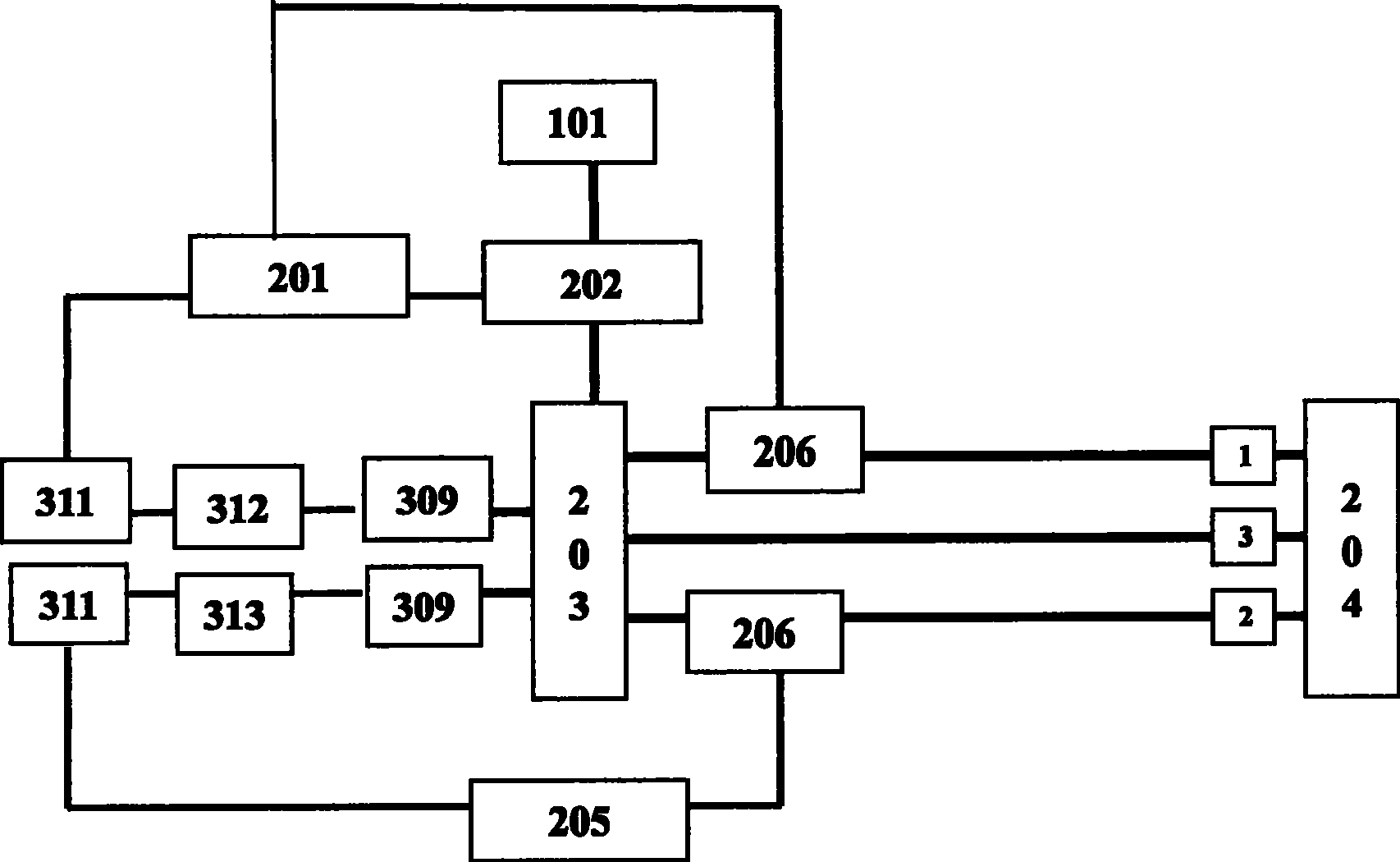

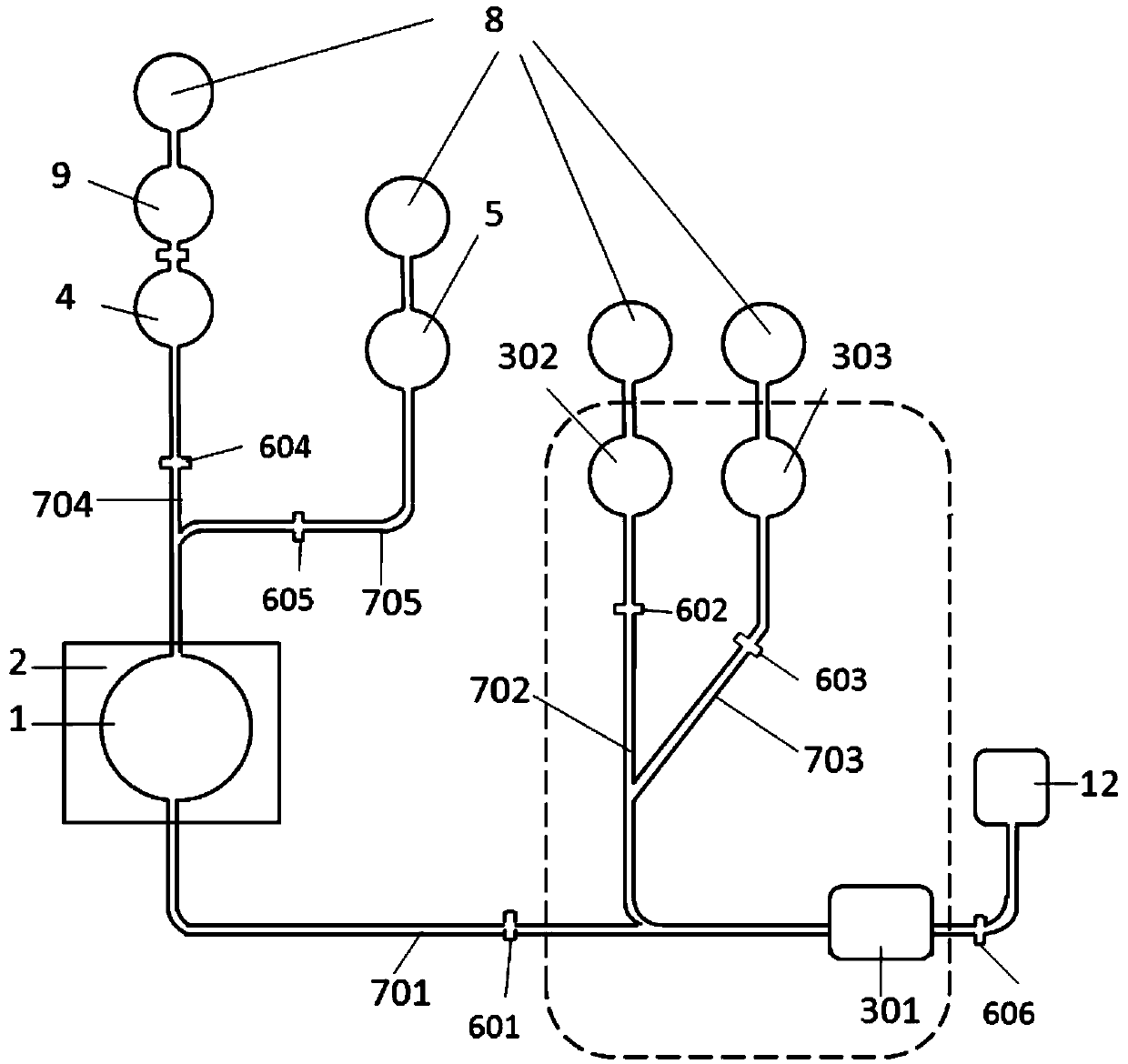

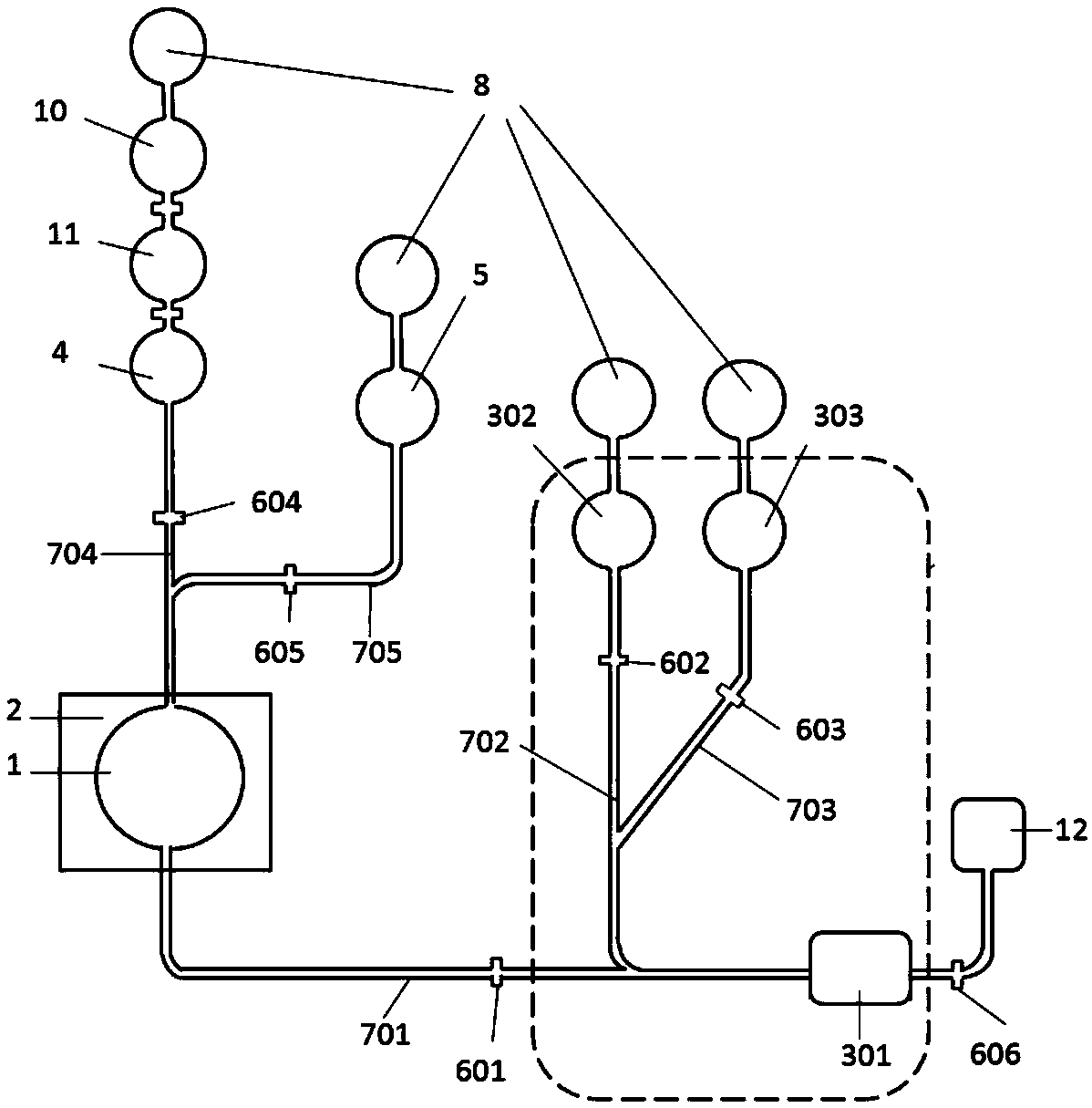

Optical-fiber security early-warning polarization-phase combined control system

ActiveCN101692137AOvercoming phase fadingStable operating pointVibration measurement in solidsOptical fibre/cable installationSignal processing circuitsControl system

The invention provides an optical-fiber security early-warning polarization-phase combined control system for the security protection and early warning of buried pipelines, structures or important facilities and regions, which relates to the technical field of mechanical vibration measurement, impact measurement and pipeline systems. A polarization modulator (202) is connected in serial between a continuous monochromatic laser (101) and a wave combining-dividing device (203); the wave combining-dividing device (203) is connected with two photoelectric detectors (309) and (310) through optical fiber; the output ends of the two photoelectric detectors (309) and (310) are connected with an A / D (312) and an A / D (313) respectively; the output ends of the A / D (312) and the A / D (313) are connected with photoelectric signal processing circuits (311) respectively; the output end of one photoelectric signal processing circuit (311) is connected with a polarization controller (201); the output end of the polarization controller (201) is connected with the polarization modulator (202) and a phase modulator (206) connected in serial with optical fiber (1) or (2); the output of the other photoelectric signal processing circuit (311) is connected with a phase controller (205); and the output of the phase controller (205) is connected with the phase modulator (206) connected in serial with the optical fiber (1) or (2).

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

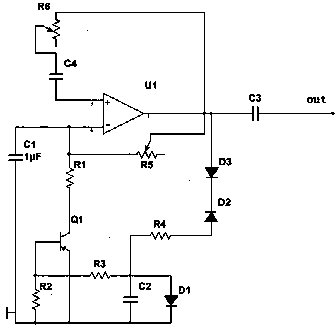

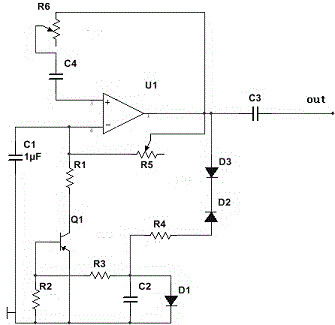

Audio signal circuit

InactiveCN103475977ASimple structureThe signal output is stableTransducer circuitsCapacitanceVoltage amplitude

The invention discloses an audio signal circuit which comprises an operational amplifier, a triode, a variable resistor, a resistor, a capacitor and a diode. The audio signal circuit uses the triode which works in a variable resistance area to form stable nonlinear resistance output and can maintain constant output voltage by adjusting the variable resistor in the circuit and adjusting the strength of feedback. Furthermore, the problem of improving the stability of output voltage amplitude is solved. The audio signal circuit is simple in structure, stable in signal output, little in clutter and suitable for small-power electronic systems.

Owner:昆山龙仕达电子材料有限公司

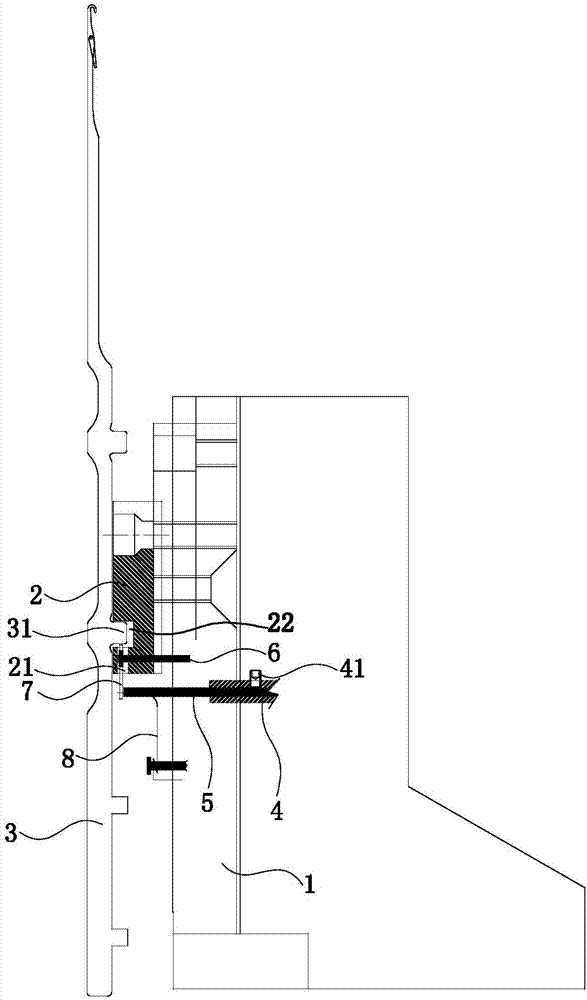

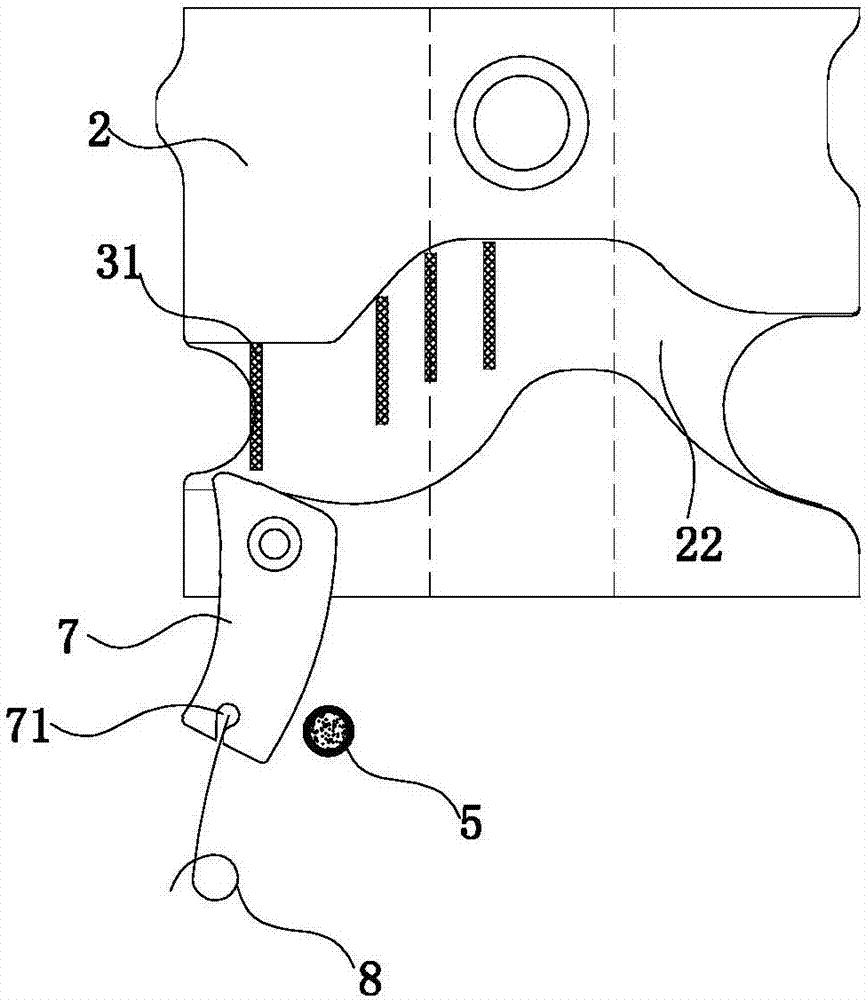

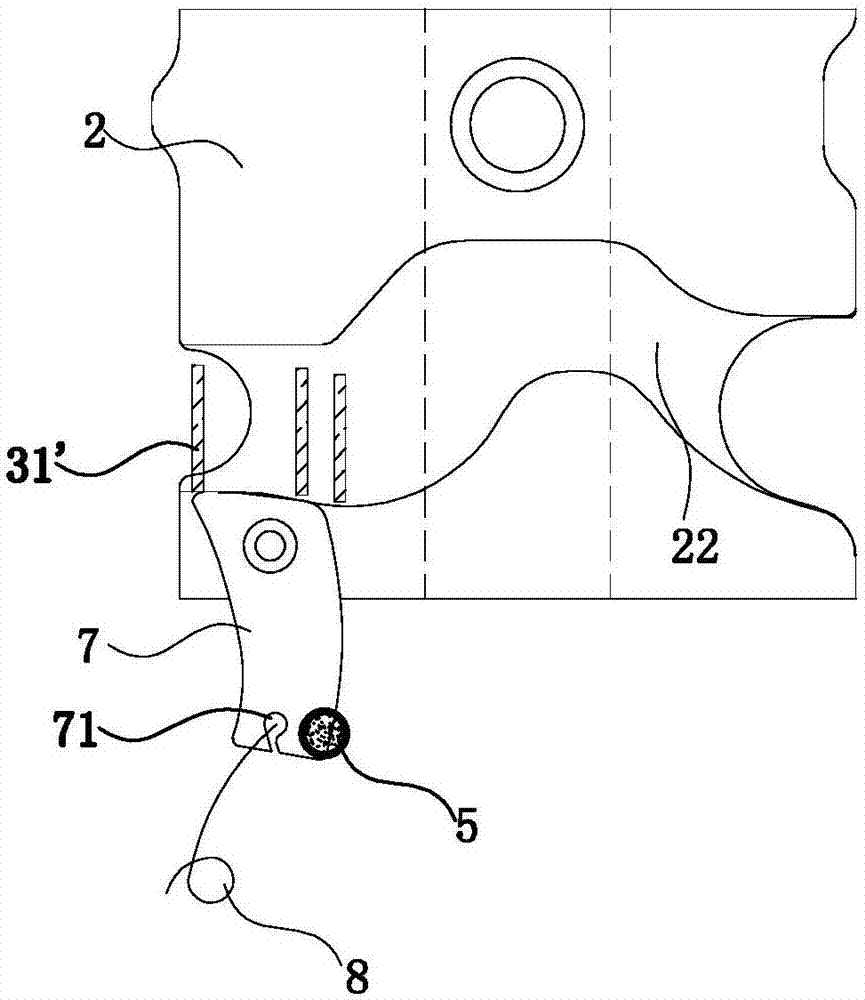

Circular weft knitting machine broken needle detection mechanism

The invention relates to a circular weft knitting machine broken needle detection mechanism. The circular weft knitting machine broken needle detection mechanism is arranged on a triangle of a saddle and comprises a pin arranged on the triangle, a swinging piece rotatably arranged at the free end of the pin, a sensor arranged on the saddle and a reset spring arranged on the saddle, the free end of the reset spring is connected with the swinging piece which is arranged in the triangle and located on the lower potion of a needle butt of a knitting needle, when the knitting needle move up and down, the needle butt can make contact with the swinging piece and press the swinging piece to rotate, and when the swinging piece swings, the sensor can be triggered.

Owner:SHISHI BAOXIANG KNITTING MACHINERY

Pressure transducer having stress concentration

InactiveCN106197785AHigh sensitivityPlay the role of signal amplificationForce measurement by measuring optical property variationEngineeringSignal amplification

The invention relates to a pressure transducer having stressing concentration. The pressure transducer includes a housing which assumes a cylindrical structure having two ends blocked and is provided with a mounting hole and an air exhaust hole thereon; a metal membrane which is arranged inside the mounting hole and has an circumferential edge which is fixedly connected to the inner wall of the mounting hole, the metal membrane being provided with a stress concentration groove thereon; and a FBG fiber which is fixed to the outside of the metal membrane. According to the invention, the pressure transducer adopts the metal membrane and the housing to enclose a cavity, and the metal membrane is provided with the stress concentration groove, such that a signal can be amplified and the sensitivity of the pressure sensor is higher.

Owner:北京中智永科技发展有限公司

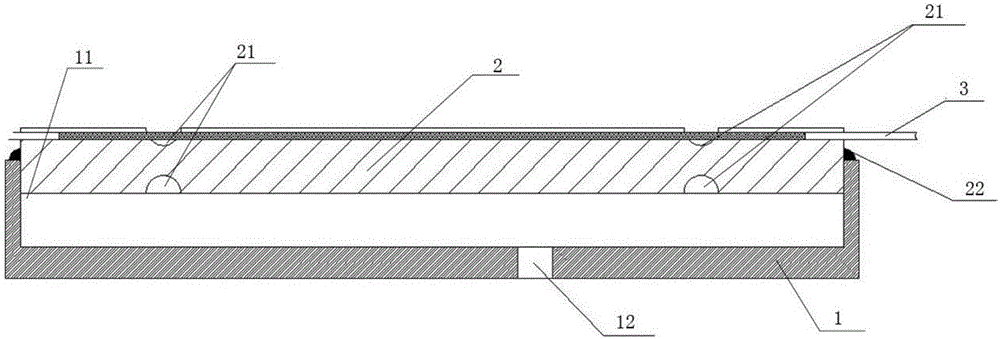

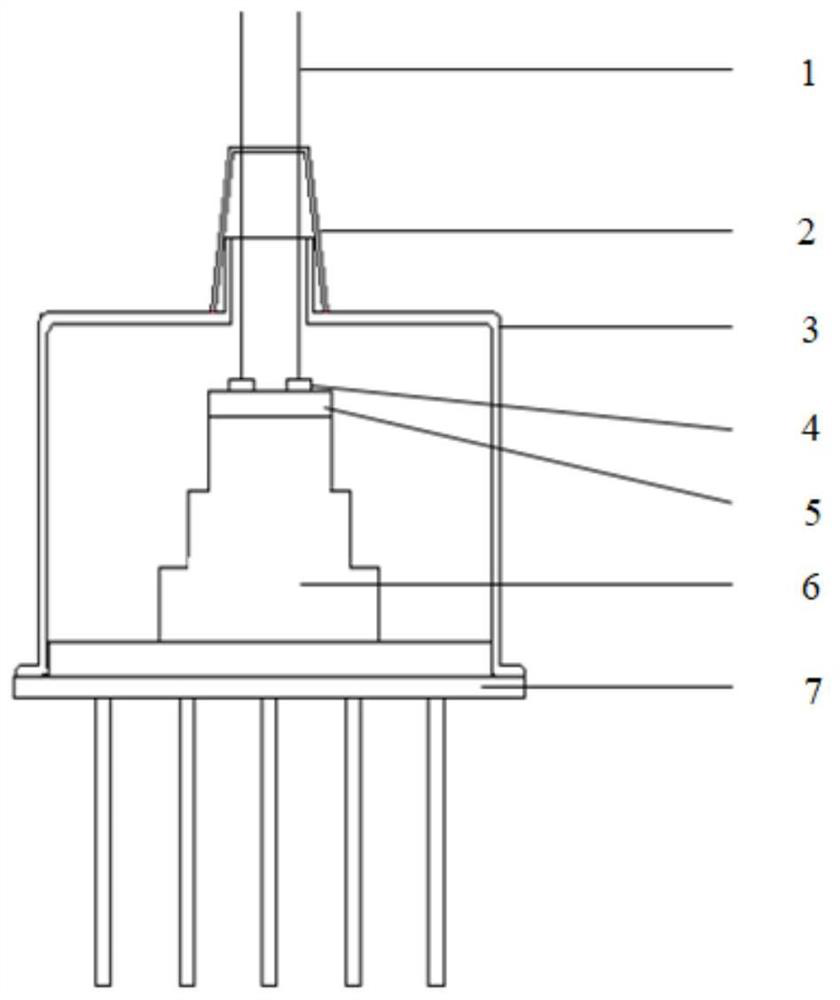

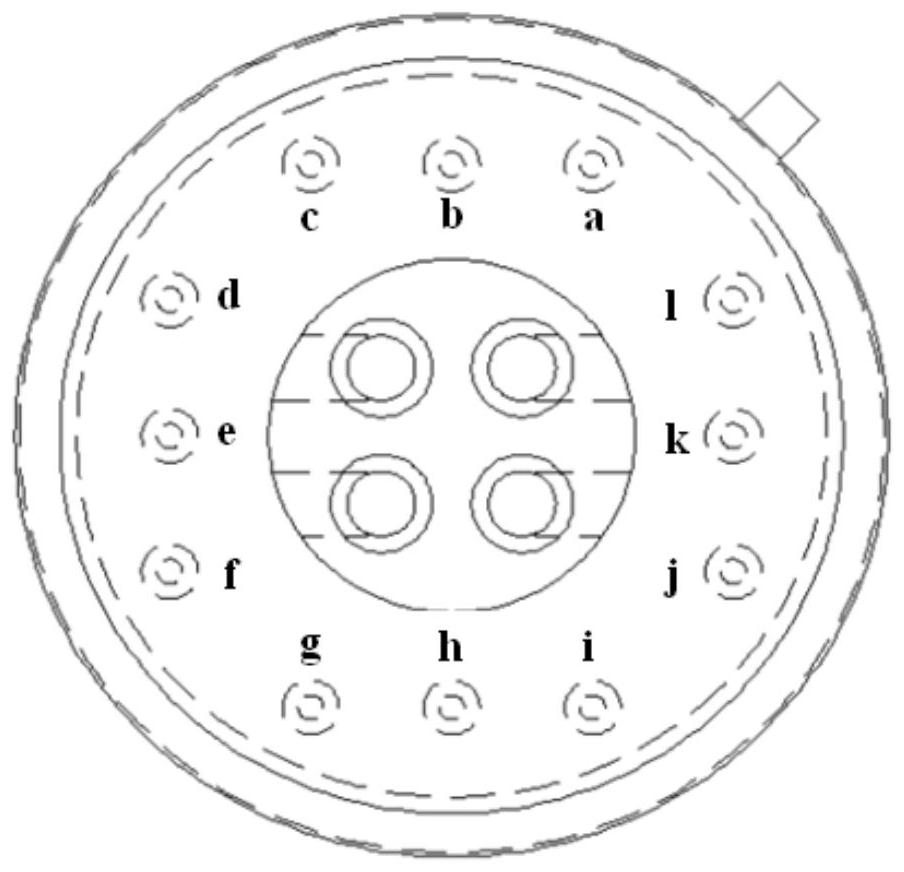

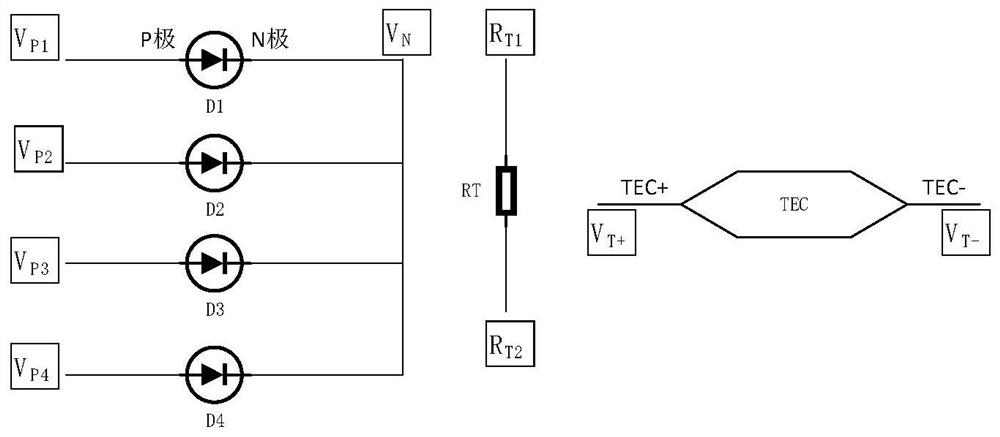

Refrigeration type photoelectric balance detector

PendingCN112992871AHigh sensitivityImprove accuracyWave based measurement systemsSolid-state devicesMechanical engineeringPhotodetection

The invention discloses a refrigeration type photoelectric balance detector. The detector comprises an input optical fiber, a protective sleeve, a tube cap, a photoelectric detection chip, a circuit board, a three-stage TEC refrigeration sheet and a tube seat, wherein the three-stage TEC refrigeration sheet is fixedly connected to the top of the tube base, the circuit board is fixed to the top of the three-stage TEC refrigeration sheet, the photoelectric detection chip is fixed to the top of the circuit board, the tube cap sleeves the three-stage TEC refrigeration sheet, the circuit board and the photoelectric detection chip, the bottom of the tube cap is fixed to the tube base, the input optical fiber is fixed to the top of the tube cap, an end portion of the input optical fiber is connected to the photoelectric detection chip, and the protective sleeve is sleeved on the top of the pipe cap and the input optical fiber. According to the detector, integration of a plurality of balance detectors is realized, and the balance detectors work at a specified temperature.

Owner:西安中科迅捷光电科技有限公司

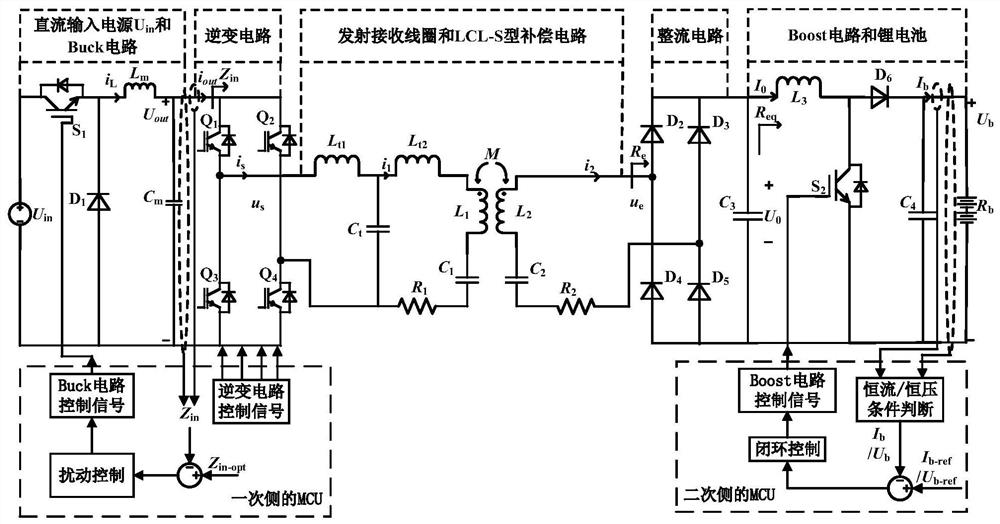

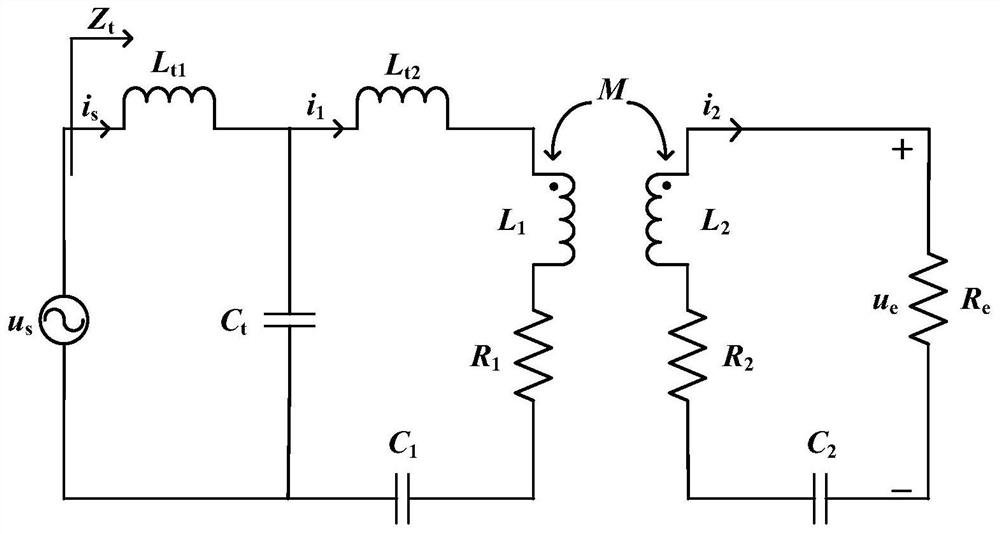

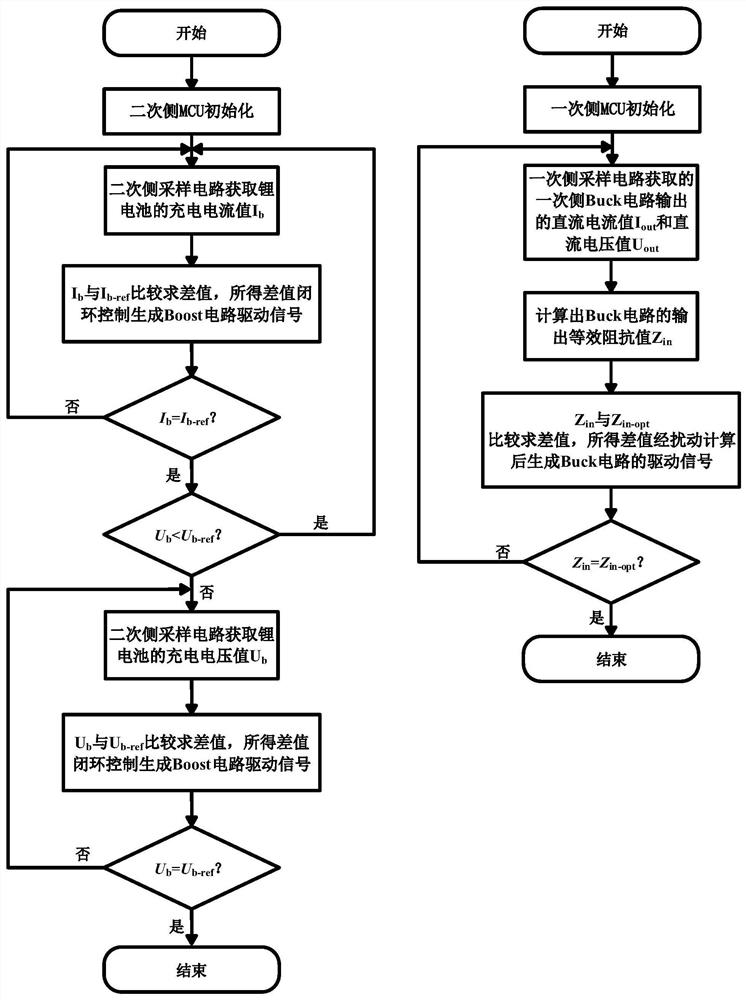

Wireless charging system and constant-current/constant-voltage charging optimization control method

ActiveCN112421792AControl objectives are clearEasy to controlBatteries circuit arrangementsSecondary cells charging/dischargingLoad circuitTransmitter coil

The invention discloses a wireless charging system and a constant-current / constant-voltage charging optimization control method, and belongs to the technical field of wireless power transmission. Thewireless charging system is characterized in that the primary side of the system comprises an input power supply, a Buck circuit, a full-bridge inverter, a primary side transmitting coil, a compensating circuit and a primary side MCU, and the secondary side of the system comprises a load, a Boost circuit, a full-wave rectifier, a secondary side receiving coil, a compensation circuit and a secondary side MCU. According to the invention, disturbance control is carried out on the output impedance of the Buck circuit by the primary side system and closed-loop control is carried out on the output current / voltage by the secondary side system, so that the output impedance of the Buck circuit can be stabilized at an optimal output impedance value while the output current / voltage is stabilized neara reference value, accurate control in the constant-current / constant-voltage charging process and optimization of the electric energy transmission efficiency of the system are achieved, and wirelesscommunication is not needed; and the sampling object of the sampling circuit is the direct current quantity, so that the implementation is easy, and the hardware requirement is low.

Owner:JIANGNAN UNIV

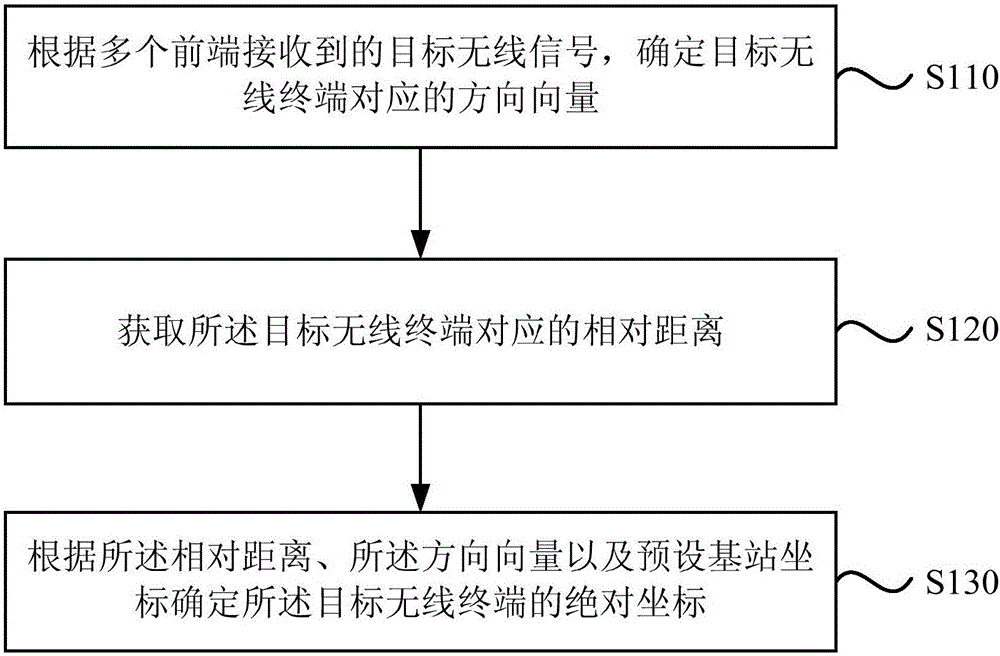

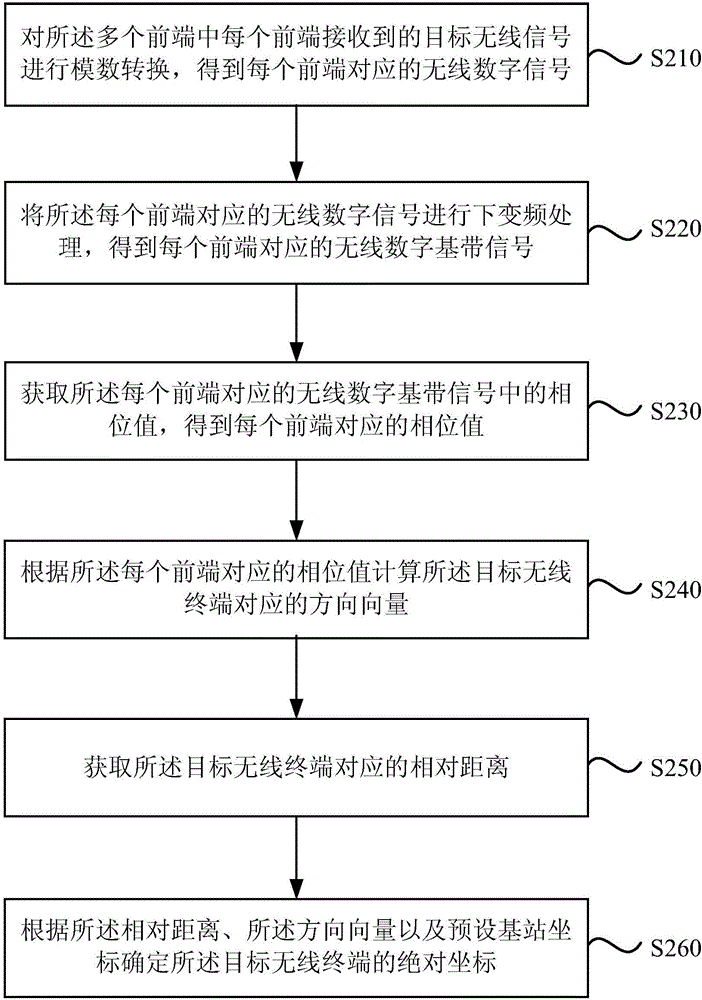

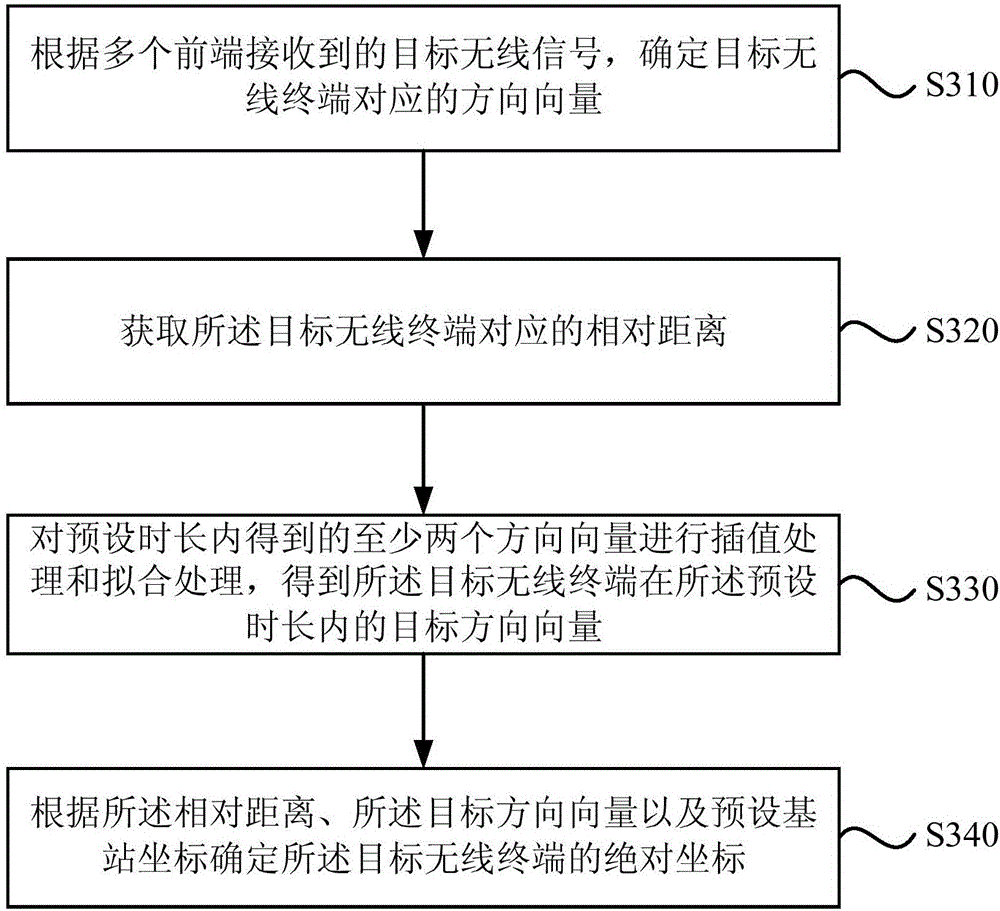

Wireless terminal positioning method and apparatus

InactiveCN106455054AStable location serviceImprove bandwidth utilizationPosition fixationWireless communicationComputer terminalThroughput

Embodiments of the present invention disclose a wireless terminal positioning method and apparatus. The method comprises the steps of determining a direction vector corresponding to a target wireless terminal according to target wireless signals received by multiple front ends; acquiring a relative distance corresponding to the target wireless terminal; and determining absolute coordinates of the target wireless terminal according to the relative distance, the direction vector and preset base station coordinates. Through adoption of the wireless terminal positioning method and apparatus, when a mobile signal is poor, a stable positioning service is provided for the user, and the bandwidth use ratio of the wireless network channel and the throughput of the wireless device are improved.

Owner:RUN TECH CO LTD BEIJING

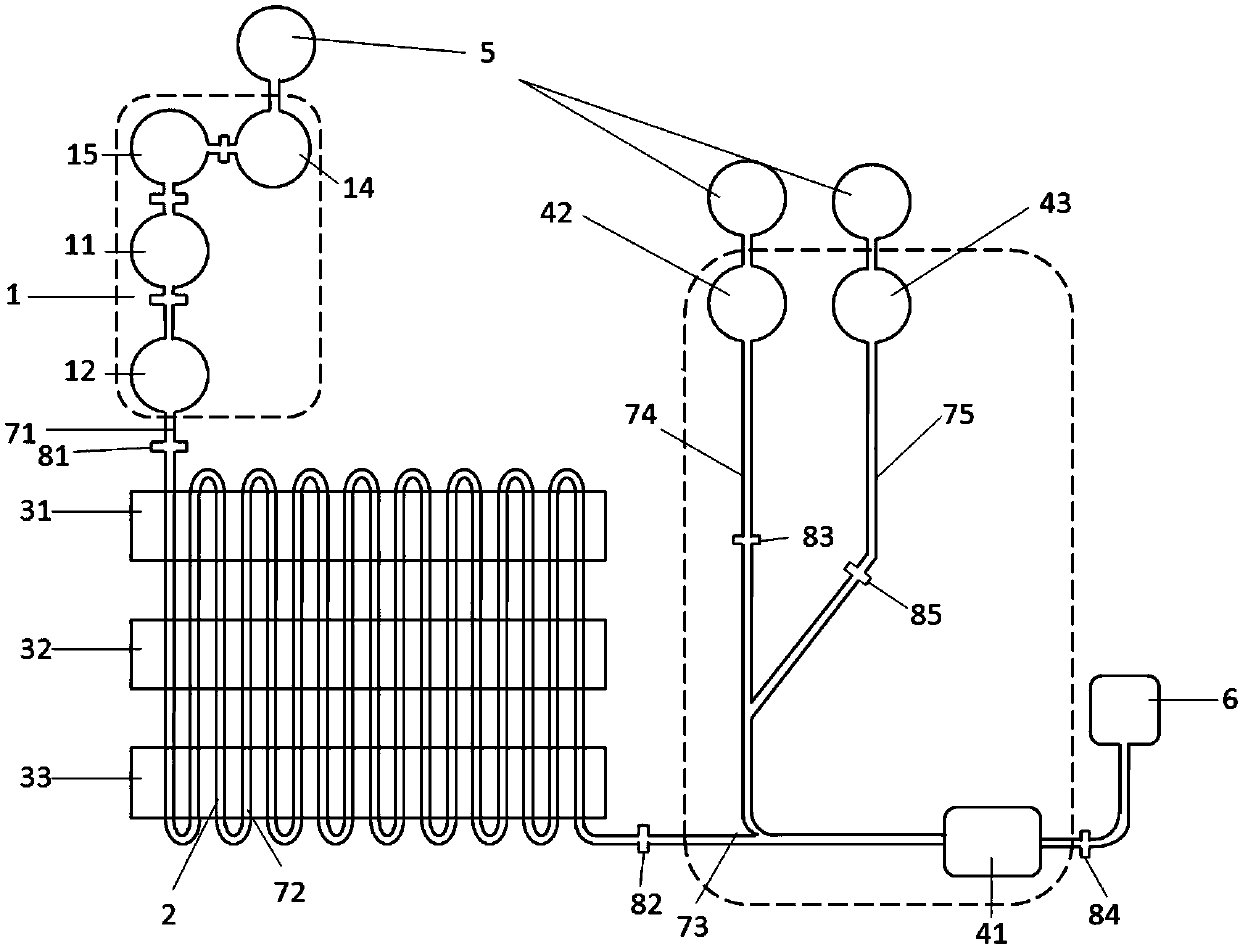

Nucleic acid detection device and detection method

InactiveCN110699438AThe signal output is stableCycle number controllableMicrobiological testing/measurementNucleic acid detectionMagnetic bead

The invention relates to a nucleic acid detection device and detection method. The device comprises a sample processor and a magnetic sensitive detector, wherein the sample processor comprises a reagent chamber, a plurality of PCR reaction microchannels which are arranged side by side, a catching chip storage chamber, a DNA modification magnetic bead storage chamber and a cleaning liquid storage chamber, wherein the top end of the first PCR reaction microchannel communicates with a reagent outlet through a first microchannel, and every two adjacent PCR reaction microchannels are in communication in heads and tails through a second microchannel; 3 temperature control devices are sequentially arranged on each PCR reaction microchannel from top to bottom; the inlet of the catching chip storage chamber communicates with the bottom end of the last PCR reaction microchannel through a third microchannel, communicates with the DNA modification magnetic bead storage chamber through a fourth microchannel, and communicates with the cleaning liquid storage chamber through a fifth microchannel; and a magnetic sensor of the magnetic sensitive detector is used for sensing and catching DNA modification magnetic beads in the magnetic sensitive detector and converting the magnetic signals of the DNA modification magnetic beads into electrical signals. When being used for detecting nucleic acid,the device disclosed by the invention is high in reaction speed and stable in signal output.

Owner:TDK CORPARATION

Optical-fiber security early-warning polarization-phase combined control system

ActiveCN101692137BOvercoming phase fadingStable operating pointVibration measurement in solidsAcceleration measurementSignal processing circuitsControl system

The invention provides an optical-fiber security early-warning polarization-phase combined control system for the security protection and early warning of buried pipelines, structures or important facilities and regions, which relates to the technical field of mechanical vibration measurement, impact measurement and pipeline systems. A polarization modulator (202) is connected in serial between acontinuous monochromatic laser (101) and a wave combining-dividing device (203); the wave combining-dividing device (203) is connected with two photoelectric detectors (309) and (310) through opticalfiber; the output ends of the two photoelectric detectors (309) and (310) are connected with an A / D (312) and an A / D (313) respectively; the output ends of the A / D (312) and the A / D (313) are connected with photoelectric signal processing circuits (311) respectively; the output end of one photoelectric signal processing circuit (311) is connected with a polarization controller (201); the output end of the polarization controller (201) is connected with the polarization modulator (202) and a phase modulator (206) connected in serial with optical fiber (1) or (2); the output of the other photoelectric signal processing circuit (311) is connected with a phase controller (205); and the output of the phase controller (205) is connected with the phase modulator (206) connected in serial with the optical fiber (1) or (2).

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

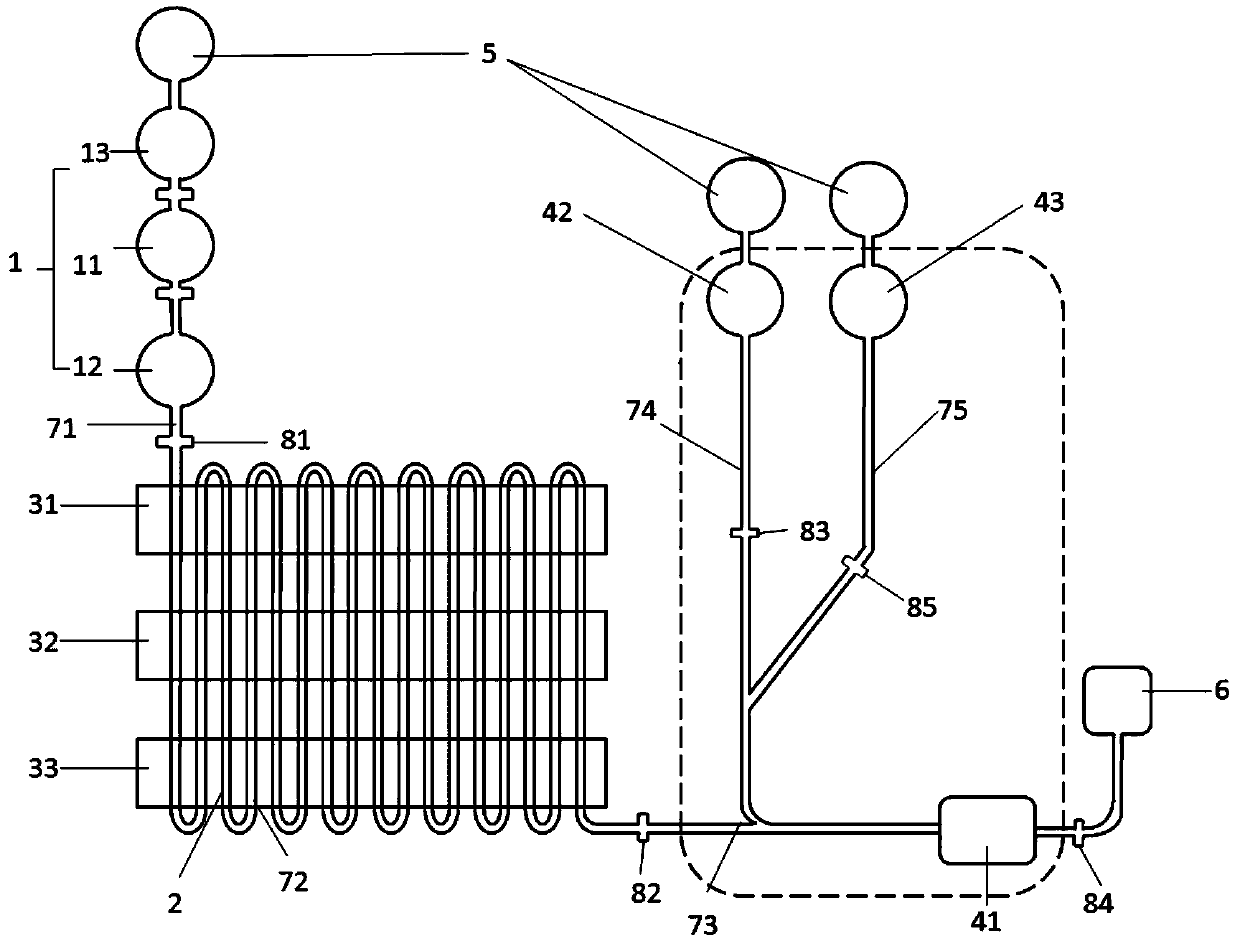

Device and method for detecting nucleic acid by isothermal amplification technology

InactiveCN110699432AThe signal output is stableQuick responseHeating or cooling apparatusMicrobiological testing/measurementMagnetic beadPhysical chemistry

The invention relates to a device and method for detecting nucleic acid by an isothermal amplification technology. The device comprises a sample processor and a magnet-sensitive detector, wherein thesample processor comprises a microflow groove, a temperature controller, a capture chip storage chamber, a DNA modification magnetic bead storage chamber and a cleaning fluid storage chamber; the temperature controller is arranged at the microflow groove; an inlet of the capture chip storage chamber communicates with a reagent outlet of the microflow groove through a first microchannel, communicates with the DNA modification magnetic bead storage chamber through a second microchannel and communicates with the cleaning fluid storage chamber through a third microchannel; valves are arranged on the first microchannel, the second microchannel and the third microchannel; and the magnet-sensitive detector comprises a magnetic sensor and a groove capable of accommodating the capture chip storagechamber, the capture chip storage chamber is inserted in the groove, and the magnetic sensor senses DNA modification magnetic beads in the capture chip storage chamber and converts magnetic signals ofDNA modification magnetic beads into electric signals. The device of the invention is high in response speed and stable in signal output when used for detecting the nucleic acid.

Owner:TDK CORPARATION

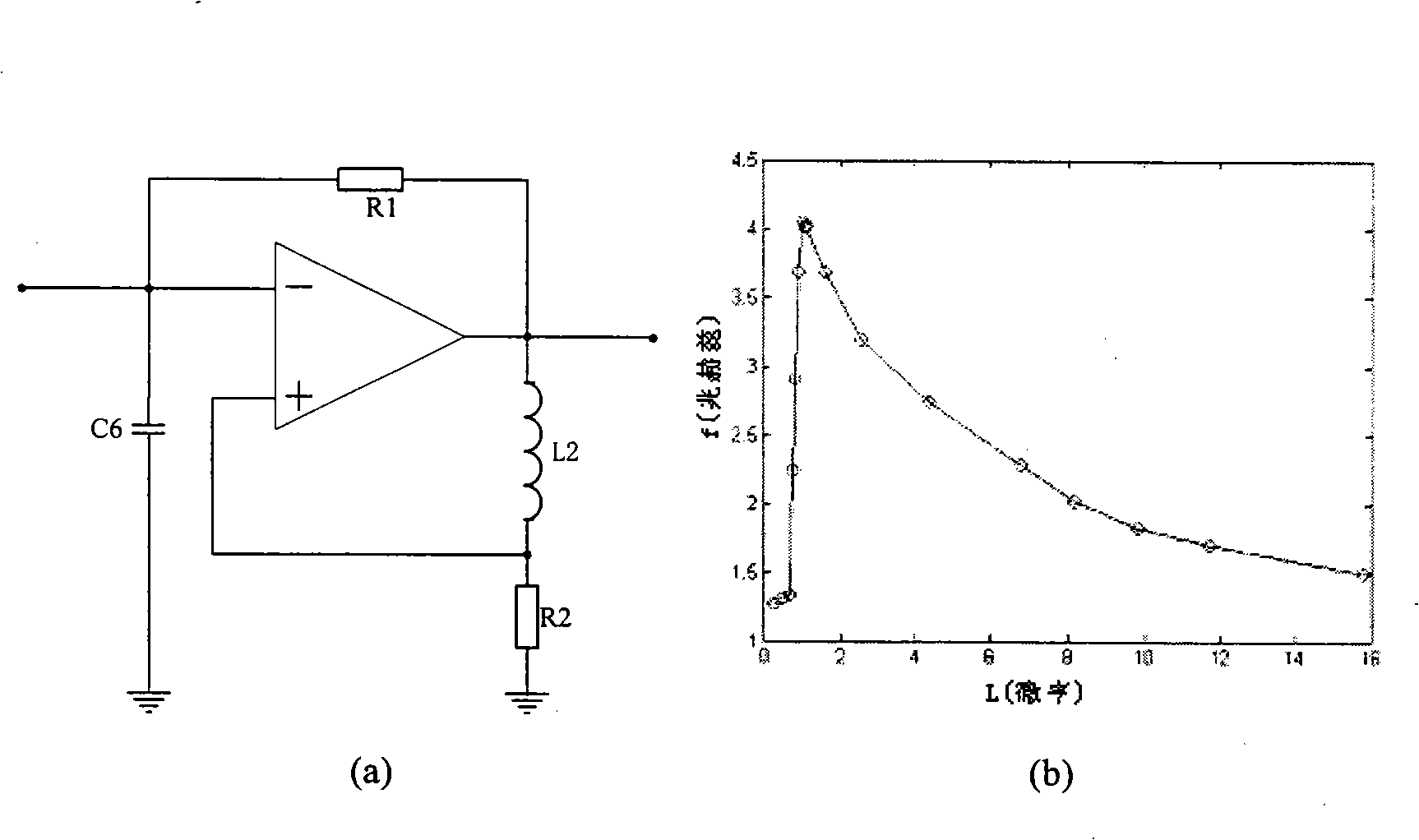

Signal source circuit

InactiveCN103475312ASimple structureThe signal output is stableElectrical apparatusCapacitanceEngineering

The invention discloses a signal source circuit which comprises a triode, a field-effect tube, a resistor and a capacitor. The signal source circuit is simple in structure, signals are output stably, the number of clutter is small, and noise is low. The signal source circuit is suitable for being used in a low-power electronic system.

Owner:KUNSHAN XINJINFU PRECISION ELECTRONICS

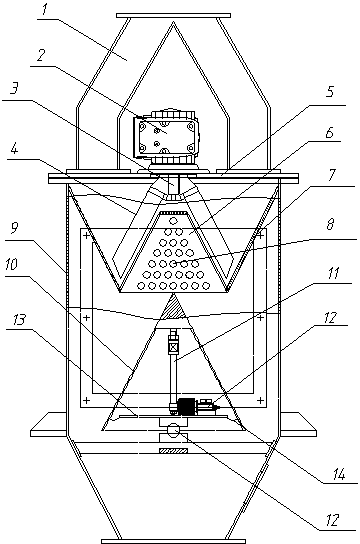

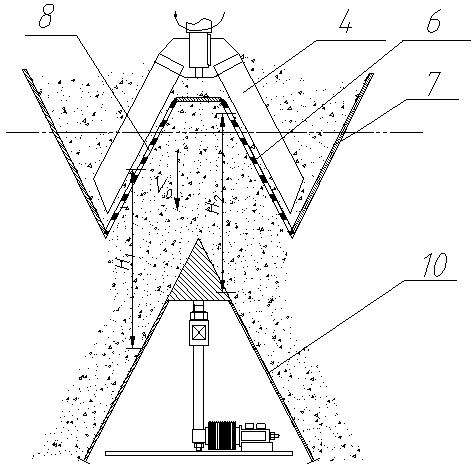

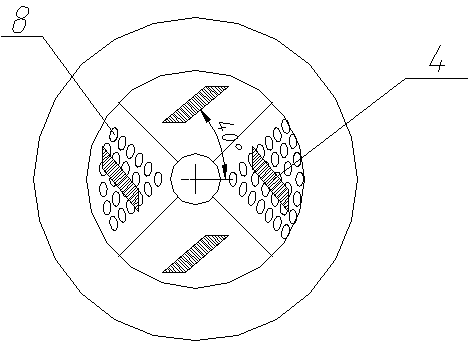

Equivalent-drop height powder impulse flowmeter

ActiveCN102706395ASolve the low measurement accuracyStable material flowVolume/mass flow by differential pressureRotational axisConical forms

The invention relates to an equivalent-drop height powder impulse flowmeter. The equivalent-drop height powder impulse flowmeter is characterized in that the upper part of a shell of the equivalent-drop height powder impulse flowmeter is provided with a herringbone material guide pipe; the shell is internally provided with a feeder, an equivalent-drop height discharger and a material supporting plate from top to bottom, the feeder is a multi-blade rotating feeder, and multiple blades of the multi-blade rotating feeder are fixed on a rotating shaft by being arrayed at intervals in a conical shape; the equivalent-drop height discharger is composed of a discharging chute and a truncated conical drum positioned in the middle of the discharging chute, the conicity of the truncated conical drum is the same as the array conicity of the blades of the multi-blade rotating feeder, and a group of small discharge holes are respectively arranged in two sector areas which are perpendicular to the central connection line direction of two discharge ports of the herringbone material guide pipe; the material supporting plate is formed into a conical material supporting plate and arranged just below the truncated conical drum through a pressure sensor assembly, the conicity of the conical material supporting plate is the same as that of the truncated conical drum, and central lines of the two conical structures are coincided; and perpendicular discharging heights from the centers of all small discharge holes positioned on the truncated conical drum to the conical material supporting plate are equivalent. The invention solves the problem of low metering accuracy of an impact plate flowmeter.

Owner:张正旸

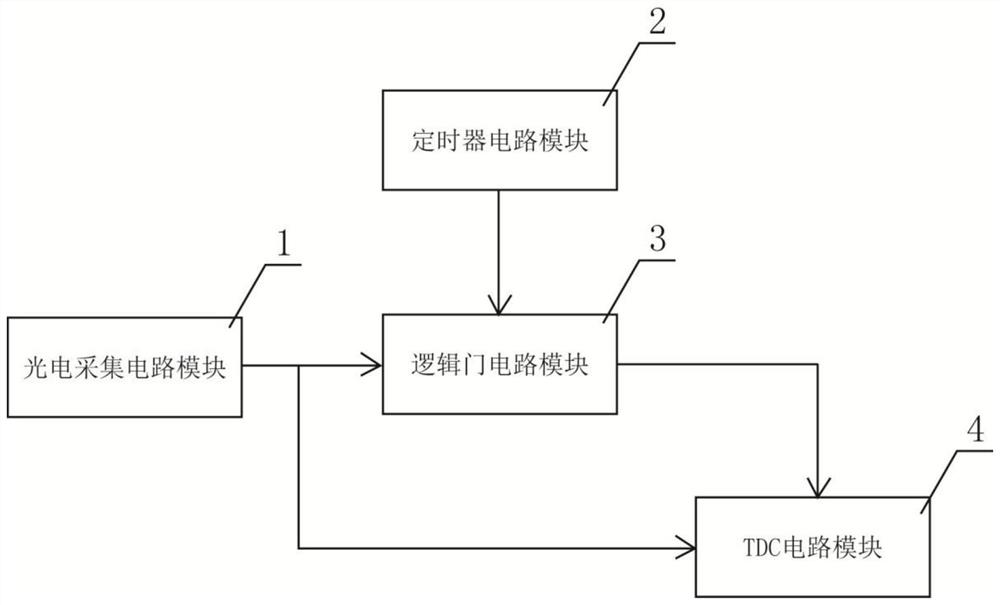

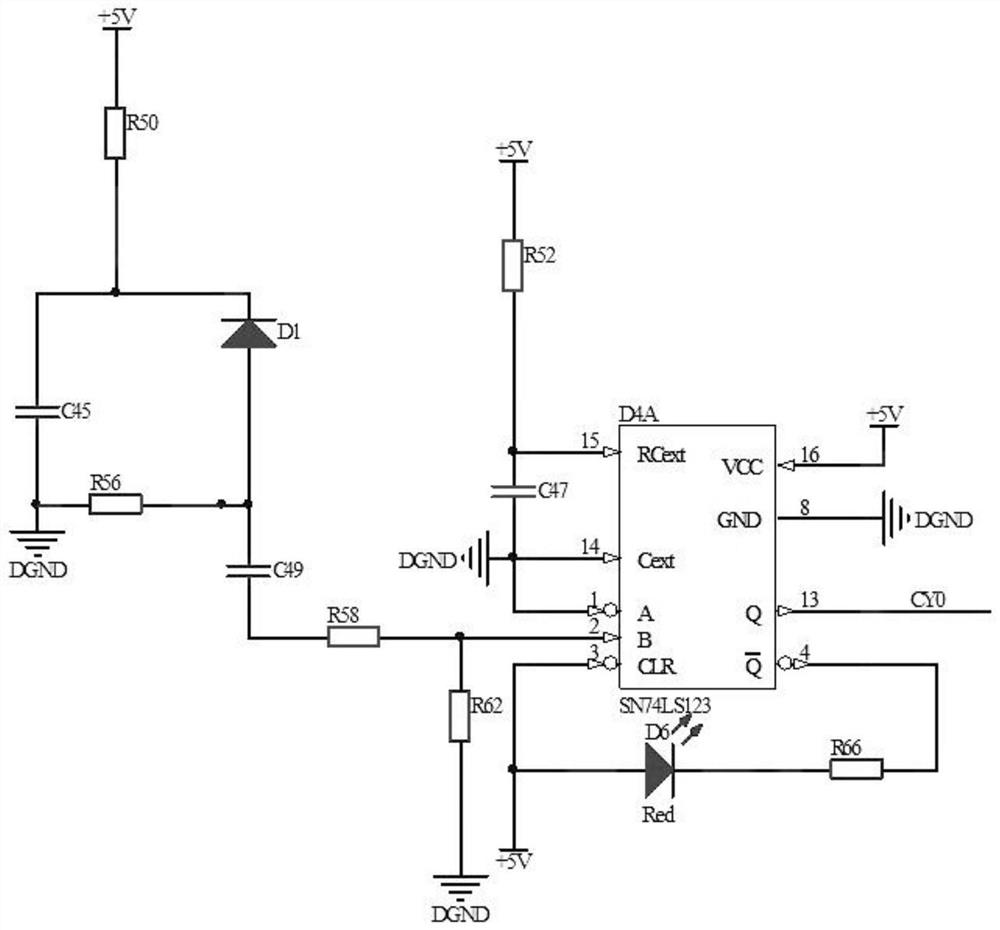

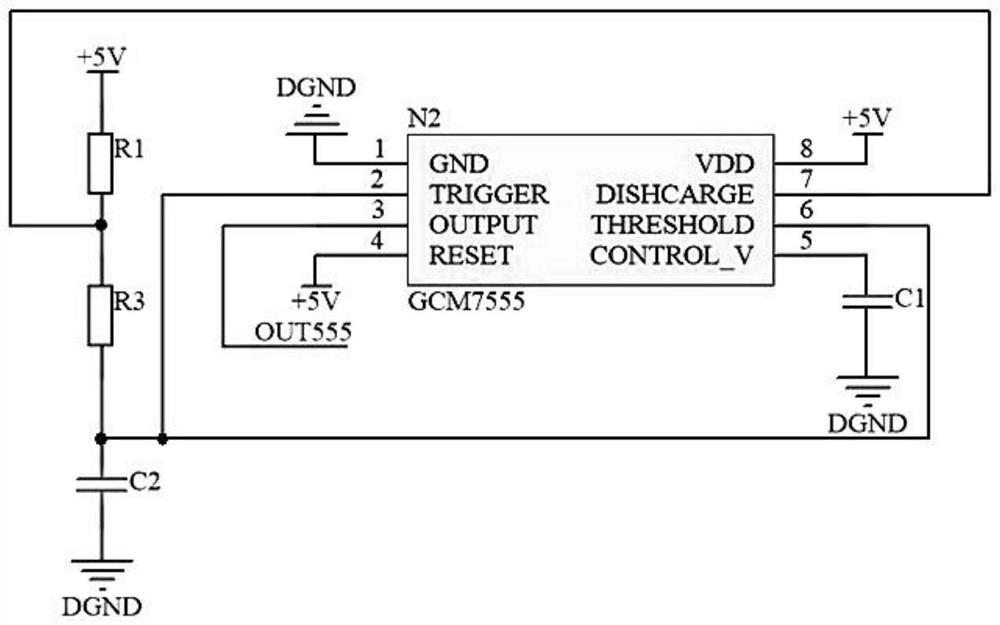

TDC-based false target supplement system

PendingCN114690192AFast signal response timeThe signal output is stableElectromagnetic wave reradiationSoftware engineeringHemt circuits

The invention provides a TDC-based false target supplement system, and the system comprises a photoelectric collection circuit module which is used for transmitting sampling signals to a logic gate circuit module and a TDC circuit module; the timer circuit module is used for sending continuous pulse signals to the logic gate circuit module; the logic gate circuit module is used for supplementing the target number of the echo signals by using the sampling signals and the pulse signals, and then sending the supplemented echo signals to the TDC circuit module; and the TDC circuit module is used for receiving signals sent by the logic gate circuit module and the photoelectric acquisition circuit module. According to the invention, under the condition that a real target is not influenced, the echo signal returned by the target is supplemented, so that the TDC chip can acquire the set target number, and multi-target distance calculation is carried out.

Owner:BEIJING ORIENTAL SHARP LASER TECH

Single point vertical geophone

ActiveCN103995287BHigh conductivity reliabilityThere will be no on-off phenomenonSeismic signal receiversGeophoneEngineering

The invention discloses a single-point perpendicular seismic detector. Two single-lead insulator binding posts are fixed to an upper cover. The lower ends of the single-lead insulator binding posts are welded to conductive lead springs, the lower ends of the conductive lead springs are welded to binding posts in coil rack binding post holes, and the other ends of the binding posts are connected with a leading-out terminal of an upper coil and a leading-out terminal of a lower coil in a welded mode; a coil rack is an integrated piece, the lower end of the coil rack is connected to the outer edge of a lower leaf spring in a pressed mode, the lower end of a lower magnetic shoe is connected to the inner edge of the lower leaf spring in a pressed mode, a boss of a lower cover is sleeved with the lower leaf spring, a groove in the upper end of the coil rack is connected to the outer edge of an upper leaf spring in a pressed mode, the upper end of an upper magnetic shoe is connected to the inner edge of the upper leaf spring in a pressed mode, and a lower boss of the upper cover is sleeved with the upper leaf spring; the upper end of the upper magnetic shoe is higher than the upper end of the upper coil and the lower end of the lower magnetic shoe is lower than the lower end of the lower coil; the deformation direction of a main reinforcing bar of the upper leaf spring and the deformation direction of a main reinforcing bar of the lower leaf spring are respectively anticlockwise. The single-point perpendicular seismic detector is simple in structure, low in cost, high in use reliability, long in service life, narrow in winding, wide in magnetic field, evener in magnetic field and more stable in output, and the number of dropping-resistant times is over 8000.

Owner:保定永诚天峰物探设备制造有限公司

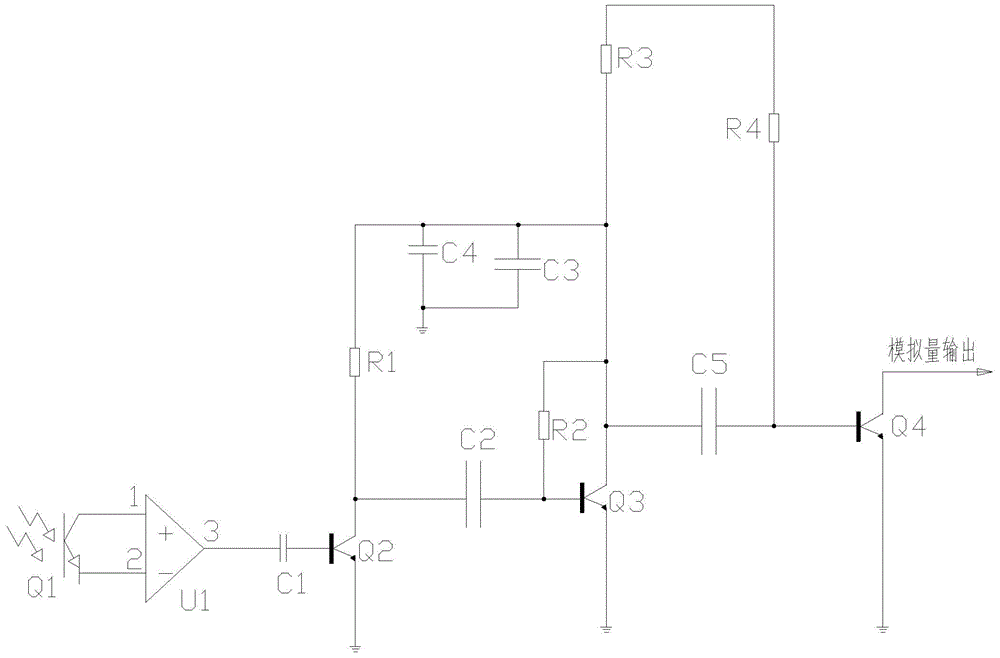

Signal receiving circuit of energy resource monitoring device

InactiveCN104599479ASimple structureInnovative designNon-electrical signal transmission systemsElectromagnetic receiversCapacitanceAudio power amplifier

The invention discloses a signal receiving circuit of an energy resource monitoring device. The signal receiving circuit comprises a first triode used for receiving an infrared signal, wherein a signal amplifier is connected to the first triode, the signal amplifier is connected to a base electrode of a second triode by virtue of a first capacitor, an emitter electrode of the second triode is grounded, a collector electrode of the second triode is divided into two paths, one path of the collector electrode of the second triode is connected to a base electrode of the third triode by virtue of a second capacitor, the other path of the collector electrode of the second triode is connected to one end of a first resistor, an emitter electrode of the third triode is grounded, a collector electrode of the third triode is connected to a base electrode of a fourth triode by virtue of a fifth capacitor, an emitter electrode of the fourth triode is grounded, a collector electrode is used for outputting an analog signal, the other end of the first resistor is connected to the collector electrode of the third triode, a third resistor and a fourth resistor which are serially connected together are connected in parallel to two ends of the fifth capacitor, a signal is amplified by the signal amplifier after being received by the first triode, and then output after being coupled and amplified by the second triode, the third triode and the fourth triode, and the signal is output stably.

Owner:姜刘

an audio signal circuit

InactiveCN103475977BSimple structureThe signal output is stableTransducer circuitsCapacitanceVoltage amplitude

The invention discloses an audio signal circuit which comprises an operational amplifier, a triode, a variable resistor, a resistor, a capacitor and a diode. The audio signal circuit uses the triode which works in a variable resistance area to form stable nonlinear resistance output and can maintain constant output voltage by adjusting the variable resistor in the circuit and adjusting the strength of feedback. Furthermore, the problem of improving the stability of output voltage amplitude is solved. The audio signal circuit is simple in structure, stable in signal output, little in clutter and suitable for small-power electronic systems.

Owner:昆山龙仕达电子材料有限公司

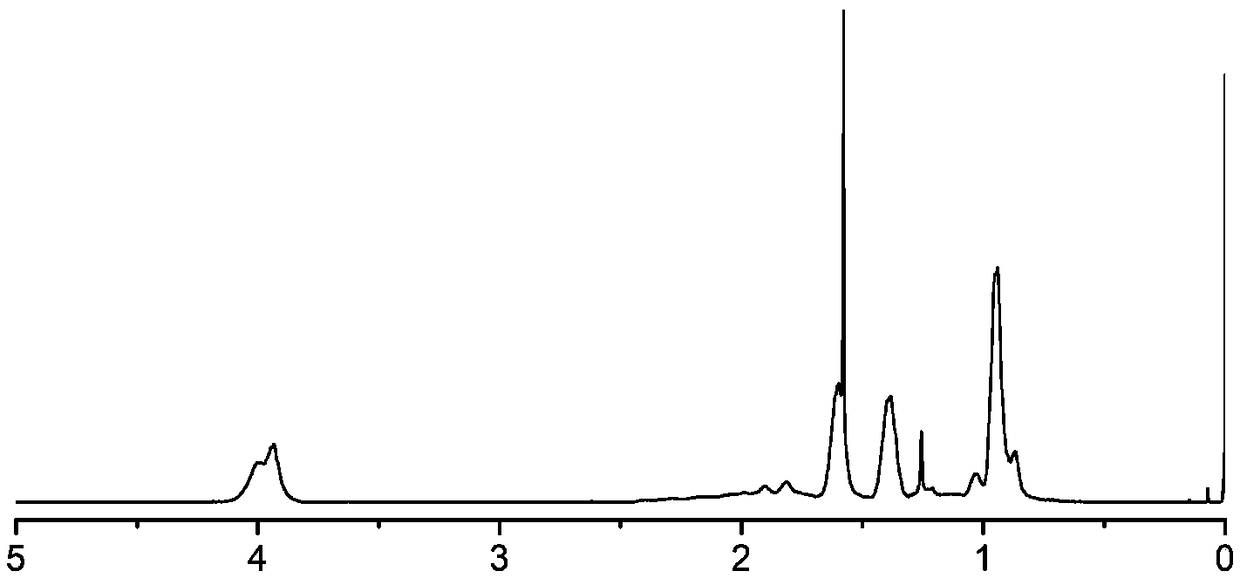

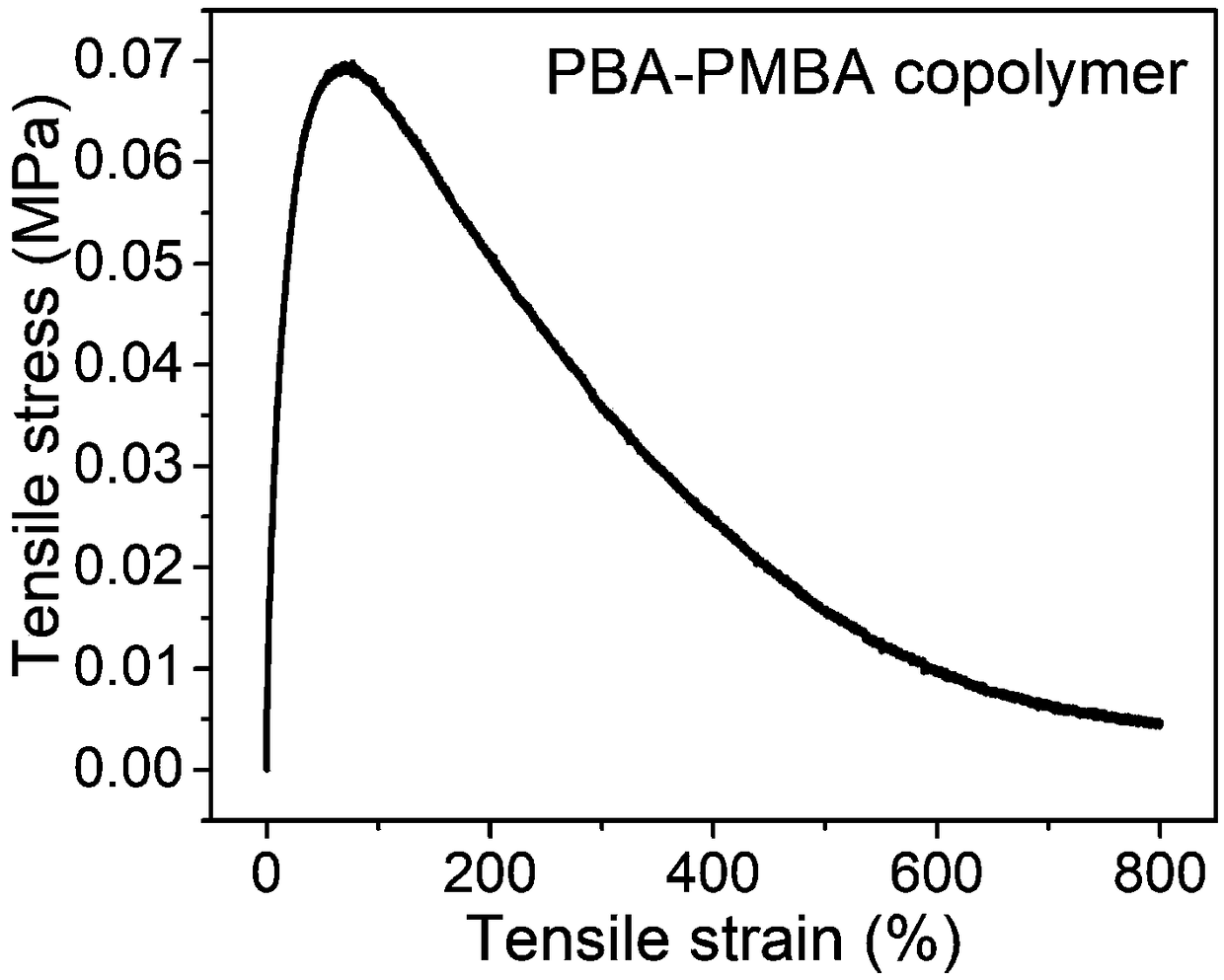

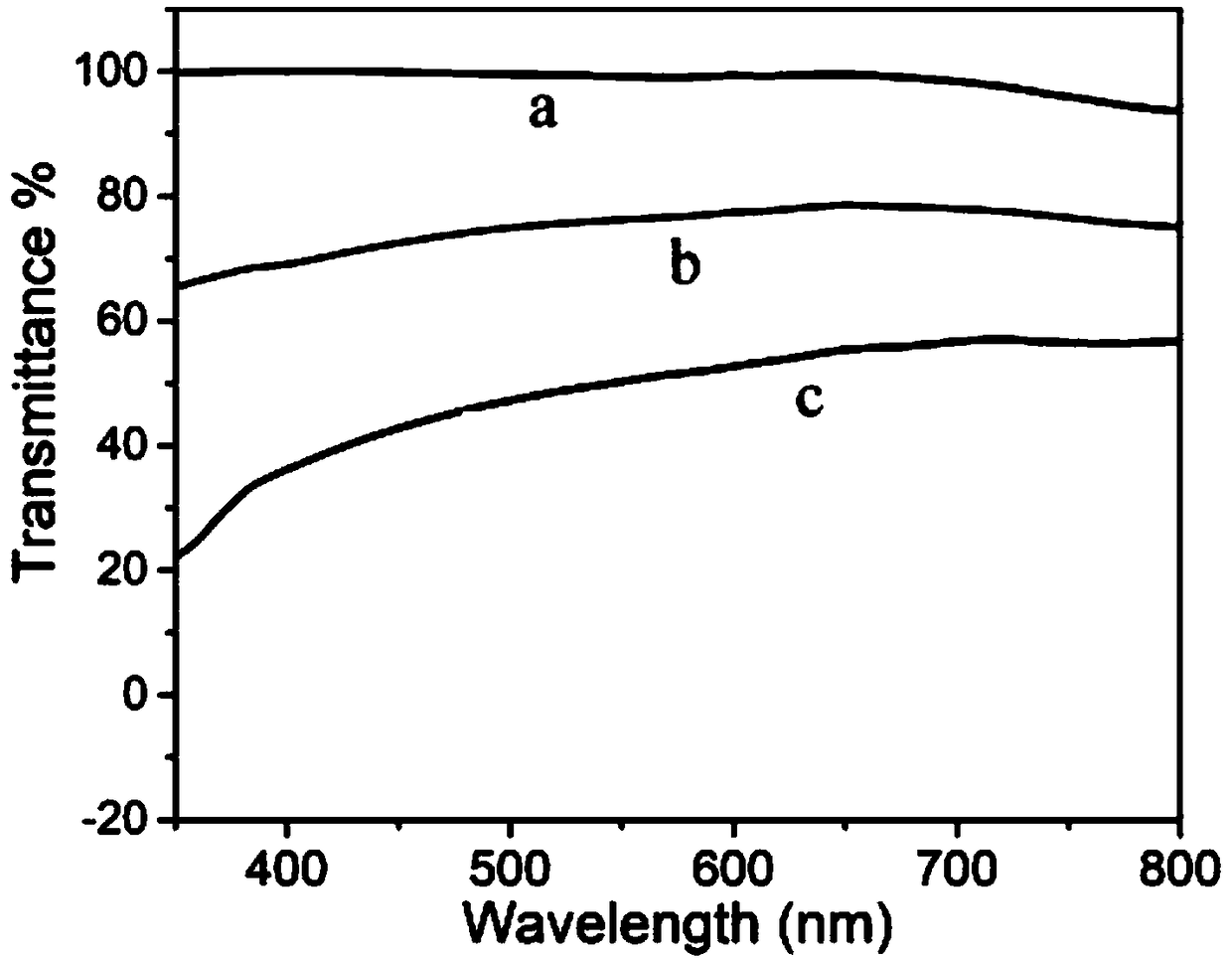

Polybutyl acrylate-poly-n-butyl methacrylate copolymer for nano generators and self-driven sensors and preparation method thereof

ActiveCN109096431AImprove flexibilityHigh transparencyForce measurement using piezo-electric devicesElectrical/magnetic solid deformation measurementPolymer scienceNanogenerator

The invention relates to a preparation method of a polybutyl acrylate-poly-n-butyl methacrylate copolymer for nano generators and self-driven sensors and application of the polybutyl acrylate-poly-n-butyl methacrylate copolymer to nano new energy. The preparation method of the electropositivity-including polybutyl acrylate-poly-n-butyl methacrylate copolymer for nano generators and self-driven sensors is simple; the prepared copolymer has excellent mechanical property, transparency and favorable betatopic capability. By using the polybutyl acrylate-poly-n-butyl methacrylate copolymer for flexible nano generators and self-driven sensors, prepared friction nano generators have excellent mechanical property and transparency, prepared friction nano generators are high in power and stable in output performance, and prepared self-driven sensors are excellent in mechanical property and transparency, high in sensitivity and stable in signal output.

Owner:HUNAN UNIV OF TECH

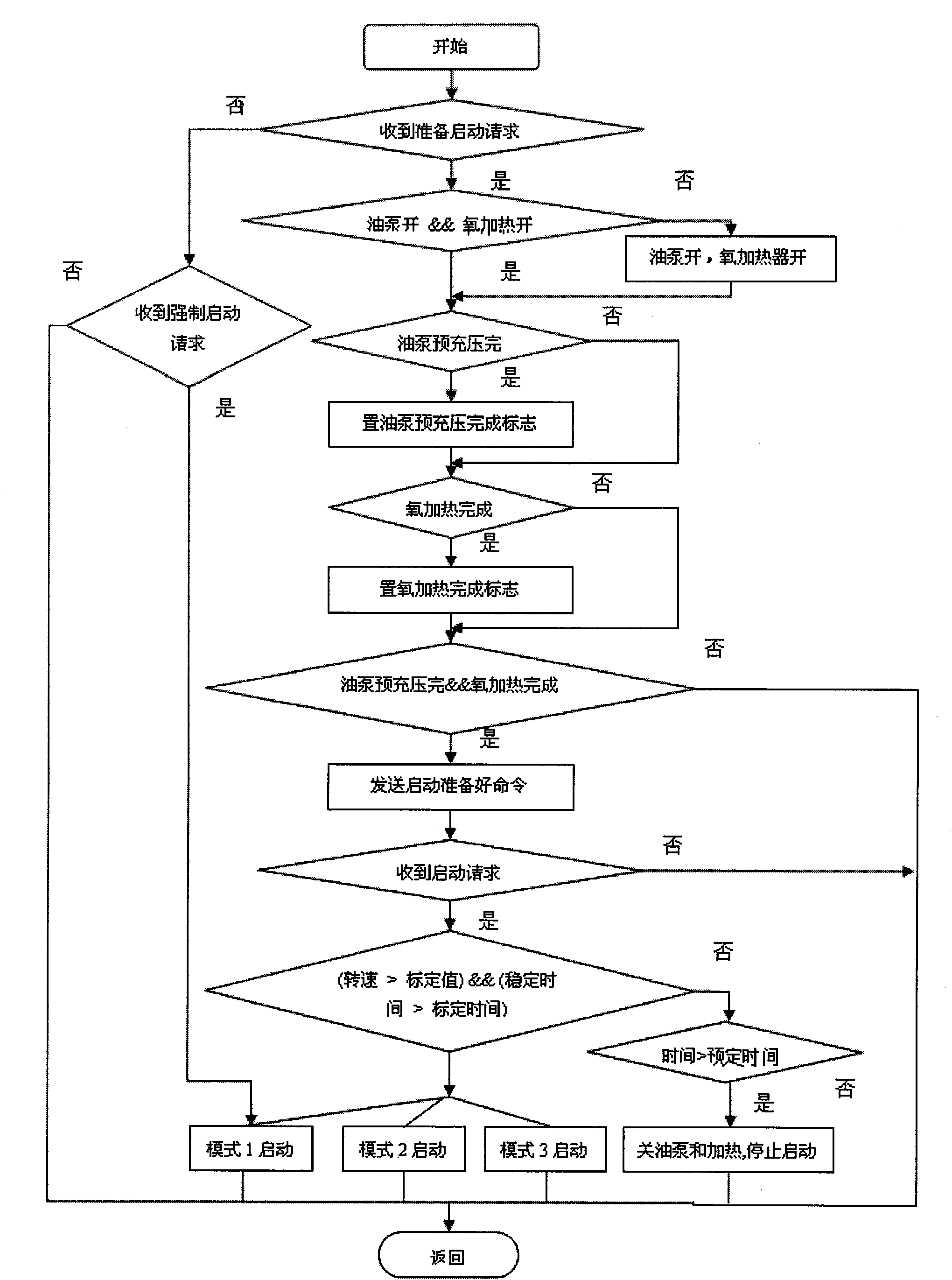

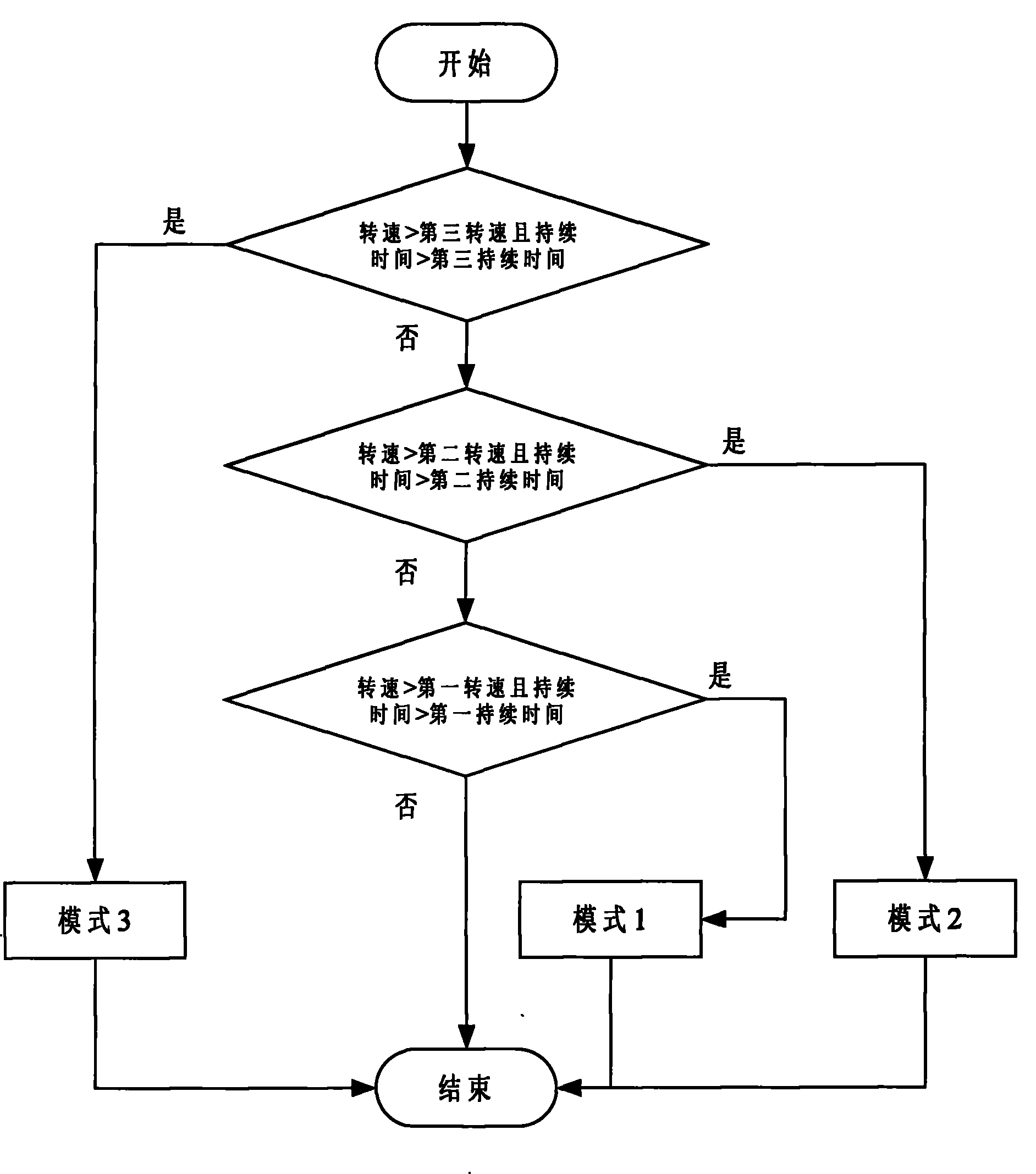

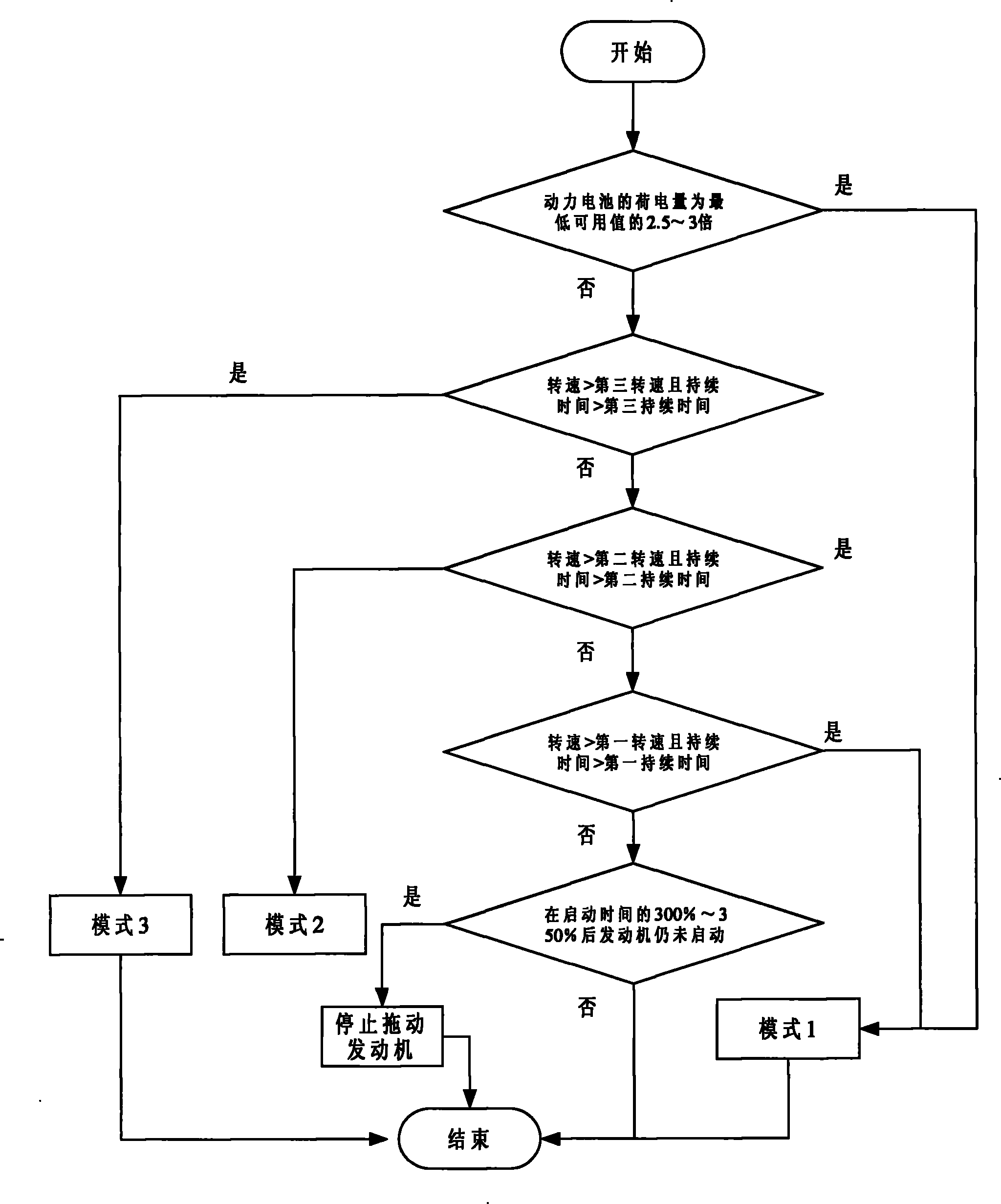

Method for starting engine and starting control device

ActiveCN101377155BEasy dischargeImprove boot qualityElectrical controlMachines/enginesEngineeringControl theory

Owner:BYD CO LTD

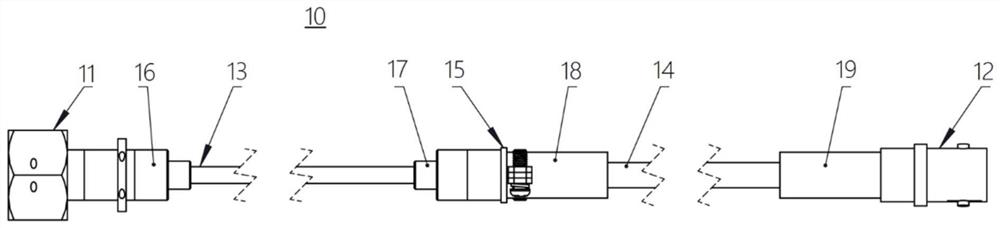

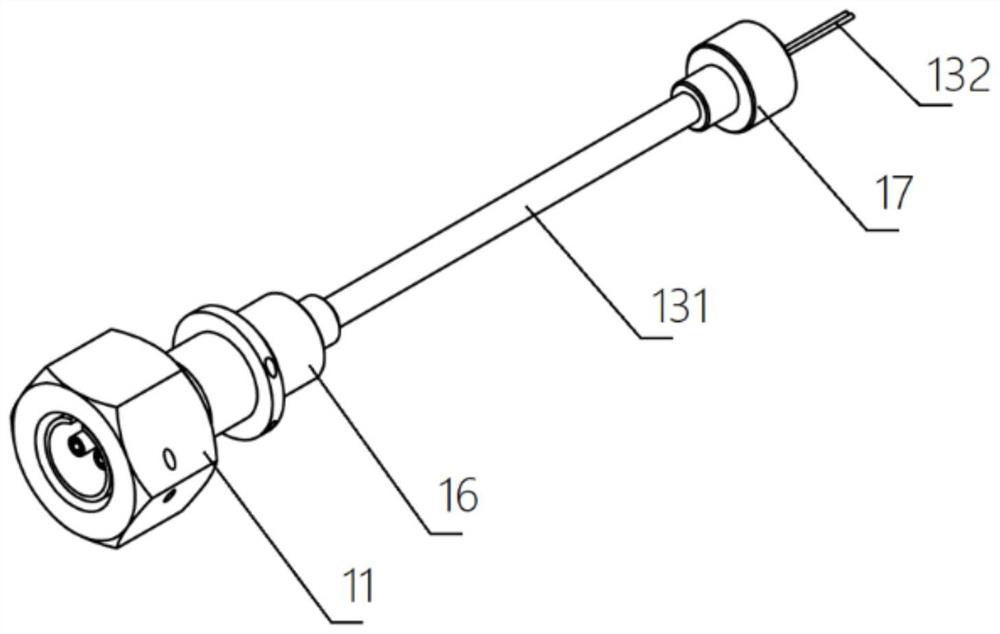

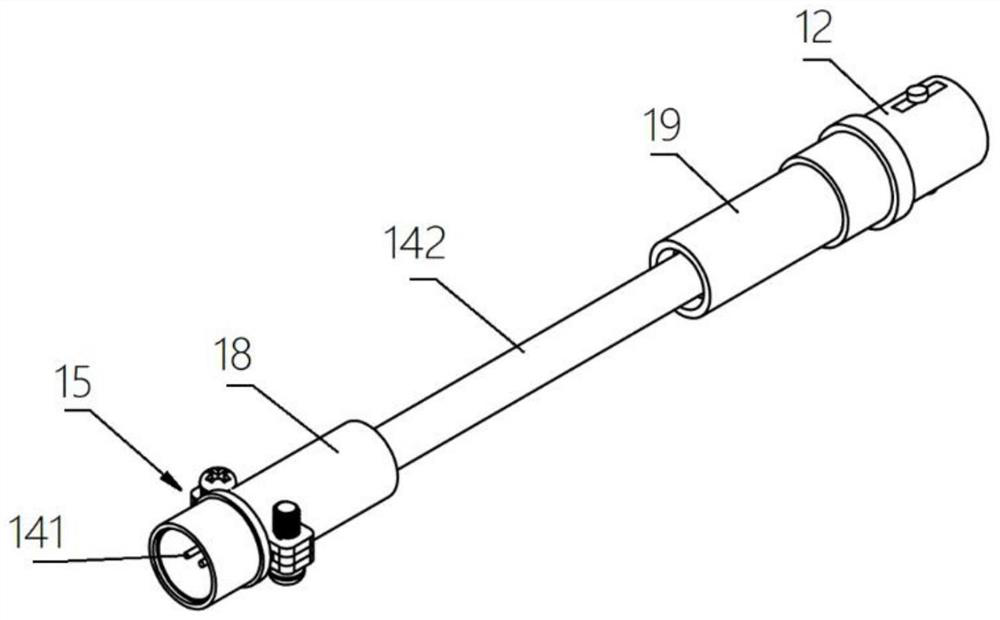

Armored cable, jig, assembling method of armored cable and sensor

PendingCN112735646ASolve the problem of low yieldAchieve receptionContact member assembly/disassemblySubsonic/sonic/ultrasonic wave measurementStructural engineeringMechanical engineering

The invention discloses an armored cable, a jig, an assembling method of the armored cable and a sensor. The armored cable comprises a high-temperature device, a low-temperature device, a high-temperature line segment and a low-temperature line segment, the high-temperature line segment and the low-temperature line segment are located between the high-temperature device and the low-temperature device, the high-temperature device is connected to the high-temperature line segment, and the low-temperature device is connected to the low-temperature line segment. And the high-temperature line segment is connected with the low-temperature line segment through a connecting device. According to the invention, the overall cost of the armored cable is reduced, the low-temperature line segment is easy to process, the cost rate is high, and the problem that the yield of the armored cable with a single high-temperature line segment is low is solved.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

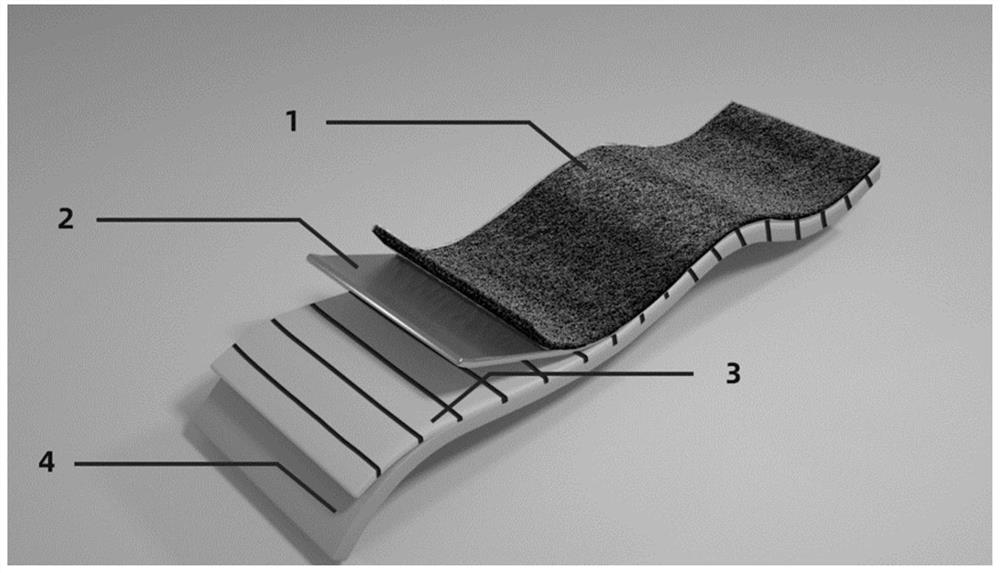

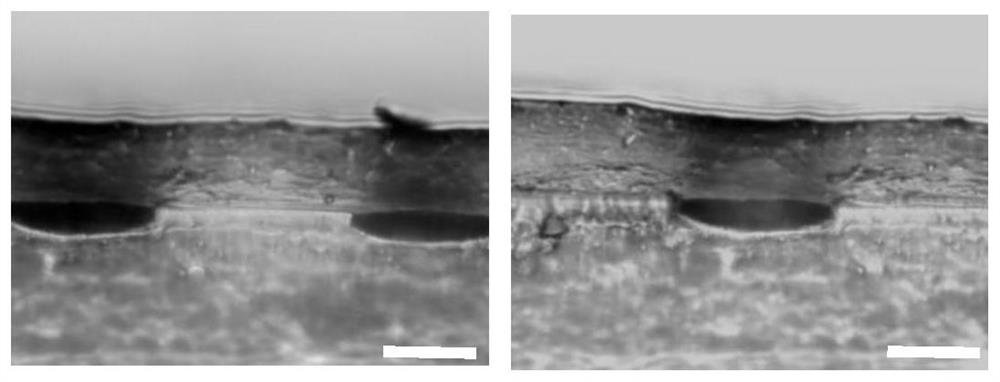

A Flexible Strain Sensor with Strain Isolation Effect

ActiveCN110726364BHigh sensitivityEasy to stretchElectrical/magnetic solid deformation measurementHuman bodyElastomer

The invention relates to a flexible strain sensor with strain isolation effect. The strain sensor includes: a flexible substrate, the surface of the flexible substrate is prefabricated with a parallel crack structure or a grid crack structure obtained by stretching by a certain method; a strain isolation layer, the strain isolation layer has a modulus much smaller than that of the substrate an elastomer; a conductive filler coated on the strain isolation layer as a strain response layer; and electrodes at both ends of the strain response layer. The flexible crack strain sensor obtained by the invention can obtain greater stretchability while maintaining higher sensitivity. In addition, in order to adapt to the complex strain conditions of the human body, the substrate provided by the invention has a network crack structure to realize the multi-directional detection function. The invention solves the problem of limited tensile performance when the crack strain sensor has high sensitivity, and cannot adapt to the complex The question of contingencies.

Owner:XIANGTAN UNIV

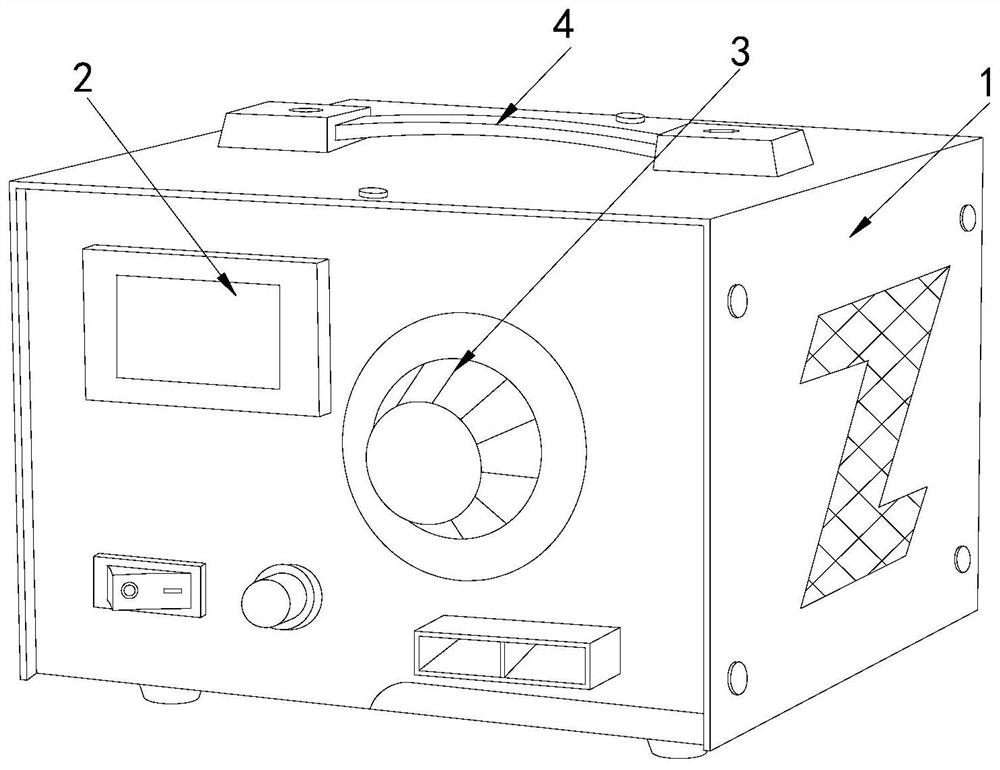

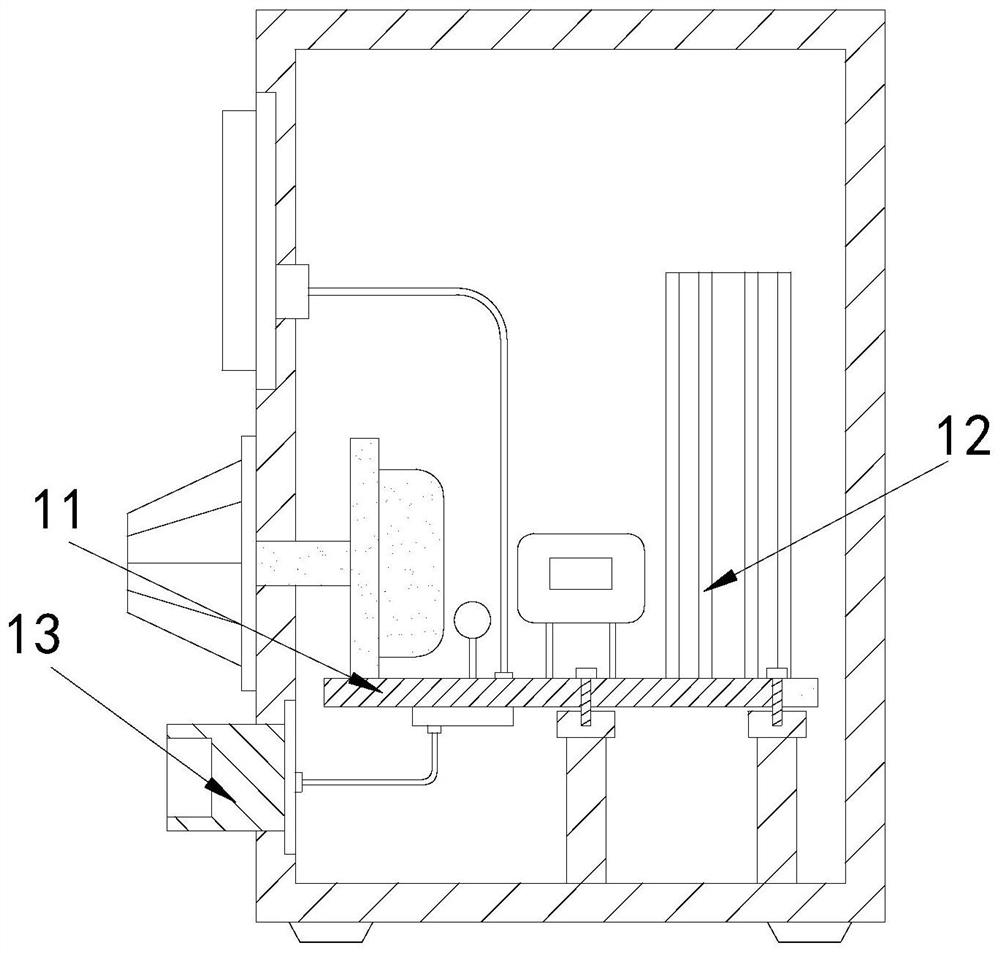

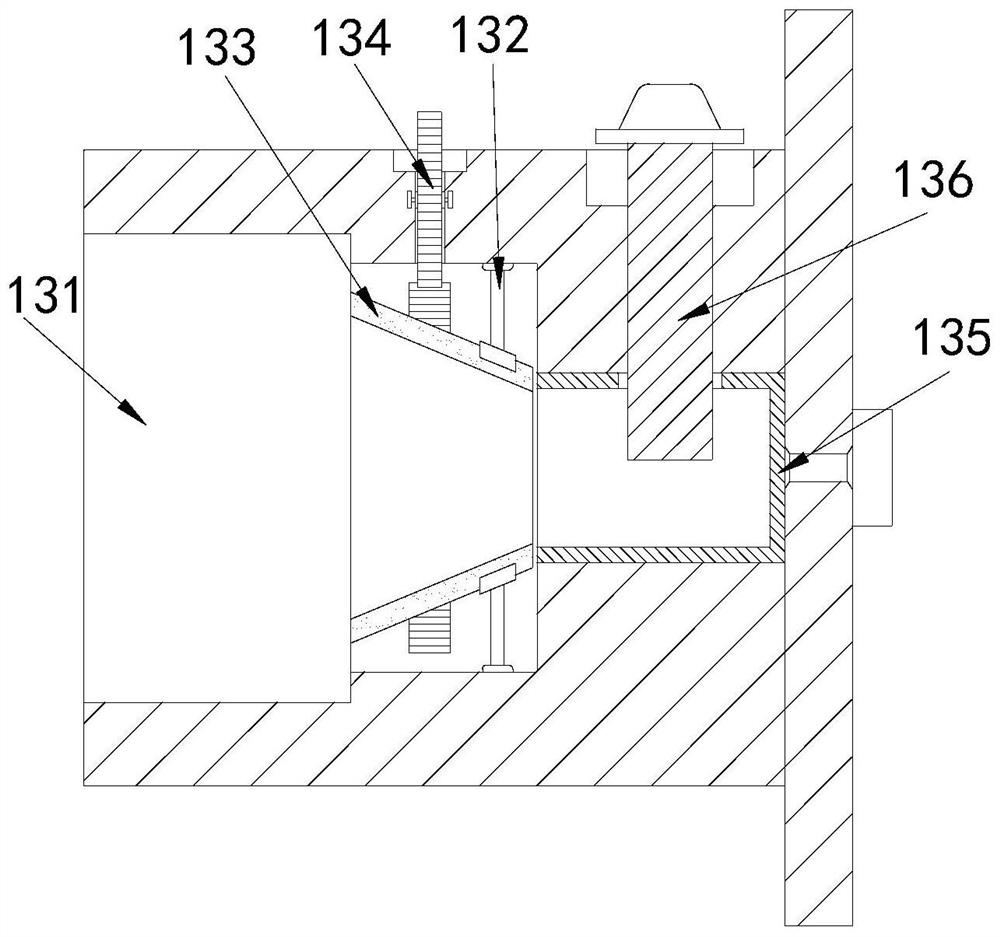

Voltage regulating equipment based on single-chip microcomputer

InactiveCN112886322AAvoid sheddingThe signal output is stableEngagement/disengagement of coupling partsEngineeringHeat sink

The invention discloses voltage regulating equipment based on a single-chip microcomputer, which structurally comprises a main body, a display screen, a regulating button and a handle, wherein the display screen is arranged at the top of the front end of the main body, the regulating button is arranged at the right end of the display screen, the handle is clamped in the middle of the top of the main body, the main body comprises a circuit board, cooling fins and a power connector, the power connector comprises a concave groove, a clamping frame, a wire frame, an adjusting tooth block, a conductive frame and a pressing device, the wire frame comprises a frame body, a threaded groove, a movable tooth block and a clamping groove, and the threaded groove comprises a groove body, a material guide block and a wire groove.According to the invention, the wire guiding frame rotates, so that the silk thread can be in contact with the threaded groove, and the silk thread is guided backwards through the threaded groove, so that the bifurcated silk thread is screwed into a silk strip, and the silk strip can be firmly arranged in the conductive frame under the fixation of the pressing device, the situation that the connecting wire falls off is avoided, and the single-chip microcomputer can stably output signals.

Owner:蔡绍雄

System for transporting plate-shaped bottom die

PendingCN114132736AReduce shipping errorsGuaranteed accuracyControl devices for conveyorsTotal factory controlSignal processingControl theory

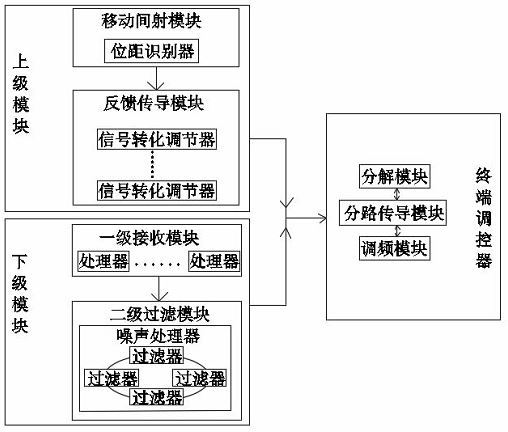

The invention relates to the technical field of intelligent adjustment, in particular to a plate-shaped bottom die transportation system which comprises a superior unit used for signal generation and a subordinate unit matched with the superior unit for signal receiving, and the superior unit and the subordinate unit jointly act to transmit signals to a terminal regulator; a decomposition module used for signal processing and a frequency modulation module used for signal output are embedded in the terminal regulator, the stability of signal output and receiving can be effectively guaranteed through the arrangement of the upper-level unit and the lower-level unit, meanwhile, it is guaranteed that the plate-shaped bottom die is positioned and monitored in real time in the transportation process, and the transportation error rate is reduced to the maximum extent.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

Underground signal receiving and transmitting device

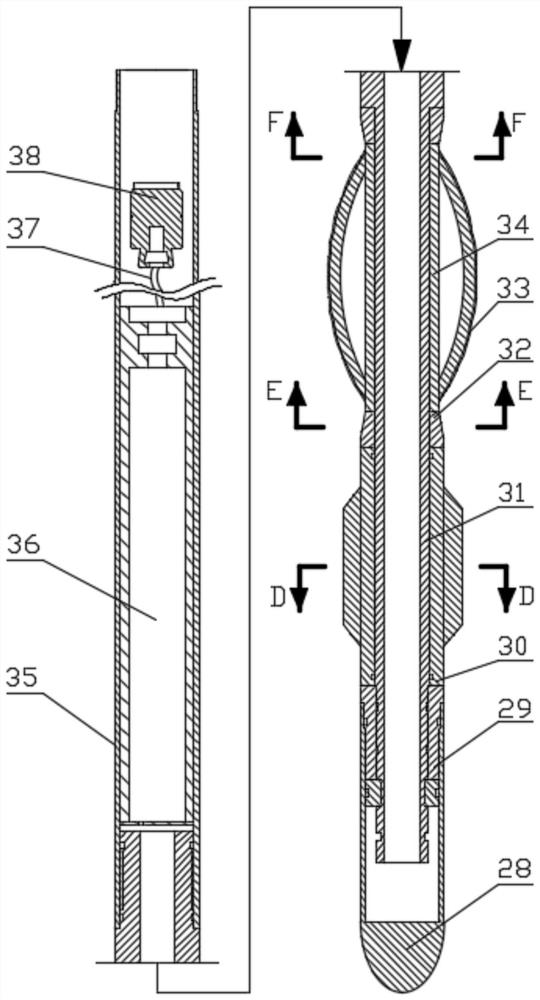

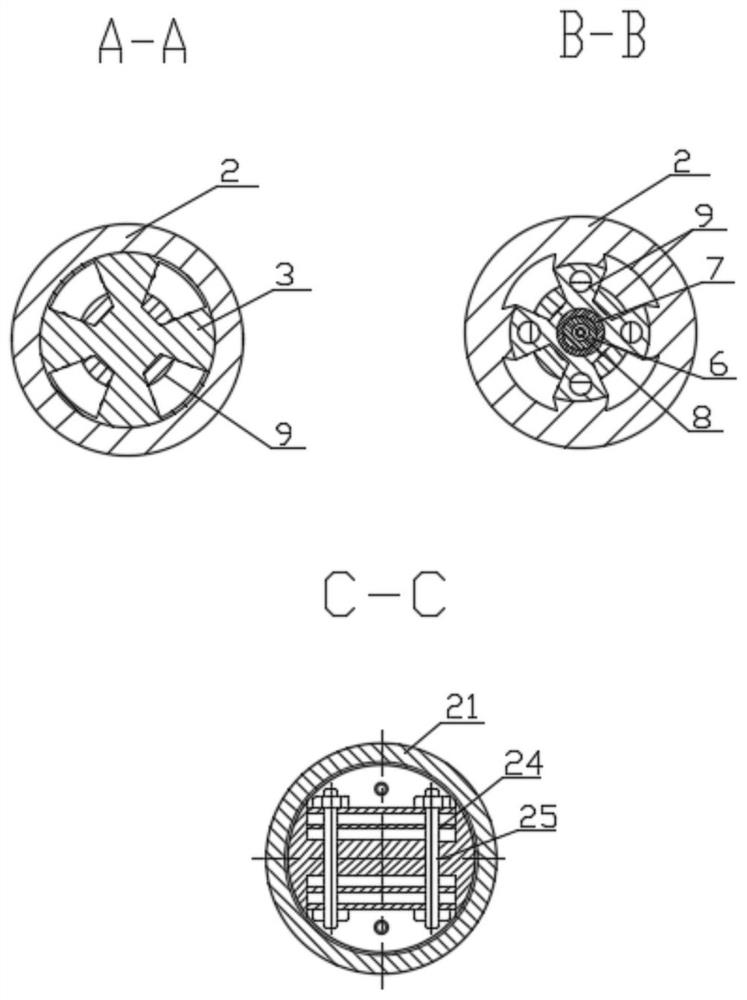

ActiveCN113482606AQuality improvementImprove decoding performanceSurveyTransmissionThermodynamicsWell drilling

Owner:SOUTHWEST PETROLEUM UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com