Blade type level gage

A material level meter and vane-type technology, applied in the field of material level meter, can solve the problems of poor versatility, failure to meet the bag filter, large error, etc., and achieve the effect of small error, wide applicability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the description of the drawings and specific embodiments, but it is not intended to limit the scope of protection thereof.

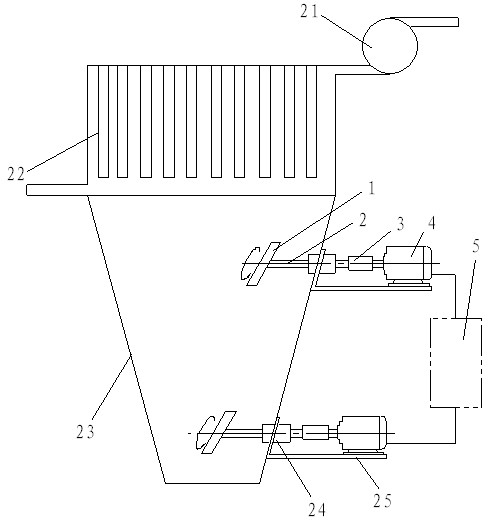

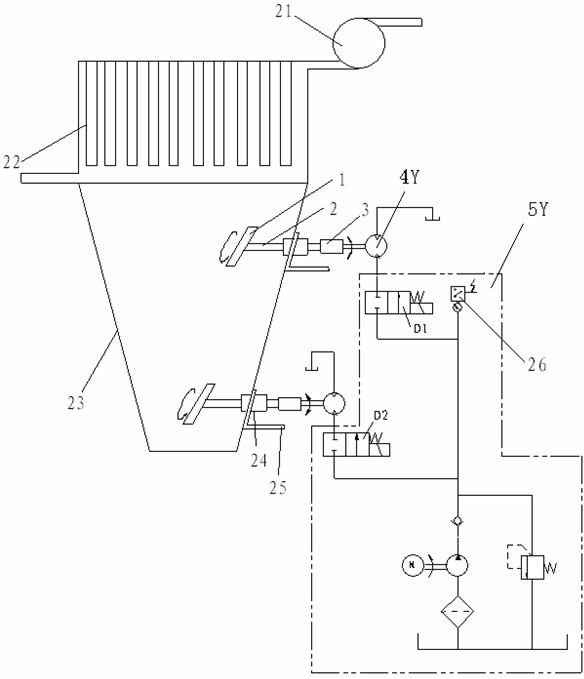

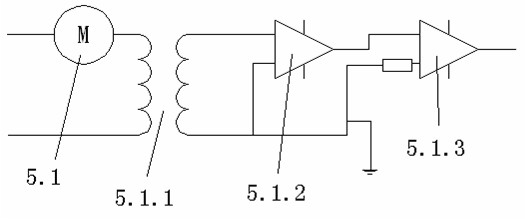

[0018] see figure 1 , image 3 , a vane-type material level gauge, including a vane 1, a transmission shaft 2, a power unit 4 and a signal acquisition control unit 5, the output shaft of the power unit 4 is connected to the transmission shaft 2, and the vane 1 is fixed on the transmission shaft 2 , the signal acquisition control device 5 is connected with the power device 4 .

[0019] see figure 1 , the power unit 4 adopts a motor, the output shaft of the motor is connected with the input end of the reducer 3, the output end of the reducer 3 is connected with the transmission shaft 2, and two blades 1 are fixed on the other end of the transmission shaft 2, the blades 1 is in contact with the dust during the rotating motion to generate motion resistance; the transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com