A Flexible Strain Sensor with Strain Isolation Effect

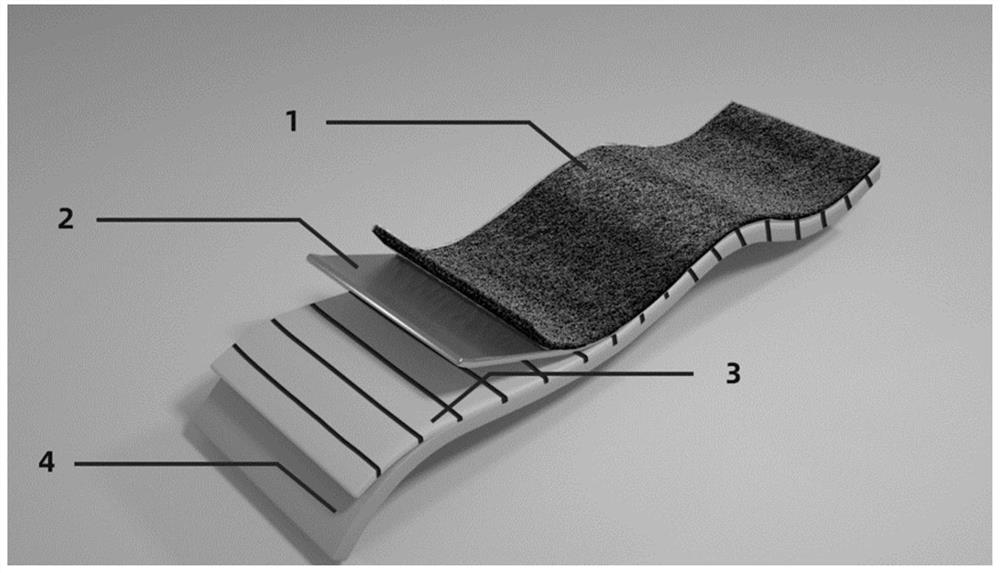

A technology of strain sensor and isolation effect, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problem of limited tensile performance, achieve large tensile performance, wide application prospects, and stable signal output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1. Mix the precursor of polydimethylsiloxane PDMS and curing agent in a weight ratio of 10:1, pour it into a self-made rectangular mold, and use a vacuum pump for 1 hour of degassing treatment, and then place it in a dry place It is cured by heating at 100°C for 2 hours in an oven.

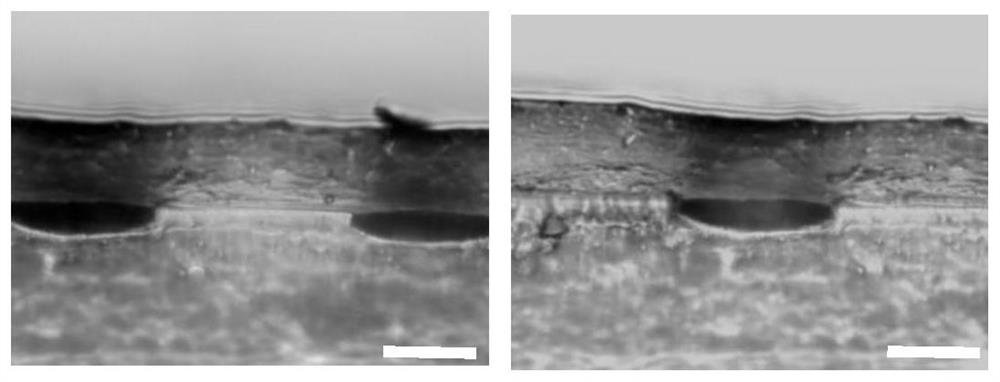

[0050] Step 2. The cured PDMS is peeled off from the mold to obtain a long PDMS spline. Put the PDMS strip in UV / O3 treatment for 20min to produce SiOx oxide layer on the surface. A uniaxial tensile strain is then applied at both ends of the spline, thereby creating cracks on the surface of the spline.

[0051] Step 3. The liquid Ecoflex was spin-coated on the glass slide at a high speed of 2000 rpm by a spin coater to obtain an uncured Ecoflex layer of about 70 μm. Place it at room temperature for 10 minutes to make the uncured Ecoflex transform into a semi-cured state.

[0052] Step 4. Paste the surface with prefabricated cracks in the substrate and Ecoflex in a semi-cured state, ...

Embodiment 2

[0057] Step 1. Mix the precursor of polydimethylsiloxane PDMS and curing agent in a weight ratio of 10:1, pour it into a self-made rectangular mold, and use a vacuum pump for 1 hour of degassing treatment, and then place it in a dry place It is cured by heating at 100°C for 2 hours in an oven.

[0058] Step 2. The cured PDMS is peeled off from the mold to obtain a long PDMS spline. Put the PDMS sample strip in UV / O3 treatment for 10min to produce SiOx oxide layer on the surface. A uniaxial tensile strain is then applied at both ends of the spline, thereby creating cracks on the surface of the spline.

[0059] Step 3. The liquid Ecoflex was spin-coated on the glass slide at a high speed of 2000 rpm by a spin coater to obtain an uncured Ecoflex layer of about 70 μm. Place it at room temperature for 10 minutes to make the uncured Ecoflex transform into a semi-cured state.

[0060] Step 4. Paste the surface with prefabricated cracks in the substrate and Ecoflex in a semi-cured ...

Embodiment 3

[0068] Step 1. Step 1. Mix the precursor of polydimethylsiloxane PDMS and curing agent evenly in a weight ratio of 10:1, pour it into a self-made square mold, and use a vacuum pump for 1 hour of degassing treatment, and then Place in a drying oven and heat at 100°C for 2 hours to cure.

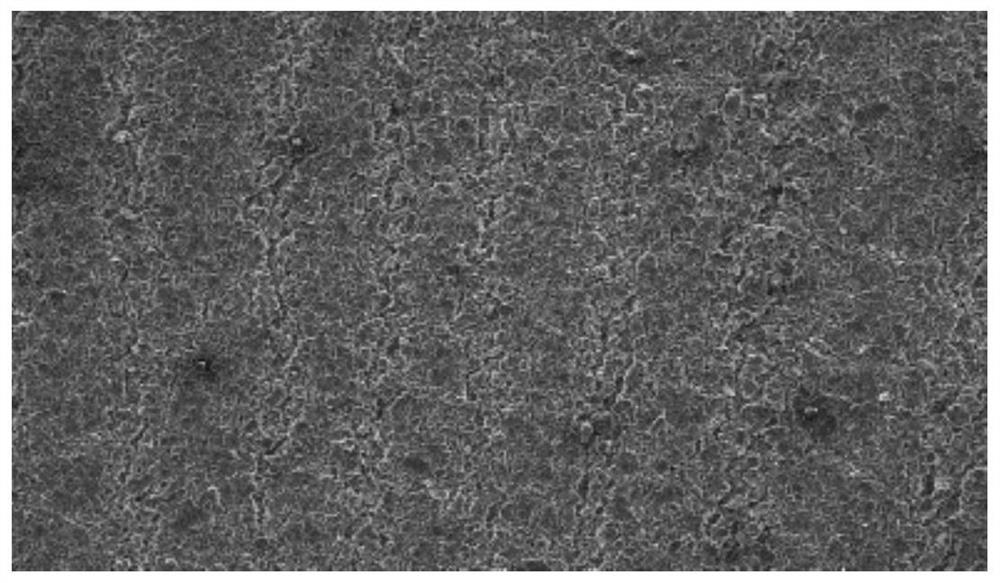

[0069] Step 2. Peel the cured PDMS from the mold to obtain a square PDMS substrate. Make a cross-shaped mask through a paper cutter, and define a cross-shaped area on the PDMS substrate for UV / O 3 Treat for 10min, produce SiO on the surface x oxide layer. A first uniaxial stretch of 150% was applied at both ends of the substrate, resulting in long cracks perpendicular to the stretching direction on the substrate surface. Subsequently, a second uniaxial stretch of 200% is applied in a direction perpendicular to the first uniaxial stretch, so that short cracks perpendicular to the second stretch are generated on the surface of the substrate to form a network crack structure.

[0070] Step 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com