Pressure transducer having stress concentration

A technology of pressure sensor and stress concentration, which is applied in the fields of identification, communication, marine environment monitoring, marine resource development, and underwater detection. It can solve the problems of high sensor cost, poor electromagnetic resistance, poor pollution ability, and pressure sensors that cannot be used. The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

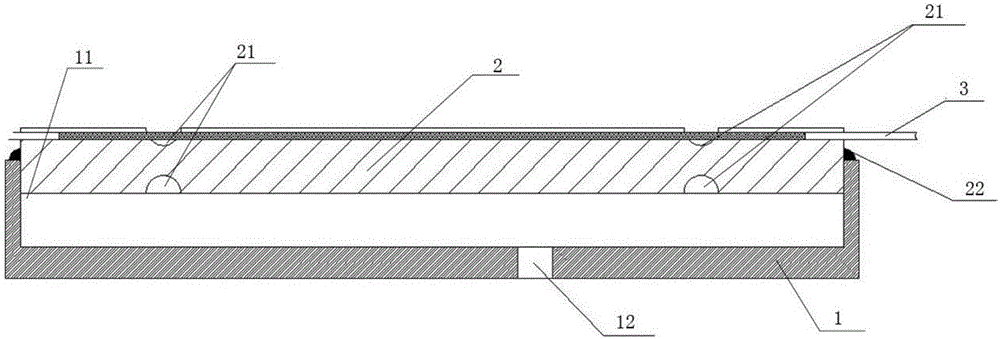

[0022] Such as figure 1 As shown, a pressure sensor with stress concentration in this embodiment includes:

[0023] Shell 1, a cylindrical structure with both ends of the shell 1 blocked, and the shell 1 is provided with an installation hole 11 and an air extraction hole 12;

[0024] A metal film 2, the metal film 2 is arranged in the installation hole 11 and its peripheral edge is fixedly connected with the inner wall of the installation hole 11; the metal film 2 is provided with a stress concentration groove 21; the metal film 2 is connected with the inner wall of the installation hole 11; The soldering point 22 formed by welding the mounting hole 11 is as figure 1 shown;

[0025] FBG optical fiber 3 , the FBG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com