Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "The method is simple and economical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

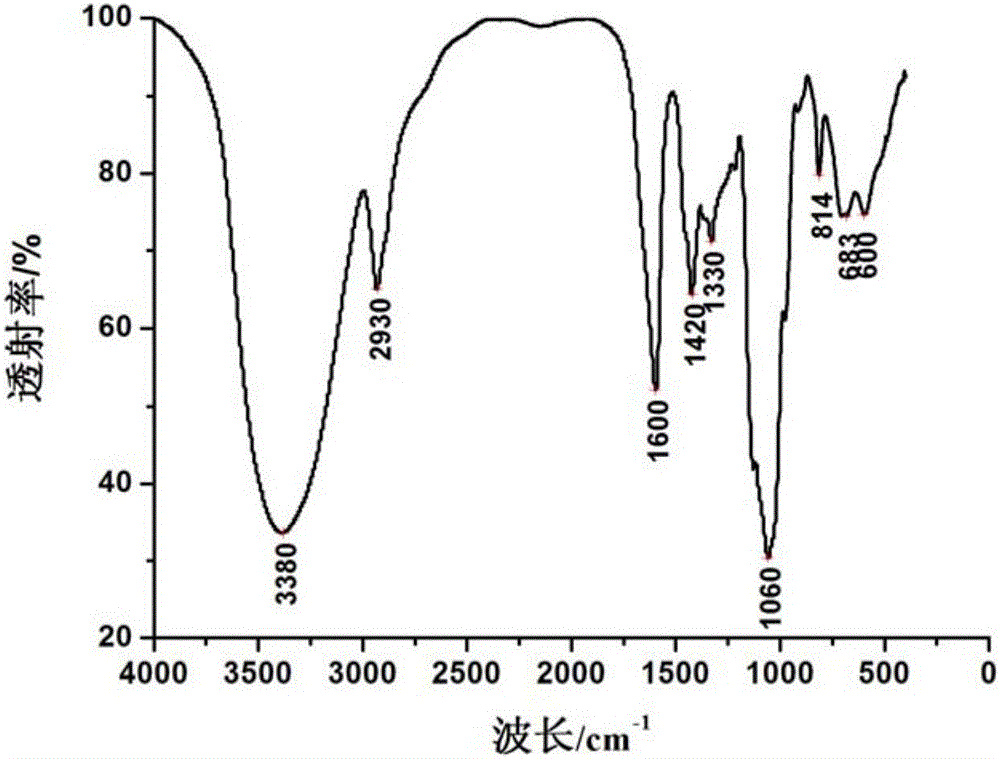

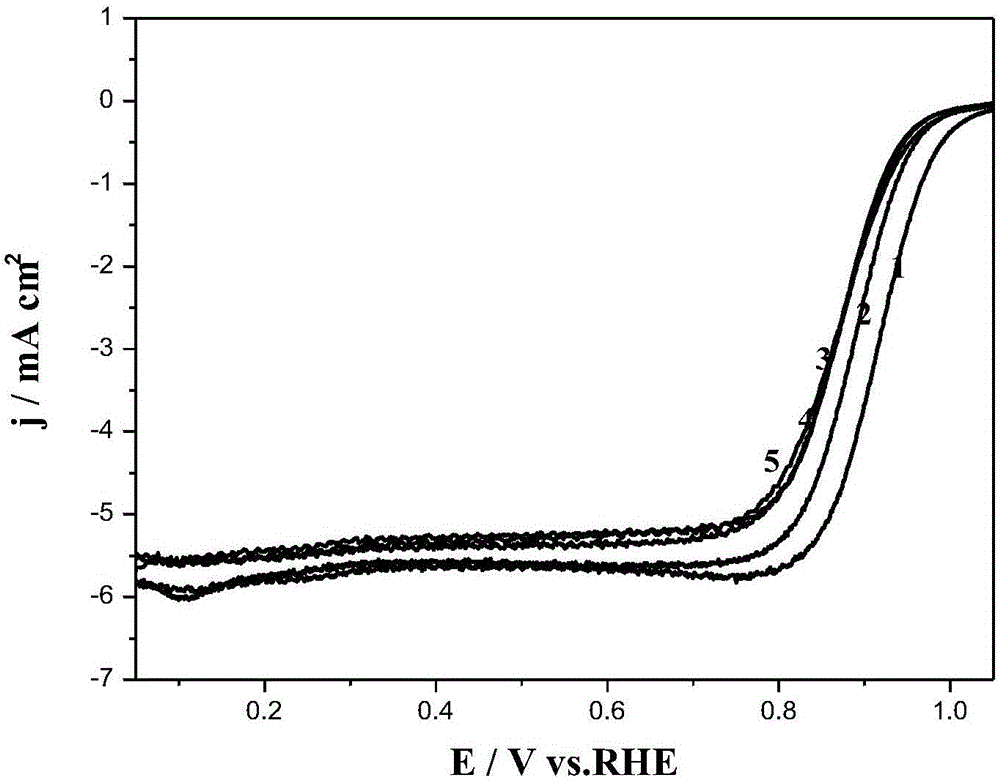

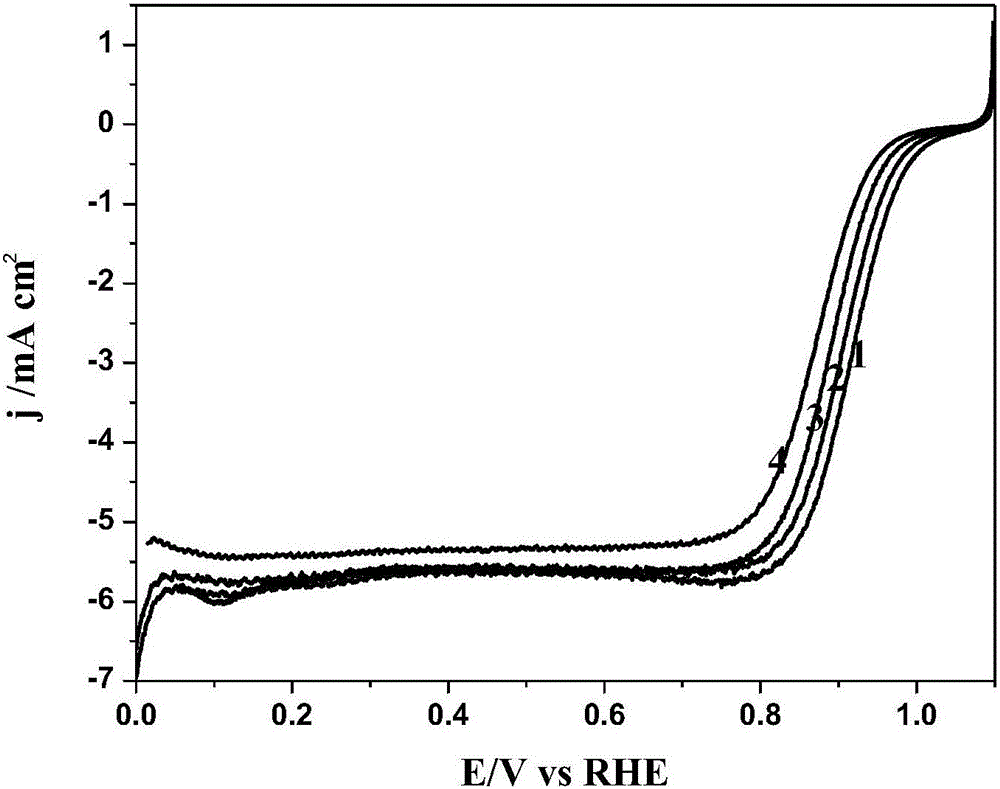

Preparing method for high-activity and high-stability composite catalyst for fuel cells

ActiveCN105107541AIncrease profitReduce dosagePhysical/chemical process catalystsCell electrodesHigh activitySilicon dioxide

The invention provides a preparing method for a high-activity and high-stability composite catalyst for fuel cells and belongs to the technical field of fuel cells. The preparing method includes the steps that firstly, the surface of a Pt / C catalyst is wrapped by a layer of dopamine, and the dopamine is used for adsorbing a metal precursor through the good adsorbing performance on metal cations; secondly, silicon dioxide is used for packaging a polymer, the pyrolysis losses and heat treatment morphology conversion of a polymer precursor are controlled through morphology fixing and range limiting functions of the silicon dioxide, alloy nano particles and an N-doped carbon modified layer are further synthesized through high-temperature pyrolysis under the surface segregation effect of platinum and transition metal, and the low-platinum-nonmetal composite structure catalyst with the hollow alloy nano particles wrapped by N-doped carbon is constructed. According to the preparing method for the high-activity and high-stability composite catalyst for the fuel cells, migration agglomerating and growing in the sintering process of the catalyst are overcome, the size of the particles is effectively controlled, the catalyst has high high-activity surface area, operation is simple, industrial production is easy, and the catalyst can be widely applied to the fuel cells with proton exchange membranes serving as electrolytes.

Owner:重庆铈坦新材料技术研究院有限公司

Method for recovering cupric ion from copper plating cleaning fluid

ActiveCN101418463AIncrease investment costThe method is simple and economicalCellsCopper platingDecomposition

The invention discloses a method for recovering copper ions in copper-plating cleaning solution. The method comprises the following steps of filtration pretreatment, first-stage cyclic separation, second-stage cyclic separation and chemical concentration. The method which adopts a membrane cyclic separation technique plus a chemical concentration method realizes the decomposition, concentration and complete on-line recycling of electroplating waste liquid, realizes real zero emission, is very simple and economical, and solves the problem of the industrialization of an electroplating waste liquid treatment zero-emission technique from research experiments to practical application.

Owner:NANJING YUANQUAN TECH CO LTD

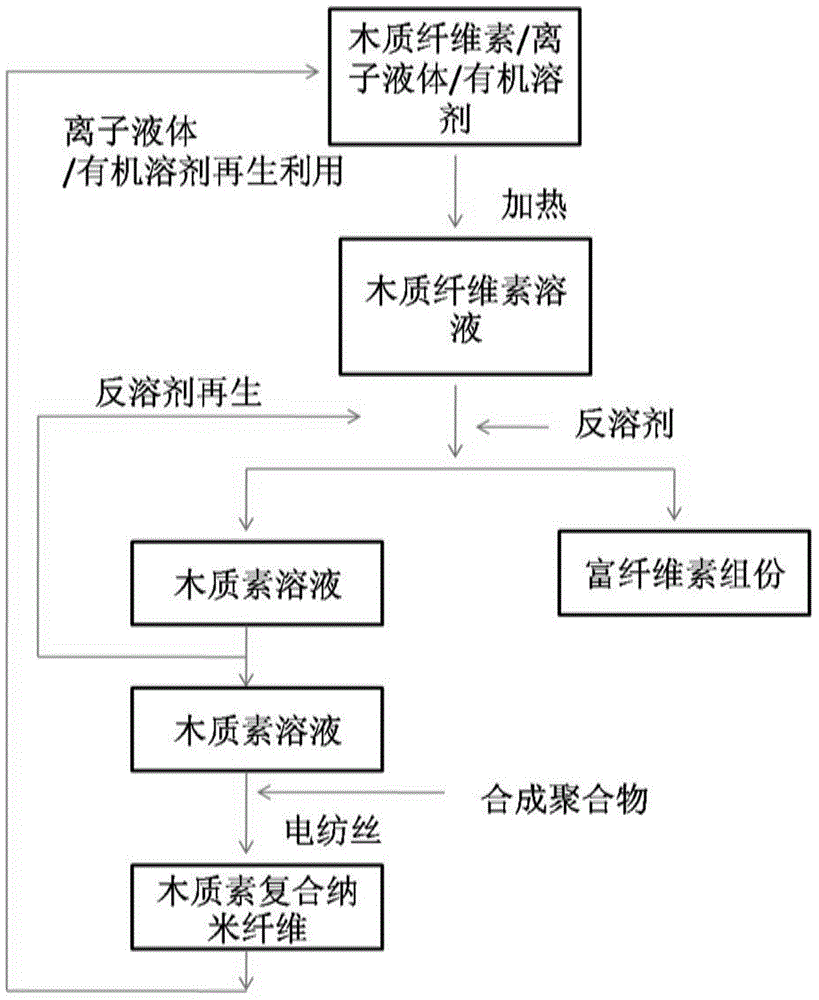

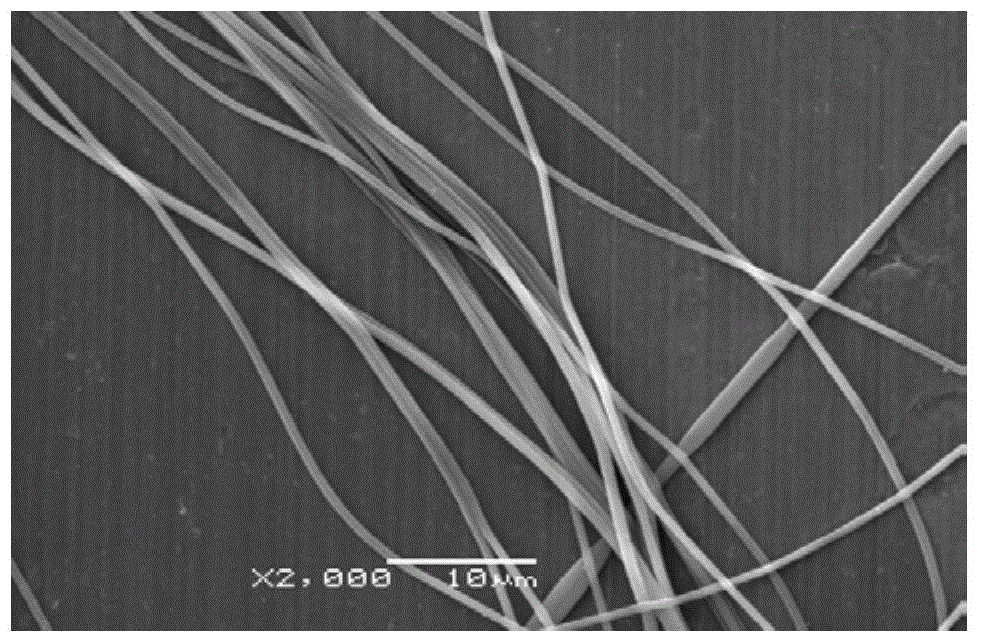

Method for extracting and preparing lignin composite nano fibers in situ

InactiveCN104947244ALow costImprove efficiencyConjugated artificial filamentsBulk chemical productionElectrospinningIon

The invention provides a method for extracting and preparing lignin composite nano fibers in situ, which takes natural lignocellulose biomasses as raw materials. The method comprises the following steps: (1) taking natural lignocellulose as the raw materials; (2) dissolving the natural lignocellulose and extracting lignin by taking a commixed electrolyte solution composed of ion liquid / an organic solvent as a solvent; (3) precipitating cellulose and semi-cellulose in the natural lignocellulose by an anti-solvent, and separating to obtain a lignin electrolyte solution; (4) adding with synthesized polymers at different parts relative to the lignin into the obtained lignin electrolyte solution to obtain a lignin-synthesized polymer electrolyte electrostatic spinning raw solution; and (5) preparing the lignin composite nano fibers by using the spinning solution through an electrostatic spinning technology. According to the method provided by the invention, all components in corn straws can be efficiently utilized; a technological process is simple and the dissolving can be recycled; the method is pollution-free and environmentally friendly, and economical and energy-saving properties are realized; and the prepared lignin-based electrostatic spinning composite fibers are uniform and continuous, have good thermal stability and can be biologically degraded.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solid/gel electrolyte battery having a binder composed of an inorganic-organic hybrid polymer and method for the production of said battery

InactiveCN104871272AReduce weightGood flexibilitySolid electrolytesHybrid capacitor electrolytesEngineeringPolymer

The invention relates to a lithium battery or a combination thereof with a double-layer capacitor, said battery being characterized by a solid electrolyte or gel electrolyte and a binder made of inorganic-organic hybrid polymer. By means of the new binder concept presented here, it is possible to revolutionize the contacting of the individual components in said batteries and thus to enable a fundamental improvement of the ion transport. Associated therewith is a new, fast, simple, and flexible production method for lithium batteries that optimizes said batteries in regard to safety, stability, environmental friendliness, and performance.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Catalyst for synthesis of 2-and 4-picolines, process for preparing 2- and 4-picoline and process for preparing the catalyst

InactiveCN1886195AAvoid environmental pollutionThe method is simple and economicalOrganic chemistryHeterogenous catalyst chemical elementsPicolineOrganic chemistry

Owner:COUNCIL OF SCI & IND RES

Separation wall for carrying out in situ separation repair on pollution site and construction method thereof

The invention discloses a separation wall for carrying out in situ separation repair on a pollution site and a construction method thereof. The separation wall consists of unpolluted in situ soil and bentonite, wherein the mass ratio of the in situ soil to the bentonite is 95:5 to 85:15. The construction method of the separation wall comprises the following steps of: a first step of excavating a trough body in a region on the periphery of the pollution site, wherein soil digged out from the trough body is the unpolluted in situ soil; a second step of preparing bentonite slurry; a third step of pouring the bentonite slurry into the trough body; a fourth step of preparing back filling, i.e. adding bentonite dry powder in the unpolluted in situ soil, uniformly mixing the unpolluted in situ soil and the bentonite dry powder to form the back filling; and a fifth step of filling back the back filling mixed with the bentonite into the trough body and uniformly stirring the back filling and the bentonite slurry in the trough body. Due to the adoption of the technical scheme, the construction cost of the separation wall can be reduced, the separation response time is shortened, and the separation effect is improved. Meanwhile, the construction method is simple.

Owner:SOUTHEAST UNIV

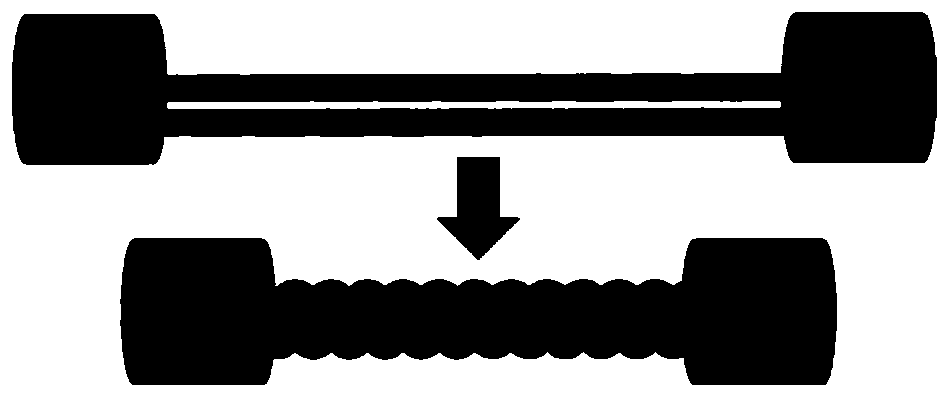

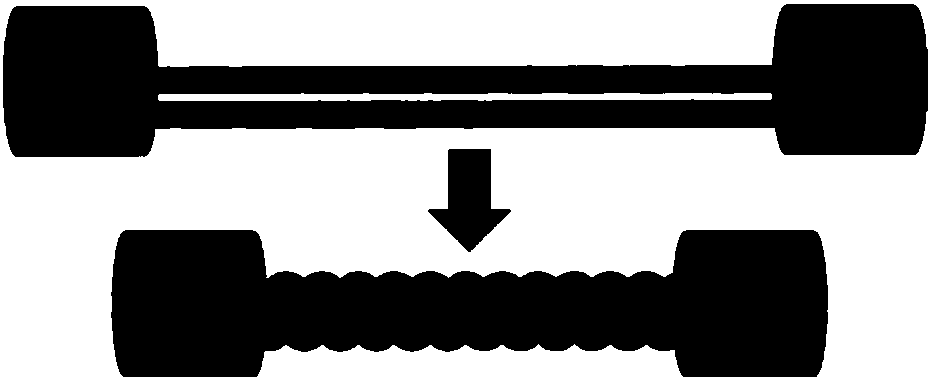

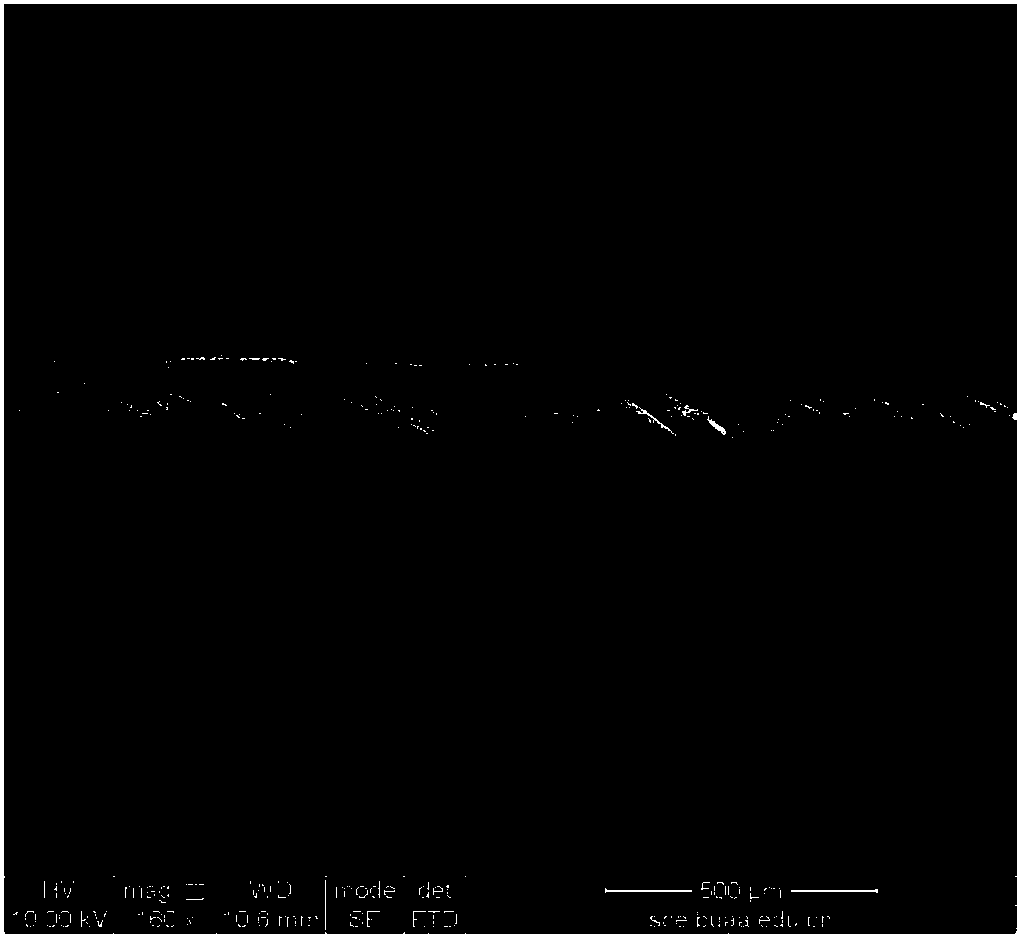

Multi-scale helical structure fiber bundle and preparation method thereof

ActiveCN107841808AAchieve compositeRealize large-scale mass productionElectro-spinningNon-woven fabricsFiber bundleElectrospinning

The invention discloses a multi-scale helical structure fiber bundle and a preparation method thereof. Through an electrospinning technique and a twisting and multistrand overtwist method, the preparation method of the multi-scale helical structure fiber bundle succeeds in preparing a series of multi-scale helical structure fiber bundles. The multi-scale helical structure fiber bundles can compound varied materials and integrate varied functions and have excellent intensity, flexibility, stretchability and resilience. Moreover, the diameter and length of the fiber bundles can be controlled, and the fiber bundles can be randomly bent and weaved and have broad application.

Owner:BEIHANG UNIV

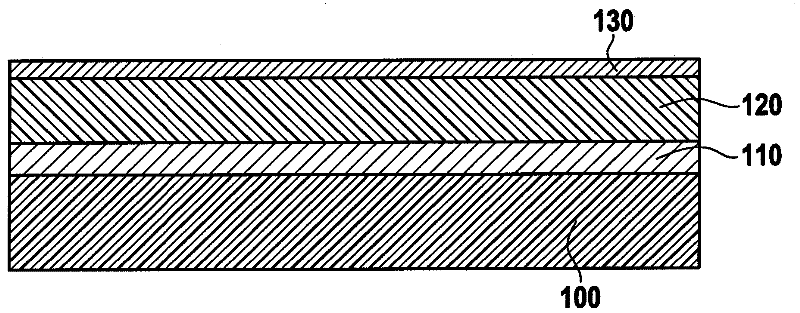

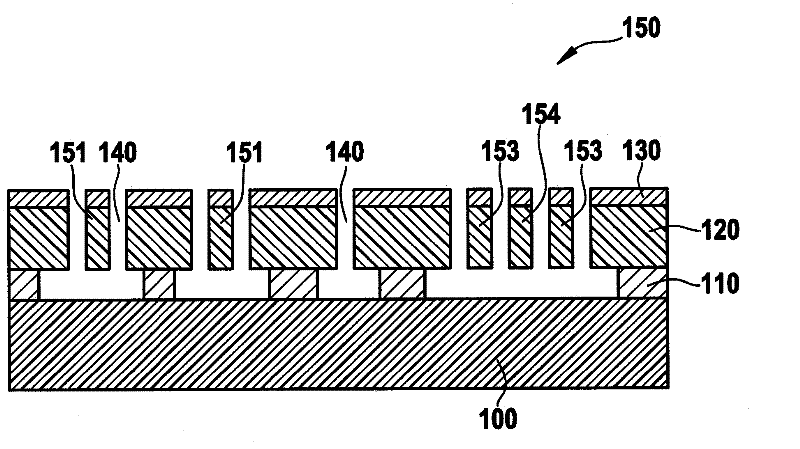

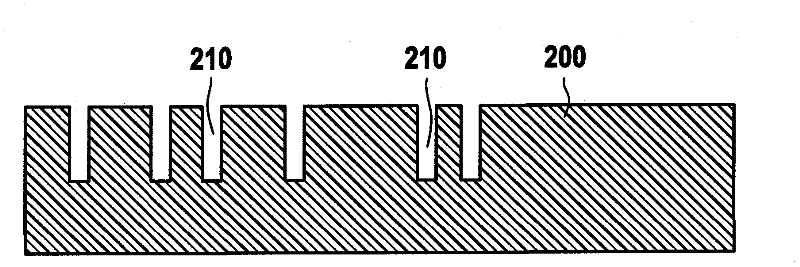

Micromechanical component and method for the production thereof

ActiveCN102164848AThe method is simple and economicalDecorative surface effectsForming microstructural systemsMaterials scienceClosed cavity

The invention relates to a method for producing a micromechanical component (300) that comprises providing a first substrate (100), forming a microstructure (150) on the first substrate (100), wherein the microstructure (150) comprises a moving function element (151), providing a second substrate (200), and forming in the second substrate (200) an electrode (251) for capacitively measuring a deflection of the function element (151). The method further comprises connecting the first and the second substrates (100; 200), wherein a closed cavity which encloses the function element (151) is formed, and wherein the electrode (251) adjoins the cavity in an area of the function element (151).

Owner:ROBERT BOSCH GMBH

Method for cultivating aphelenchoides besseyi by using carrot callus

InactiveCN102696554AMaintain parasitism and pathogenicityEasy to operateAnimal husbandryStreptomycin sulphateAgar

The invention discloses a method for cultivating aphelenchoides besseyi by using carrot callus and belongs to the technical field of plant nematodes cultivation and preservation. The method includes specific steps of washing fresh carrots clean, soaking in alcohol, firing unit surfaces of the carrots become dark red, peeling the surfaces, cutting into slices, placing in a sterilization petri dish containing water agar, sealing, placing in an incubator, and cultivating until the carrot callus is grown out; disinfecting the aphelenchoides besseyi by using streptomycin sulfate solution, centrifuging, precipitating, evenly mixing by using sterile water, centrifuging continuously, finally precipitating, diluting by using the sterile water, and dropping on the carrot callus in dispersing mode; and placing the carrot callus with inoculation of the aphelenchoides besseyi in a black incubator, and cultivating at the temperature of 25 DEG C-30 DEG C or preserving at the temperature of 20 DEG C-25 DEG C. The method for cultivating the aphelenchoides besseyi by using the carrot callus can cultivate and reproduce the aphelenchoides besseyi simply and largely and can also maintain parasitic and pathogenic force of the aphelenchoides besseyi to the plant.

Owner:SOUTH CHINA AGRI UNIV

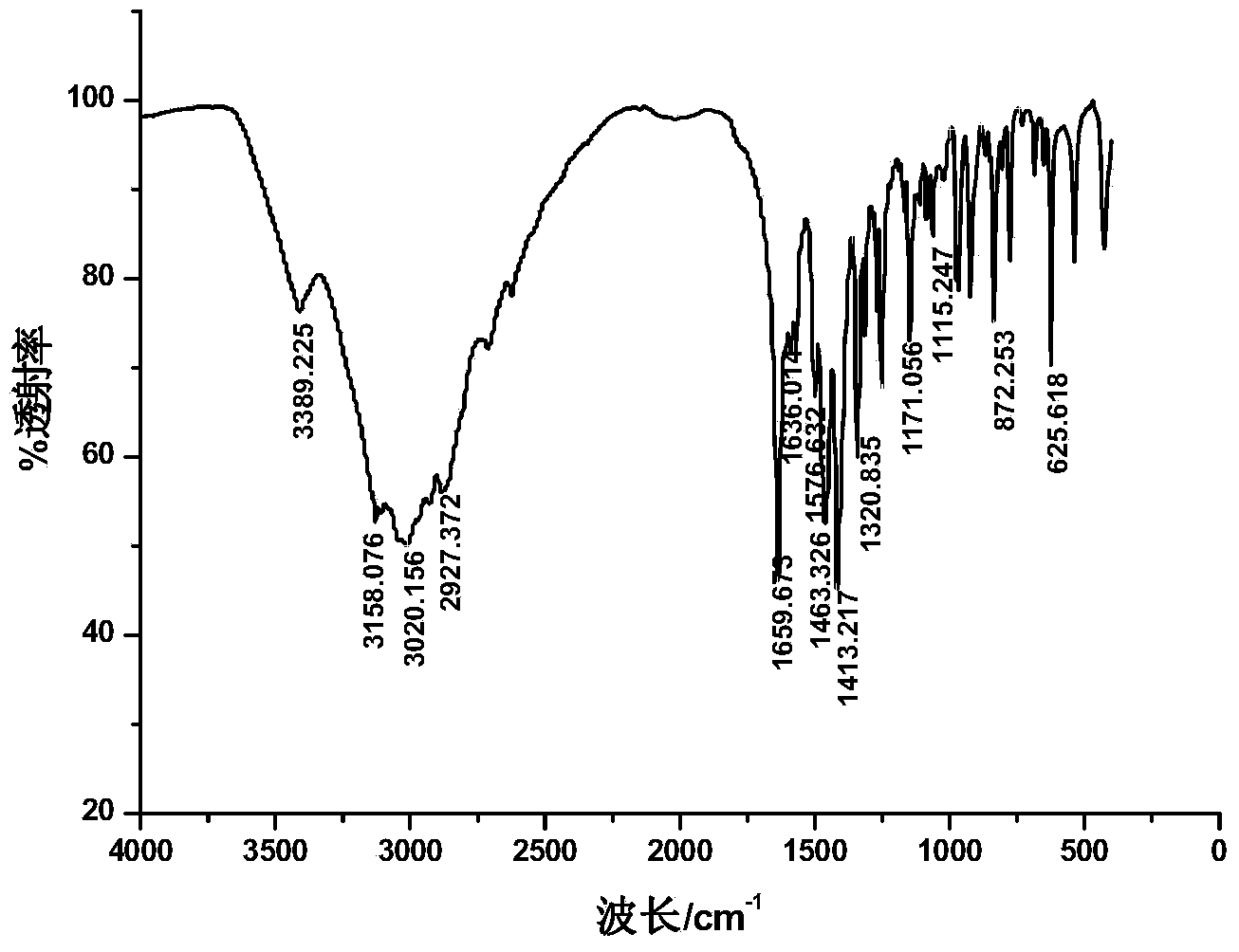

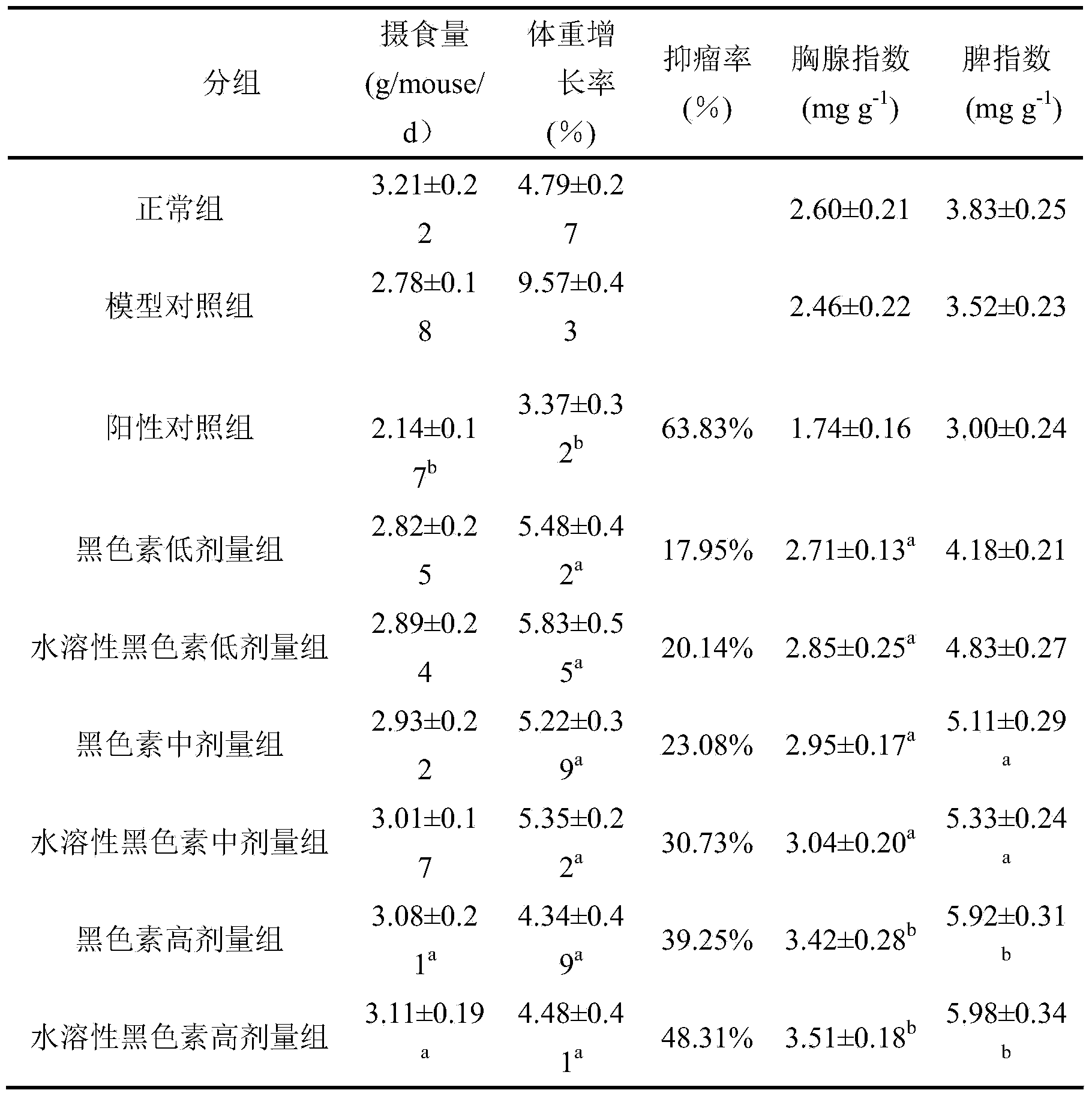

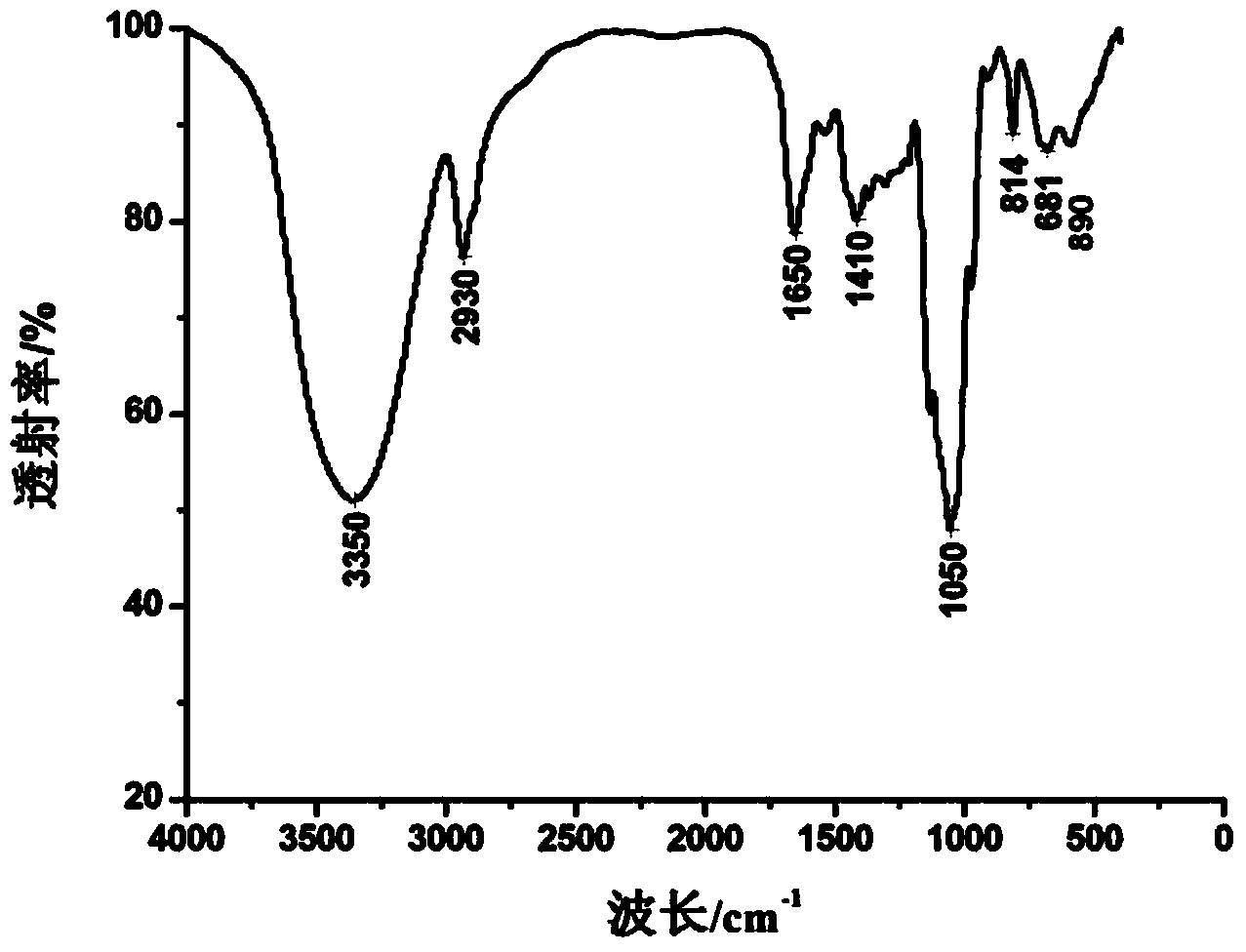

Application of water-soluble lachnum melanin in preparing medicine for inhibiting liver cancer

InactiveCN103720722ANo side effectsThe method is simple and economicalFungi medical ingredientsPill deliveryDrugLachnum

The invention discloses an application of water-soluble lachnum melanin in preparing a medicine for inhibiting liver cancer. The application is characterized in that intracellular melanin generated by lachnum of which the strain preservation number is CCTCC (China Center for Type Culture Collection) No:M2011054 is modified by a histidine molecule to obtain water-soluble lachnum melanin. Pharmacodynamic experiments prove that the water-soluble lachnum melanin has a remarkable function of inhibiting liver cancer, and does not have toxic or side effect; the preparation method is simple and economical, so that the lachnum intracellular melanin of which the strain preservation number is CCTCC (China Center for Type Culture Collection) No:M2011054 and the water-soluble melanin thereof are subjected to a pharmaceutical conventional preparation method, and an effective dose of the water-soluble lachnum melanin and a proper amount of medical auxiliaries are mixed to prepare oral tablet or capsule type medicines for inhibiting liver cancer.

Owner:HEFEI UNIV OF TECH

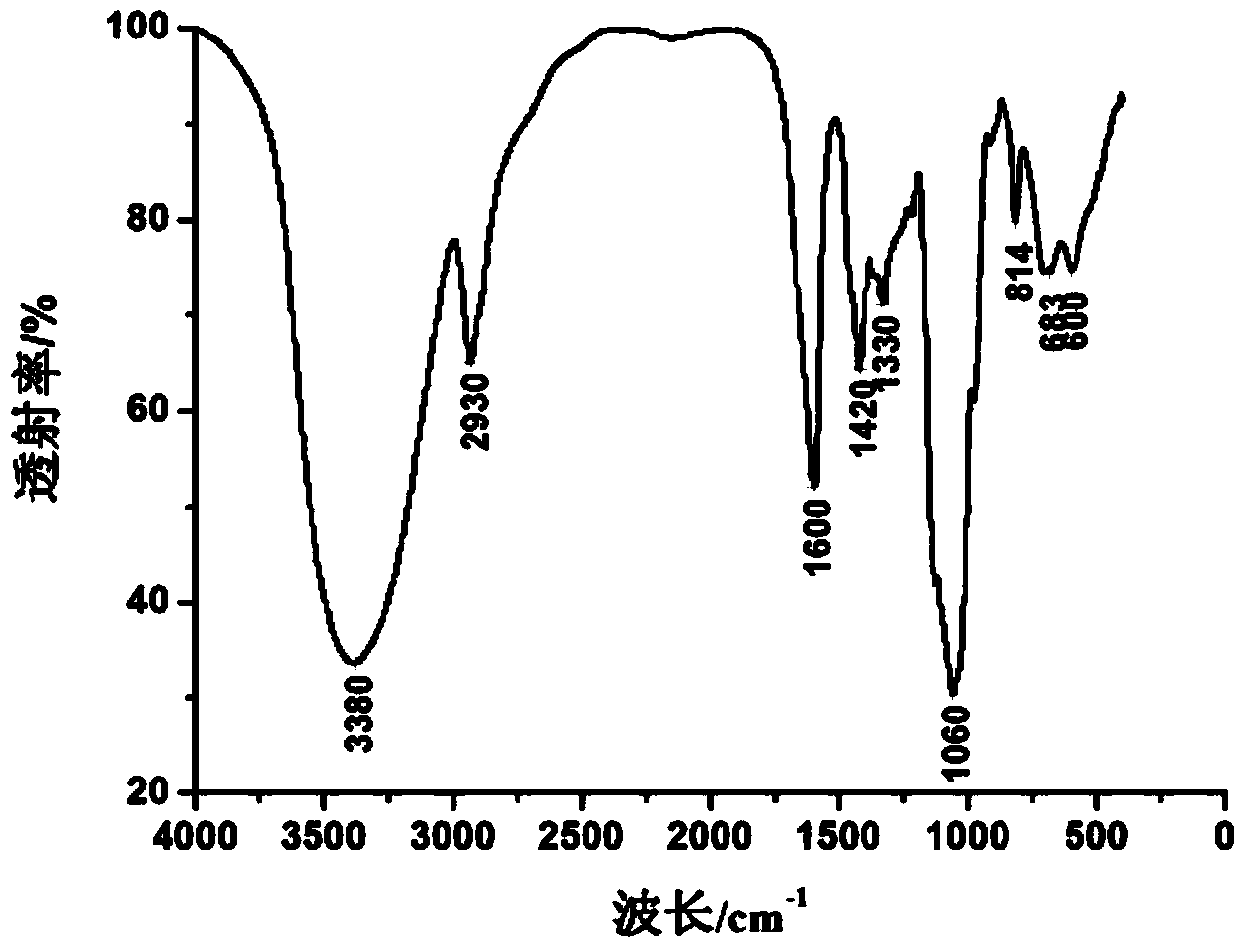

Lachnum exopolysaccharides carboxymethylation derivative and application thereof in preparation of renal failure-resistant medicines thereof

InactiveCN103755827AImprove the state of pathological tissueLower creatinineOrganic active ingredientsUrinary disorderSide effectChloroacetic acids

The invention discloses a lachnum exopolysaccharides carboxymethylation derivative and an application thereof in preparation of chronic renal failure-resistant medicines. The lachnum exopolysaccharides carboxymethylation derivative is characterized in that lachnum exopolysaccharides with the strain collection number of CCTCC No: M 2011196 are subjected to chloroacetic acid carboxymethylation modification to obtain the lachnum exopolysaccharides carboxymethylation derivative, and the lachnum exopolysaccharides carboxymethylation derivative in an effective dose and medical auxiliary materials are prepared into tablets and capsules for clinical use according to a conventional preparation method in pharmaceutics due to the effect of obviously resisting chronic renal failure. The pharmacodynamic experiment proves that the exopolysaccharides and carboxymethylation derivative has an obvious effect of resisting chronic renal failure and does not have a toxic or side effect, and the preparation method is simple and economic.

Owner:HEFEI UNIV OF TECH

Water-soluble lachnum melanin and application thereof in preparation of lead-removing promoting medicine

InactiveCN104069133ASignificant lead-expelling functionOvercome the side effects of damageBacteria material medical ingredientsAntinoxious agentsSide effectChloroacetic acids

The invention discloses a water-soluble lachnum melanin and an application thereof in preparation of lead-removing promoting medicines. The water-soluble lachnum melanin is characterized by being prepared by modifying the intracellular melanin produced by the lachnum with the strain preservation number of CCTCC No:M2011054 via chloroacetic acid. According to the pharmacological action experiment for promotion of lead removal from a rat infected with the lead, the result shows that the water-soluble lachnum melanin has an obvious lead-removing promoting function and cannot generate toxic and side effects, so that the side effect defects that certain essential elements such as Zn, Cu, Fe and the like in vivo are lost and certain organs are damaged, which are caused by the existing western medicine during the lead removing, are overcome. Thus, the lead-removing promoting function of the water-soluble lachnum melanin is ensured. The method disclosed by the invention is simple and economical. The water-soluble lachnum melanin can be applied to the preparation of the tablet-type or capsule-type lead-removing promoting medicines for oral administration.

Owner:HEFEI UNIV OF TECH

Instant radix millettiae speciosae and preparation method and consumption method thereof

InactiveCN105768077ASolve the problem of severe foamingRetain nutrientsNatural extract food ingredientsFood dryingMedicineBULK ACTIVE INGREDIENT

Owner:桂林亦元生现代生物技术有限公司

A fresh-keeping method of Indian truffle

InactiveCN102273503AIncrease valueSimple and economical way to keep freshFruits/vegetable preservation by freezing/coolingTuber indicumSurface cleaning

The invention aims at providing a simple and easy fresh-keeping method of tuber indicum (Chinese truffle). The fresh-keeping method comprises the steps of material selection, surface cleaning, disinfection sterilization, preserving substrate preparation, preparation of vessels for preserving a truffle material, and embedment and storage. The fresh-keeping method also comprises requirements of a preserving temperature and the like. The fresh-keeping method is simple and economic and does not need special equipment. Through the fresh-keeping method, a fresh-keeping period can be extended to a period of 3 to 6 months; an original shape, original color and original ingredients cannot be changed; spoilage deterioration is avoided; loss is avoided; transportation is convenient; market supply time and seasons are extended; and the maximum values of goods are reflected.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

Method for improving activity of dye decolorizing peroxidase

PendingCN111593061AIncreased specific enzyme activityThe method is simple and economicalBacteriaMicroorganism based processesMolecular biologyDye decolorizing peroxidase

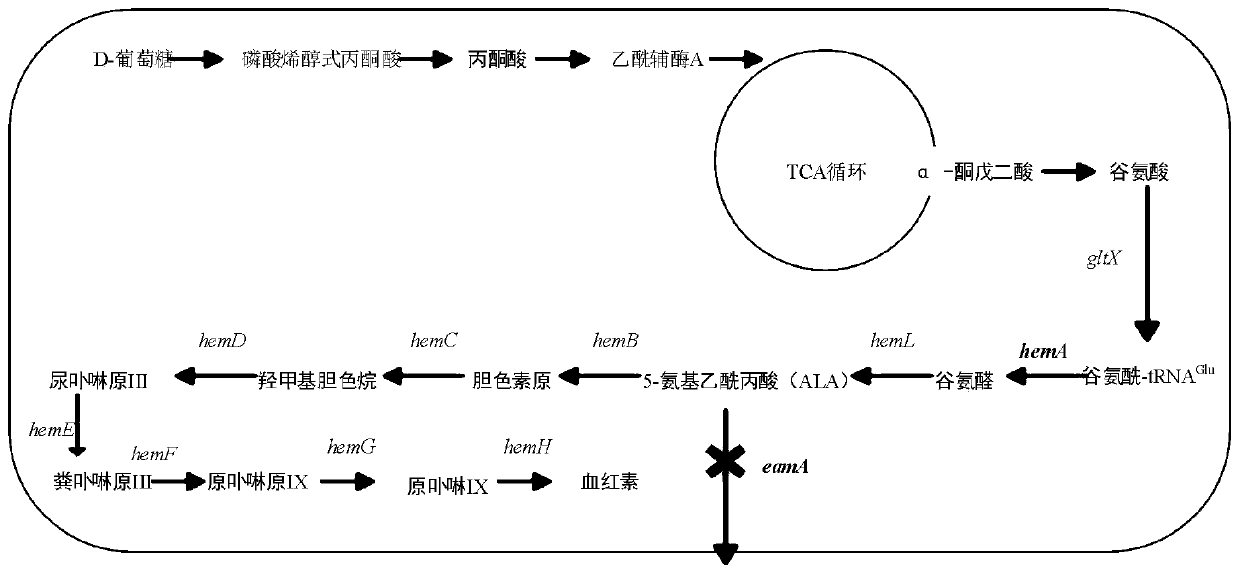

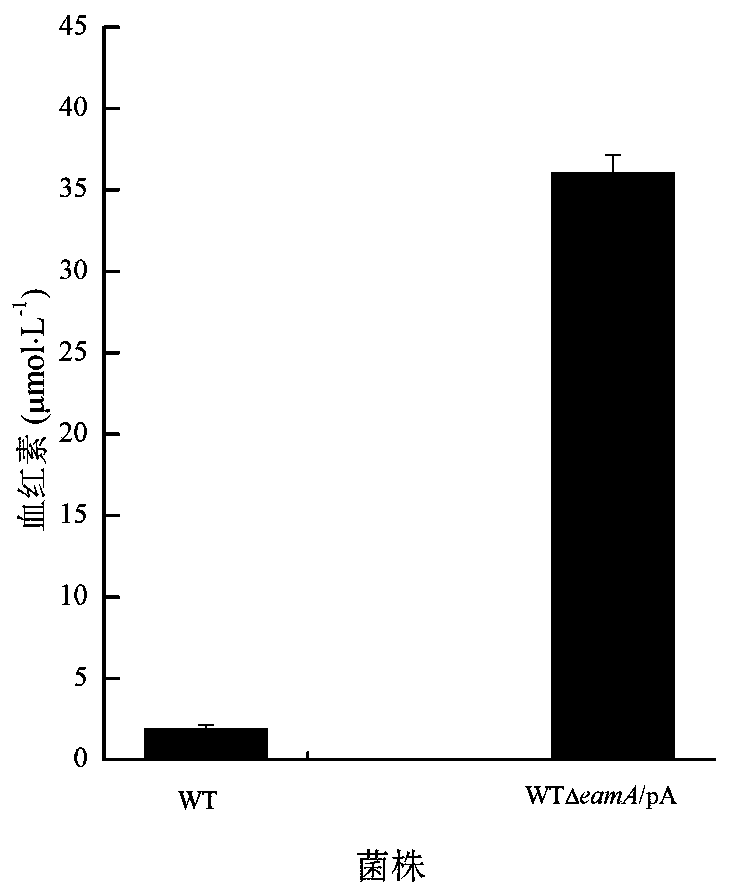

The invention discloses a method for improving the activity of dye decolorizing peroxidase, and belongs to the field of enzyme engineering. The method comprises the following steps: jointly connectinga gene for coding dye decolorizing peroxidase (DyP) and a gene hemA for coding escherichia coli endogenous glutamyl-tRNA reductase to a vector pET28a to obtain a recombinant vector, and transferringthe recombinant vector into escherichia coli from which coding escherichia coli endogenous channel protein gene eamA is knocked out for expression. A result shows that the specific enzyme activity ofthe expressed recombinant DyP is remarkably improved. The method is simple, convenient and economical, and has application value.

Owner:JIANGNAN UNIV

Method for manufacturing a part or a supported microstructure by laser exposure of a metal oxalate layer

InactiveCN108699701AAvoid continuityAvoid uniformityPhotomechanical apparatusLiquid/solution decomposition chemical coatingOxalateLaser exposure

The invention relates to a method for manufacturing a metallic, ceramic or composite part or a metallic, ceramic or composite supported microstructure by laser exposure from metal oxalates, and to thepart and the microstructure obtained by said method, as well as to the uses thereof.

Owner:UNIV PAUL SABATIER TOULOUSE III +1

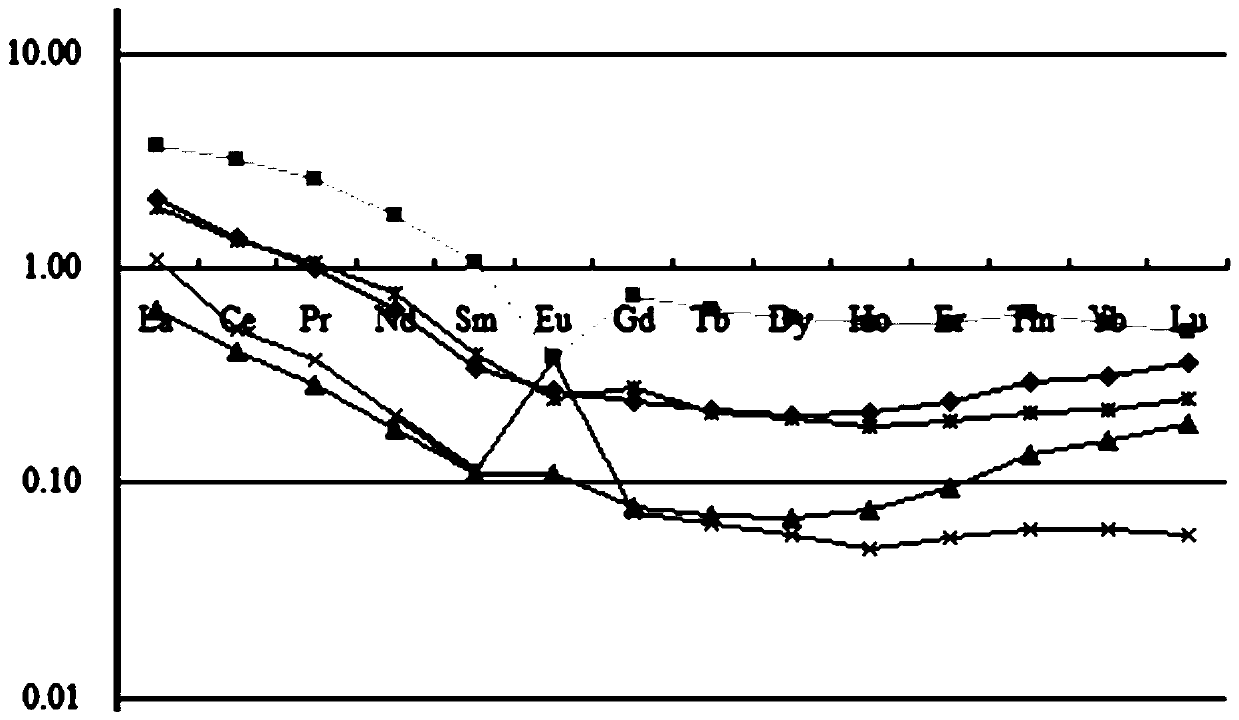

Method for determining rare earth elements in super-based rock by ICP-MS

InactiveCN110715974AQuality improvementLower requirementPreparing sample for investigationMaterial analysis by electric/magnetic meansRare-earth elementPhysical chemistry

The invention provides a method for determining rare earth elements in a super-based rock by ICP-MS. The method comprises the following steps: accurately weighing a powder sample and putting the powder sample into a sample dissolving bomb; adding high-purity nitric acid and high-purity hydrofluoric acid in sequence; putting the sample dissolving bomb into a steel sleeve, screwing and putting the sample dissolving bomb into a drying oven for heating; after the sample dissolving bomb is cooled and the cover is opened, putting the sample dissolving bomb on an electric heating plate and evaporating to dryness; adding nitric acid and evaporating to dryness again; adding high-purity nitric acid and ultrapure water; putting the sample dissolving bomb into the steel sleeve, screwing and putting the sample dissolving bomb into the drying oven for heating; putting the sample dissolving bomb on the electric heating plate and evaporating to dryness; adding hydrochloric acid and evaporating to dryness again; adding hydrochloric acid and dissolving; centrifuging the sample by utilizing a centrifugal machine; taking supernatant and putting the supernatant on a column; adding hydrochloric acid towash the column and adding hydrochloric acid to connect the sample; after evaporating the sample to dryness, adding nitric acid; after evaporating to dryness again, adding nitric acid and fixing the volume; finally, determining the content of the rare earth elements in the sample by ICP-MS. According to the method provided by the invention, the ultralow-low-content rare earth elements in the super-based rock can be effectively detected; an obtained rare earth partition curve is smooth in distribution and a detection result is accurate and reliable.

Owner:武汉上谱分析科技有限责任公司

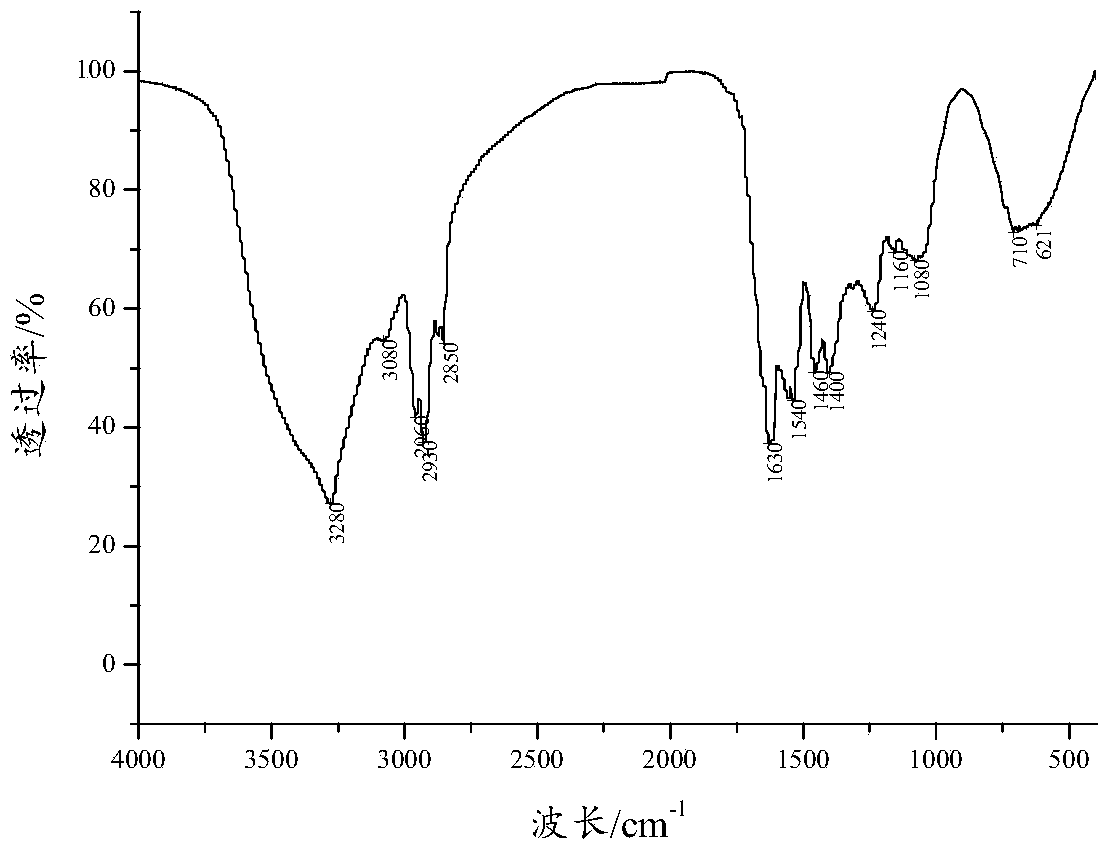

A process for the production of carnitine from [beta] -lactones

InactiveCN103003257AThe method is simple and economicalInhibit side effectsOrganic compound preparationAmino-carboxyl compound preparation(R)-CarnitineKetone

The invention relates to a method for the production of L-carnitine, wherein a [beta] -lactone, which is a 4-(halomethyl)oxetane-2-one, is converted into carnitine with trimethylamine (TMA), wherein the [beta] -lactone is not subjected to a basic hydrolysis step before being contacted with the trimethylamine. The invention also relates to a carnitine having a unique impurity profile.

Owner:LONZA LTD

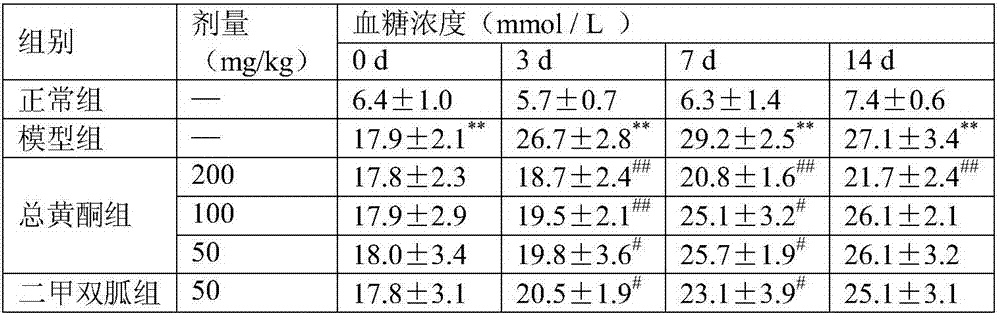

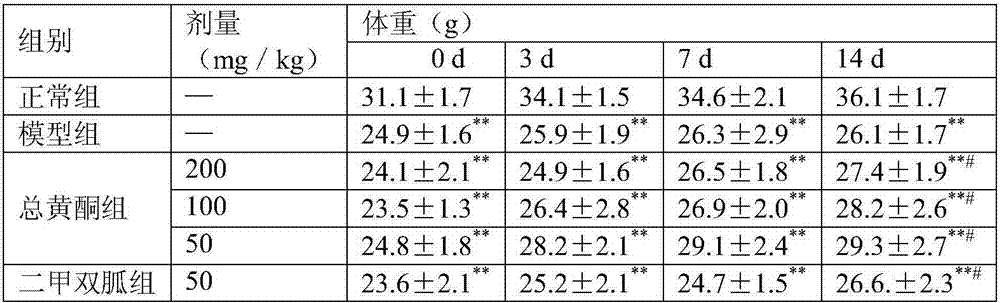

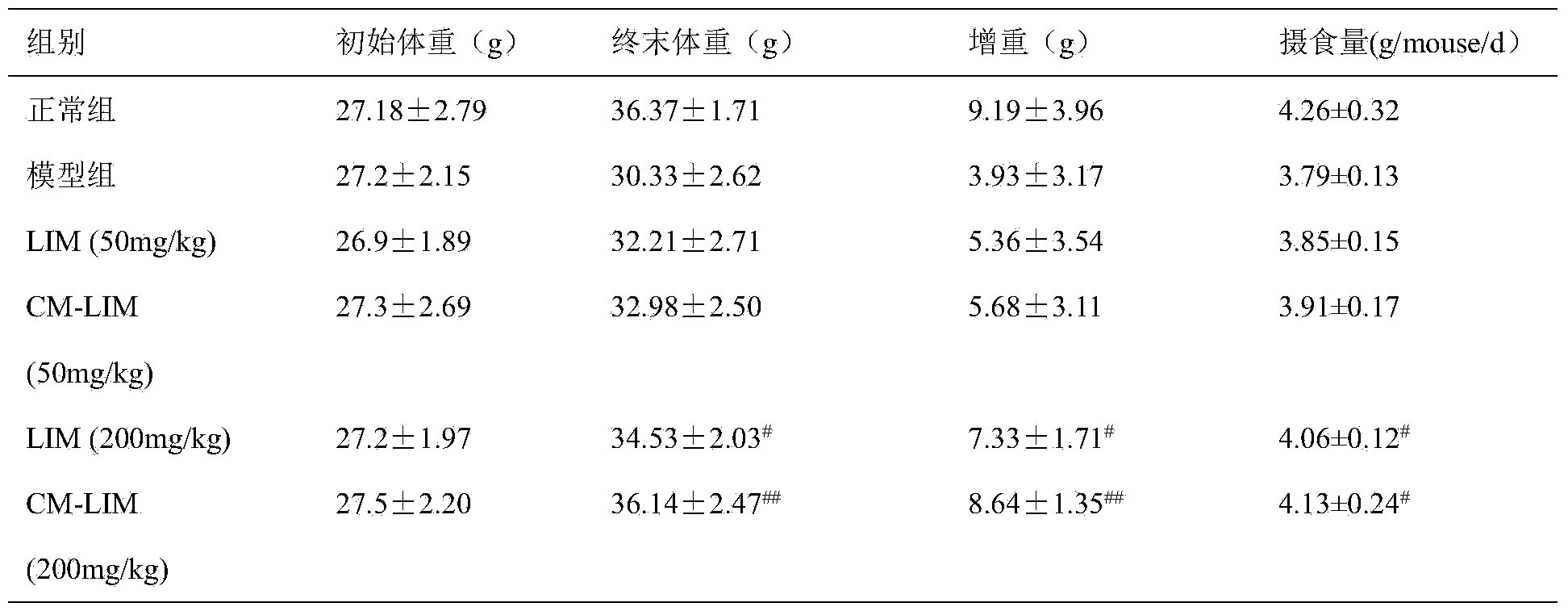

Preparation method and application of hypoglycemic Chinese hickory leaf total flavonoids

InactiveCN107252440ASignificant effectGood hypoglycemic effectMetabolism disorderFood ingredient functionsMedicineFlavones

The invention relates to a preparation method and application of hypoglycemic Chinese hickory leaf total flavonoids; the Chinese hickory leaf total flavonoids exhibit good hypoglycemic effect at all doses, have significant effect for diabetes mellitus, and are applicable to the preparation of drugs, health foods and the like for preventing or treating diabetes mellitus.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

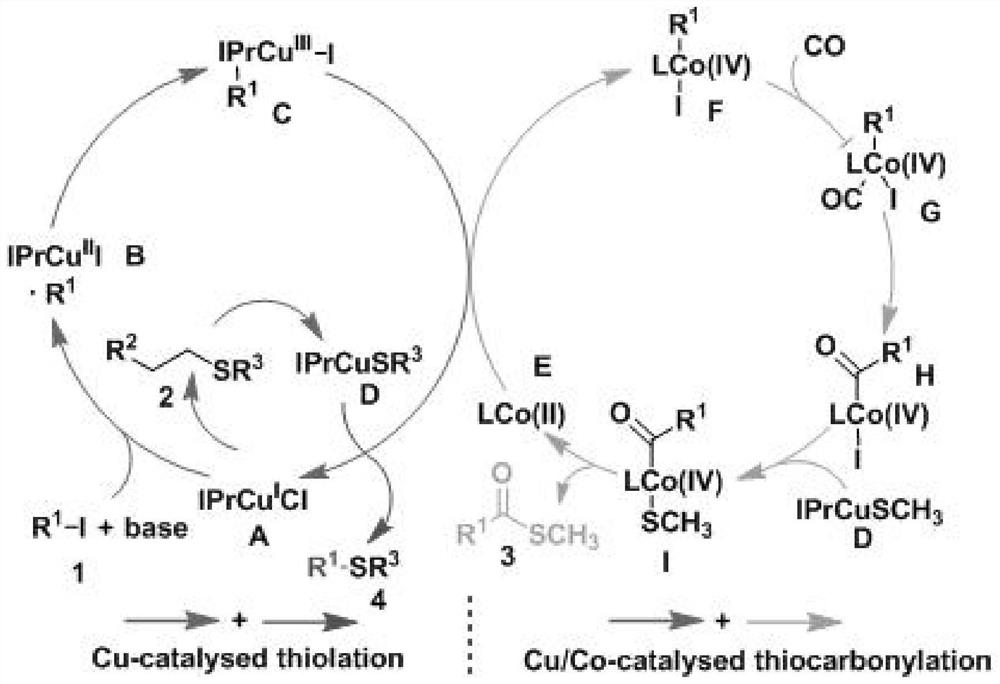

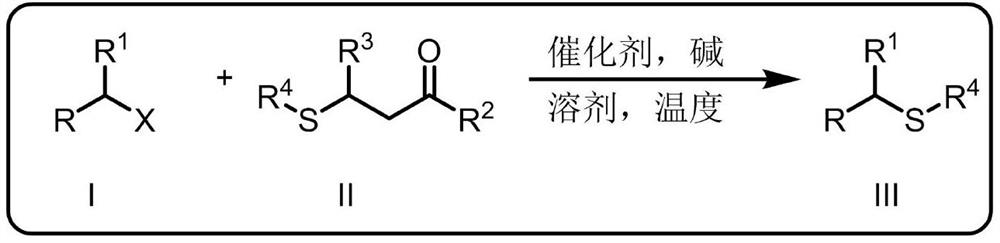

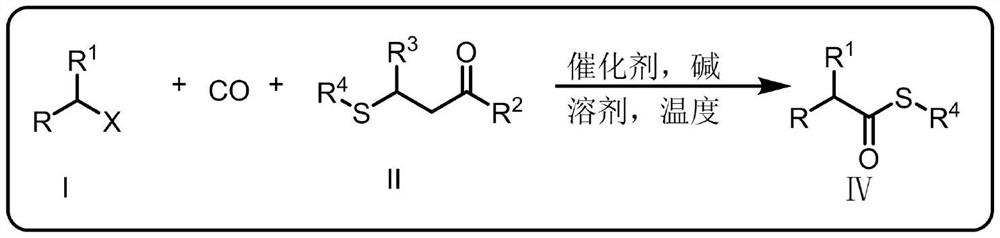

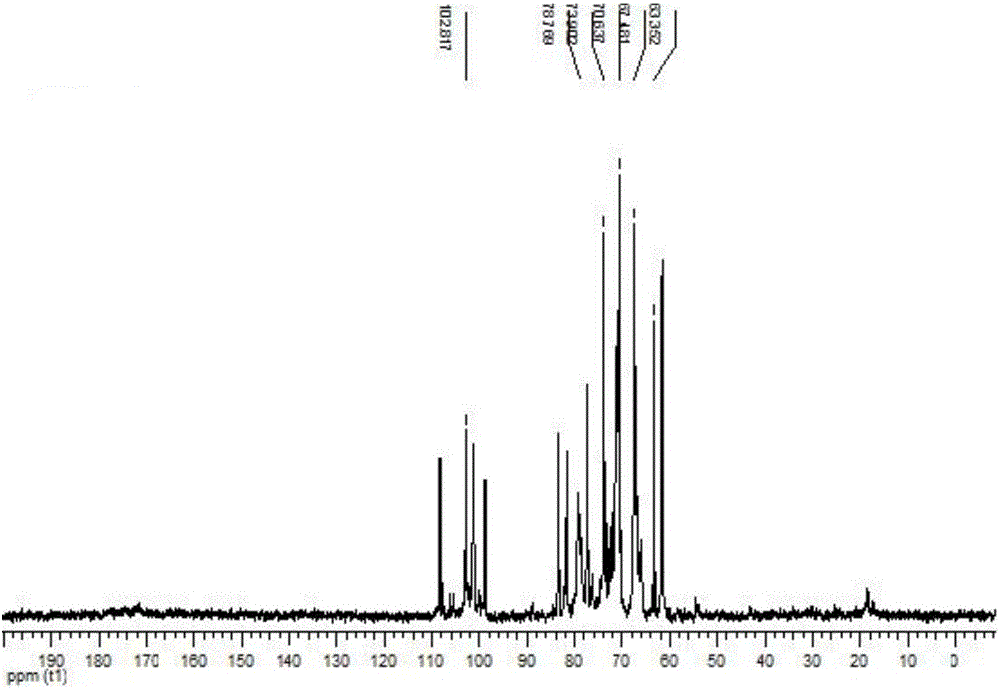

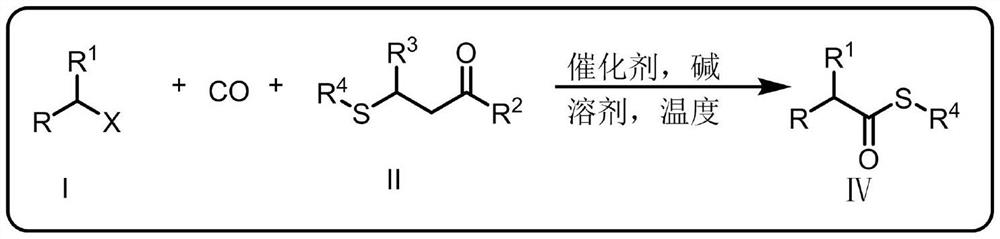

Synthetic method for thioetherification and thiocarbonylation of halogenated alkane

ActiveCN113511991AAchieve synthesisReduce usageChemical recyclingSulfide preparationAlkanePropanoic acid

The invention relates to the technical field of organic synthesis, in particular to a synthetic method for thioetherification and thiocarbonylation of halogenated alkane. According to the method, a 3-methylthiopropionic acid methyl ester derivative is used as a vulcanizing reagent to realize thioetherification and thiocarbonylation of halogenated alkane; IPrCuCl is used as a catalyst to realize thioetherification; in the presence of carbon monoxide, IPrCuCl and bis-salicylamide ethyl cobalt are used for co-catalysis to obtain thioester; and the vulcanizing reagent is easy to synthesize, mild in reaction condition and high in practicability. According to the invention, thiol with strong smell, high toxicity and environmental pollution is not used, good functional group tolerance and excellent yield and purity are achieved, harsh reaction conditions are not needed, and the method is suitable for industrial production.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for improving propionic acid output of acetic bacteria through pulsed magnet field

PendingCN105820977AHigh acid productionIncrease productionBacteriaVinegar preparationPulsed magnetPropanoic acid

The invention discloses a method for improving the propionic acid output of acetic bacteria through pulsed magnet field, and relates to the field of bioengineering. According to the method, acetic bacteria are treated through the pulsed magnet field with different magnet field strengths and number of pulses, so that acetic bacteria mutant strains with increased propionic acid output are obtained. The method ensures that the propionic acid output is increased by 20 to 60 percent, and the hereditary stability is good.

Owner:JIANGSU UNIV

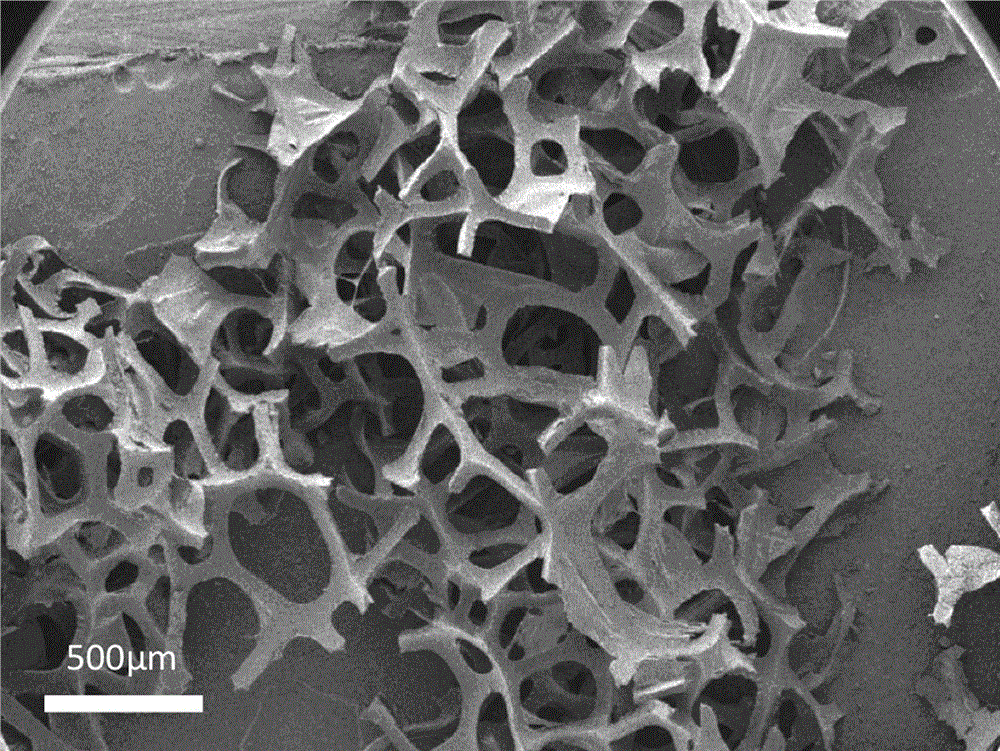

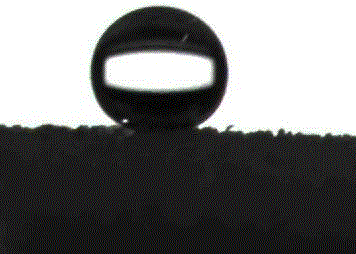

Method for preparing super-hydrophobic super-oleophilic porous material

InactiveCN104606925AThe method flow is simpleEasy to operateNon-miscible liquid separationOrganic matterRubbing

Owner:ZHENGZHOU UNIV

A kind of preparation method of environment-friendly CI disperse orange 29

ActiveCN104629493BThe method is simple and economicalConforms to EU standardsOrganic dyesDisperse dyeSlurry

Owner:浙江双冠染料有限公司

Two-line sterile line propagating method for rice in high mountain region

InactiveCN109429617AThe method is simple and economicalPromote economic technologyPlant protectionSeed immunisationAgricultural scienceAgricultural engineering

The invention discloses a two-line sterile line propagating method for rice in a high mountain region. The two-line sterile line propagating method for the rice in the high mountain region comprises the following steps: a, performing field transforming; b, performing seed treatment; c, sowing; d, transplanting in the same field; e, performing fertilizer management; f, performing water management;and g, performing disease and insect prevention and control. The method is simple and economic; the propagating of dual purpose genic male sterile lines of the rice is performed successfully in the mode of regulating and controlling the development of a sterile line during growth duration through cold spring serially irrigating and cultivating technologies; and the two-line sterile line propagating method for the rice in the high mountain region has the advantages of low economical cost, simple technology and high operability.

Owner:铜仁科学院

A kind of multi-scale helical structure fiber bundle and preparation method thereof

ActiveCN107841808BAchieve compositeRealize large-scale mass productionElectro-spinningNon-woven fabricsPolymer scienceFiber bundle

The invention discloses a multi-scale helical structure fiber bundle and a preparation method thereof. Through an electrospinning technique and a twisting and multistrand overtwist method, the preparation method of the multi-scale helical structure fiber bundle succeeds in preparing a series of multi-scale helical structure fiber bundles. The multi-scale helical structure fiber bundles can compound varied materials and integrate varied functions and have excellent intensity, flexibility, stretchability and resilience. Moreover, the diameter and length of the fiber bundles can be controlled, and the fiber bundles can be randomly bent and weaved and have broad application.

Owner:BEIHANG UNIV

Method for producing ceramic die core

The invention provides a method for producing a ceramic die core. The method comprises the following steps of (1) producing a ceramic die core blank; (2) pre-treating a filler for the shaping of the ceramic die core, specifically adding the filler to be treated into a nonmetal material hopper with de-ionized water, continuously stirring slurry obtained by mixing powder and de-ionized water, continuously dropwise adding analytically pure hydrochloric acid to adjust the pH value of the slurry to 4 to 6, stopping adding analytically pure hydrochloric acid when the pH value is changed by less than or equal to 0.2 within 5 minutes, continuing stirring the slurry for 10 to 60 minutes, standing and settling the slurry for 4 to 12 hours, pouring an upper-layer solution, washing settled powder for 1 to 3 times by using de-ionized water until the pH value of an obtained solution is 6 to 8, drying the powder finally sinking to the bottom at 100 to 140 DEG C, calcining the powder for 4 to 6 hours at 1200 to 1500 DEG C, and crushing and sieving the powder; (3) performing shaping calcination; (4) performing reinforcement reconditioning. The method is simple, economical and low in time consumption, manpower is saved, energy consumption is eliminated, the production efficiency of the ceramic die core is greatly improved, and the quality of the ceramic die core is improved.

Owner:DONGFANG TURBINE CO LTD

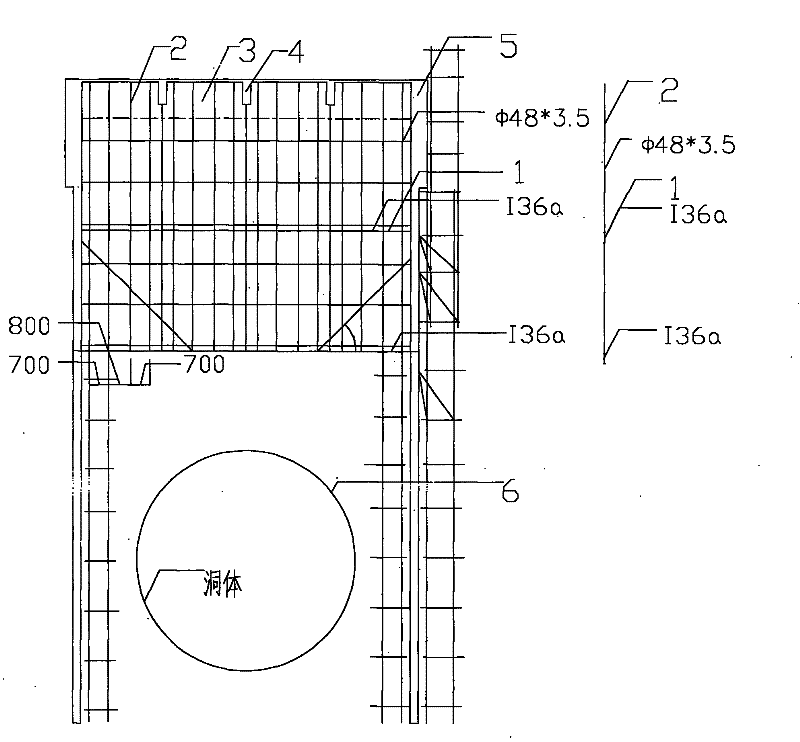

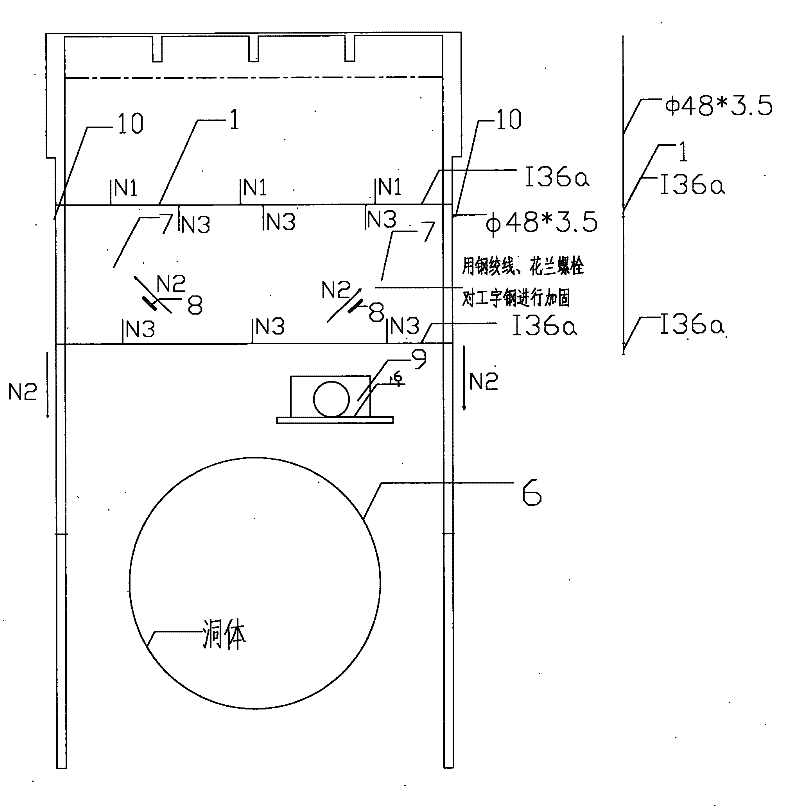

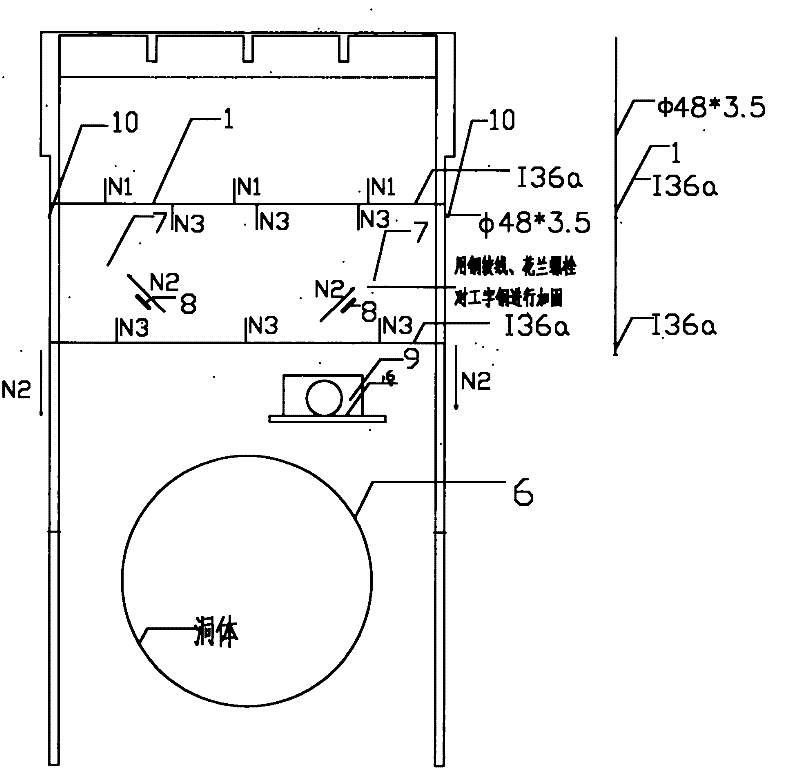

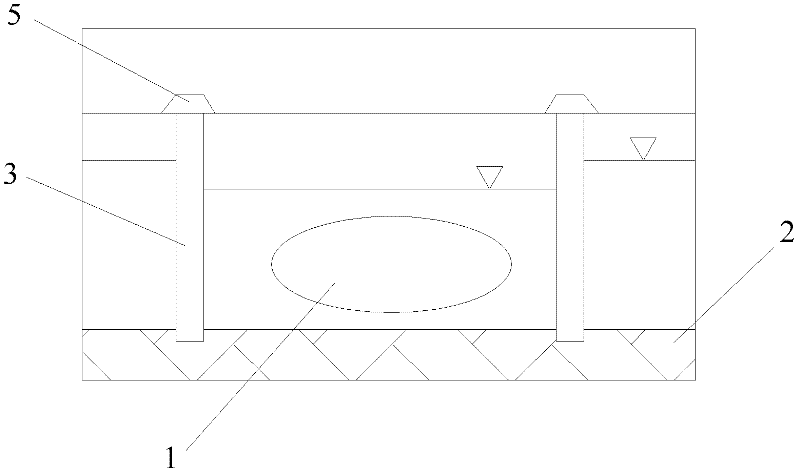

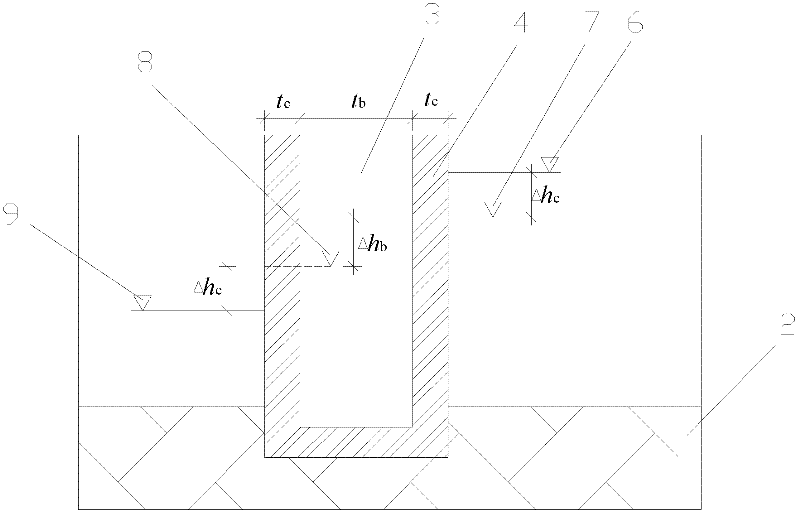

Construction method for large-span cast-in-situ beam slab support system of plant

InactiveCN101929244BRealize measurable and controllablePlay a supporting roleForms/shuttering/falseworksShoresSupporting systemFalsework

The invention relates to a construction method for a large-span cast-in-situ beam slab support system of a plant, which is characterized in that a middle part and an upper part of a shear wall are respectively buried with I-shaped steel to stretch over a room, and a pull ring 9 is welded on the one-third, a cross part, of the middle I-shaped steel 1 for obliquely drawing a steel wire rope 7 between wall bodies, a roof full scaffold is supported on two layers of the I-shaped steel 1 to unload the I-shaped steel 1 through obliquely drawing the I-shaped steel 1 and the steel wire rope 7 between the shear walls with a turnbuckle 8, and the forced deformation of the support system is measured and controlled by measuring the deformation of the I-shaped steel 1 in the concrete casting and loading process. The embodiment scheme of the construction method is that the settlement deformation of the I-shaped steel 1 in different loading stages can be measured through a leveling instrument in the process of the concrete casting and loading process, if the deformation exceeds a preset limit value, the I-shaped steel is unloaded through fastening the turnbuckle 8 to strain the steel wire rope 7,so as to prevent the deformation from exceeding the preset limit value, and the loading deformation value of the support system can be continuously kept in the limit value range through circulating operation, thereby achieving the effective measureable and controllable effect.

Owner:中国人民解放军63926部队

Carboxymethylated Derivatives of Exopolysaccharides of Trichodia granulosa and Their Application in the Preparation of Anti-renal Failure Drugs

InactiveCN103755827BImprove the state of pathological tissueLower creatinineOrganic active ingredientsUrinary disorderSide effectChloroacetic acids

The invention discloses a lachnum exopolysaccharides carboxymethylation derivative and an application thereof in preparation of chronic renal failure-resistant medicines. The lachnum exopolysaccharides carboxymethylation derivative is characterized in that lachnum exopolysaccharides with the strain collection number of CCTCC No: M 2011196 are subjected to chloroacetic acid carboxymethylation modification to obtain the lachnum exopolysaccharides carboxymethylation derivative, and the lachnum exopolysaccharides carboxymethylation derivative in an effective dose and medical auxiliary materials are prepared into tablets and capsules for clinical use according to a conventional preparation method in pharmaceutics due to the effect of obviously resisting chronic renal failure. The pharmacodynamic experiment proves that the exopolysaccharides and carboxymethylation derivative has an obvious effect of resisting chronic renal failure and does not have a toxic or side effect, and the preparation method is simple and economic.

Owner:HEFEI UNIV OF TECH

A kind of synthetic method of thioetherification and thiocarbonylation of halogenated alkanes

ActiveCN113511991BAchieve synthesisReduce usageChemical recyclingSulfide preparationAlkanePropanoic acid

Owner:ANHUI AGRICULTURAL UNIVERSITY

Catalyst for synthesis of 2-and 4-picolines, process for preparing 2- and 4-picoline and process for preparing the catalyst

InactiveCN100448534CThe method is simple and economicalAvoid redundancyOrganic chemistryHeterogenous catalyst chemical elements4-Methylpyridine2-Methylpyridine

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A process for the production of carnitine from [beta] -lactones A process for the production of carnitine from [beta] -lactones](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7251808d-d6b2-4845-bb2c-2c094083bd22/BDA00002750081600031.PNG)

![A process for the production of carnitine from [beta] -lactones A process for the production of carnitine from [beta] -lactones](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7251808d-d6b2-4845-bb2c-2c094083bd22/BDA00002750081600041.PNG)

![A process for the production of carnitine from [beta] -lactones A process for the production of carnitine from [beta] -lactones](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7251808d-d6b2-4845-bb2c-2c094083bd22/BDA00002750081600111.PNG)