Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Stripping is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

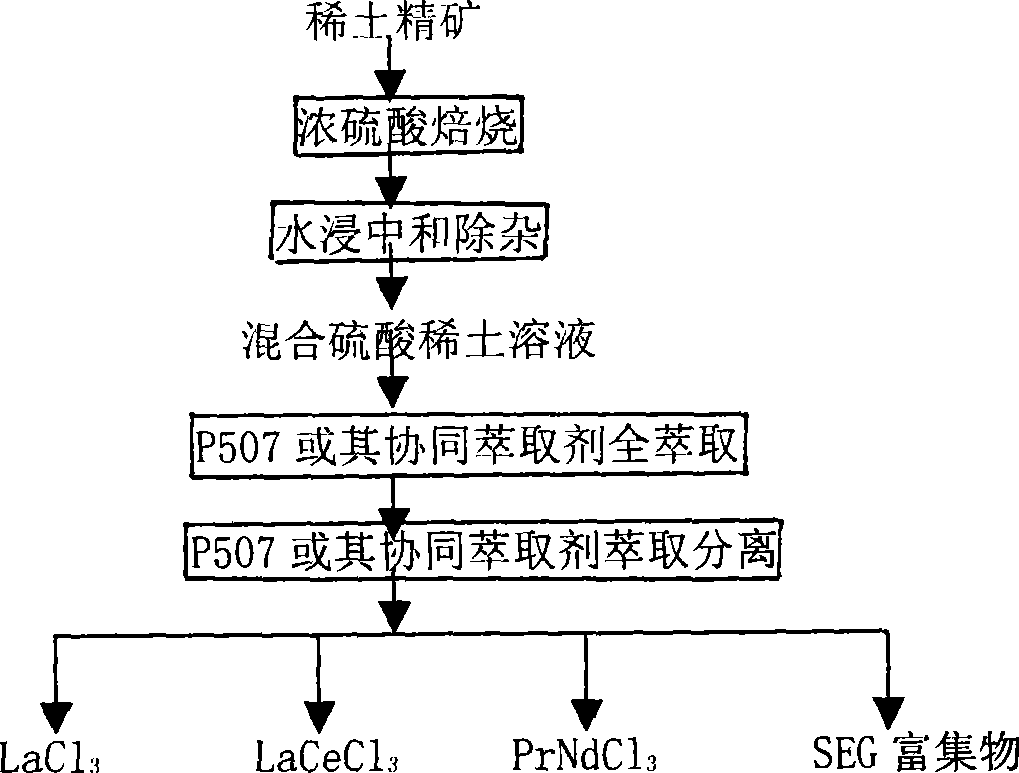

Process for solvent extraction separation purification of rare earth element

ActiveCN101319275AStripping is easyReduce acid and alkali consumptionProcess efficiency improvementRare-earth elementNitrate

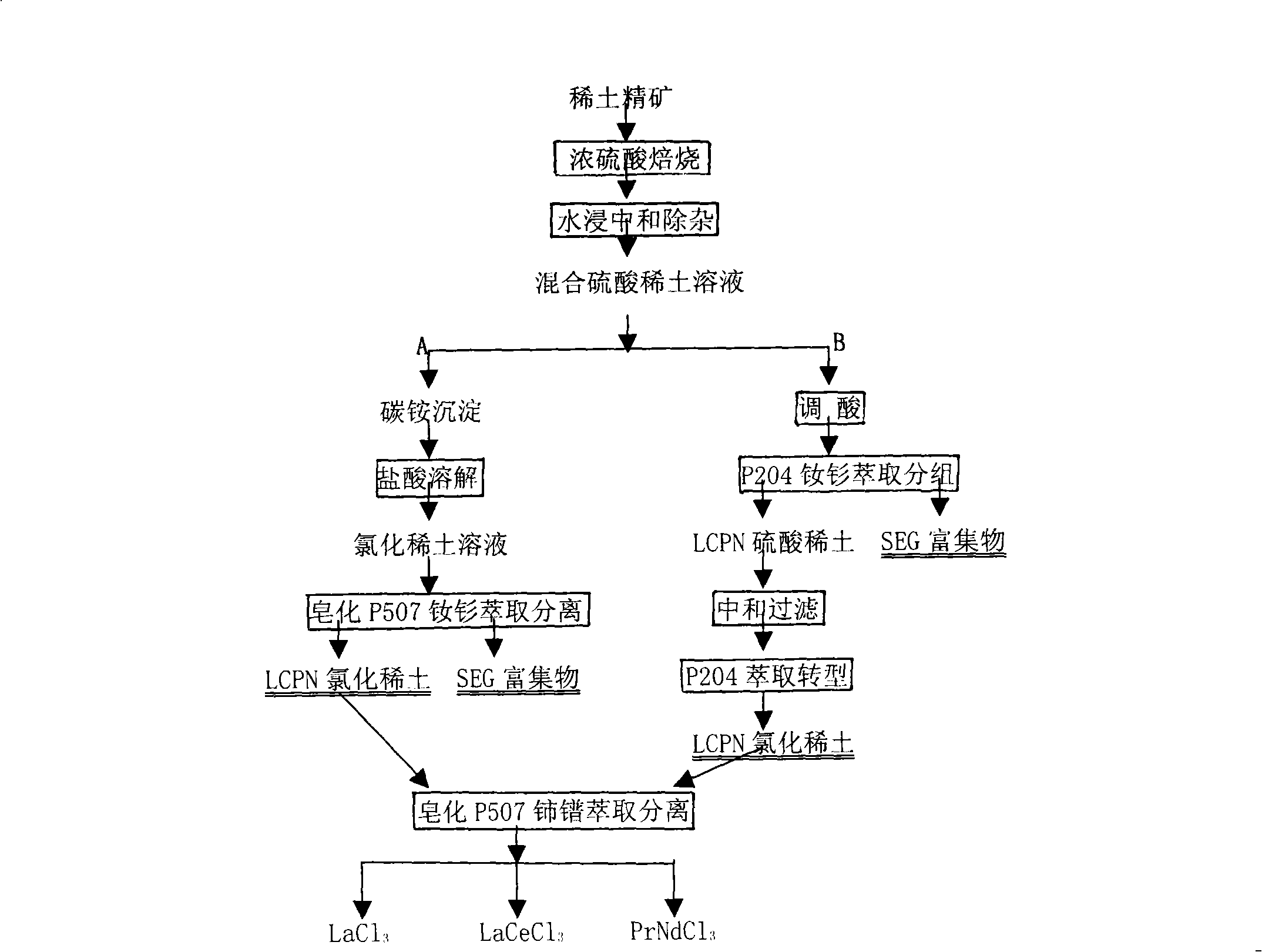

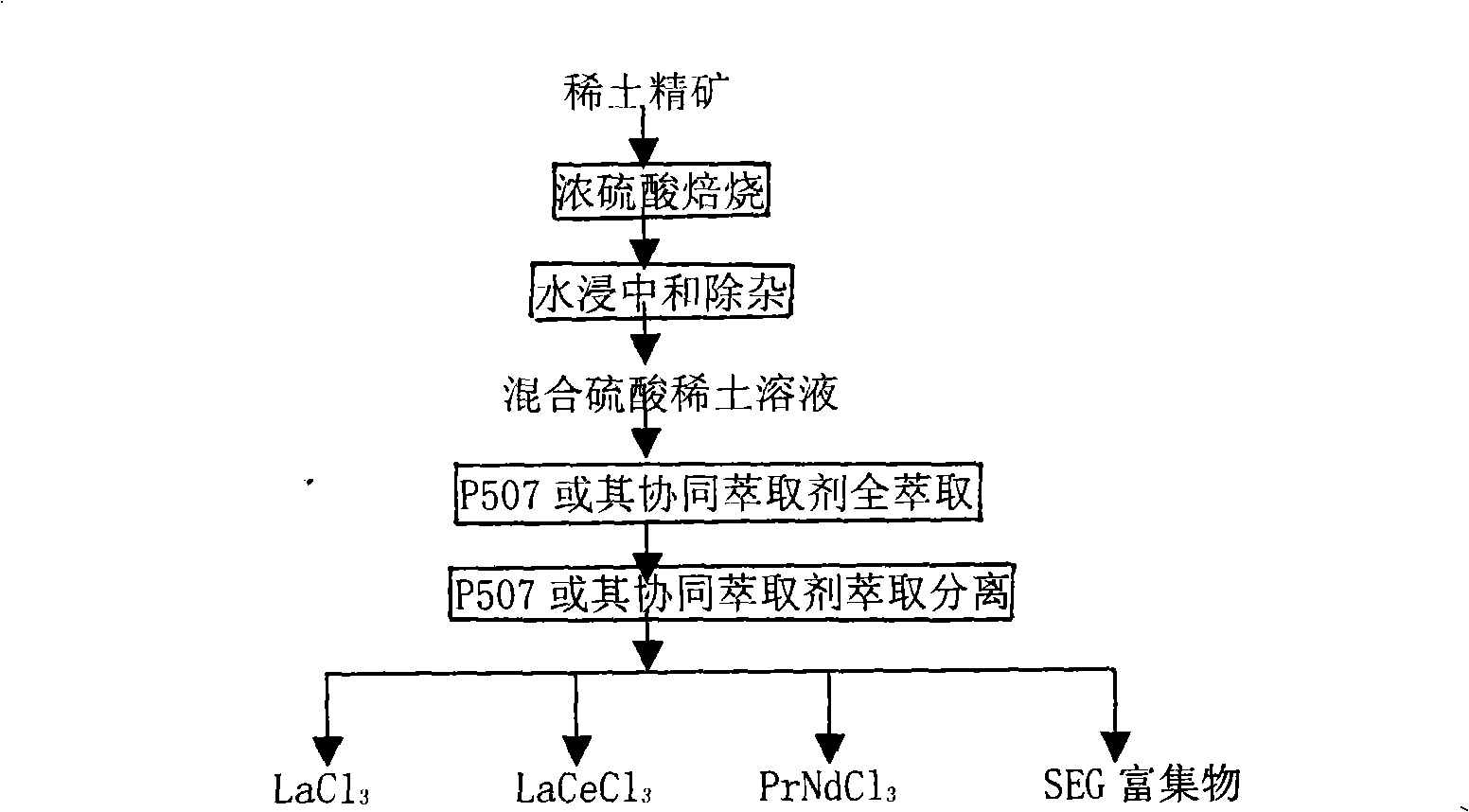

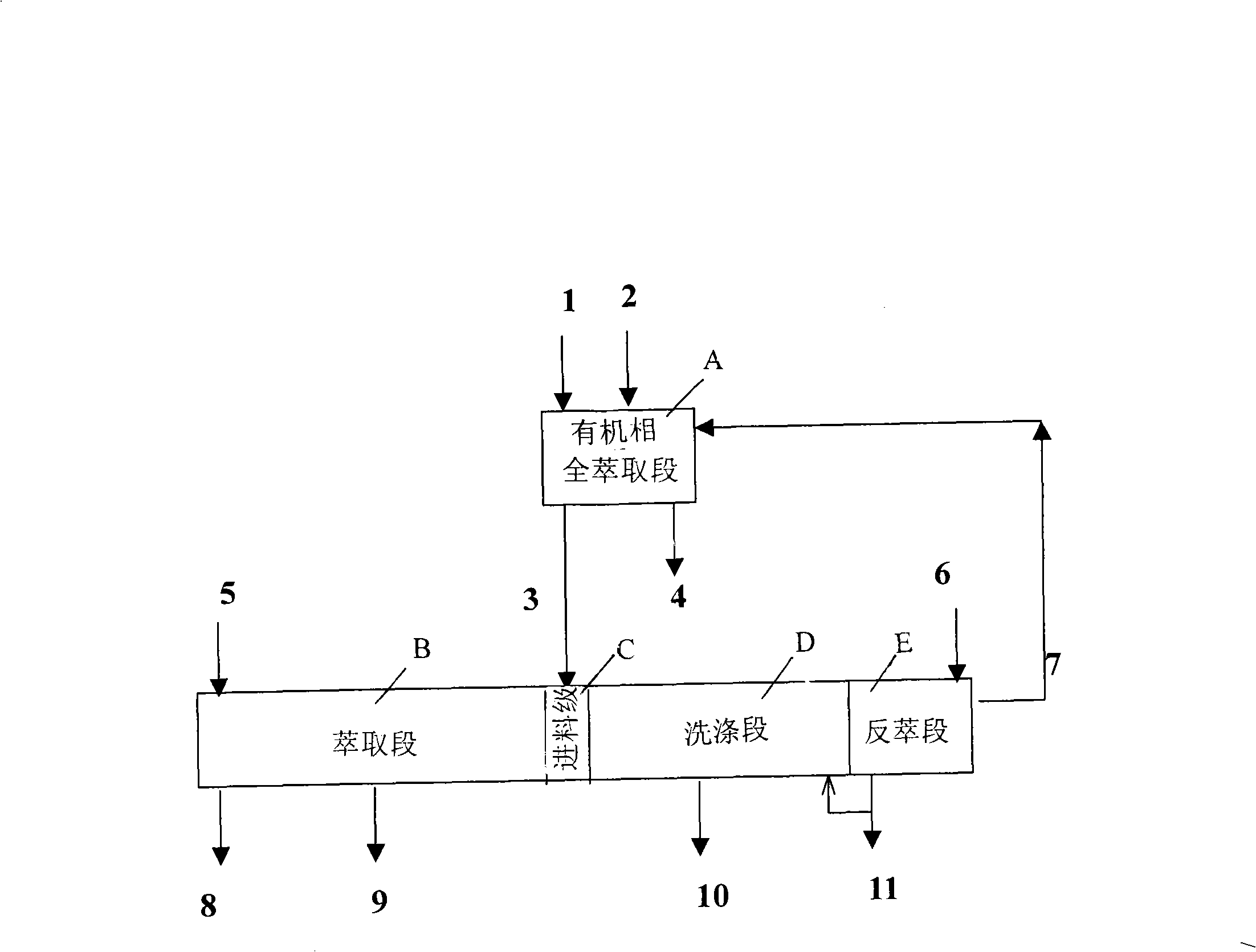

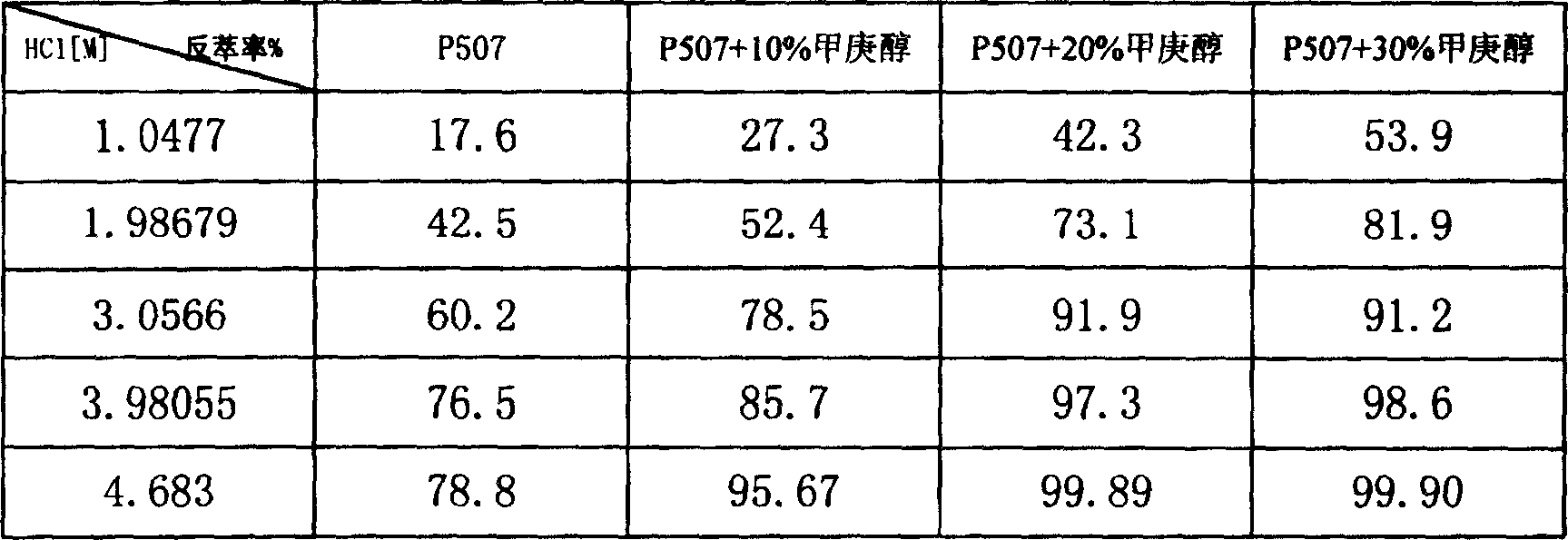

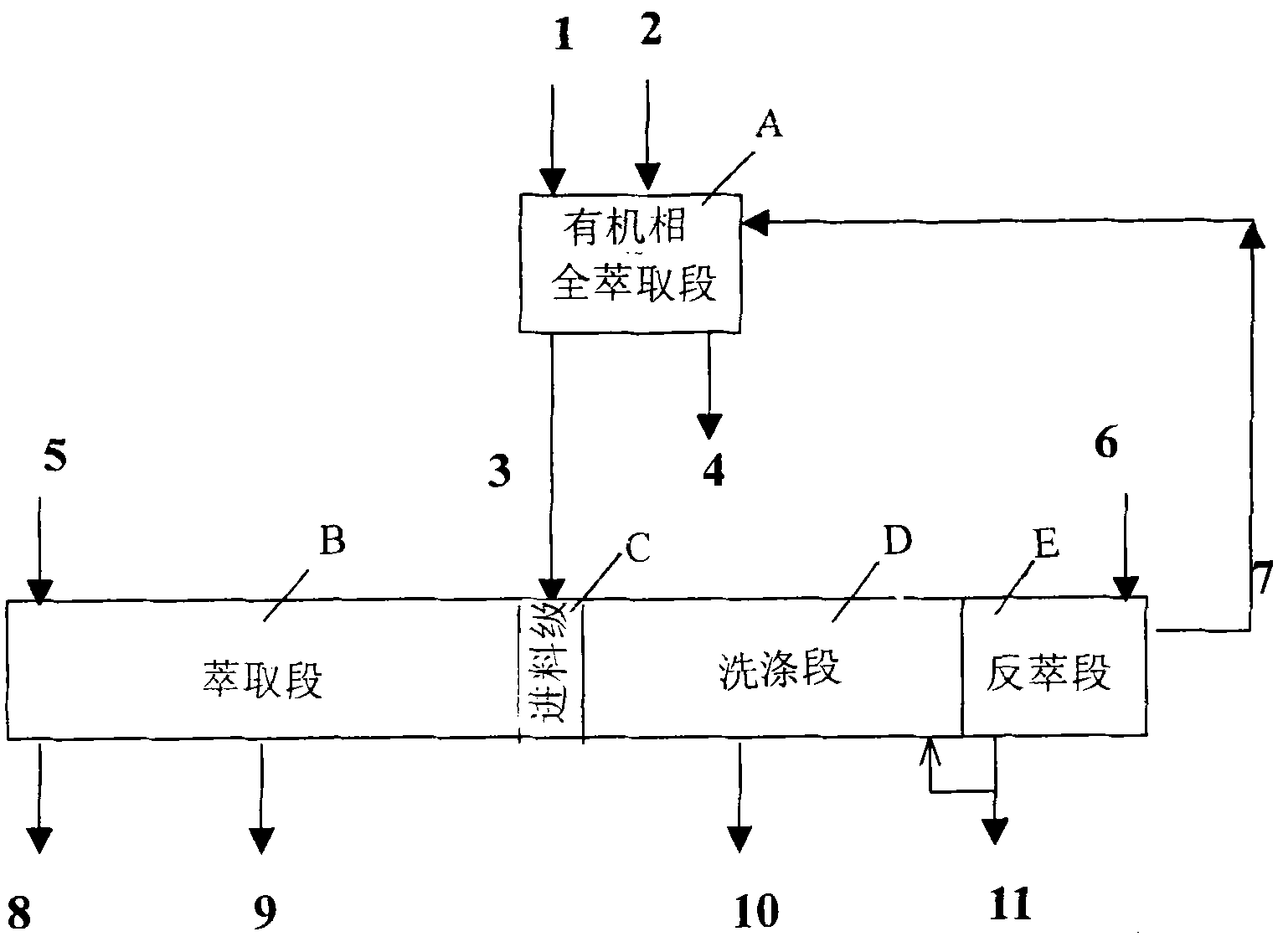

The invention provides a process method for separating and purifying rare earth elements by solvent extraction. The method takes a mixed rare earth sulfate solution obtained from a rare earth ore treated by sulphuric acid as a raw material, directly adopts a nonsaponifiable P507 extraction agent or a synergistic extraction agent containing the P507 to completely extract rare earth in a material liquid into an organic phase, and then takes the organic phase as a rare earth material liquid to extract, separate and purify the rare earth or directly backextract to produce mixed chlorinated rare earth or rare earth nitrate. The process method is simple and flexible, does not saponify the organic phase during the extraction and separation process, does not produce ammonia nitrogen waste water, is easy to backextract middle and heavy rare earths, and has less consumption of acid and base and low production cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Technique for extracting and separating rare earth elements from non-saponification system

ActiveCN101050488AReduce residual acidReduce acid consumptionProcess efficiency improvementRare-earth elementSulfate

This invention provides a process for extracting and separating rare earth elements by using non-saponification extractant. The process comprises: utilizing rare earth sulfate solution containing two or more rare earth elements obtained by treating rare earth ore as the raw material, performing Nd / Sm multi-stage fractionation and extraction by using non-saponification extractant P507 to obtain Sm / Eu / Gd enriched product and La / Ce / Pr / Nd extraction raffinate, and further extracting and separating rare earth compounds with non-saponification extractant. The process has such advantages as no emulsification under low-acidity extraction, easy back extraction of medium-molecular-weight rare earth elements, low acid consumption, and high productivity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN1804063AImprove stripping efficiencyReduce acid consumptionProcess efficiency improvementRare-earth elementMaterial consumption

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

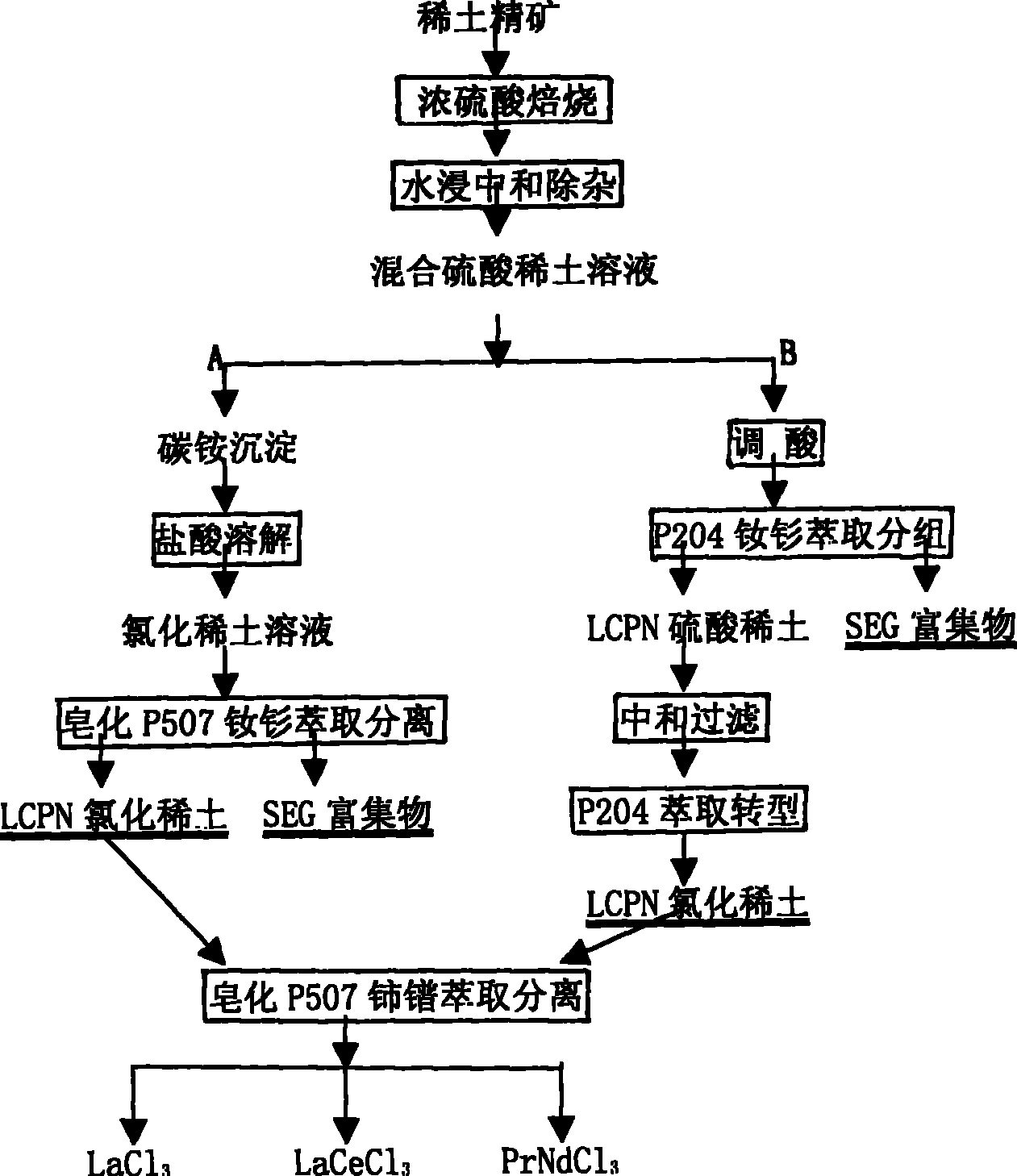

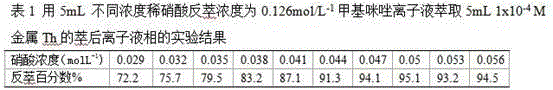

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN101294245ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains the thorium and high-valence cerium, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (4) and the thorium are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain the products including pure cerium and pure thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements after impurity removal. The technological methodn has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (4), the thorium and trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium is recovered as products, and the pollutions caused by thorium-containing waste residue and the ammonia-nitrogen containing wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for extracting palladium from high-level liquid waste

ActiveCN101713026AMinimizeAchieve simplicityProcess efficiency improvementLiquid wasteAfter treatment

The invention provides a method for extracting palladium from high-level liquid waste, which belongs to the technical field of radioactive waste after treatment. The high-level liquid waste adopts nitric acid system, and the method comprises the following concrete steps of: a, adequately mixing the high-level liquid waste with extract phase; b, separating extract phase containing palladium from the mixture after extraction equilibrium; c, washing the separated extract phase containing palladium; d, repeating steps b and c 1 to 5 times; e, adding stripping agent to the washed extract phase containing palladium to perform back extraction; and the method is characterized in that triisobutyl phosphine sulfide (TiBPS) is adopted as extracting agent, and thinning agent is added for preparing the extract phase. The method has the following advantages: a, the extracting ratio of palladium in the nitric acid system is high by using TiBPS as extracting agent; b, the concentration range of adaptable nitric acid is wide, Purex process can be directly linked, mixtion is not required in the extraction process, and waste minimization and processing equipment simplification can be realized; c, the selectivity is good; and d, back extraction is easy.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

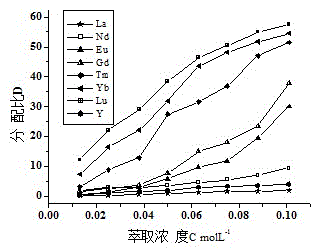

Technology for separating rare earth element by extraction system added with modifier

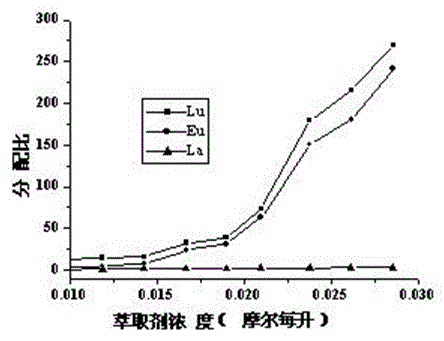

InactiveCN100352954CHigh selectivityStripping is easyProcess efficiency improvementAlkaneRare-earth element

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

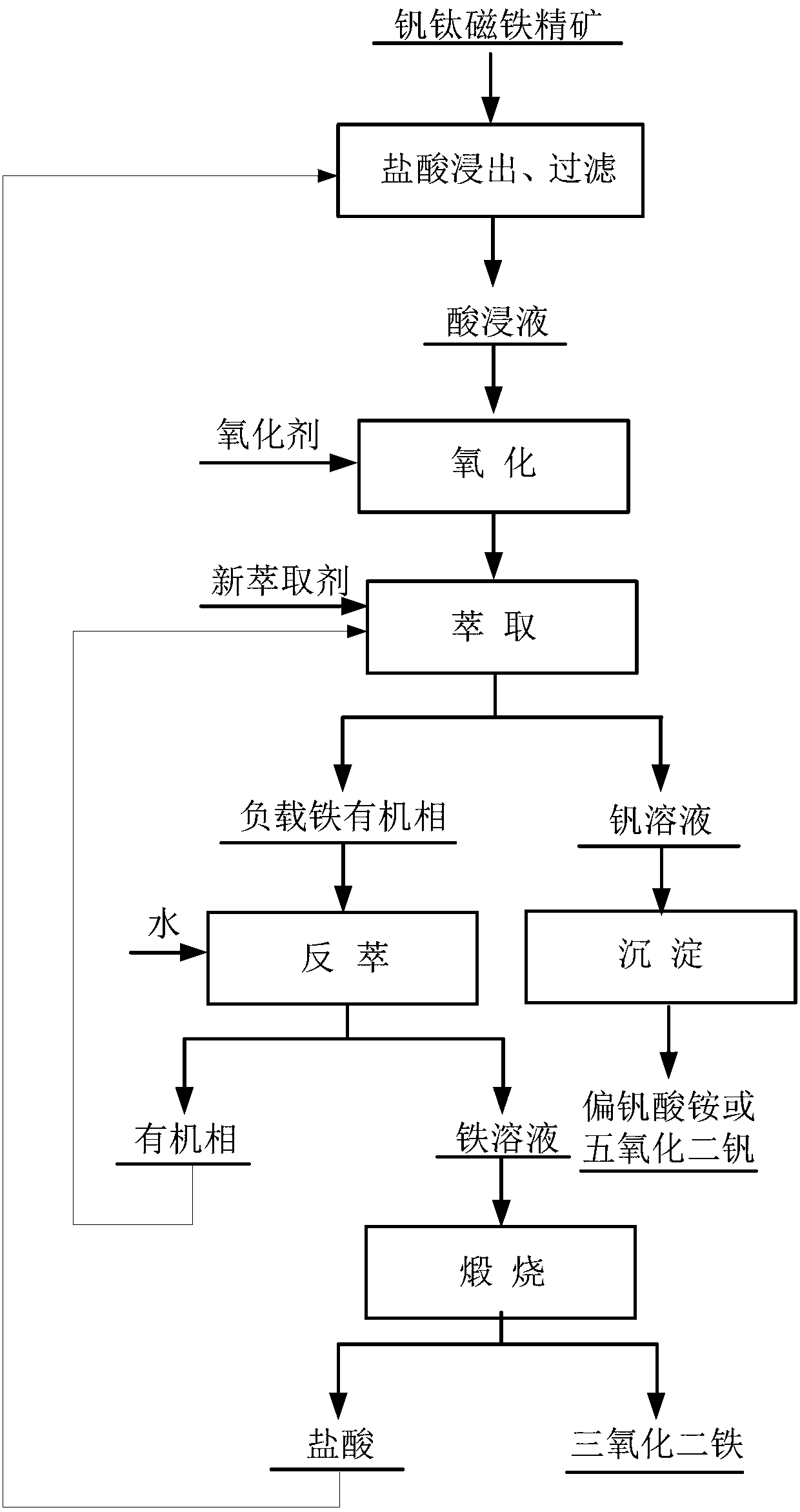

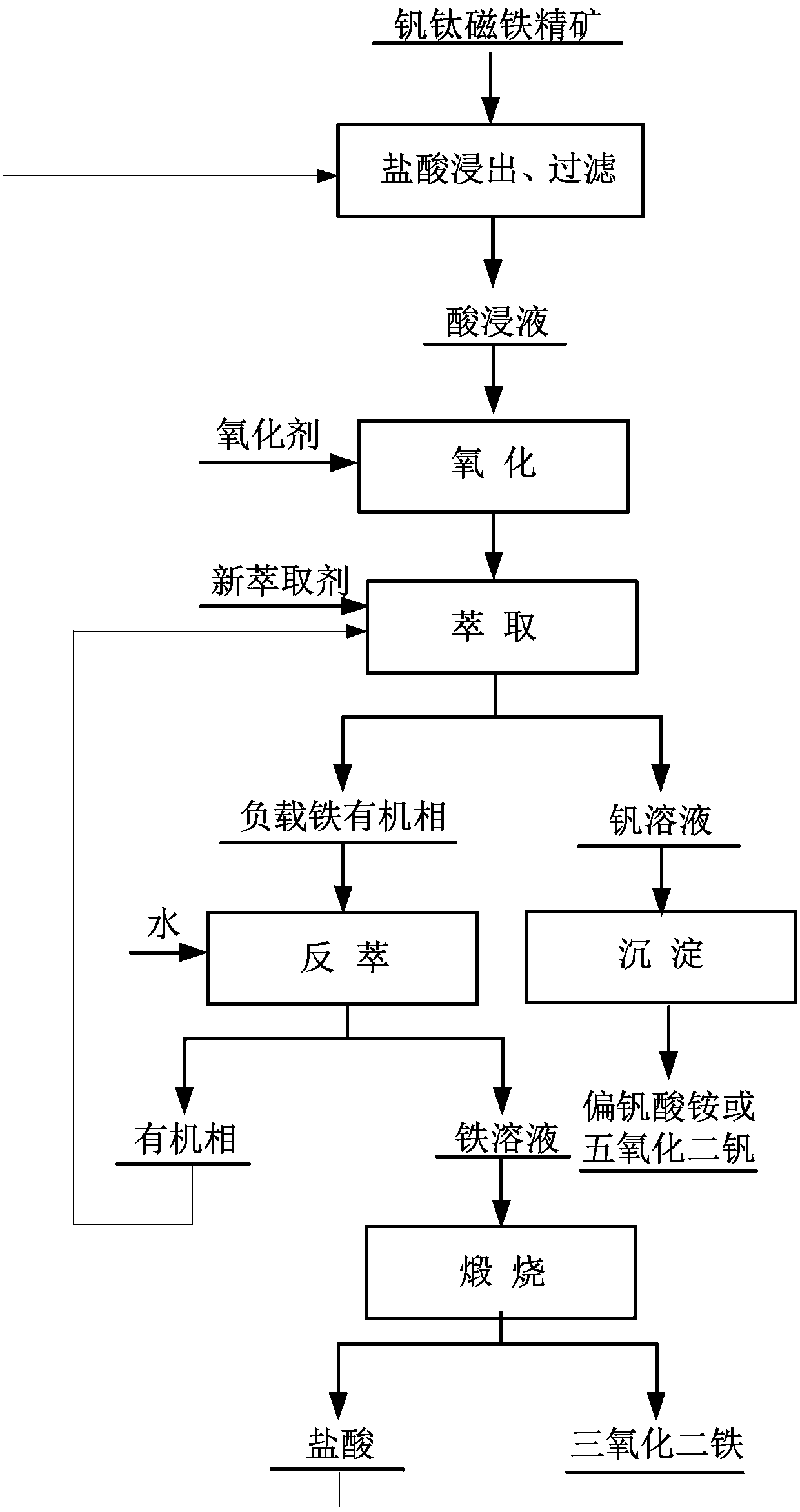

Method for extracting iron and vanadium from vanadium-titanium magnetite concentrates

ActiveCN103276211AImprove reaction efficiencyEfficient leachingFerric oxidesAcid dissolutionMagnetite

The invention belongs to the field of hydrometallurgy and in particular relates to a method for extracting iron and vanadium from vanadium-titanium magnetite concentrates. The method comprises the following steps of: 1) carrying out acid dissolution and leaching on vanadium-titanium magnetite concentrates and hydrochloric acid; 2) oxidizing Fe<2+> in acid leaching solution obtained in the step 1) into Fe<3+> with an oxidizing agent; 3) extracting iron from the oxidized acid leaching solution obtained in the step 2) with an extracting agent to obtain an organic phase and vanadium-containing raffinate; (4) carrying out back extraction on the organic phase obtained in the step 3) to obtain an extracting agent and an iron-containing acid solution; 5) calcining the iron-containing acid solution obtained in the step 4) to obtain hydrochloric acid and iron trioxide; and 6) treating the vanadium-containing raffinate obtained in the step 3) to obtain ammonium vanadate or vanadium pentoxide. The method has the advantages that the added values of products are high, the recovery rate of vanadium is greatly increased, and the environmental pollution can be avoided.

Owner:河北中科同创钒钛科技有限公司

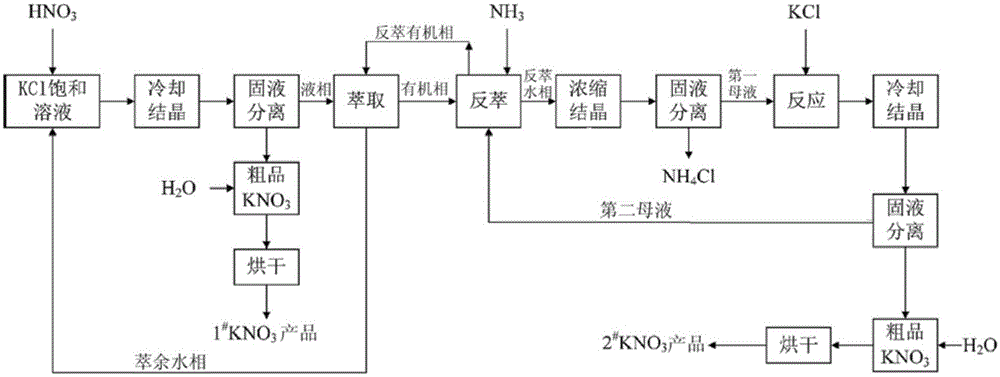

Method for preparing sodium nitrate through solvent extraction

ActiveCN105036158ALow costSimple extraction processAlkali metal nitrate preparationPotassium nitrateChloride

The invention provides a method for preparing sodium nitrate through solvent extraction. The method includes the following steps that step1, a potassium chloride saturated solution with the temperature of 50 DEG C-70 DEG C is prepared, nitric acid is added to react with the potassium chloride saturated solution at the temperature of 50 DEG C-70 DEG C, cooling crystallization and solid-liquid separation are performed, and an obtained solid phase is washed with water and dried to obtain a potassium nitrate product; step2, an extraction agent is added into a liquid phase obtained in solid-liquid separation in the step1, and a raffinate water phase is returned into a reaction vessel in the step1; 3, an organic phase obtained in extraction in the step2 is mixed with water or a second mother solution, ammonia gas is led into the mixture for reverse extraction, and a reverse extraction organic phase is returned to the step2; 4, condensation crystallization and solid-liquid separation are performed on a reverse extraction water phase in the step3 to obtain ammonium chloride and a first mother solution, potassium chloride is added into the first mother solution and reacts with the first mother solution at the temperature of 60 DEG C-80 DEG C, cooling crystallization and solid-liquid separation are performed to obtain a solid phase and the second mother solution, the obtained solid phase is washed and dried to obtain a potassium nitrate product, and the second mother solution is returned to the step3.

Owner:SICHUAN UNIV

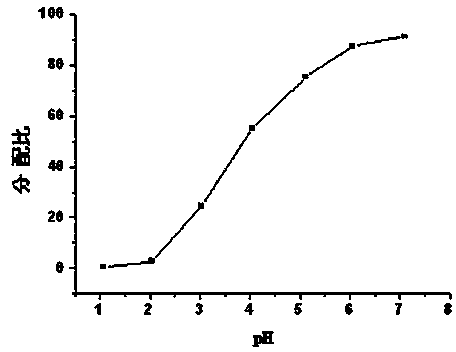

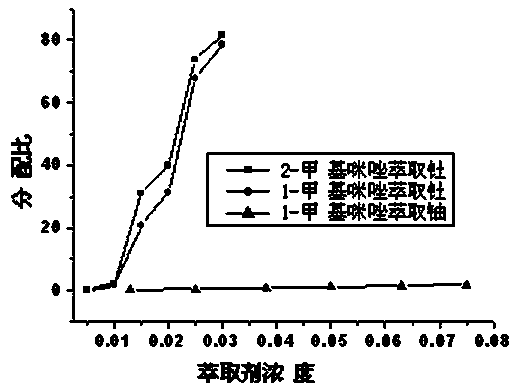

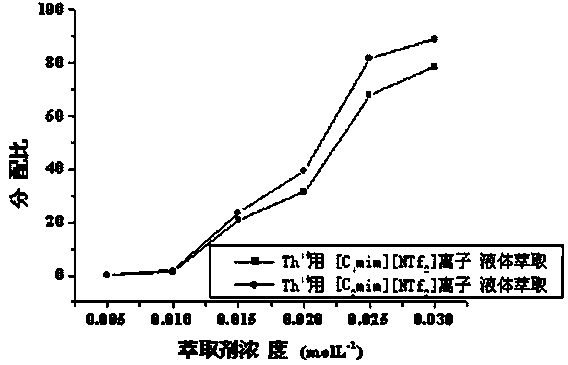

Method for separating uranium and thorium and reagent used for separation

InactiveCN103451426AAvoid adjustmentAvoid Co-Extraction Reagent InsufficiencyIonic liquidMethyl palmoxirate

The invention discloses a method for separating uranium and thorium and an extraction agent used for separation. According to the method, uranium and thorium nitrate mixed aqueous solution is placed in imidazolyl ionic liquid diluent in which the reagent is dissolved or n-amyl alcohol diluent in which the reagent is dissolved, thorium is extracted, and uranium stays in an aqueous phase. The extraction agent used for separation is1-methylimidazole showed in a first formula or 2-methylimidazole showed in a second formula. The method and the reagent have the advantages that the extraction agent is cheap and can be obtained easily, an extraction system is simple, extraction efficiency is high, the number of used extraction agents is small, and specificity is strong.

Owner:LANZHOU UNIVERSITY

Process for solvent extraction separation purification of rare earth element

ActiveCN101319275BStripping is easyReduce acid and alkali consumptionProcess efficiency improvementRare-earth elementNitrate

Owner:GRIREM ADVANCED MATERIALS CO LTD

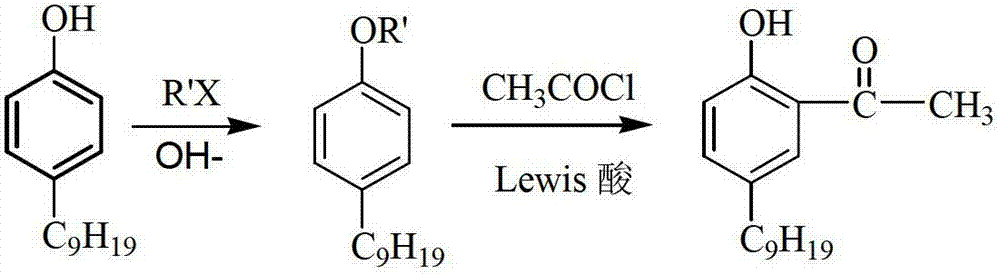

Technique for synthesizing 2-hydroxy-5-tert octyl acetophenone

InactiveCN102731278AHigh purityHigh yieldOrganic compound preparationCarbonyl compound preparationChemical synthesisFries rearrangement

The invention discloses a technique for synthesizing 2-hydroxy-5-tert octyl acetophenone, belonging to the field of organic chemistry synthesis, characterized by using Fries rearrangement reaction of octylphenyl esters to synthesize 2-hydroxy-5-tert octyl acetophenone. The application of oximation products of the synthesized 2-hydroxy-5-tert octyl acetophenone by the technique as a copper extractant can raise the purity of copper and reduce the discharge amount of waste acid in wet copper smelting process. According to the invention, few by-product is produced in the process, there is no need for high temperature vacuum distillation and other purification steps, only acidification, washing and the like are needed, thus by the technique in 2-hydroxy-5-tert octyl acetophenone, the product has high purity and high yield, and the post-treatment is simple.

Owner:TSINGHUA UNIV

Technique for extraction separation of quadravalence cerium, thorium, fluorine and cerium less tervalence rare earth from sulphuric acid rare earth solution

ActiveCN101294244BNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementAmmoniacal nitrogen

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, fluorine and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains high-valence cerium, the fluorine, the thorium and ferrum, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (1V), the thorium, the fluorine, and the ferrum are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain three products that are the cerium, the fluorine, and the thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or thesynergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements. The technological method has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (1V), the thorium, the fluorine, the ferrum and the trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium and the fluorine are recovered as products, and the pollutions caused by thorium-containing waste residue, fluoride-containing wastewater and the ammonia-nitrogen wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, greenenvironmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN100584969CNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for extracting palladium from high-level liquid waste

ActiveCN101713026BHigh palladium extraction ratioHigh extraction ratioProcess efficiency improvementLiquid wasteAfter treatment

The invention provides a method for extracting palladium from high-level liquid waste, which belongs to the technical field of radioactive waste after treatment. The high-level liquid waste adopts nitric acid system, and the method comprises the following concrete steps of: a, adequately mixing the high-level liquid waste with extract phase; b, separating extract phase containing palladium from the mixture after extraction equilibrium; c, washing the separated extract phase containing palladium; d, repeating steps b and c 1 to 5 times; e, adding stripping agent to the washed extract phase containing palladium to perform back extraction; and the method is characterized in that triisobutyl phosphine sulfide (TiBPS) is adopted as extracting agent, and thinning agent is added for preparing the extract phase. The method has the following advantages: a, the extracting ratio of palladium in the nitric acid system is high by using TiBPS as extracting agent; b, the concentration range of adaptable nitric acid is wide, Purex process can be directly linked, mixtion is not required in the extraction process, and waste minimization and processing equipment simplification can be realized; c, the selectivity is good; and d, back extraction is easy.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

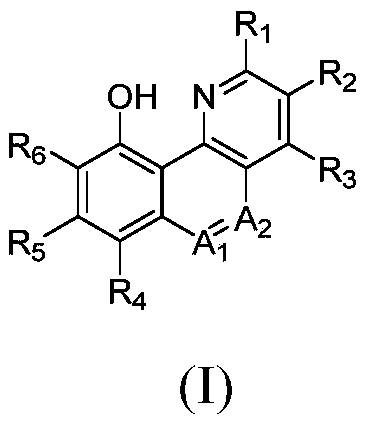

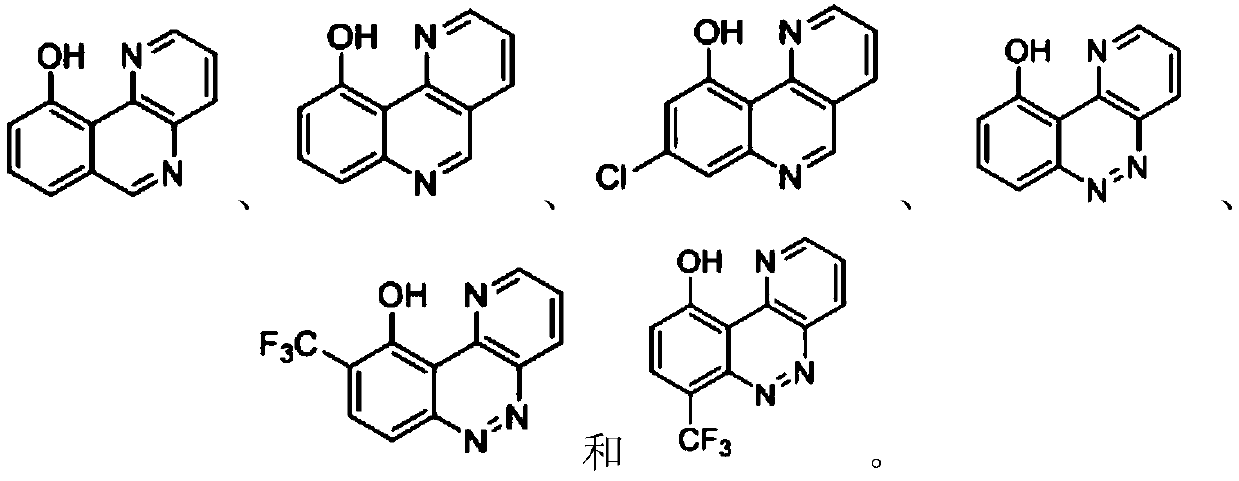

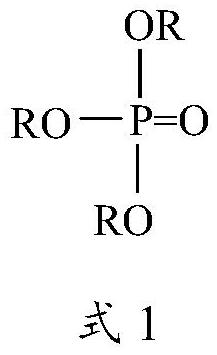

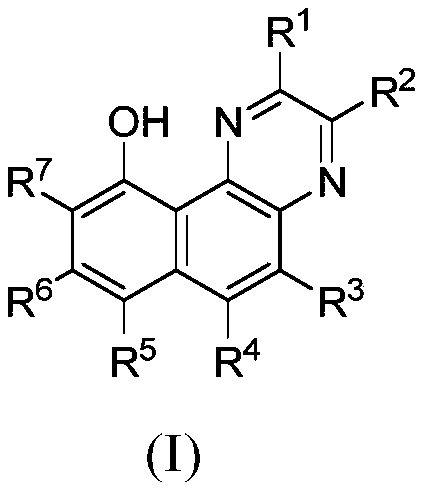

Benzo-heterocyclic type compounds and application thereof

ActiveCN109706323ASimple manufacturing methodEfficient separation and extractionOrganic chemistryProcess efficiency improvementLithiumSeparation coefficient

The invention discloses benzo-heterocyclic type compounds and application thereof, and particularly provides a compound shown in a formula (I) in the text. An extraction agent composed of the type ofcompounds has a high extraction rate towards lithium ions and a high separation coefficient towards lithium isotopes, and can realize efficient extraction and separation of the lithium isotopes. Please see the specification for the formula (I).

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of lutetium nitrate feed liquid

PendingCN112028106AReduce Chloride ContentEasy to makeRare earth metal nitratesRare earth metal compounds preparation/treatmentEnvironmental chemistrySodium hydroxide

The invention discloses a preparation method of lutetium nitrate feed liquid. The preparation method comprises the following steps: mixing naphthenic acid, octanol and kerosene to obtain an organic extraction agent; then adding a sodium hydroxide solution into the organic extraction agent, and carrying out saponification reaction to obtain a saponified organic extraction agent; then carrying out rare earth saponification in a cascade reaction mode, and mixing and reacting the obtained saponification organic extraction agent and lutetium chloride feed liquid and then standing for phase splitting; then adopting a multi-stage washing mode, taking an organic phase obtained in the last-stage extraction section to be mixed with a water phase or nitric acid in a next-stage washing section for reaction, and then standing for phase splitting; and mixing the organic phase obtained in the last-stage washing section with the water phase or nitric acid in the next-stage back extraction section in amulti-stage back extraction mode, reacting, standing, and carrying out phase splitting to obtain a water phase, namely lutetium nitrate feed liquid, in the last-stage back extraction section. The method effectively solves the problems that the existing lutetium nitrate feed liquid production process is complicated, and the content of chloride ions and sodium ions in the obtained lutetium nitratefeed liquid is high.

Owner:CHALCO GUANGXI RARE EARTH DEV CO LTD

Preparation method of high-purity thorium nitrate

InactiveCN106480329AHigh stripping rateFacilitate strippingProcess efficiency improvementSalting outKerosene

The invention provides a preparation method of high-purity thorium nitrate. The preparation method comprises the steps that HNO3 and NaNO3 are used as salting-out agents for allocating a Th(NO3)4 solution to form a mixed solution, and a P350-sulfonated kerosene organic phase is used for extracting the mixed solution; a NaNO3 solution is adopted for washing the obtained organic phase loaded with Th; and a fluorine-containing water solution is adopted for reversely extracting the washed organic phase loaded with Th. The process has the advantages that when high-purity water is adopted for thorium reverse extraction, F<-> in an added HF or NaF solution can be easily coordinated with Th<4+> to form [ThFx]<4>-x, so that reverse extraction of a P350 system with Th<4+> loaded is promoted, and the reverse extraction rate of thorium can be improved; and the product quality can reach the standards that ThO2 / Th(NO3)4.6H2O is larger than or equal to 46%, and the ThO2 purity is larger than 99.9995%.

Owner:永州市湘江稀土有限责任公司

Composite extractant, preparation thereof and application thereof in metal indium extraction

InactiveCN101660047AStripping is easyExtraction inhibitionProcess efficiency improvementIndiumPhosphate

The invention relates to a composite extractant used in a metal indium extraction process. The composite extractant is formed by mixing Bis(2-ethylhexyl)phosphate (P204), trioctylphosphine oxide and hexylphosphine oxide mixture liquid (C923) and trialkyphosphine oxides (TRPO) according to certain proportion. After being diluted with sulfonated kerosene, the composite extractant is used as an extractant used for metal indium extraction. The composite extractant has good chemical stability, good selectivity and high indium extraction efficiency which can achieve more than 90%, simultaneously canreduce the extractant emulsification, is easy for re-extraction, and the demand to extraction conditions of a system is not high.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

Heavy rare earth and light rare earth separation method and extraction agent

InactiveCN103451427BAvoid the limitations of low solubilityLess quantityProcess efficiency improvementRare-earth elementNitrate

The invention discloses a heavy rare earth and light rare earth separation method and a heavy rare earth and light rare earth separation extraction agent. The method includes the step of conducting extraction on a rare earth element and nitrate mixed aqueous solution through imidazolyl ionic liquid where the extraction agent is dissolved or chloroform where the extraction agent is dissolved or a 1-pentanol diluent where the extraction agent is dissolved so that heavy rare earth elements can be extracted and yttrium and light rare earth elements can be kept in the aqueous phase, wherein the extraction agent which is used is 1-methylimidazole shown in the chemical formula 1 or 2-methylimidazole shown in the chemical formula 2 when the diluent is the imidazolyl ionic liquid or the chloroform, and the extraction agent which is used is 2-methylimidazole shown in the chemical formula 2 when the diluent is the 1-pentanol diluent. The heavy rare earth and light rare earth separation method and the heavy rare earth and light rare earth separation extraction agent have the advantages that the extraction agent is low in price and can be easily obtained, the extraction system is simple, the extraction efficiency is high, the amount of the extraction agent which is used is small, and the specificity is strong.

Owner:LANZHOU UNIVERSITY

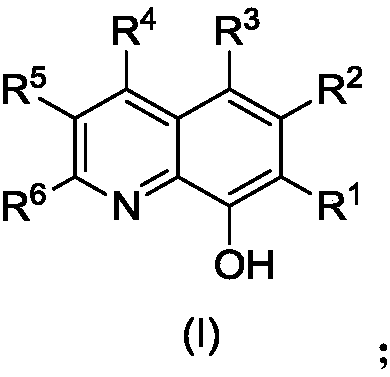

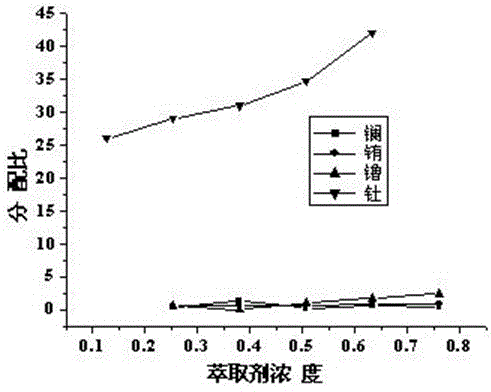

Extractant composition and resource utilization method of iron-containing wastewater

PendingCN112390320ALarge extraction capacityHigh selectivityIron compounds preparationWater contaminantsEnvironmental chemistryPhosphate

The invention provides an extractant composition. The extractant composition comprises the following components in percentage by mass: 20-40% of a phosphate extractant as shown in a formula 1, 35-50%of C6-C10 monohydric alcohol and the balance of a diluent. The invention further provides a resource utilization method of the iron-containing wastewater, and the extractant composition is used in theresource utilization method. The extractant composition disclosed by the invention does not need to use an organic amine extractant, is simple in extraction system and relatively low in cost, and does not easily generate a third phase even under high-concentration iron, so that the extractant composition can be suitable for extraction treatment of various iron-containing wastewater. The resourceutilization method provided by the invention can effectively extract and separate iron from the iron-containing wastewater for resource utilization, is very suitable for large-scale application, and has important economic and social values;.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN100404706CResidual acid reductionStripping is easyProcess efficiency improvementRare-earth elementNitrate

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Extraction system and application thereof

ActiveCN108950247AEfficient extractionHigh extraction recoveryProcess efficiency improvementLithiumDiluent

The invention discloses an extraction system and application thereof. The extraction system comprises a compound and a modifier shown in the formula (I), and the molar ratio of the compound shown in the formula (I) to the modifier shown in the formula (I) is 0.2:1-5:1. When the extraction system contains diluents, the application preferably comprises the following steps that an organic phase is used for extracting a lithium containing solution obtained after waste battery wet processing, and an organic phase loaded with lithium ions is obtained. According to the extraction system and the application thereof, the recycling rate of the extraction process is high, the balance time is short, reverse extraction and operation are easy, and good practicability and economical efficiency are achieved. Through the extraction system, rapid and efficient extraction of the lithium ions can be achieved; and as is shown in the embodiment, the single-level extraction recycling rate of the lithium canreach 89%, and the multi-level total recycling rate can reach 99%. The formula is shown in the specification.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Thorium element and rare earth element separation method and separation reagent

InactiveCN103451425BAvoid the limitations of low solubilityAvoid adjustmentProcess efficiency improvementRare-earth elementAmyl alcohol

The invention discloses a method for separation of thorium elements from rare earth elements and an extraction agent used in the method. According to the method, a mixed aqueous solution of thorium and rare earth nitrate is subjected to extraction through an n-amyl alcohol diluent, wherein the extraction agent is dissolved in the n-amyl alcohol diluent; the thorium elements are extracted, and the rare earth elements are lest in an aqueous phase. The extraction agent used in the method is 1- methylimidazole as shown in formula 1. The method for separation of the thorium elements from the rare earth elements and the extraction agent used in the method have the advantages that the extraction agent is low in price and easy to obtain, an extraction system is relatively simple, extraction efficiency is quite high, the quantity of the used extraction agent is quite small, and the specificity is strong.

Owner:LANZHOU UNIVERSITY

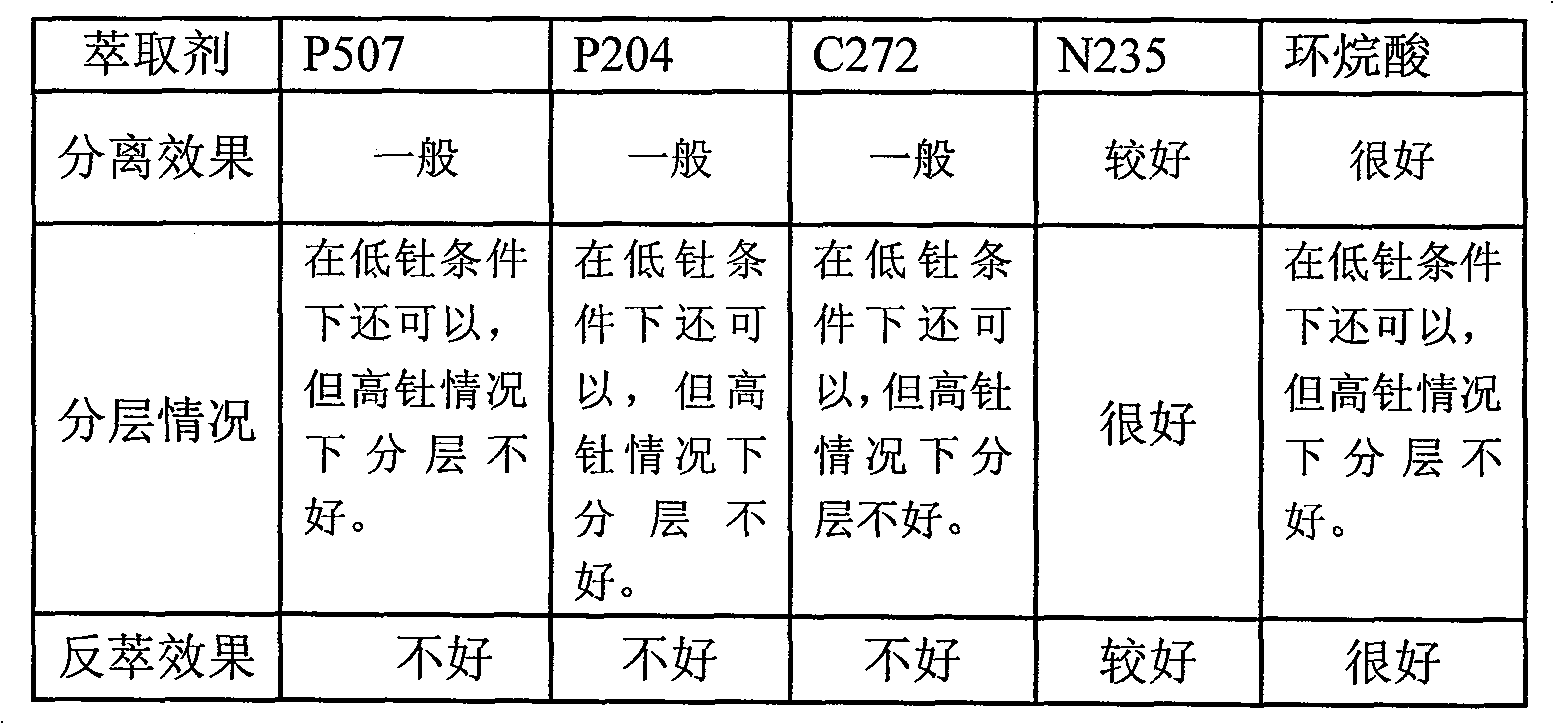

Preparation method of low-thorium lutetium oxide

ActiveCN101748275BEasy to separateThe separation effect is achievedRare earth metal compoundsProcess efficiency improvementLutetiumKerosene

The invention relates to a preparation method of low-thorium lutetium oxide, comprising the following steps of: firstly carrying out 3-10 level of primary countercurrent extraction on lutetium oxide extracted from a solvent as a raw material by adopting an isooctanol or kerosene solution of 0.5-2.0mol / L of N235 extracting agent, and then carrying out 3-10 level of countercurrent washing selectivebackextraction on organic phases of extracted thorium by adopting 0.1-2mol / L of alkali abluent solution; then separating the low-thorium lutetium oxide by a kerosene solution of 0.1-1.0mol / L of another extracting agent, carrying out 3-10 level of countercurrent washing selective backextraction on the organic phases of the extracted thorium by adopting 0.5-2mol / L of acidic abluent solution, carrying out oxalic precipitation, washing and dehydration on aqueous-phase lutetium oxide after thorium removal, and burning at the condition of 750-1000 DEG C to obtain a product, namely, the low-thorium lutetium oxide. In the method, rare earth and thorium are thoroughly separated, and the organic extracting agent is low in price.

Owner:江阴加华新材料资源有限公司

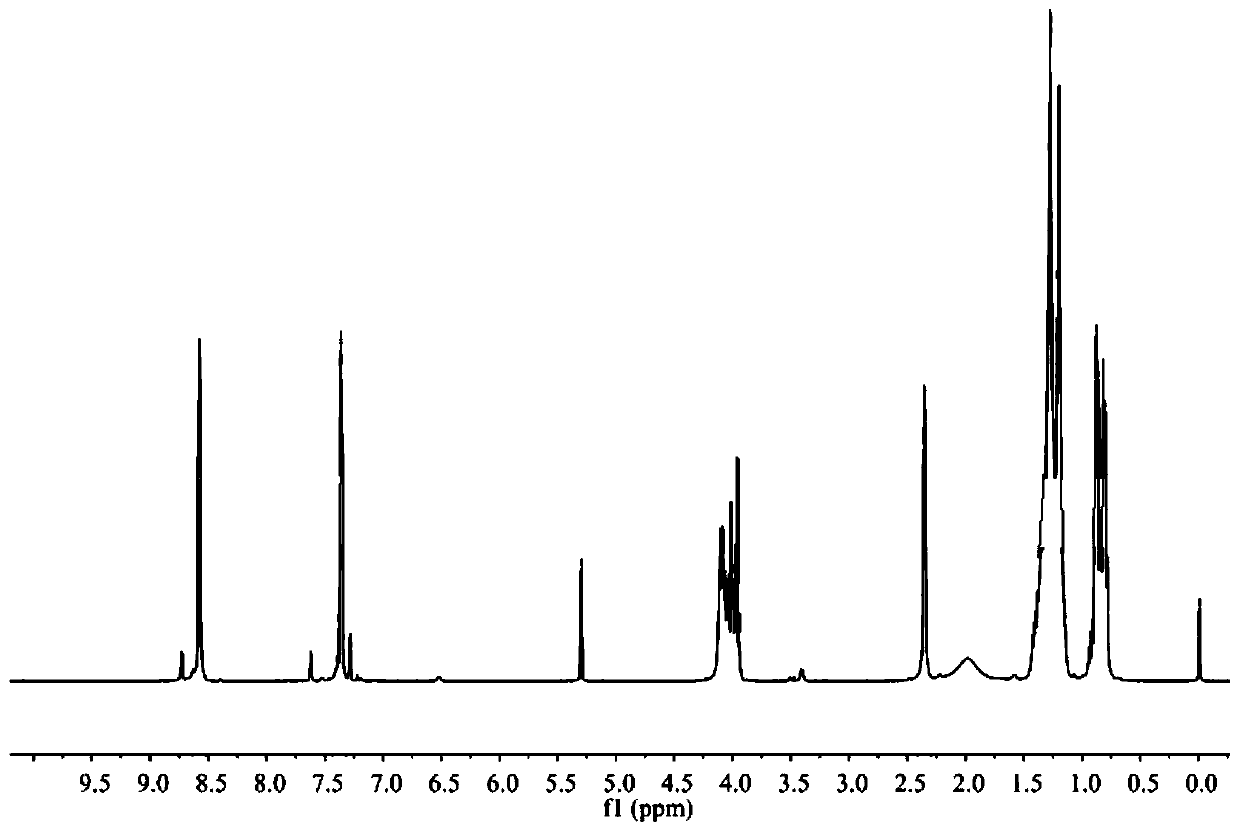

Pyrazine compound and application thereof

ActiveCN109851567ASimple manufacturing methodEfficient extractionOrganic chemistryProcess efficiency improvementLithiumIsotope

The invention discloses a pyrazine compound and application thereof. In particular, the present invention provides a compound represented by the formula (I), wherein the extractant composed of the compound has a high extraction rate for lithium ions, and the organic phase is easy to enrich lithium-7 isotopes, so as to realize the extraction and separation of lithium isotopes.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

A kind of pyridyl phosphoramide compound and its preparation method and application as nickel-cobalt extractant

ActiveCN108822147BStrong electron supply abilityRapid phase separationGroup 5/15 element organic compoundsPhase timeManganese

The invention discloses a pyridinylphosphoramide compound and its preparation method and its application as a nickel-cobalt extractant. Pyridine-4-formaldehyde and alkyl primary ammonia are subjected to an amaldehyde condensation reaction to generate a Schiff base intermediate. Addition reaction between Schiff base intermediate and dialkyl phosphite to obtain pyridyl phosphoramide compound. The preparation method has the advantages of environmental protection, mild conditions, simple process, short process, etc.; the synthesized pyridyl phosphoramide compound is combined with P204 as a nickel-cobalt synergistic extractant for the extraction and separation of cations containing nickel, cobalt, and magnesium manganese. It has the characteristics of high extraction capacity, short phase separation time, excellent extraction and stripping performance, etc., and has a good industrial application prospect.

Owner:CENT SOUTH UNIV

A kind of sugar analysis three-phase system and method for extracting and separating Fe (Ⅲ), Cr (Ⅲ) and Ni (ⅱ)

ActiveCN109913666BStripping is easyFast separationProcess efficiency improvementActive agentAmyl alcohol

The invention relates to the technical field of separation of iron, nickel and chromium, in particular to a three-phase system and method of sugar analysis for extracting and separating iron Fe(Ⅲ), nickel Ni(II) and chromium Cr(Ⅲ), which can be used for waste Separation of iron, nickel and chromium in slag and waste liquid. The present invention first selects saponified P507 as surfactant, n-pentanol as co-surfactant, and n-heptane as organic phase to construct a microemulsion; then, constructs a three-phase system of saponified P507 microemulsion, acetonitrile and sugar solution, and creatively proposes A sugar precipitation three-phase system and method for extracting and separating iron, nickel and chromium is proposed, and the method can better realize the separation of iron, nickel and chromium. The advantages of the present invention are that the preparation process of the three-phase system is simple, and the amount of P507 and organic phase is less, the operation is simpler, the equipment is friendly, the separation speed is fast, the separation efficiency is high, the stripping step is simple, and the organic phase and sugar after stripping All can be recycled and easily used in industry on a large scale.

Owner:BINZHOU UNIV

Method for extracting iron and vanadium from vanadium-titanium magnetite concentrates

ActiveCN103276211BHigh recovery rateImprove product added valueFerric oxidesAcid dissolutionMagnetite

The invention belongs to the field of hydrometallurgy and in particular relates to a method for extracting iron and vanadium from vanadium-titanium magnetite concentrates. The method comprises the following steps of: 1) carrying out acid dissolution and leaching on vanadium-titanium magnetite concentrates and hydrochloric acid; 2) oxidizing Fe<2+> in acid leaching solution obtained in the step 1) into Fe<3+> with an oxidizing agent; 3) extracting iron from the oxidized acid leaching solution obtained in the step 2) with an extracting agent to obtain an organic phase and vanadium-containing raffinate; (4) carrying out back extraction on the organic phase obtained in the step 3) to obtain an extracting agent and an iron-containing acid solution; 5) calcining the iron-containing acid solution obtained in the step 4) to obtain hydrochloric acid and iron trioxide; and 6) treating the vanadium-containing raffinate obtained in the step 3) to obtain ammonium vanadate or vanadium pentoxide. The method has the advantages that the added values of products are high, the recovery rate of vanadium is greatly increased, and the environmental pollution can be avoided.

Owner:河北中科同创钒钛科技有限公司

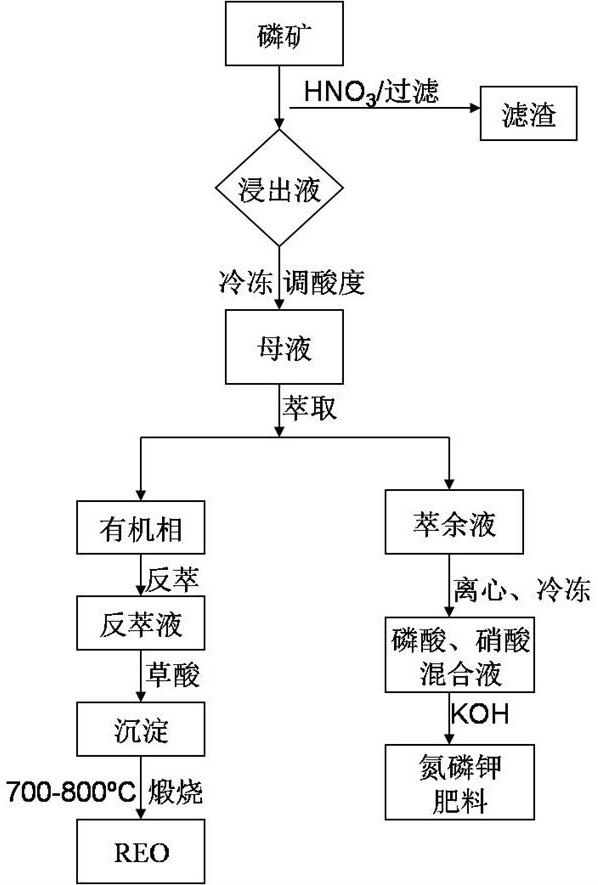

A method for recovering rare earth from the process of decomposing phosphate rock with nitric acid

ActiveCN107988495BEasy extractionSpeed up extractionProcess efficiency improvementRare-earth elementO-Phosphoric Acid

The invention discloses a method for comprehensively recovering rare earth from phosphate rock containing rare earth. The rare earth-containing phosphate rock is leached with nitric acid solution, and then the solid-liquid separation is obtained to obtain the rare earth-containing solution. It does not need to be neutralized. The rare-earth-containing solution can be extracted-back-extracted under strong acid conditions to recover rare earth elements. By adding nitric acid for leaching, the presence of phosphoric acid in the leaching solution increases the acidity of the leaching solution, which further promotes the extraction efficiency of rare earths. The extraction efficiency can reach more than 98%, and the phosphoric acid does not extract, and the impurity ions are almost not extracted. It realizes good separation of phosphorus and rare earth in phosphate rock, can broaden the product chain of nitrophosphate fertilizer enterprises, and creates a road of comprehensive recovery and utilization of rare earth resources, which is beneficial to the utilization of rare earth-containing phosphate rock resources.

Owner:UNIV OF JINAN

Benzoheterocyclic compounds and their applications

ActiveCN109706323BSimple manufacturing methodEfficient separation and extractionOrganic chemistryProcess efficiency improvementLithiumSeparation factor

The invention discloses a benzoheterocyclic compound and its application. Specifically, the present invention provides the compound shown in the formula (I) herein, the extraction agent composed of this type of compound has a high extraction rate for lithium ions, has a high separation coefficient for lithium isotopes, and can realize efficient extraction and separation of lithium isotopes .

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com