Extraction system and application thereof

An extraction and system technology, applied to the improvement of process efficiency, etc., can solve the problems of small organic phase lithium loading, low extraction efficiency, and high acidity of back extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

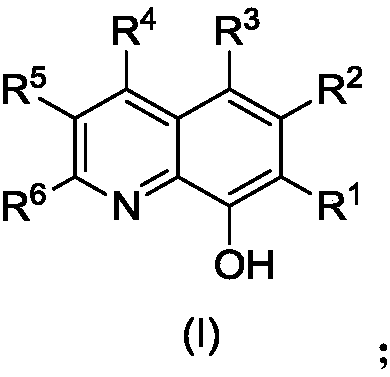

[0063] Extraction system: extractant: 8-hydroxyquinoline 0.50mol / L; modifier: dioctylmethylsulfonium chloride 0.50mol / L; diluent: chloroform. Aqueous phase: Lithium-containing solution after wet treatment of waste batteries. Mainly contains: 0.20mol / L Li + , 0.50mol / L Na + ;0.30mol / L K + Plasma.

[0064] Extraction method: add a certain amount of KOH to the aqueous phase of the lithium-containing waste liquid, adjust the pH value to 13-14, compare the extraction system with the aqueous phase at a ratio of 1:1, and extract equilibrium after single-stage extraction contact for 3 minutes, and separate phases; use 2mol / L of hydrochloric acid is used as the stripping solution, and the lithium product is obtained after stripping. The concentration of lithium in the raffinate was 0.07mol / L. The single-stage extraction recovery of lithium was 65%.

Embodiment 2

[0066] Extraction system: extractant: 0.60 mol / L of 7-propyl-8-hydroxyquinoline; modifier: 0.80 mol / L of dinonylmethylsulfonium chloride; diluent: sulfonated kerosene. Water phase: Lithium-containing solution after wet treatment of waste batteries, mainly containing: 0.08mol / L Li + , 0.52mol / L Na + Plasma.

[0067] Extraction method: add a certain amount of NaOH to the aqueous phase of the lithium-containing waste liquid, adjust the pH value to 13-14, and compare the extraction system with the aqueous phase at a ratio of 1:1. After 3 minutes of single-stage extraction, the extraction is balanced and the phases are separated; use 0.5 The hydrochloric acid of mol / L is used as stripping solution, and lithium product is obtained after stripping. The concentration of lithium in the raffinate is 0.009mol / L. The single-stage extraction recovery of lithium was 89%.

Embodiment 3

[0069] Extraction system: extractant: 5,7-dichloro-8-hydroxyquinoline 0.30mol / L; modifier: trinonylmethylammonium chloride 0.30mol / L; diluent: dichlorobenzene. Water phase: Lithium-containing solution after wet treatment of waste batteries, mainly containing: 0.08mol / LLi + , 0.52mol / L Na + Plasma.

[0070] Extraction method: add a certain amount of NH to the aqueous phase of lithium-containing waste liquid 4 OH, adjust the pH value to >9, the extraction system is compared with the water phase at 1:1, the single-stage extraction is in contact for 3 minutes, the extraction is balanced, and the phases are separated; use 1.0mol / L hydrochloric acid as the stripping solution, and after stripping, get lithium products. The concentration of lithium in the raffinate is 0.015mol / L. The single-stage extraction recovery of lithium was 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com