Technology for separating rare earth element by extraction system added with modifier

A technology of heavy rare earth elements and modifiers, applied in the direction of improving process efficiency, can solve the problems of high acidity and incompleteness of heavy rare earth ion stripping, and achieve the effect of high selectivity and easy stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

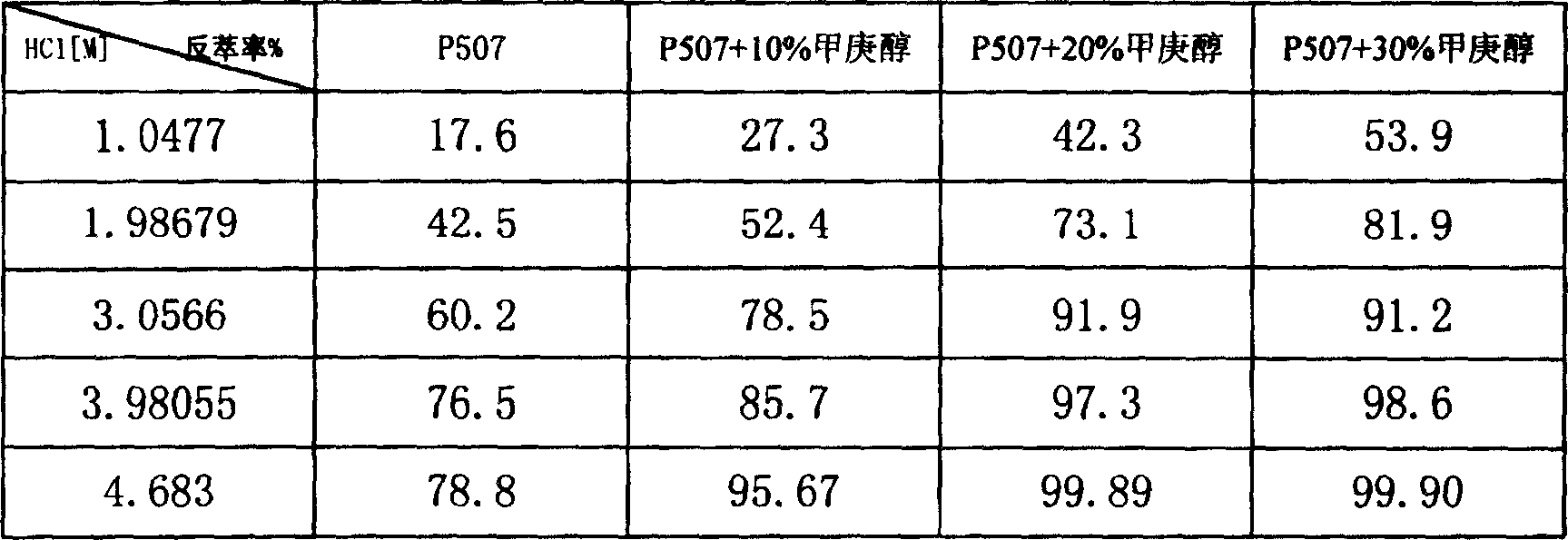

[0011] The experimental temperature is 10-35°C. Compared with the condition of 1:1, the acidity of the water phase is fixed, and the chlorinated or nitrated rare earth is used as the feed liquid, and the pH of the feed liquid is <6.0; P507 is used as the extraction agent, and the ratio of ROH is changed according to the physical phenomenon. Good, high extraction efficiency, high selectivity requirements, determine the addition ratio of ROH, that is, the ratio of adding alcohol is 1%-50% (volume percentage), and the optimal ratio is 10%-30%.

Embodiment 2

[0013] The experimental temperature is 10-35°C, and under the condition of 1:1, the extraction agent is saturated with chlorinated or nitrated rare earth feed solution several times to determine the saturation capacity of the P507+ROH extraction system;

[0014] Additives

[0015] 30%

Embodiment 3

[0017] The extraction temperature is 25+-1°C, the acidity of the water phase is fixed, and the rare earth chloride YbCl is selected 3 , compared to the condition of 1:1, with P507 as the extractant, C P507 = 1.5M, add different proportions of methylheptanol as the extraction system, after the extraction is saturated, use 1-6 HCl to compare the 2:1 back-extraction extract, and determine the acidity of the back-extraction;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com