Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Simple injection molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

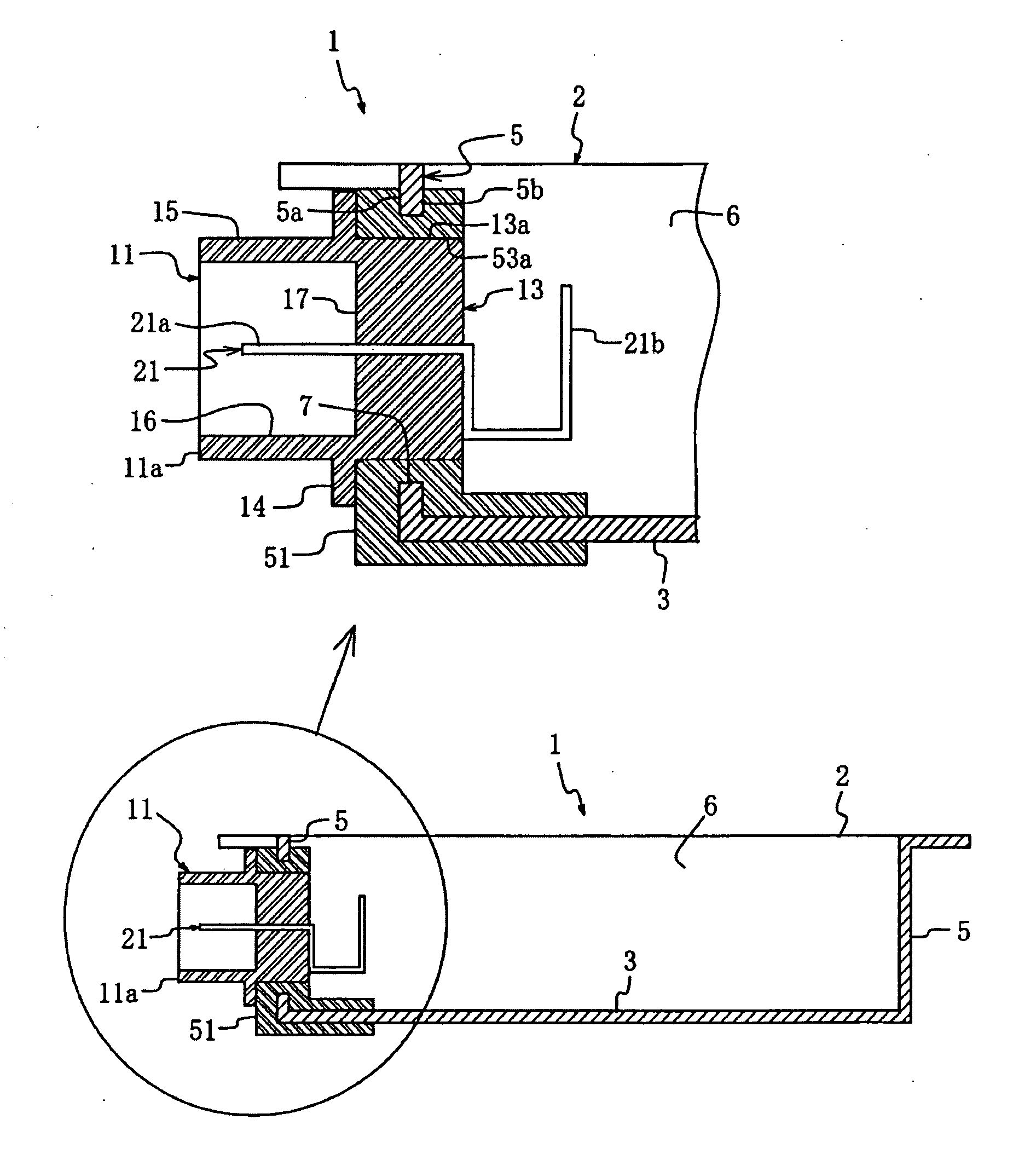

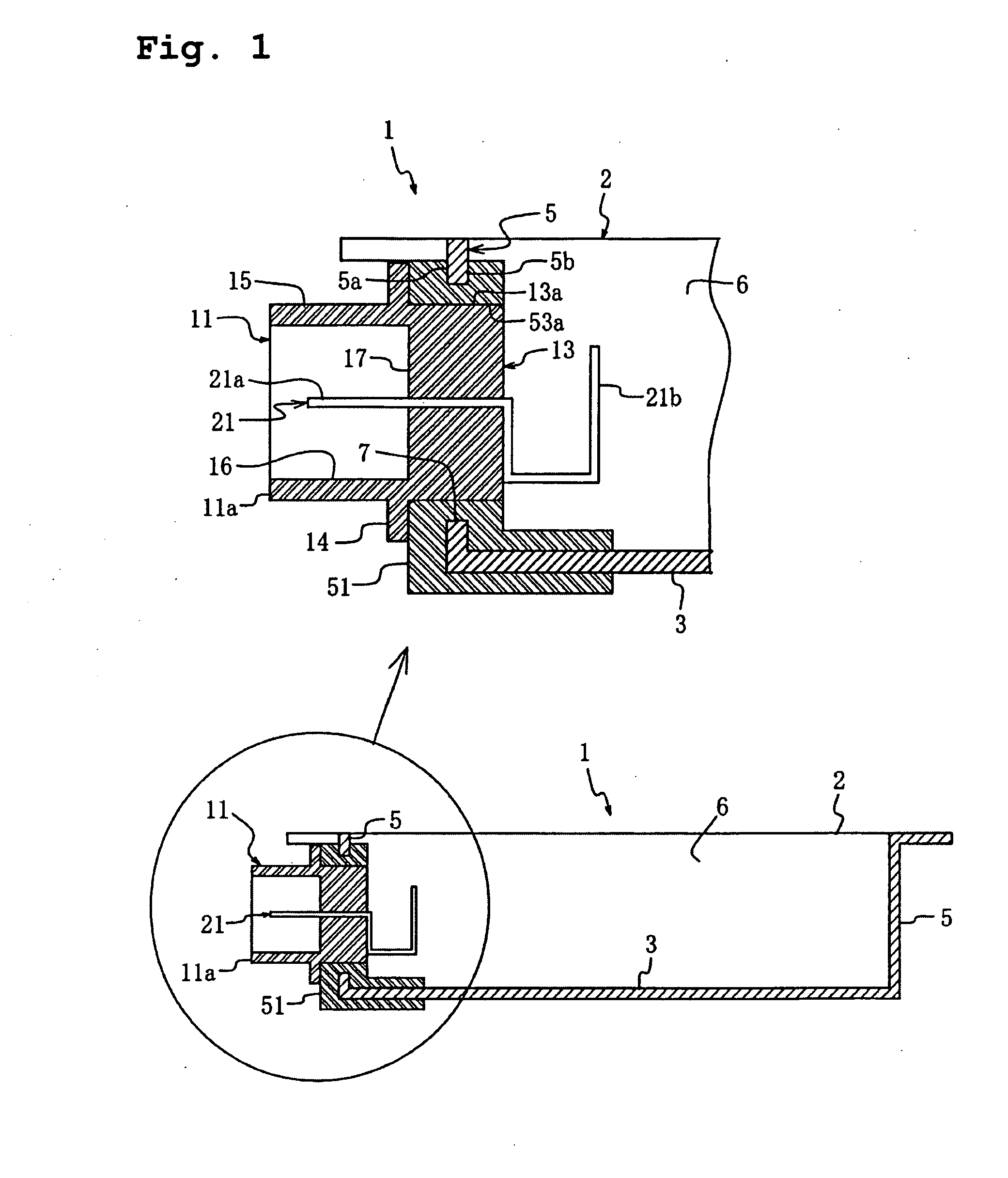

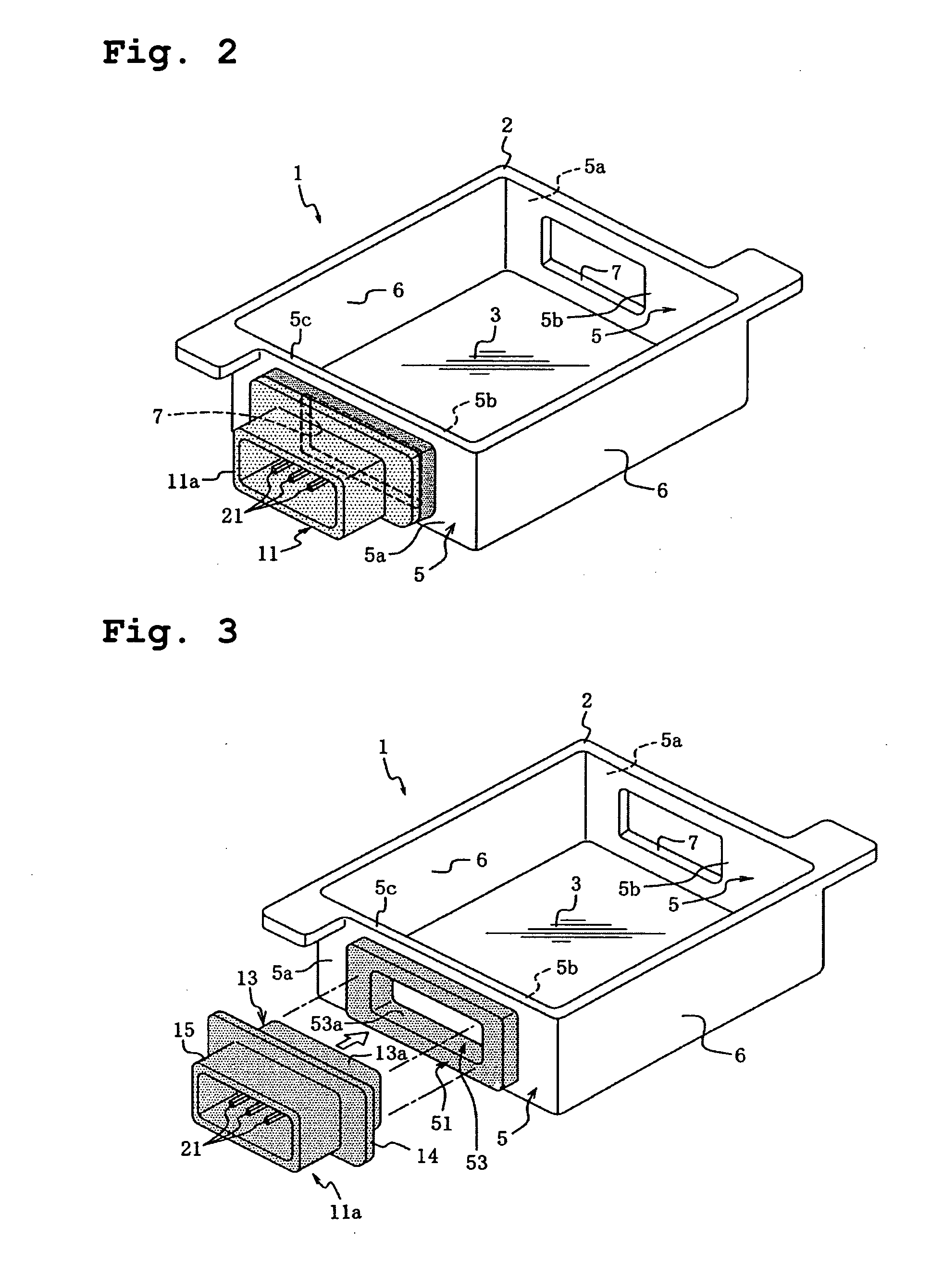

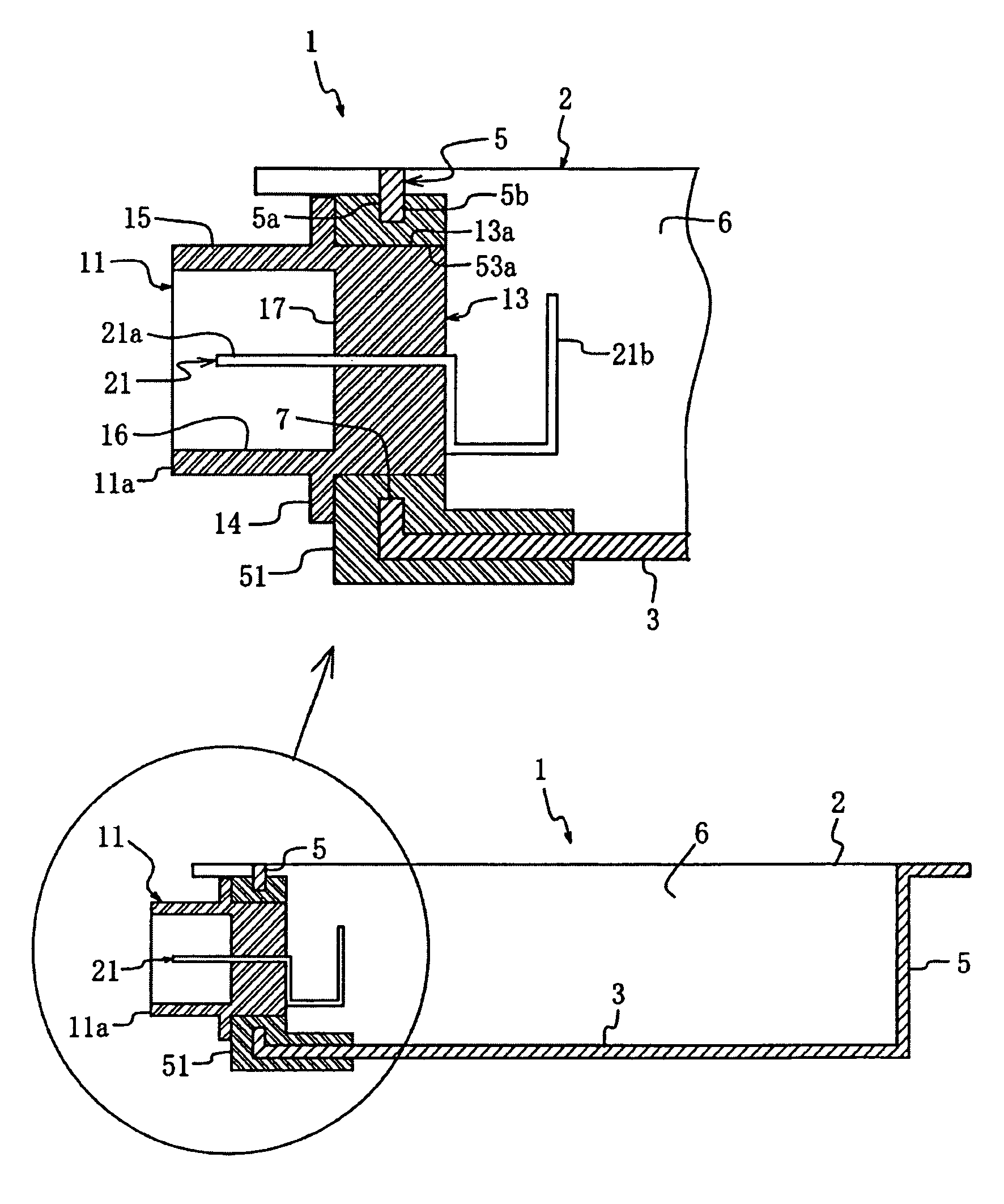

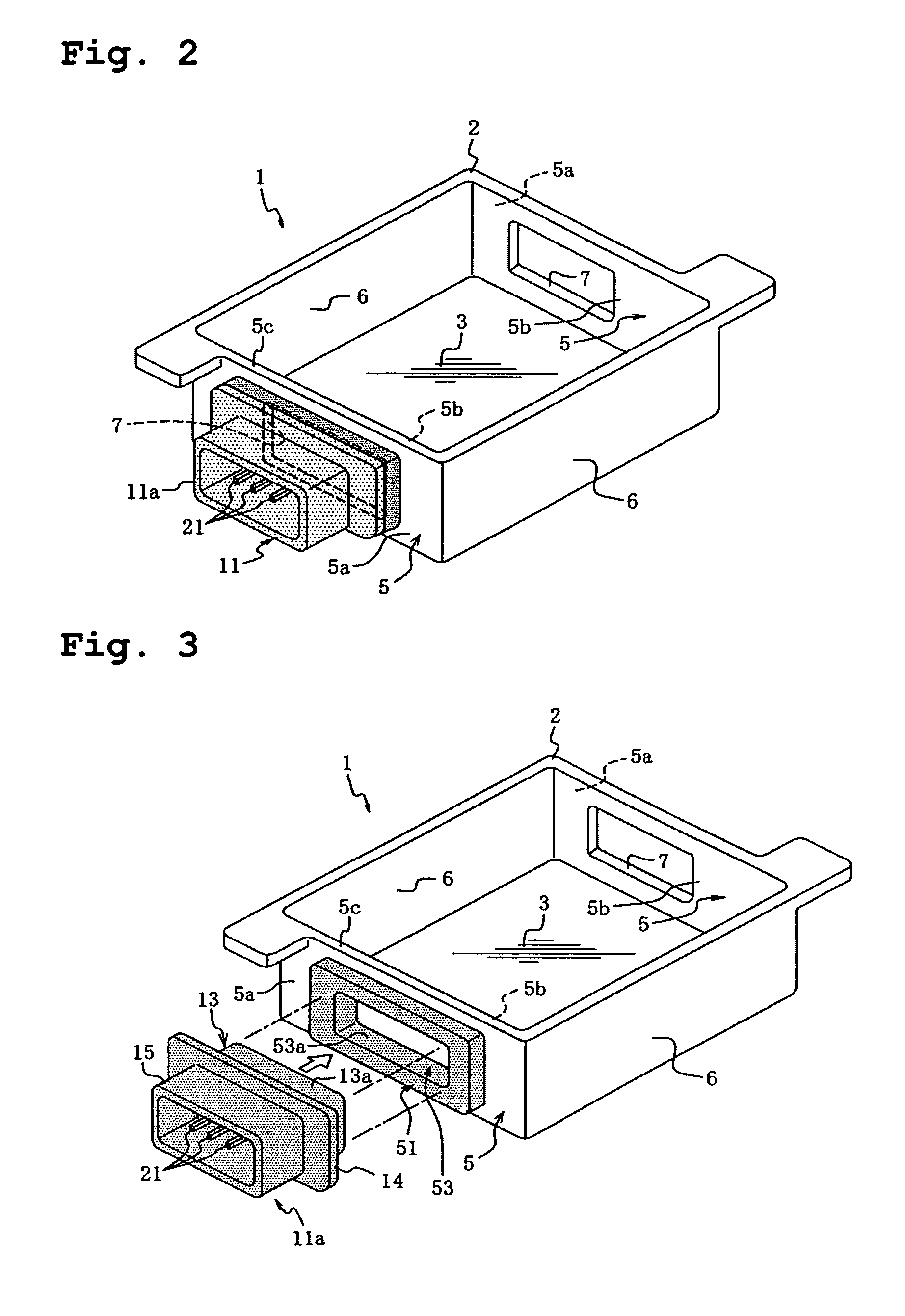

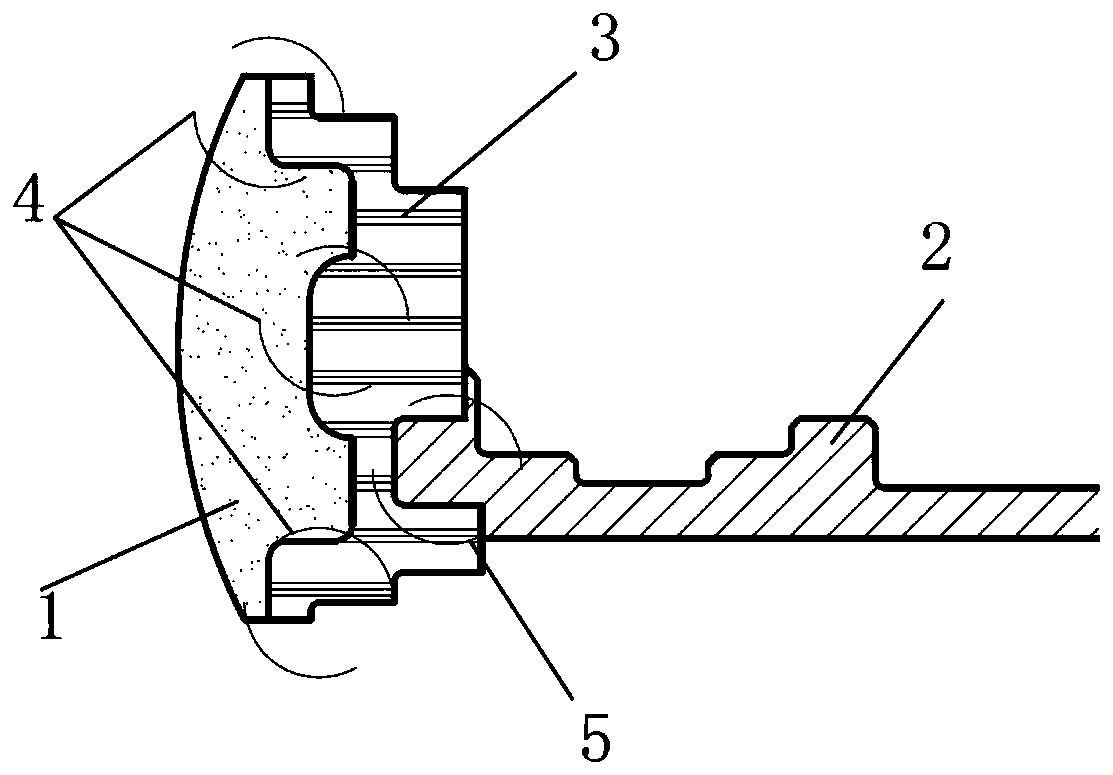

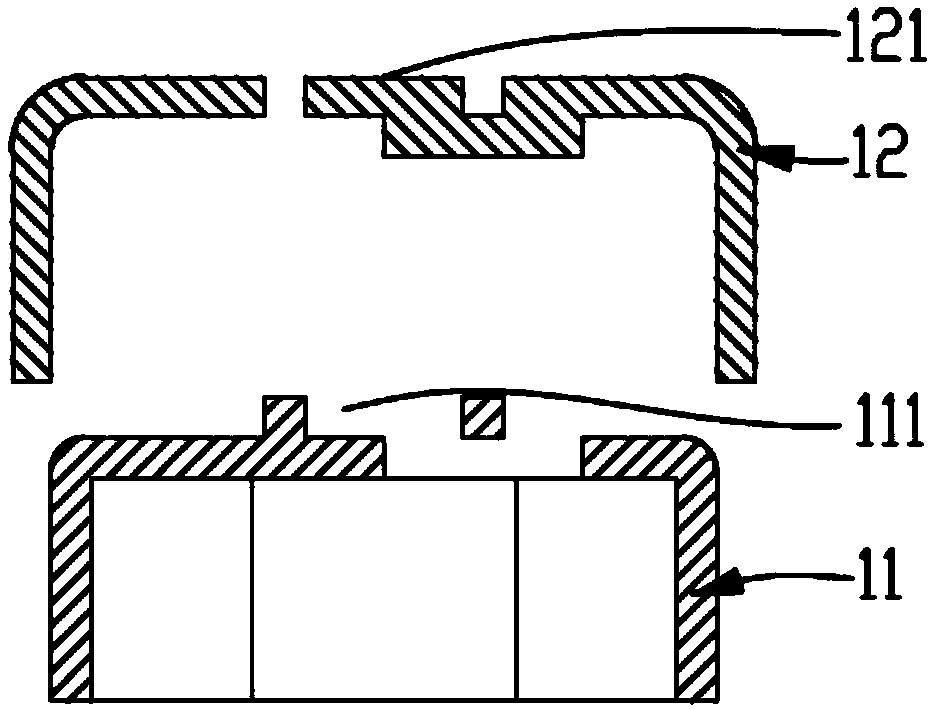

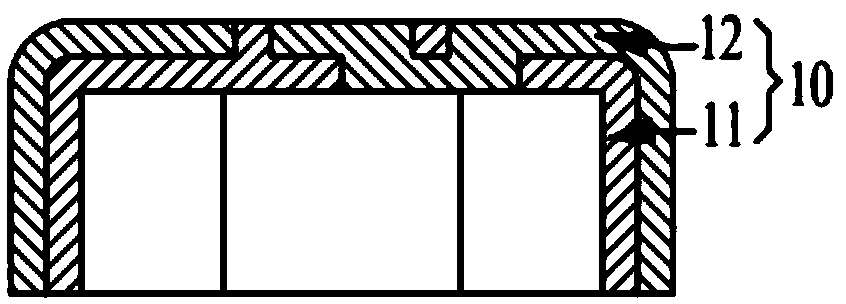

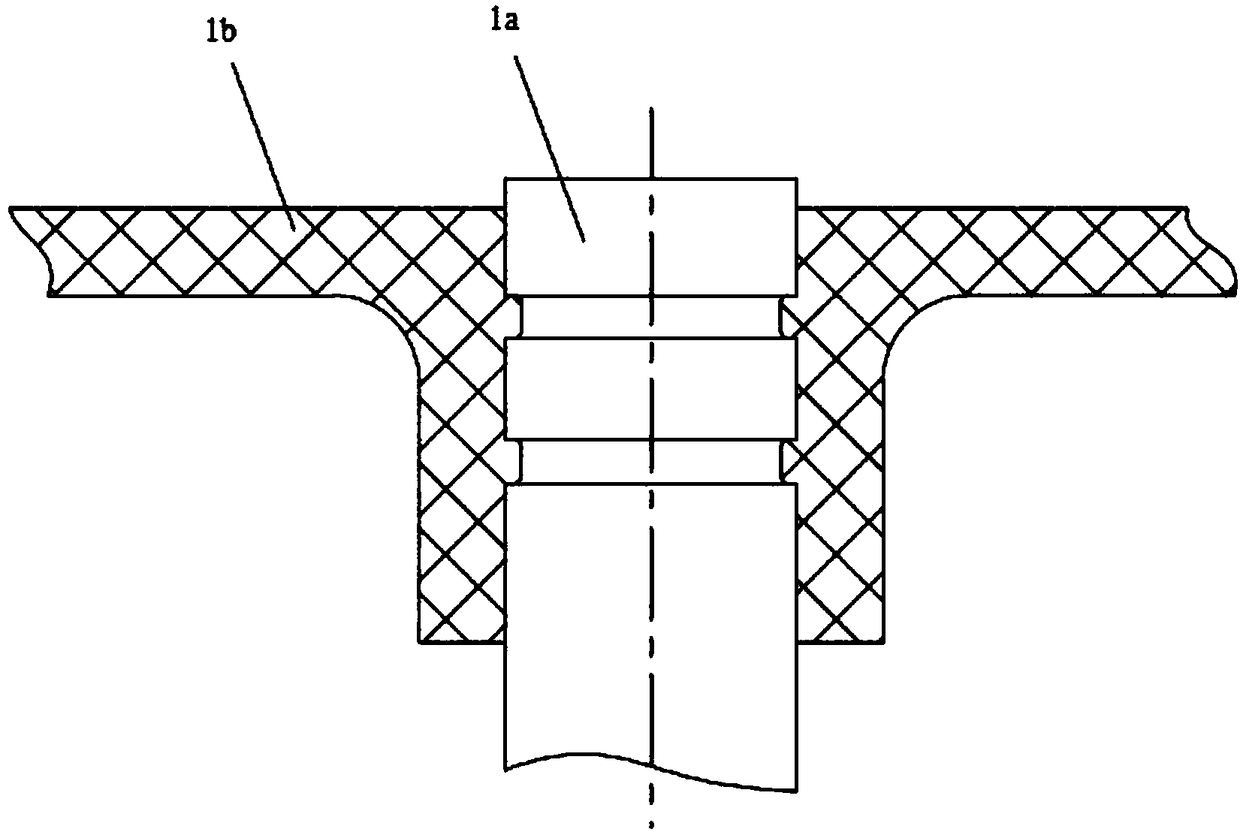

Metal-resin compound member

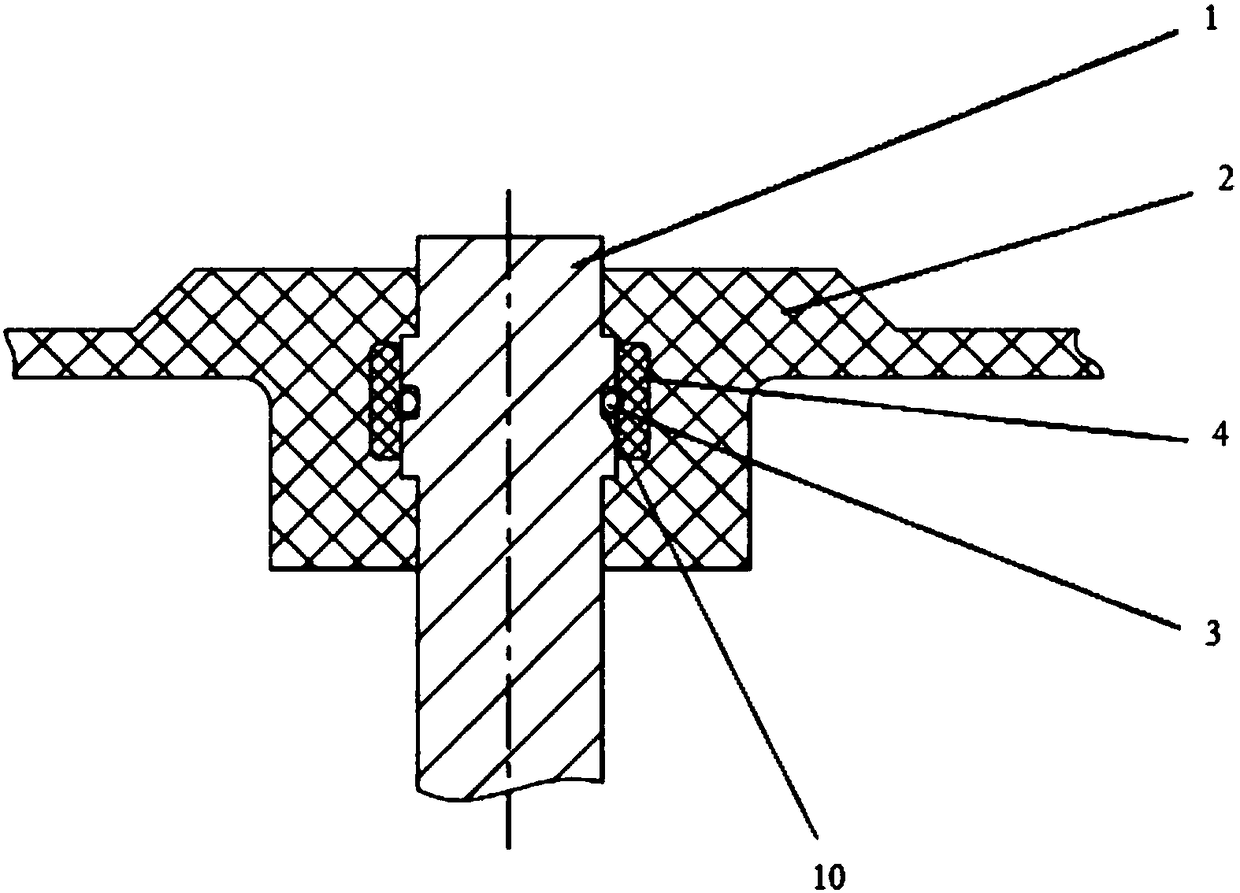

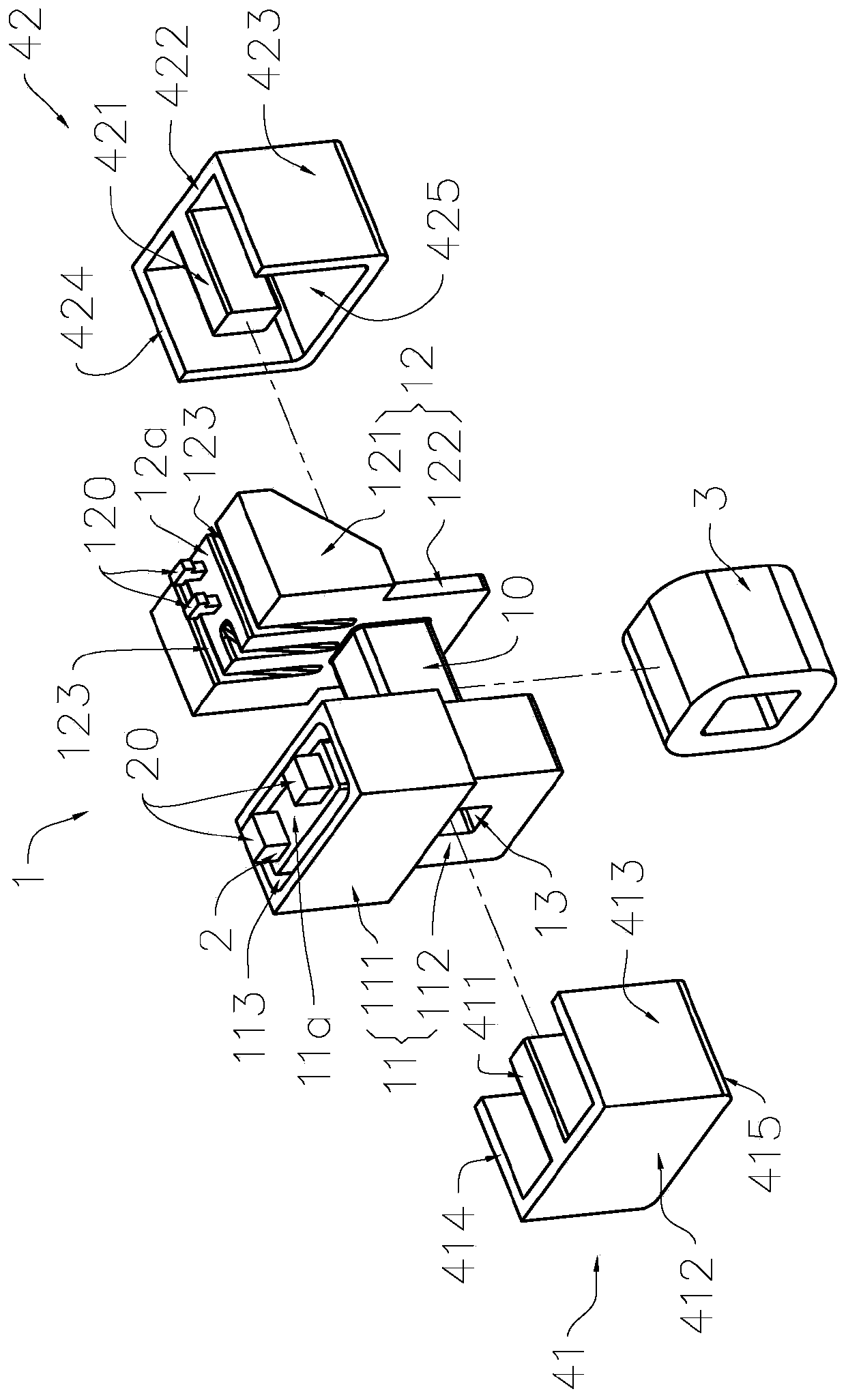

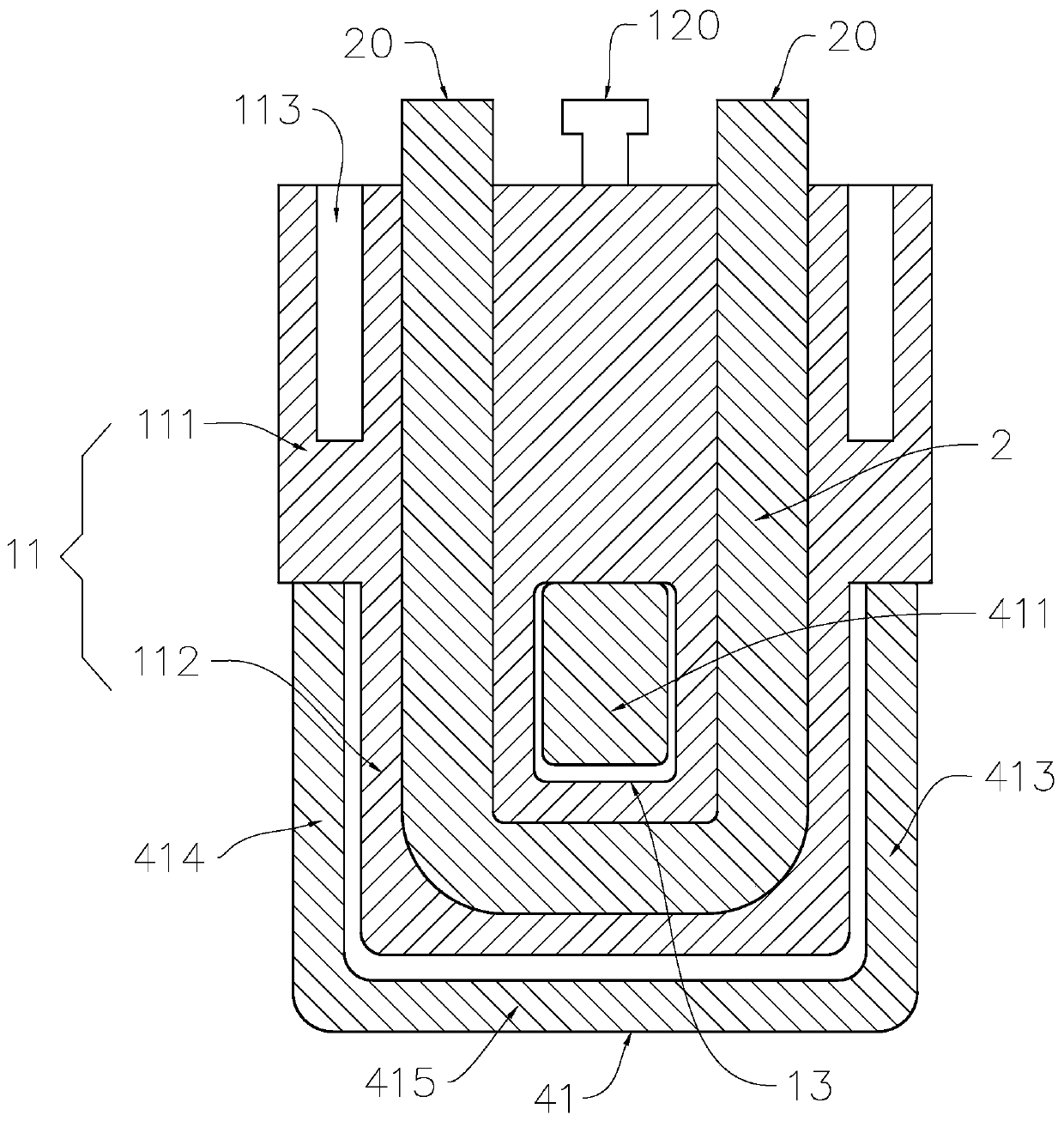

ActiveUS20100255732A1Improve joint strengthImprove reliabilityLine/current collector detailsSecuring/insulating coupling contact membersEngineeringMechanical engineering

A case comprised of a metal-resin composite body having a connector including a terminal fitting, the connector being integrated with an opening of a wall of a case main body so that the connector sandwiches an edge of the wall.

Owner:NGK SPARK PLUG CO LTD

Metal-resin compound member

ActiveUS8357015B2Less complicated shape and configurationComplicated shape and configurationLine/current collector detailsSecuring/insulating coupling contact membersEngineeringMechanical engineering

A case comprised of a metal-resin composite body having a connector including a terminal fitting, the connector being integrated with an opening of a wall of a case main body so that the connector sandwiches an edge of the wall. The connector is comprised of a base resin formed by injection molding so as to sandwich the wall. A separately-manufactured connector is welded to the base resin. Forming the base resin on the case main body provides a less complicated configuration of the case compared to a case where a connector is formed directly to the case main body.

Owner:NGK SPARK PLUG CO LTD

Photo-setting adhesive for press key bonding injection moulding

InactiveCN101475779APracticalNo solvent requiredNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceAdhesive

The invention discloses a photocuring adhesive for key-press splicing and injection molding. The photocuring adhesive comprises the following compositions in percentage by weight: 30 to 80 percent of organosilicon acrylate, 5 to 30 percent of acrylate oligomer, 2 to 30 percent of acrylate monomer, 0.1 to 10 percent of light evocating agent, 0.1 to 10 percent of aerosil, 0.1 to 10 percent of coupling agent and 0.1 to 5 percent of additive. The invention also discloses a method for preparing the photocuring adhesive for key-press splicing and injection molding, application of the adhesive to a key-press part and a simple injection molding process. The photocuring adhesive has good splicing property, elasticity, solvent resistance, and excellent electrical performance and weather resistance; and a product has good maneuverability such as levelling, defoaming, easy demoulding, and the like in injection molding.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

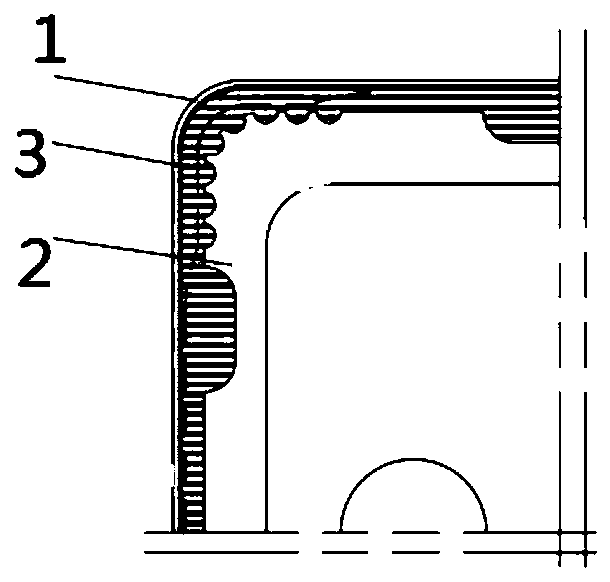

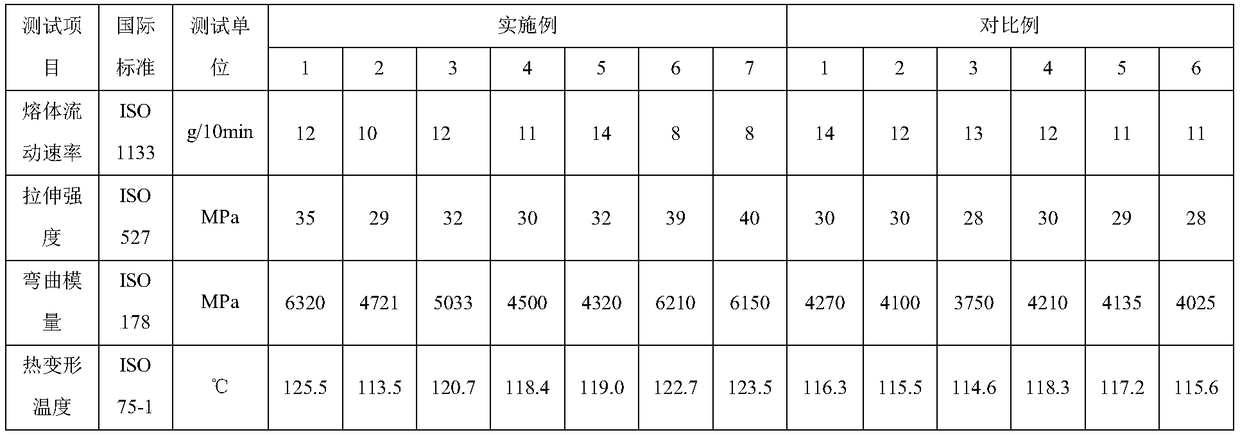

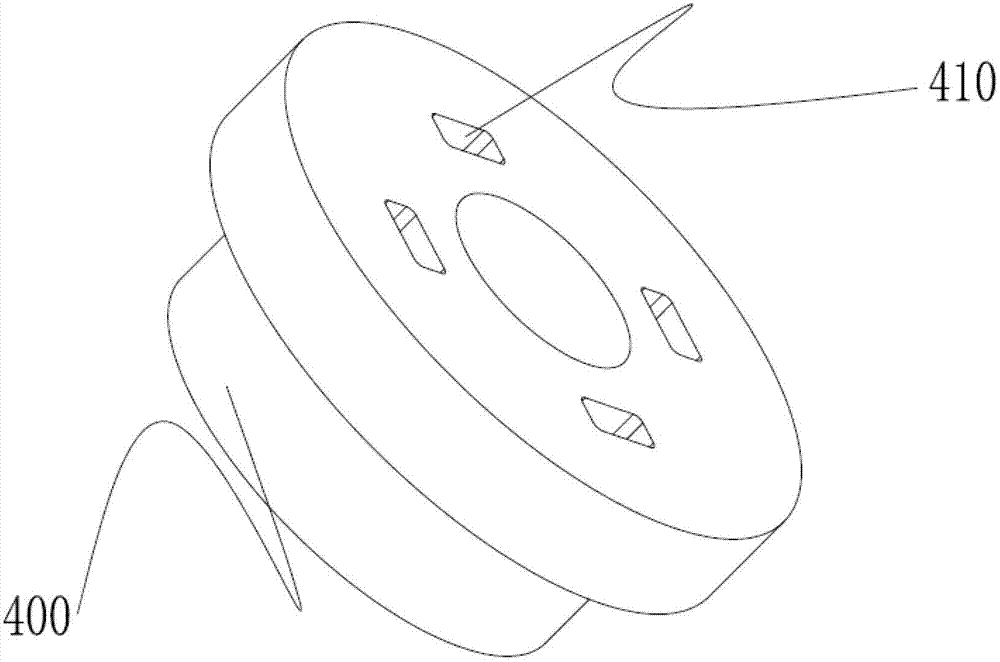

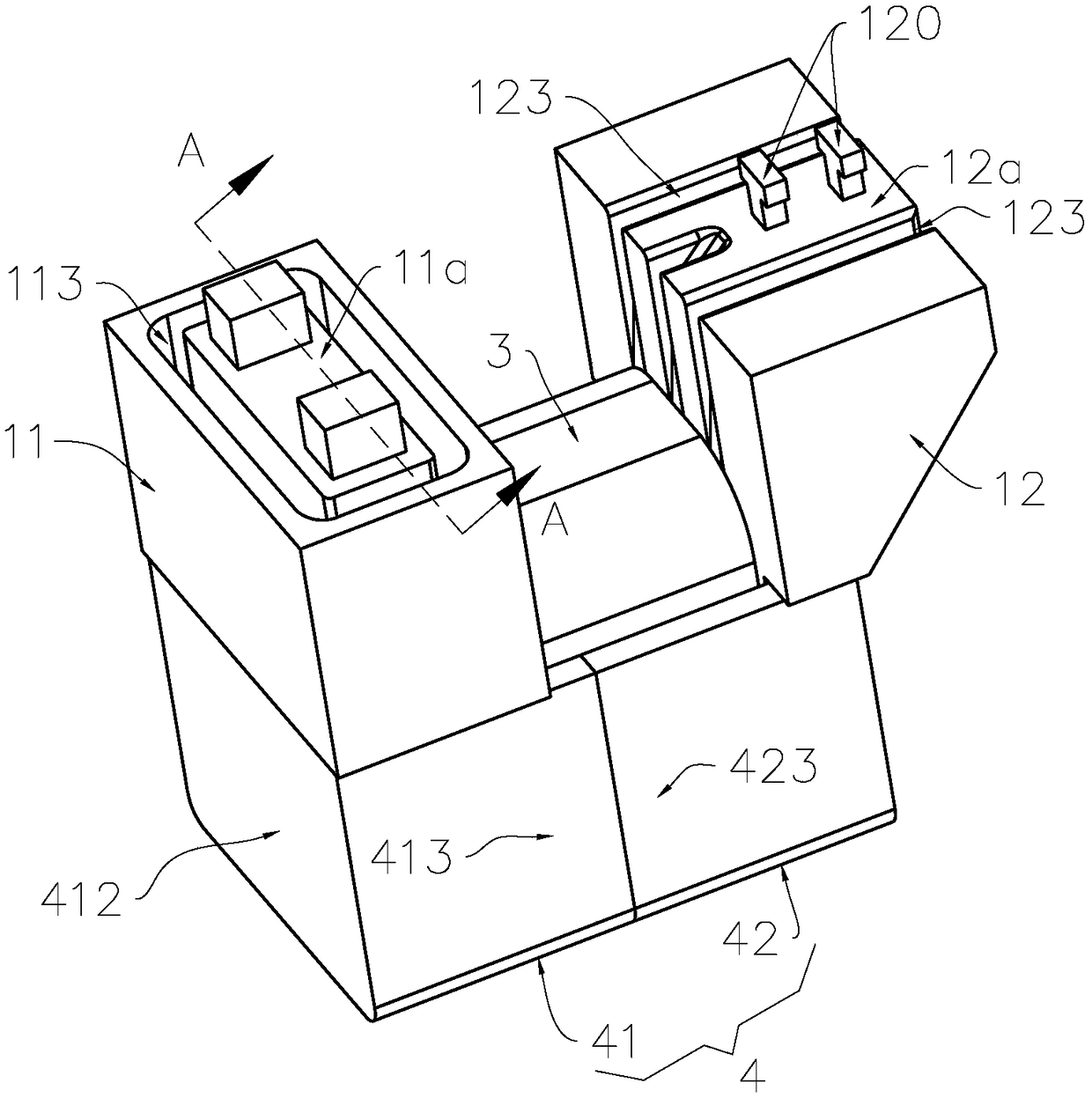

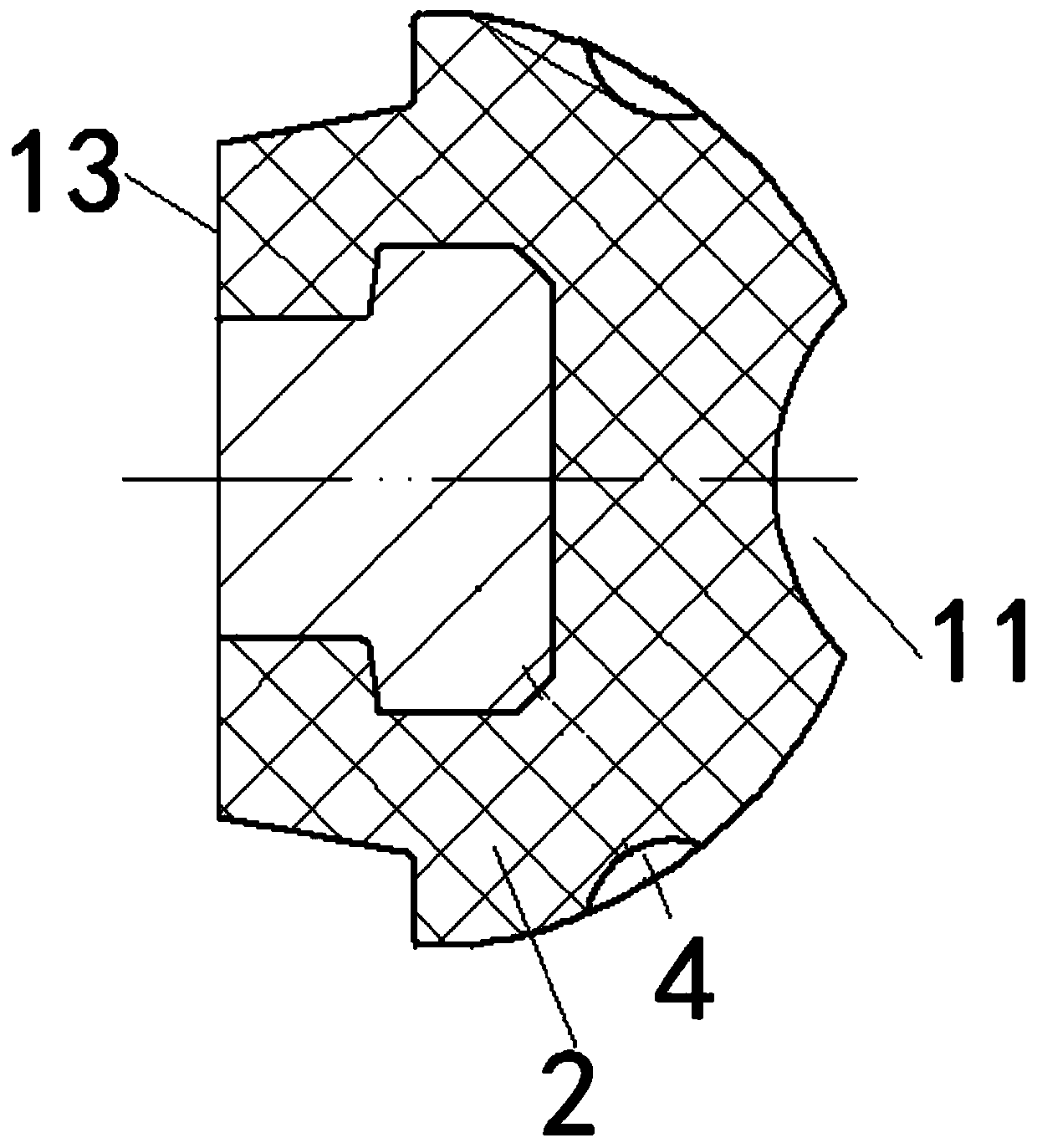

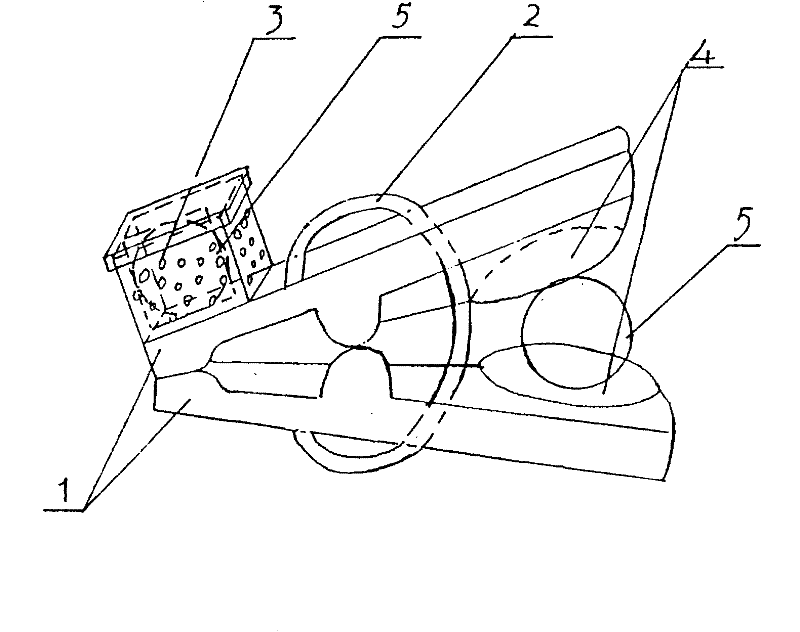

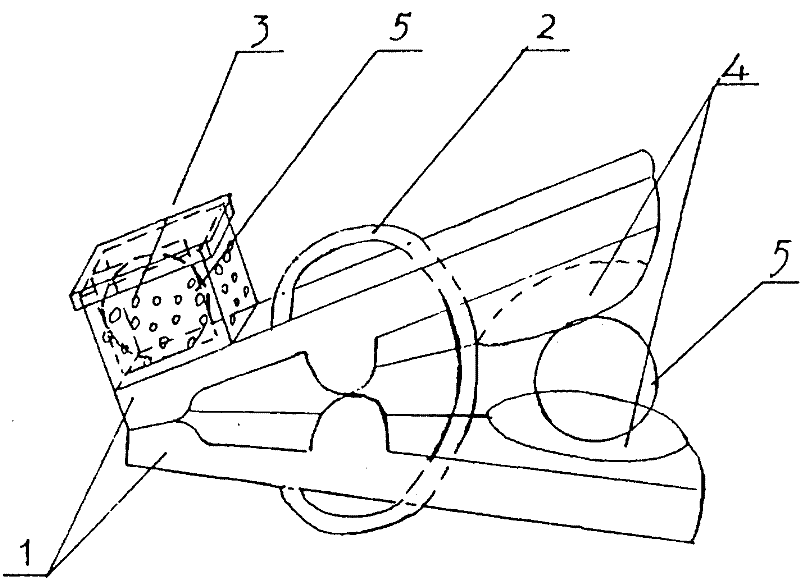

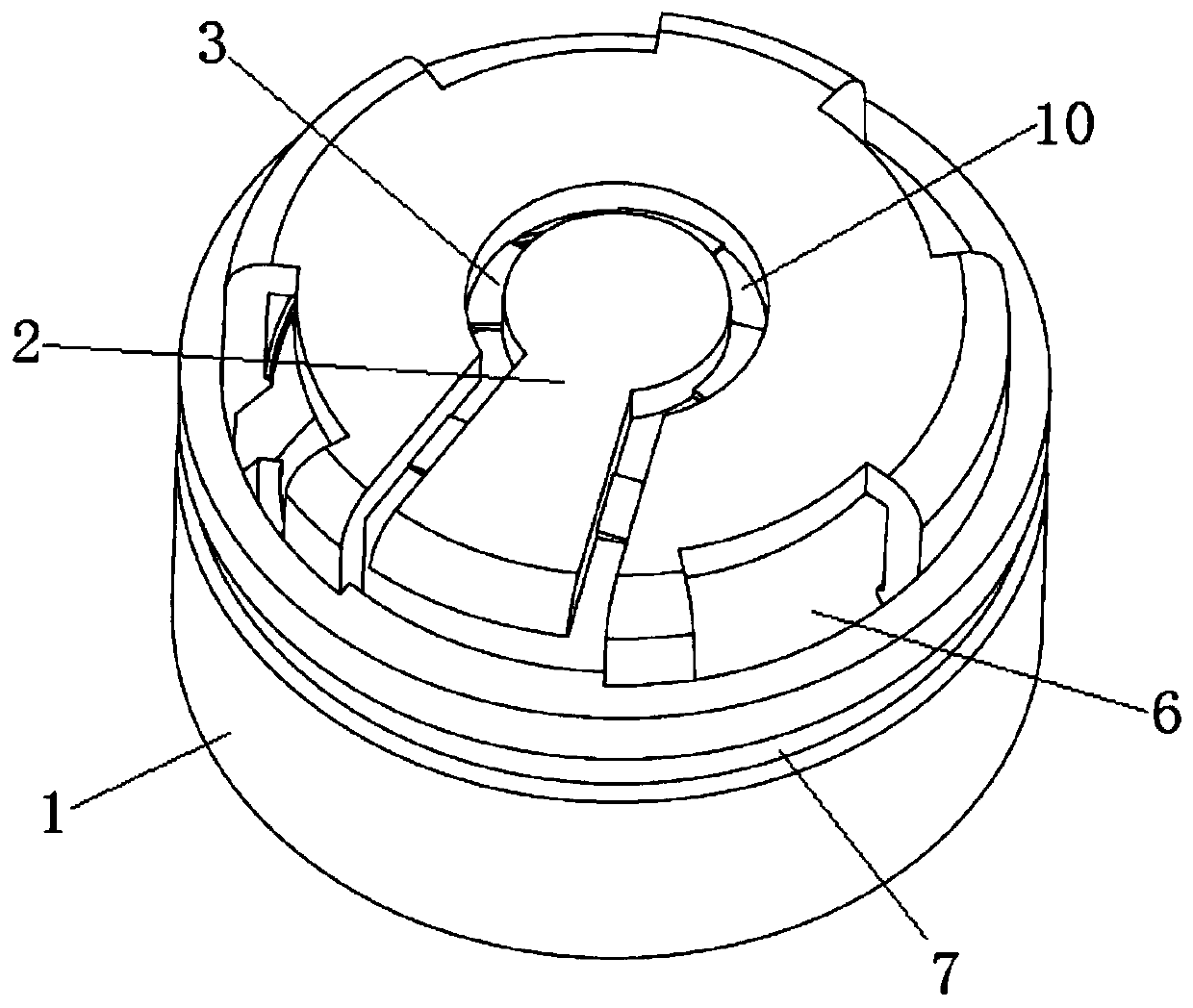

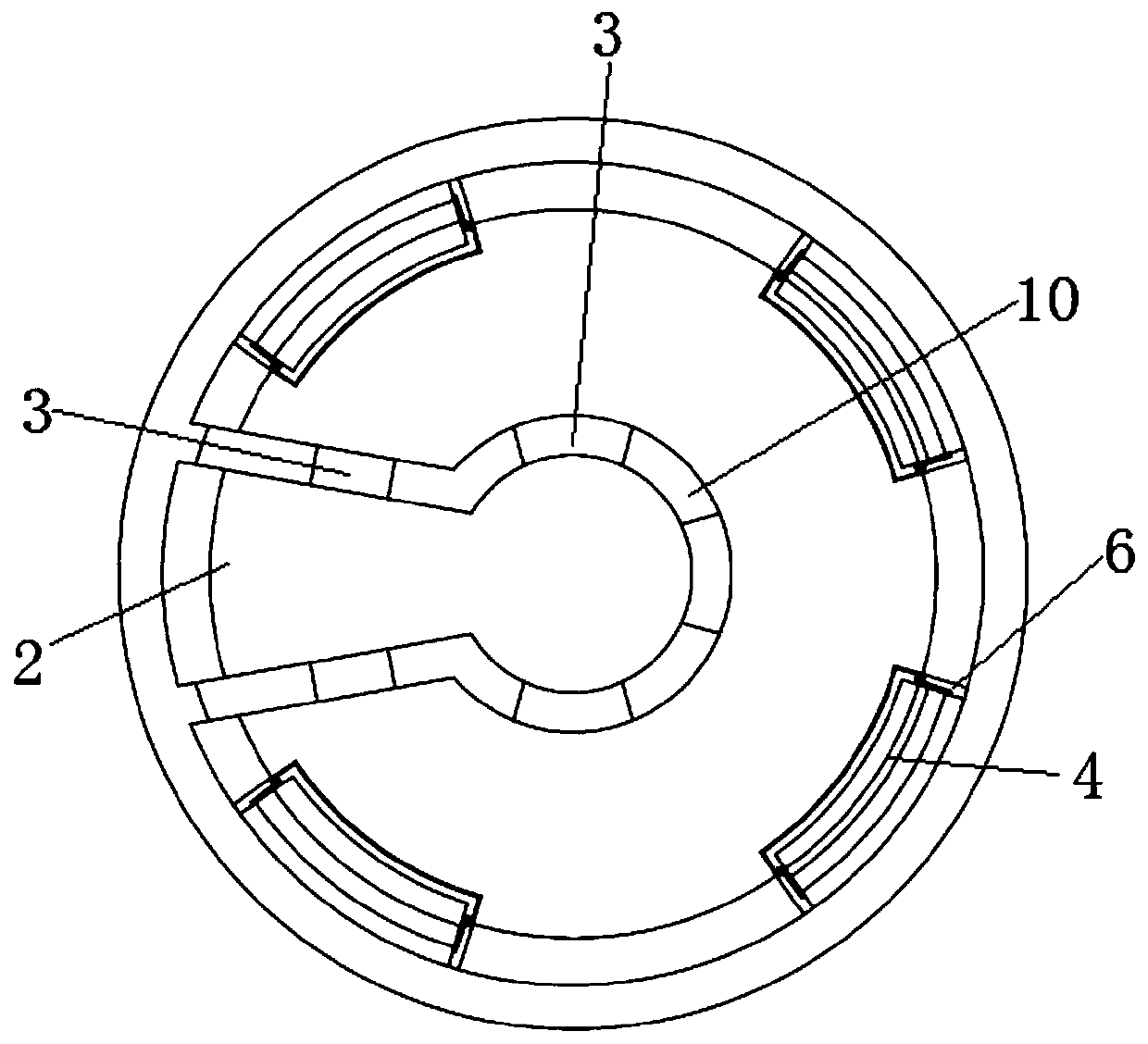

Combined motor stator component and sleeve used for wet operation pump and assembly method thereof

InactiveCN102723793AReduce wall thicknessReduce air gapMagnetic circuit rotating partsMagnetic circuit stationary partsStator coilEngineering

The invention relates to a combined motor stator component and sleeve used for a wet operation pump. The combined motor stator component and sleeve comprises a stator component and a sleeve, wherein the stator component comprises a stator iron core, a stator coil and a pole piece; a plurality stator teeth distributed at intervals extend integrally from the periphery of the stator iron core, one end of the pole piece is connected with the stator teeth in a matching way, the sleeve is integrally injected on the other end of the pole piece, and one or more positioning parts is / are arranged on the end face or the side face of a non-injection sleeve of the pole piece. The invention further relates to an assembly method of the combined motor stator component and sleeve, wherein the pole piece is placed and located in an injection mold, the sleeve is obtained by injection on the pole piece, then the other end of the pole piece is connected in a matching way with the stator teeth to obtain the combined motor stator component and sleeve for the wet operation pump. According to the invention, the pole piece is stably positioned in the injection mold to guarantee the injection molding effect of the sleeve.

Owner:CHANGZHOU XINYA ELECTROMOTOR

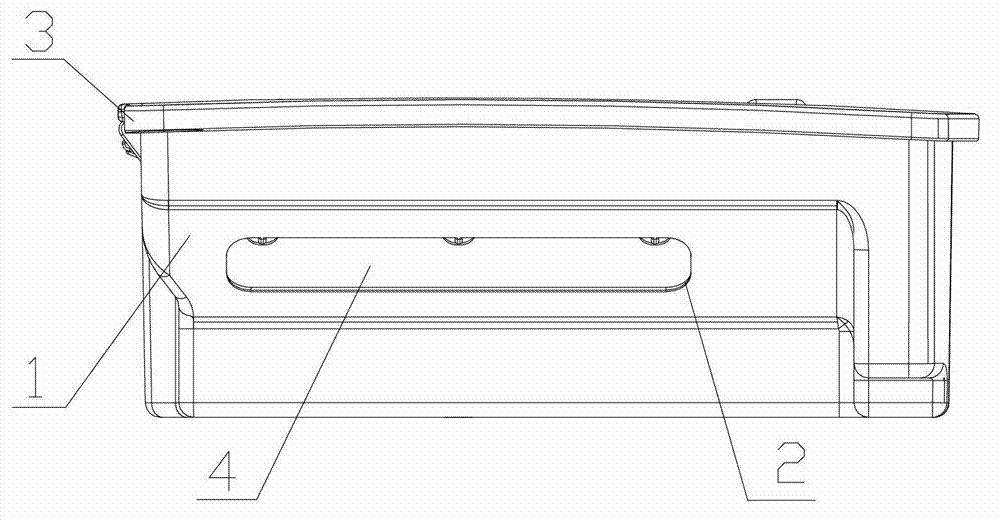

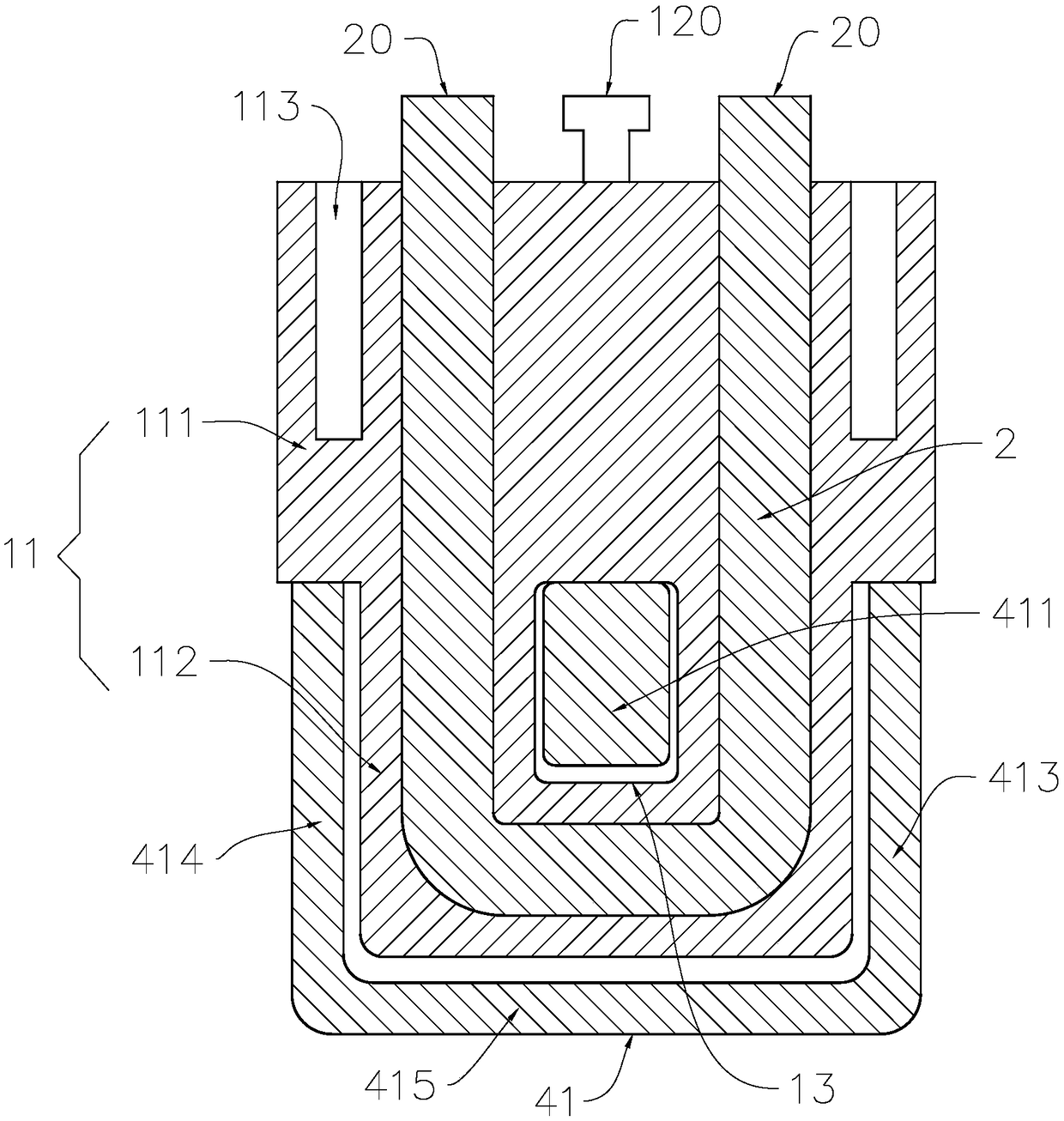

Intelligent dust collector and dust collection box thereof

InactiveCN103584800AImprove airtightnessExtended service lifeSuction filtersEngineeringDust collector

The invention discloses a dust collection box of an intelligent dust collector. The dust collection box comprises a box body and a box cover. The box body is provided with an upper opening, an air inlet and an air outlet are arranged on opposite side walls of the box body correspondingly, and a damper capable of being opened in one way is arranged at the air inlet. One end of the box cover is hinged to one end of the upper opening of the box body, the box cover caps the upper opening of the box body completely, grooves corresponding to the upper opening are formed at four edges of the box cover, and sealing parts are arranged in the grooves. The parts of the dust collection box are manufactured by a simple plastic injection process, the dust collection box is convenient to assemble and dissemble, and defective rate during production is reduced. Besides, as the whole dust collection box is designed with no fastening screws or disposable barb structures and can be assembled and dissembled repeatedly, the service life of the dust collection box is prolonged. In addition, the volume fraction of the dust collection box is increased as dust is compressed repeatedly. The invention further provides the intelligent dust collector comprising the dust collection box.

Owner:NANJING LG PANDA APPLIANCES

Ceramic composite middle frame of mobile terminal and preparation method thereof

ActiveCN110324467ANo damageFirmly connectedTelephone set constructionsAntenna designCeramic composite

The invention discloses a ceramic composite middle frame of a mobile terminal. The frame comprises a ceramic frame and a metal middle plate. The ceramic frame and the metal middle plate are connectedthrough a plastic framework. The metal middle plate and the ceramic frame are provided with lap joint structures. Meshing structures are arranged on the two sides of the plastic framework. A meshing structure on one side of the plastic framework is connected with the lap joint structure of the ceramic frame, and a meshing structure on the other side of the plastic framework is connected with the lap joint structure of the metal middle plate. The ceramic composite middle frame is formed by carrying out in-mold injection molding on a ceramic frame and a metal middle plate. The appearance surfaceof the middle frame has the texture that the ceramic is mild like jade and hard and wear-resistant. Local metallization can be achieved in the ceramic frame according to the antenna design requirement, natural design and layout are facilitated, and the overall middle frame is excellent in texture and effect. Meanwhile, the invention further discloses a preparation method of the ceramic compositemiddle frame for the mobile terminal.

Owner:CHAOZHOU THREE CIRCLE GRP

Structure of double colored plastic injection molding machine and process modification thereof

InactiveCN102658622ASimple injection molding processFlexible conversionPlastic injection moldingEngineering

The invention relates to a structure of a double colored plastic injection molding machine and process modification thereof. The structure comprises a die combining mechanism, injection devices and a die specially arranged for the die combining mechanism and the injection devices. The number of the injection devices is two, and one injection device has the same installing positions as a common injection machine and is installed on one side of the injection molding machine. The structure of the double colored plastic injection molding machine and process modification of the structure are characterized in that the other injection device is installed on the injection molding machine, after one injection device finishes injection of plastic slurry of one color, a controller gives commands, a die cavity is changed according to requirements, space is spared in a die, the other injection device starts injection of plastic slurry of another color, and a purpose of double colored plastic injection molding is achieved. The structure of the double colored plastic injection molding machine and the process modification of the structure have the advantages of omitting a rotating disc device and matched driving mechanism, locating mechanism and locking mechanism and reducing manufacture cost of the plastic injection molding machine. During plastic injection molding, rotating procedures are omitted, plastic injection molding time is saved, precision requirements on the die is reduced, production efficiency is greatly improved, and electrical energy consumption is reduced.

Owner:宁波赫仕机械制造有限公司

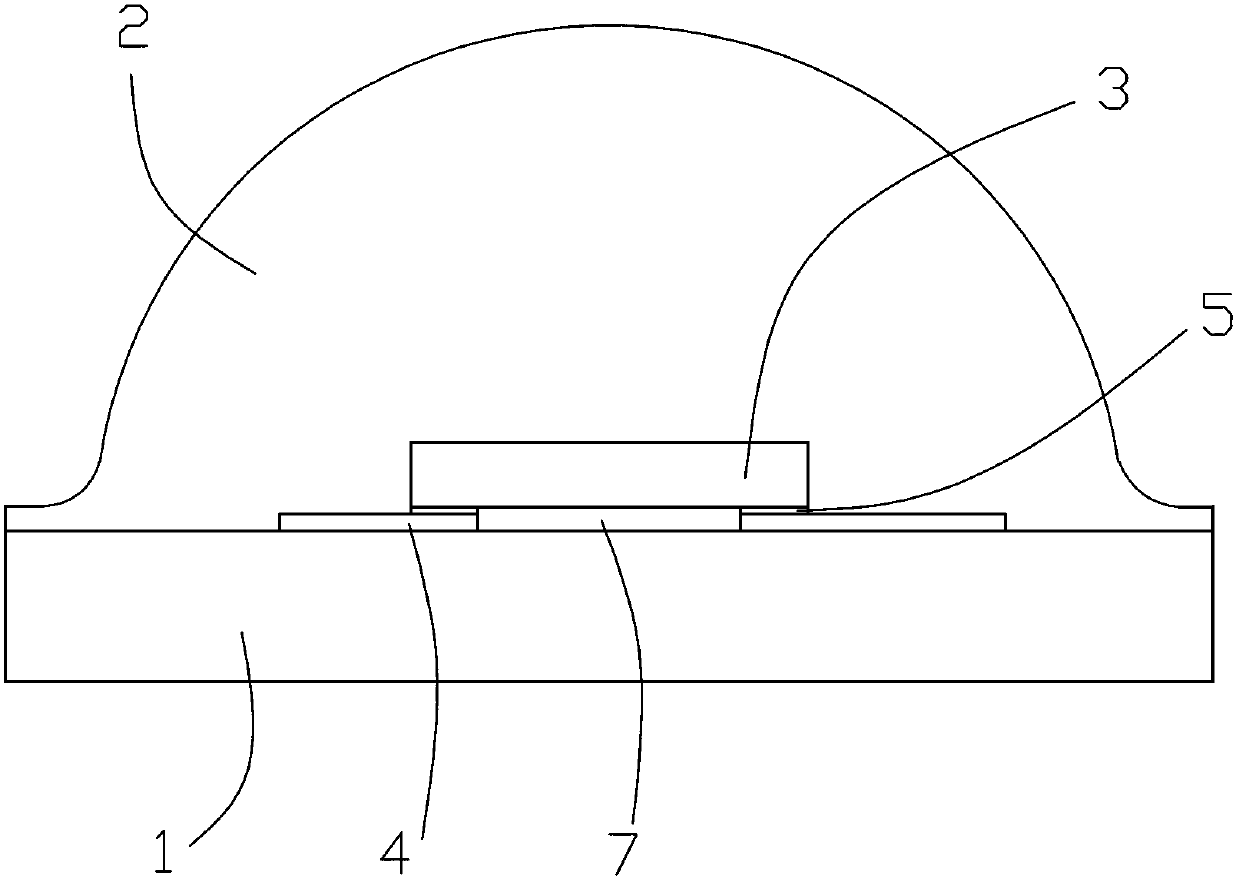

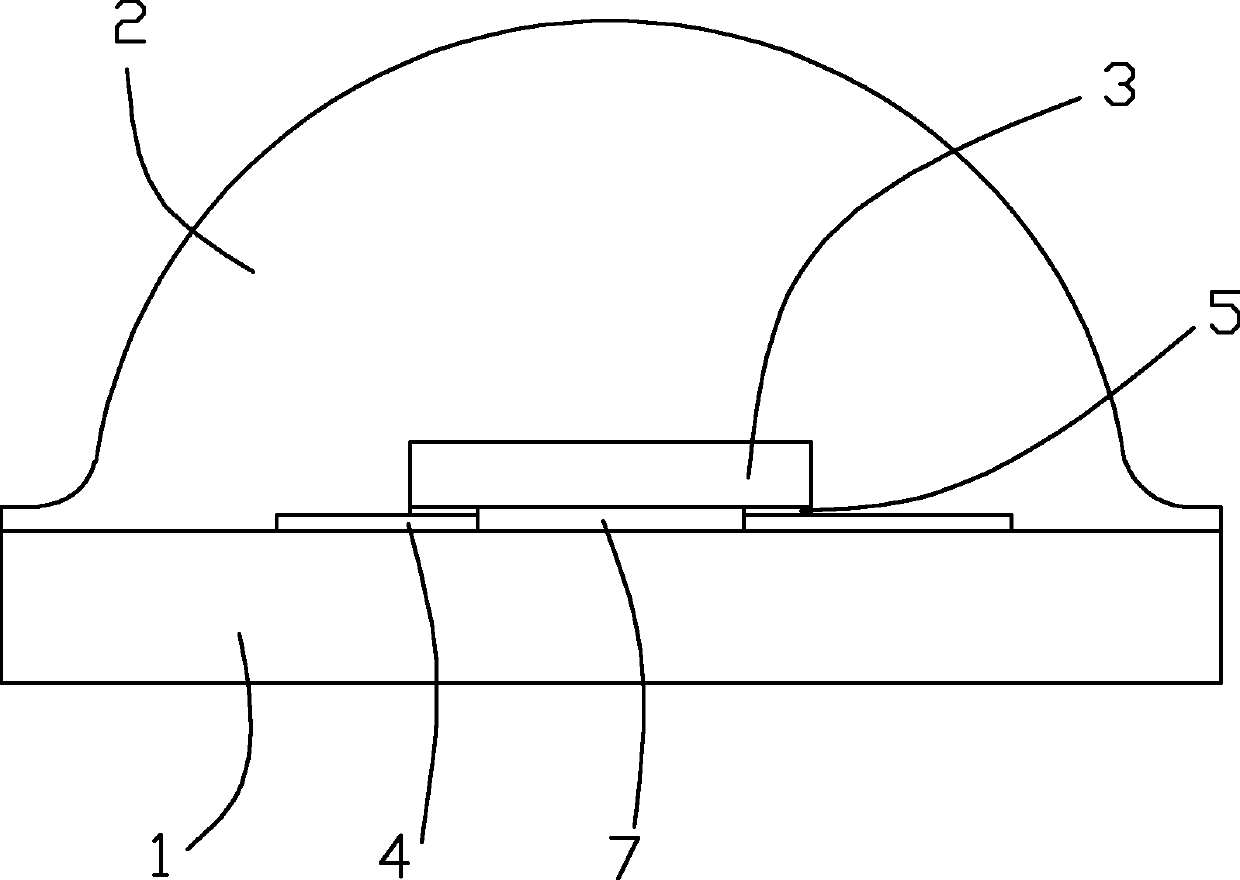

Wireless packaging structure of high-power ceramic LED (Light-emitting Diode)

InactiveCN102709438AImprove reliabilityReduce wire bonding processSolid-state devicesSemiconductor devicesState of artEngineering

The invention relates to a wireless packaging structure of a high-power ceramic LED (Light-emitting Diode). The invention resolves the problems that in the prior art, the LED lamp adopts the bonding wire process, so that the process cost and the material cost are increased; and the bonding wire electrode is arranged above a luminous chip, so that the luminous efficiency of the light-emitting chip is reduced. The LED comprises a base, two eutectic electrode bonding wire pads, the luminous chip, and a lampshade jet-molded on the base; an anode end and a cathode end are led from the two sides of the bottom of the luminous chip respectively; the luminous chip is arranged at the two eutectic electrode bonding pads; the anode end is connected with one eutectic electrode bonding pad; and the cathode end is connected with the other eutectic electrode bonding pad. The invention has advantages as follows: as the wireless packaging technology is used, the bonding wire process is reduced, the complexity of the technological process is reduced, the dependability of the semi-finished product production is improved, and the cost is saved; and because the bonding wire is not arranged over the luminous chip, the luminous efficiency of the luminous chip is improved.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

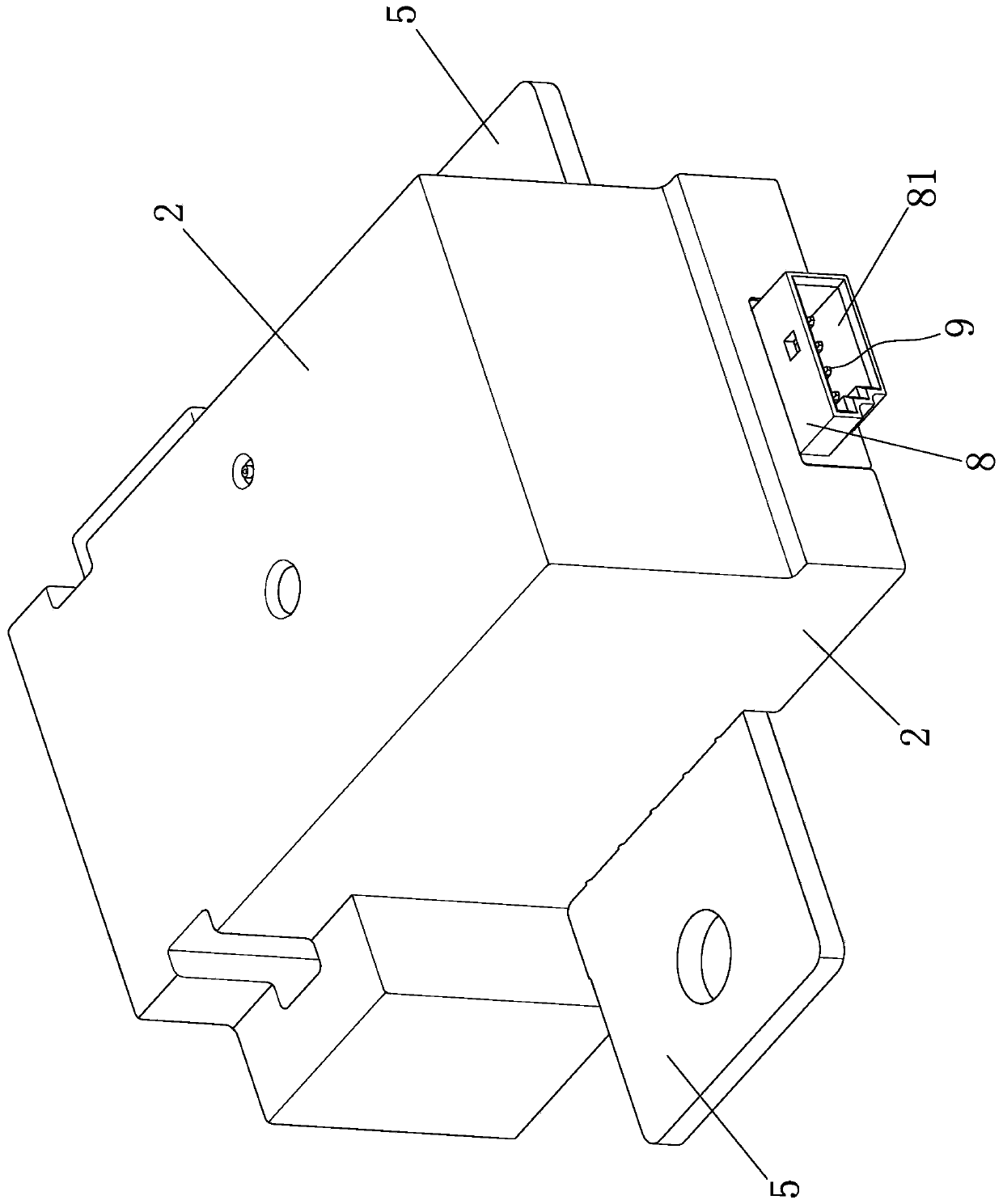

Electromagnetic relay

PendingCN110797233AImprove cooling effectImprove performanceElectromagnetic relay detailsStructural engineeringMechanical engineering

The invention discloses an electromagnetic relay, which comprises a base, a housing, a coil, a movable reed and two static reeds. The housing is fixedly connected with the base. The coil is located between the base and the housing. The movable reed is provided with a plurality of movable contacts. Each static reed comprises a plate-shaped base part, part of one side of each plate-shaped base partextends outwards and is bent to form a static contact fixing part, and a static contact is fixedly arranged on each static contact fixing part. The base is provided with avoiding through holes. The two static reeds are fixedly connected to the outer side face of the base at intervals through the plate-shaped base parts respectively, each static contact fixing part stretches into the position between the base and the housing through one avoiding through hole, and each static contact corresponds to one movable contact on the movable reed. The plate-shaped base part on each static reed partiallyextends out of the housing to form a connecting part. According to the invention, the heat dissipation effect of the static reed is well improved, the performance of the relay is improved, the preparation process is simplified, the preparation cost is reduced, and the service life of the relay is prolonged.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS CO LTD

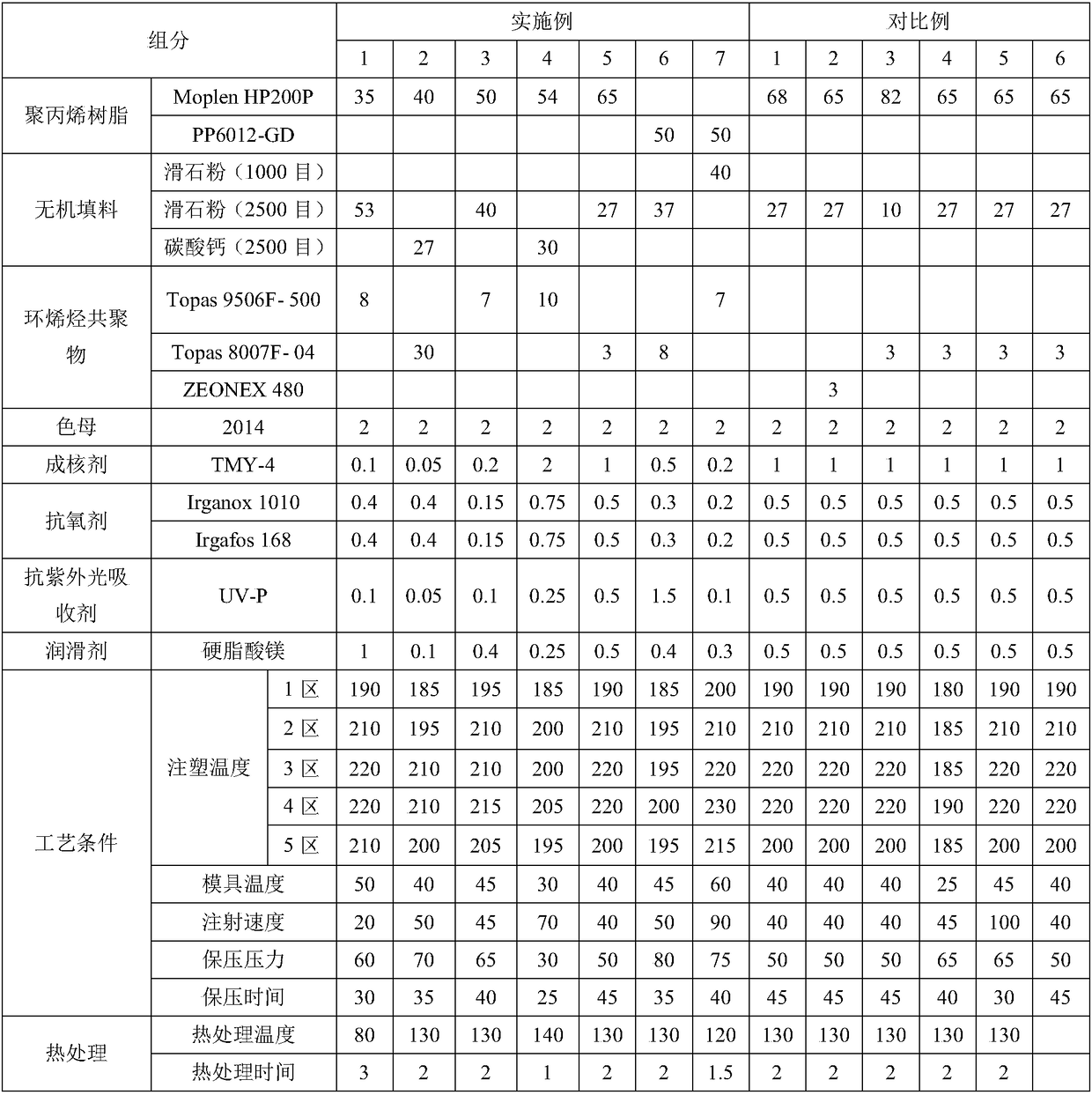

Polypropylene material with high rigidity and high heat resistance and preparation method thereof, as well as injection molding product and preparation method thereof

The invention discloses a polypropylene material with high rigidity and high heat resistance and a preparation method thereof, as well as an injection molding product and a preparation method thereof.The polypropylene material comprises polypropylene resin, an inorganic filler, a cycloolefin polymer, a color masterbatch, a nucleating agent, an antioxidant, an anti-ultraviolet light absorbent anda lubricant. The polypropylene material has the advantages of high powder filling, high crystallinity and low defect rate. The modulus, strength and heat-resistant temperature of an injection moldingfinished product can be improved by optimized design of a formula and matching with an appropriate injection molding process.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

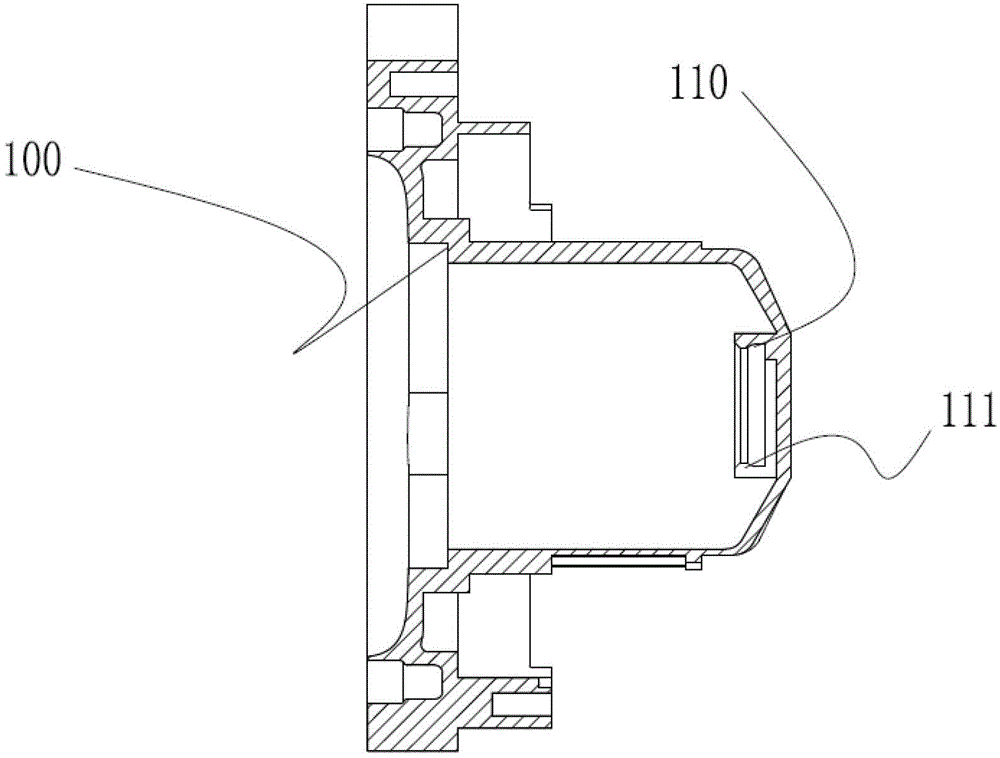

Motor bearing lubricating structure and motor for wet operating pump

ActiveCN102738962AReduce wall thicknessReduce air gapMagnetic circuit rotating partsMagnetic circuit stationary partsMechanical engineeringStator

The invention relates to a motor bearing lubricating structure for a wet operating pump. The motor for the wet operating pump comprises a sleeve, a stator component and a rotor component, wherein the sleeve is positioned between the stator component and the rotor component; a bearing is arranged between a rotating shaft of the rotor component and the bottom of the sleeve; and one or more fluid channels is / are formed on a bearing body. The invention also relates to a motor employing the bearing lubricating structure. The stator component is integrally and seamlessly connected with the sleeve through a pole shoe of the stator component; and a stator core of the stator component is connected with the pole shoe through a chase mortise structure in a matching mode. The fluid directly penetrates through the fluid channels and contacts and impacts the bearing, the problems that the bearing is dry in operation to generate high-degree wear and the temperature is raised are solved, and the service life of the motor bearing for the wet operating pump is greatly prolonged; and meanwhile, the motor for the wet operating pump is simple in structure, low in manufacturing cost and suitable for large-scale popularization and application in production.

Owner:CHANGZHOU XINYA ELECTROMOTOR

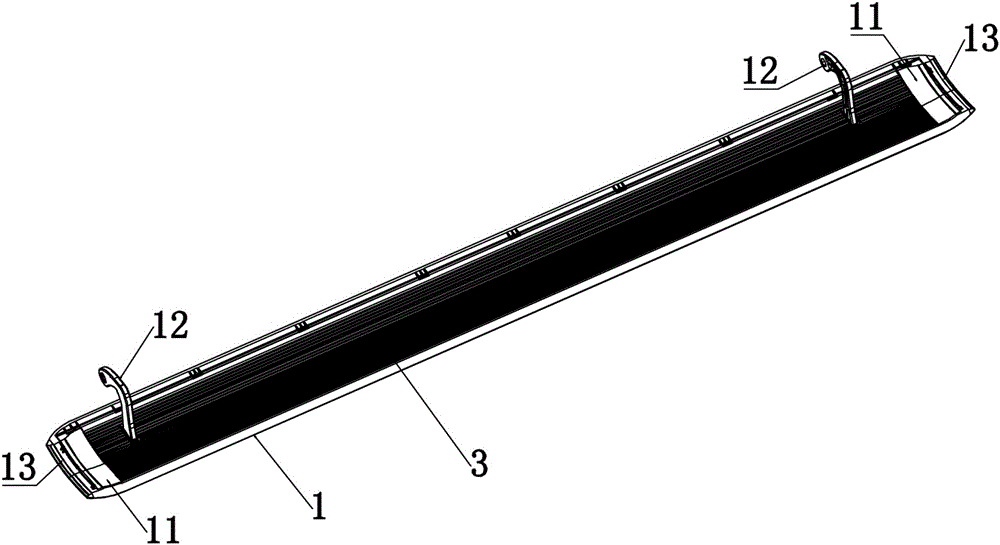

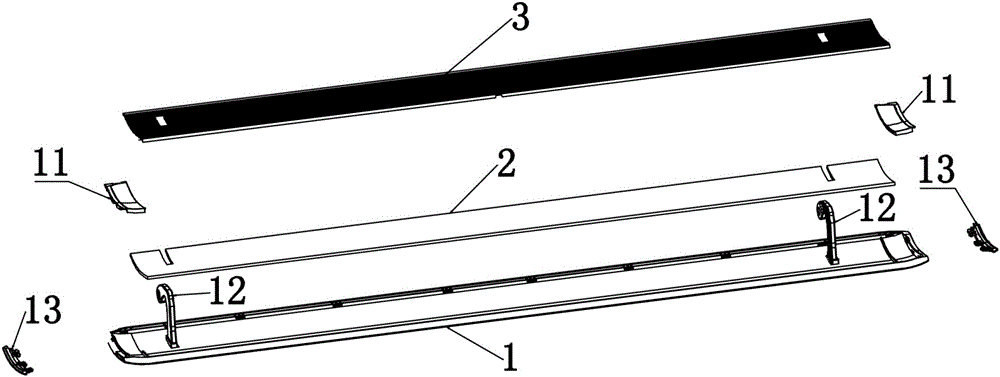

Completely-closed three-layer arc-shaped air guide plate structure of wall-mounted air conditioner

ActiveCN106524461AAvoid deformationHigh strengthCondensate preventionAir-flow control membersAlloyEngineering

The invention discloses a completely-closed three-layer arc-shaped air guide plate structure of a wall-mounted air conditioner. The completely-closed three-layer arc-shaped air guide plate structure comprises an air guide plate injection-molding part, a heat insulating part and an aluminum alloy sheet which are arc-shaped structures, wherein the aluminum alloy sheet covers the inner side surface of the air guide plate injection-molding part to prevent the air guide plate injection-molding part from being deformed; the heat insulating part is arranged on a sandwich layer between the air guide plate injection-molding part and the aluminum alloy sheet; the two sides of the air guide plate injection-molding part are separately connected with supporting end plates which are in transition with the arc surface of the aluminum alloy sheet;, so that structural strength of the curved-surface end of the air guide plate is strengthened; transmission curved bars are further arranged at the two sides of the air guide plate injection-molding part; the transmission curved bars are connected with a transmission device which drives the air guide plate to integrally retract to reduce a seam between the air guide plate and the air outlet main body. According to the completely-closed three-layer arc-shaped air guide plate structure disclosed by the invention, the aluminum alloy sheet is additionally arranged on the air guide plate injection-molding part to strengthen the integral strength of the air guide plate, so that the air guide plate is effectively prevented from being deformed; and meanwhile, the integral appearance effect of the air guide plate is improved, so that the air guide plate structure has dustproof action.

Owner:GUANGDONG CHIGO AIR CONDITIONING

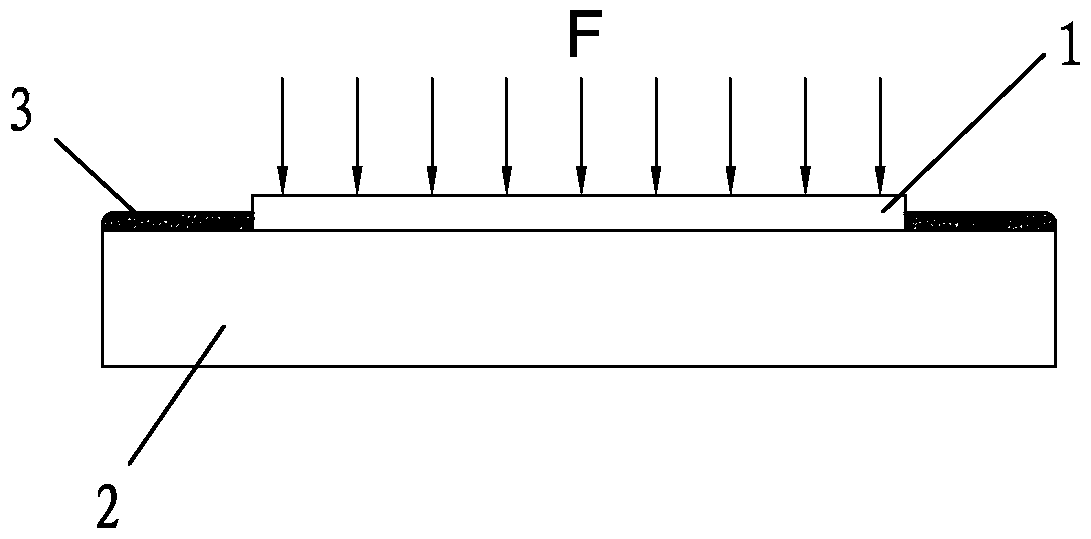

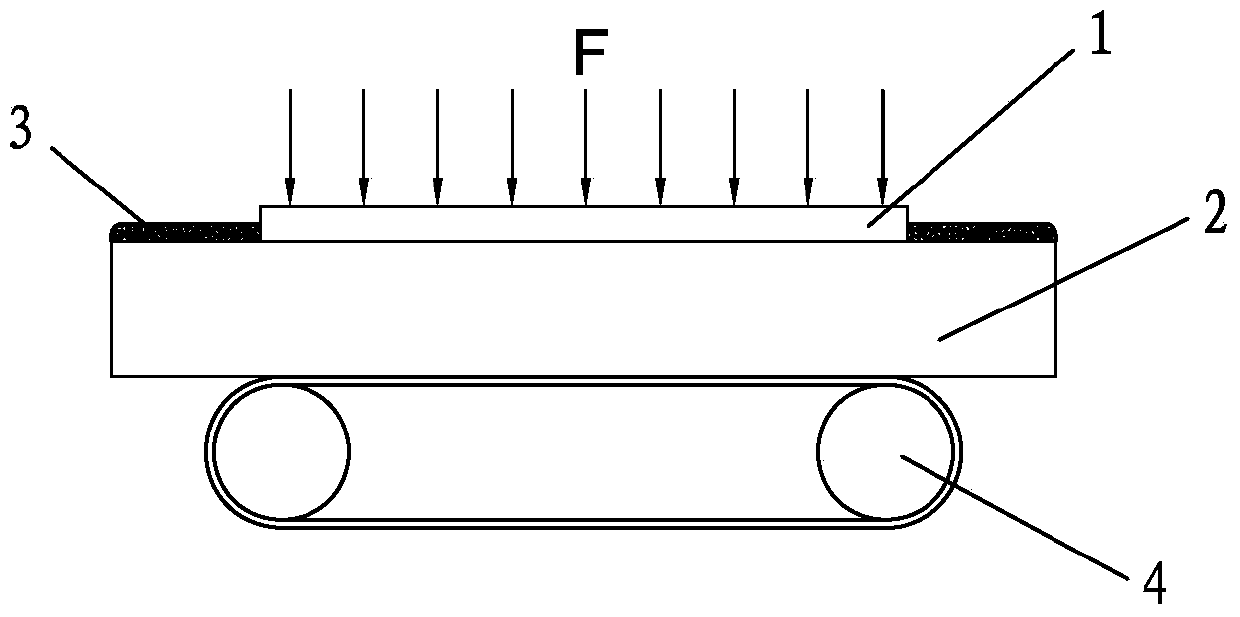

An Injection Molding Production Process for Reducing Warping of Plastic Flat Plates

The invention provides an injection molding production process capable of reducing the warping possibility of a plastic plate. The injection molding production process comprises following steps: 1. arranging a smooth platform, adding liquid to the surface of the smooth platform, and uniformly distributing the liquid on the surface of the smooth platform; 2. molding the plastic plate through the injection molding process; 3. arranging the demoulded plastic plate on the smooth platform; 4. applying force so as to enable the plastic plate to abrade the surface of the smooth platform distributed with liquid or enable the plastic plate to vibrate the smooth platform, carrying out vacuum adsorption on the plastic plate and the smooth platform through liquid, and retracting the applied force; 5. further cooling and shaping the plastic plate and the smooth platform subjected to vacuum adsorption; and 6. separating the cooled and shaped plastic plate from the smooth platform, and picking up the plastic plate. According to the injection molding process, the process flow is simple, the use range is wide, the plastic plate only needs to be flatly attached to the smooth platform distributed with liquid; due to the utilization of the vacuum adsorption force, the possibility of warping deformation of the plastic plate in the cooling and shaping process can be reduced, and on the basis of not modifying the original matched production device of injection molding production, the yield of the plastic plate is greatly increased, the injection molding production time is shortened, and the injection molding production process has market economic benefits.

Owner:莆田市多容光学电子有限公司

Transformer and manufacturing method thereof

ActiveCN108987071AStable structureSafe and reliable structureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinTransformer

A transformer provided by the invention comprises a skeleton, a primary winding, a secondary winding and a magnetic core. Wherein the skeleton is integrally formed with the primary coil, the skeletoncomprises a bobbin, and first bosses and second bosses respectively arranged at both ends of the bobbin. The skeleton is provided with through holes penetrating the bobbin, the first boss and the second boss. The primary coil is a flat coil, and the primary coil is integrally embedded in the first boss. The secondary coil is wound around the bobbin and the pins of the secondary coil are arranged on the second boss. The magnetic core includes an insertion portion inserted into the through hole and an outer portion disposed on the outer side of the skeleton. The invention also provides a manufacturing method of a transformer, comprising the following steps: opening a mold, molding the transformer skeleton by injection molding through a mold, placing a primary coil into a mold while molding the skeleton, and integrally molding the primary coil and the skeleton; installing the secondary coil and wind the secondary coil onto the skeleton; installing the core and mounting the core to the skeleton.

Owner:SUINING PUSI ELECTRONICS

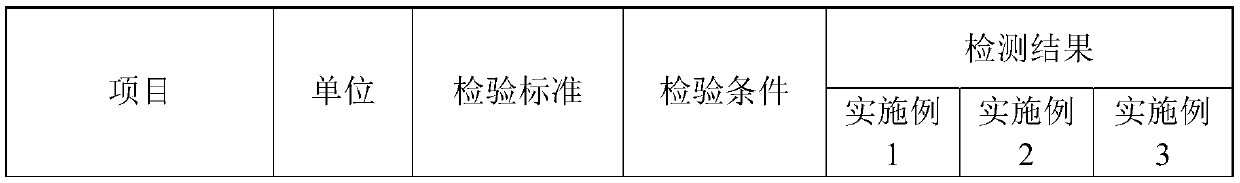

High-strength injection molding material formula

A high-strength injection molding material formula comprises materials in percentage by weight as follows: 32%-34% of nylon-66, 59%-61% of short glass fiber, 1%-4% of a toughening agent, 0.5%-1% of anantioxidant, 0.5%-1% of a flowable agent and 0.5%-1% of a plasticizer. A small household appliance injection molded part formed by injection molding with the formula has strength and hardness close to metal parts and has the advantages of being low in cost, light in mass, not prone to rusting, convenient to mold, insulating and the like. Meanwhile, the injection molding process is simple, and undesirable phenomena of flower floating, color mixing, fiber floating and the like cannot occur on workpiece surfaces.

Owner:江门市亿高电器有限公司

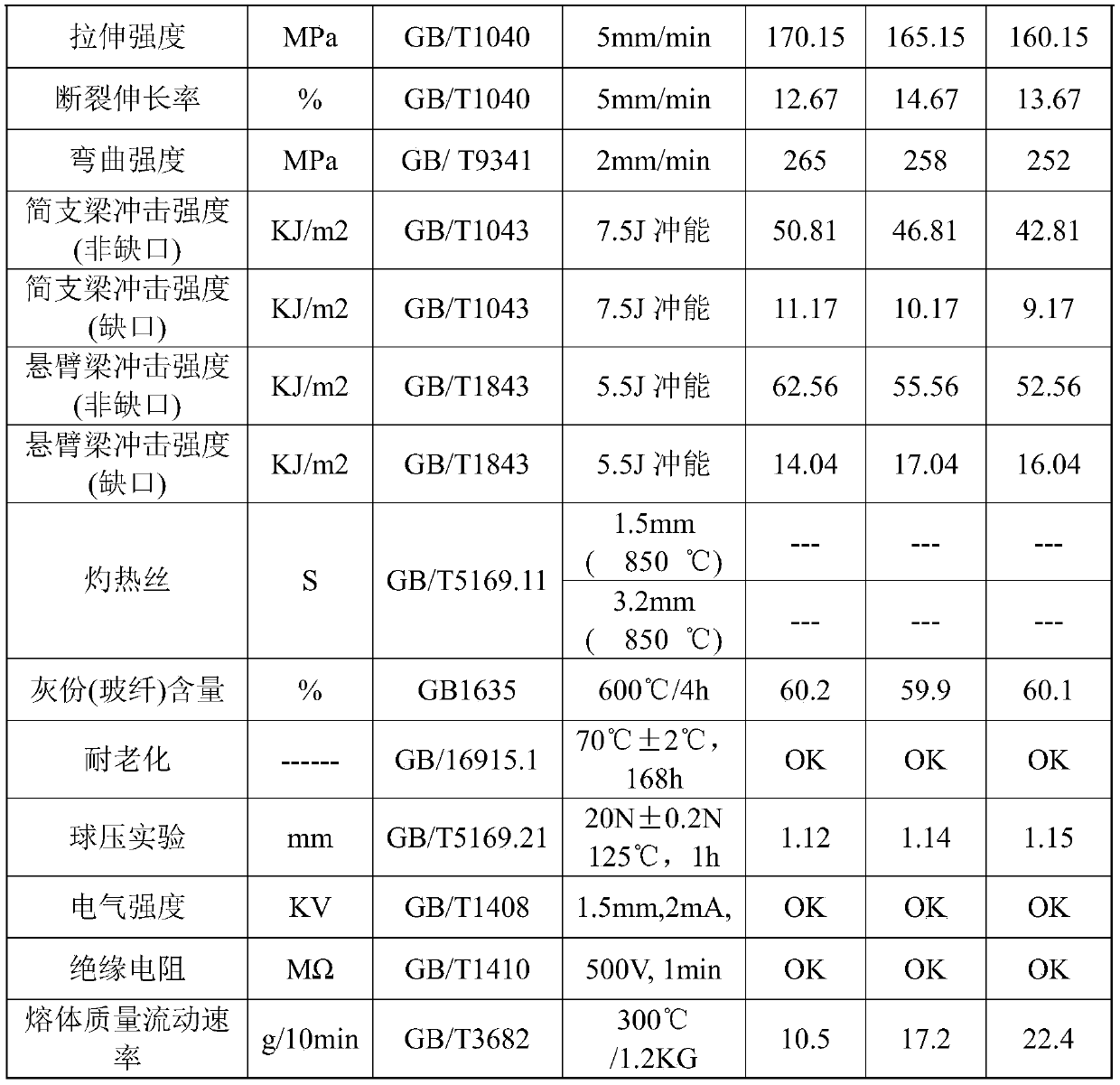

Gearbox release shifting fork supporting bolt with ball head part made of POE material and preparation method of gearbox release shifting fork supporting bolt

InactiveCN111255788AImprove wear resistanceImprove fatigue resistanceMechanical actuated clutchesScrewsGlass fiberStructural engineering

The invention discloses a gearbox release shifting fork supporting bolt with a ball head part made of a POE material and a preparation method of the gearbox release shifting fork supporting bolt. Theball head part of the bolt takes POE, or POE and glass fiber, or POE, glass fiber and molybdenum disulfide as raw materials of the ball head part of the bolt, and the ball head part of the bolt is connected to a bolt body through an injection molding process. The gearbox release shifting fork supporting bolt with the ball head part made of the POE material is simple in structure and capable of effectively improving abrasion resistance and strength of the gearbox release shifting fork supporting bolt, prolonging the service life of the gearbox release shifting fork supporting bolt, reducing maintenance frequency, effectively reducing noise in use, reducing weight and meeting the requirement for light weight of an automobile.

Owner:芜湖强振汽车紧固件有限公司

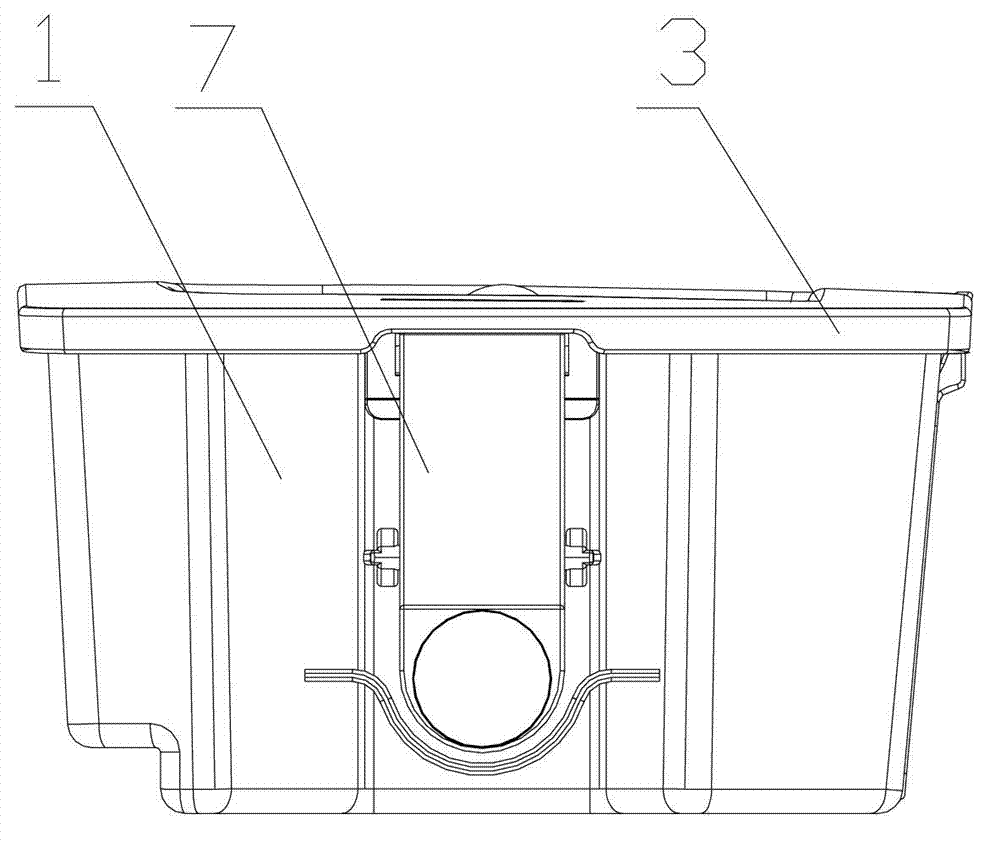

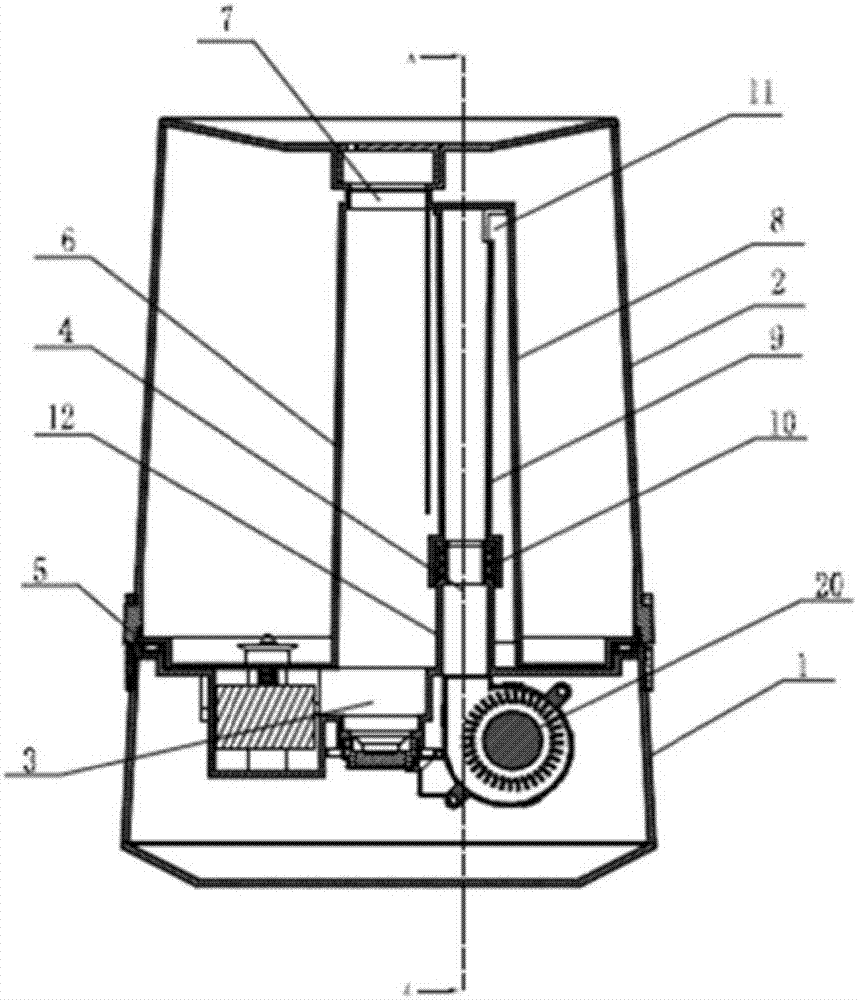

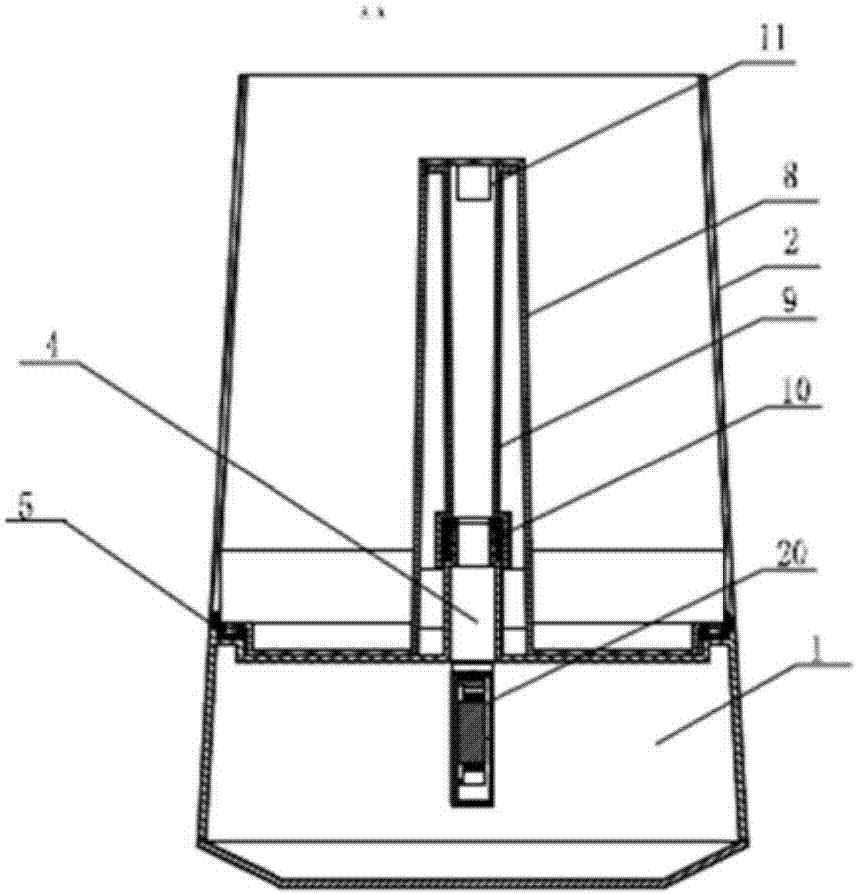

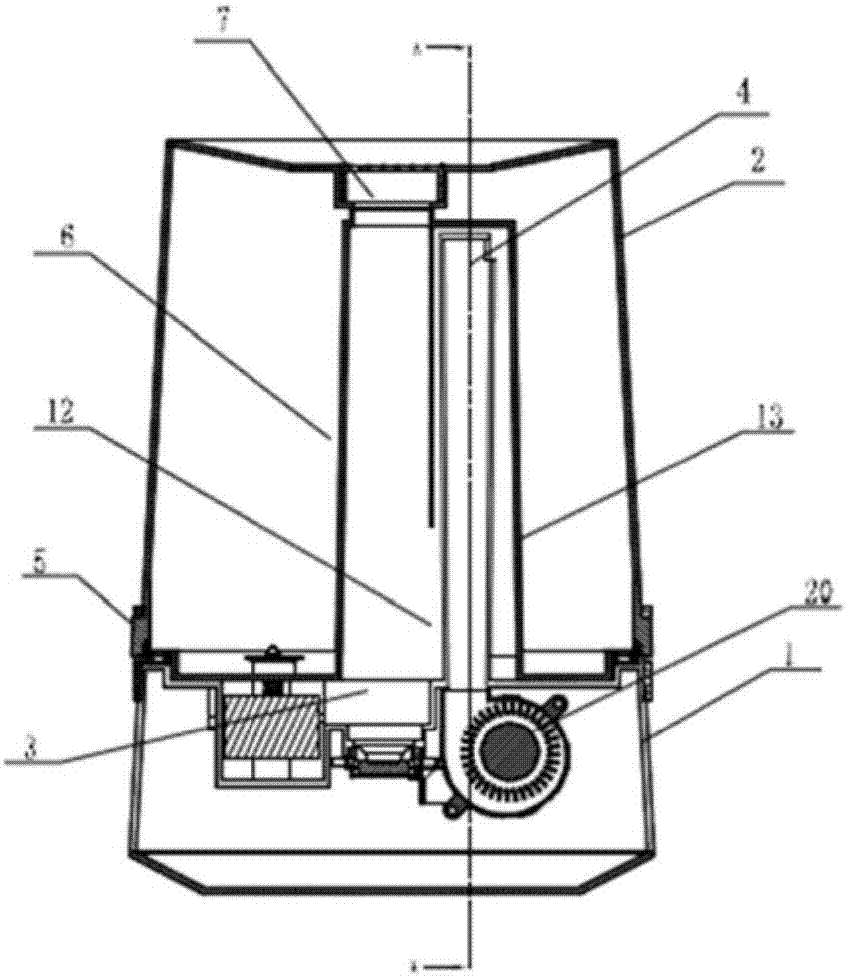

Upside adding water type humidifier with water tank and base separable

ActiveCN107421044ASimple injection molding processEasy to add waterSpace heating and ventilation safety systemsLighting and heating apparatusWater capacityWater tanks

The invention provides an upside adding water type humidifier with a water tank and a base separable and high safety. The humidifier comprises the base, the water tank and a fan; the top of the base is provided with a water channel which is provided with an atomization device; an air outlet of the fan is connected to a fog outlet channel through an air pipe; the upper part of the water tank is provided with a water inlet, and the water tank is provided with a drain hole which is provided with a drain valve; a water level control device is arranged and used for controlling the opening or closure of the drain valve according to the water level in the water channel; and the water tank is removably connected to the base, and an air outlet of the fan or at least one part of the horizontal section of the air pipe is located within the height range between 50%-98% of the maximum water capacity of the water tank. According to the upside adding water type humidifier provided by the invention, the connection mode of an air duct structure and the water tank with the base is improved, so the humidifier facilitates of adding water; moreover, even if the water level control device is failed, the water in the water tank can not enter the fan or flow out of the humidifier, so the using safety is ensured.

Owner:FOSHAN JINXINGHUI ELECTRICAL APPLIANCE

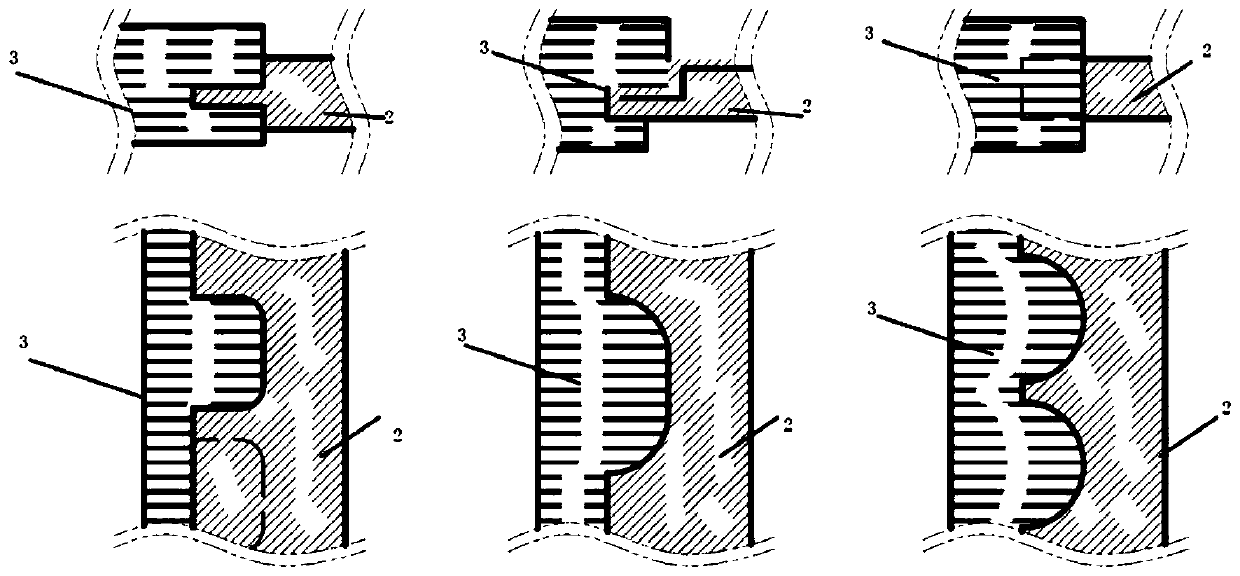

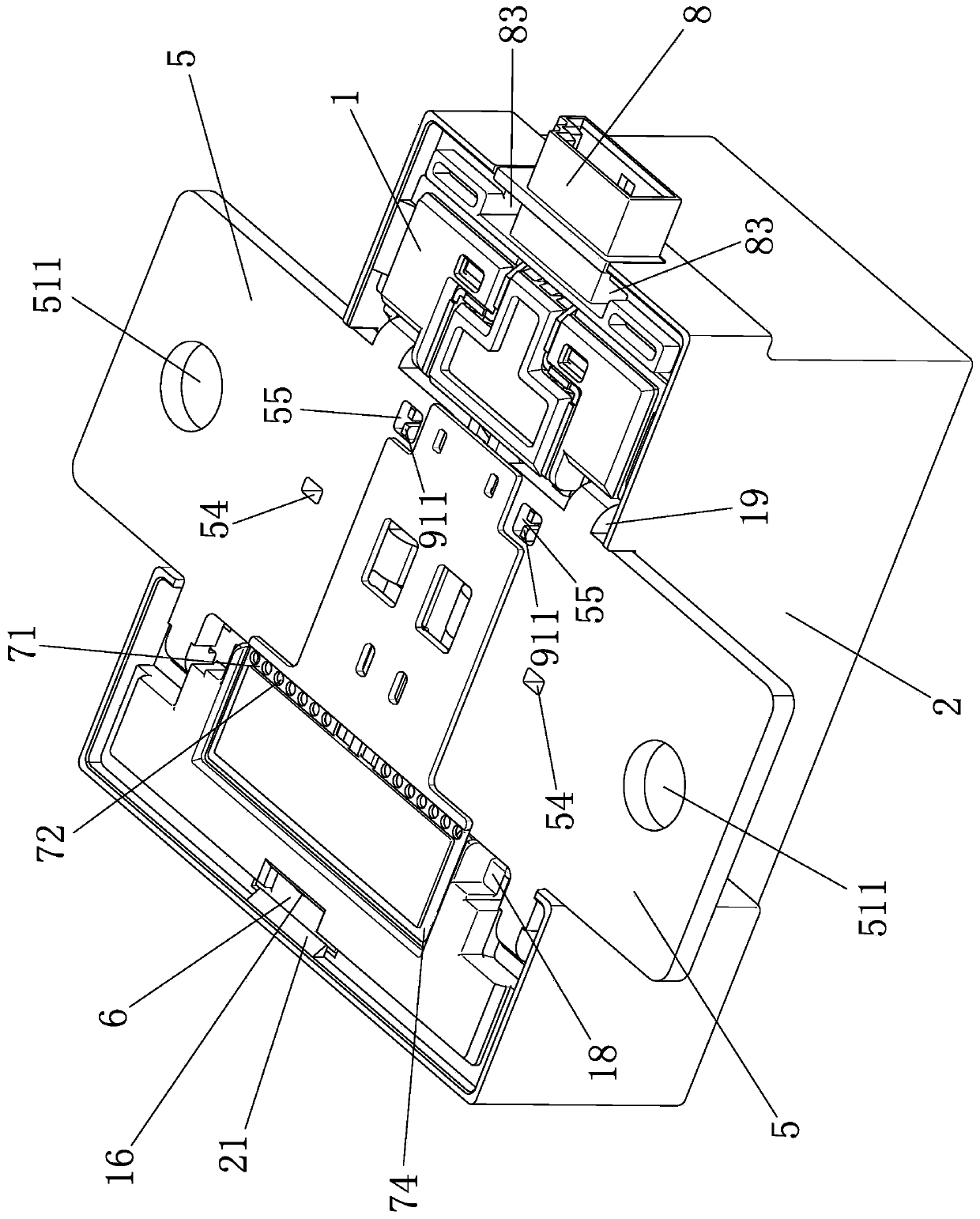

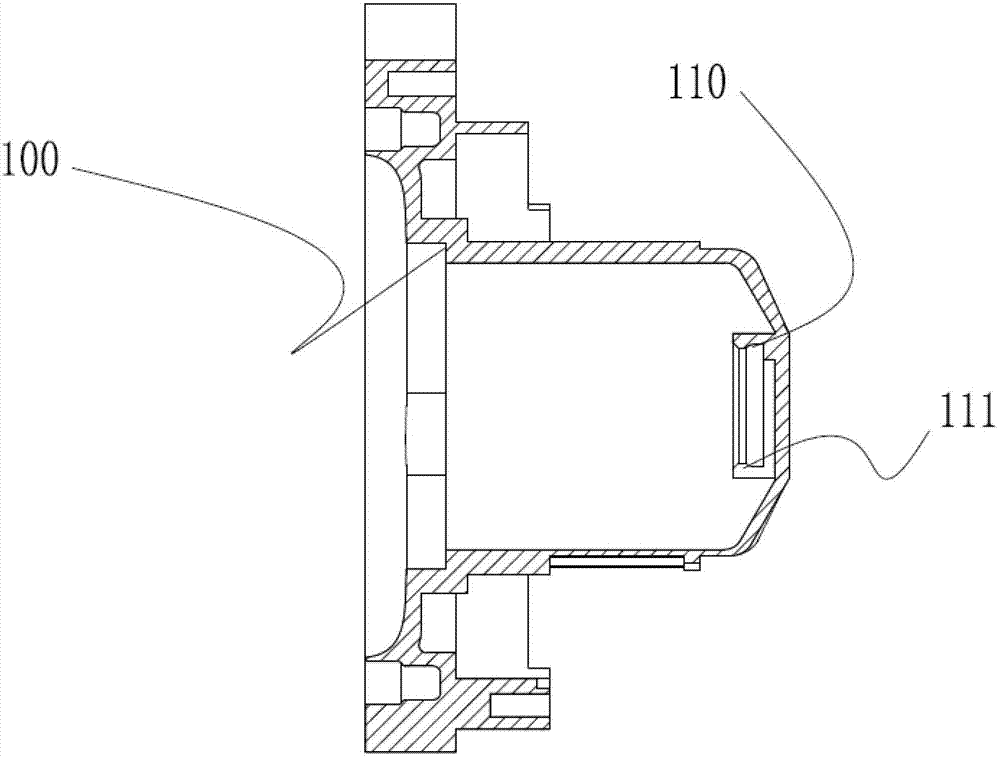

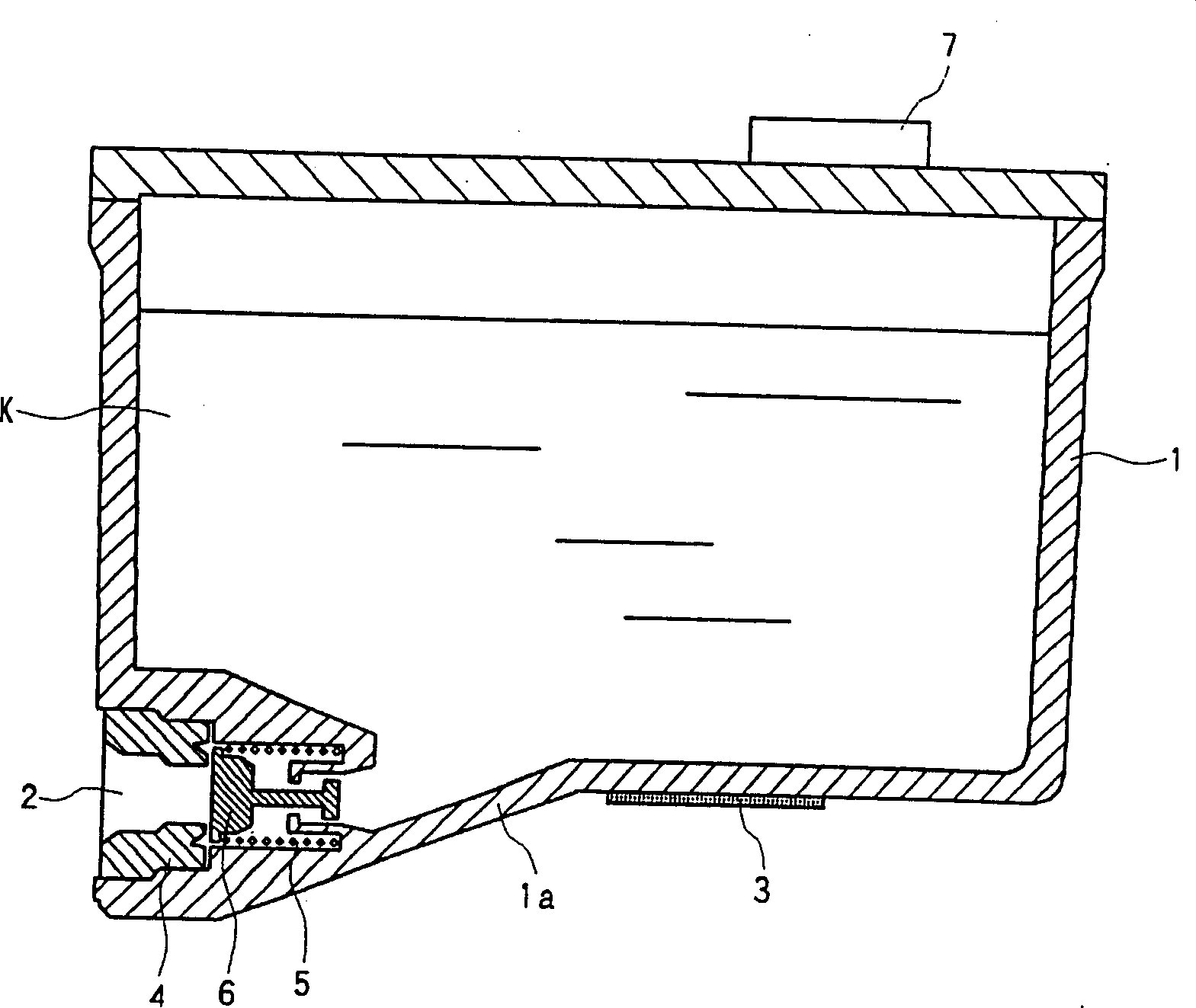

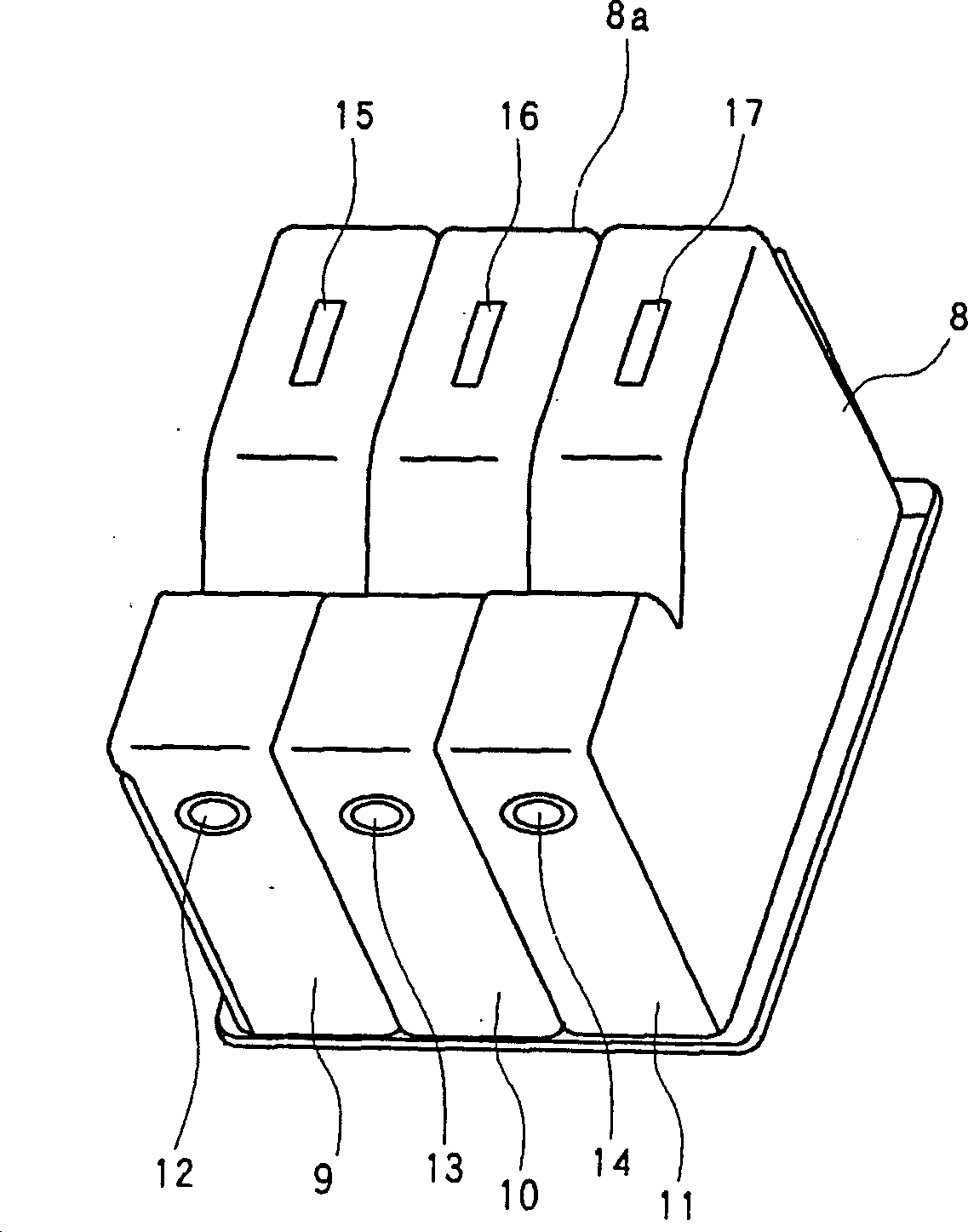

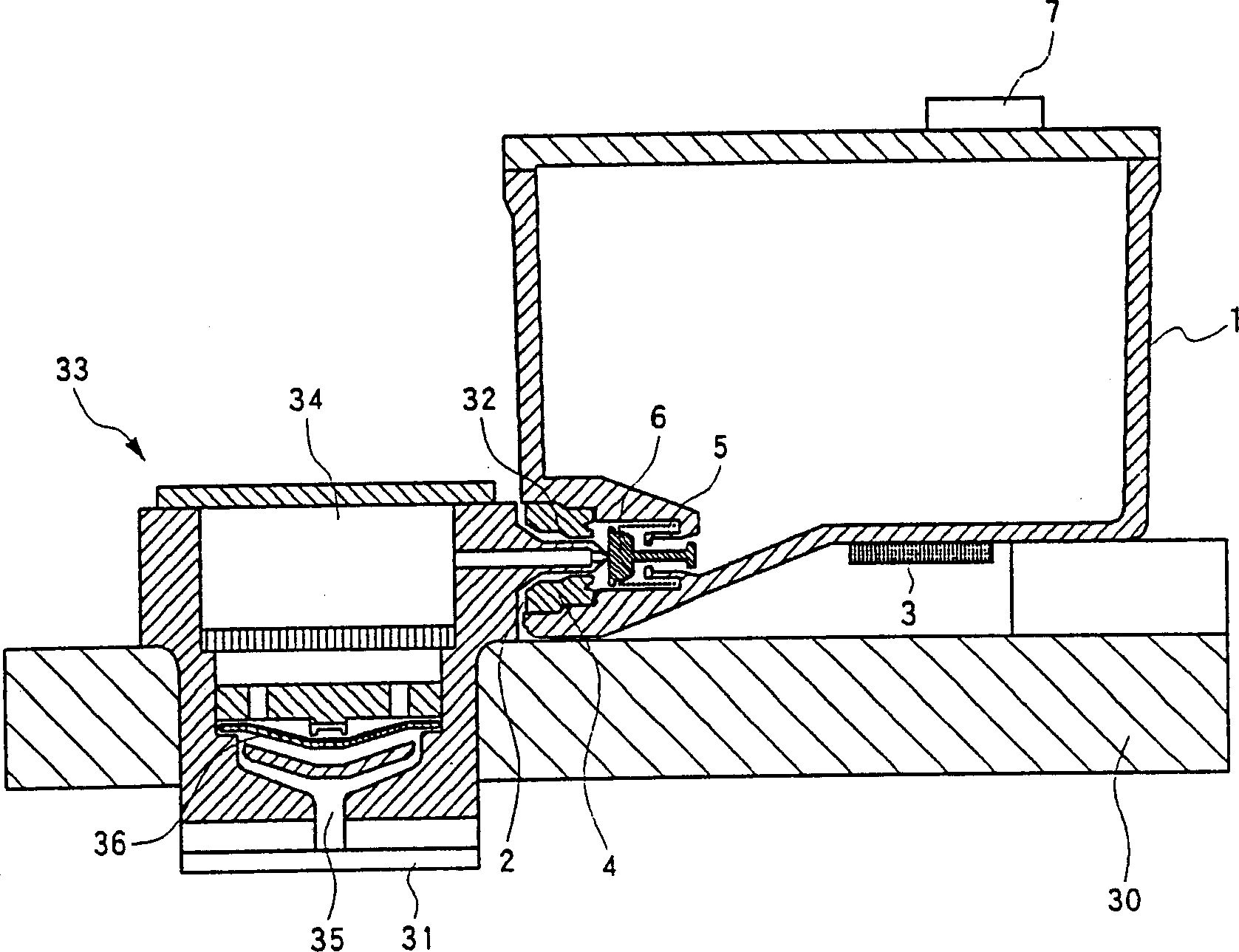

Liquid container having liquid consumption detecting device

InactiveCN1868752AImprove reliabilitySimple injection molding processMachines/enginesLubrication indication devicesElectricityEngineering

An ink cartridge serving as a liquid container, comprises a liquid sensor having a piezoelectric element which detects a consumption state of the liquid contained in the container, and a consumption data memory as a memory means. The consumption data memory is a rewritable memory which stores consumption related data which are related to the detection of the consumption state using the liquid sensor. The consumption related data are, for example, consumption state data as a result of the detection. Even when the ink cartridge is removed, the consumption state data can still be utilized. The consumption related data may be a detection characteristic detected depending on the consumption state of the liquid.

Owner:SEIKO EPSON CORP

Method for lithium battery injection molding encapsulation

InactiveCN101366131BLow stability requirementsHigh stability requirementsAssembling battery machinesSmall-sized cells cases/jacketsPolyamideEngineering

A method for packaging lithium cell by injecting plastic. A face cover of a electric core assembly can be formed by this method. The electric core assembly may be a lithium ion electric core assemblyor a polymer electric core assembly, wherein the polymer electric core assembly was packaged by a metal flake in advance. The method for packaging a lithium cell includes: providing the electric coreassembly with a output terminal into a cavity of a mould and locating therein with a location pin; melting thermoplastic polyamide resin desired to be inject at 170 to 230 degrees Centigrade, to makethe viscosity of the thermoplastic polyamide resin in the range of 340OmPa s to 10,000 mPa s; injecting the said molten thermoplastic polyamide resin into the cavity of the metal mould at the pressureof the injecting plastic in the range of 1 MPa to 10MPa, so as to inject the said thermoplastic polyamide resin into the cavity of the metal mould and coat onto the front face of the electric core assembly to form a plastic face cover.

Owner:HUIZHOU DESAY BATTERY

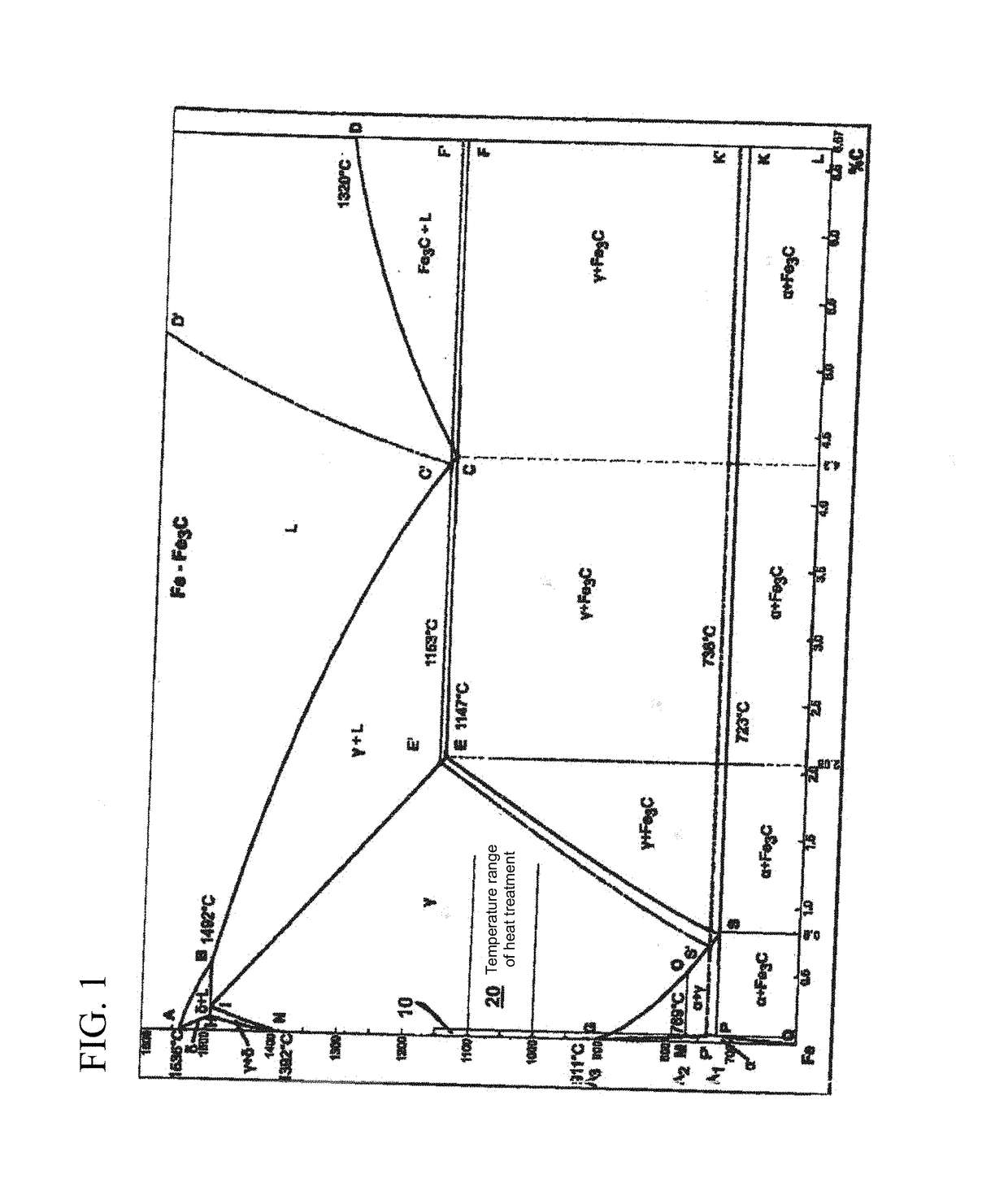

Method of manufacturing a rotor and electric machine

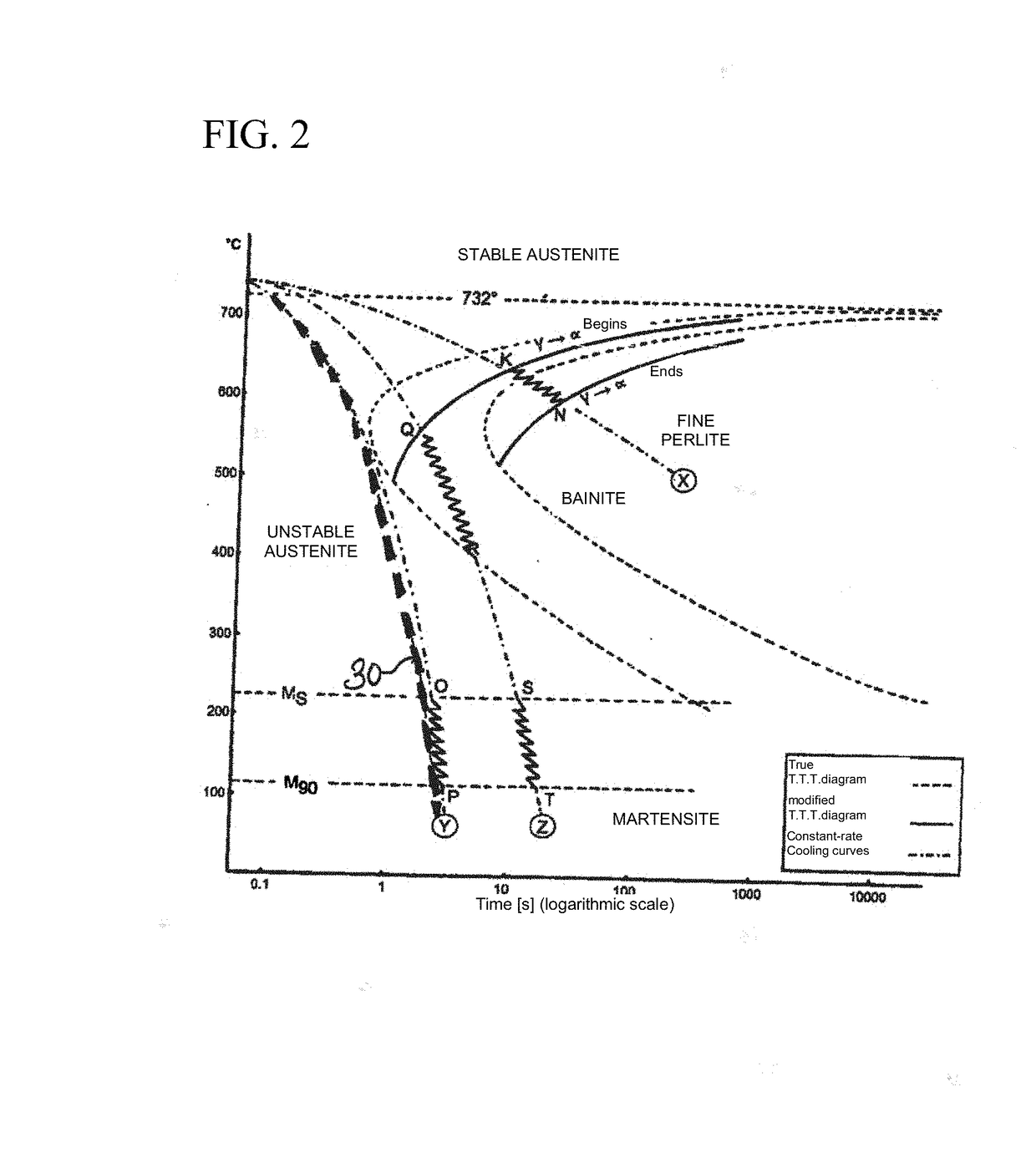

ActiveUS20180062487A1Good magnetic performanceEffective interferenceMagnetic circuit rotating partsFurnace typesElectric machineProcess region

The invention relates to a method of manufacturing a rotor for an electric machine, wherein the rotor is composed of at least one electric sheet wherein at least one electric sheet is thermally treated regionally to directly modify its magnetic permeability in the treated region.

Owner:RWTH AACHEN UNIVERSITY

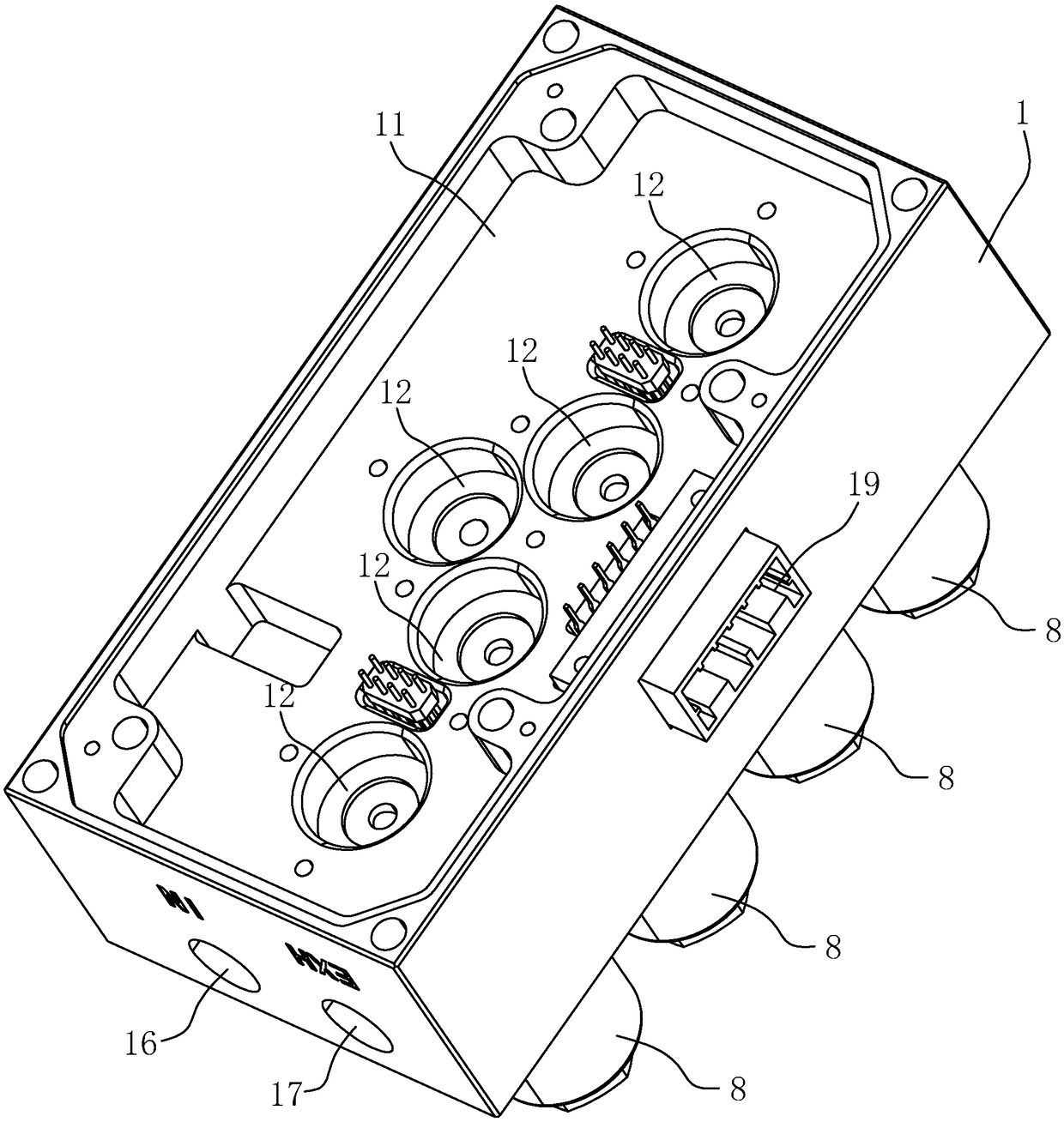

Multi-linkage valve

PendingCN109083882AStable structureSimple injection molding processServomotor componentsElectricityEngineering

The invention relates to a multi-linkage valve. The multi-linkage valve comprises a valve body, an installing plate, a control circuit board, pressure sensors and a cover plate, a cavity is formed inthe surface of the valve body, and multiple counter bored holes are formed in the bottom wall of the cavity; the installing plate is located inside the cavity and provided with through holes and installing bases, the installing bases and the through holes correspond to the counter bored holes in position and number, and the installing bases are inserted into the counter bored holes; the control circuit board is located in the cavity and gets away one side of the bottom wall of the cavity relative to the installing plate; the pressure sensors are installed inside the installing bases and electrically connected to the control circuit board through pins; the cover plate is used for sealing the cavity. The multi-linkage valve solves the problem that pressure sensors of a common linkage valve are arranged to protrude, and as a result the size is too large; the pressure sensors are arranged inside the valve body to be directly connected with the control circuit board electrically, and therefore the multi-linkage valve has the advantages of being low in production cost and small in size.

Owner:深圳市德平国瀚汽车电子科技有限公司

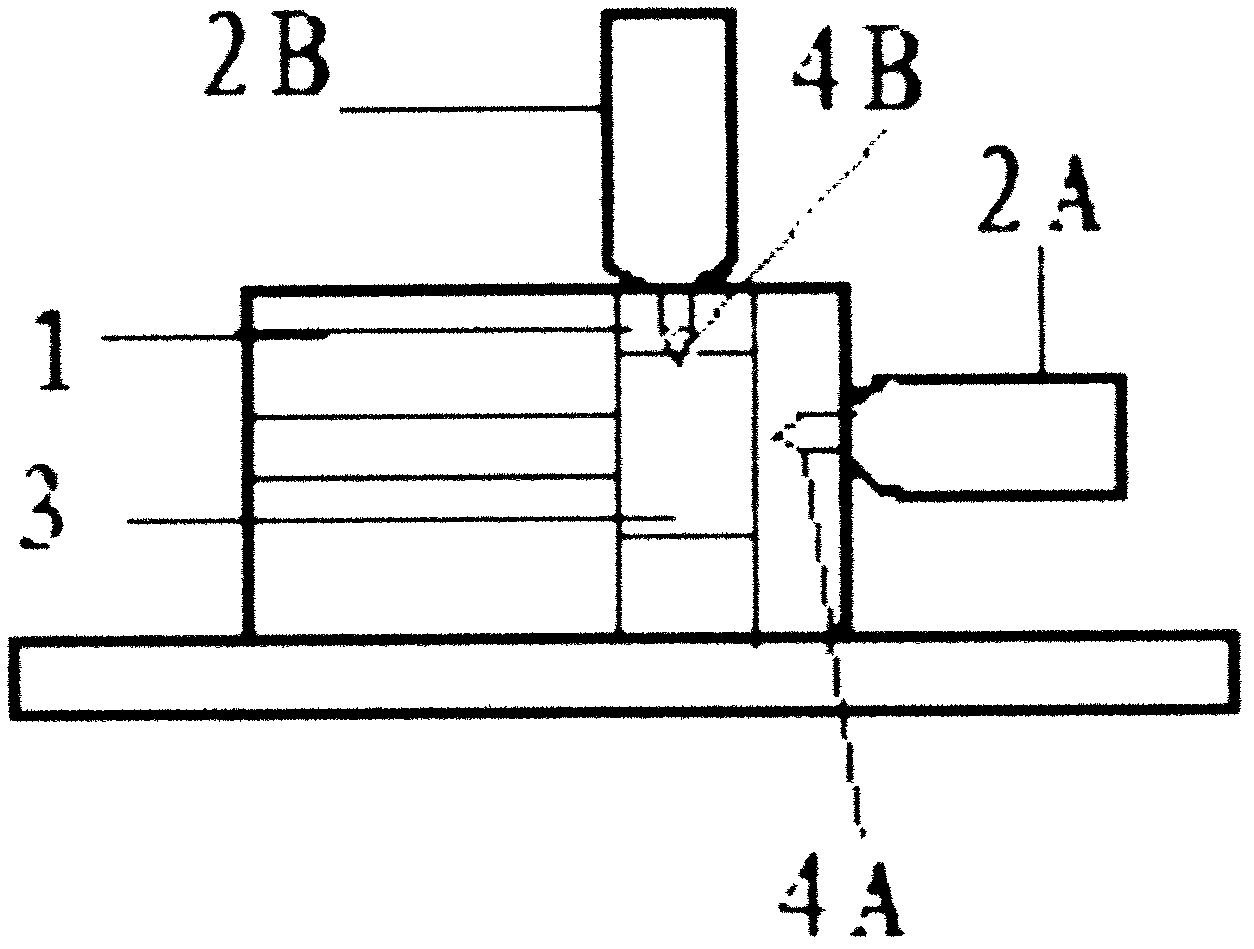

Double injection mold and double injection molding method

InactiveCN109159371ARealize the combinationSimplify the injection molding processDouble injectionMaterials science

The invention provides a double injection mold which comprises a male mold, a male mold core located on the surface of the male mold, a first female mold and a first female mold core. The male mold core and the first female mold core form a basic part forming cavity; the injection mold further comprises an auxiliary assembly mounted on the male mold and the auxiliary assembly comprises a movable warp, a first leaning column penetrating through the male mold and an auxiliary ejector pin penetrating through the male mold core. Two opposite ends of the movable warp separately bear the first leaning column and the auxiliary ejector pin. When the first leaning column is pushed by the first female mold, the first leaning column is withdrawn to the male mold, so that the other end of the movablewarp pushes the tip of the auxiliary ejector pin to extend into the basic part forming cavity, so as to form a through hole of a basic part.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

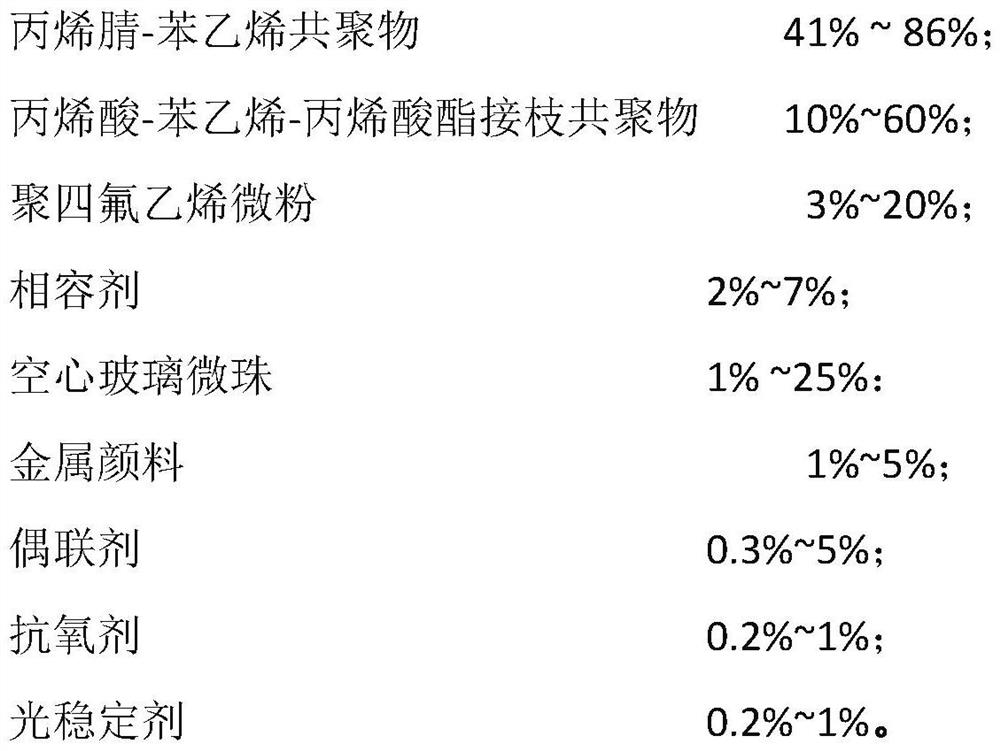

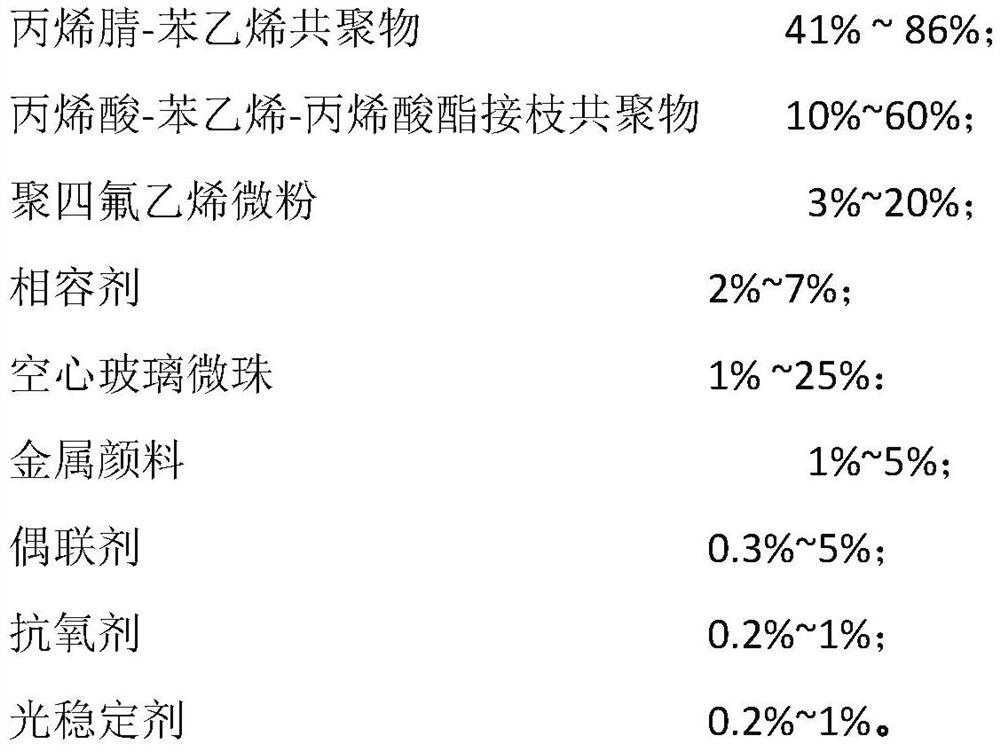

Lightweight, wear-resistant and spraying-free ASA composite material for noise reduction automobile and preparation method of ASA composite material

The invention discloses a lightweight, wear-resistant, spraying-free and noise-reducing ASA composite material for automobiles and a preparation method of the ASA composite material. The ASA compositematerial is prepared from the following raw materials in percentage by weight: 41-86% of acrylonitrile-styrene copolymer; 10%-60% of an acrylic styrene acrylate grafted copolymer; 3%-40% of vinyl fluoride micro powder; 2%-8% of a compatilizer; 1%-25% of hollow glass beads; 0.3%-5% of a coupling agent; 0.2%-1% of an antioxidant; 0.2%-1% of light stabilizer. The method comprises the steps: dividingthe hollow glass beads into three equal parts, putting 1 / 3 of the hollow glass beads and the other raw materials into a high-speed stirrer, and stirring for 5-10 minutes at the rotating speed of 500-1,800 revolutions per minute to obtain a premix; putting the premix into a double-screw extruder, adding the other two equal parts of hollow glass beads into the double-screw extruder from a side feeding hole respectively, and carrying out melt extrusion and granulation. The lightweight, wear-resistant, spraying-free and noise-reducing ASA composite material can be used for automotive interior andexterior plastic parts such as stand columns, grids, decorative strips and scratch-resistant strips.

Owner:ZHEJIANG PRET NEW MATERIALS +3

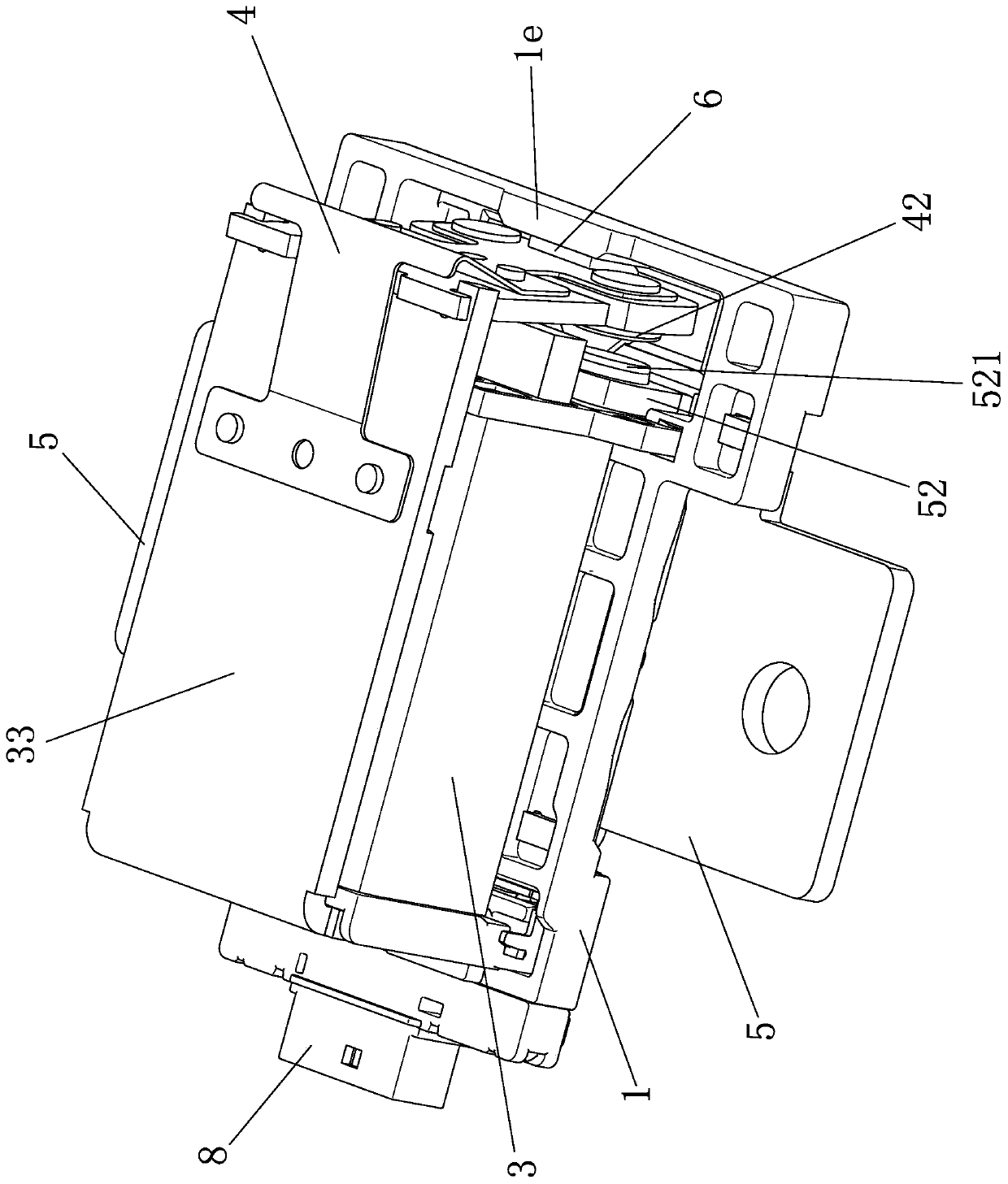

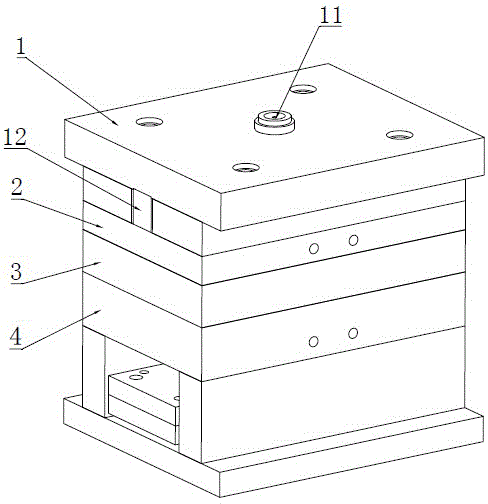

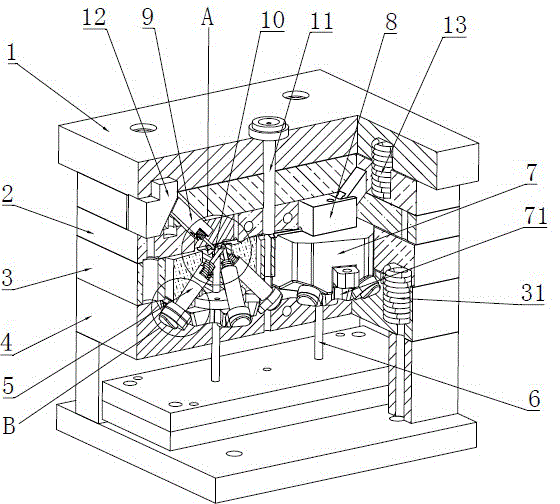

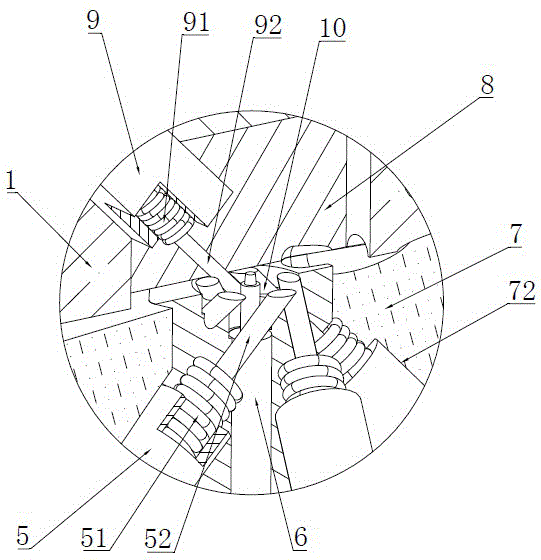

Core pulling injection mold for manufacturing multi-inclined-hole products

The invention relates to a core pulling injection mold for manufacturing multi-inclined-hole products, and mainly solves the problems about complex structure and cumber in operation during use of the existing injection mold, especially the difficulty in machining small workpieces and multi-inclined-hole workpieces. A plurality of inclined-penetration lower core pulling slideways (72) are arranged in a lower mold cavity (7); a lower core pulling elastic rod (5) is matched with the interior of each lower core pulling slideway (72) in a sliding way; a lower pulling needle (52) is arranged at the top end of each lower core pulling elastic rod (5) and stretches into a cavity (10), and the other end of each lower core pulling elastic rod (5) is in top press fit with a lower plate (4); lower elastic resetting parts (51) driving the lower core pulling elastic rods (5) to be far away from the cavity (10) are arranged between the lower core pulling elastic rods (5) and the lower mold cavity (7). The core pulling injection mold is simple in structure and convenient to operate, and can well realize multi-core-pulling operation and large-angle core pulling operation.

Owner:ZHEJIANG QUNZHEN TECH

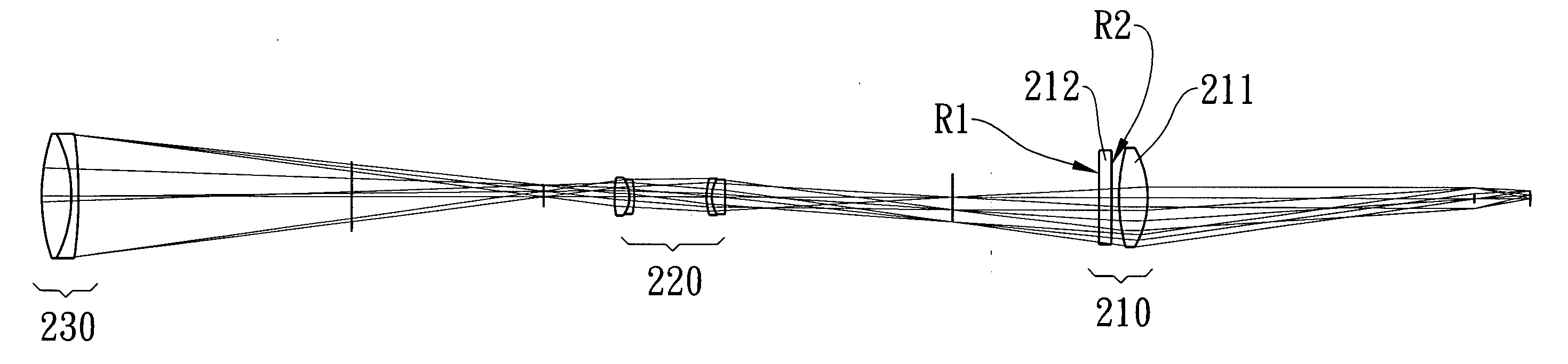

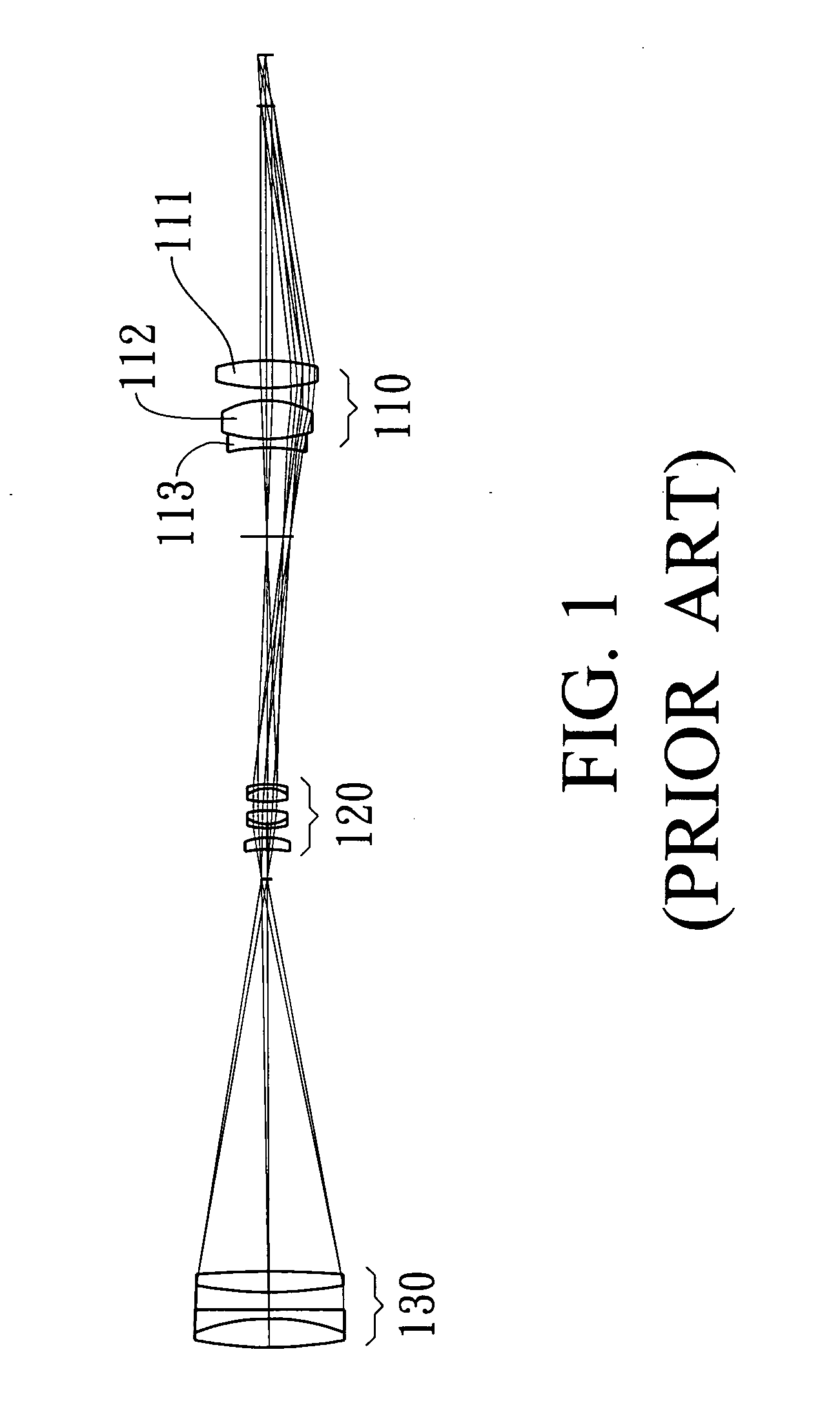

Eyepiece lens group of a riflescope system

An eyepiece lens group in a riflescope system comprises, from a front, eye side to a rear, object side, a glass lens and a plastic lens. The plastic lens has an aspherical surface and a diffractive surface, wherein the diffractive surface is on the front surface of the plastic lens and the aspherical surface is on the rear surface of the plastic lens. The aspherical surface of the plastic lens is utilized to abate the aberration. The diffractive surface of the plastic lens is utilized to abate the chromatic aberration. Therefore, the total numbers of lenses of the eyepiece lens group in the riflescope system could be reduced and the weight of the riflescope system could be reduced.

Owner:ASIA OPTICAL CO INC

Clothes clip capable of storing camphor

InactiveCN102234911AExcellent mothproofLow costTextiles and paperClothes-pegsEngineeringInjection molding process

The invention discloses a clothes clip capable of storing a camphor ball or a camphor essence block. The clothes clip can be used for fixed point moth proofing of clothes in daily life, and does not pollute the clothes. One or more small perforated boxes which can be used for storing camphor balls or camphor essence blocks and is / are provided with a cover or a plug is / are arranged outside two plastic, wood or bamboo strips of the clip, or a semicircular groove is formed inside the tail of the clip. A camphor ball can be put into the clip; when the clip holds the clothes, the held camphor ball does not drop out; and if the camphor ball or the camphor essence block is not put into the clip, the clip can be used as a common clothespin. The clothes clip has low manufacturing cost, and is practical and simple in a one-time injection molding process.

Owner:蔡欣惠

Bottle cap and bottle combination structure

The invention provides a bottle cap and a bottle combination structure. The bottle cap comprises a cap body, a pull tab, at least one self-destructing part and a connecting part; the pull tab is connected through the self-destructing part and cover a material taking port; the pull tab and the self-destructing part are integrally formed, so that before a material is taken, the material taking portis always in the state of being closed by the pull tab; since the pull tab needs not to be operated for encapsulating when bottling is completed to prevent the pull tab from being damaged by force andimprove the yield of the product; and the pull tab and the self-destructing part are integrally formed on the material taking port, the pull tab is bound to be pulled to cause breakage and damage ofthe self-destructing part when the material taking port is opened, the identification is very easy, the secondary use of a bottle cap is avoided, and the safety and the reliability of the use of the bottle cap are improved. A stopper adding section is arranged below the connecting part, and the bottle cap is installed on a bottleneck through the stopper adding section in advance, the stopper adding section is provided with a ring, close to the edge part of an opening, of the bottle cap, the ring is adapted to the external shape of the bottleneck, the bottle cap and the bottleneck are relatively fixed together without the need to change of the structure of a bottle body, the structure is simple, and the processing cost is lower.

Owner:JIANGSU HUA LAN PHARMA NEW MATERIALS LTD BY SHARE LTD

Sealing structure and forming method

InactiveCN108458195AImprove sealingImprove reliabilityPipe connection arrangementsOperabilityHot melt

The invention discloses a sealing structure and a forming method. The sealing structure is applied between a metal insert part and a main body plastic part, and is characterized in that a sealing groove is formed in the metal insert part; a sealing ring is arranged on the sealing groove; a cylindrical plastic part sleeves on the outer side of the sealing ring; the main body plastic part is arranged on the outer side of the cylindrical plastic part; and the metal insert part, the cylindrical plastic part and the main body plastic part are hot melted through injection molding. The technical scheme provided by the invention has the beneficial effects that the sealing structure and the forming method are disclosed, the sealability between the main body plastic part and the metal insert part can be improved, the reliability and the actual operability of an injection process are further improved, and in injection molding process is simple in process and lower in cost.

Owner:宁波央腾汽车电子有限公司

Transformer and its manufacturing method

ActiveCN108987071BSafe separation distanceSimple injection molding processTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinTransformer

A transformer provided by the invention comprises a skeleton, a primary winding, a secondary winding and a magnetic core. Wherein the skeleton is integrally formed with the primary coil, the skeletoncomprises a bobbin, and first bosses and second bosses respectively arranged at both ends of the bobbin. The skeleton is provided with through holes penetrating the bobbin, the first boss and the second boss. The primary coil is a flat coil, and the primary coil is integrally embedded in the first boss. The secondary coil is wound around the bobbin and the pins of the secondary coil are arranged on the second boss. The magnetic core includes an insertion portion inserted into the through hole and an outer portion disposed on the outer side of the skeleton. The invention also provides a manufacturing method of a transformer, comprising the following steps: opening a mold, molding the transformer skeleton by injection molding through a mold, placing a primary coil into a mold while molding the skeleton, and integrally molding the primary coil and the skeleton; installing the secondary coil and wind the secondary coil onto the skeleton; installing the core and mounting the core to the skeleton.

Owner:SUINING PUSI ELECTRONICS

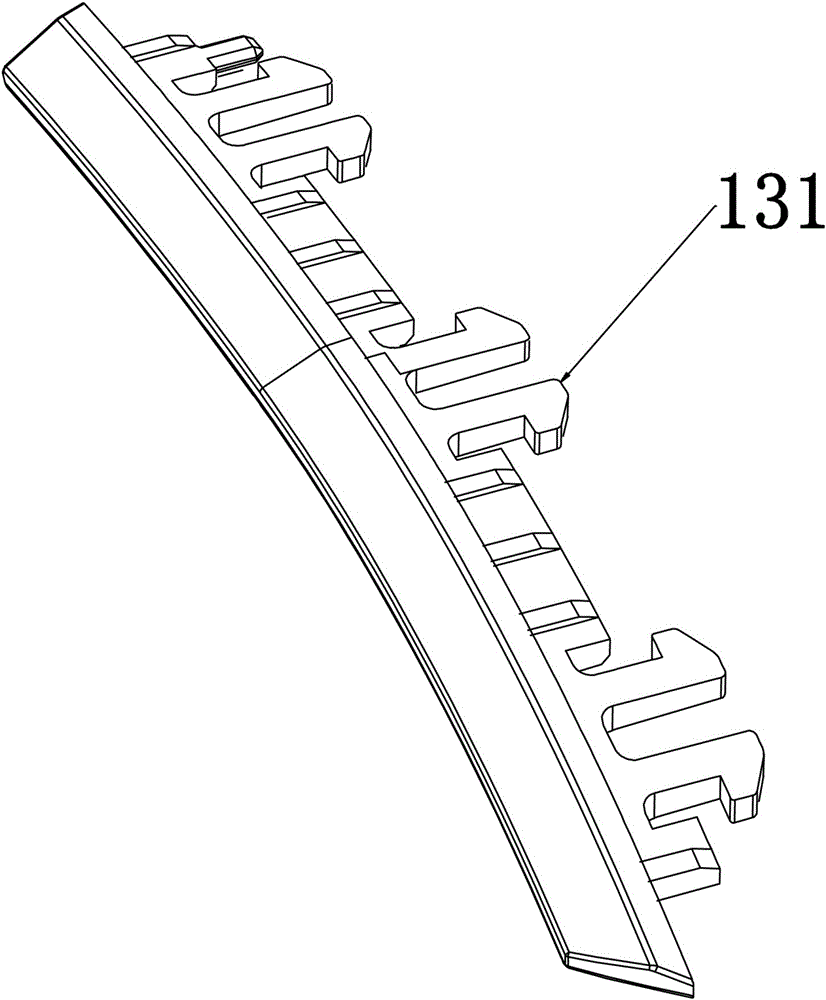

Preparation process of wiper plastic part with bones

The invention discloses a preparation process of a wiper plastic part with bones. The preparation process comprises the following steps: (1) drying materials before processing, and testing whether the materials are dried completely or not by an air injection method; (2) selecting an injection system with more temperature control sections and little self-friction heating during plasticization, wherein the actual weight of a product is not less than 2 / 3 of the injection amount of a machine; (3) molding a blank by a hot runner mold, wherein a heat insulation plate is arranged between the mold and a mold plate of an injection molding machine; and (4) measuring by the air injection method at melting temperature, wherein the temperature is set to be 290-315 DEG C. In the step (1), the temperature for drying the materials is 170 DEG C, and the time is above 3-4h. The preparation process disclosed by the invention has the characteristics of simple process and good product quality.

Owner:LIUZHOU JINDUN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com