Wireless packaging structure of high-power ceramic LED (Light-emitting Diode)

A packaging structure, high-power technology, applied in the direction of electrical components, electrical solid-state devices, circuits, etc., can solve the problems of increasing process costs and material costs, reducing the light-emitting efficiency of light-emitting chips, etc., to reduce complexity, save costs, and improve light output rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

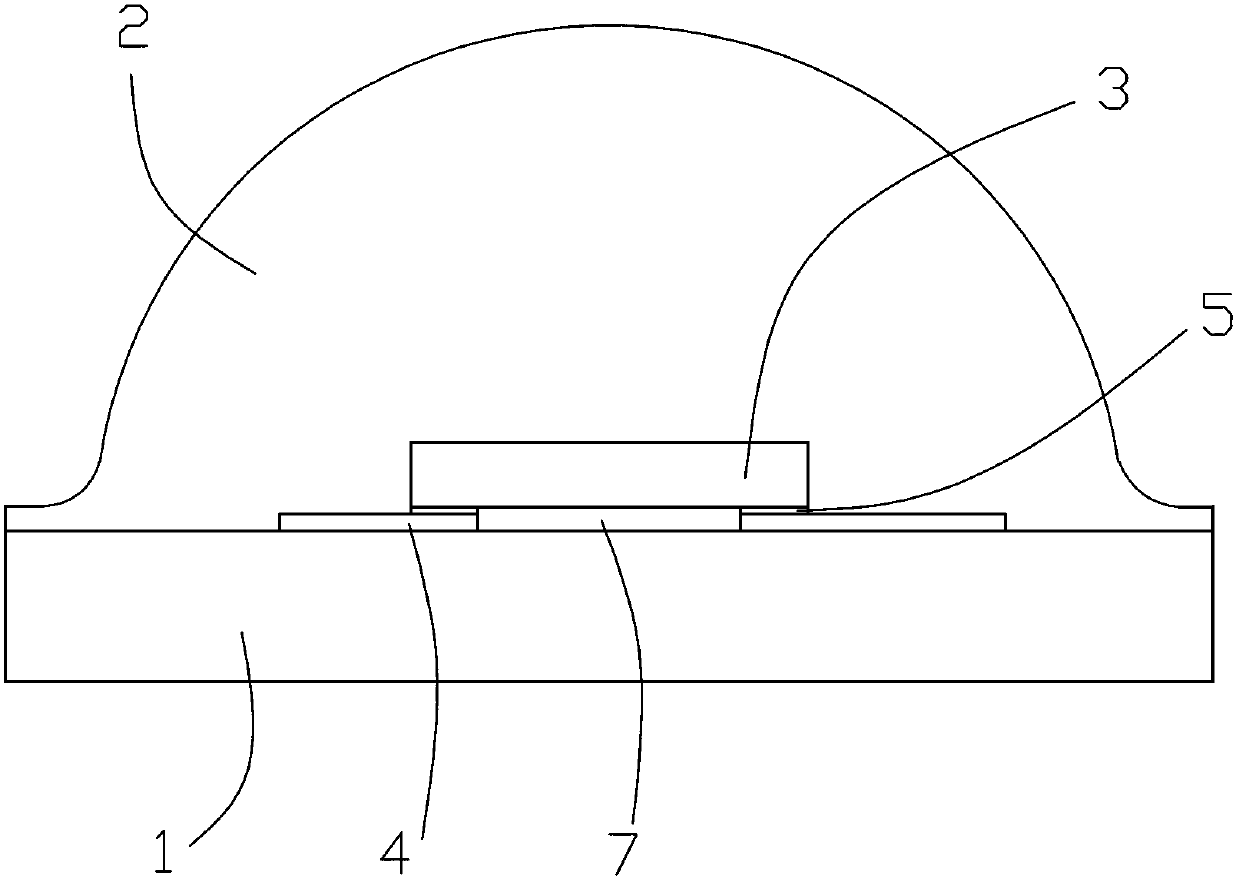

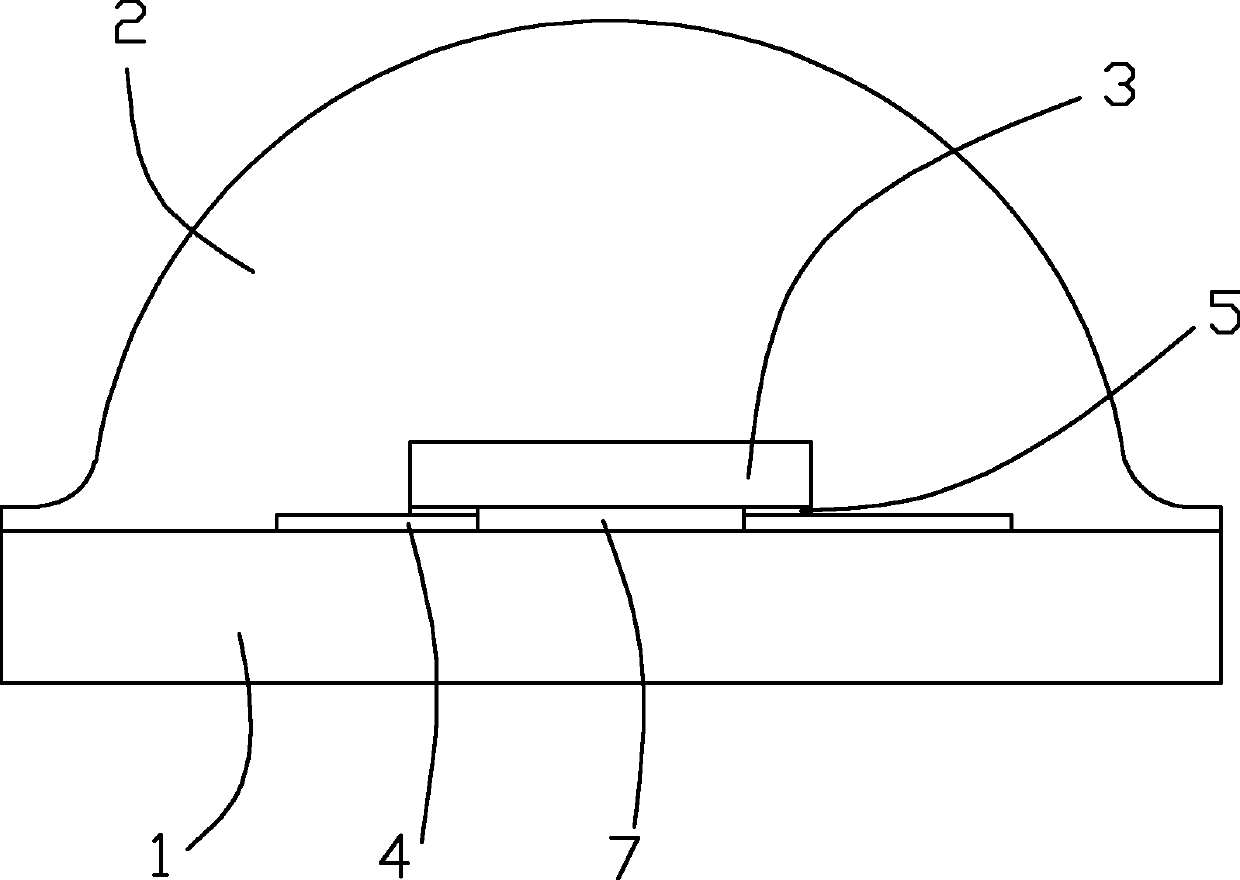

[0019] In this embodiment, a high-power ceramic LED wireless packaging structure, such as figure 1 As shown, there is a base 1, which is a ceramic base, and two eutectic electrode pads 4 are arranged on the base, such as figure 2 As shown, two pins 6 are arranged on the bottom of the base, and the two pins are positive pins and negative pins respectively, and two eutectic electrode pads are respectively connected to the two pins. A light-emitting chip 3 is arranged on the eutectic electrode pad, and the light-emitting chip is a high-power light-emitting chip. On both sides of the bottom of the light-emitting chip, a positive electrode terminal and a negative electrode terminal are drawn respectively, and the positive electrode terminal and the negative electrode terminal protrude from the bottom of the light-emitting chip. On the surface, there is a layer of tin gold layer 5 on the positive electrode terminal and the negative electrode terminal. The thickness of the tin gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com