Ceramic composite middle frame of mobile terminal and preparation method thereof

A ceramic composite and mobile terminal technology, applied in branch office equipment, telephone structure, telephone communication, etc., can solve the problems of inability to form an effective combination, poor affinity between metal alloy and plastic, and inability to form a reliable combination under natural conditions, etc. It achieves the effect of convenient natural design and layout, simplified in-mold injection molding process, and rich CMF effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

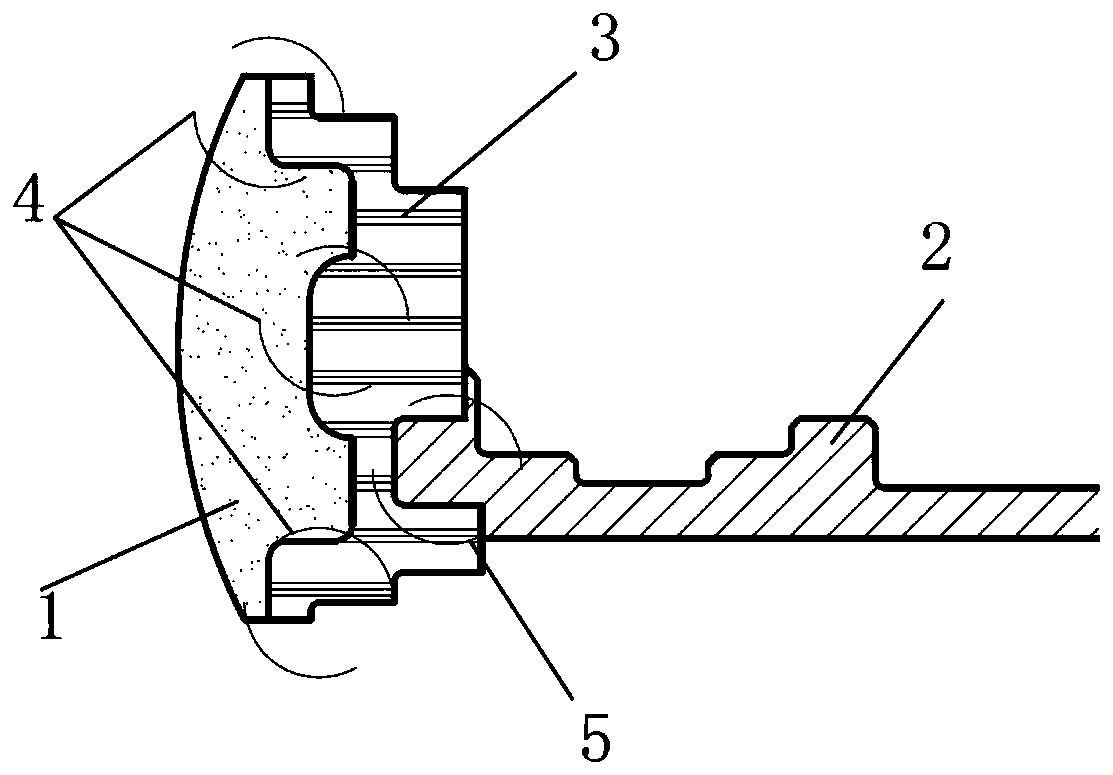

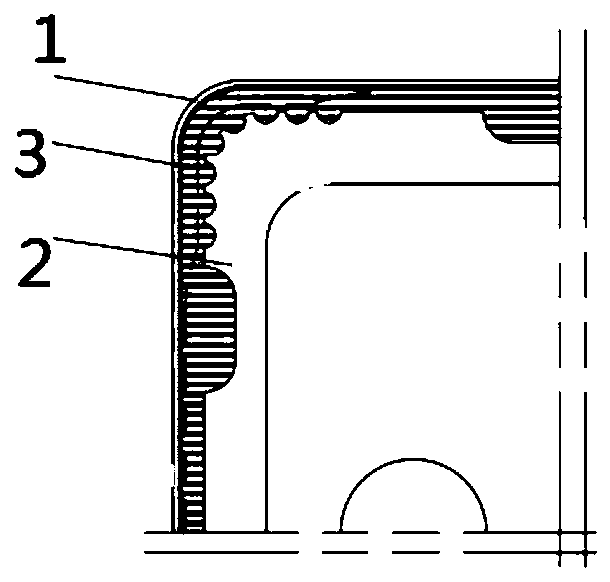

[0052] An embodiment of the ceramic composite middle frame of the mobile terminal according to the present invention, the cross-sectional schematic diagram of the ceramic composite middle frame of the mobile terminal described in this embodiment is as follows figure 1 As shown, the local schematic diagram is shown in figure 2 Shown:

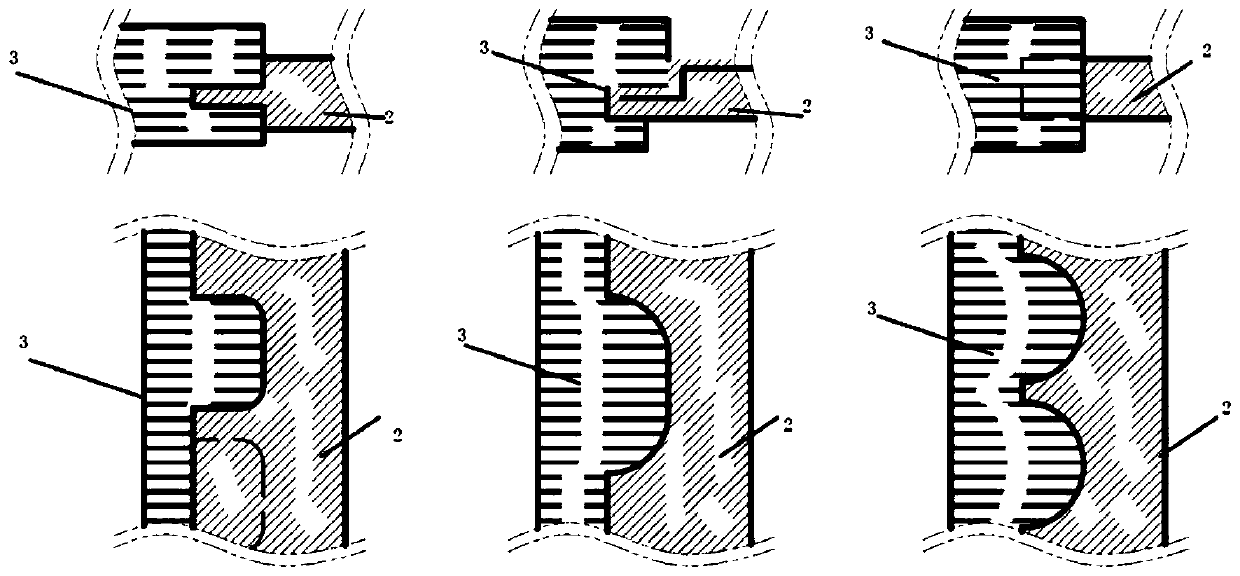

[0053] Including ceramic frame 1, metal middle plate 2, ceramic frame 1 and metal middle plate 2 are connected by plastic framework 3, metal middle plate 2 and ceramic frame 1 are provided with overlapping structures, and both sides of plastic framework 3 are provided with occlusal structures The occlusal structure on one side of the plastic frame 3 is connected to the lap structure of the ceramic frame 1, and the occlusal structure on the other side of the plastic frame 3 is connected to the lap structure of the metal middle plate 2. The specific connection forms include but are not limited to image 3 As shown in : the overlapping structure i...

Embodiment 2

[0063] An embodiment of the ceramic composite middle frame of the mobile terminal according to the present invention, the structure and size of the ceramic frame, the plastic skeleton, and the metal middle plate of the mobile terminal ceramic composite middle frame described in this embodiment are the same as those in Embodiment 1, and the different The ceramic composite middle frame in this embodiment is partially metallized and provided with metal contacts 6. The method for preparing the ceramic composite middle frame of a mobile terminal in this embodiment includes the following steps:

[0064] (1) Roughly process the ceramic shell and complete the standard processing of in-mold injection molding;

[0065] (2) Carrying out surface activation treatment to the ceramic housing obtained in step (1);

[0066] (3) The ceramic shell is subjected to structural processing of local metallized structural holes and wire grooves;

[0067] (4) Embedding partial metal contacts into the c...

Embodiment 3

[0073] In this example, the effects of the dimensions of the ceramic outer frame, the plastic skeleton, and the metal middle plate on the strength of the ceramic composite middle frame of the mobile terminal described in the present invention are studied. The structure and size are all within the scope of the present invention. The control group 1 is a conventional stainless steel aluminum alloy composite frame, and the control group 2 is a conventional aluminum alloy plastic partition frame. Specifically, each of the experimental groups 1-8 and the control group 1-2 The size setting and strength results are shown in Table 1 and Table 2:

[0074] Table 1

[0075]

[0076] Table 2

[0077]

[0078] It can be seen from Table 2 that the ceramic composite middle frame has good practical application performance.

[0079] In addition, the appearance of the ceramic composite middle frame in the present invention was compared with the stainless steel middle frame and aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com