Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Rich in rare earth resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

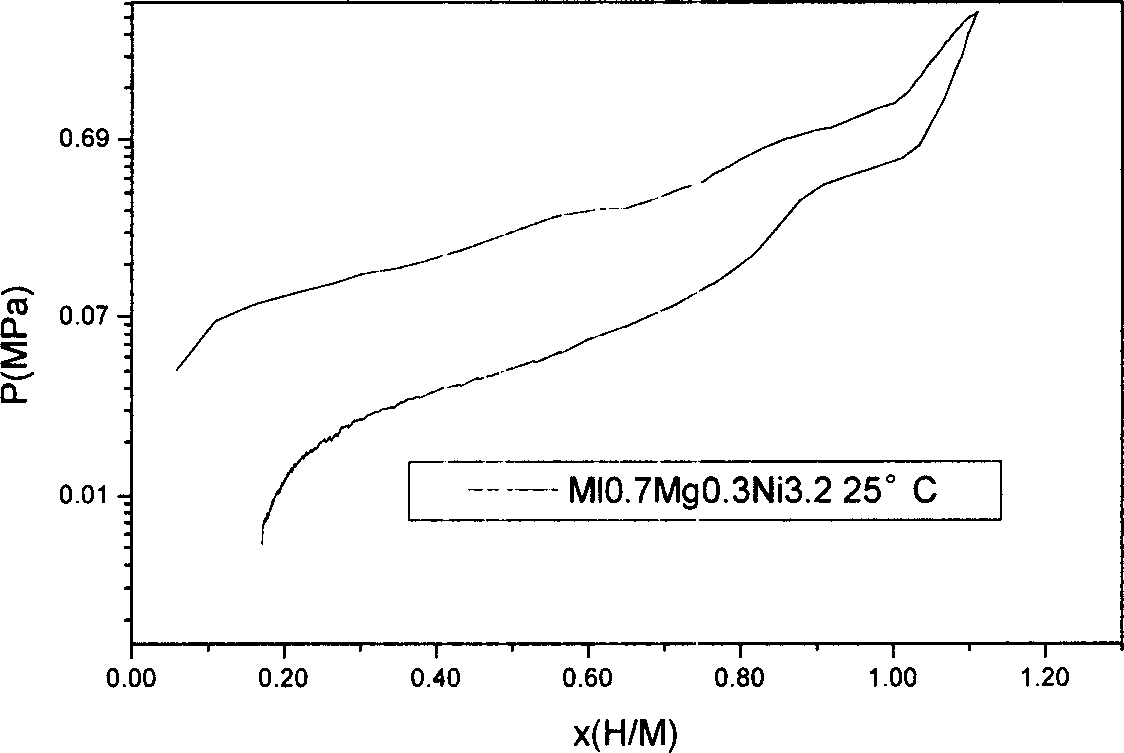

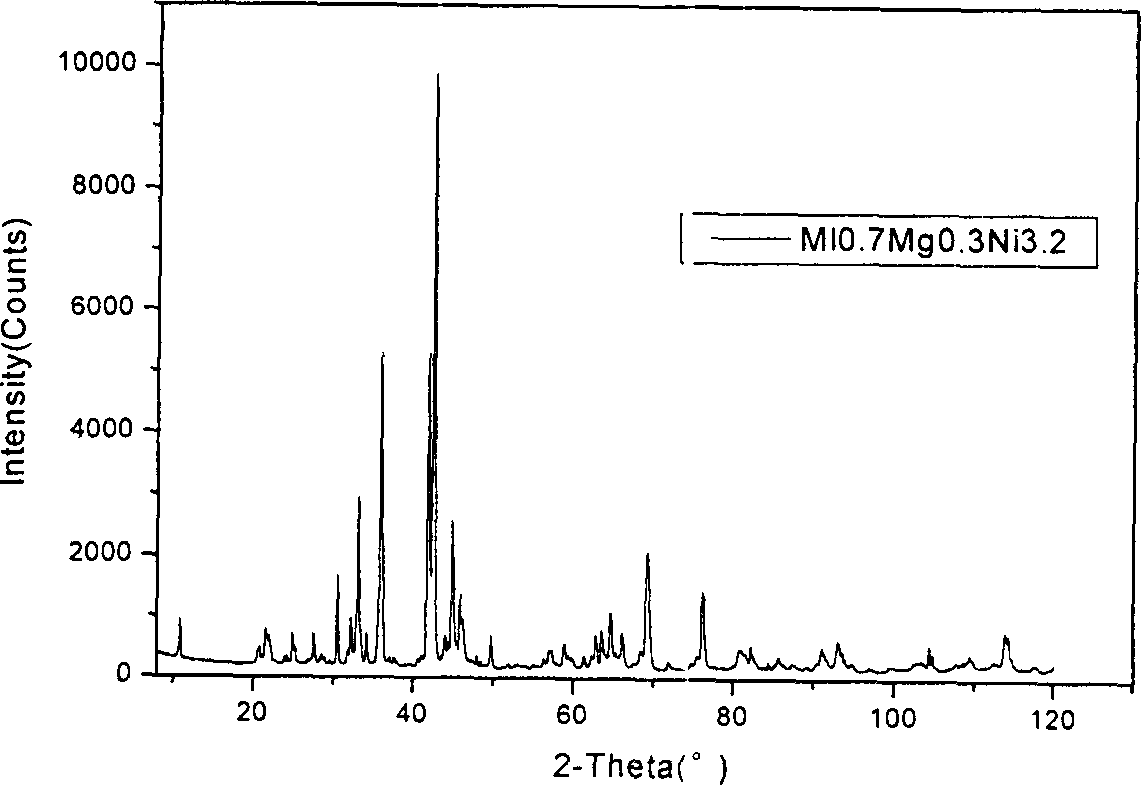

Nano crystal multiphase mixed rare earth-magnesium system hydrogen-storing alloy and its preparation method

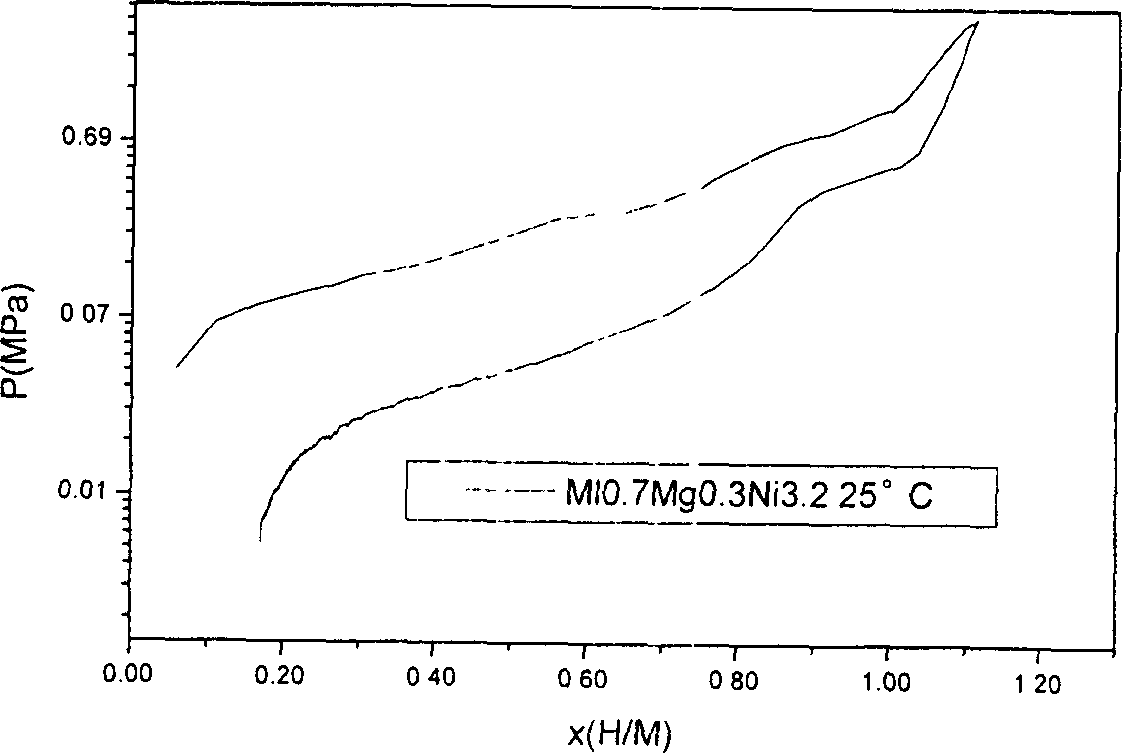

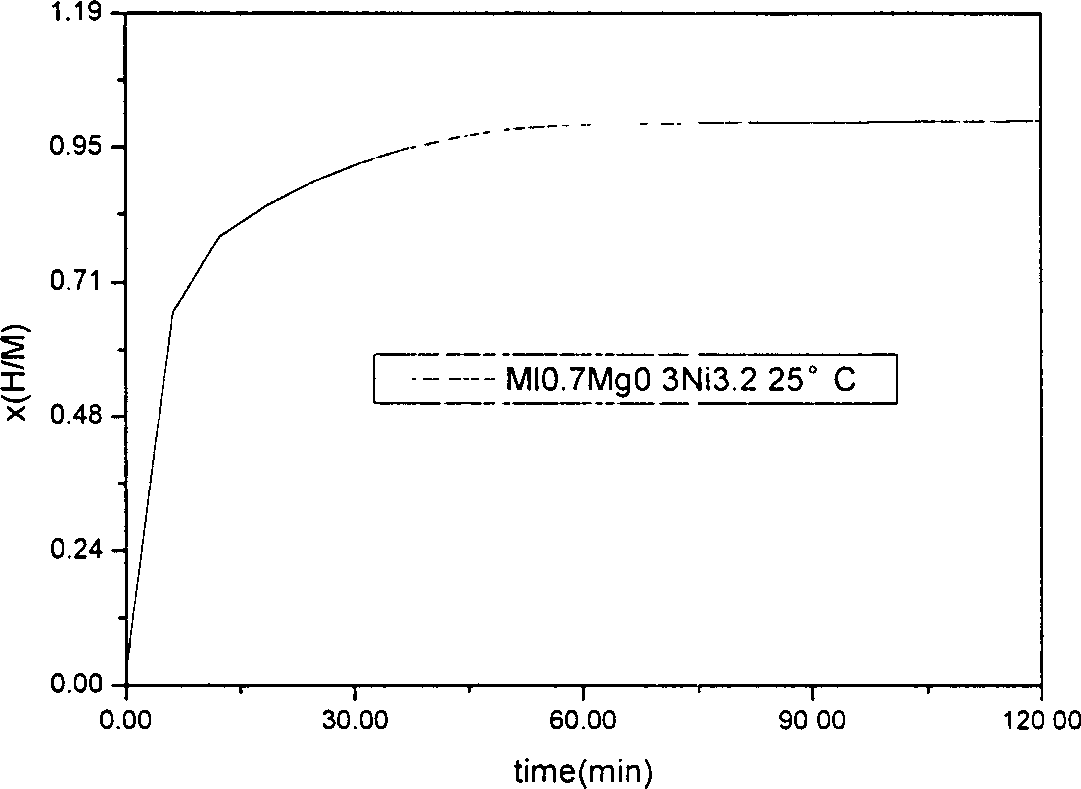

InactiveCN1443861AHigh hydrogen storage capacityImprove cycle stabilityCell electrodesNickel accumulatorsRare earthShielding gas

The present invention relates to a nano crystal multi-phase mixed rear earth-magnesium system hydrogen-storing alloy and its preparation method. The preparation method of said alloy includes the following steps: smelting, homogenizing annealing, etc. and its smelting process is placing the La-enriched mixed rare earth, metal magnesium and metal nickel into an induction smelting furnace crucible according to a certain proportion, evacuating, charging protective gas, regulating power and temp. to melt metal, heat-insulating and fully stirring, injecting the molten metal into water-cooling ingotmould, cooling and discharging. Said alloy has anique components and multi-phase nano crystal structuer, and has good circulation stability.

Owner:SOUTH CHINA UNIV OF TECH

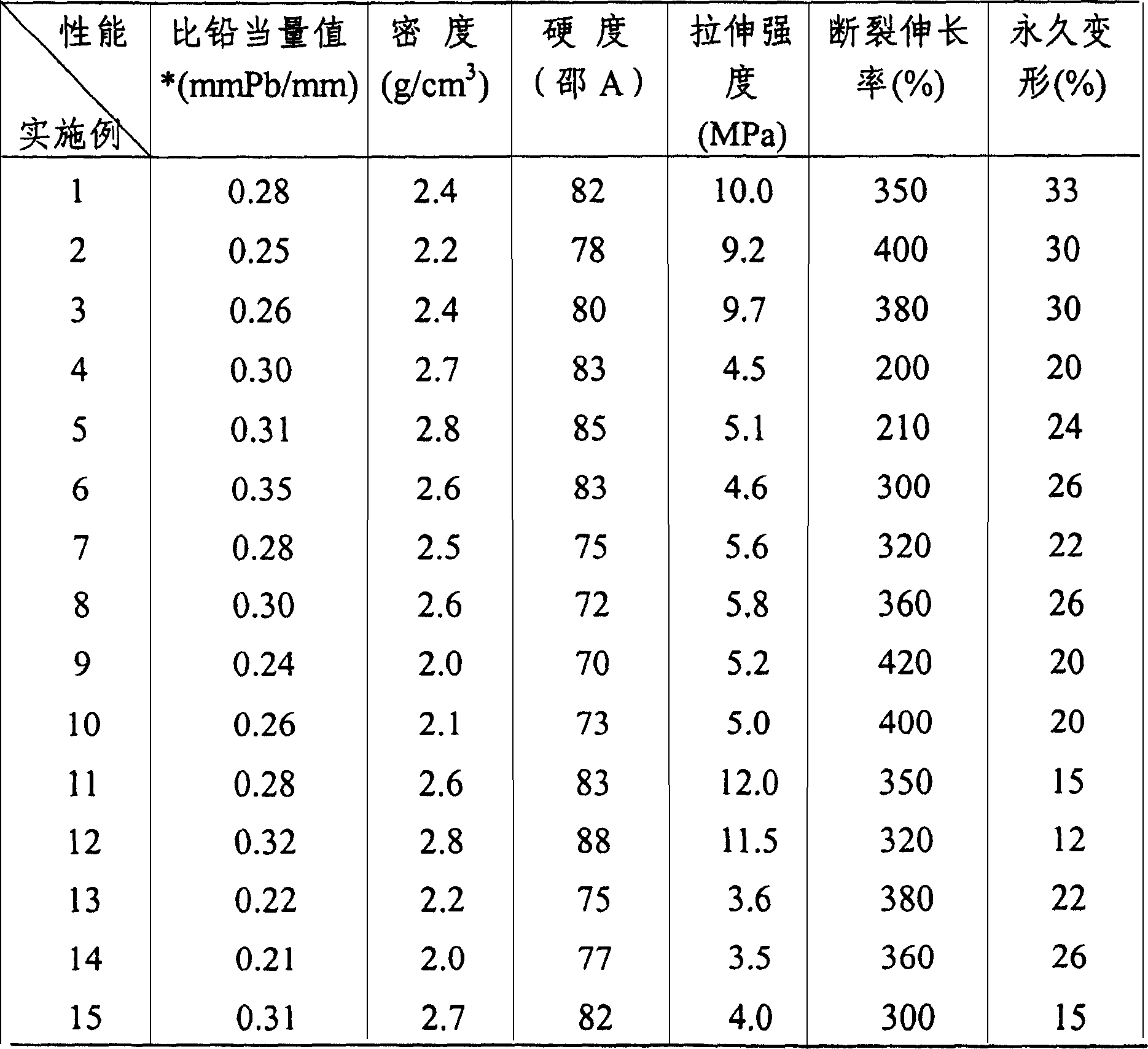

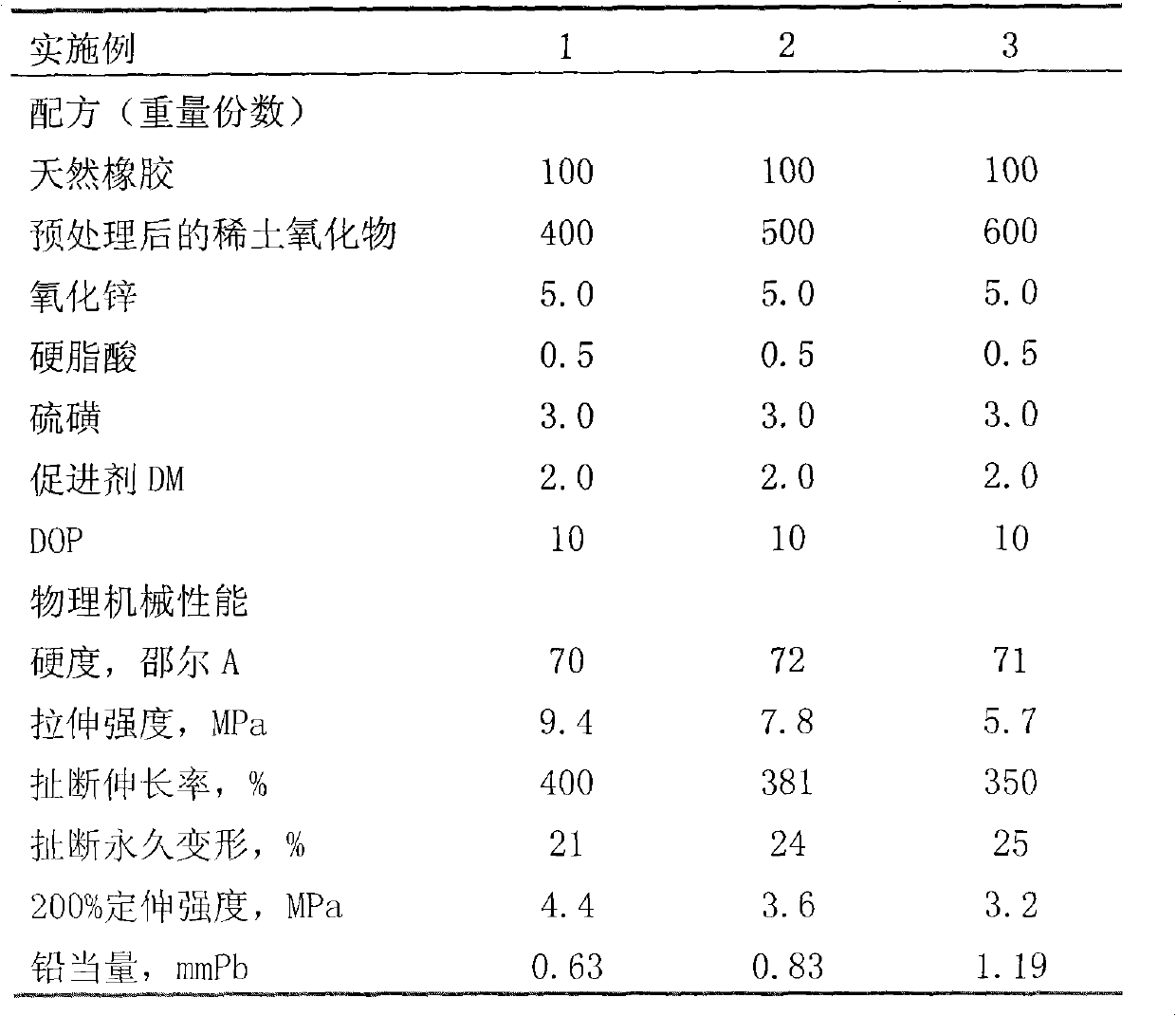

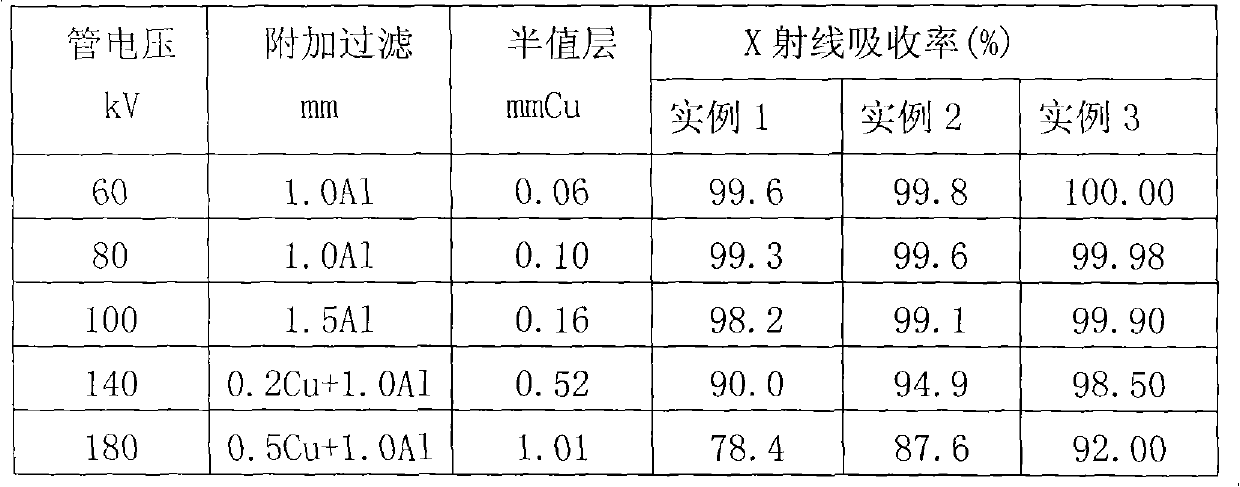

Rare earth modified full non-lead X-ray screen rubber

InactiveCN1787117AIdeal X-ray shielding performanceImprove mechanical propertiesShieldingX-rayRare earth

The invention relates to a rare-earth modified all lead-free X-ray screening rubber, making surface modification processing on a part of the organic rare-earth and making organization reaction processing on the other part to prepare organic rare-earth salt, then adding them both to rubber in a certain proportion, so as to obtain the modified all lead-free X-ray screening rubber, making the screening property and mechanical property of the material achieve the desired effects. It can be widely applied to medical diagnosis X-ray machines, X-ray diffraction meters, and emitters of electron microscopes as well as the protection of working personnel on the occasions of generating X-rays.

Owner:BEIJING UNIV OF CHEM TECH

REMg3 type hydrogen storage alloy and its preparation method

A hydrogen bearing REMg3 alloy has a molecular formula: RE1.2-xMg3Niy, where RE is rare-earth mixture, x=0-0.4 and y=0-1. Its preparing process includes proportionally loading RE, Mg and Ni in crucible of induction furnace, vacuumizing, filling protective gas, smelting and cooling.

Owner:SOUTH CHINA UNIV OF TECH

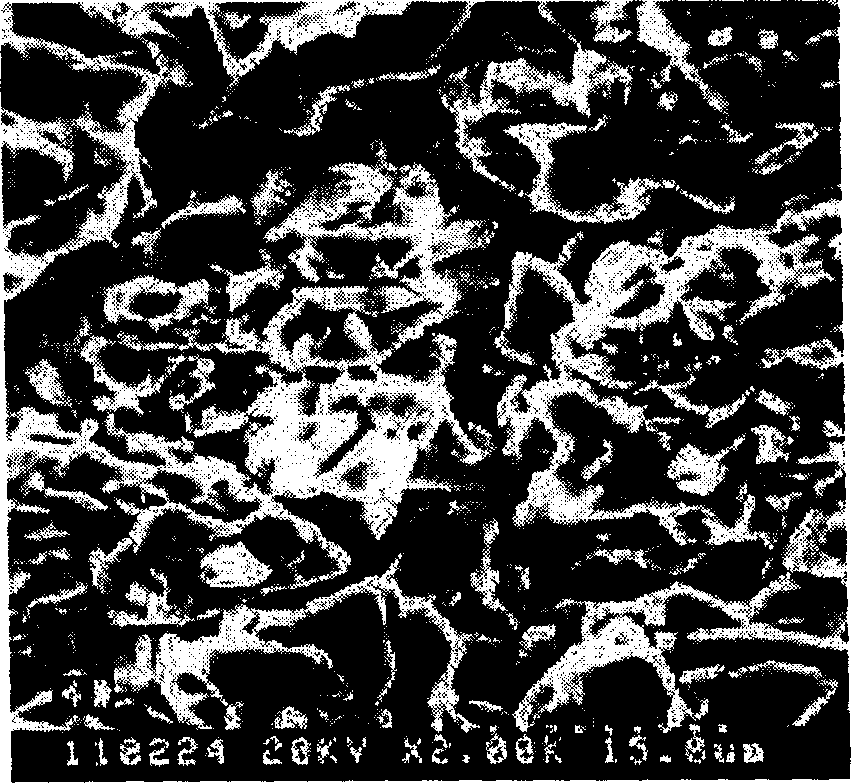

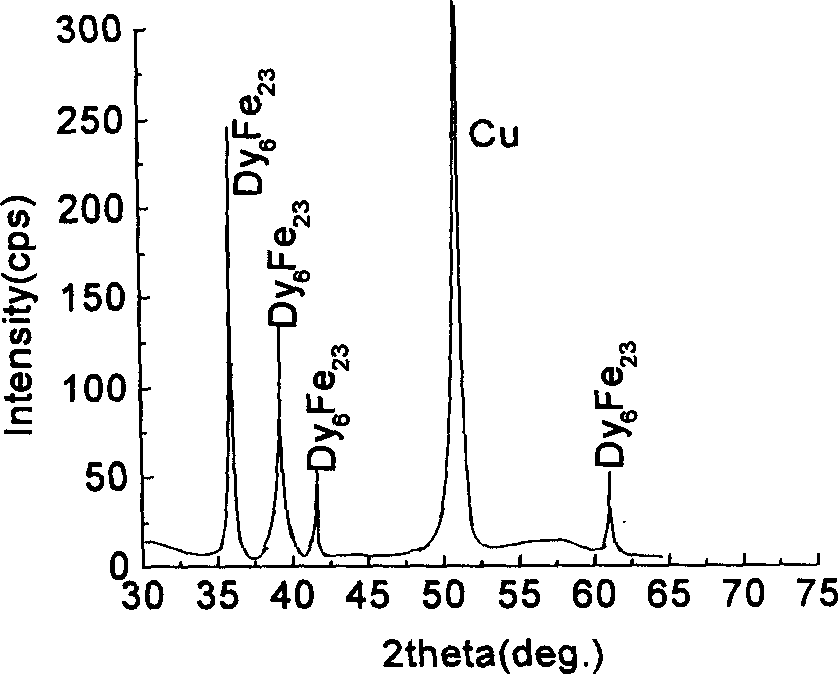

Method for preparing rare earth alloy through sweeping electric potential sedimentation

A process for preparing RE alloy in organic solvent by scan potentia deposition method includes preparing the plating liquid from dimethyl sulfoxide (or formamide) as solvent, RE nitrate and Fe-series chloride as main salt and tartaric acid or citric acid as complexing agent, pretreating the basic metal body, and plating said basic metal body in said plating liquid at 18-35 deg.C and 2-100 mv / s of scan speed for 10-35 min to generate RE alloy film on the basic metal body. Its advantages are high uniformity, compectness and adhesion of film, and nano-class granularity.

Owner:SUN YAT SEN UNIV

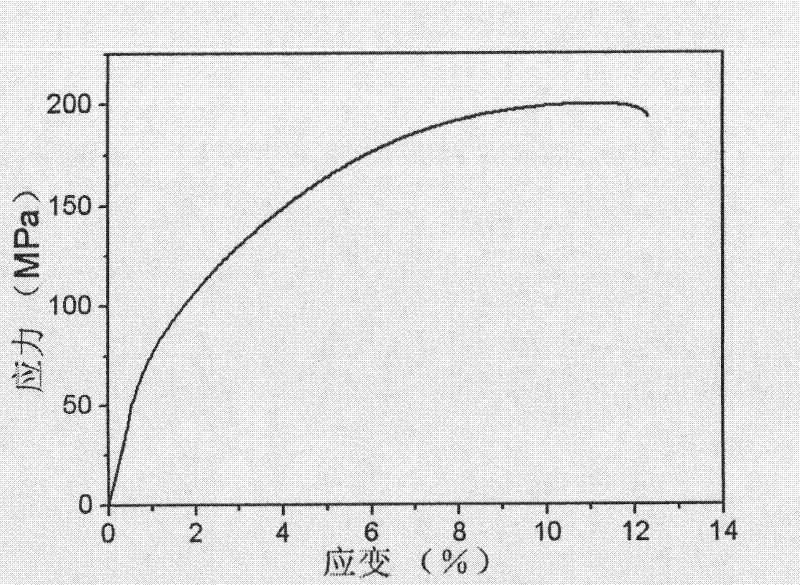

Magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium

InactiveCN103469039AGood casting performanceImprove antioxidant capacityRare earthThermal deformation

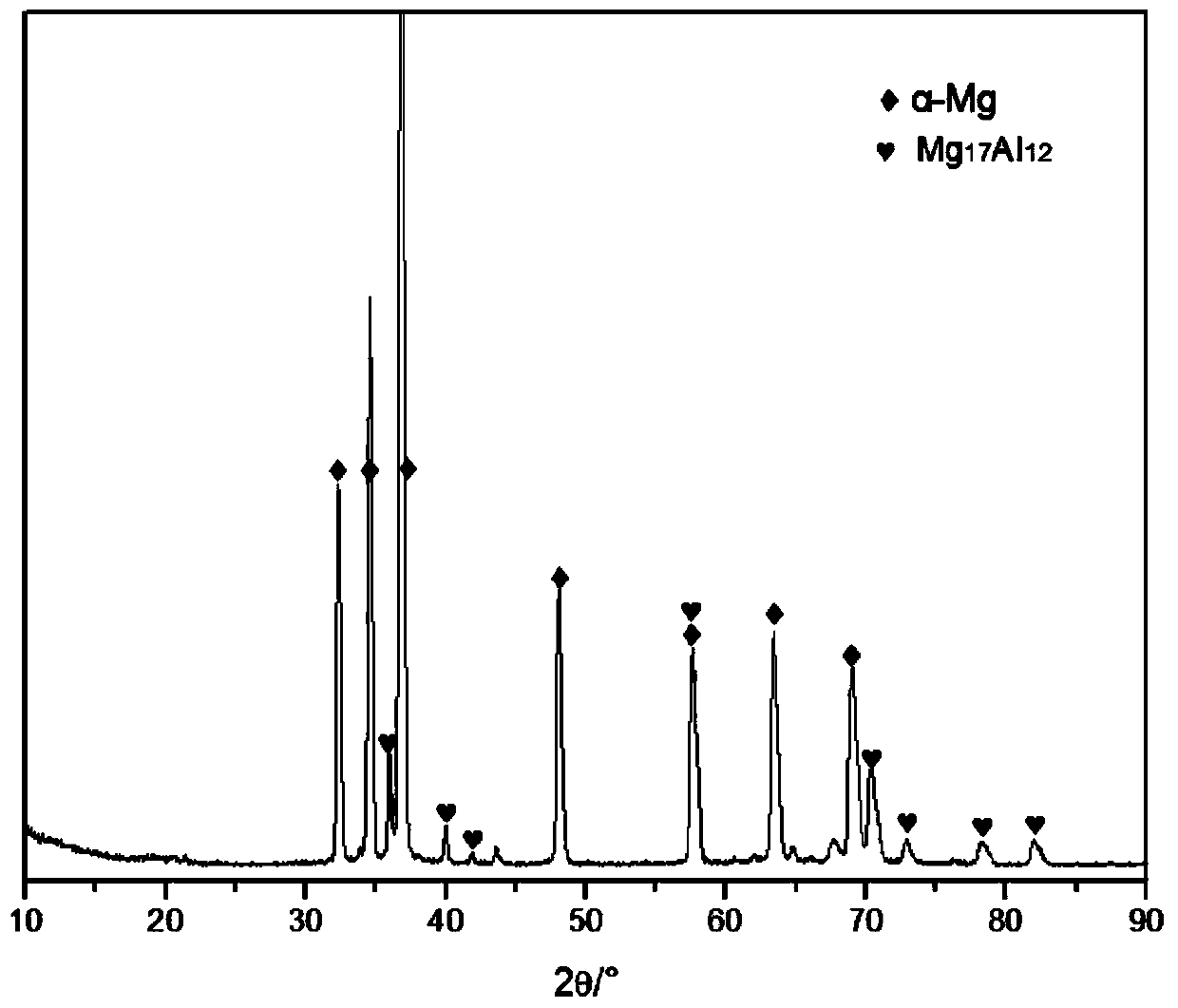

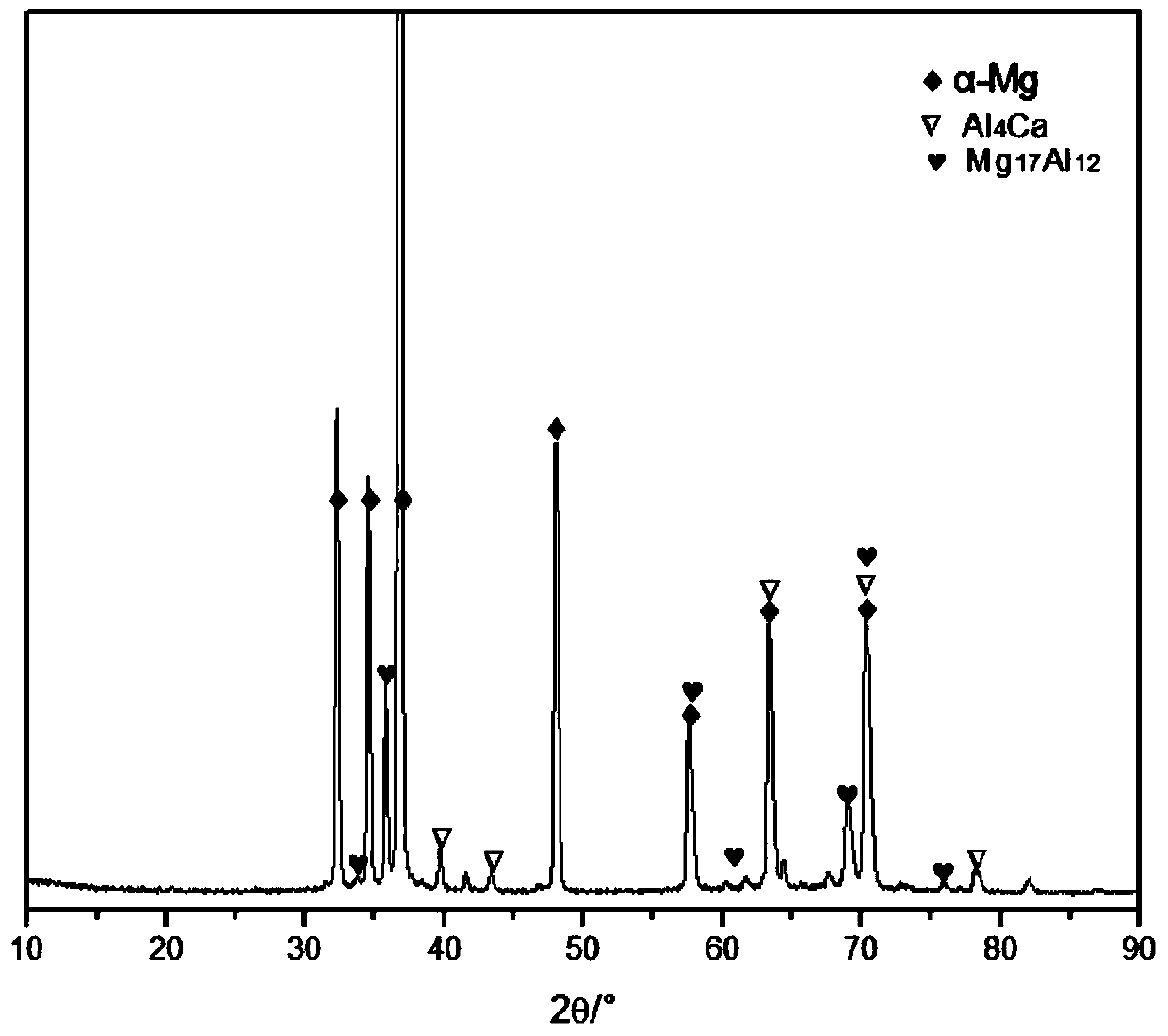

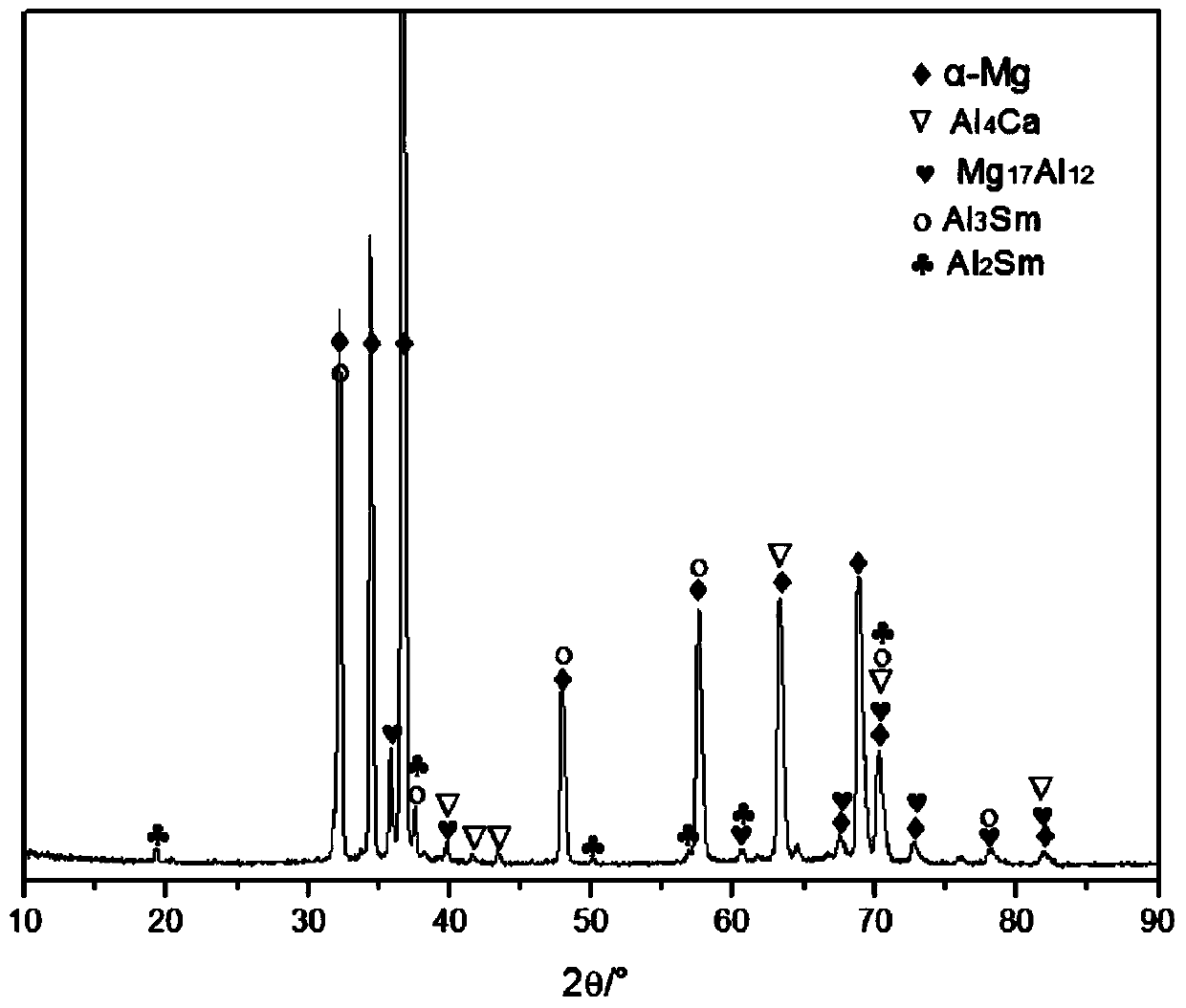

The invention relates to a magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium. The wrought magnesium alloy comprises the following components by mass percent: 5.3% to 6.0% of Al (aluminum), 0.7% to 1.0% of Zn (zinc), 0.4% to 0.5% of Ca (calcium), 0.2% to 1.5% of Sm (samarium), less than or equal to 0.15% of inevitable impurities and the balance of Mg (magnesium), wherein all the components taken as raw materials in proportion are fused and rapidly cooled in a salt bath; an obtained alloy spindle is annealed in a homogenization manner at 400 DEG C and air-cooled to reach a room temperature; then the hot extrusion is carried out on the alloy spindle at 360 DEG C according to the extrusion ratio being 25:1, so that the magnesium-aluminum-zinc wrought magnesium alloy containing the calcium and the rare-earth samarium is obtained. After the thermal deformation is carried out on the magnesium alloy, the tensile strength and the yield strength of the magnesium alloy are improved. Thus, the foundation for actual production applications of the wrought magnesium alloy is laid.

Owner:CHONGQING UNIV

High-strength wear-resistant copper alloy and preparation method thereof

The invention relates to a high-strength wear-resistant copper alloy which is characterized by being prepared from the following components in percentage by weight: 8.0-10.0% of nickel, 2.0-4.0% of tin, 1.5-3.5% of iron, 3.5-5.5% of aluminum, 0.03-0.2% of lanthanum and cerium compound rare earth, less than or equal to 0.1% of inevitable impurities and the balance of copper. The preparation method comprises the following steps: proportioning; casting; heating; extruding; annealing; and obtaining a finished product. According to the high-strength wear-resistant copper alloy provided by the invention, a principle of multiple elements in small amounts is adopted, so that the comprehensive mechanical property and wear resistance of the copper alloy are finally improved by virtue of adding elements such as nickel, tin, iron, aluminum and rare earth. Meanwhile, the good processing performance of the alloy is guaranteed. The alloy is a lead-free copper alloy material which is free from damage to the environment and a human body in production and use and has excellent cold and hot forming property, excellent mechanical property, good corrosion resistance and high strength and wear resistance. Furthermore, the copper alloy is simple in production process and easy to operate, and can be used for realizing large-scaled production. The copper alloy is especially suitable for wear-resistant parts such as cylinders, copper sleeves and bearing bushes under low-speed heavy-load work.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

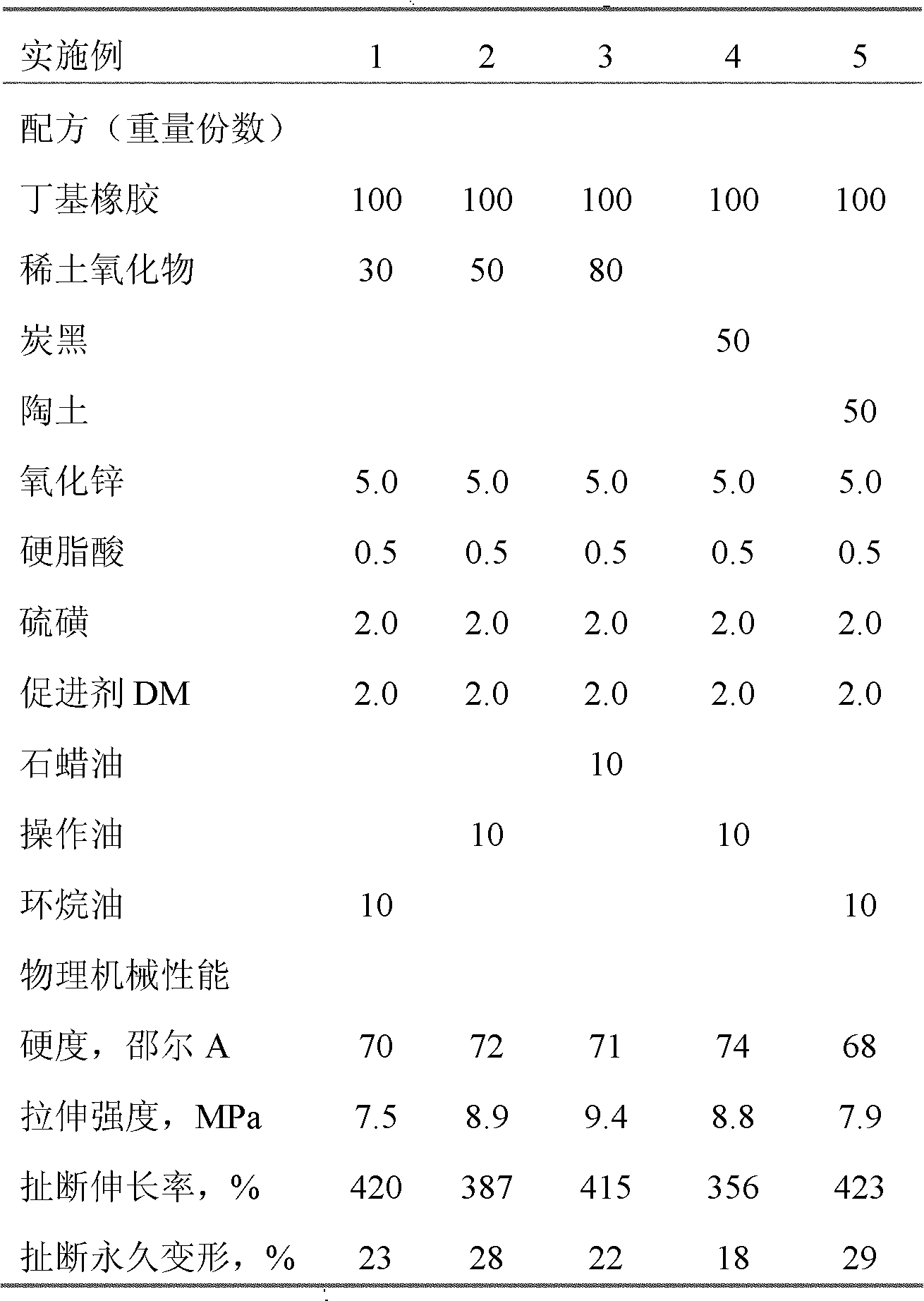

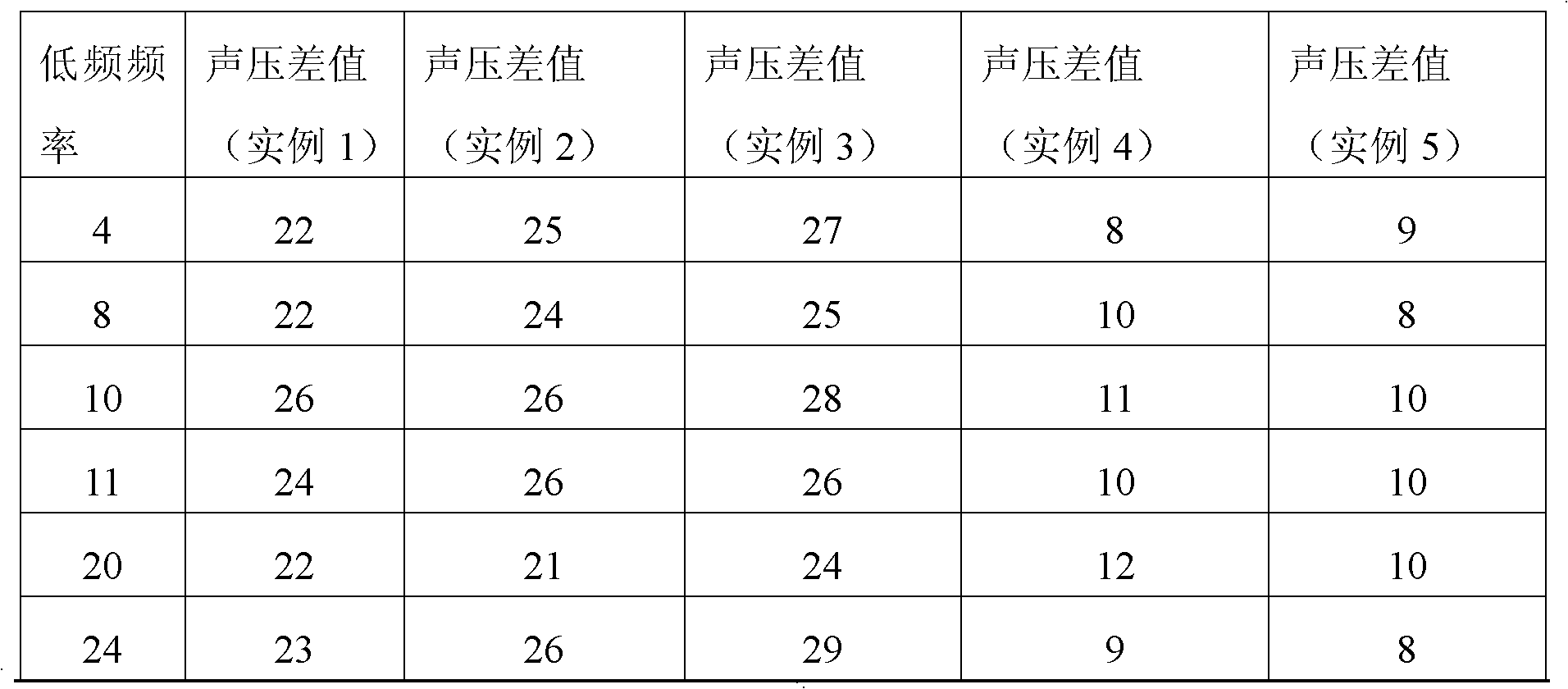

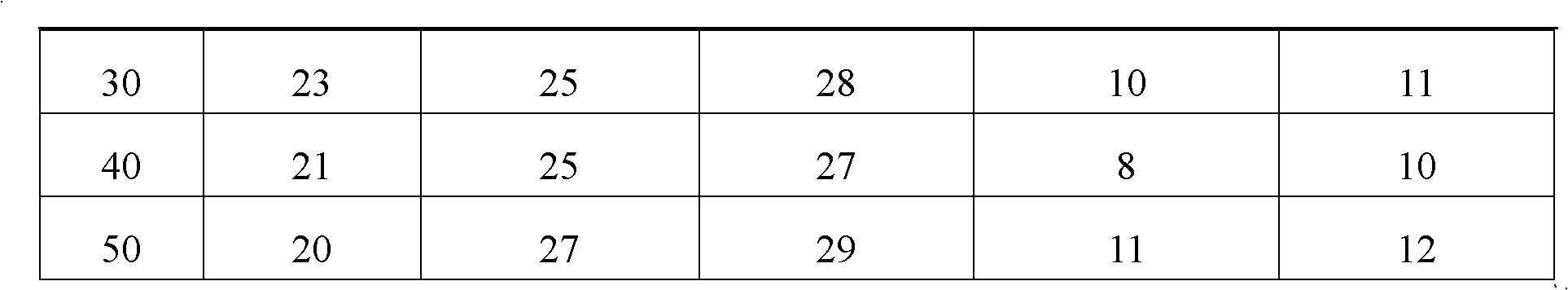

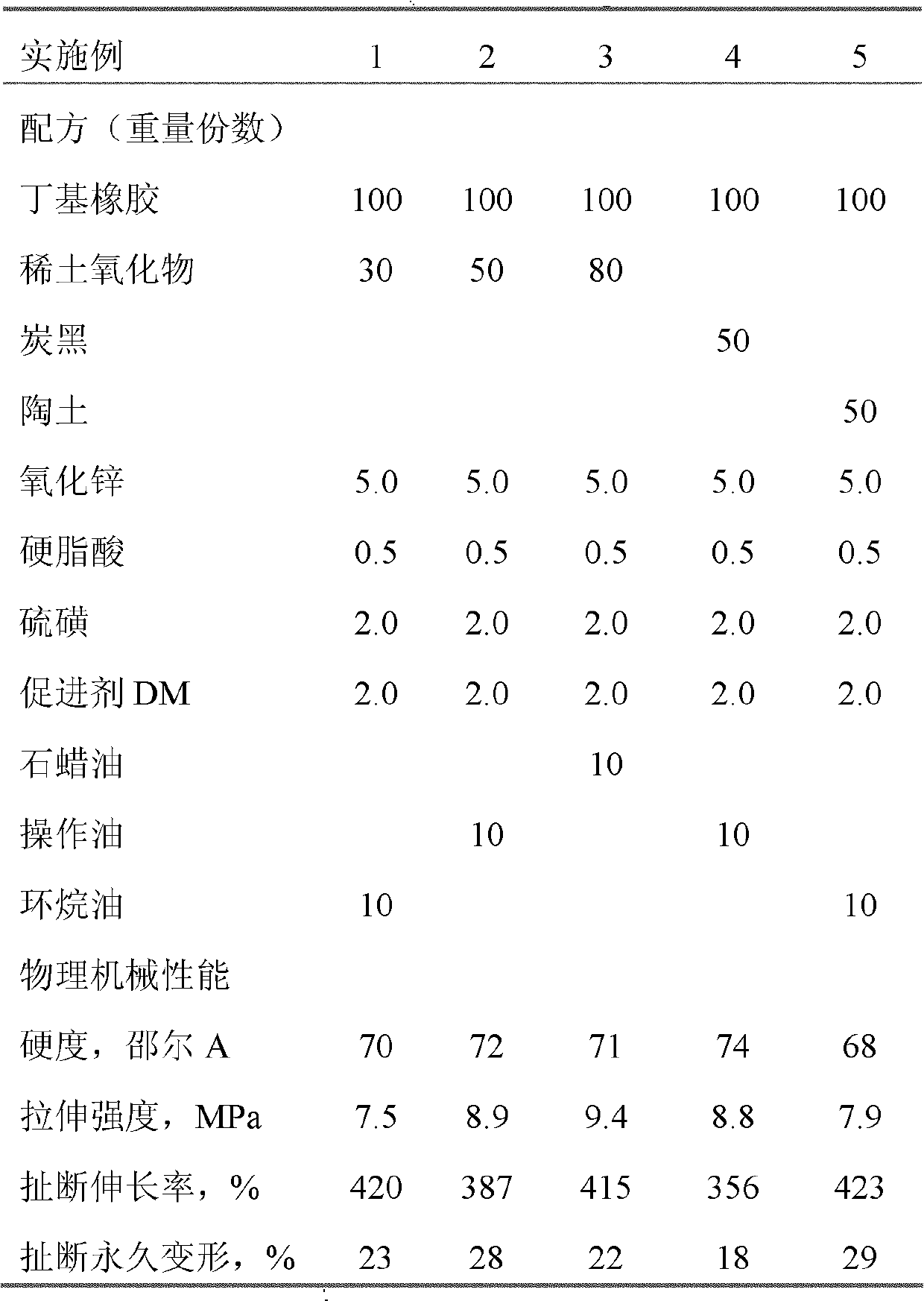

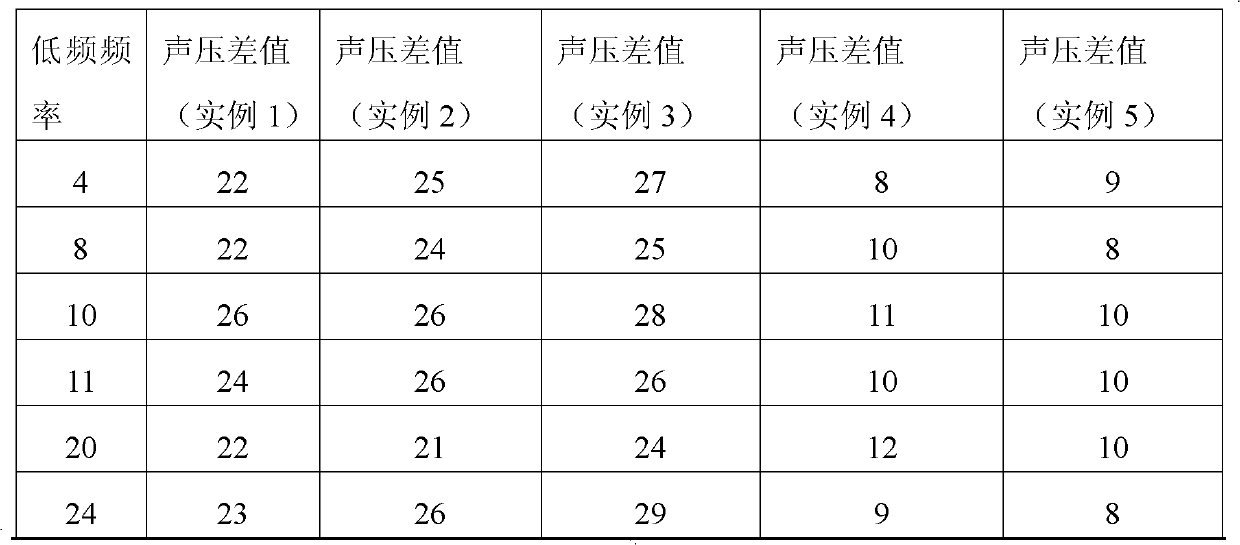

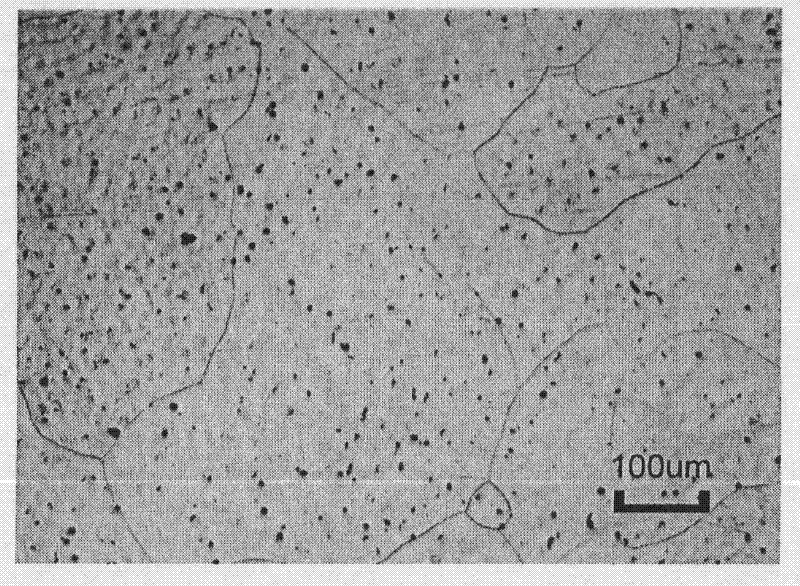

Method for preparing rare-earth oxide/rubber composite material for low-frequency sound absorption

The invention relates to a method for preparing rare-earth oxide / rubber composite material for low-frequency sound absorption, which comprises the following steps of: 1) pretreating rare-earth oxides; 2) selecting raw materials; 3) adding the pretreated rare-earth oxides, rubber, zinc oxide, stearic acid, sulfur, a softener and benzothiazole disulfide into an internal mixer or an open mill sequentially for mixing to obtain mixing rubber; and vulcanizing the mixing rubber to obtain the rare-earth oxide / rubber composite material for the low-frequency sound absorption. The method has the advantages that: 1, the mechanical property of the composite material is improved; 2, the rare-earth oxide / rubber composite material is lighter than concrete and heavy metal plates; 3, a process is simple, and the production cost is low; and 4, the method is favorable for improving the flow property and machinability of the rare-earth oxide / rubber composite material.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

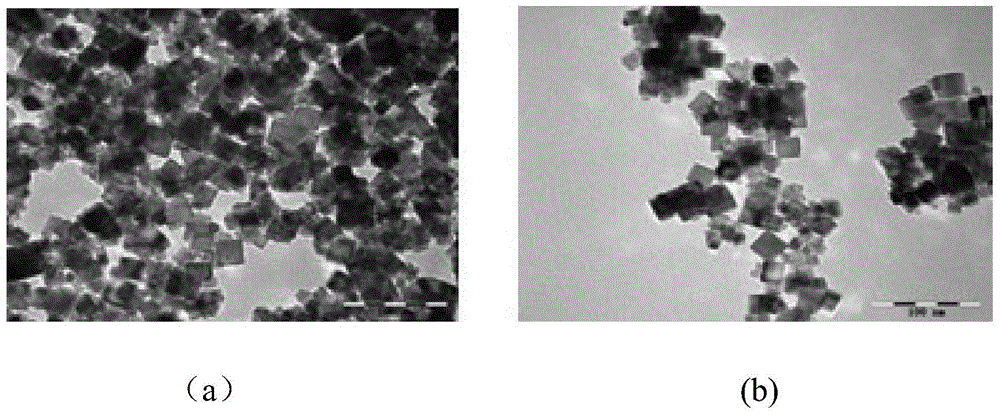

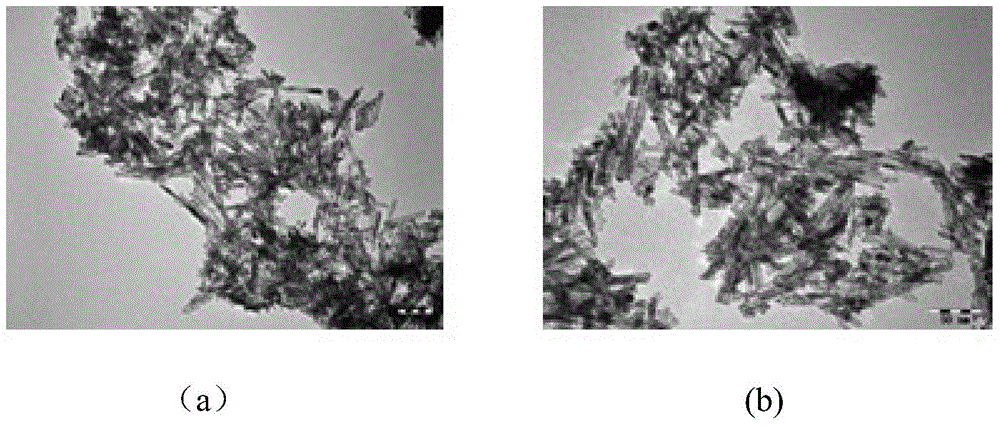

Denitration catalyst employing shape effect for enhancing low temperature activity, preparation method and application thereof

InactiveCN105664924AReduce and avoid poisoningExtended service lifeGas treatmentDispersed particle separationPtru catalystGlass furnace

The invention discloses a preparation method of a denitration catalyst employing shape effect for enhancing low temperature activity, which belongs to the technical field of control of atmosphere pollution. The method comprises the following steps: 1) weighing a CeO2 carrier and dissolving the CeO2 carrier in deionized water, weighing a manganous nitrate solution according to a mol ratio of Mn to Ce being 1.5:5-2:5, dumping the weighed CeO2 carrier in the manganous nitrate solution to obtain reaction liquid; 2) evaporating the reaction liquid under oil bath to dryness, then placing the material in a roasting oven for drying the material at the temperature of 105-115 DEG C to obtain a dried material; and 3) calcinating the dried material in a muffle furnace at the temperature of 395-405 DEG C for 3-4 hours to obtain the denitration catalyst employing shape effect for enhancing low temperature activity which takes CeO2 as the carrier. The invention also discloses the catalyst prepared by the method and an application thereof. The denitration catalyst has the advantages of good low temperature activity, high selectivity and wide activity temperature window. The preparation method has the advantages of simple and controllable process, and convenient operation process, and can be used in tail ends of the flue gas purifying apparatus in fire coal power plants, cement plants, and glass kilns and furnaces. The preparation method has the characteristics of energy saving and environmental protection.

Owner:NANJING UNIV

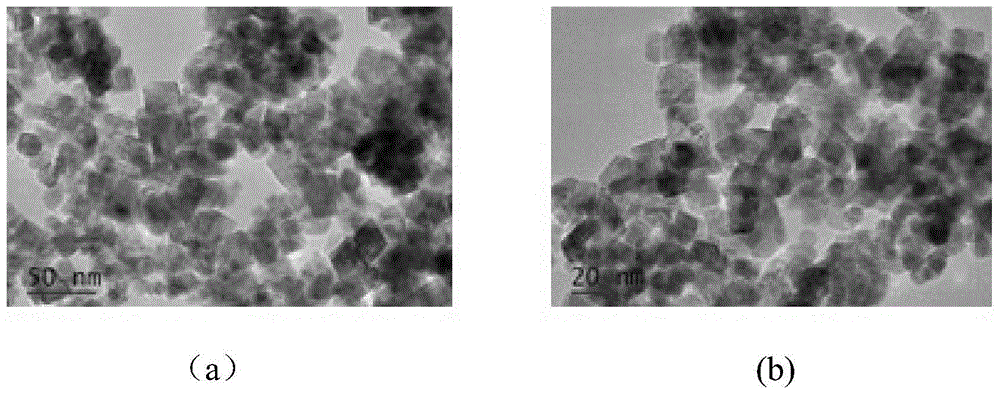

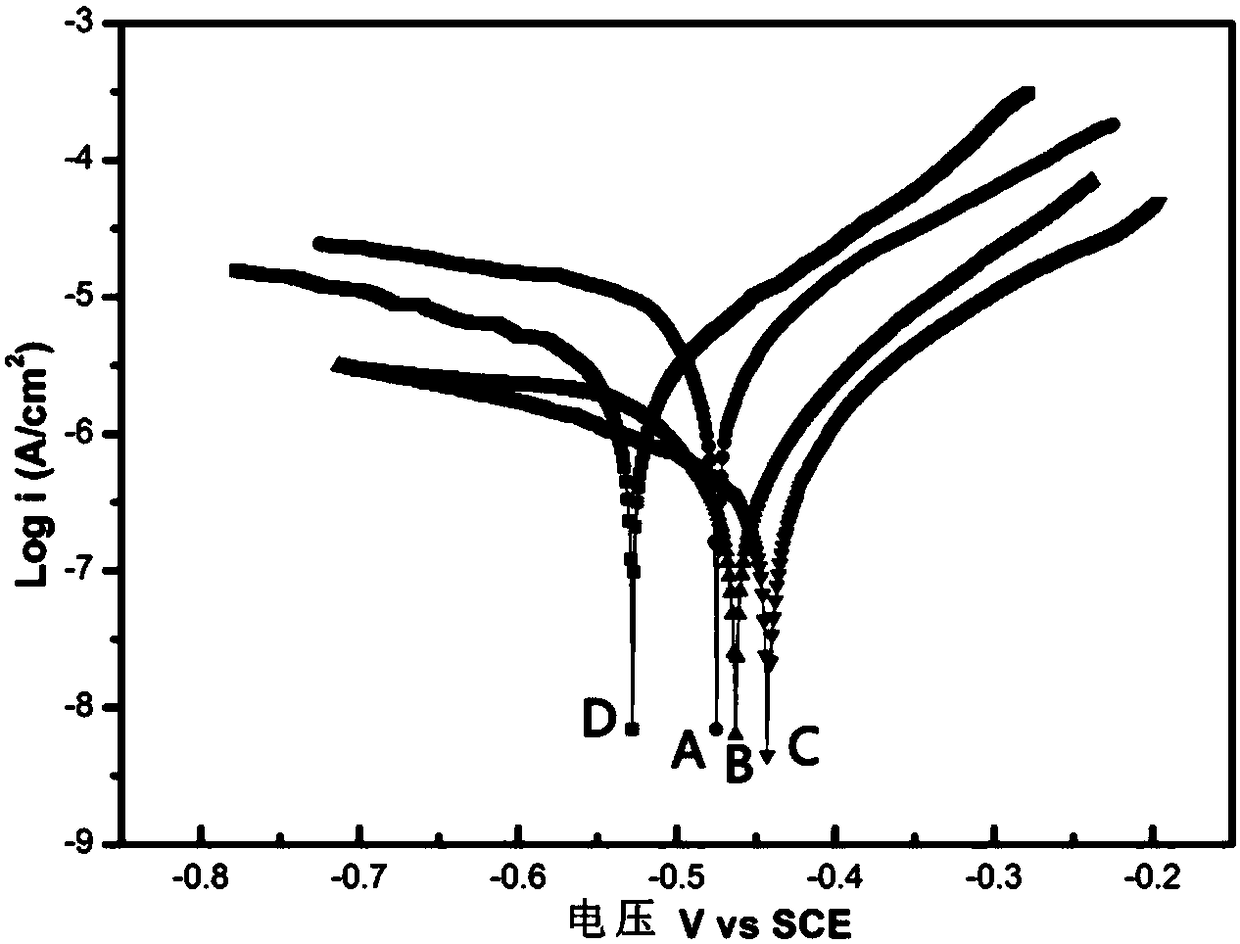

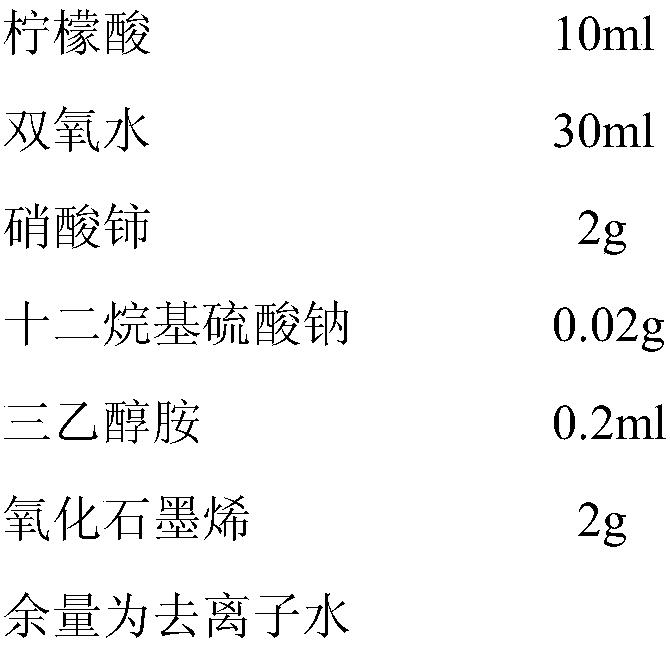

GO-doped environment-friendly passivator, and preparation method and application thereof

The invention disclosed a GO-doped environment-friendly passivator, and a preparation method and application of the GO-doped environment-friendly passivator. The GO-doped environment-friendly passivator per liter comprises 10-80 ml of citric acid, 20-80 ml of hydrogen peroxide, 2-5 g of cerous nitrate, 0.01-0.1 g of lauryl sodium sulfate, 0.1-0.5 ml of triethanolamine, 1-5 g of graphene oxide, andthe balance deionized water. The environment-friendly passivator does not contain chromic acid. A passive film with good corrosion resistance, oxidation resistance and stability can be formed on thestainless steel surface by adding a stainless steel workpiece into the passivator of 50-70 DEG C for passivating treatment for 20-50 minutes.

Owner:SHANGHAI INST OF TECH

Rare earth gluconate coordination compound fish bait additive

InactiveCN1394521AImprove disease resistanceImprove survival rateAnimal feeding stuffInfrared lampRare earth

The chemical formula of said invented additive of fish bait is La(C6H11O7)3, where Ln=La, Ce, Pr, Nd and Sm; and its preparation method includes the following steps: adding water into rare earth carbonate, stirring to make it into paste material; dissolving gluconic acid in water to prepare saturated solution, then adding the aqueous solution of gluconic acid into the rare earth carbonate paste, stirring them under the condition of 40-50 deg.C, until it has no escaped bubble, continuously reacting for 30-50 min to obtain fuel reaction, then evaporating and concentrating to separate out product, filtering, natural drying in the air or drying under the infrared lamp so as to shorten drying time. Its product rare earth glucontate coordination compound yield can be up to 92.6-94.3%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

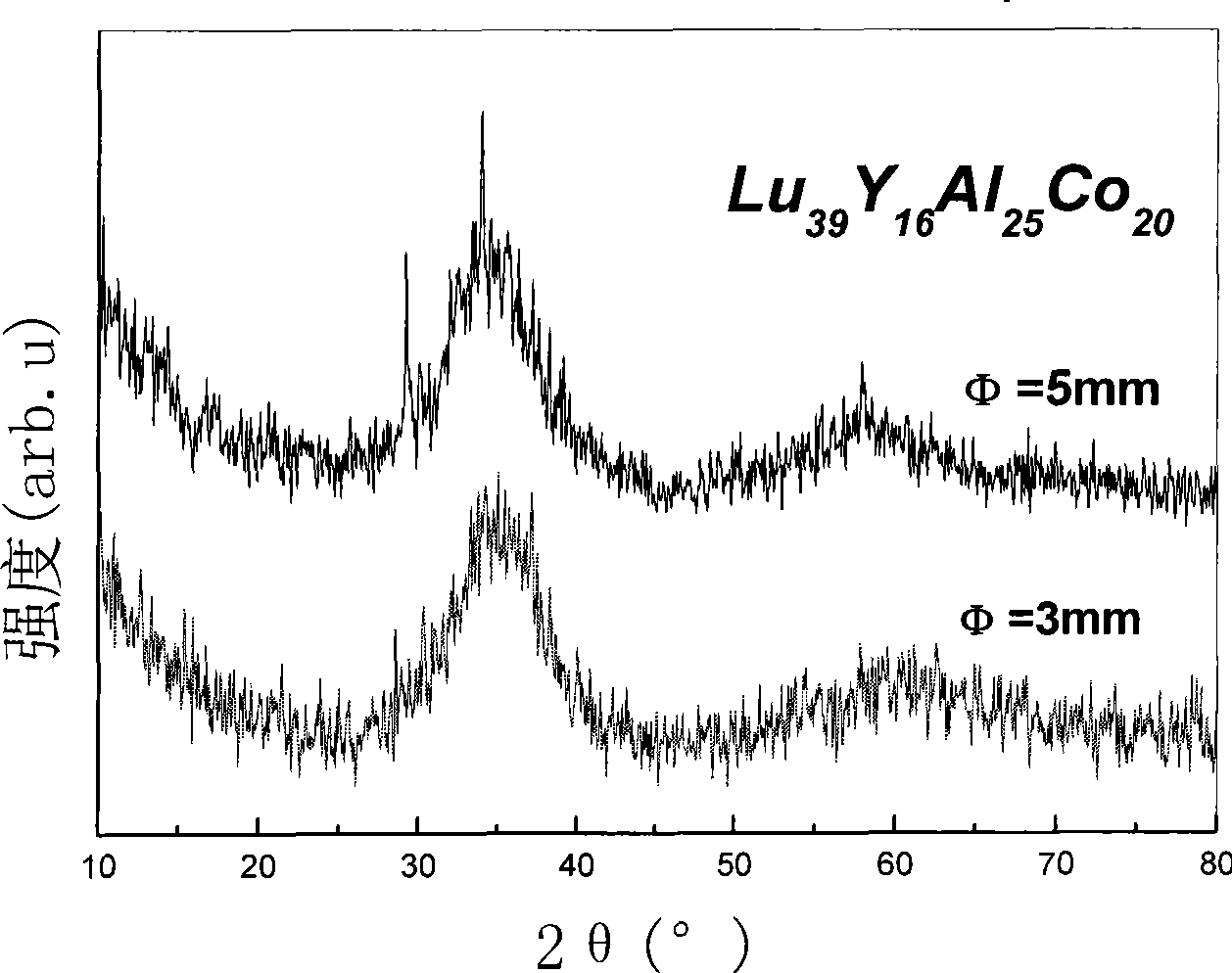

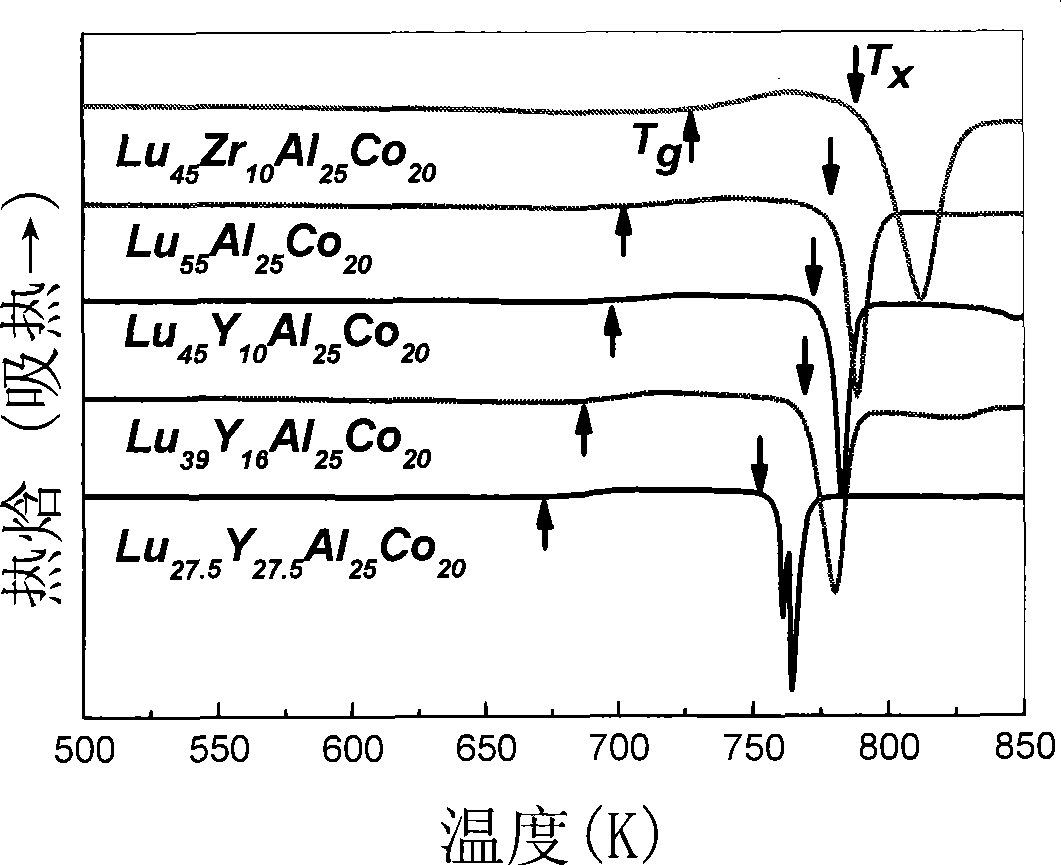

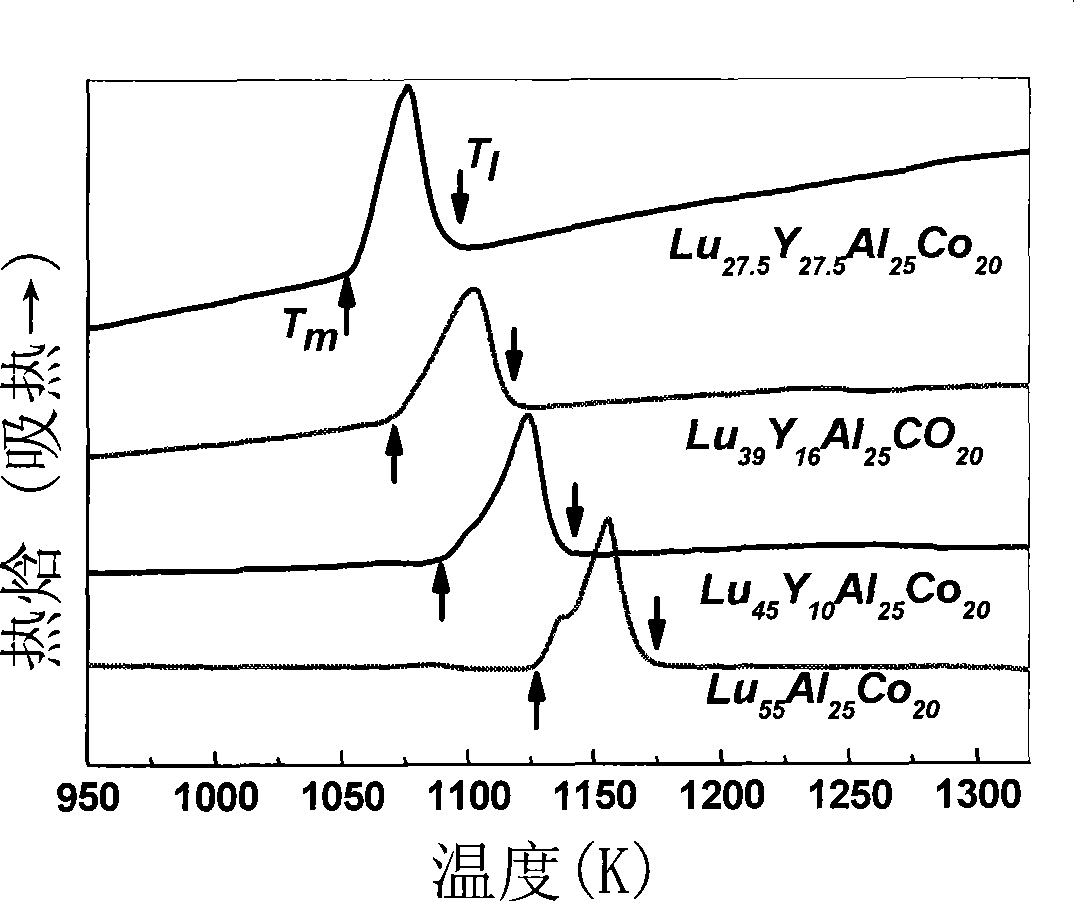

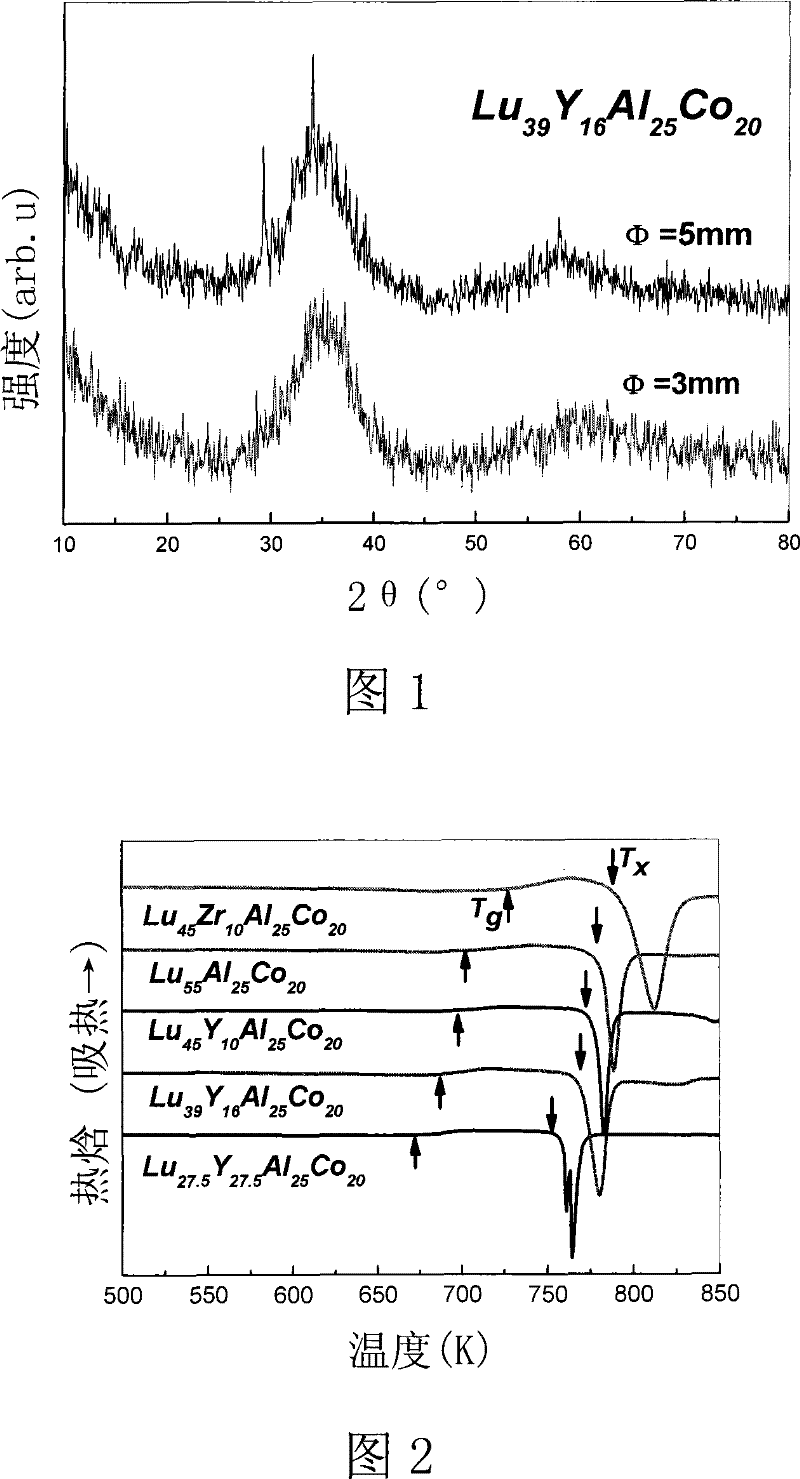

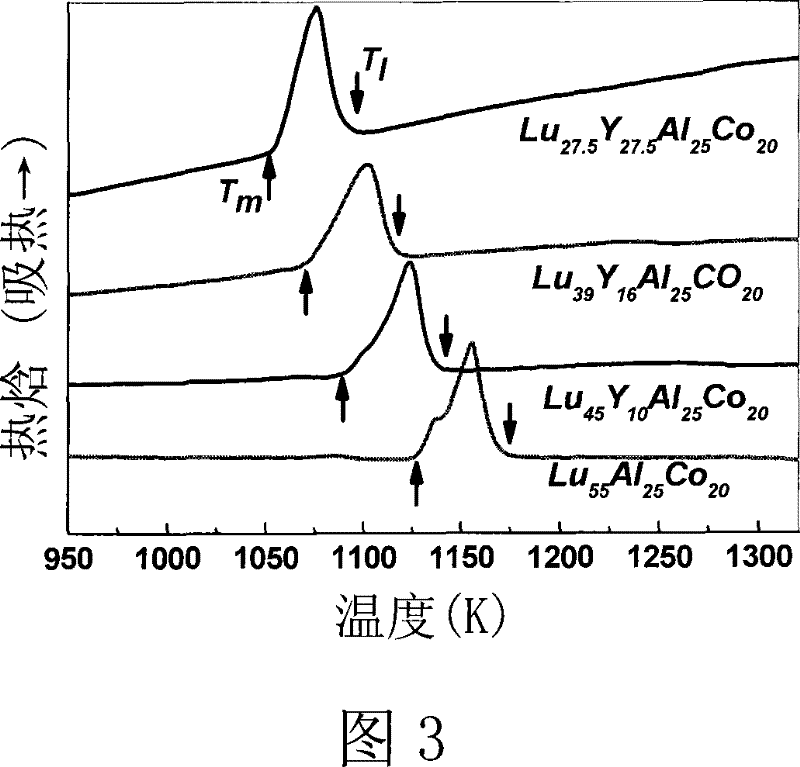

Lutetium based bulk amorphous alloy and preparation thereof

InactiveCN101497973AImprove the ability to formLow critical cooling rateLutetiumElectric arc furnace

The invention relates to a lutetium-based block amorphous alloy which takes lutetium as major components and contains at least 50 percent of amorphous phase according to percentages by volume, and the components of the lutetium-based block amorphous alloy are shown as in a formula I, wherein X is zirconium or / and yttrium, a is larger than or equal to 20 and less than or equal to 60, b is larger than or equal to 0 and less than 30, c is larger than or equal to 20 and less than 30, d is larger than or equal to 10 and less than 30, and in addition, a plus b plus c plus c plus d equals 100. A preparation method of the lutetium-based block amorphous alloy comprises the following steps: the components are molten according to required atomic proportions in an electric arc furnace with titanium-absorption argon atmosphere to obtain a master alloy cast ingot; the master alloy cast ingot is remolten by a conventional metal mold casting method, and melts are sucked into a water-cooling copper mould by a suction casting device in the electric arc furnace to obtain the lutetium-based block amorphous alloy. The invention has strong crystallization-inhibited capacity, simple preparation and lower cost and is easy to form large-size amorphous alloy. And the formula I is LuaXbAlcCod.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

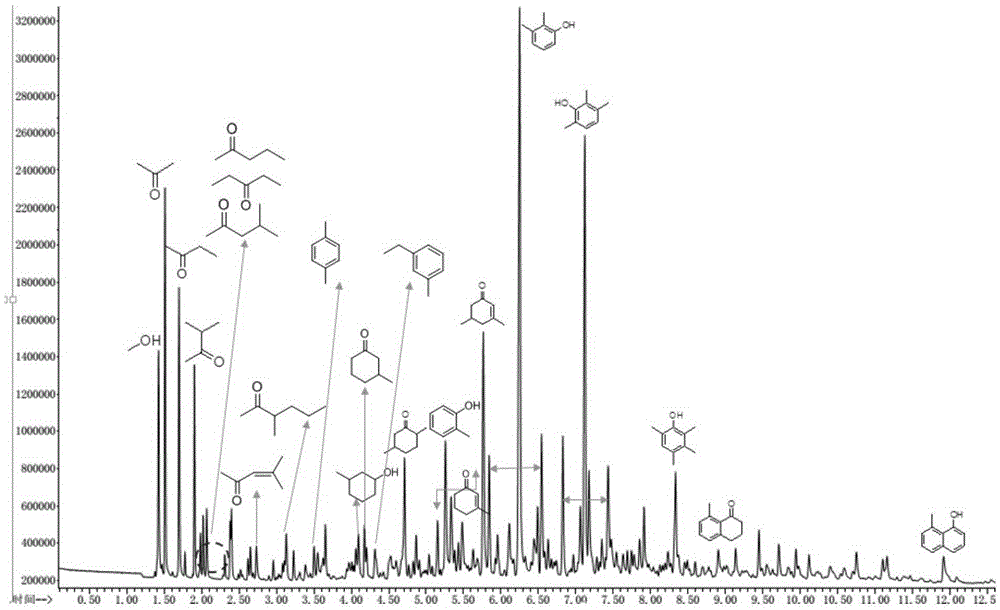

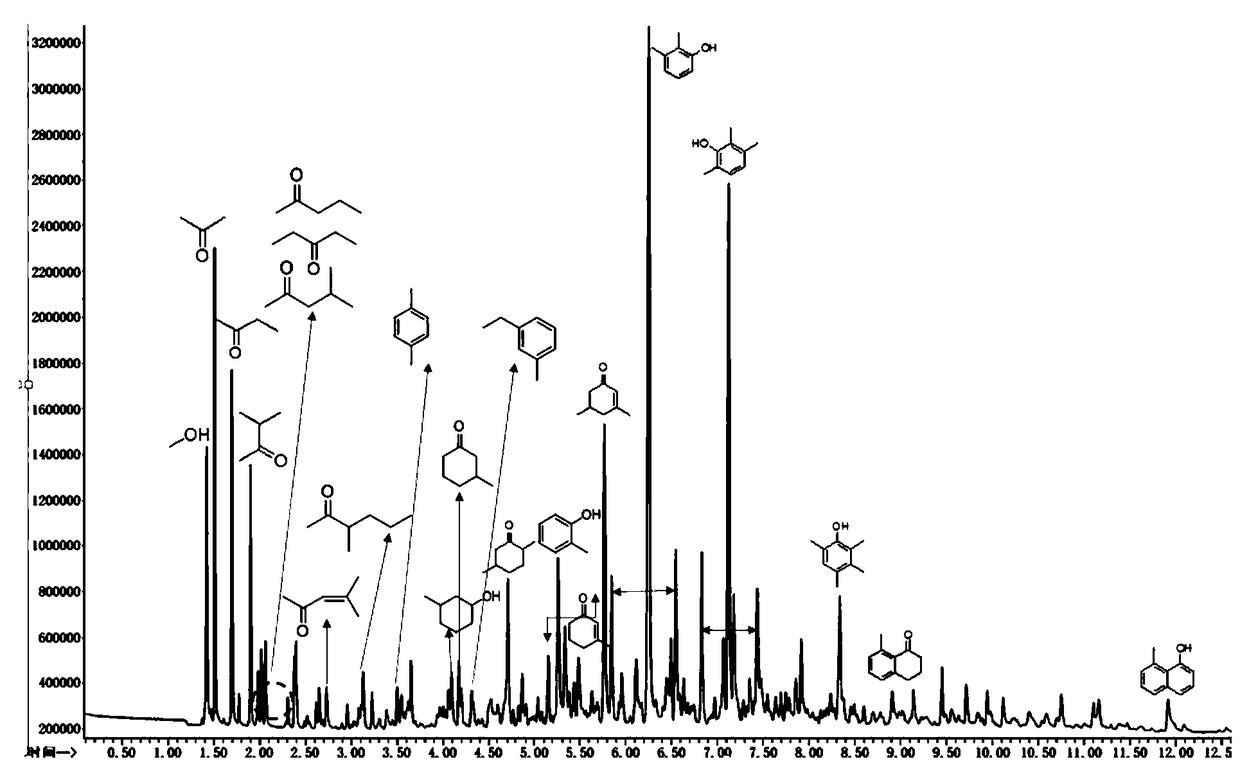

Method for preparing phenol compound

ActiveCN106518627AAvoid dependencyWide variety of sourcesOrganic chemistryOrganic compound preparationAcetic acidAlcohol

The invention relates to a method for preparing a phenol compound. According to the method, acetic acid and methanal, or acetic acid, methanal and methyl alcohol are adopted as reactants, and th phenol compound is prepared under the catalytic effect of cerium dioxide (CeO2). Reaction is conducted in a fixed bed reactor under normal pressure with the reaction temperature being 300-550 DEG C. According to the method, the reaction conversion percent is high, the maximum reaction conversion percent reaches 100%, and the overall selectivity of the phenol compound reaches 85%; and in addition, the CeO2 is selected as the catalyst which is low in cost, easy to prepare, high in efficiency and capable of being regenerated through calcination and carbon deposit removal, and the method has potential application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rare earth modified full non-lead X-ray screen rubber

InactiveCN1314052CIdeal X-ray shielding performanceImprove mechanical propertiesShieldingX-rayRare earth

The invention relates to a rare-earth modified all lead-free X-ray screening rubber, making surface modification processing on a part of the organic rare-earth and making organization reaction processing on the other part to prepare organic rare-earth salt, then adding them both to rubber in a certain proportion, so as to obtain the modified all lead-free X-ray screening rubber, making the screening property and mechanical property of the material achieve the desired effects. It can be widely applied to medical diagnosis X-ray machines, X-ray diffraction meters, and emitters of electron microscopes as well as the protection of working personnel on the occasions of generating X-rays.

Owner:BEIJING UNIV OF CHEM TECH

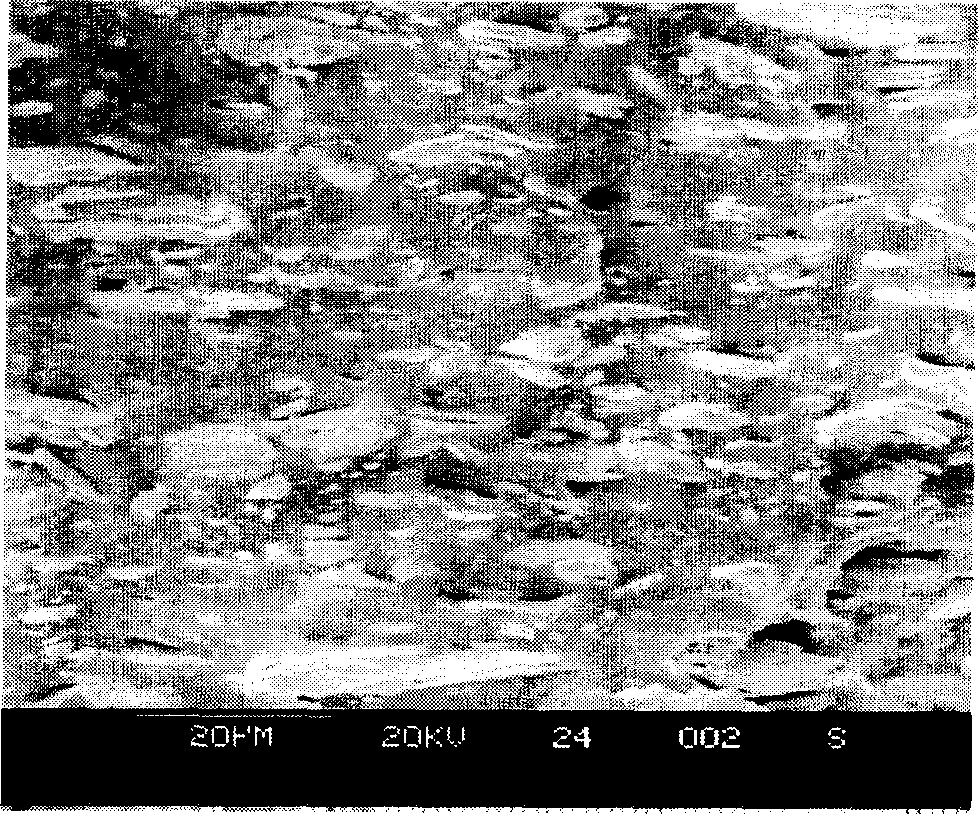

Nano crystal multiphase mixed rare earth-magnesium system hydrogen-storing alloy and its preparation method

InactiveCN1208487CHigh hydrogen storage capacityImprove cycle stabilityCell electrodesNickel accumulatorsRare earthShielding gas

The present invention relates to a nano crystal multi-phase mixed rear earth-magnesium system hydrogen-storing alloy and its preparation method. The preparation method of said alloy includes the following steps: smelting, homogenizing annealing, etc. and its smelting process is placing the La-enriched mixed rare earth, metal magnesium and metal nickel into an induction smelting furnace crucible according to a certain proportion, evacuating, charging protective gas, regulating power and temp. to melt metal, heat-insulating and fully stirring, injecting the molten metal into water-cooling ingotmould, cooling and discharging. Said alloy has anique components and multi-phase nano crystal structuer, and has good circulation stability.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing rare-earth oxide/rubber composite material for low-frequency sound absorption

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing rare earth alloy through sweeping electric potential sedimentation

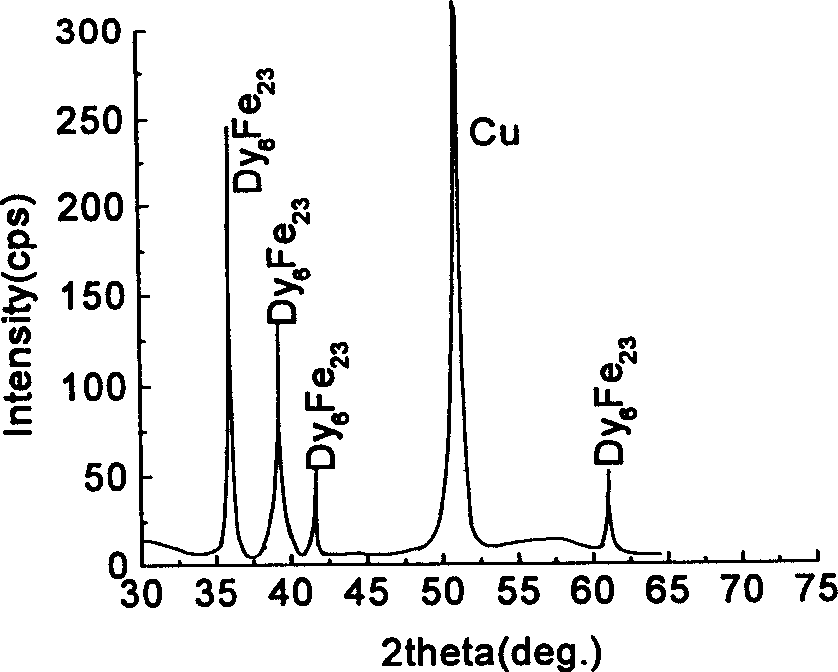

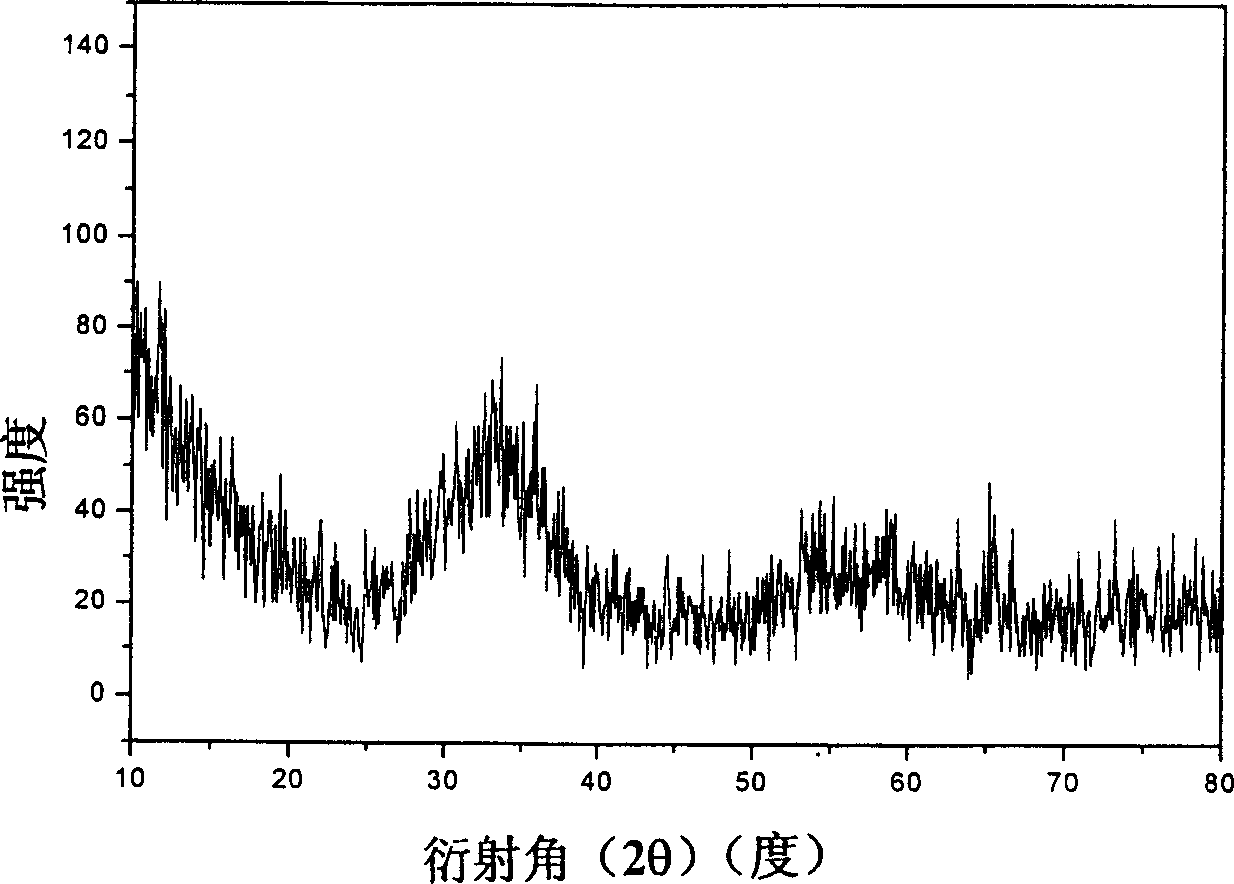

The invention relates to a method for preparing rare earth alloys in an organic solvent by means of a scanning potential deposition method. Use dimethyl sulfoxide or dimethyl formamide as solvent, rare earth nitrate and iron series chloride as the main salt, tartaric acid or citric acid as complexing agent, mix the main salt and complexing agent with the solvent according to the following concentration ratio Prepared into plating solution: rare earth nitrate 15~50.7g・L -1 , iron chloride 6~20g・L -1 , complexing agent 10~25g・L -1 ;Place the pretreated metal substrate in the above plating solution for plating; scan speed 2~100mV・s -1 , The operating temperature is controlled at 18-35°C, and the plating time is 10-35 minutes. The rare earth alloy film obtained by the method is uniform, dense and has good adhesion; compared with the constant potential and constant current scanning potential deposition method, the appearance and performance of the film are obviously improved. EDAX, SEM, X-ray diffraction and other techniques were used to characterize the rare earth alloy film, and it was found that the amorphous alloy film obtained by electrodeposition turned into a crystalline state after high temperature crystallization, and the average particle size was calculated to reach the nanometer level.

Owner:SUN YAT SEN UNIV

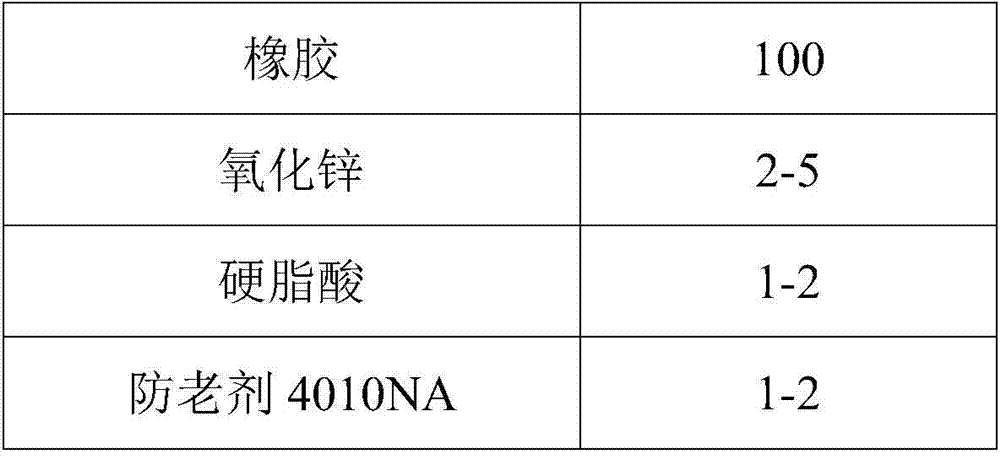

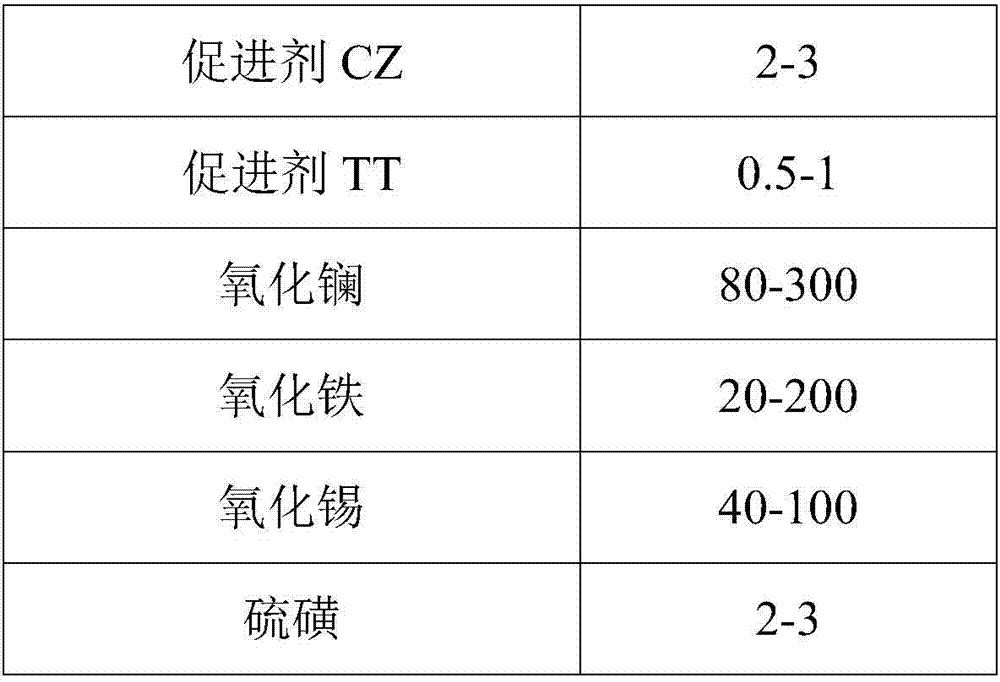

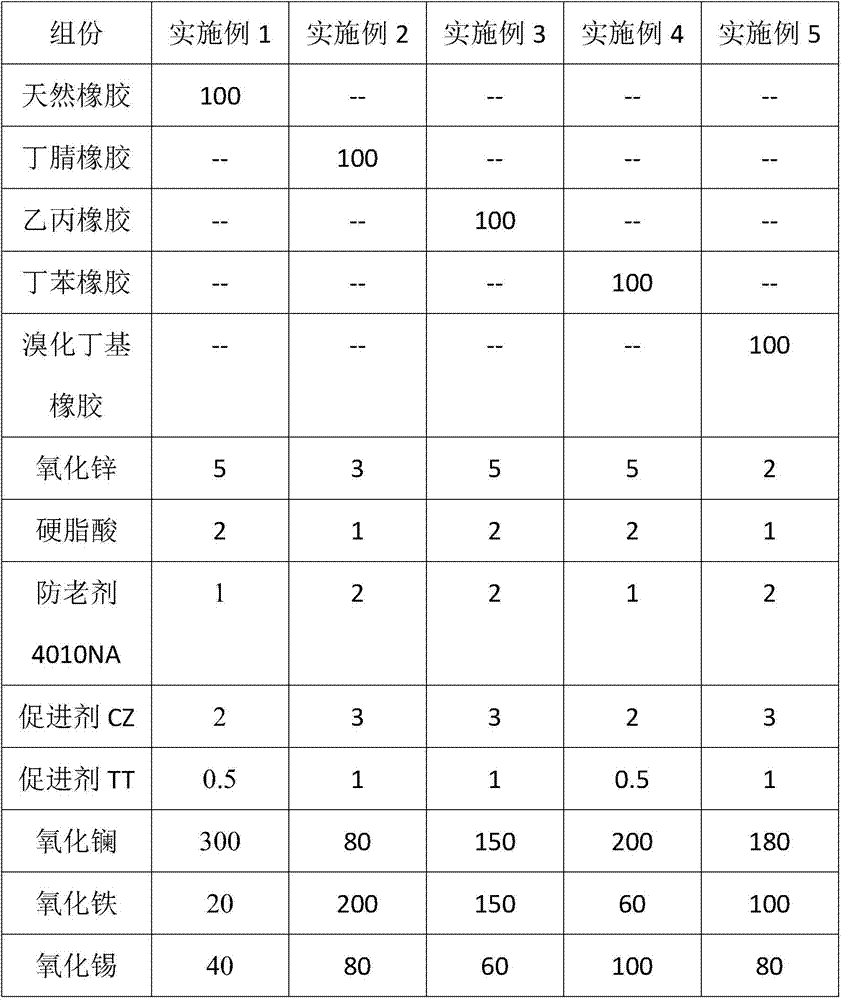

A low-voltage x-ray protective material

ActiveCN105602021BIdeal X-ray shielding performanceImprove mechanical propertiesPhysical chemistryStearic acid

The invention discloses a low-voltage X-ray protection material and belongs to the field of X-ray protection. The low-voltage X-ray protection material is mainly prepared from, by weight, 2-5 parts of rubber, 2-5 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of antiager 4010NA, 2-3 parts of promoter CZ, 0.5-1 part of promoter TT, 80-300 parts of lanthanum oxide, 20-200 parts of iron oxide, 40-100 parts of tin oxide and 2-3 parts of sulfur. According to the lead-free X-ray shielding rubber, the content of added mixed filler is large, high dispersity is achieved, and the X-ray shielding and mechanical properties of the material are ideal.

Owner:BEIJING UNIV OF CHEM TECH

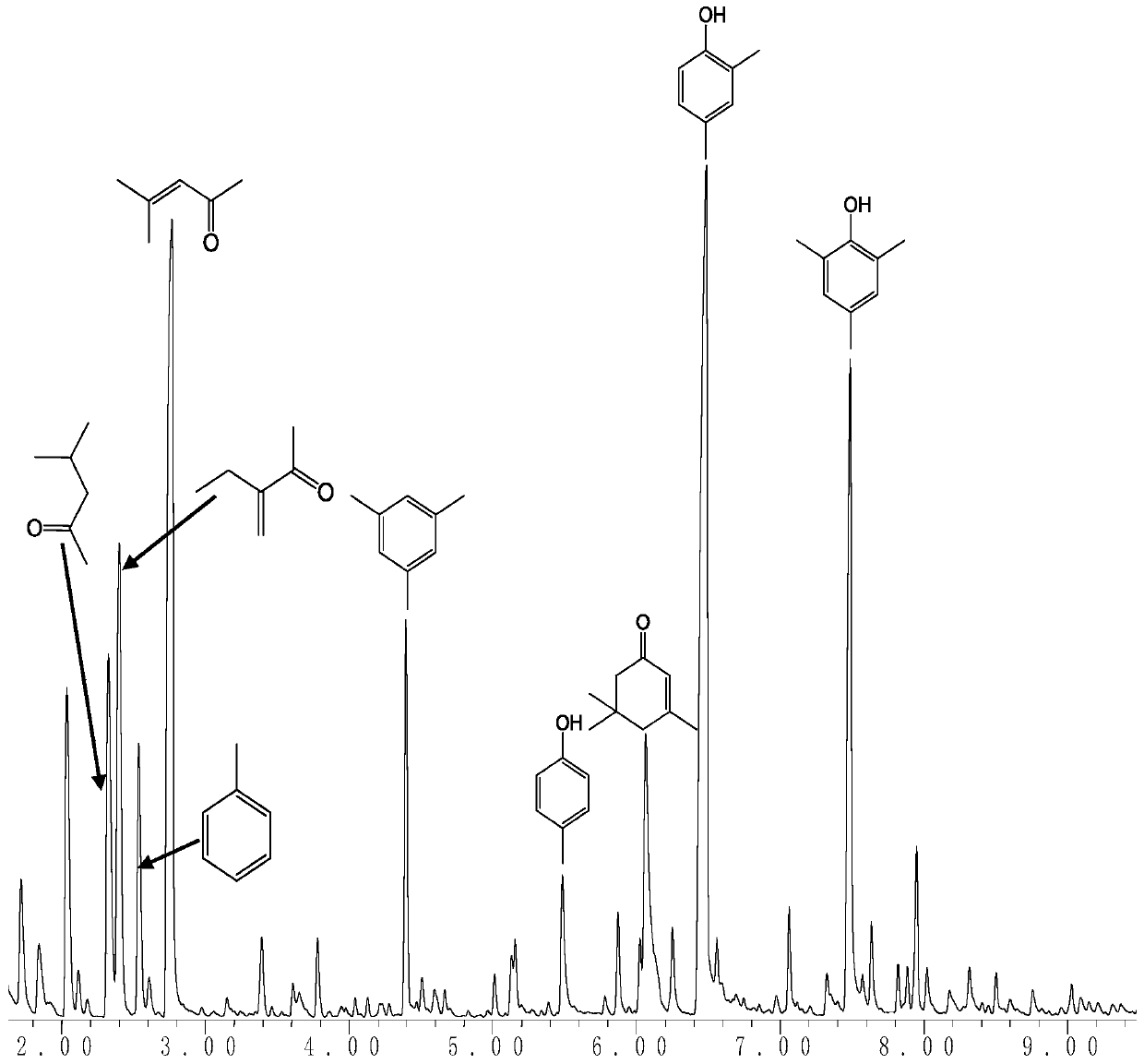

Method for preparing phenolic compounds by catalytic conversion of acetone with ceria

ActiveCN106431847BHigh reaction conversion rateEasy to makeOrganic chemistryOrganic compound preparationFixed bedReaction temperature

The invention relates to a method for preparing phenolic compounds by catalyzing acetone conversion with cerium oxide. The method uses acetone as a reactant, in ceria (CeO 2 ) under the catalysis of the preparation of phenolic compounds. The reaction conditions are as follows: the reaction is carried out in a fixed bed reactor under normal pressure, the reaction temperature is 340°C-450°C, and the feed rate of acetone is 0.01mL·min ‑1 ~0.1mL·min ‑1 , nitrogen as the carrier gas, the flow rate is 20mL min ‑1 ~80mL·min ‑1 After the reaction, the product composition was determined by mass spectrometry and quantified by chromatography. The method is characterized in that (1) the reaction conversion rate is high, and the total selectivity of phenolic compounds reaches 53%; (2) with CeO 2 As a catalyst, the catalyst is cheap, easy to prepare and high in efficiency, and can be regenerated after being calcined to remove carbon deposits, so it has potential application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

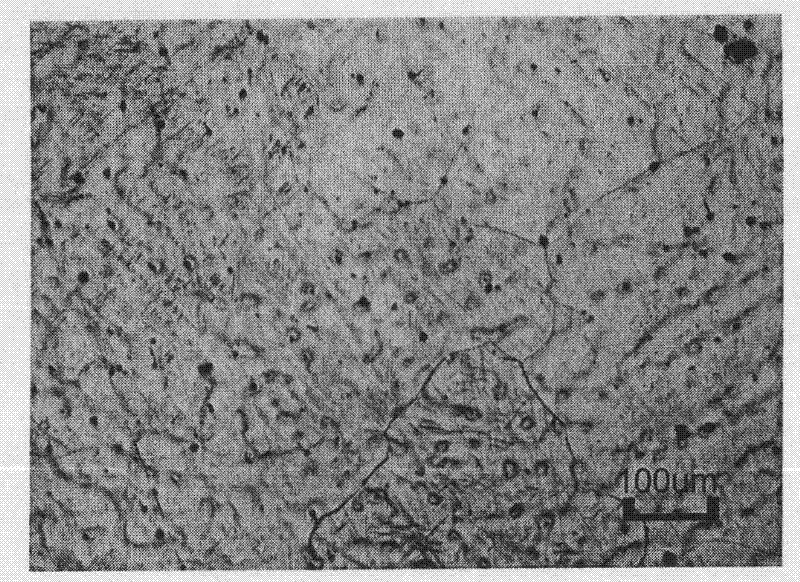

Gadolinium-base block amorphous alloy and its preparing method

This invention refers to a kind of Gd big amorphous alloy, whose main component is Gd. It also contains at least 50% by volume of amorphous phase, and its composition can be indicated by the formula below: GdaAlbNicCudMe. (50<=a<=80, 5<=b<=20, 5<=c<=20, 5<=d<=20, 0<=e<=15, a+b+c+d+e=100). The transitional subgroup metal element M said above is Sc, Nb, Ti, Cr, Mn, Fe, Co, Y, La, Pr, Nd or Hf. The alloy is made in arc furnace of argon atmosphere, and the argon is adsorbed by Ti. The components said above are melted in the arc furnace to get mother alloy cast ingot. Then the conventional metal casting method is used to molt the mother alloy cast ingot. After that, we use the inspiring-and-casting device in the arc furnace to inspire the bath into the water-cooling copper mould. At last, the alloy comes out. This alloy has the strong ability to suppress crystallization, so it is easy to form big amorphous alloy. Besides, it is easy to make and costs little. Also, the alloy has good magnetic performance and magneto-optic performance, so it can be used as function material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A kind of high-strength wear-resistant copper alloy and its preparation method

The invention relates to a high-strength wear-resistant copper alloy which is characterized by being prepared from the following components in percentage by weight: 8.0-10.0% of nickel, 2.0-4.0% of tin, 1.5-3.5% of iron, 3.5-5.5% of aluminum, 0.03-0.2% of lanthanum and cerium compound rare earth, less than or equal to 0.1% of inevitable impurities and the balance of copper. The preparation method comprises the following steps: proportioning; casting; heating; extruding; annealing; and obtaining a finished product. According to the high-strength wear-resistant copper alloy provided by the invention, a principle of multiple elements in small amounts is adopted, so that the comprehensive mechanical property and wear resistance of the copper alloy are finally improved by virtue of adding elements such as nickel, tin, iron, aluminum and rare earth. Meanwhile, the good processing performance of the alloy is guaranteed. The alloy is a lead-free copper alloy material which is free from damage to the environment and a human body in production and use and has excellent cold and hot forming property, excellent mechanical property, good corrosion resistance and high strength and wear resistance. Furthermore, the copper alloy is simple in production process and easy to operate, and can be used for realizing large-scaled production. The copper alloy is especially suitable for wear-resistant parts such as cylinders, copper sleeves and bearing bushes under low-speed heavy-load work.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

A kind of high manganese wear-resistant aluminum bronze alloy and preparation method thereof

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Tough antiflaming magnesium alloy and preparation method thereof

InactiveCN101787473BLow costImprove processing efficiencyGas emission reductionRare-earth elementCrucible

The invention discloses tough antiflaming magnesium alloy and a preparation method thereof. The alloy contains the following chemical constituents by weight percent: 5.0-12.0% of Gd, 0.5-3.0% of Er, 0-1.0% of Mn and 0-0.8% of Zr, the weight proportions of the limited impurity elements are Fe<0.005%, Si<0.05%, Cu<0.015% and Ni<0.002% and the allowance is Mg. The preparation method is as follows: preheating industrial pure magnesium in a crucible under the protection of N2 and SF6 to skim off the scum, adding corresponding Mg-Gd, Mg-Zr, Mg-Mn and Mg-Er intermediate alloys in batches, after the intermediate alloys are melted, adding refining agent for refining, and finally when the alloy liquid reaches the temperature of 720 DEG C, pouring the alloy liquid to a metal mold. By controlling the contents of the special rare earth elements, the invention enables the magnesium alloy to have high strength and toughness while being flame-retardant. The magnesium alloy can be prepared and processed under the condition of no flame retardancy protection and can undergo the processes of casting, die-casting, high-speed cutting and heat treatment directly under atmospheric environment.

Owner:BEIJING UNIV OF TECH

Location nitration process for chlorobenzene

InactiveCN1245374CEasy to recycleReduce the contrast ratioNitro compound preparationO-nitrochlorobenzeneRare-earth element

Chlorobenzene located nitrification method is a method for preparing nitro chlorobenzene of an intermediate in fine chemical industry, especially a method for improving the yield of o-nitro chlorobenzene by using water soluble Lewis acid to catalytically nitrifying chlorobenzene. The provided method comprises: nitric acid, chlorobenzene and water soluble Lewis acid catalyst are put into the 1,2-dichloroethane solvent to react at the temperature of 30C. to 100C. with the mol ratio of 1-3:1:0.01-0.15, and the reaction time is 3-30 hours, after cooled to room temperature, the mixture is washed by water, extracted by chloroform, dried in the rotary evaporator, separated by chromatographic column to obtain yellow oily liquid. The water soluble Lewis acid catalyst has the molecular formula as follows: Ln(OSO2CF3)3, wherein Ln is Sc or Y or La family rear earth element, or M(OSO2CF3)4, wherein M is Hf or Zr.

Owner:SOUTHEAST UNIV

Preparation of rare-earth oxide / natural rubber composite material for X radiation protection

InactiveCN101486809BEvenly dispersedImprove mechanical propertiesRadiation safety meansPigment treatment with non-polymer organic compoundsAbsorption capacitySulfur

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of method for preparing phenolic compound

ActiveCN106518627BAvoid dependencyWide variety of sourcesOrganic chemistryOrganic compound preparationAcetic acidAlcohol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing phenolic compounds

ActiveCN106518628BAvoid dependencyWide variety of sourcesOrganic chemistryOrganic compound preparationAcetic acidFixed bed

The present invention relates to a method for preparing phenolic compounds. The method adopts acetic acid, formaldehyde, or acetic acid, formaldehyde and methanol as reactants, and prepares phenolic compounds under the catalysis of doped ceria. 550°C, after the reaction, the product composition was determined by mass spectrometry and quantified by chromatography. The reaction conversion rate of the method of the present invention is high, the maximum conversion rate of the reaction reaches 100%, and the total selectivity of phenolic compounds reaches 95%; in addition, the present invention selects doped ceria as the catalyst, and the catalyst is cheap, simple to prepare and high in efficiency , can be regenerated by roasting to remove carbon deposits, and has potential application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lutetium-based bulk amorphous alloy and preparation method thereof

InactiveCN101497973BImprove the ability to formLow critical cooling rateLutetiumElectric arc furnace

The invention relates to a lutetium-based bulk amorphous alloy, which uses lutetium as the main component and contains at least 50% by volume of an amorphous phase, and its composition is shown in formula I, wherein: X is zirconium or / and yttrium, 20 ≤a≤60, 0≤b<30, 20≤c<30, 10≤d<30, and a+b+c+d=100. The alloy is prepared by smelting each of the above-mentioned components according to the required atomic ratio in an electric arc furnace with titanium adsorbing argon atmosphere to obtain a master alloy ingot; The ingot is re-melted, and the melt is sucked into the water-cooled copper mold by using the suction casting device in the electric arc furnace. The lutetium-based bulk amorphous alloy of the invention has strong ability to inhibit crystallization and is easy to form a large-sized amorphous alloy; moreover, the preparation is simple and the cost is low. Lu aX bAl cCo d (Formula I)

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Rare earth gluconate coordination compound fish bait additive

InactiveCN1185953CImprove disease resistanceImprove survival rateAnimal feeding stuffInfrared lampRare earth

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

REMg3 type hydrogen storage alloy and its preparation method

A hydrogen bearing REMg3 alloy has a molecular formula: RE1.2-xMg3Niy, where RE is rare-earth mixture, x=0-0.4 and y=0-1. Its preparing process includes proportionally loading RE, Mg and Ni in crucible of induction furnace, vacuumizing, filling protective gas, smelting and cooling.

Owner:SOUTH CHINA UNIV OF TECH

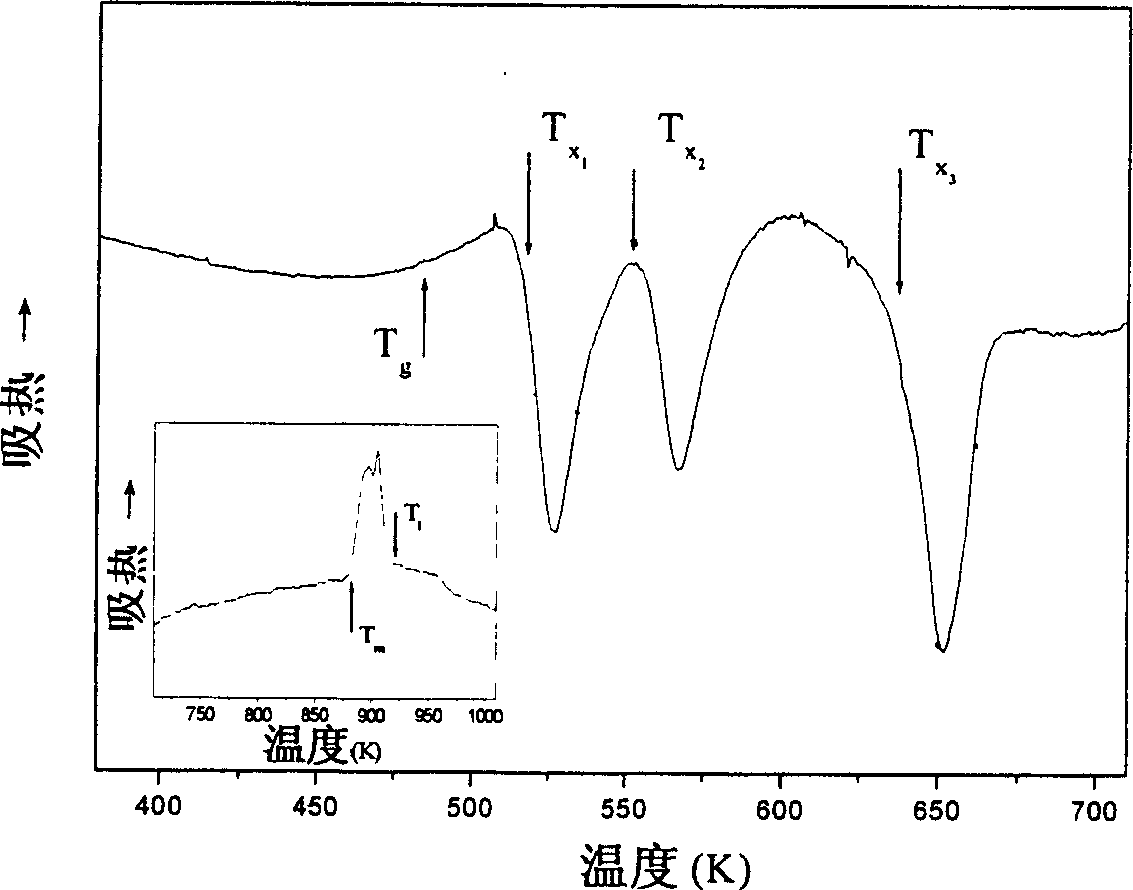

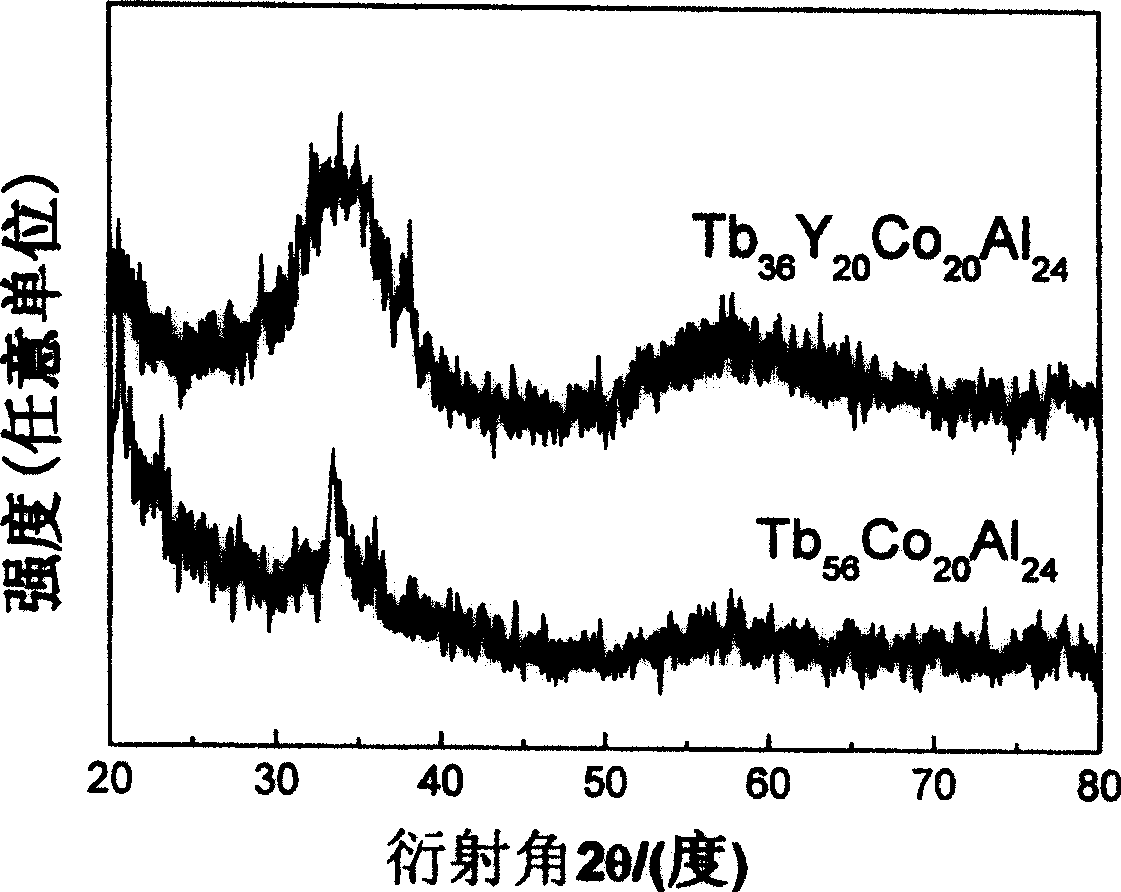

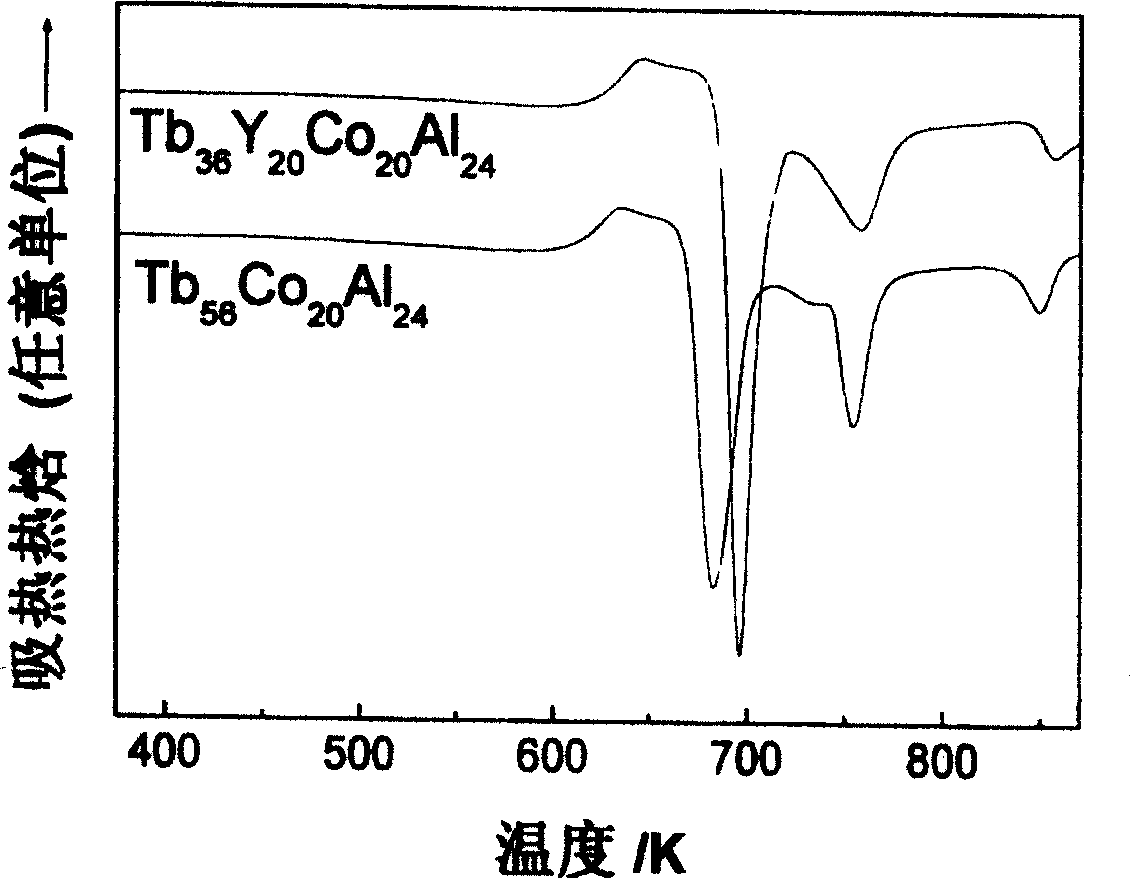

Terbium base noncrystal alloy and its preparing method

The present invention relates to a terbium base alloy, using terbium as main constituent. It is composed of TbaCobAlc or TbdCoeAlfYgMh; said M being transition group metallic element Sc, Nb, Ti, Cr, Mn, Fe, La, Pr, Ce or Nd..Every dimensionality of said terbium base bulk amorphous alloy dimension is not less than one mm, cut-off diameter not less than 3mm, having high glass forming ability, crystallization temperature at 650-700 k, glass transition temperature at 600-650 k,supercooling liquid field width at 25-75 k; having good magnetic characteristics and magnetostrictive property.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com