Method for preparing rare earth alloy through sweeping electric potential sedimentation

A rare earth alloy and deposition method, applied in the field of rare earth alloy preparation, can solve the problems of inability to precipitate on the substrate, rough adhesion of the alloy film, poor performance of the alloy film, etc., and achieve huge potential economic and social benefits. The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

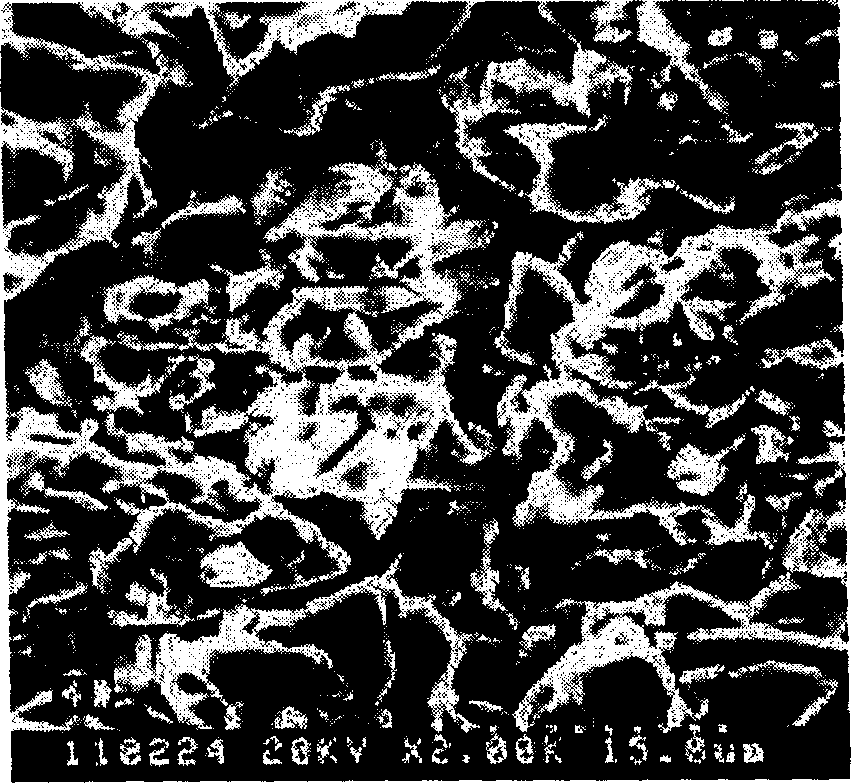

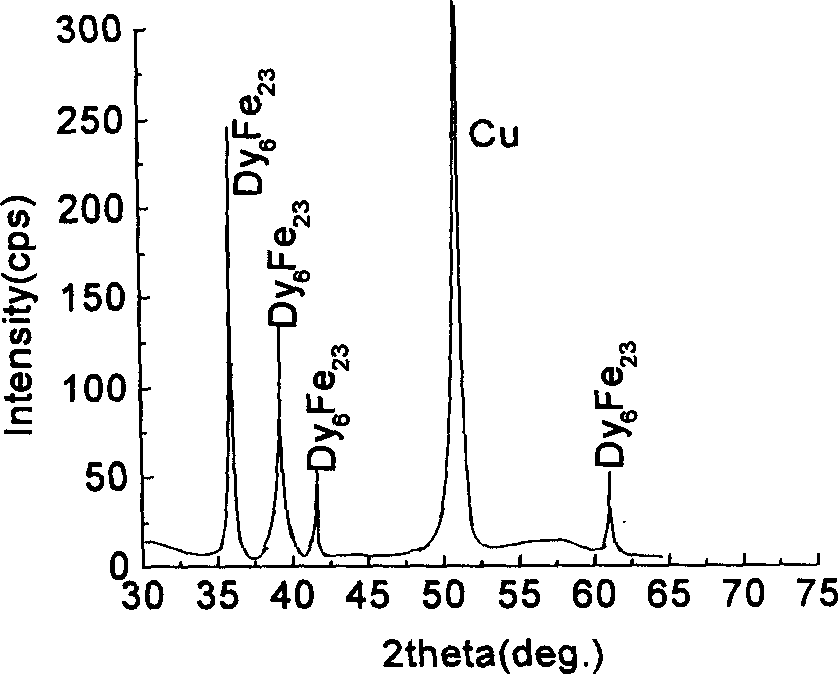

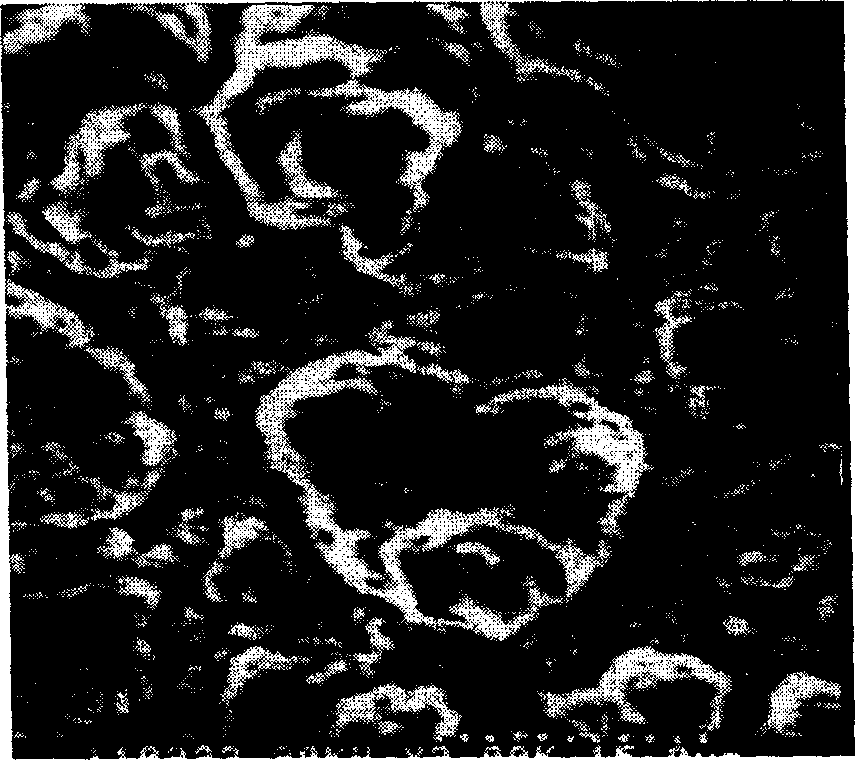

Image

Examples

Embodiment Construction

[0027] Table 1 shows the composition, content ratio and operating conditions of the plating solutions of Examples 1-15 of the present invention.

[0028] Reality

Shi

example

The concentration of each component in the plating solution (g L -1 )

operating conditions

Thulium nitrate

Europium nitrate

Ferrous chloride

scanning speed

(mV / s)

time

(min)

1

15

15

10.6

10

15

2

20

10.6

5

15

3

30

20

2

15

4

15

20

10.6

100

15

5

25

19.2

10.6

10

15

6

15

6.5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com