A low-voltage x-ray protective material

A light protection, low voltage technology, applied in the field of X-ray protection, can solve the problems of high chemical toxicity, high price, reduced use value, etc., and achieve the effects of rich rare earth resources, good application prospects and diverse varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

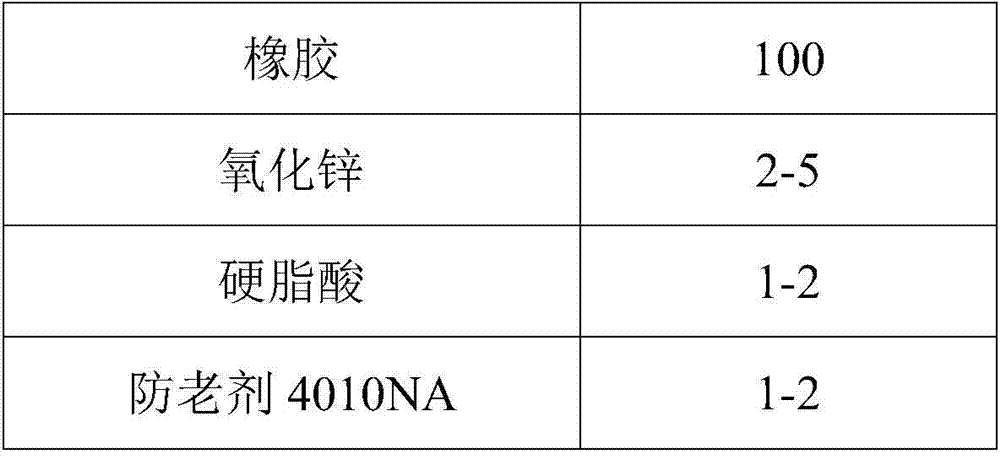

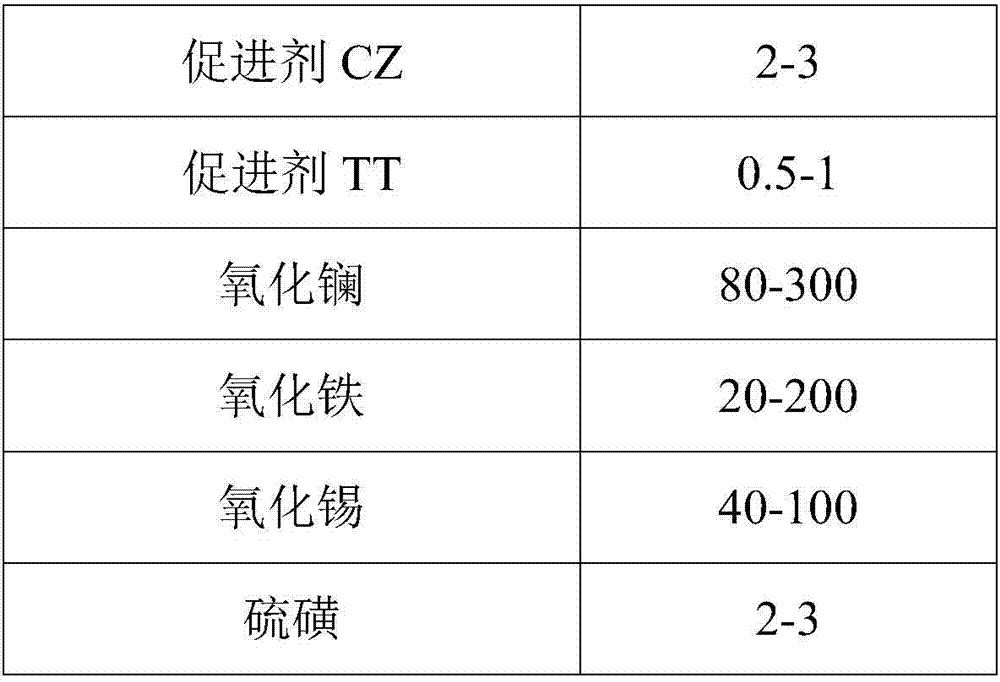

[0017]

[0018]

[0019] Carry out mixing and processing according to the raw materials and dosage in the listed formula: add rubber raw rubber to the open mill, masticate for 1-2 minutes, add zinc oxide, stearic acid, anti-aging agent in turn, and mix for 1-2 minutes; then add Accelerator, mix for 1-2 minutes; then add lanthanum oxide, iron oxide and tin oxide in sequence, mix for 10-15 minutes; finally, add cross-linking agent, mix for 1-2 minutes, and make composite material.

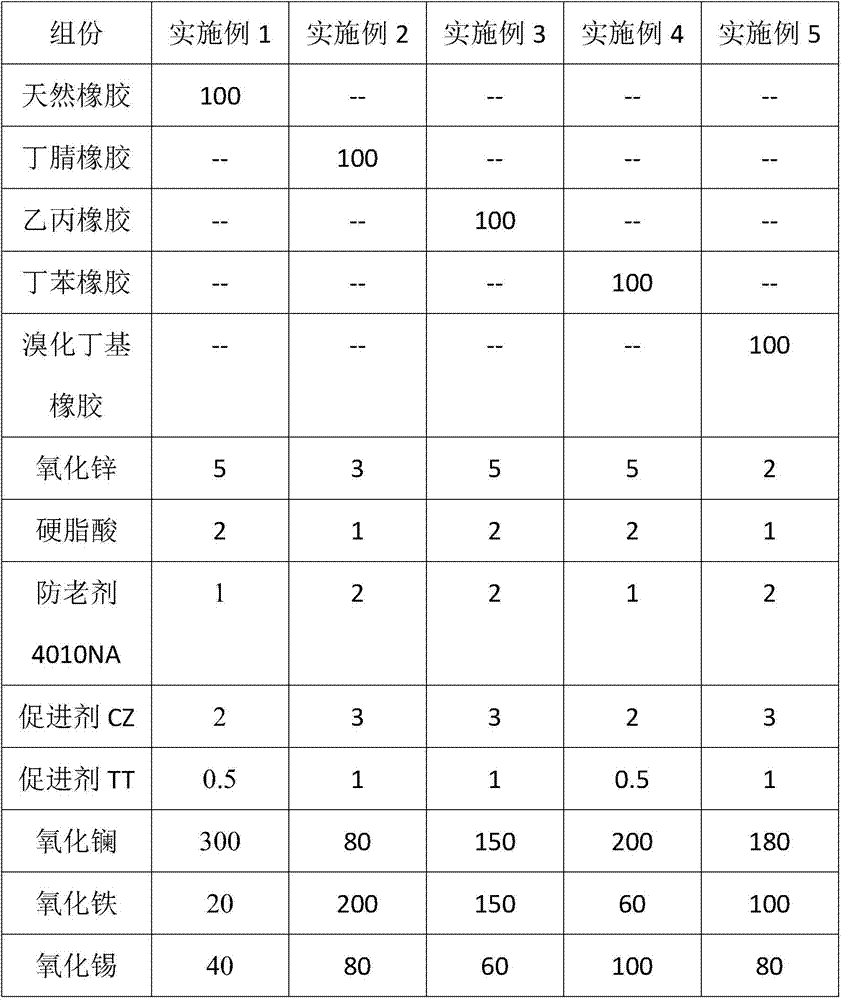

[0020] Below is the performance of the low-voltage X-ray protective material of embodiment:

[0021]

[0022] *The specific lead equivalent value in the table represents the thickness value of the composite material per unit thickness (mm) equivalent to the pure lead plate, and the higher the value, the better the shielding perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com