Preparation of rare-earth oxide / natural rubber composite material for X radiation protection

A rare earth oxide and natural rubber technology, which is applied in the treatment of dyed low-molecular organic compounds, radiation safety devices, etc., can solve the problems of unfavorable weight of anti-X-ray materials, low weight percentage, environmental pollution, etc., to save separation cost, Low production cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the rare earth oxide / natural rubber composite material that is used for X-ray protection, it comprises the steps:

[0023] 1) Pretreatment of rare earth oxides: according to the parts by weight of each raw material: 100 parts of rare earth oxides, 3 parts of coupling agents, select rare earth oxides and coupling agents; place rare earth oxides and coupling agents in In the high-speed mixer, stir at a high speed of 1200r / min for 10min to obtain the pretreated rare earth oxide for subsequent use; the coupling agent is a titanate coupling agent, which is NTC-201 produced by Nanjing Shuangzha Chemical Factory;

[0024] The rare earth oxide is a single rare earth oxide, lanthanum oxide (La 2 o 3 ).

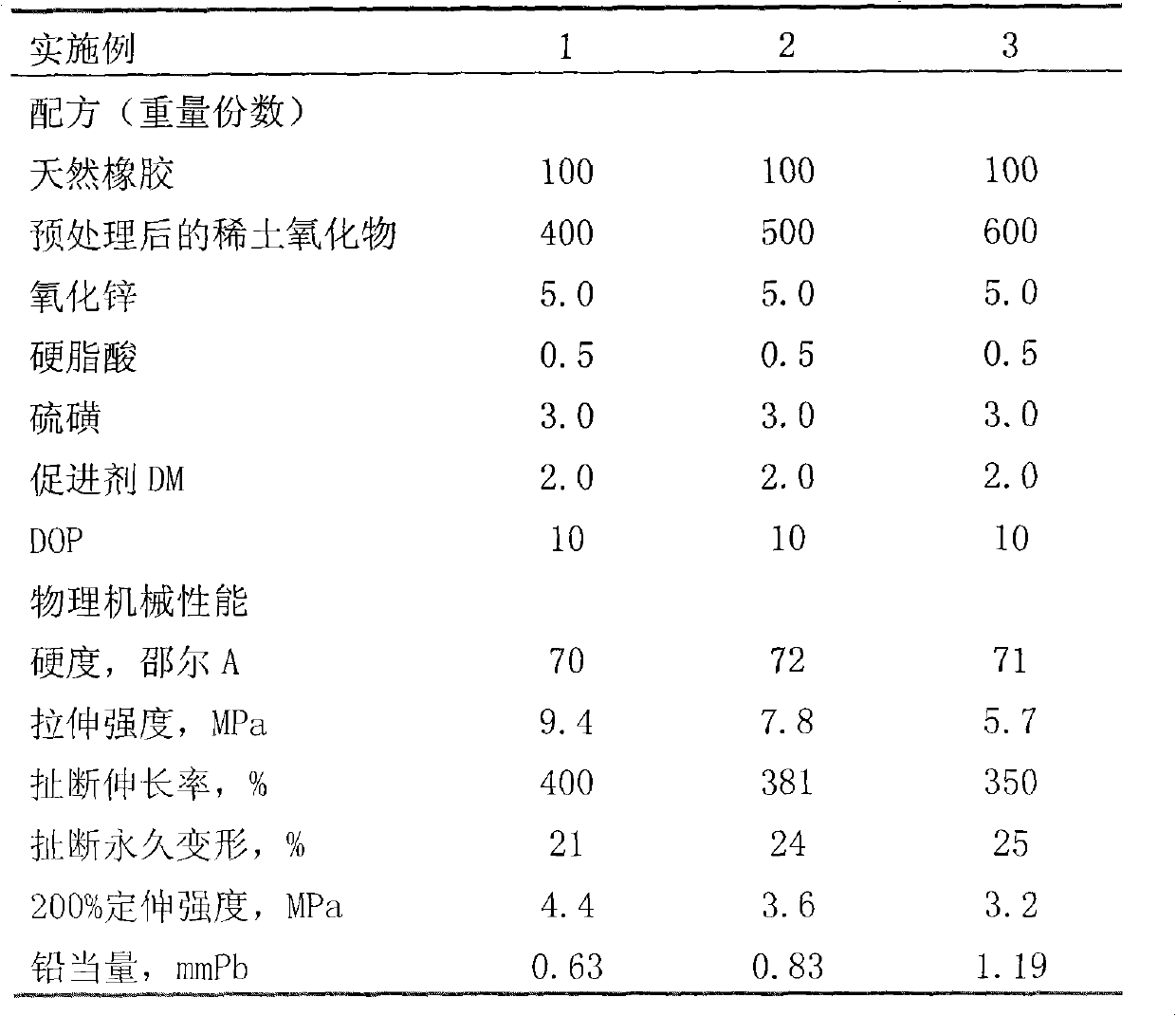

[0025] 2) Selection of raw materials: according to the formula in Table 1, select natural rubber, pretreated rare earth oxide, zinc oxide, stearic acid, sulfur, benzothiazole disulfide (accelerator DM) and softener, and set aside; Described softening...

Embodiment 2

[0028] Basically the same as Example 1, the difference is: the rare earth oxide used is a mixture (lanthanum oxide and cerium oxide), wherein lanthanum oxide (La 2 o 3 ) and cerium oxide (Ce 2 o 3 ) each account for 50% by weight, and the ratios of rare earth oxides and natural rubber are different, see Table 1.

Embodiment 3

[0030] Basically the same as Example 1, the difference is that used is a single rare earth oxide, europium oxide (Eu 2 o 3 ), commercially available. And the ratio of rare earth oxide and natural rubber is different, see Table 1.

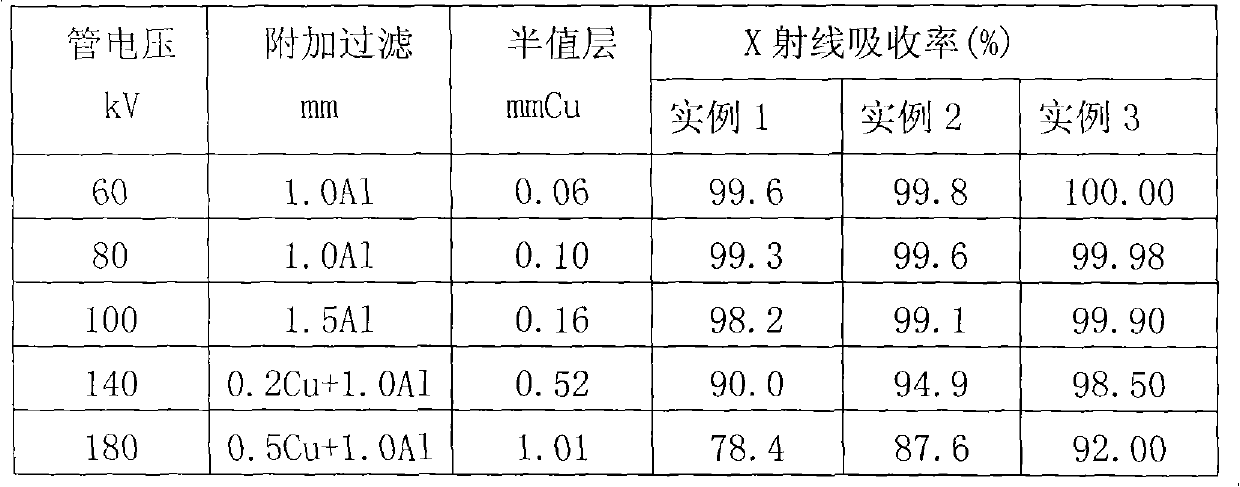

[0031] Lead equivalent test conditions: X-ray tube voltage 100kV, half-value layer 0.16mmCu, the lead equivalent of each sample is the average value of the measurement results of three different parts.

[0032] X-ray absorptivity test: The inherent filter of the X-ray machine is 2mmAl, and the absorptivity of each sample is the average value of the measurement results of three different parts.

[0033] X-ray absorption rate=(1-air kerma rate passing through the sample / incident air kerma rate)×100%.

[0034] The test results of Examples 1-3 are shown in Table 1 and Table 2. From the obtained results, the rare earth oxide / natural rubber composite material for X-ray protection prepared by the present invention not only has excellent shielding perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com