Method for preparing rare-earth oxide/rubber composite material for low-frequency sound absorption

A technology of rare earth oxides and composite materials, which is applied in the field of preparation of rare earth oxides/rubber composite materials, can solve problems such as high price, and achieve the effects of low production cost, improved mechanical properties, and saved separation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for a rare earth oxide / rubber composite material for low-frequency sound absorption, comprising the steps of:

[0025] 1) Pretreatment of rare earth oxides: according to the parts by weight of each raw material: 100 parts of rare earth oxides, 3 parts of coupling agents, select rare earth oxides and coupling agents; place rare earth oxides and coupling agents in In a high-speed mixer, stir at a high speed of 1200r / min for 10min to obtain the pretreated rare earth oxide for subsequent use; the coupling agent is a titanate coupling agent;

[0026] The rare earth oxide is a single rare earth oxide, lanthanum oxide (La 2 o 3 ), the purity is 99.8% (mass percentage), and the particle size is 0.3-4 μm.

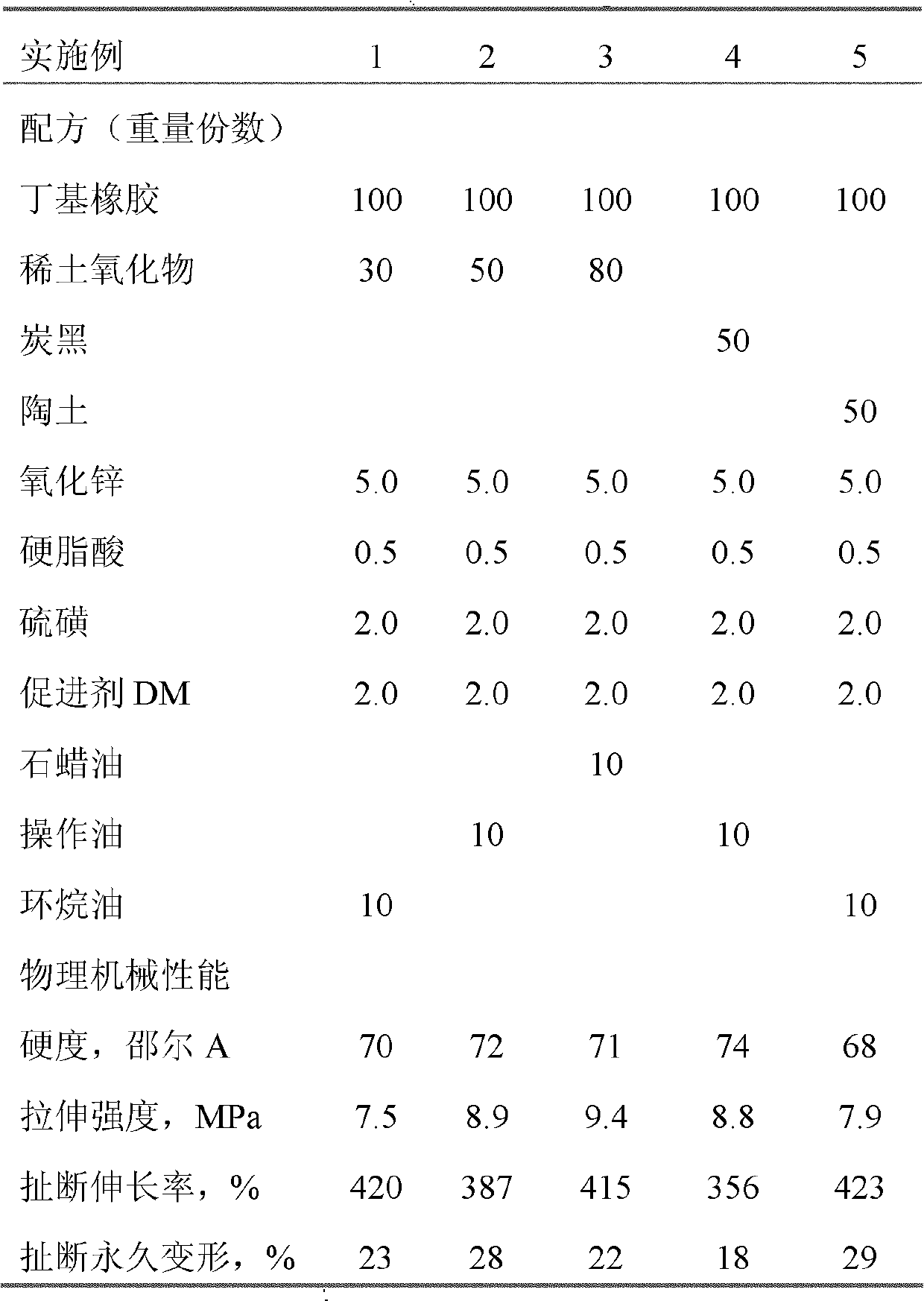

[0027] 2) Selection of raw materials: According to the formula in Table 1, select butyl rubber, pretreated rare earth oxide, zinc oxide, stearic acid, sulfur, benzothiazole disulfide (accelerator DM) and softener, and reserve ;

[0028] 3) In the inte...

Embodiment 2

[0030] It is basically the same as Example 1, except that the rare earth oxide used is a mixture (lanthanum oxide and cerium oxide), the purity is 99.8% (mass percentage), and the particle size is 0.3-4 μm, wherein lanthanum oxide (La 2 o 3 ) and cerium oxide (Ce 2 o 3 ) each account for 50% by weight, and the ratio of rare earth oxide and rubber is different, see Table 1.

Embodiment 3

[0032] Basically the same as Example 1, the difference is that used is a single rare earth oxide: europium oxide (Eu 2 o 3 ), commercially available, with a purity of 99.8% (mass percentage), a particle size of 0.3-4 μm, and different ratios of rare earth oxides and rubber, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com