Gadolinium-base block amorphous alloy and its preparing method

A technology of amorphous alloys and bulk, applied in the field of alloys, can solve the problems of rare earth-based amorphous alloy preparation and performance research, etc., and achieve the effects of low cost, simple preparation, and rich rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, Gd 60 Cu 20 al 10 Ni 10 Preparation of Bulk Amorphous Alloy

[0031] Gd, Cu, Al and Ni with a molar ratio of 60:20:10:10 are used to prepare gadolinium-based bulk amorphous alloys with a purity of more than 99.9%. Melt in an electric arc furnace with an argon atmosphere, mix evenly, and obtain a master alloy ingot of Gd-Cu-Al-Ni quaternary alloy after cooling; then use a conventional metal mold casting method to remelt the ingot and use the The suction casting device, the master alloy melt is sucked into the water-cooled copper mold, and the composition is Gd 60 Cu 20 al 10 Ni 10 , a bulk amorphous alloy with a diameter of 1.5mm.

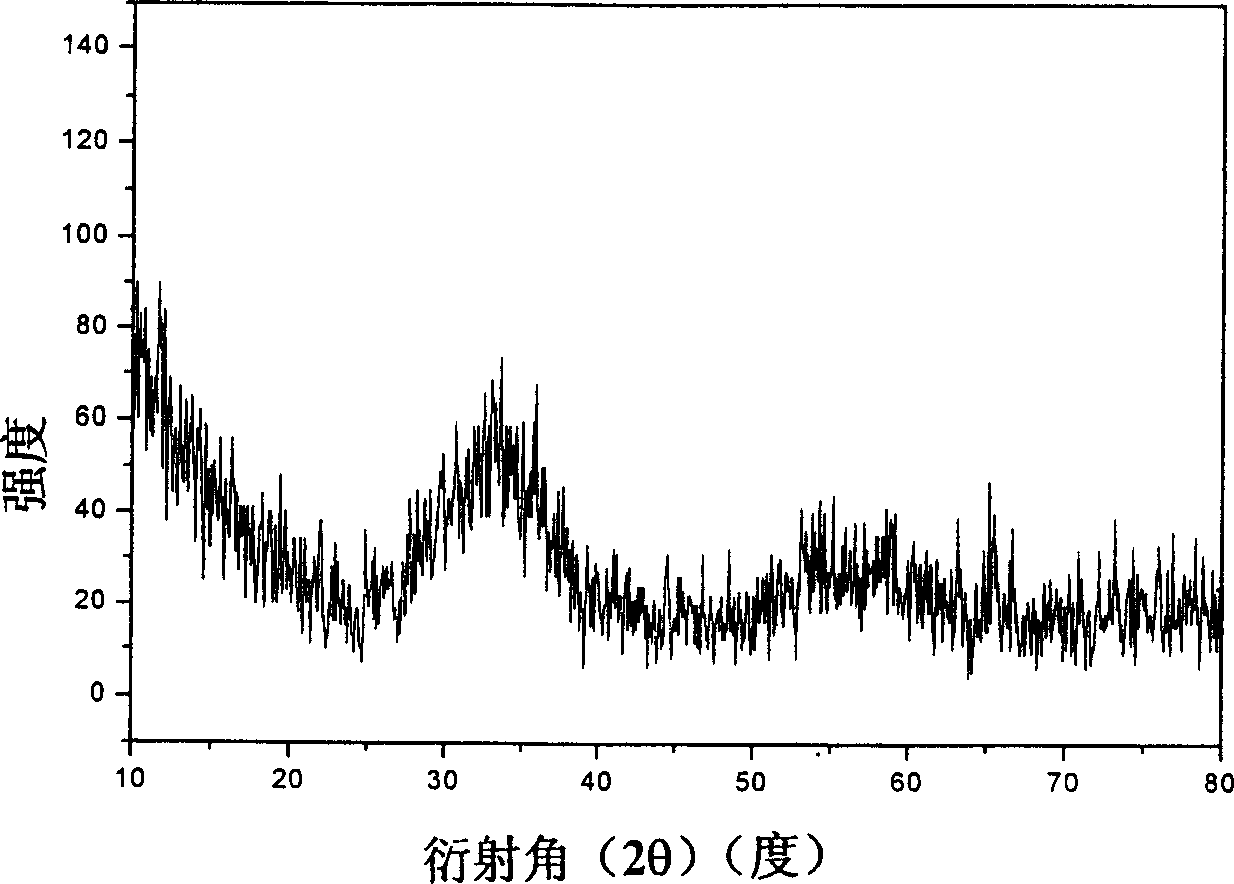

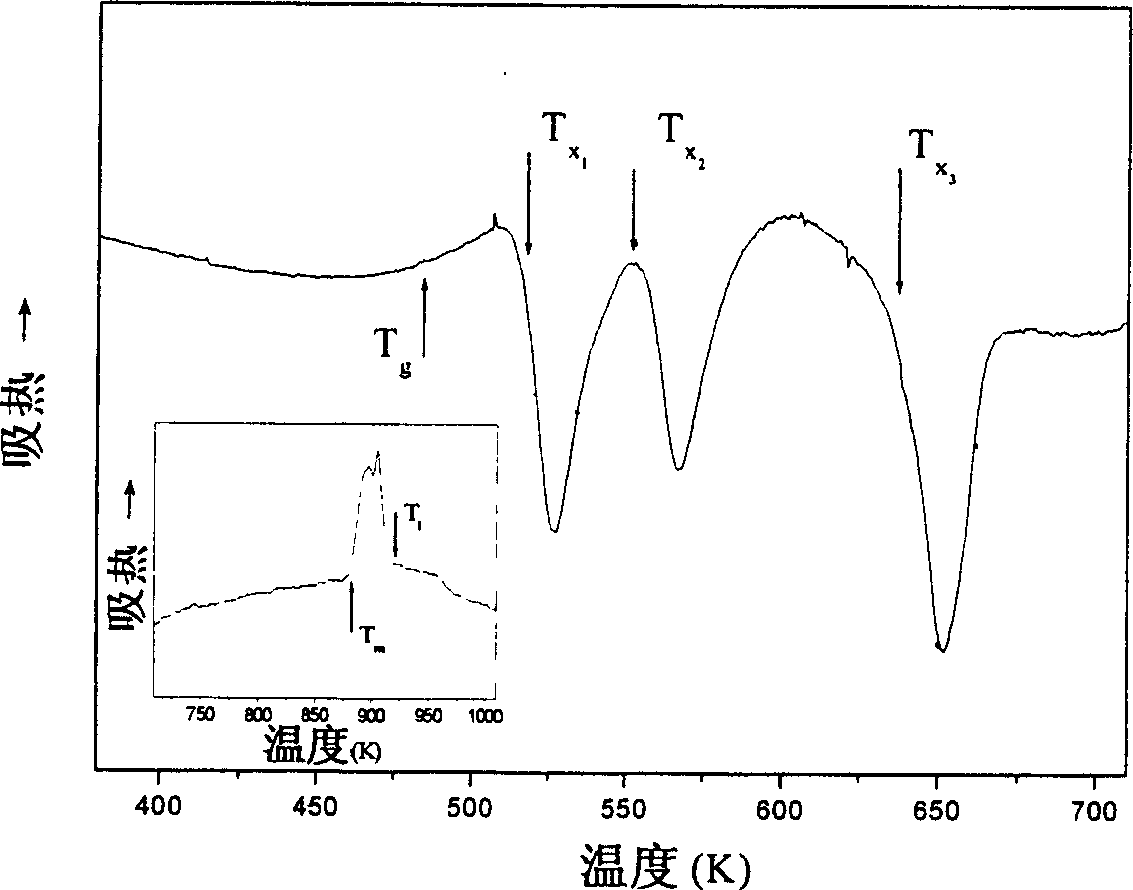

[0032] Such as figure 1 X-ray diffraction (XRD) shown proves that the alloy is completely amorphous. Such as figure 2 The thermal analysis (DSC) diagram shown, its glass transition temperature (T g ), crystallization onset temperature (T x ), the width of the subcooling interval (ΔT=T x -T g ) are 481K, 514K and ...

Embodiment 2~19

[0034] Various ratios of gadolinium-based bulk amorphous alloys were prepared according to the method of Example 1, and their compositions and thermophysical parameters are listed in Table 1.

[0035] Reality

apply

example

T g

(K)

T x

(K)

ΔT

(K)

T m

(K)

T l

(K)

T rg

gamma

1

Gd 60 Cu 20 al 10 Ni 10

481

514

33

880

925

0.55

0.366

2

Gd 60 Cu 10 Al 10 Ni 10 Fe 10

498

538

39

897

931

0.567

0.340

3

Gd 60 Cu 15 Al 5 Ni 10 Fe 10

520

557

37

910

945

0.571

0.380

4

Gd 60 al 15 Ni 15 Cu 10

477

516

39

871

913

0.547

0.371

5

Gd 65 al 10 Ni 10 Cu 10 Nb 5

488

523

35 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com