Lutetium based bulk amorphous alloy and preparation thereof

An amorphous alloy and base block technology, applied in the field of alloys, can solve problems such as limited composition system, and achieve the effects of inhibiting crystallization ability, low critical cooling rate, and abundant rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

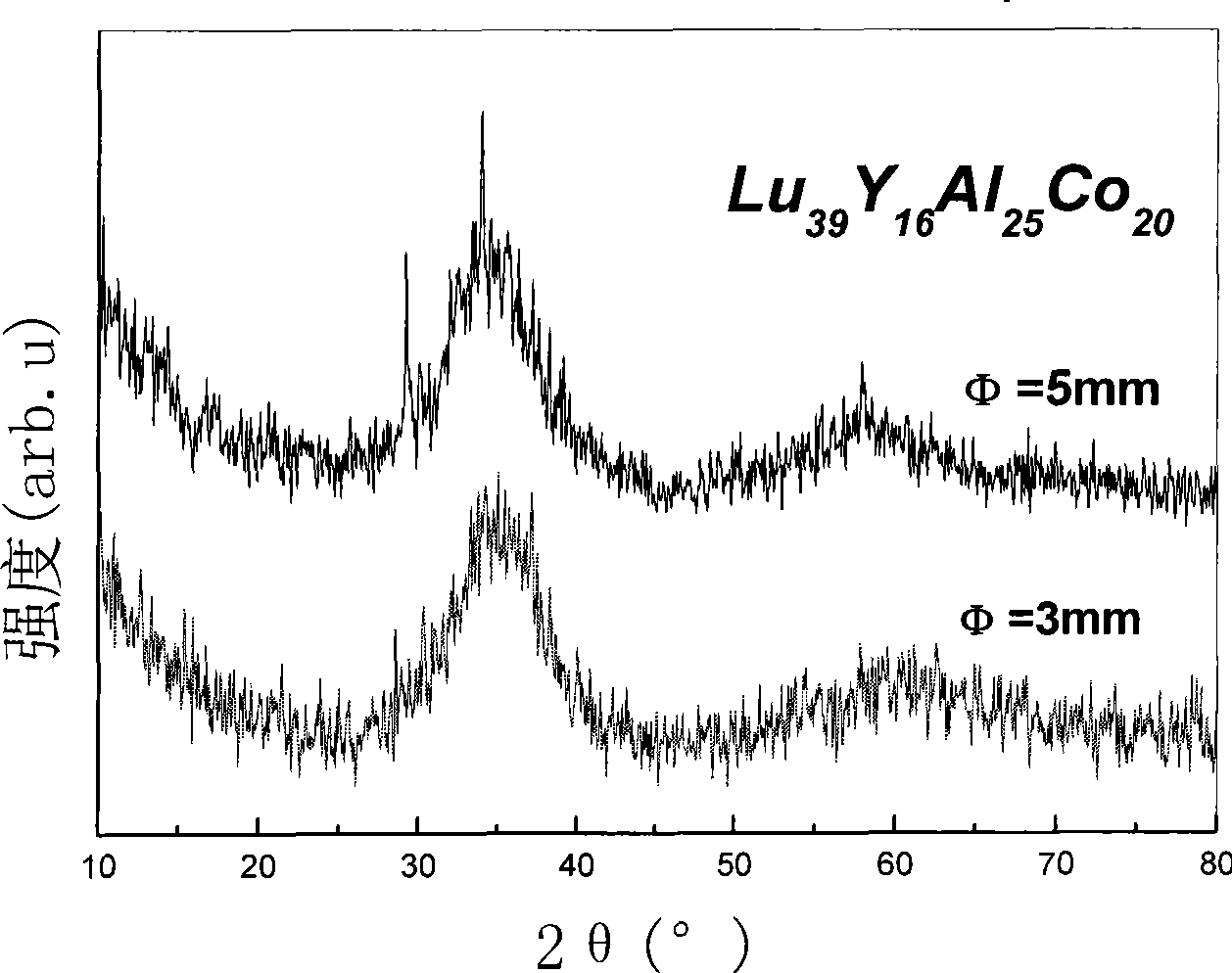

[0028] Embodiment 1, Lu 39 Y 16 Al 25 co 20 Preparation of bulk amorphous alloys

[0029] Lu, Y, Al and Co with a purity of more than 99.9% and a molar ratio of 39:16:25:20 are used to prepare a lutetium-based bulk amorphous alloy. Melt in an electric arc furnace with an argon atmosphere, mix evenly, and obtain a master alloy ingot of Lu-Y-Al-Co quaternary alloy after cooling; then use a conventional metal mold casting method to remelt the ingot and use The suction casting device sucks the master alloy melt into the water-cooled copper mold, and the composition is Lu 39 Y 16 Al 25 co 20 , a bulk amorphous alloy with a diameter of 3 to 5 mm.

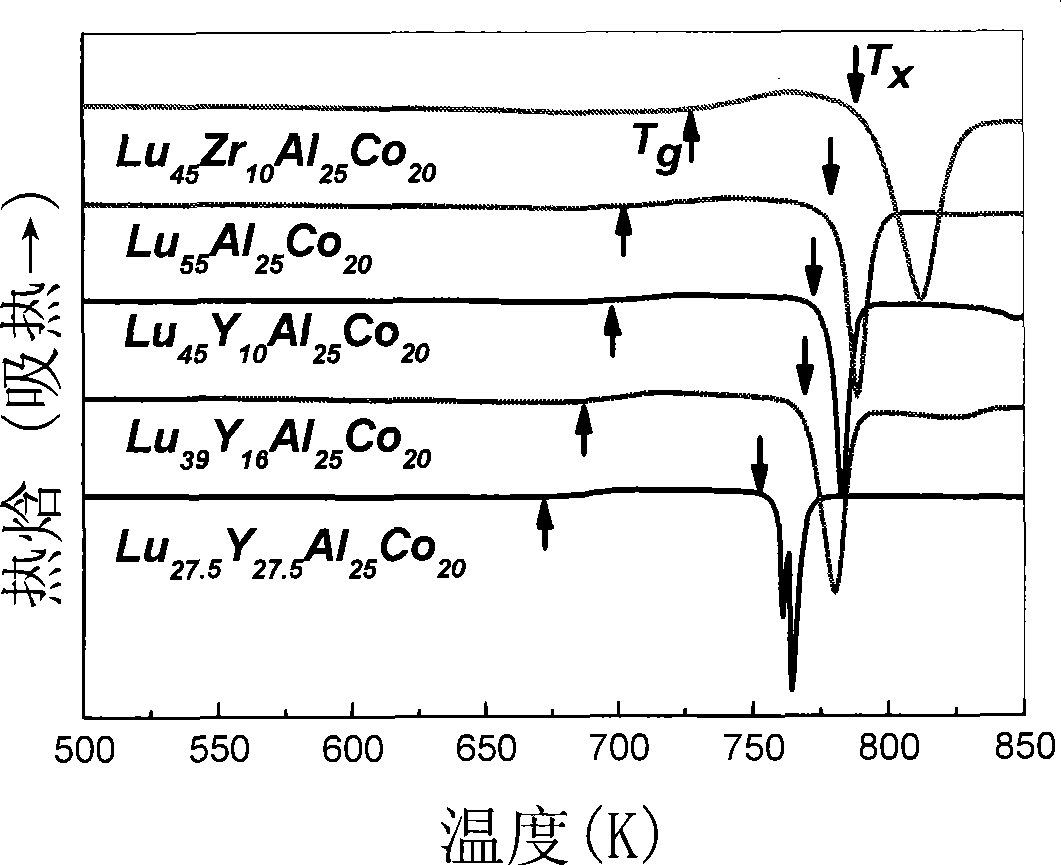

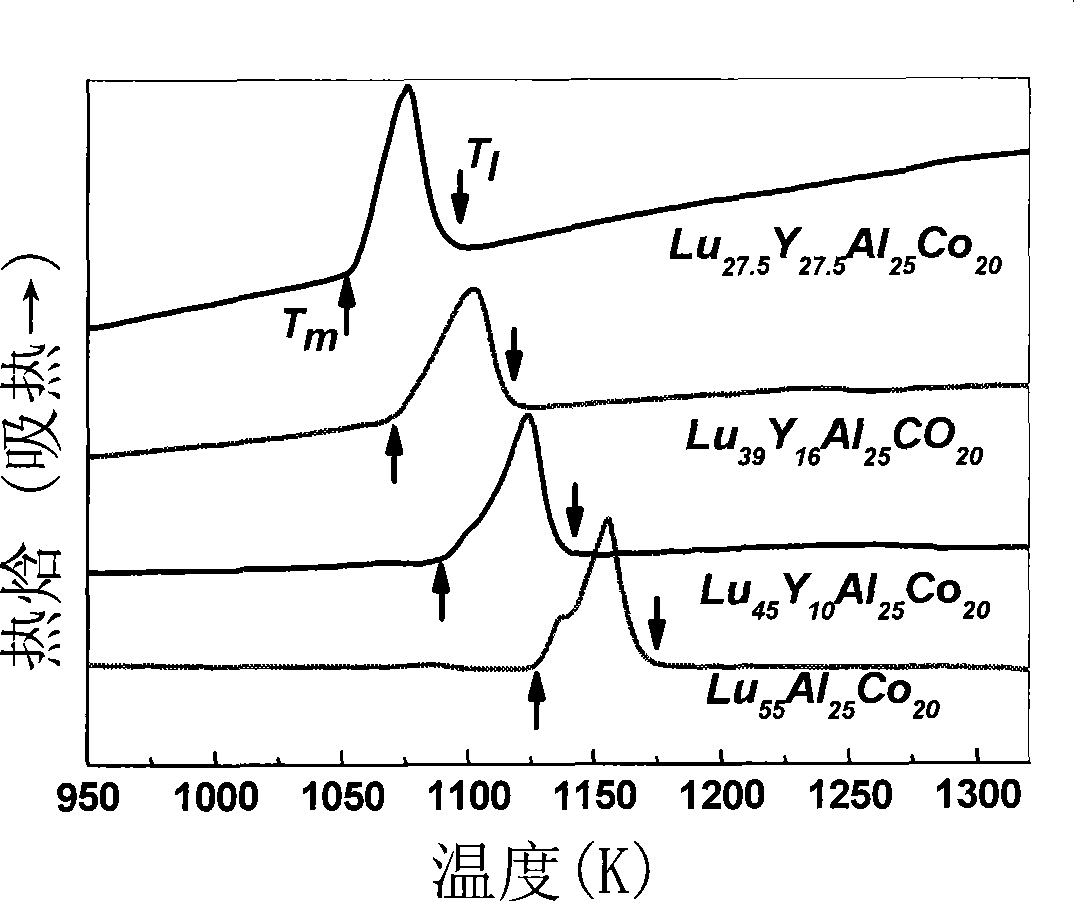

[0030] Such as figure 1 X-ray diffraction (XRD) shown proves that the alloy is completely amorphous. Such as figure 2 The thermal analysis (DSC) diagram shown, its glass transition temperature (T g ), crystallization onset temperature (T x ), the width of the subcooling interval (ΔT=T x -T g ) are 687, 769 and 83K, respect...

Embodiment 2~9

[0032] Various ratios of lutetium-based bulk amorphous alloys were prepared according to the method of Example 1, and their compositions and thermophysical parameters are listed in Table 1.

[0033] Table 1. Composition and thermophysical parameters of lutetium-based bulk amorphous alloys

[0034] Reality

Shi

example

T g

(K)

T x

(K)

T m

(K)

T l

(K)

ΔTg

(K)

T rg

r 1 Lu 39 Y 16 al 25 co 20 687 769 1072 1117 82 0.641 0.426 2 Lu 55 Al 25 co 20 701 781 1127 1167 80 0.622 0.418 3 Lu 45 Y 10 Al 25 co 20 698 775 1093 1136 77 0.639 0.423 4 Lu 27.5 Y 27.5 al 25 co 20 673 756 1055 1090 83 0.638 0.429 5 Lu 40 Zr 15 al 25 co 20 728 793 1164 1206 65 0.625 0.410 6 Lu 60 Al 30 co 10 714 797 1131 1173 83 0.609 0.422 7 Lu 25 Y 30 Al 20 co 25 669 742...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com