Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Reliable stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

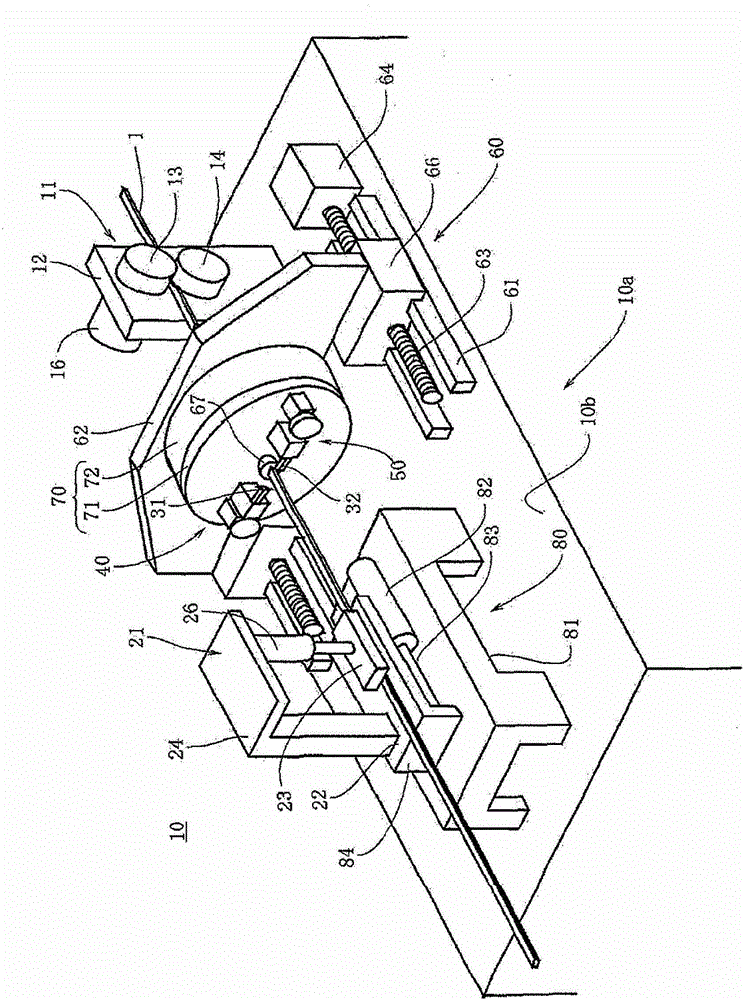

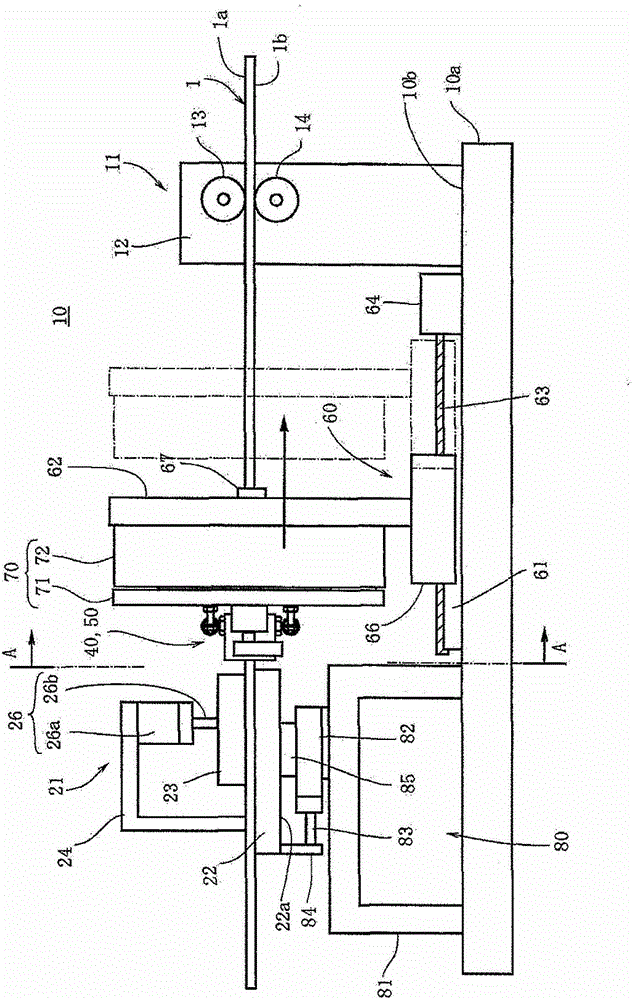

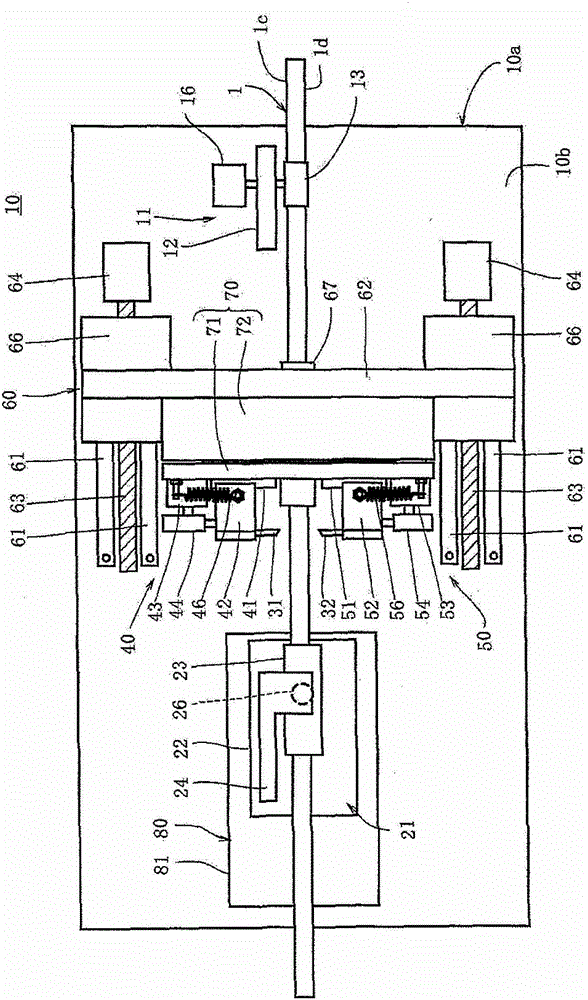

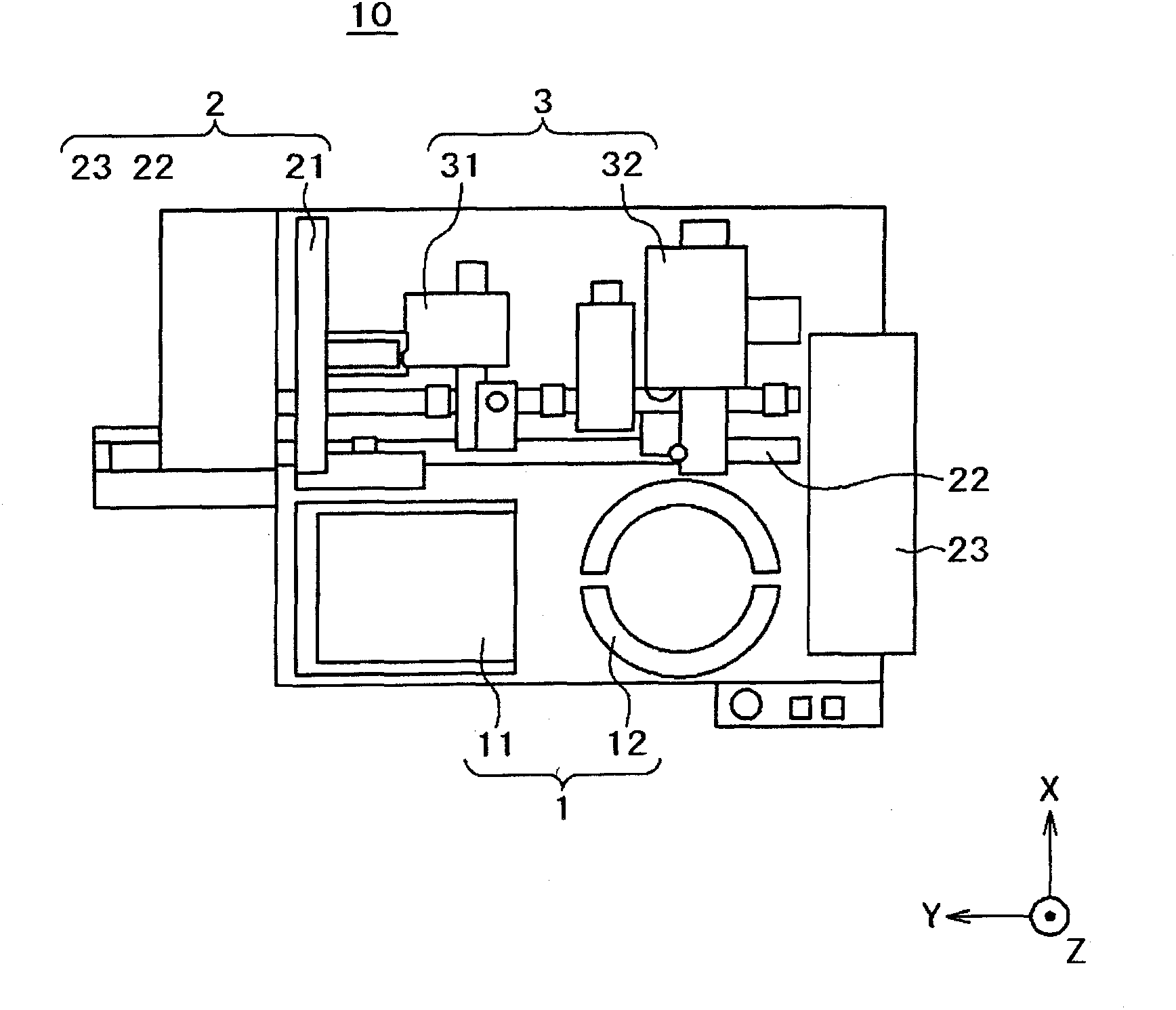

Wire protection film stripping device and wire protection film stripping device method

ActiveCN103151735AReliable strippingEasy and reliable to stripApparatus for removing/armouring cablesTectorial membraneEngineering

The invention discloses a wire protection film stripping device and a wire protection film stripping device method which can strip a protection film which covers the wire circumferentially, easily and reliably. The wire protection film stripping device comprises a wire supporting unit used for supporting the wire, a pair of cutting members facing each other across the wire, cut applying units which enables the pair of cutting members to abut on the protection film formed on the outer surface of the wire from the two sides of the wire and apply cuts to the protection film, a cutting member relative motion unit which enables the pair of cutting members applying the cuts to the protection film to move relatively along the length direction of the wire, and a cutting member rotation unit which enables the pair of cutting members facing each other across the wire to rotate with the wire serving as the rotation center. The cutting member rotation unit comprises a rotation member allowing the wire to pass through and being capable of rotating with the wire ass the rotation center. The pair of cutting members are arranged on the rotation member.

Owner:NITTOKU ENG CO LTD

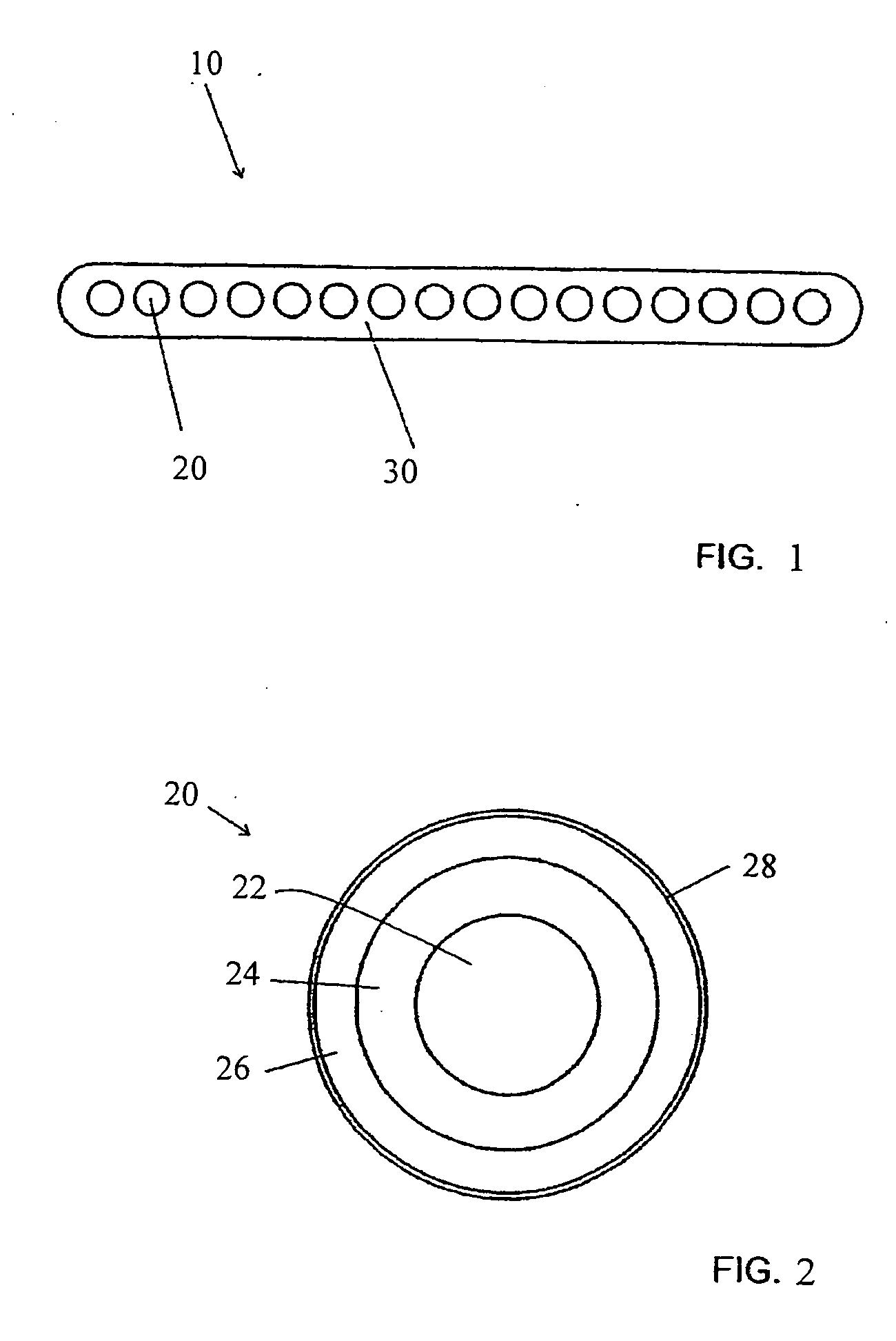

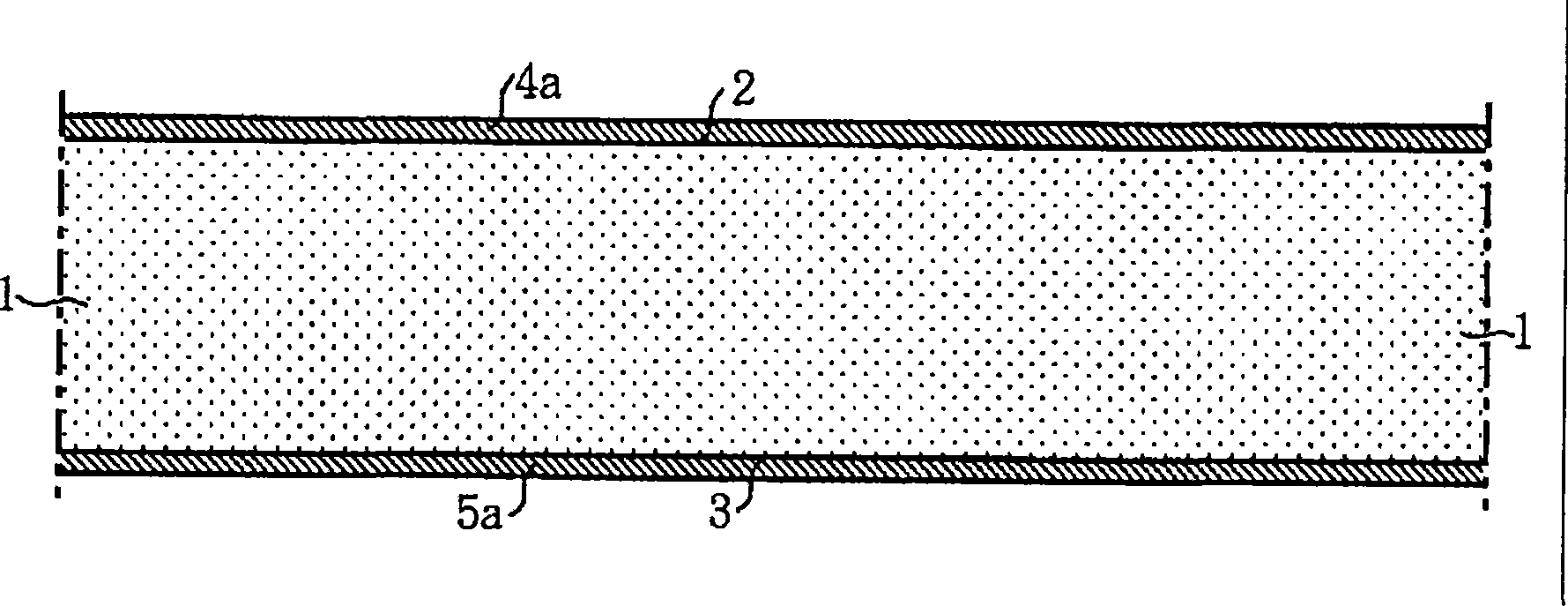

Optical fiber ribbon with improved stripability

ActiveUS20070122093A1SuitableSuitable strip cleanlinessOptical fibre with multilayer core/claddingFibre mechanical structuresFiber coatingCompound (substance)

An optical fiber ribbon includes a plurality of optical fibers encapsulated within a matrix material, where the optical fiber coating(s) and the matrix material(s), and optionally any ink layers thereon, are characterized by compatible chemical and / or physical properties, whereby the fiber coating and matrix and any ink layers therebetween can be reliably stripped from the optical fibers to afford a suitable strip cleanliness. Novel ink formulations that can be used in the making of such fiber optic ribbons, methods of making such ribbons, and their use are also described.

Owner:CORNING INC

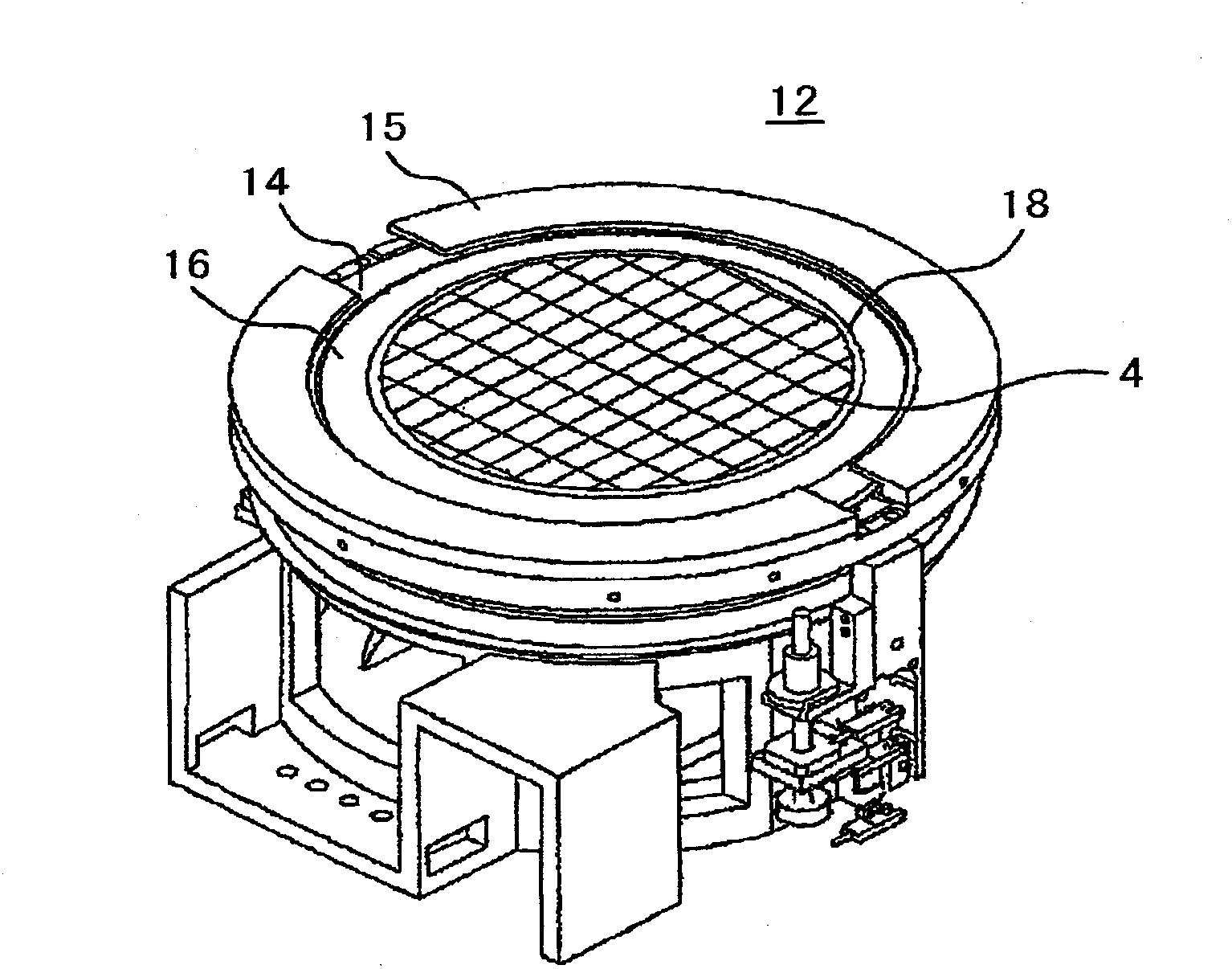

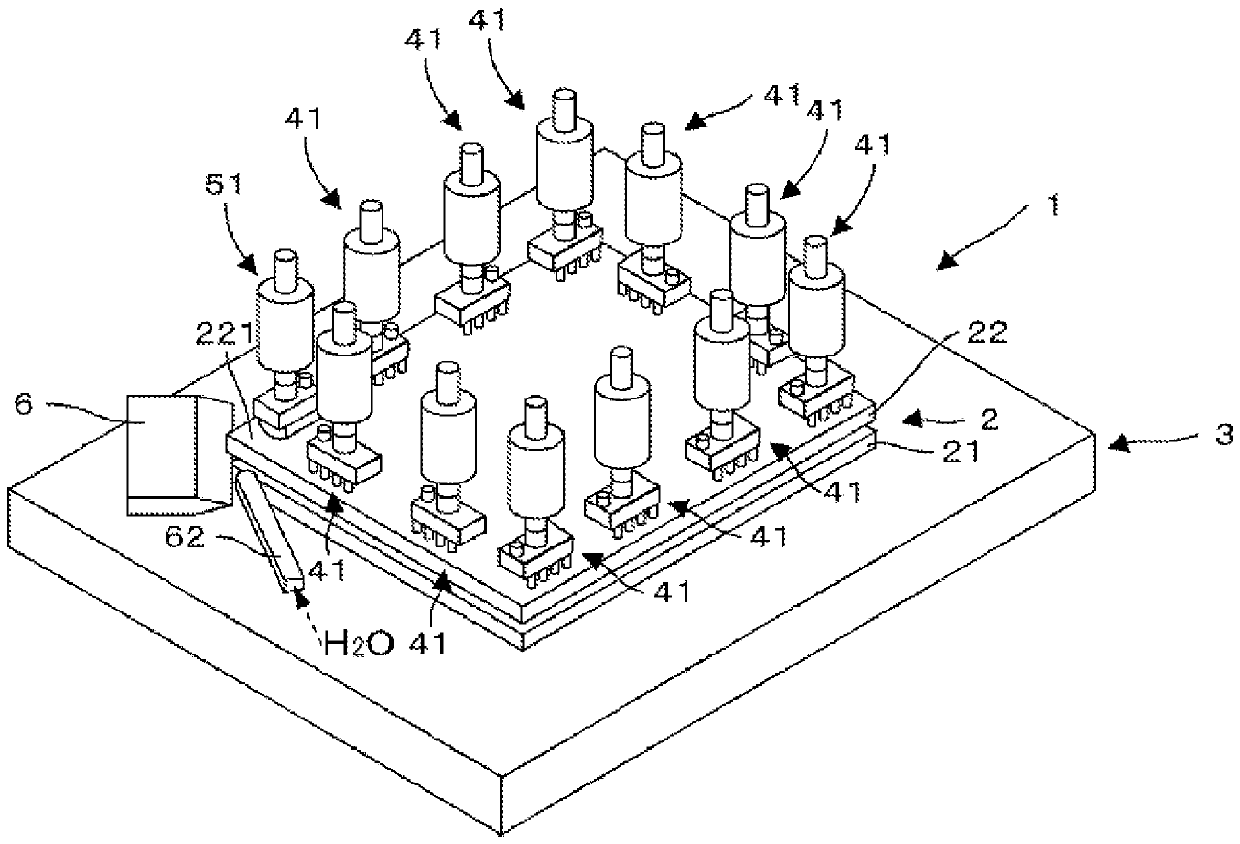

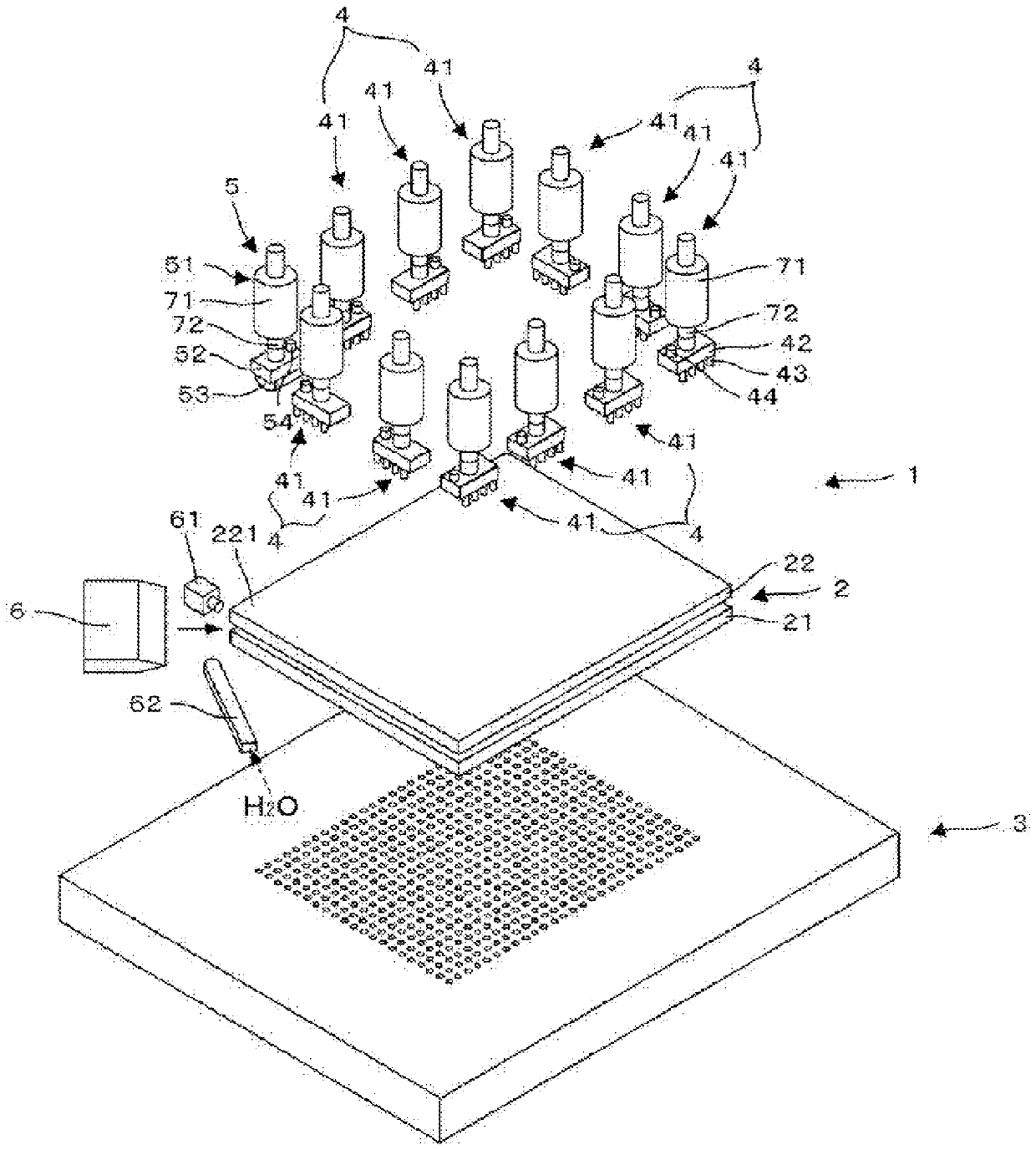

Pick-up method of die bonder and die bonder

ActiveCN102693930AReliable strippingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

Owner:FASFORD TECH

Optical fiber ribbon with improved stripability

ActiveUS7257299B2Suitable strip cleanlinessReliable strippingOptical fibre with multilayer core/claddingFibre mechanical structuresMaterials scienceFiber coating

An optical fiber ribbon includes a plurality of optical fibers encapsulated within a matrix material, where the optical fiber coating(s) and the matrix material(s), and optionally any ink layers thereon, are characterized by compatible chemical and / or physical properties, whereby the fiber coating and matrix and any ink layers therebetween can be reliably stripped from the optical fibers to afford a suitable strip cleanliness. Novel ink formulations that can be used in the making of such fiber optic ribbons, methods of making such ribbons, and their use are also described.

Owner:CORNING INC

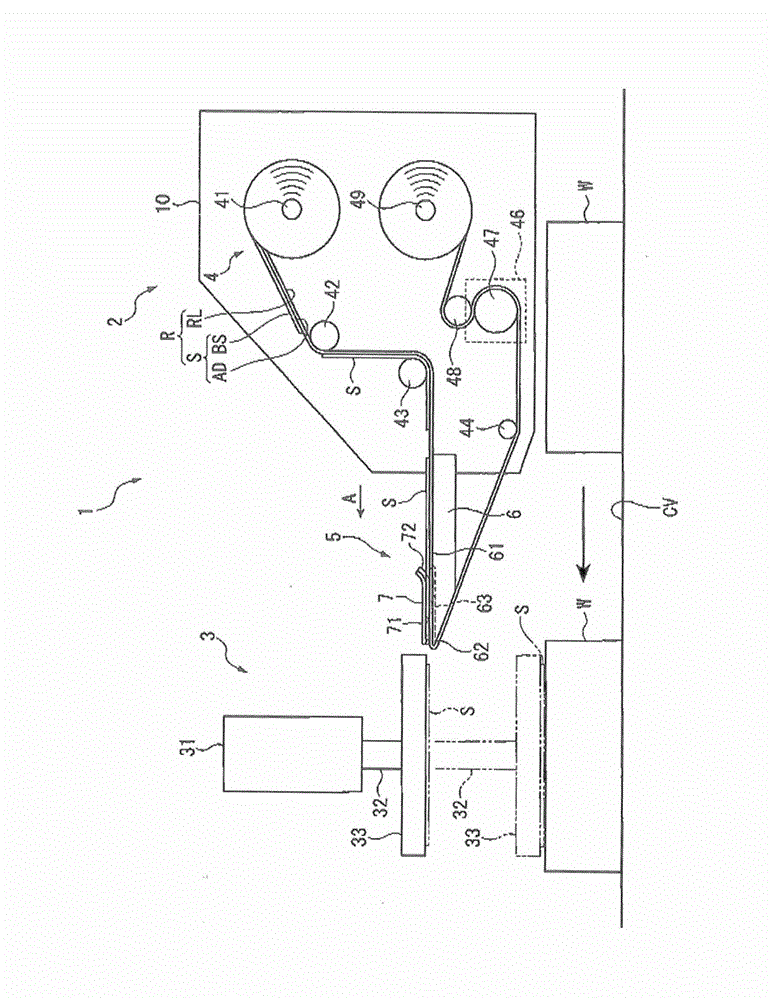

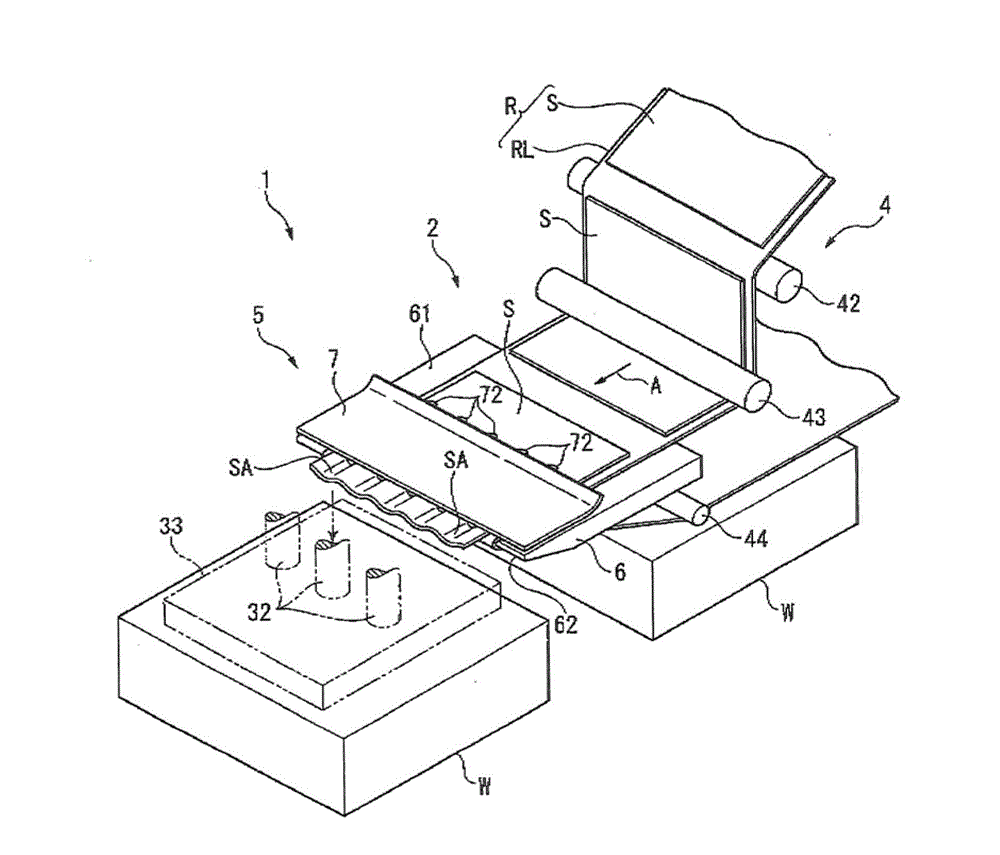

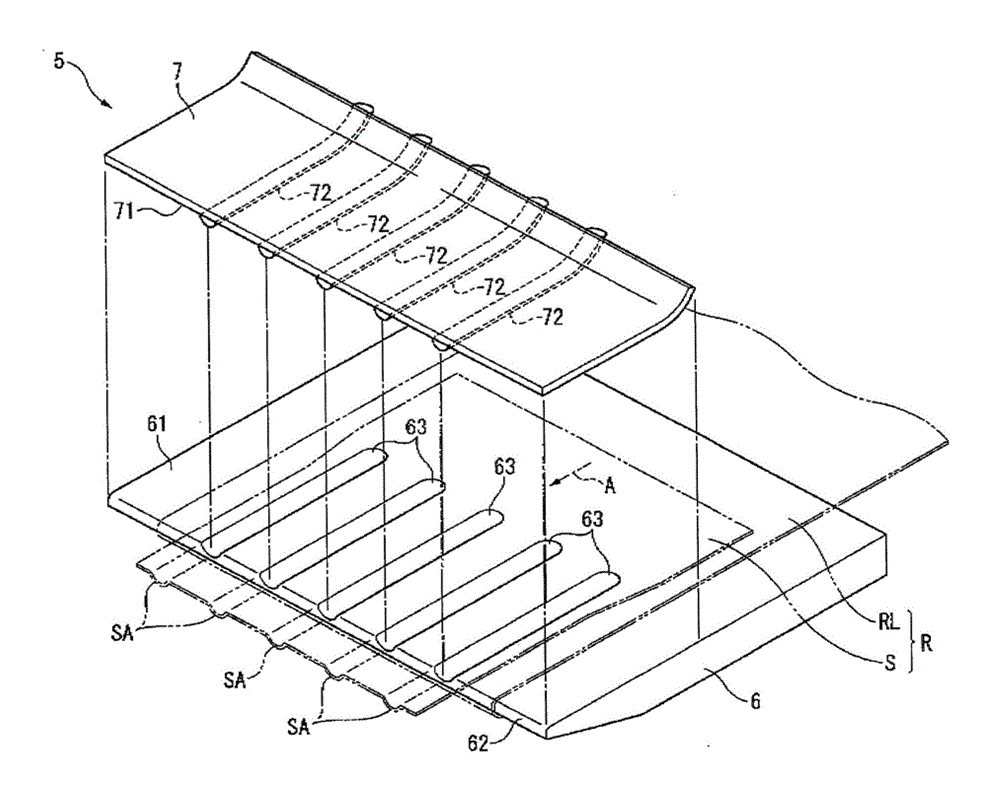

Sheet separation apparatus and separation method, and sheet attaching apparatus and attaching method

A sheet separation apparatus (2) comprises: a feeding means (4) for feeding a raw fabric (R) in which an adhesive sheet (S) has been temporarily attached to a separation sheet (RL),and a separation means (5) for separating the adhesive sheet (S) from the separation sheet (RL). The separation means (5) comprises: a separation member (6) that has a bending end edge (62) for bending the separation sheet (RL),and a tracking means for forming a concave / convex-shaped transverse region (SA) at least in the adhesive sheet (S) in the feeding direction thereof. The separation member (6) comprises: a guide surface part (61) that continues to the bending end edge (62) and also guides the raw fabric (R),and a first concave / convex part (63) that is formed in the guide surface part (61) in the feeding direction of the raw fabric (R) and opens at the bending end edge (62). The tracking means comprises a guide member (7) provided with a second concave / convex part that fits together with the first concave / convex part (63) in a state where the raw fabric (R) is disposed between the separation member (6) and the second concave / convex part. The second concave / convex part comprises a convex part (72) that is provided extending to the bending end edge (62) in the feeding direction of the first concave / convex part.

Owner:LINTEC CORP

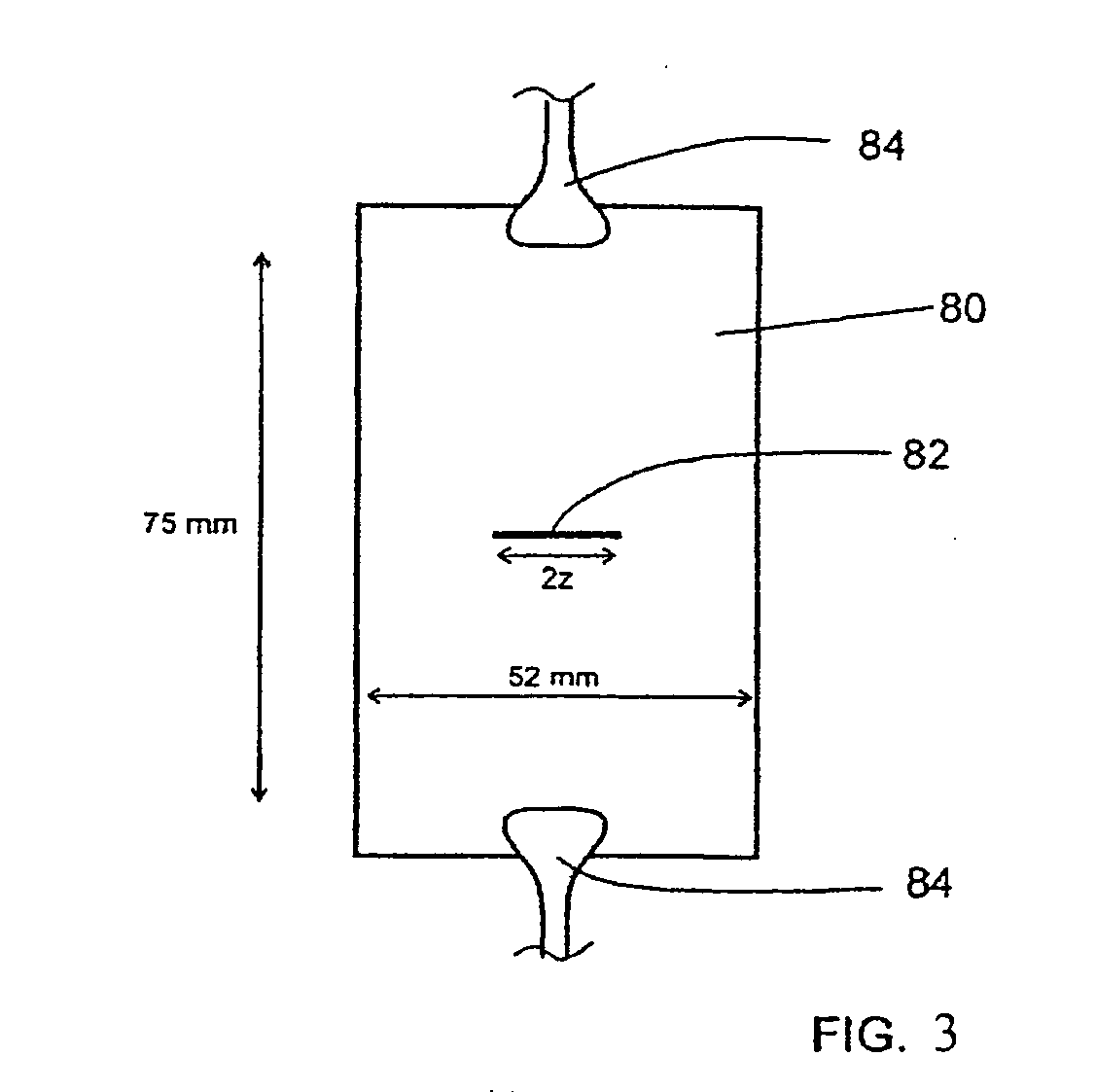

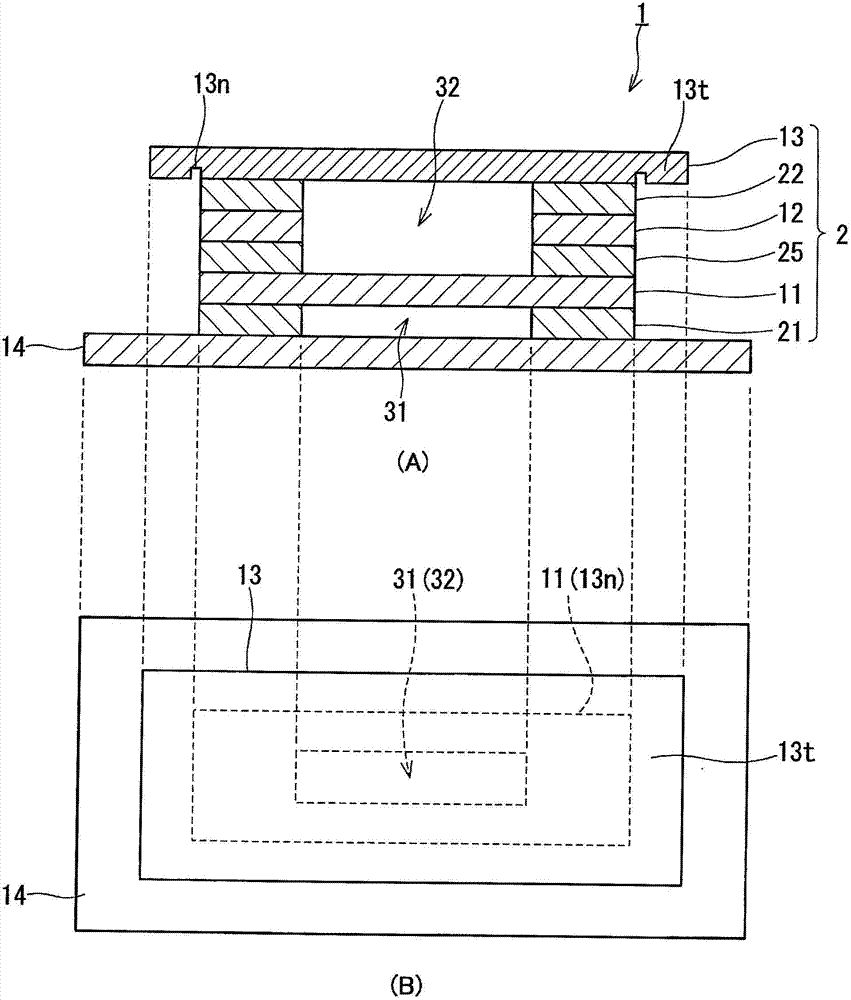

Water-resistant sound transmitting member, production method therefor, and water-resistant sound transmitting member carrier

ActiveCN103202036AHigh adhesive forceReliable strippingLayered productsTransducers for subaqueous useEngineeringWater resistant

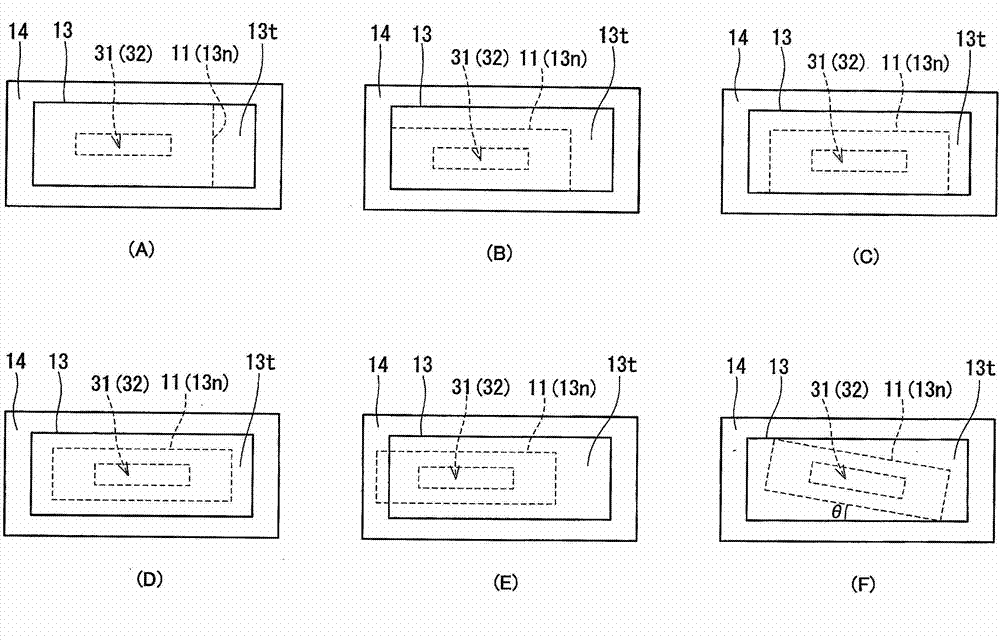

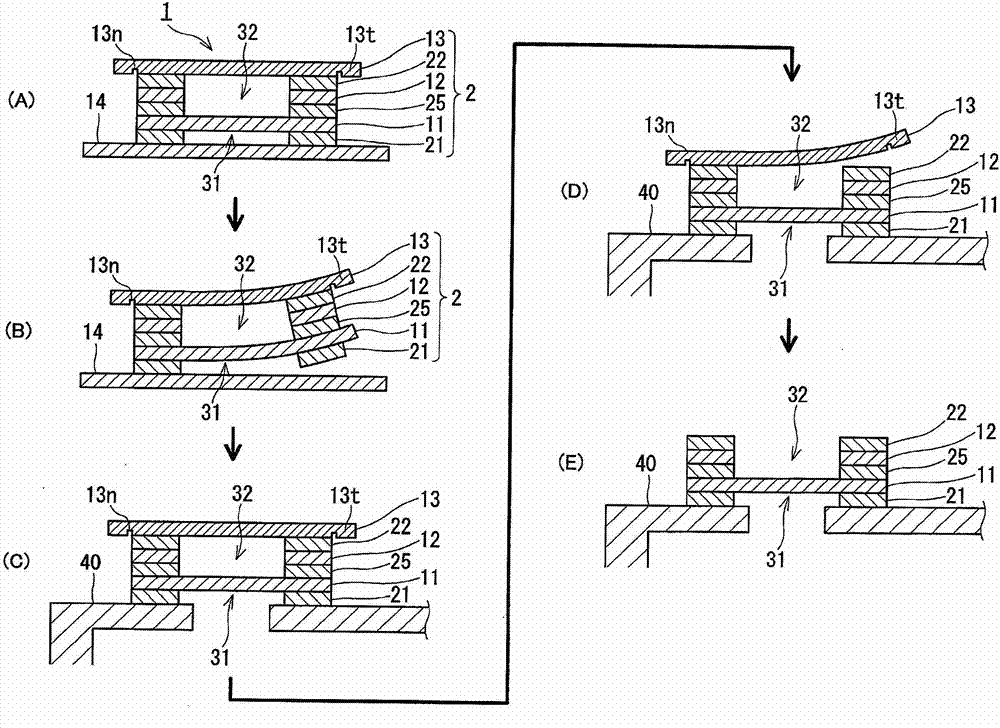

Provided is a water-resistant sound transmitting member that is reliably released from a release paper when a protruding section of a tab is pulled. A production method for this water-resistant sound transmitting member (2) includes: a step in which a first layer (71), a preliminary film body (61), a second layer (72), and a preliminary tab body (63) are laminated in said order and a laminate (52a) is prepared; a step in which a blade (90) is inserted from the first layer (71) in the laminate (52a) towards the preliminary tab body (63), the first layer (71), the preliminary film body (61), and the second layer (72) are cut and a first adhesive layer (21), a water-resistant sound transmitting film (11), and a second adhesive layer (22) are formed, and a notch (13n) that connects to the end surfaces of first adhesive layer (21), the water-resistant sound transmitting film (11), and the second adhesive layer (22) is disposed in a surface on the second layer (72) side of the preliminary tab body (63); and a step in which the preliminary tab body (63) is cut and the tab (13) is formed.

Owner:NITTO DENKO CORP

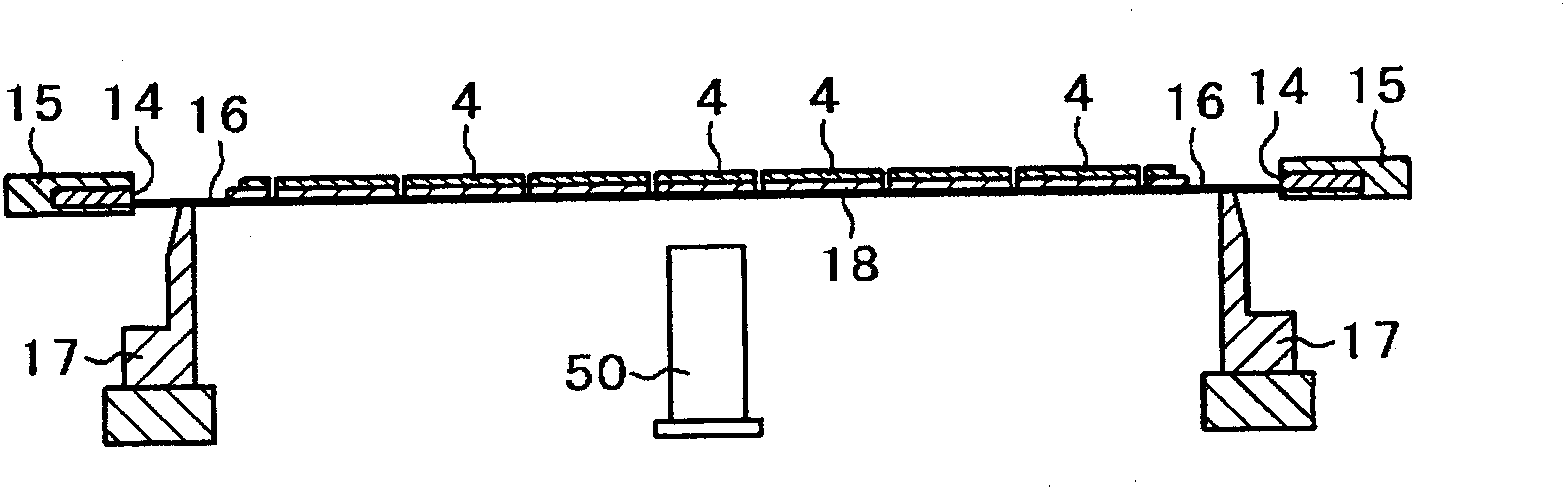

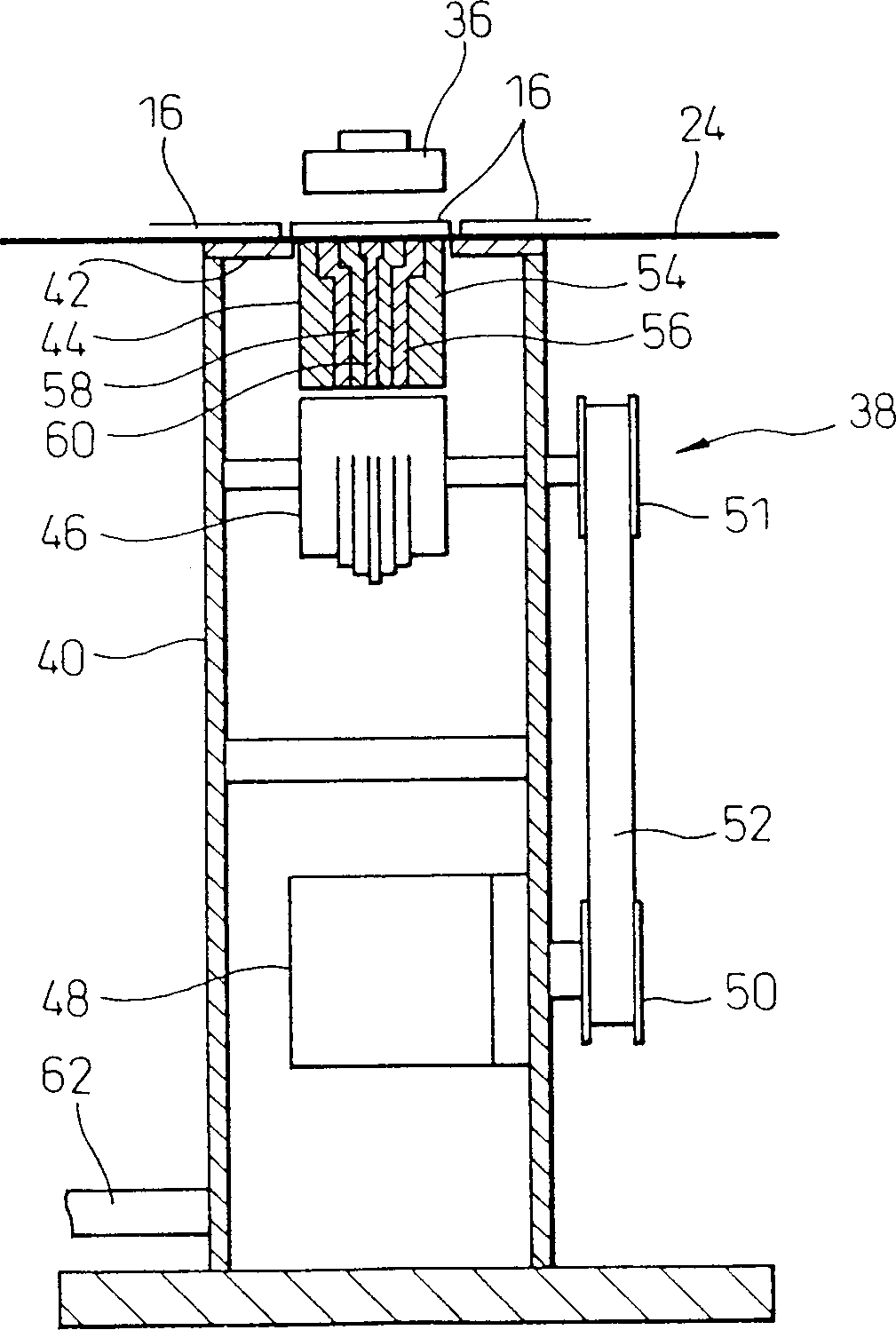

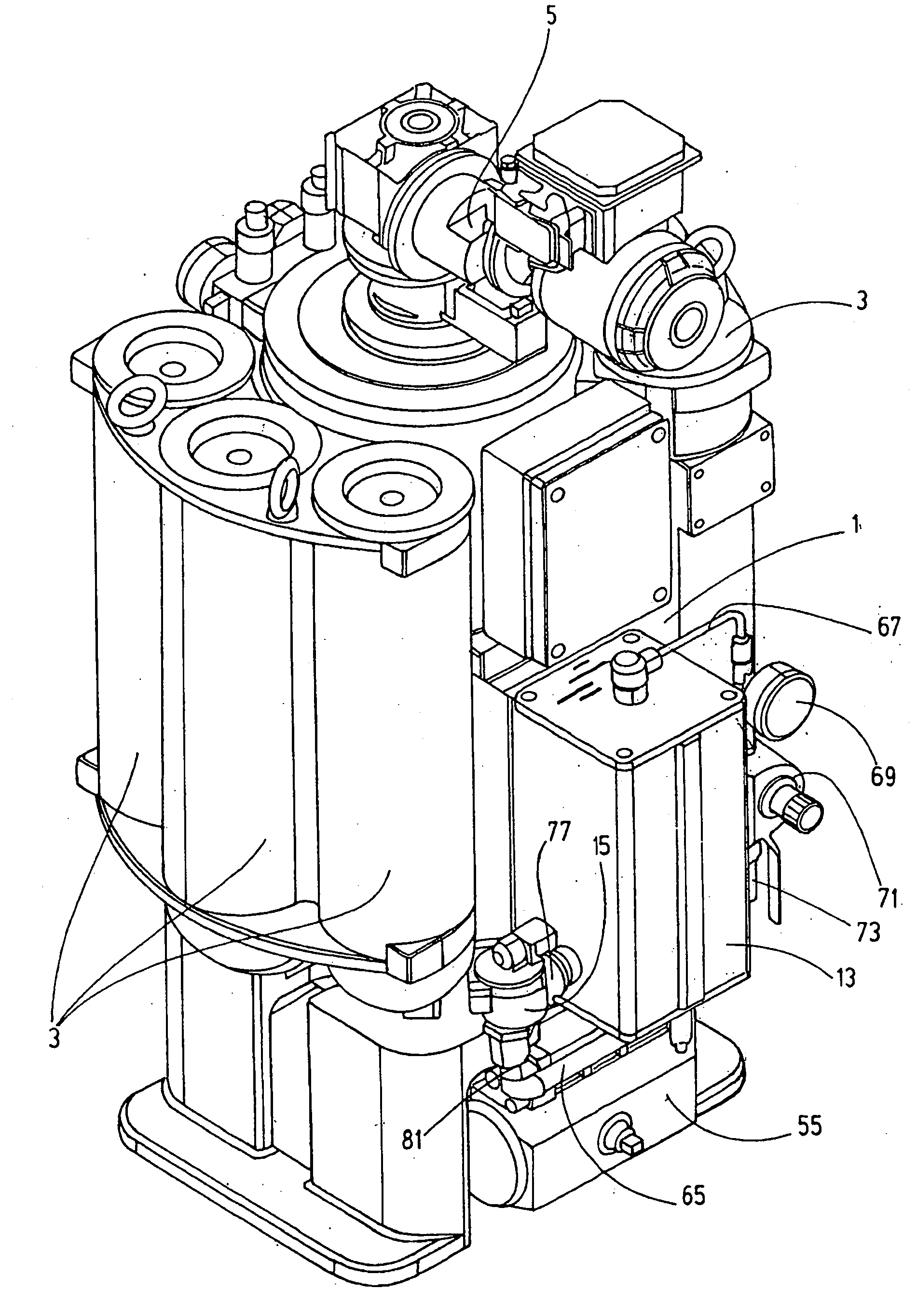

Substrate transfer mechanism and subtrate transfer apparatus, particle removal method, program, and storage medium

ActiveCN1696030AReliable removalReliable strippingSemiconductor/solid-state device manufacturingCharge manipulationTemperature controlRotary stage

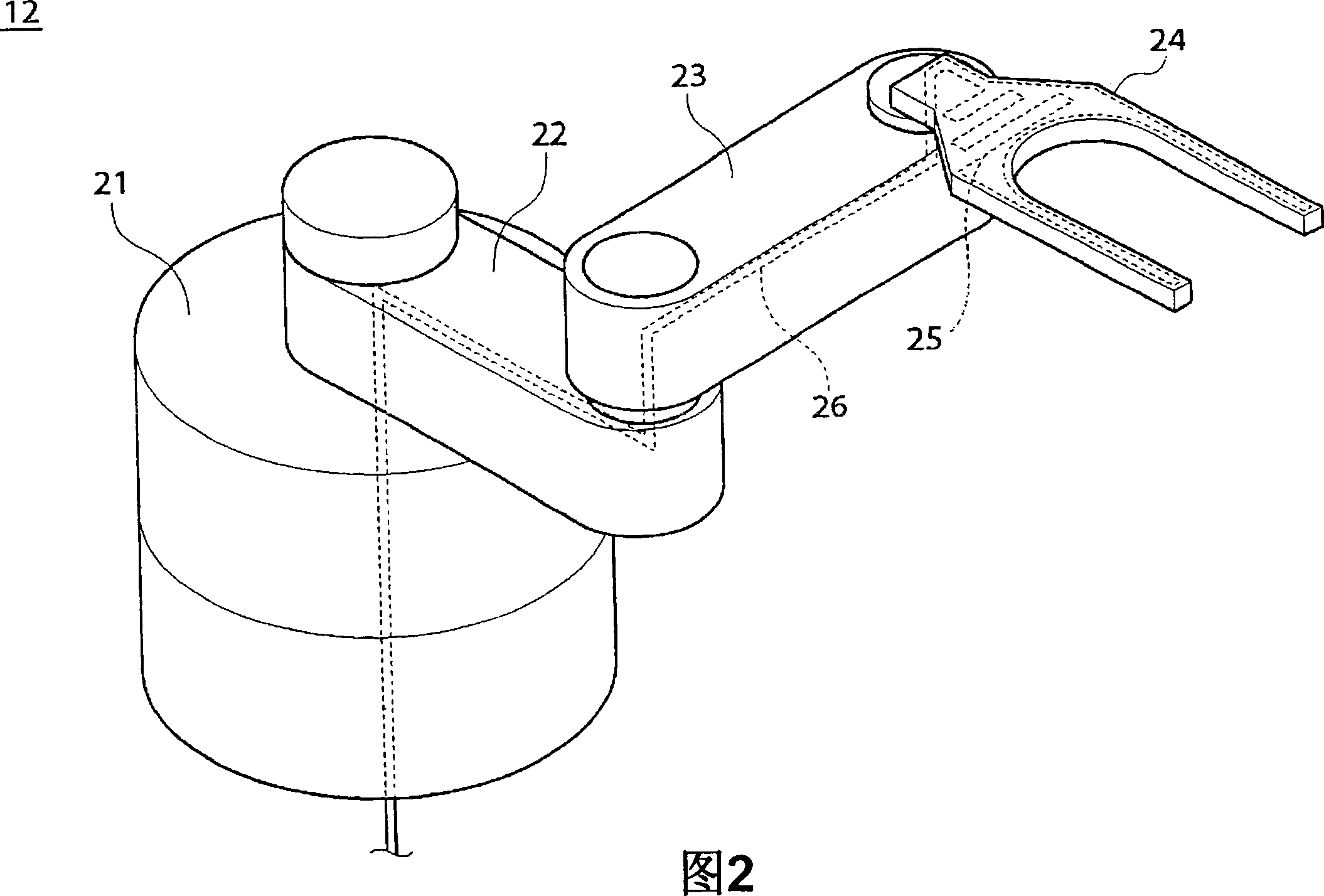

A substrate transfer mechanism for transferring a substrate includes a mounting table on which the substrate is mounted; an arm member connected to the mounting table and moving it. The substrate transfer mechanism further includes a temperature control unit for controlling temperature of the mounting table, wherein the temperature control unit forms a temperature gradient in the mounting table. The temperature control unit includes a detector for detecting temperature in an environment or a chamber in which the substrate transfer mechanism is installed a heater for heating the mounting table and a controller for controlling an operation of the heater based on the temperature in the environment or the chamber detected by the detector.

Owner:TOKYO ELECTRON LTD

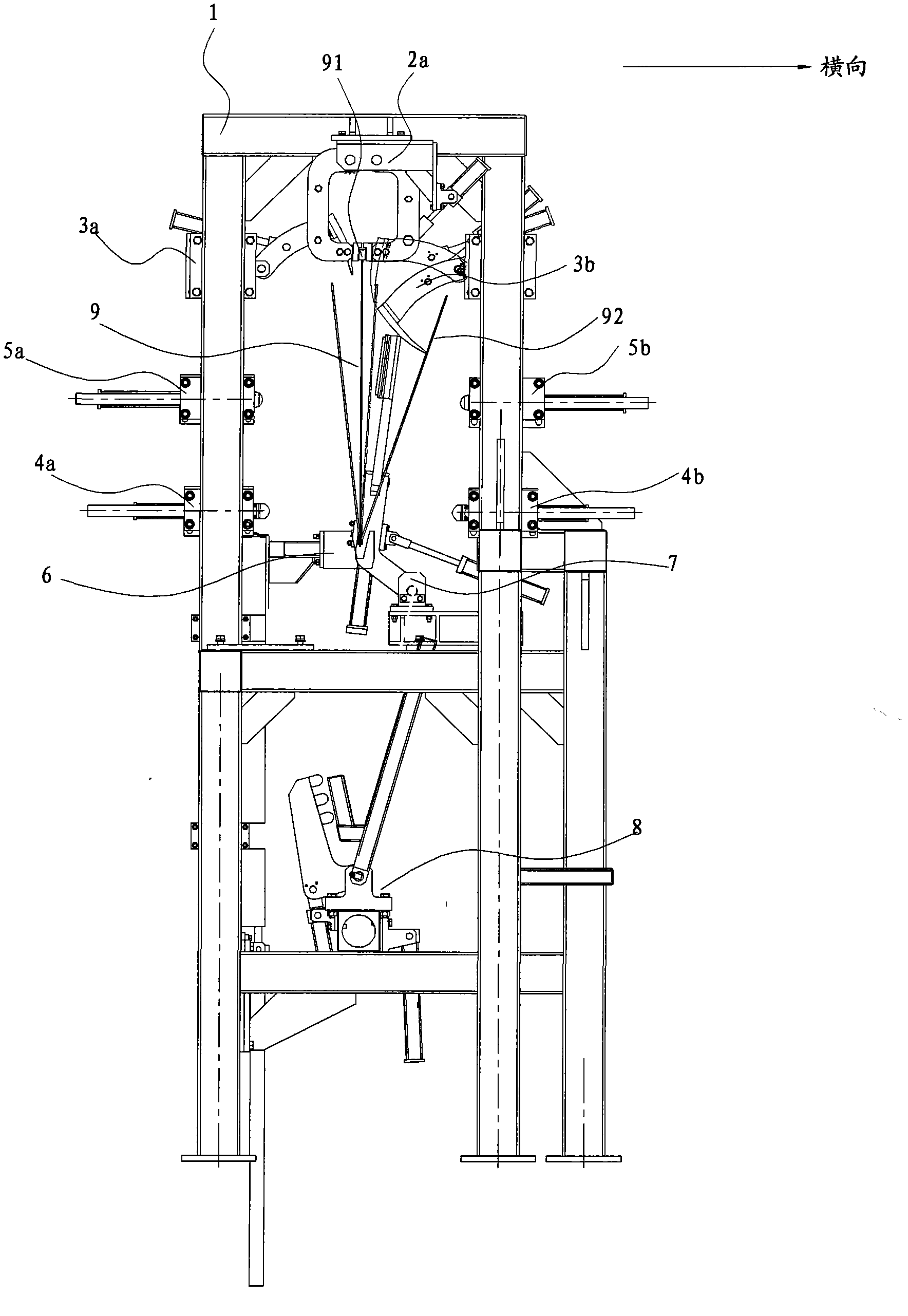

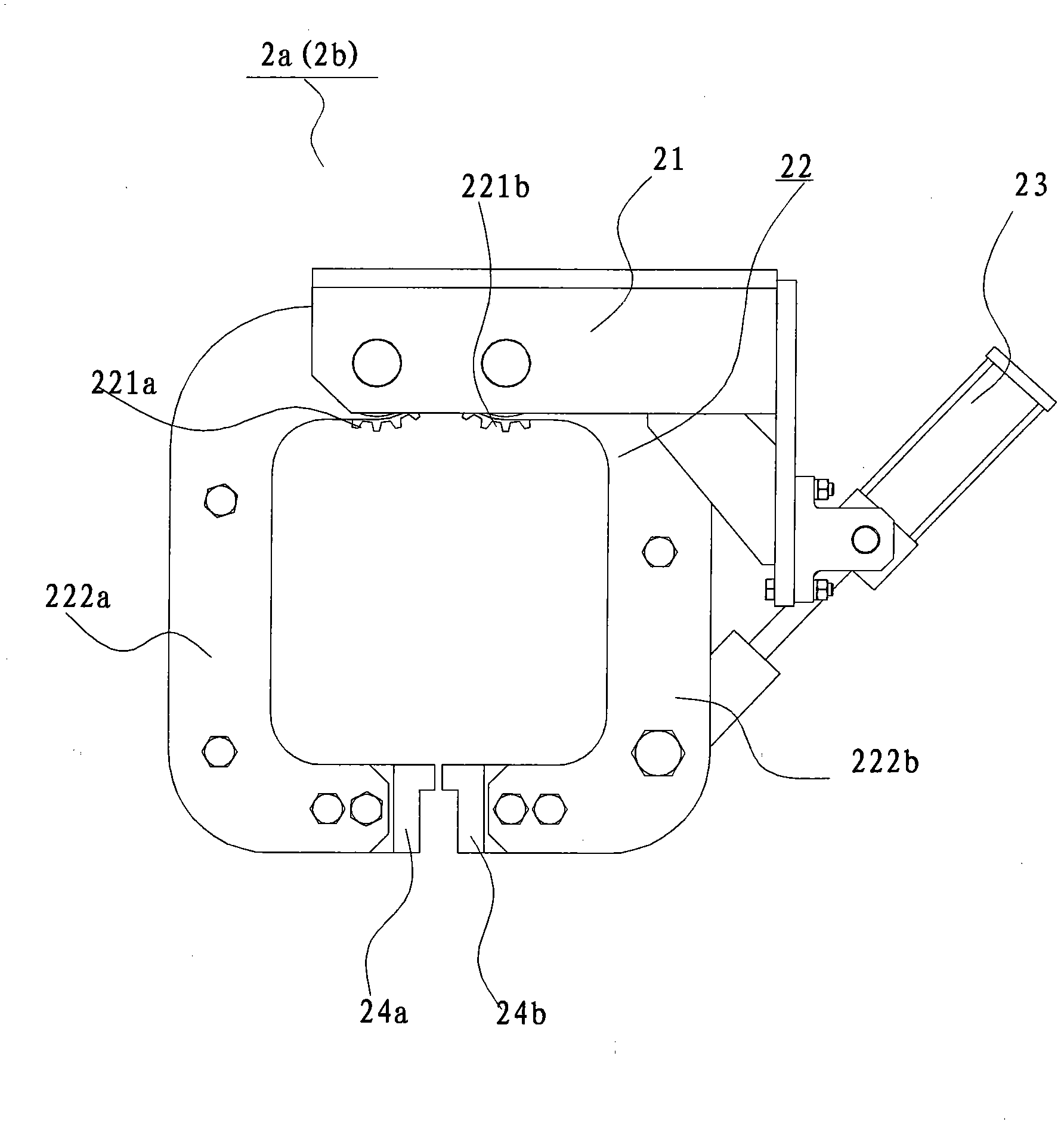

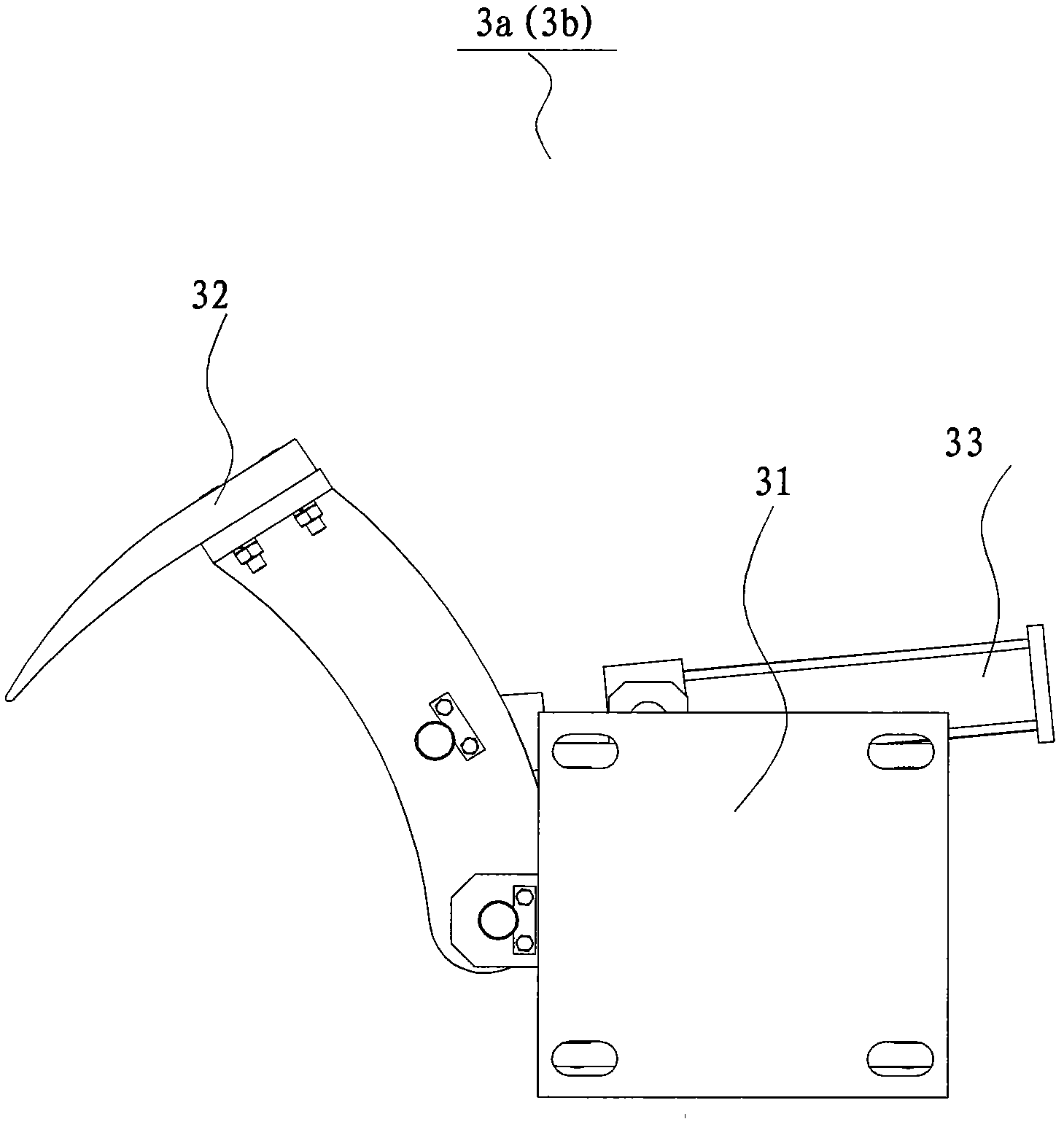

Negative plate delaminating device

ActiveCN102051642AAvoid scratchesQuality improvementElectrolysis componentsPhotography auxillary processesMechanical engineeringMetal

The invention discloses a negative plate delaminating device, comprising a rack and a delaminating component. The delaminating component is arranged on the rack and comprises clamping mechanisms, a plate-releasing mechanism, a bottom-locating mechanism, a plate-loosening mechanism and a plate-receiving mechanism, wherein the clamping mechanisms are mutually arranged above the rack at interval in the longitudinal direction; the plate-releasing mechanism is used for delaminating deposition metal plates from the two sides of the negative plate; the bottom-locating mechanism is used for locating the bottom end of the negative plate; the plate-loosening mechanism is arranged at the two transverse sides of the rack and comprises a push rod which moves along the transverse direction and arrangedon the rack for thrusting the negative plate; and the plate-receiving mechanism comprises at least one plate-receiving platform which can vertically move and is used for bearing the deposition metal plates. According to the negative plate delaminating device in the embodiment of the invention, the plate-receiving mechanism is arranged below the delaminating component to bear the delaminated deposition metal plates, thus the work noise and the device damage caused by impact of the device below are both avoided; and the deposition metal plate can not be scratched during the process of sliding, thus the appearance and the quality are reliable.

Owner:JIANGXI NERIN EQUIP

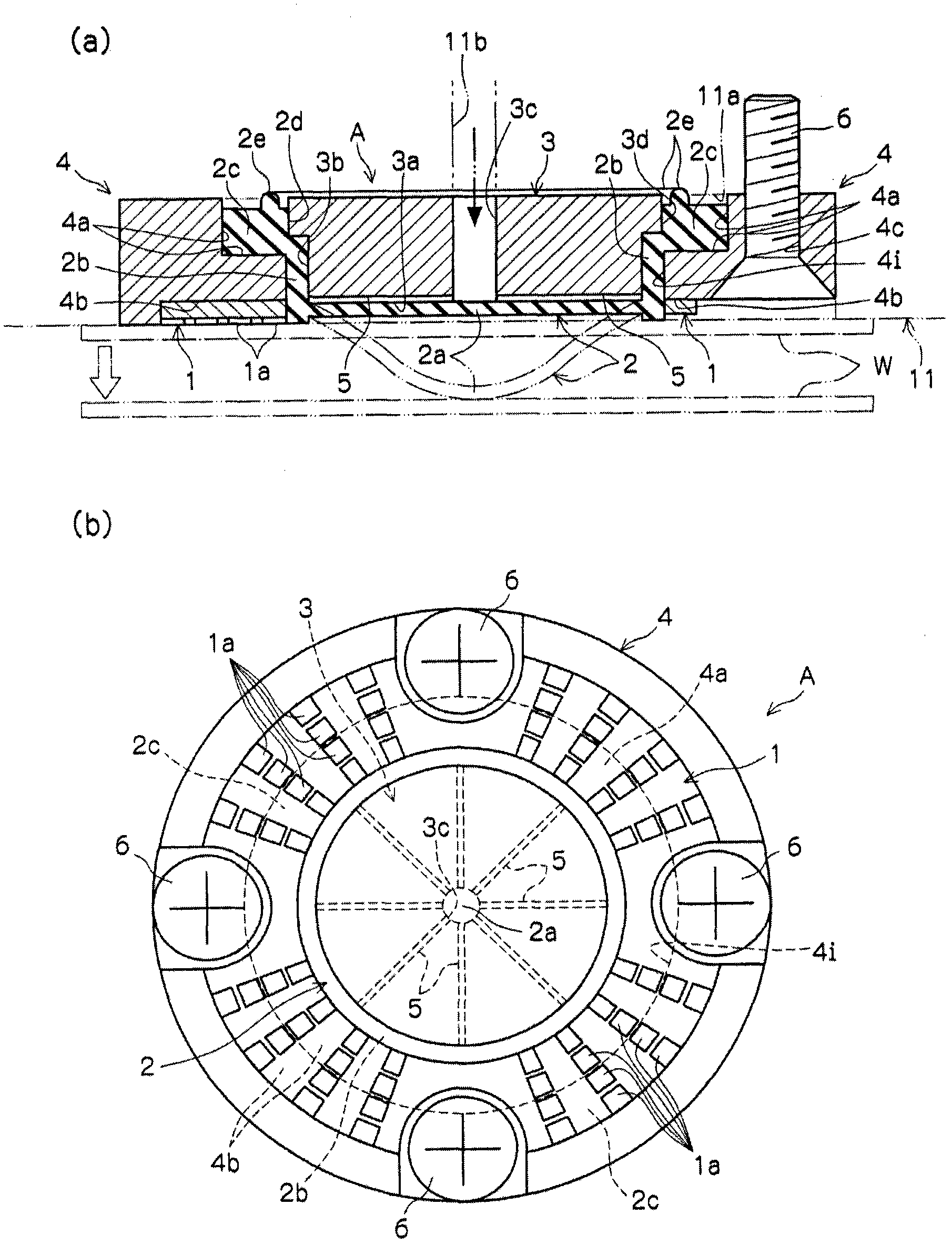

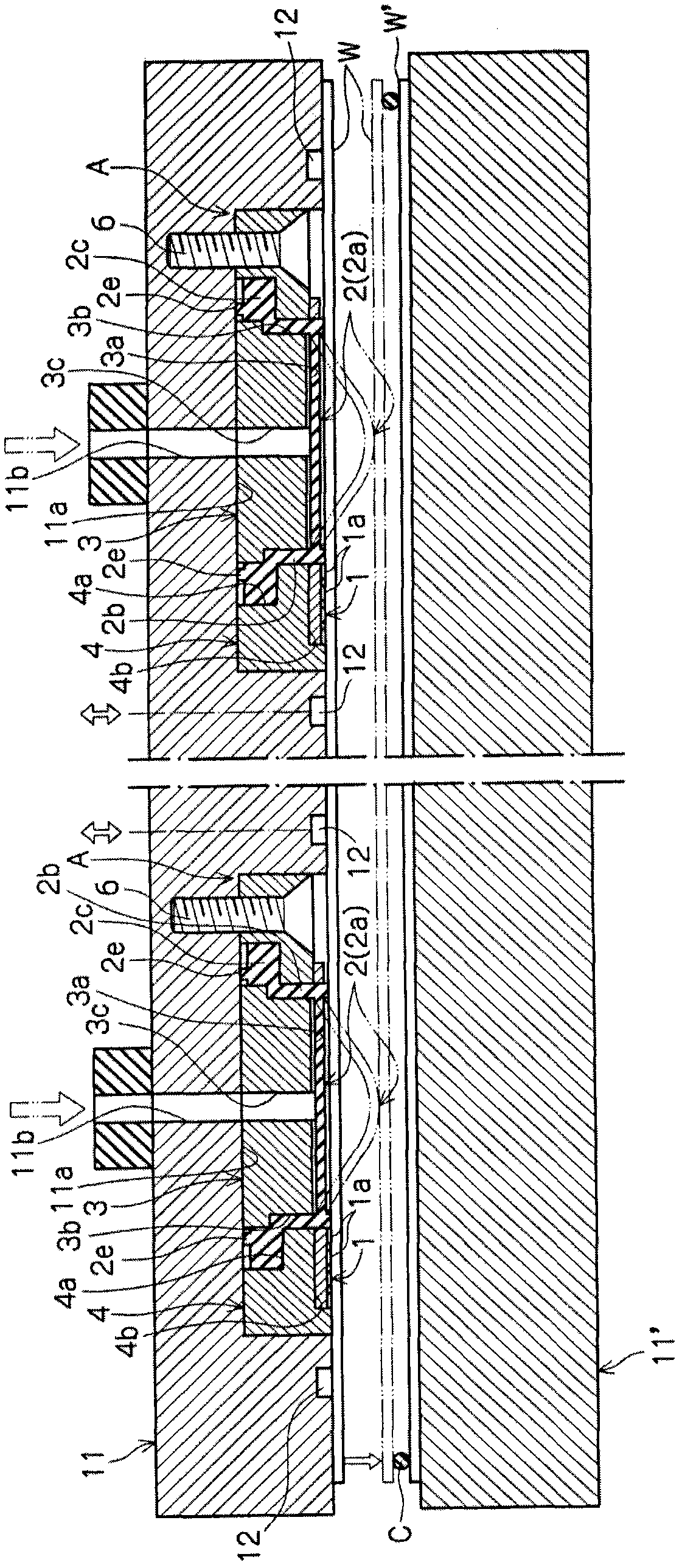

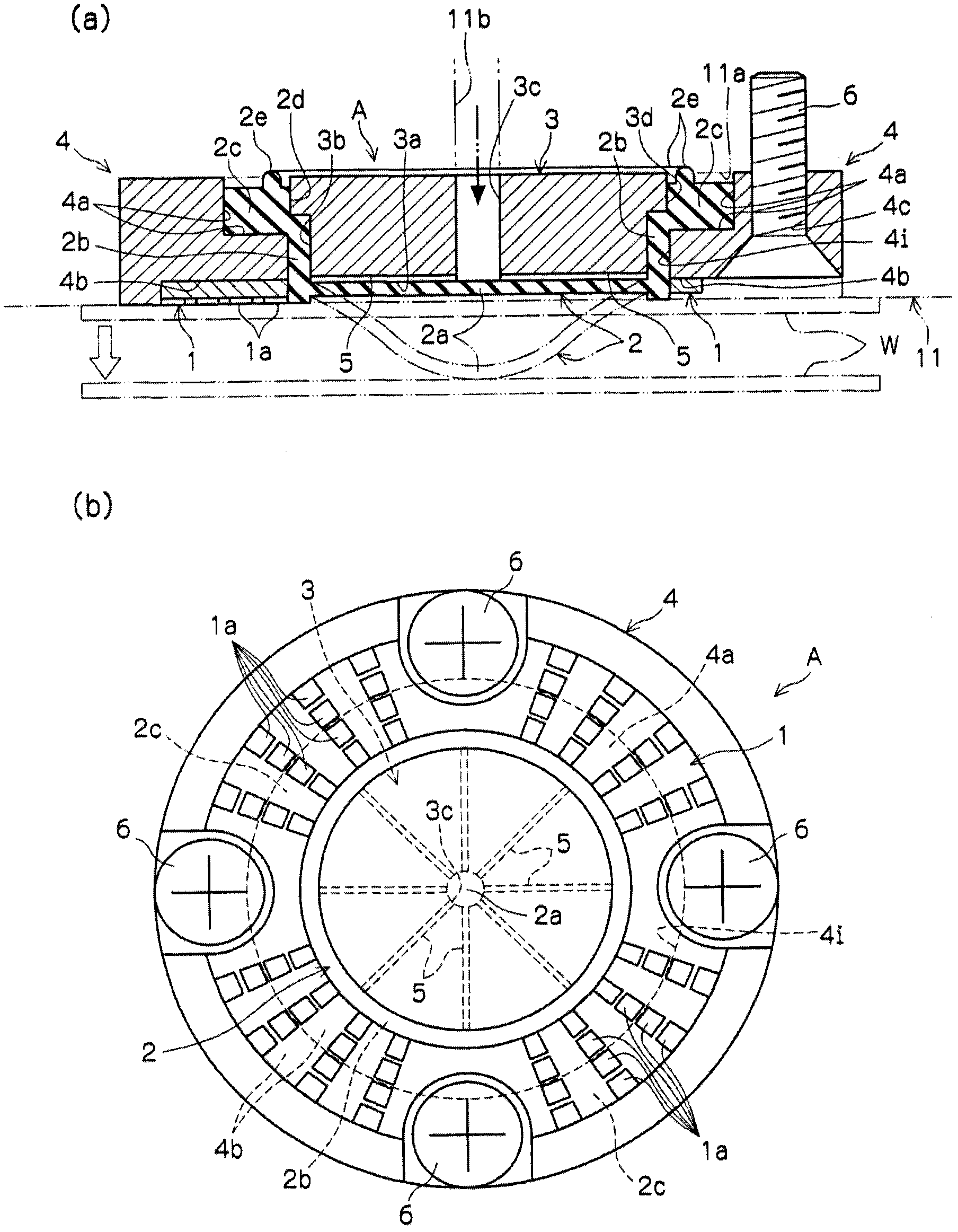

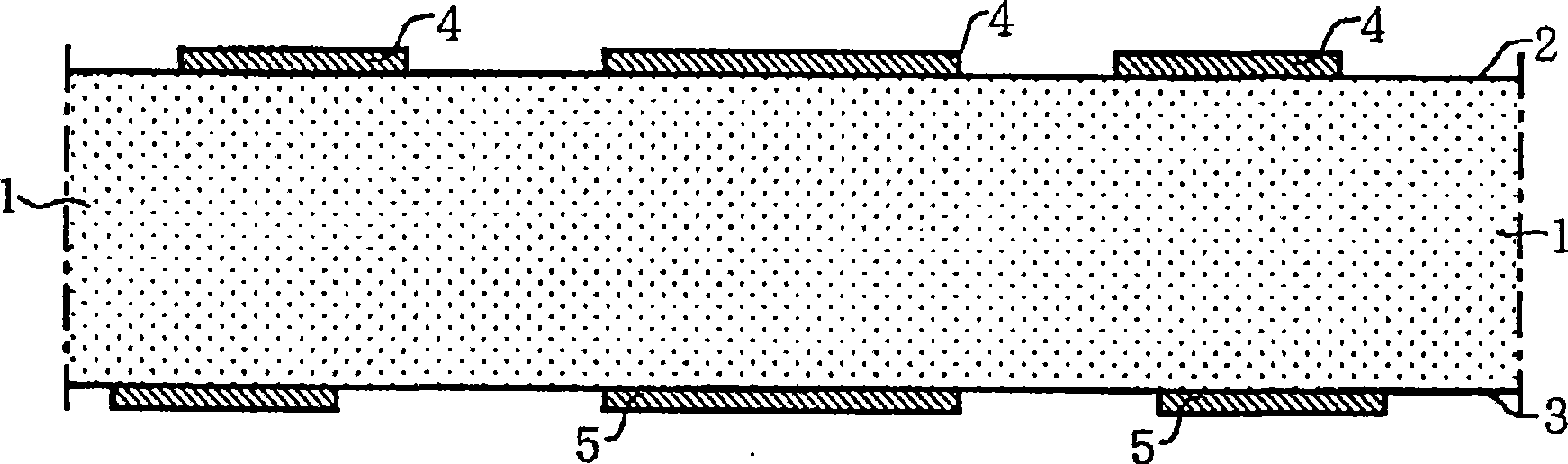

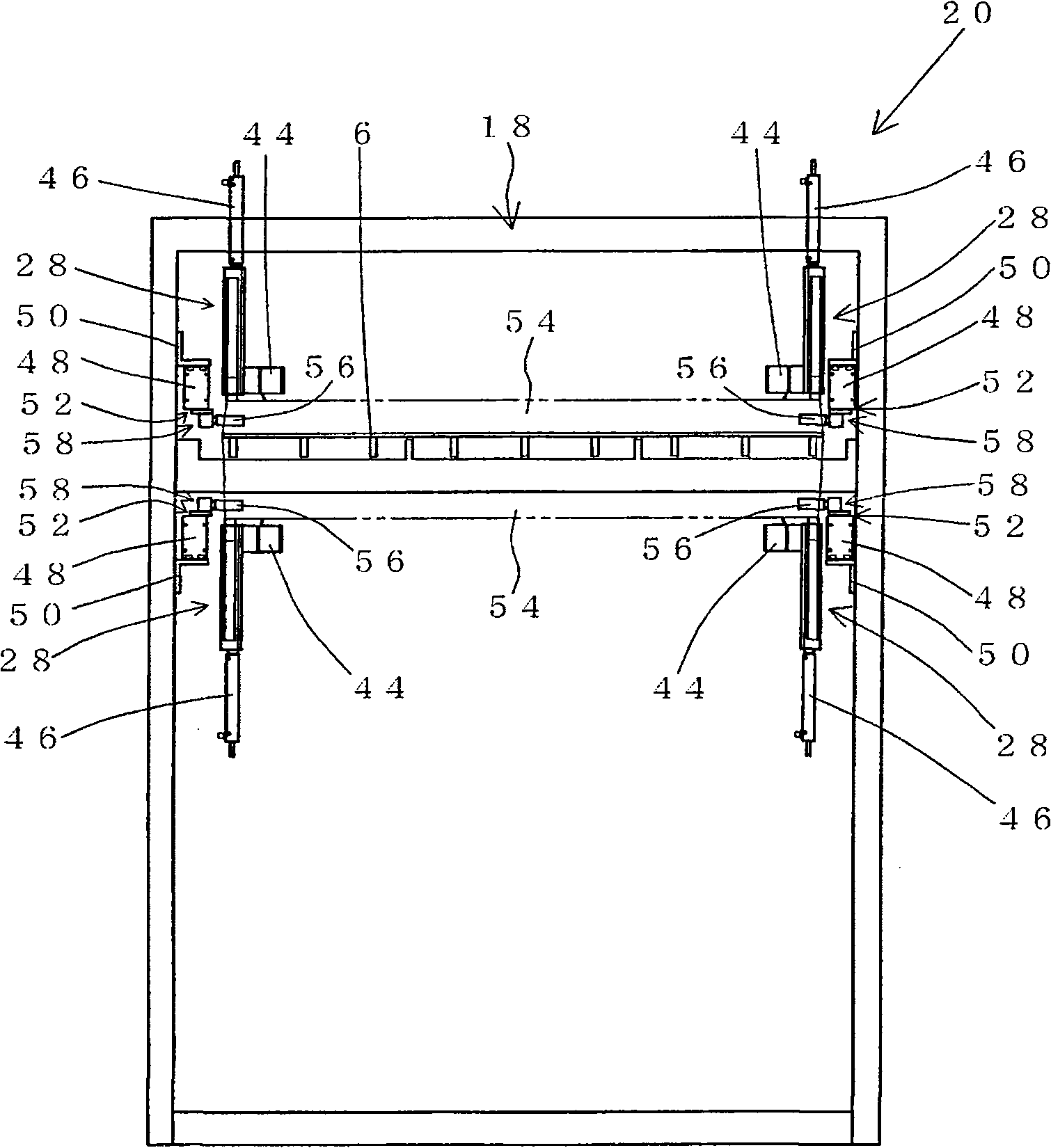

Working attaching chuck device and work piece laminating machine

ActiveCN102649336AEasy to form a unitImprove peel forceLamination ancillary operationsLaminationEngineeringPeel force

The invention provides a working attaching chuck device and a work piece laminating machine. By using the invention, attaching parts can be easily formed and a peeling part can be unitized, at the same time the peeling performance can be improved. In the invention, an installation protruding part (2c) of the peeling part (2) is clamped into a part between the side surface (3b) of a supporting member (3) and a clamping concave part (4a) of an ring-shaped part (4) in a manner that the installation protruding part can not move along the deformation direction towards the deformation part (2a). The attaching part (1) is connected to the outer edge of the deformation part (2a), and then is disposed on an installation surface (4a) of the ring-shaped part (4), thereby integrating the peeling part (2), the supporting member (3) and the attaching part (1) into one body by using the ring-shaped part (4). In addition, the deformation part (2a) and the attaching surface (1a) are adjacent to each other, and connected together, therefore, when the plate-shaped work piece (W) attached to the attaching surface (1a) by the deformation of the deformation part (2a), a larger peeling force can be obtained, and the flexure generated during the peeling process of the plate-shaped work piece (W) can be reduced to the minimal degree.

Owner:SHIN ETSU ENG

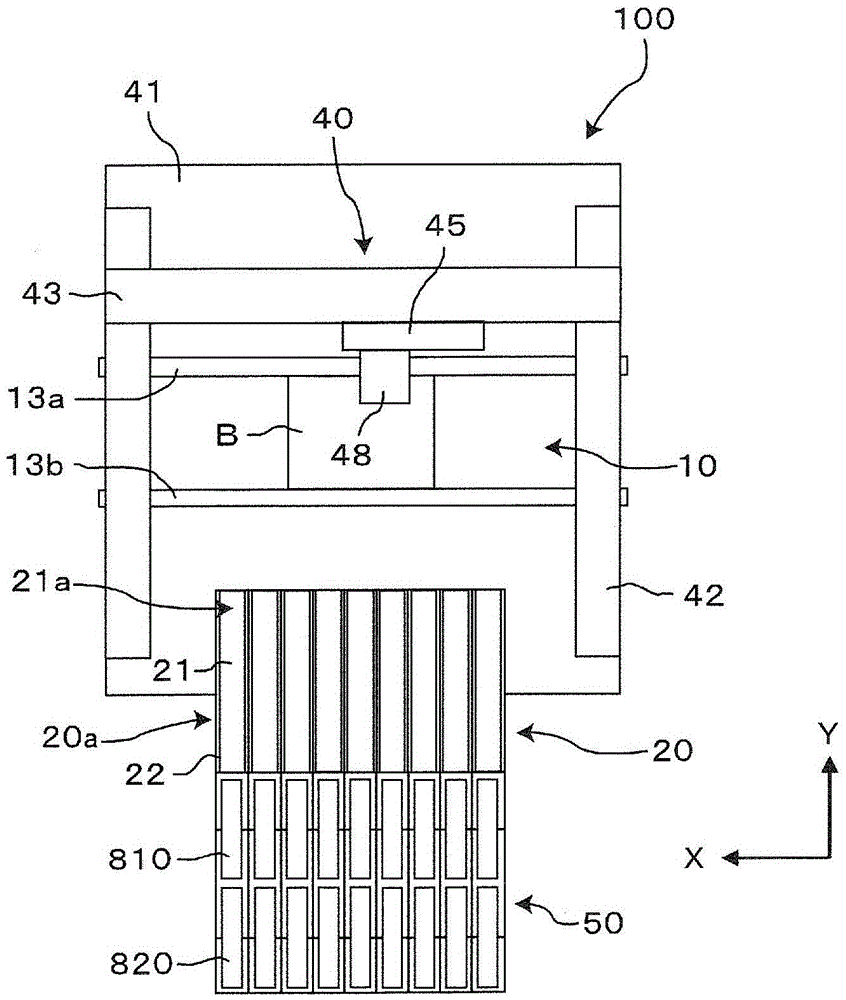

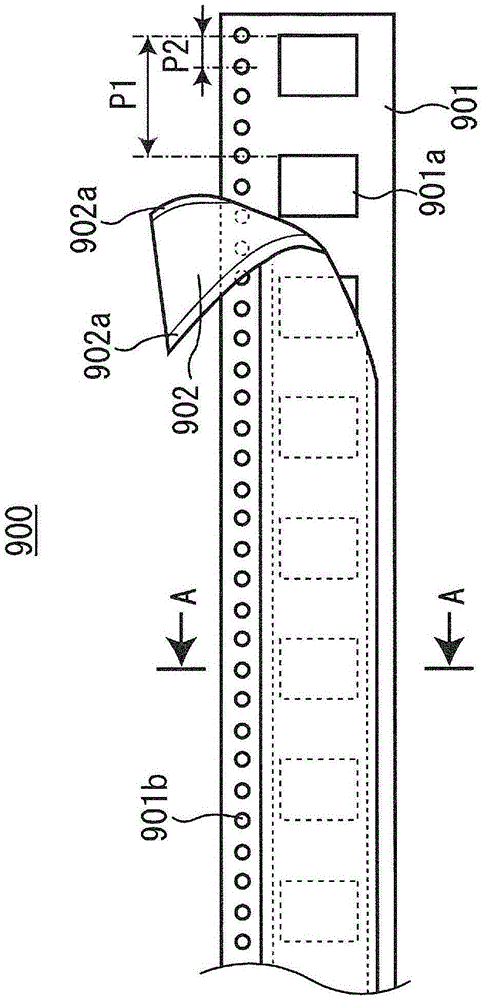

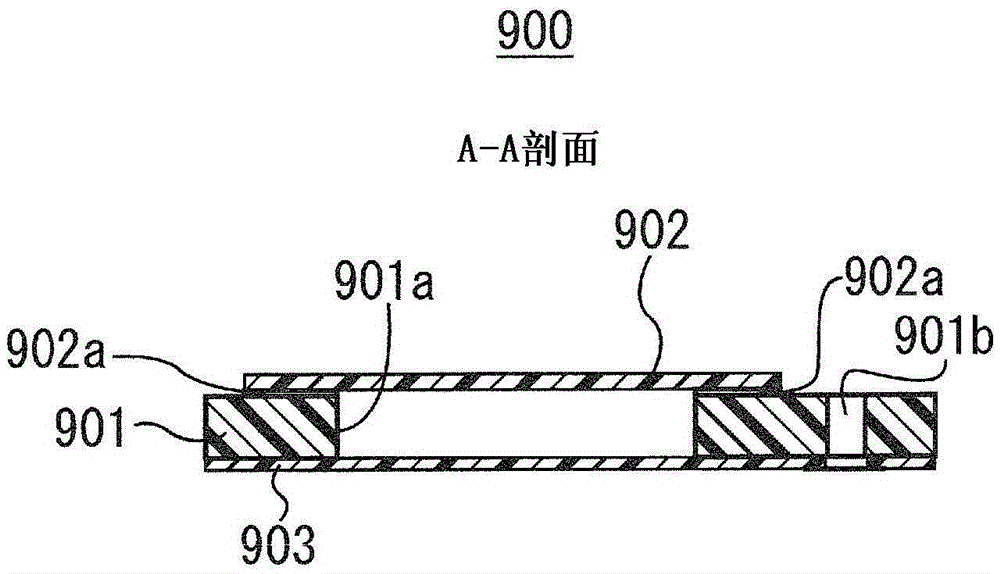

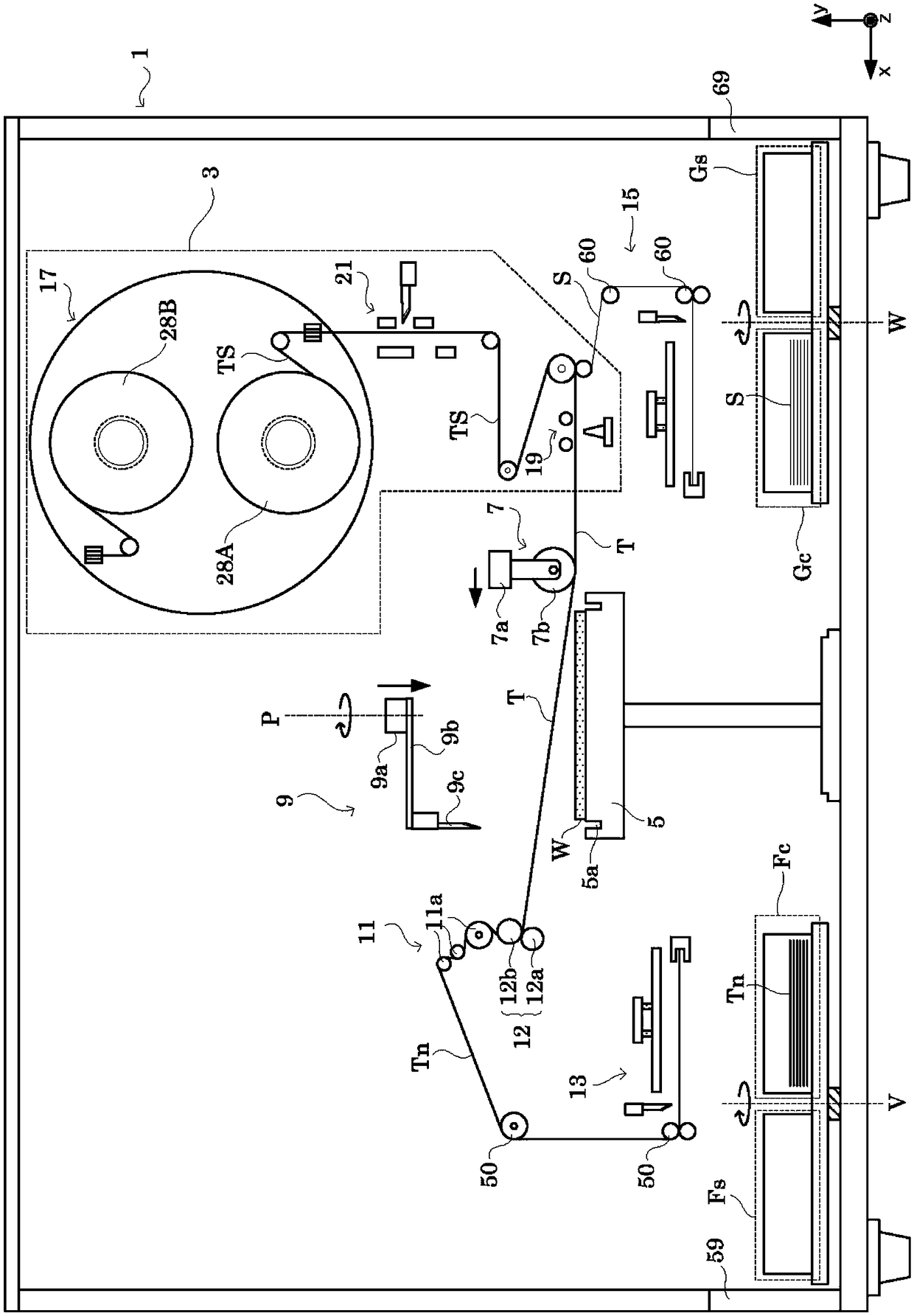

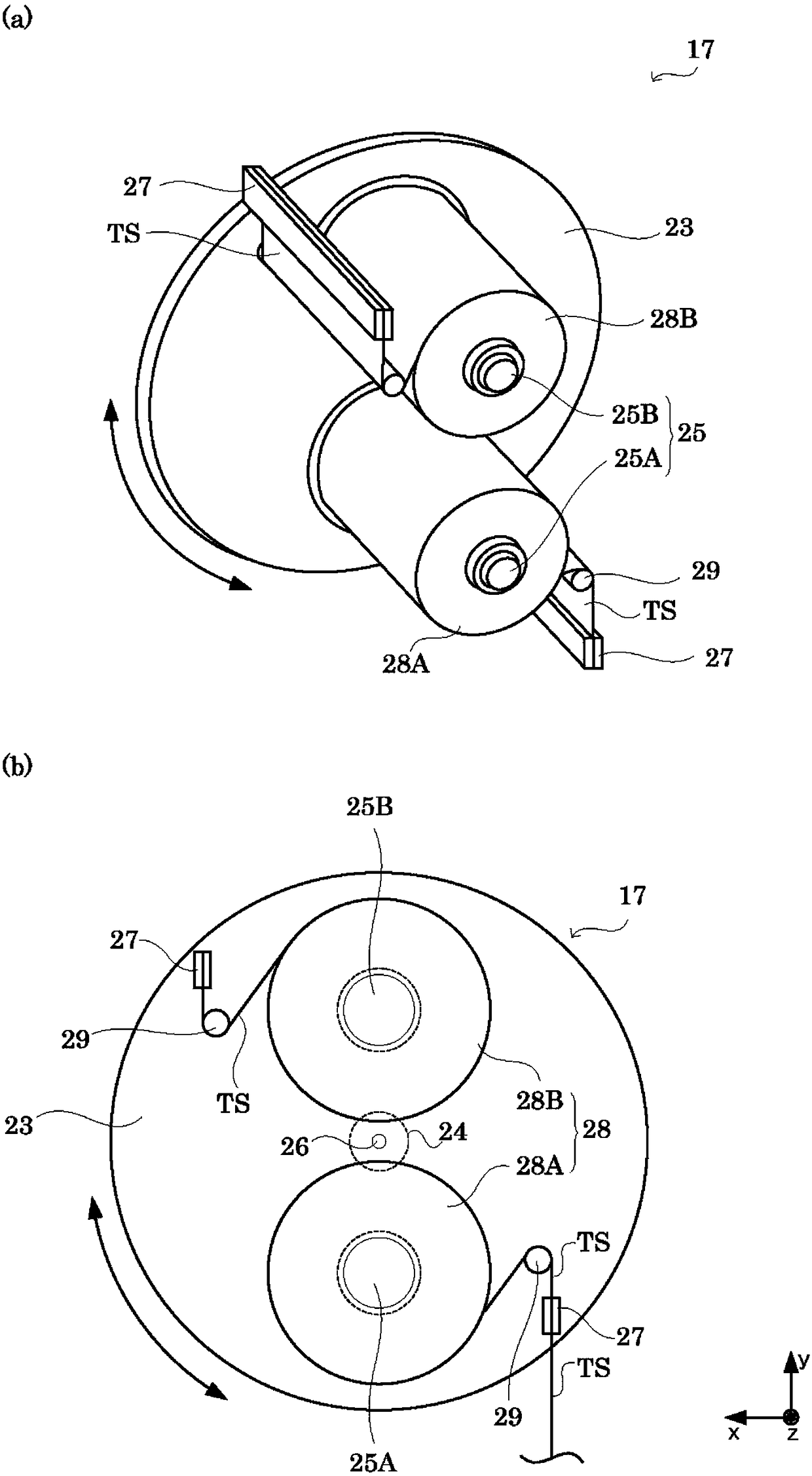

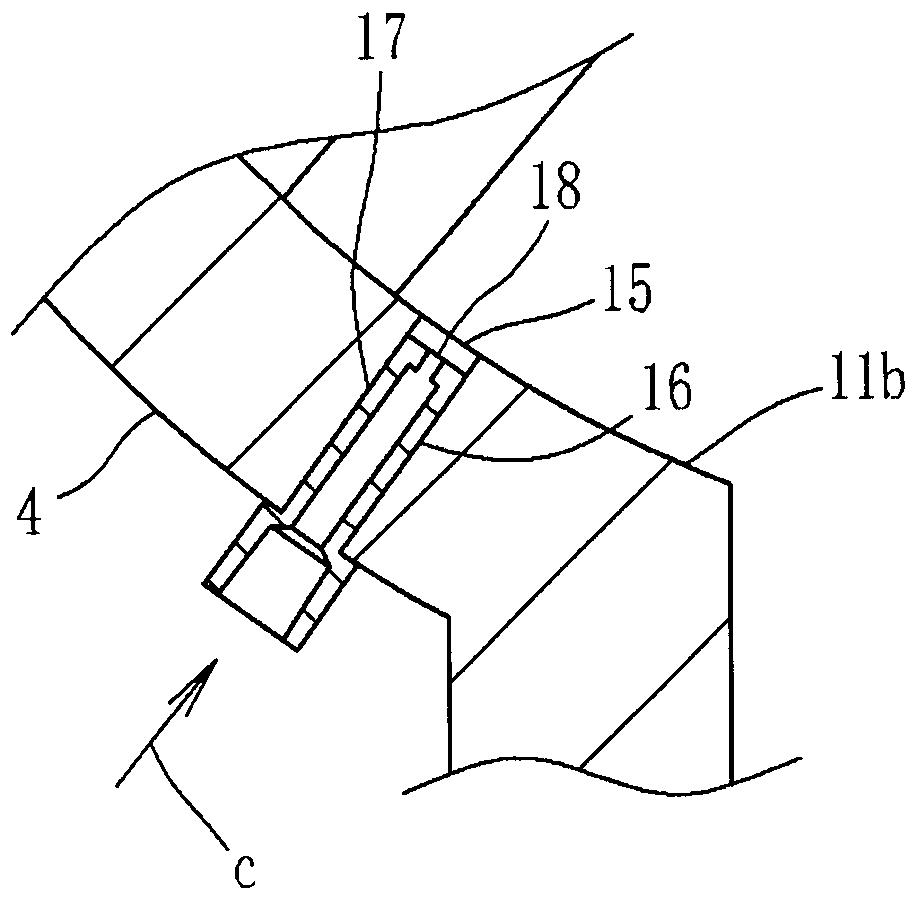

Feeder

The purpose of the present invention is to provide a non-splicing feeder provided with a plurality of sprockets in a transport direction, said non-splicing feeder accurately supplying components held in a carrier tape to a supply position. The feeder comprises: a main unit (21b); a first sprocket (61) which is rotatably disposed at a supply position (21a) of the main unit (21b), and upon which first engaging projections (61a) are formed; and a second sprocket (62) which is rotatably disposed on the main unit (21b) at a transport direction upstream side of a carrier tape (900) relative to the first sprocket (61), and upon which second engaging projections (62a) are formed. Tooth-thickness dimensions of the second engaging projections (62a) are set to be smaller than tooth-thickness dimensions of the first engaging projections (61a).

Owner:FUJI KK

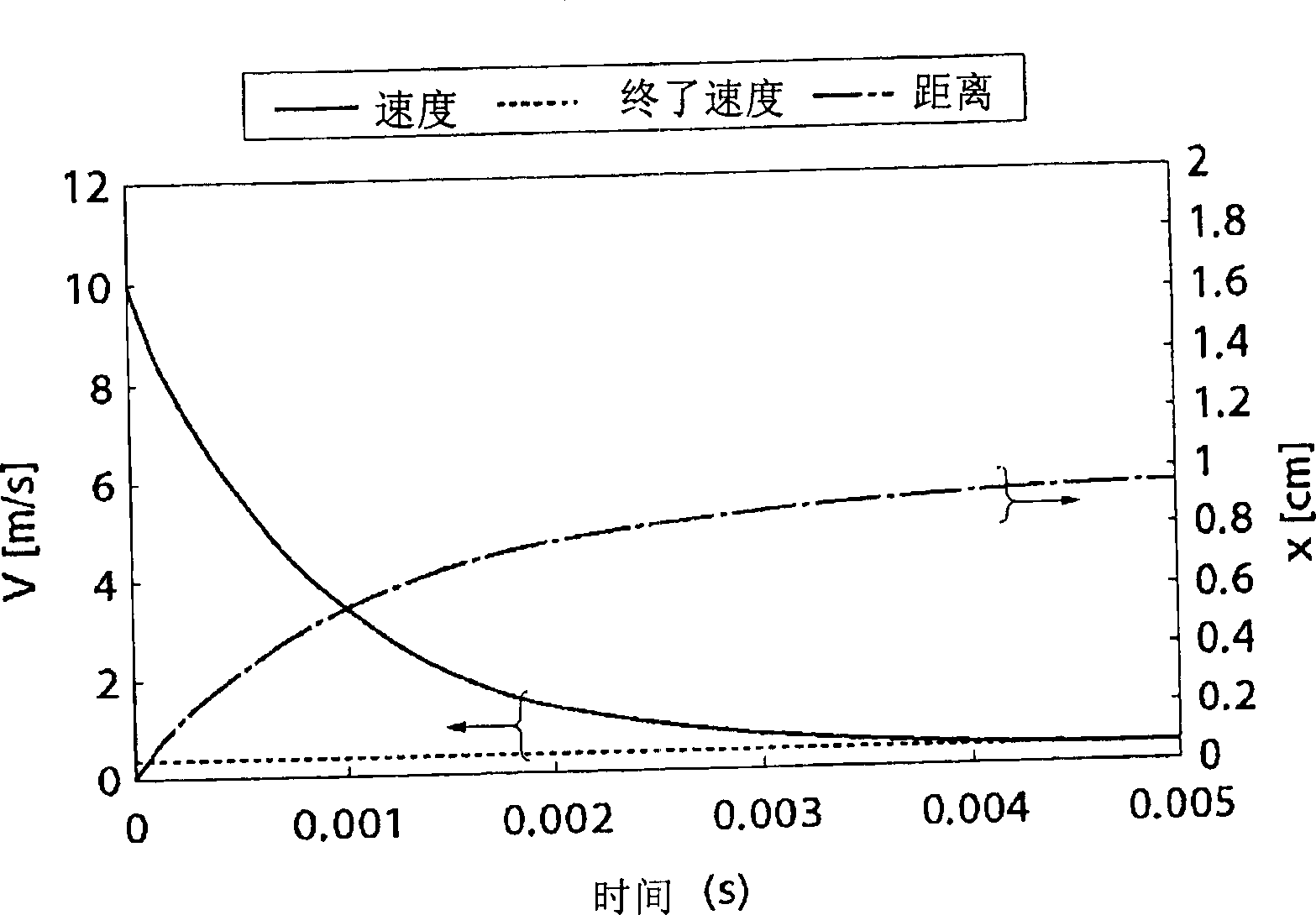

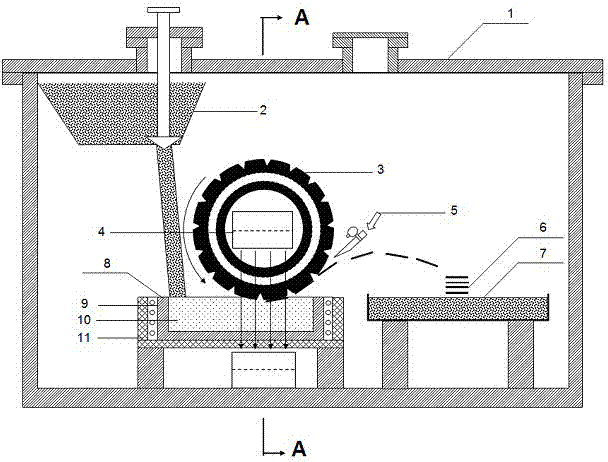

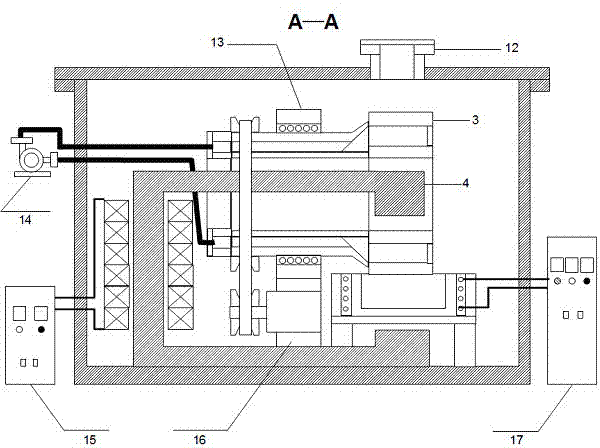

Method for continuously manufacturing high-silicon steel sheet and continuous casting device

The invention discloses a method for continuously manufacturing a high-silicon steel sheet and a continuous casting device. Pure iron powder and silicon powder are placed in a molten pool in a certain mass percent for alloy melting preparation, the molten pool is located in a strong magnetic field area generated by a magnet yoke coil in the whole process, after alloy is molten and is evenly mixed, an upper toothed water cooling copper disc rotating at high speed achieves fast cooling, a high-silicon steel thin belt is formed, the sheet is blown open through an air cutter above the sheet and is reliably stripped from the copper disc, and therefore the aim of manufacturing the high-silicon steel sheet through a direct extraction method is achieved, and the high-silicon steel sheet stripped from the copper disc enters a lower collection chamber with a soft pad or an air pad. the thickness, internal quality and surface quality of the high-silicon steel sheet can be controlled by controlling the immersion depth of the tooth face of the water cooling copper disc and alloy melt, the cooling water flow of the water cooling cooper disc, the rotating speed of the water cooling copper disc and the magnetic field intensity of an outer reinforcing static magnetic field. The size of the tooth face of the water cooling copper disc is controlled to control the width and length of the high-silicon steel sheet.

Owner:SHANGHAI UNIV

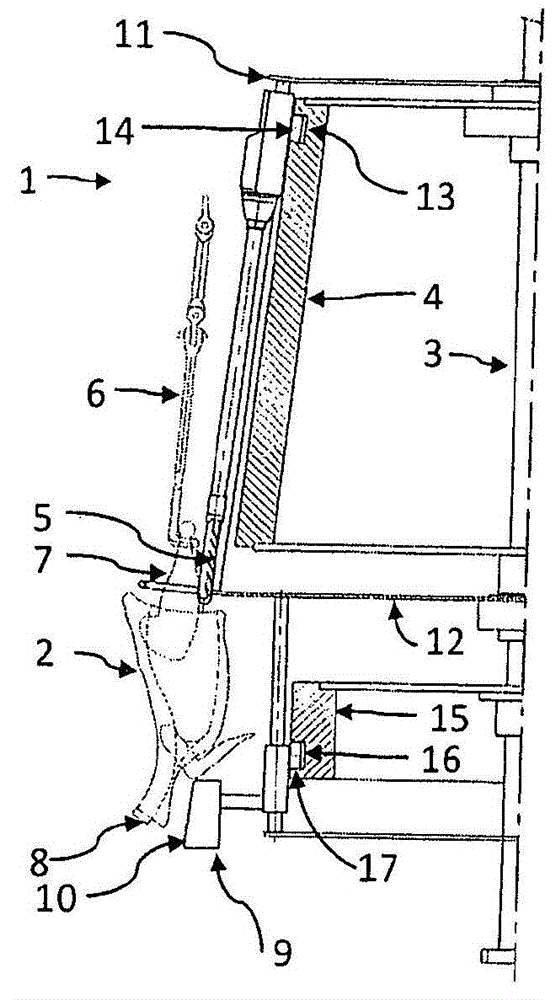

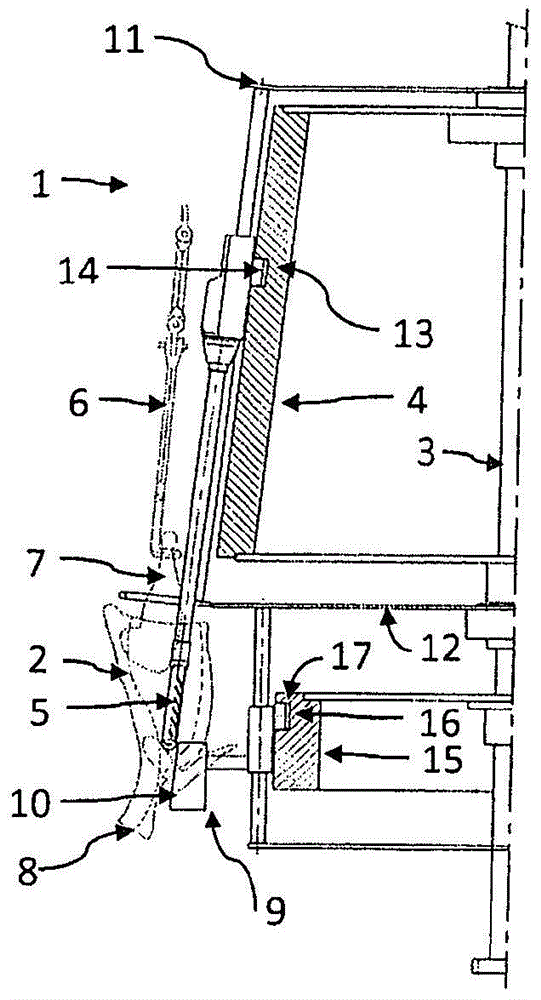

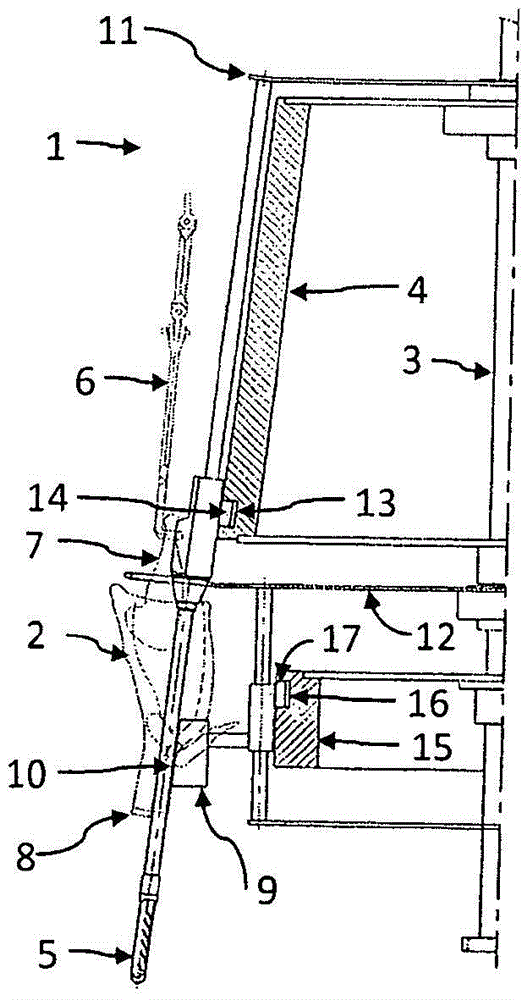

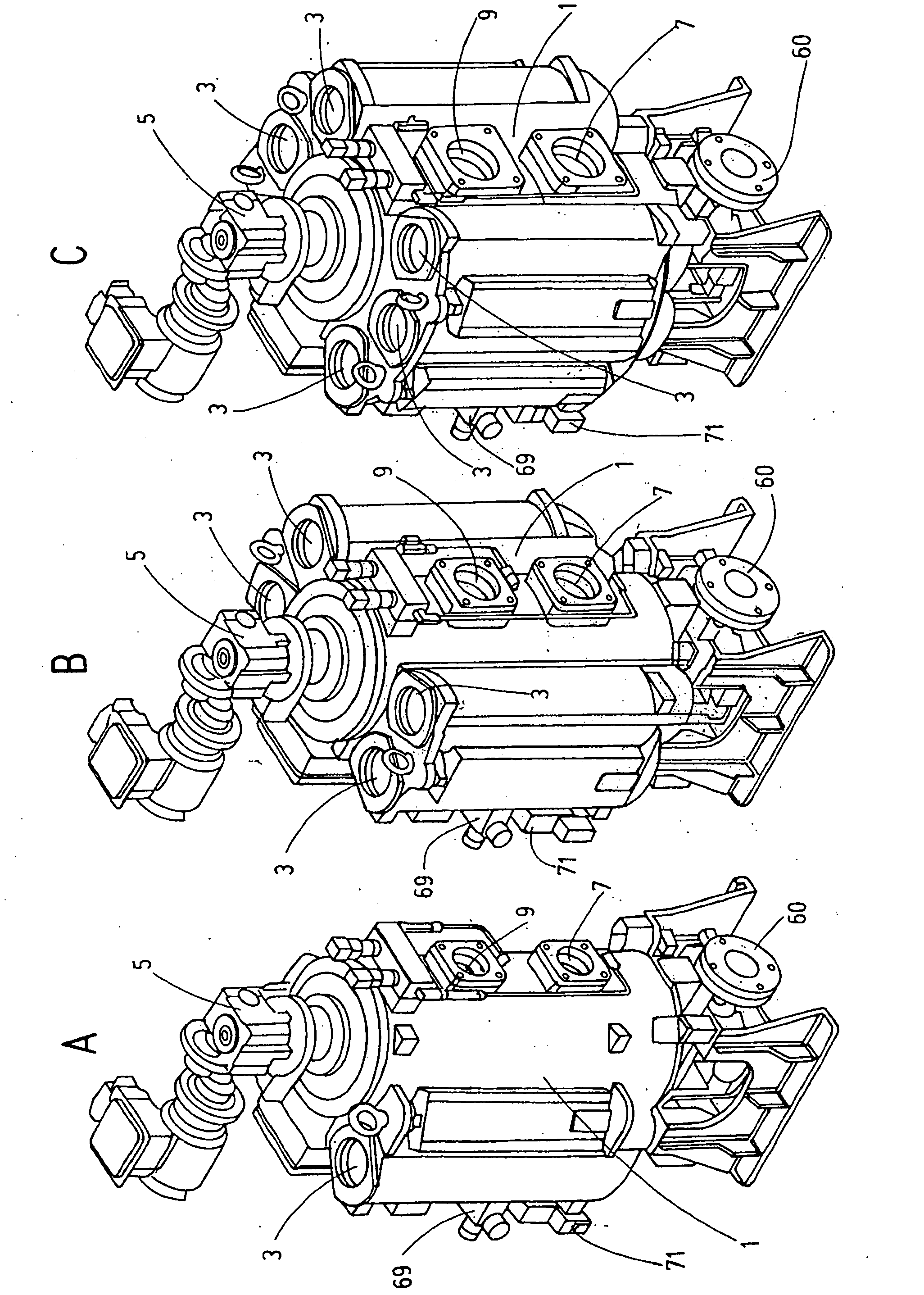

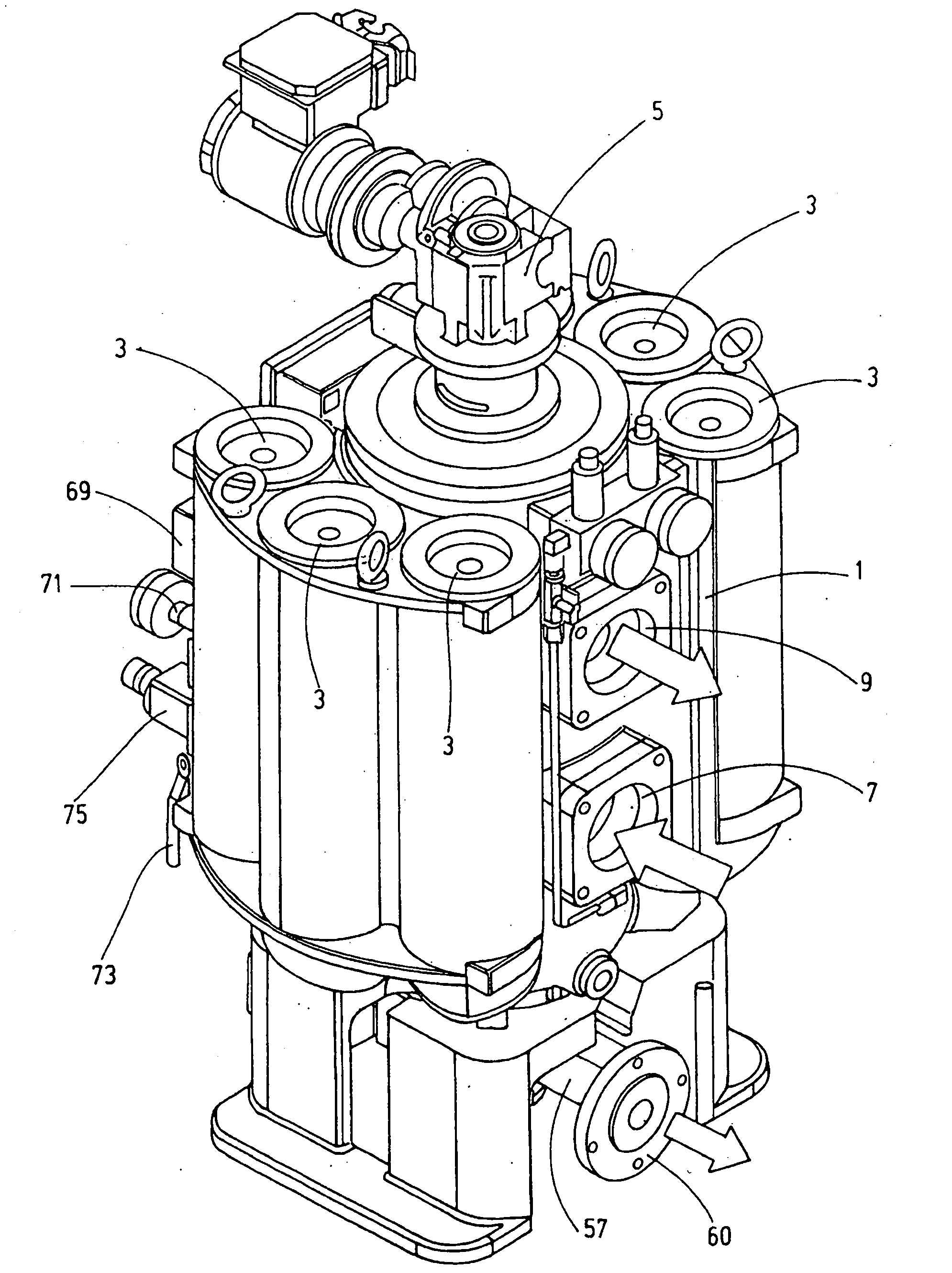

An apparatus for carrying out an operation on slaughtered poultry

ActiveCN105265558AReliable strippingMeat/sausage hanging-upPoultry eviscerating devicesEngineeringElectrical and Electronics engineering

An apparatus for carrying out an operation on slaughtered poultry, comprising suspension devices for suspending the poultry by the legs, a first drum which at its periphery is provided with a first curve formed by a first groove which is being traced by a first projection that connects to a first processing organ so as to arrange that movement of the first processing organ along the periphery of the first drum causes said first processing organ to be placed in an operational position with respect to the poultry being suspended by the legs. Further there are second processing means that cooperate with a second drum provided with a second curve formed by a second groove which is being traced by a second projection connected with the second processing means so as to arrange that by its movement along the periphery of the second drum said second processing means is positioned in its operational position with reference to the poultry. The apparatus further has the feature that the first drum and the second drum are rotationally adjustable with respect to each other.

Owner:MEYN FOOD PROCESSING TECH

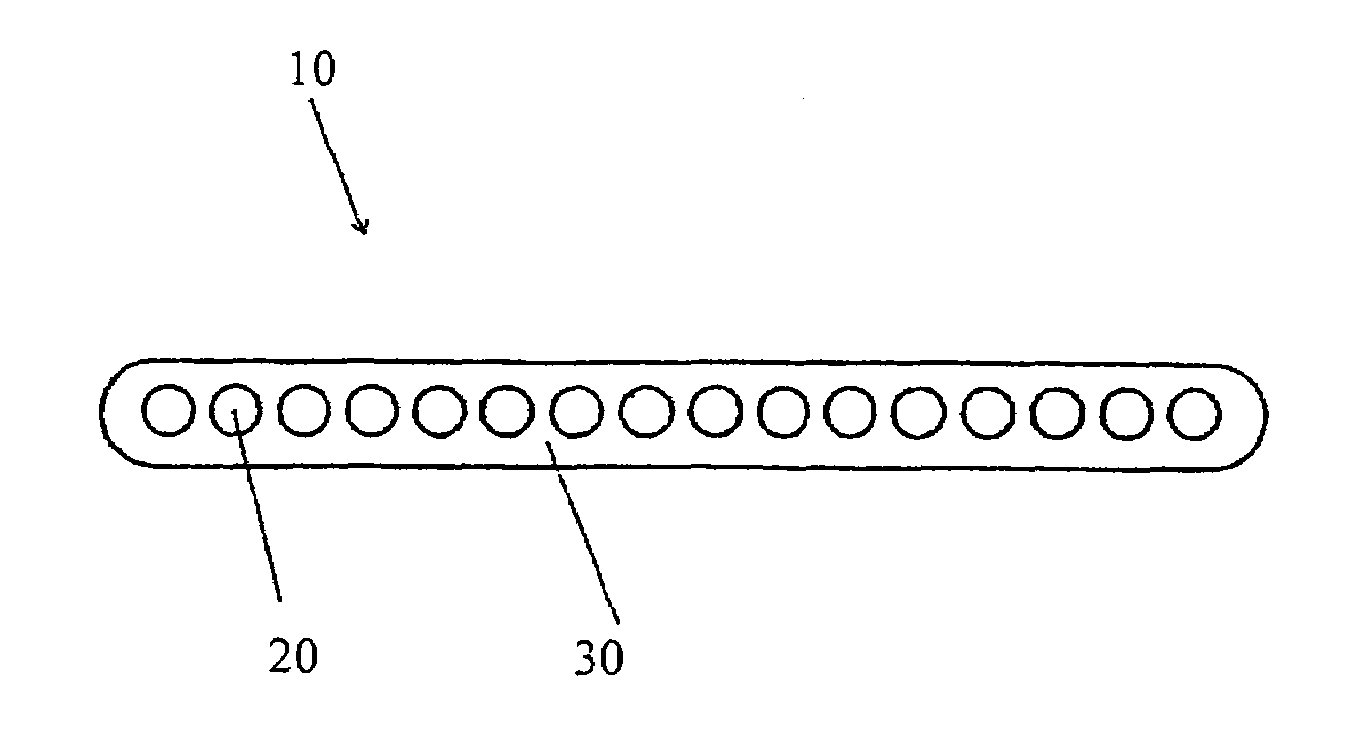

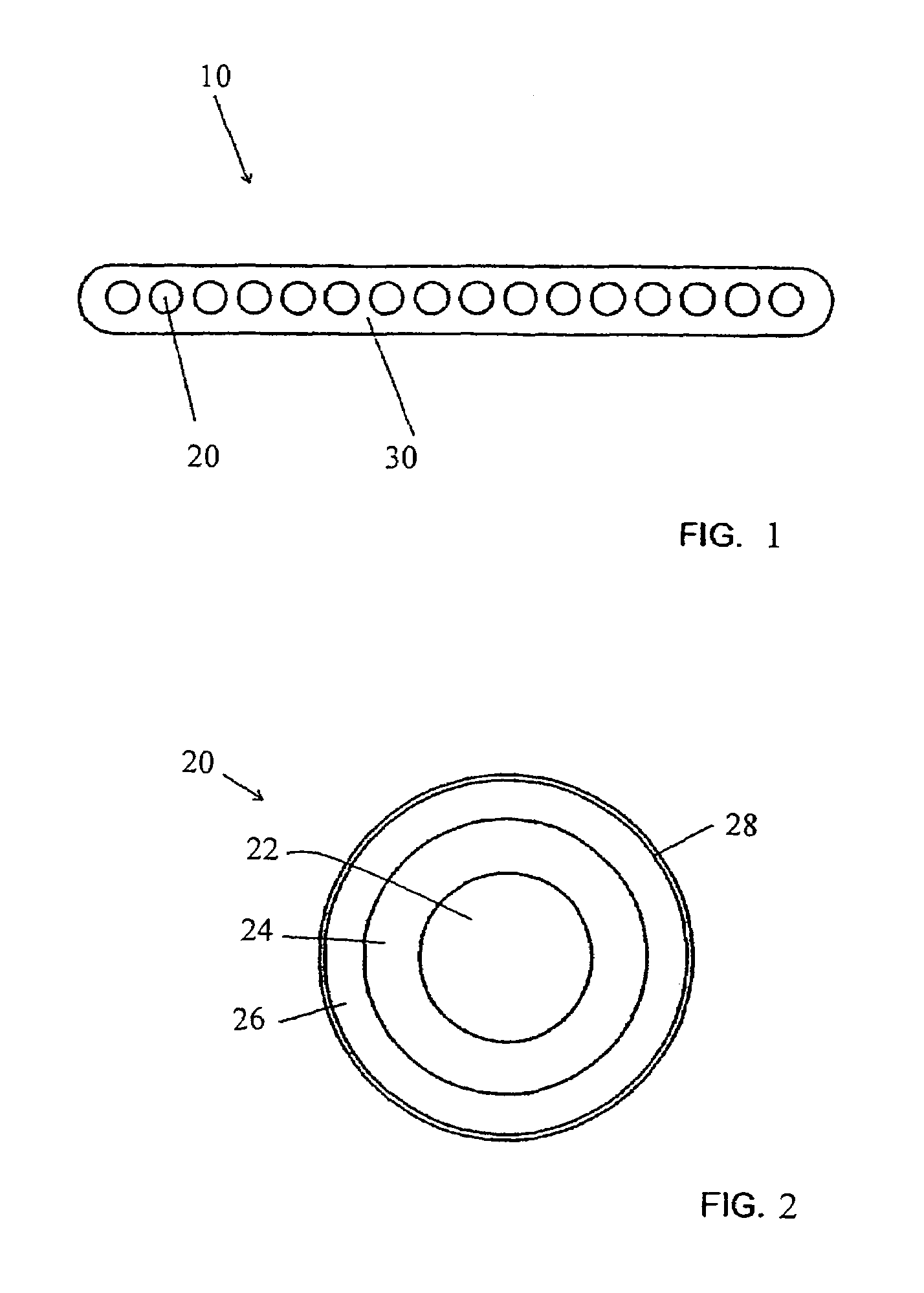

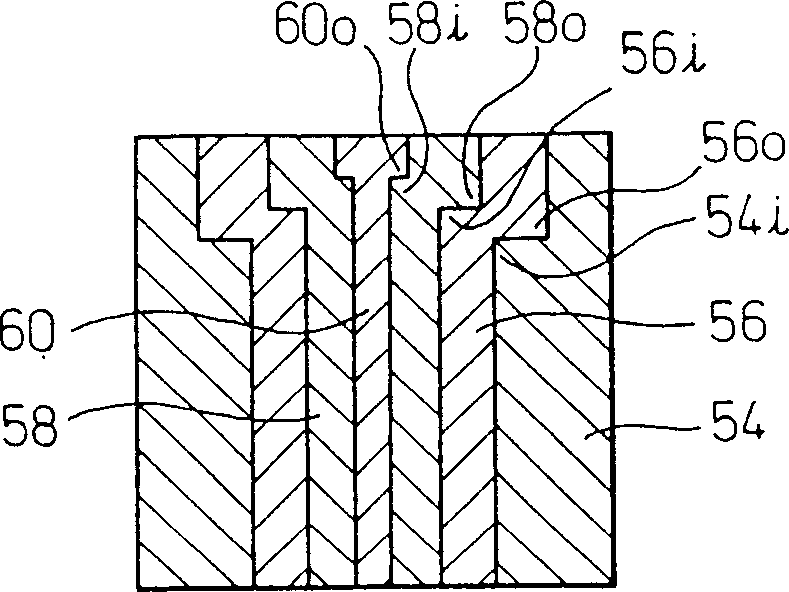

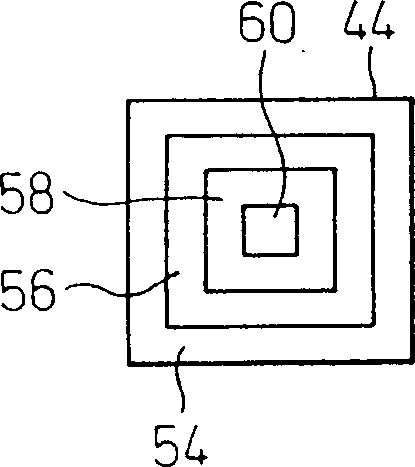

Method and device for stripping semiconductor device by ring-type contact unit

InactiveCN1414602AReliable strippingThe overall thickness is thinSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeSemiconductor chip

In a semiconductor device manufacturing process, a semiconductor wafer is diced into a plurality of semiconductor chips, which are then peeled, from a dicing tape, using a peeling device. The peeling device includes a plurality of annular contact members arranged one after another from the outside to the inside, and the annular contact members are operated so that the semiconductor chip is successively peeled from the tape from the outer circumferential portion thereof toward the central portion thereof.

Owner:SOCIONEXT INC

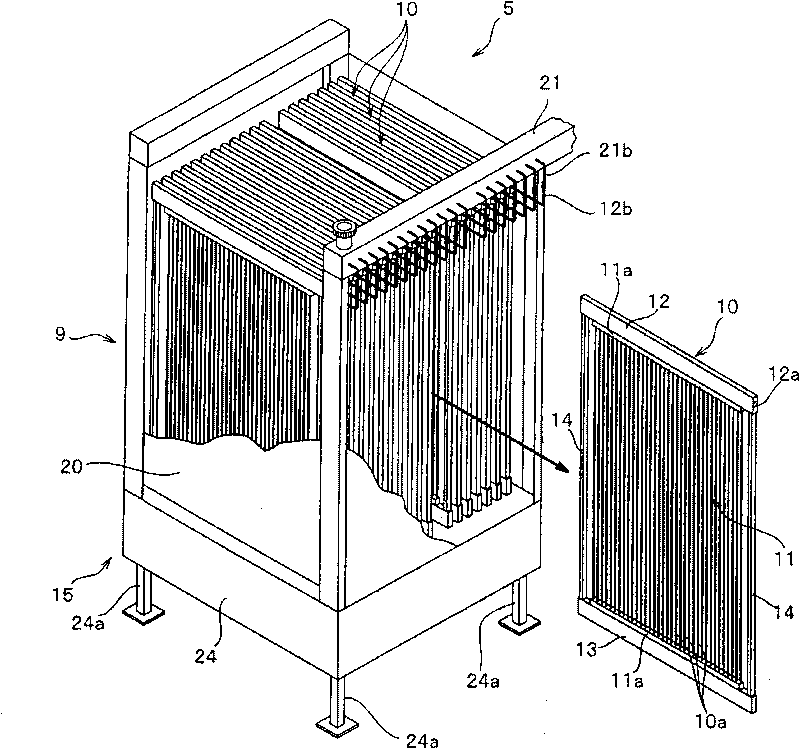

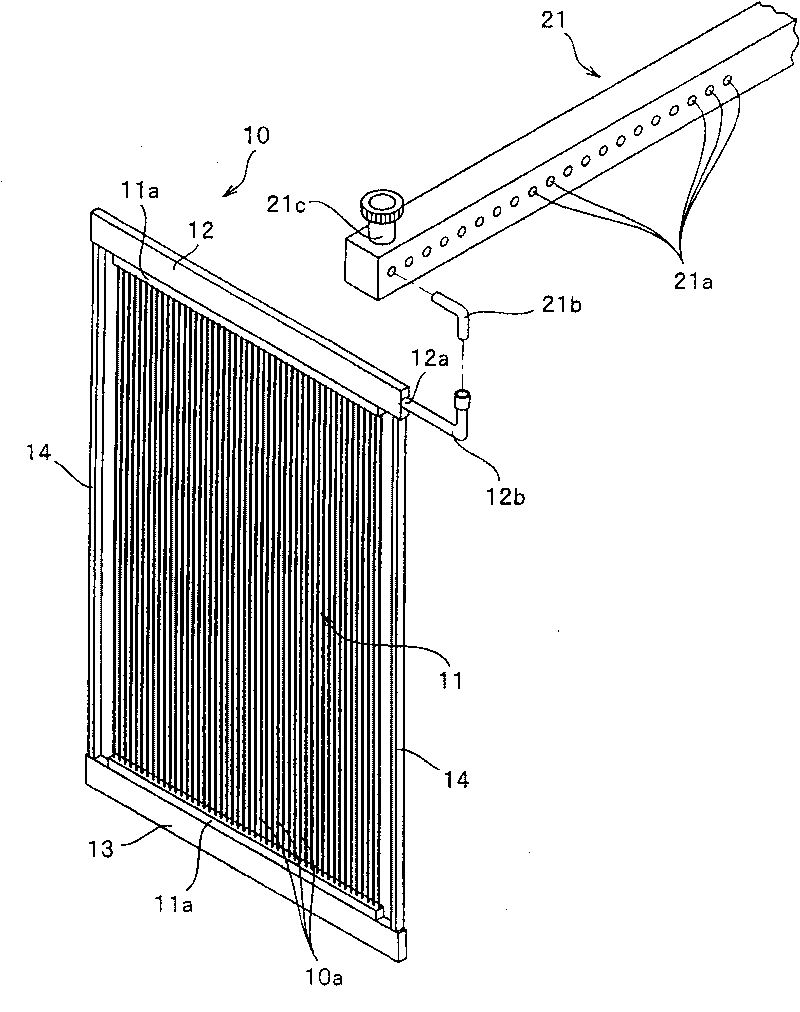

Filtering apparatus

ActiveCN103517744AReliable strippingImprove washing effectStationary filtering element filtersFiltrationEngineering

A filtering apparatus with a plurality of filtering elements (11) which can be accommodated in a filter housing (1) having a filter inlet (7) for fluid to be filtered and a filter outlet (9) for the filtered fluid, wherein during the filtration operation, at least one of the filtering elements (11) can be back-flushed by means of a back-flushing device (45, 49) in order to dedust the effective filtering surface of said filtering element, the back-flushing device comprising a pressure control device (19) for assisting the back-flushing operation, is characterized in that the pressure control device comprises a hydraulic accumulator (19), the one fluid chamber (47) of which can be filled during the filtration operation with a quantity of dedusted fluid and can be connected for a back-flushing operation via a back-flushing guide (45) to the clean side (29) of the filtering element (11); to be dedusted, and in that, for a back-flushing operation, a further fluid chamber (48) of the hydraulic accumulator (19) can be subjected to a gas pressure in order, by means of a resultant movement of the separating element (59) of the hydraulic accumulator (19), to at least partially again dispense the filling amount of the dedusted fluid for the back-flushing operation from the first fluid chamber (47).

Owner:HYDAC PROCESS TECH

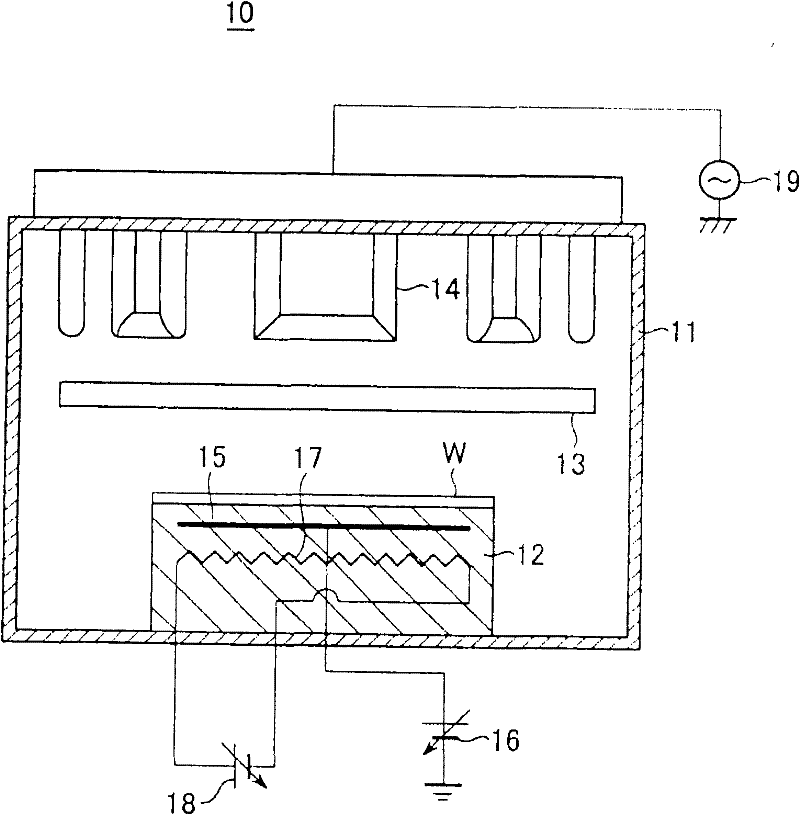

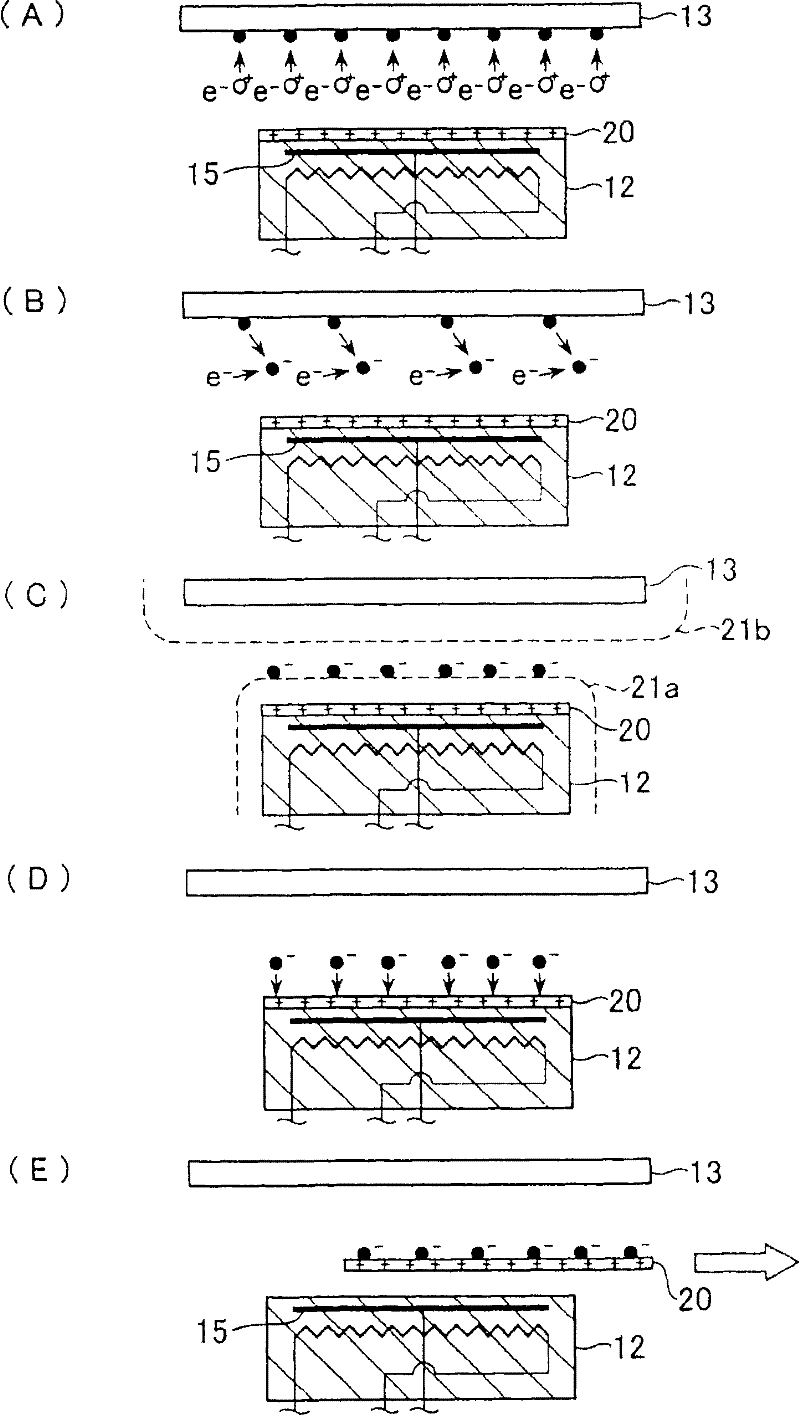

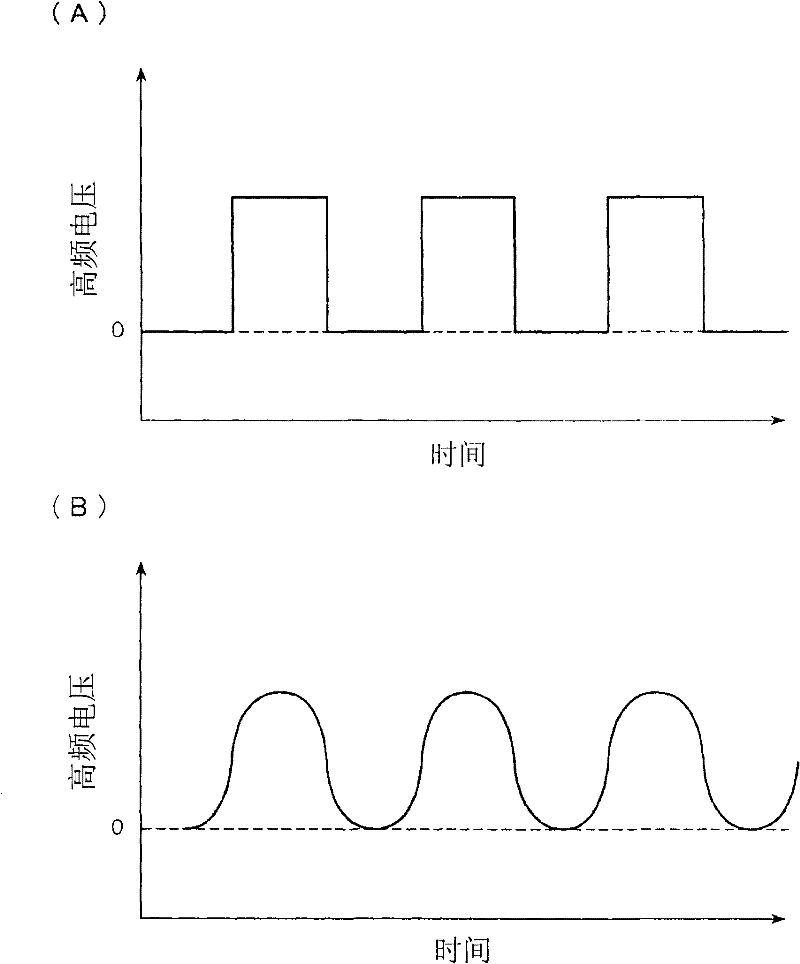

Component cleaning method

InactiveCN101752224AEasy to cleanPrevent adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingForeign matterEngineering

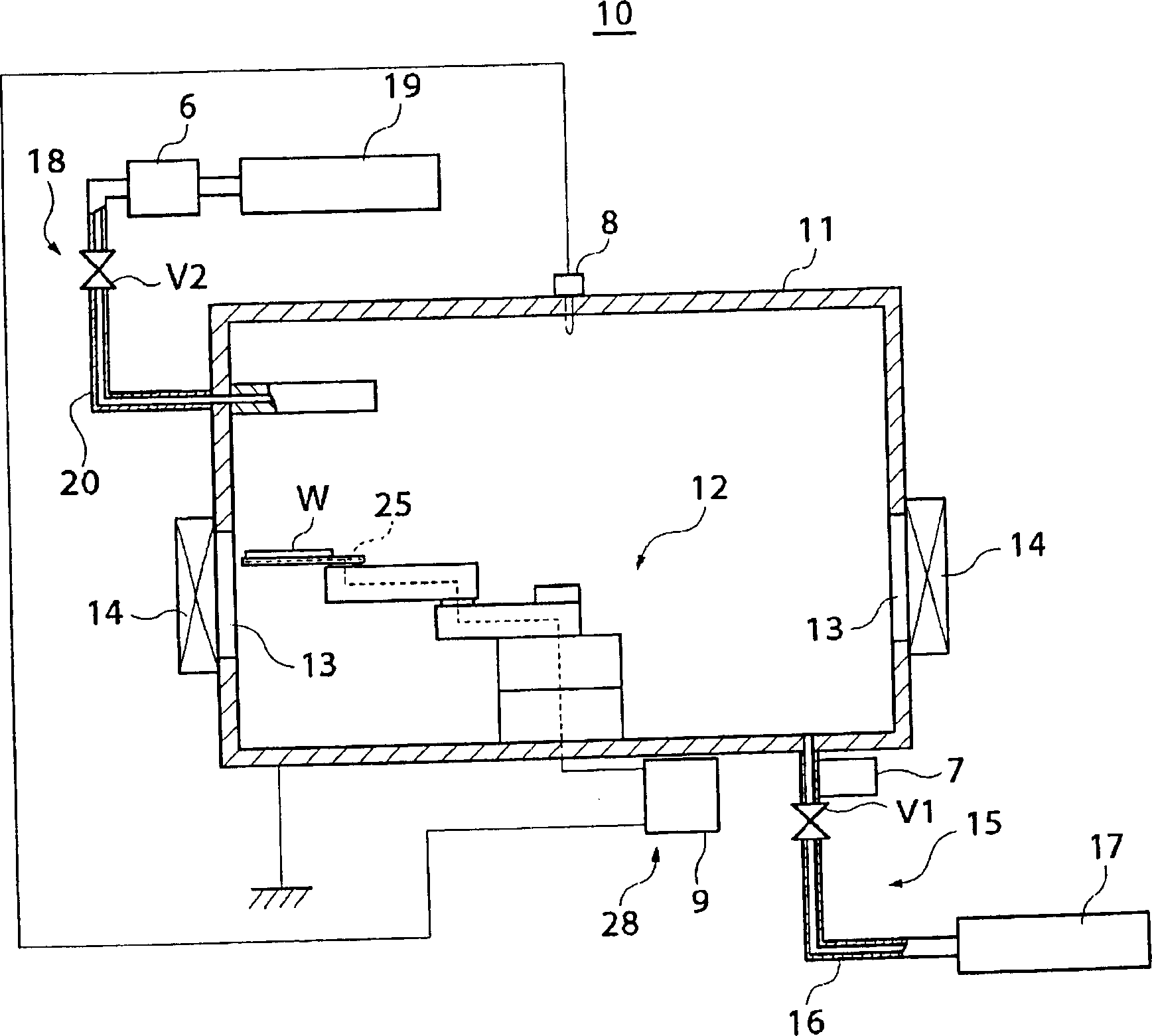

The invention provides a component cleaning method capable of preventing foreign substances from adhering to other components and cleaning the component conveniently. A wafer dry cleaning apparatus (10) comprises: a treatment chamber (11), a carrying bench (12) used for carrying wafer (W) disposed on the lower part in the treatment chamber (11), a adhered particles trapping plate (13) arranged relatively to the carrying bench (12) in the treatment chamber (11) and a plasma generation apparatus (14) used as a inductive coupling type plasma generation apparatus. The method comprises: moving a false wafer (20) into the treatment chamber (11); generating positive electric potential on the surface of the false wafer (20); generating surface wave plasma and stopping the generation of the surface wave plasma repeatedly on the false wafer (20) in the region nearer to the trapping plate; and moving the false wafer (20) out from the treatment chamber (11).

Owner:TOKYO ELECTRON LTD

Substrate separation apparatus for stacked body

InactiveCN106256013AReliable strippingAvoid desorptionLamination ancillary operationsElectroluminescent light sourcesBiomedical engineeringWedge shape

Owner:SEMICON ENERGY LAB CO LTD

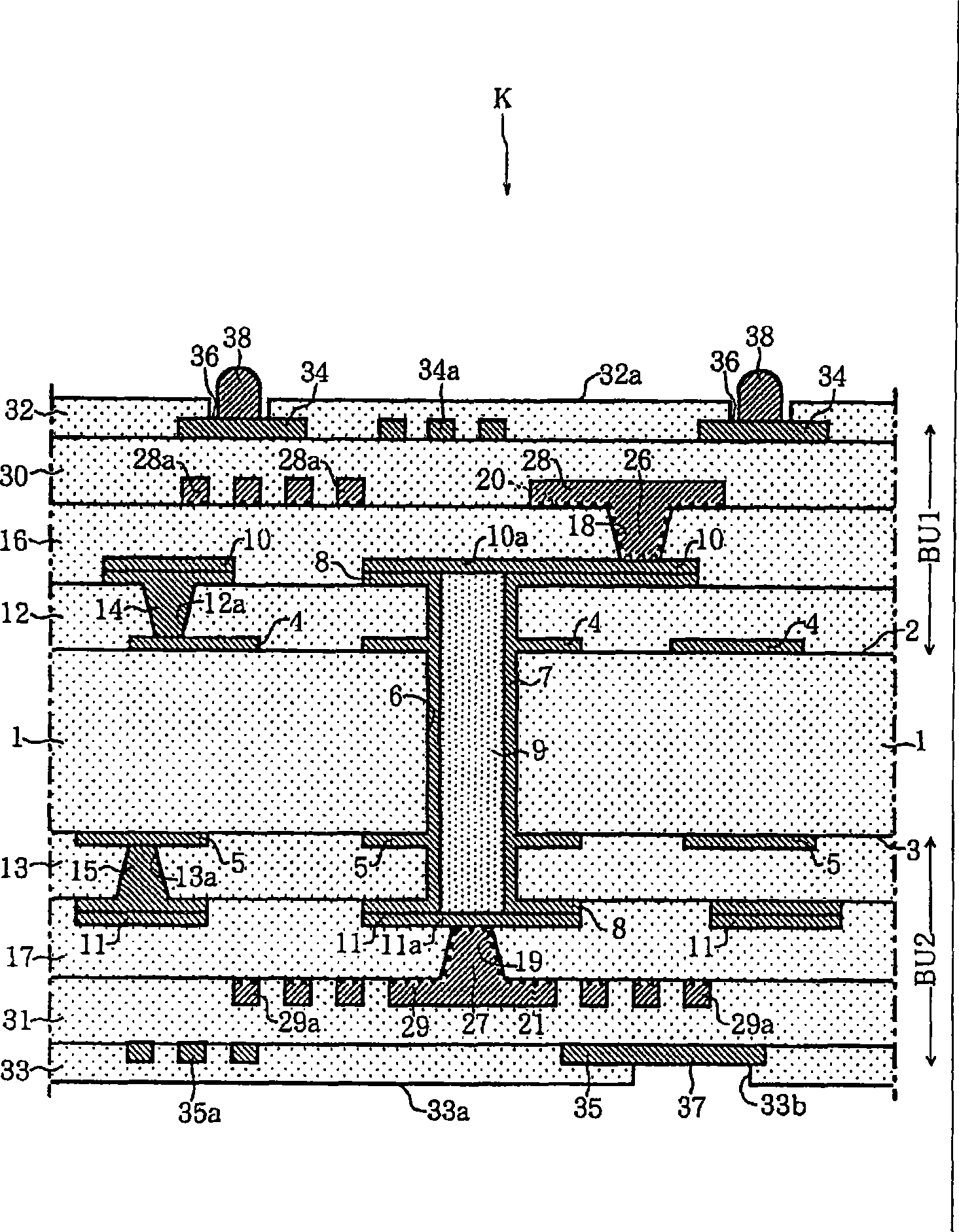

Method for producing wiring substrate

InactiveCN101400220AEasy to shapeImprove yieldInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentResistFilm material

The present invention provides a method for manufacturing a wiring substrate, which can increase the finished product rate in a developing working procedure and can actually form a fine wiring pattern layer with excellent shape. In the method for manufacturing a wiring substrate K according to the invention, metal layers (20, 21) are formed on the surface of resin insulation layers (16, 17) firstly. Then the exposure and develping based on alkali are executed after affixing photosensitive dry film materials (22, 23) with aliki resistance on the metal layers (20, 21) for forming plating resits (22a, 22b) with a preset pattern. Then plating is executed for forming wiring pattern layers (28, 29) on the openings (24, 25) of plating resists (22a, 22b). Afterwards, the plating resists (22a, 22b) are stripped with organic amine stripping liquid. Lastly, the metal layers (20, 21) positioned at the right lower part of plating resists (22a, 22b) are eliminated.

Owner:NGK SPARK PLUG CO LTD

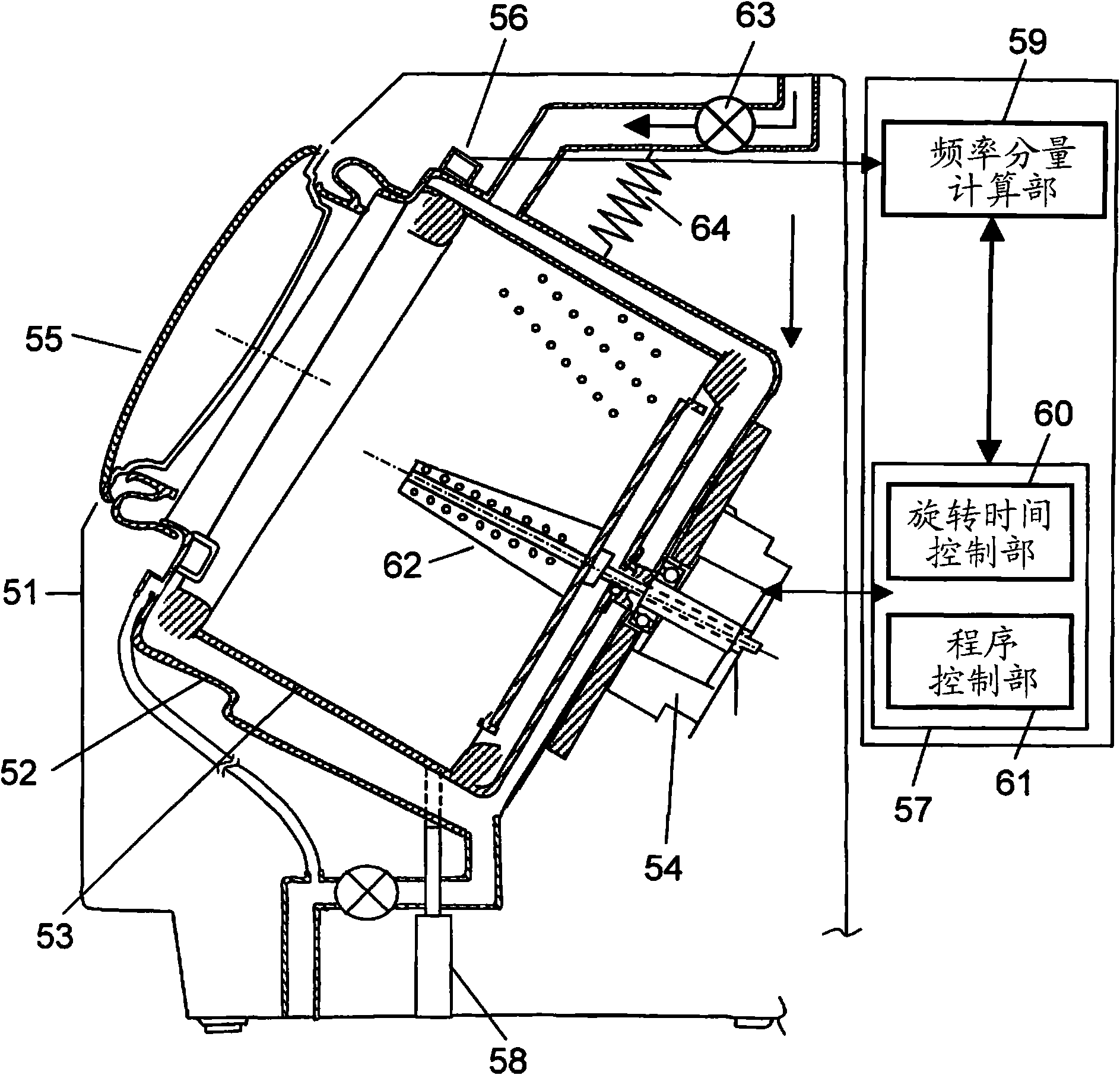

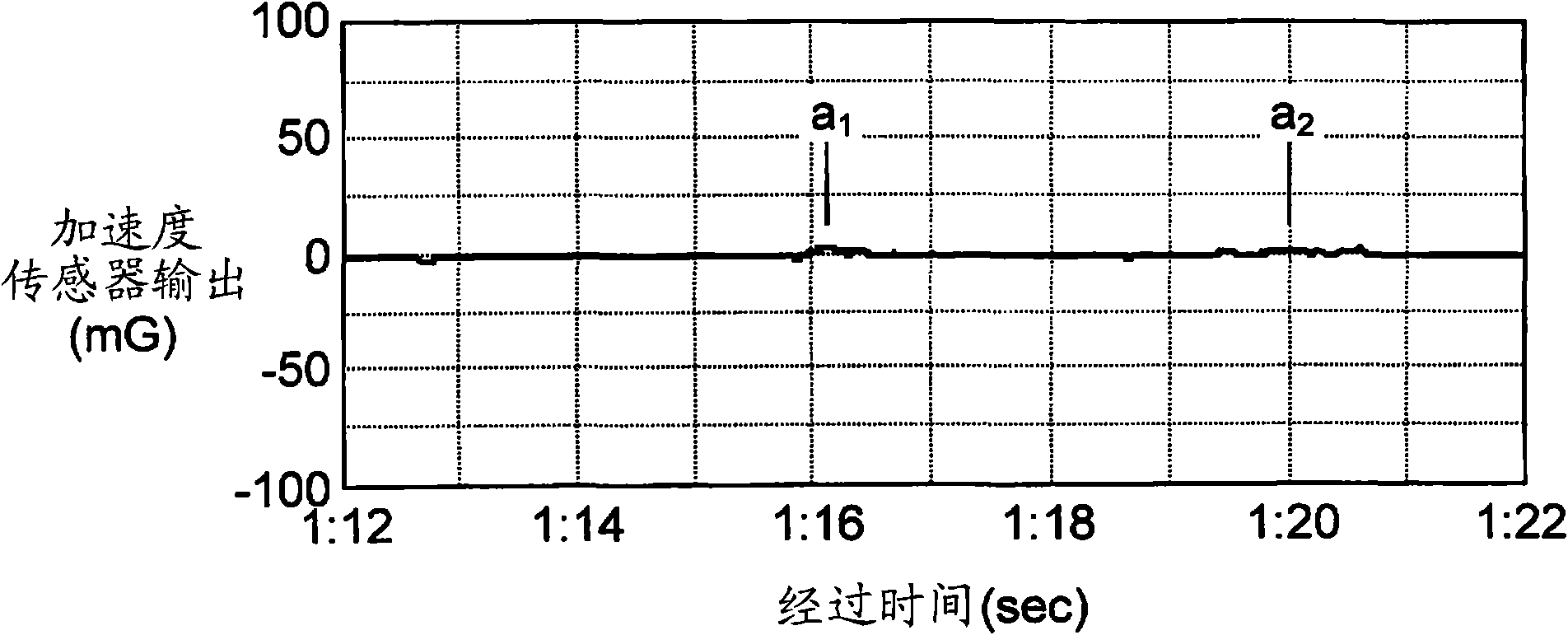

Drum-type washing machine

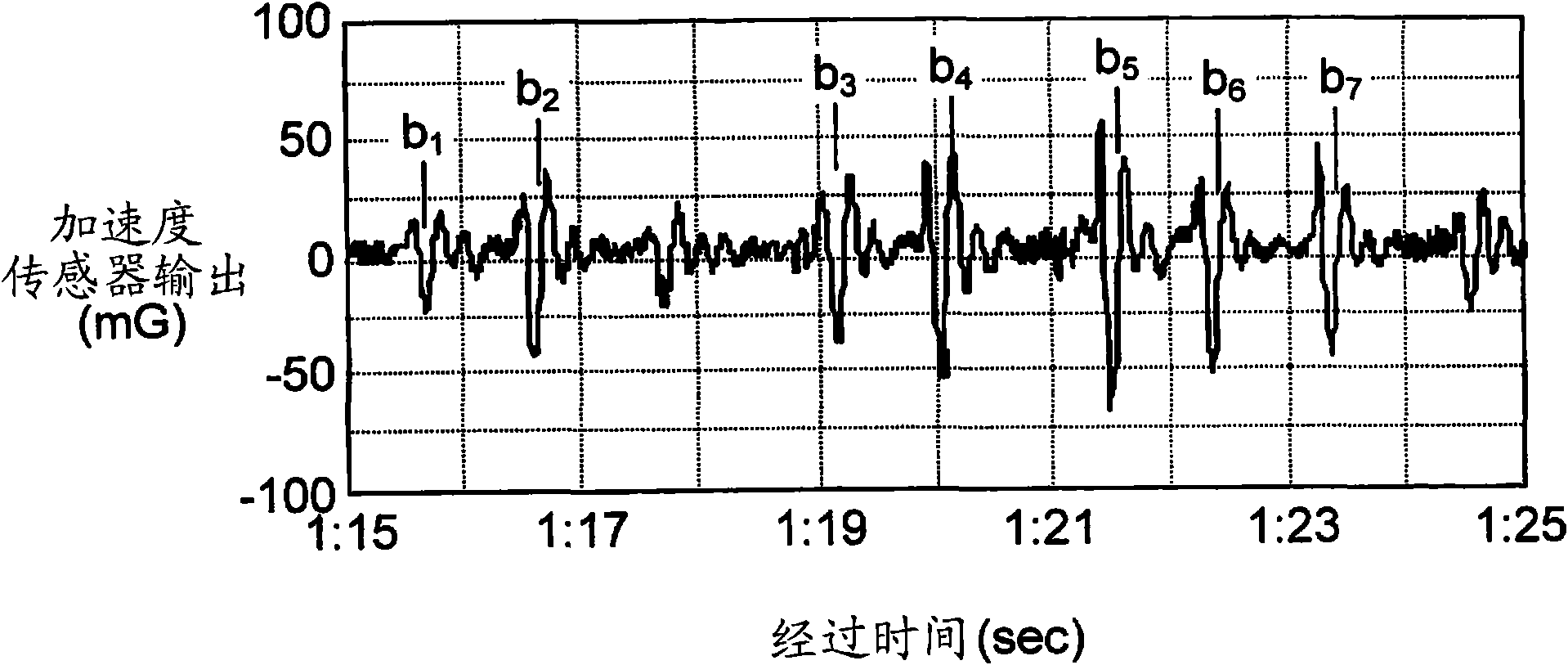

InactiveCN101624772AReliable strippingImprove drying effectOther washing machinesControl devices for washing apparatusEngineeringLaundry

A drum-type washing machine is disclosed, and during a step of peeling the laundry off rotary drum (53), controller (57) of the washing machine compares a magnitude of vibrations sensed by acceleration sensor (56) and corresponding to a rotary cycle of rotary drum (53) with another magnitude of vibrations sensed by acceleration sensor (56) and corresponding to another rotary cycle of drum (53), so that the controller (57) determines whether or not the laundry is peeled off the inner wall of drum (53). This structure allows sensing accurately the vibration of water tub (52) and also sensing more properly the status whether or not the laundry in drum (53) is peeled off.

Owner:PANASONIC CORP

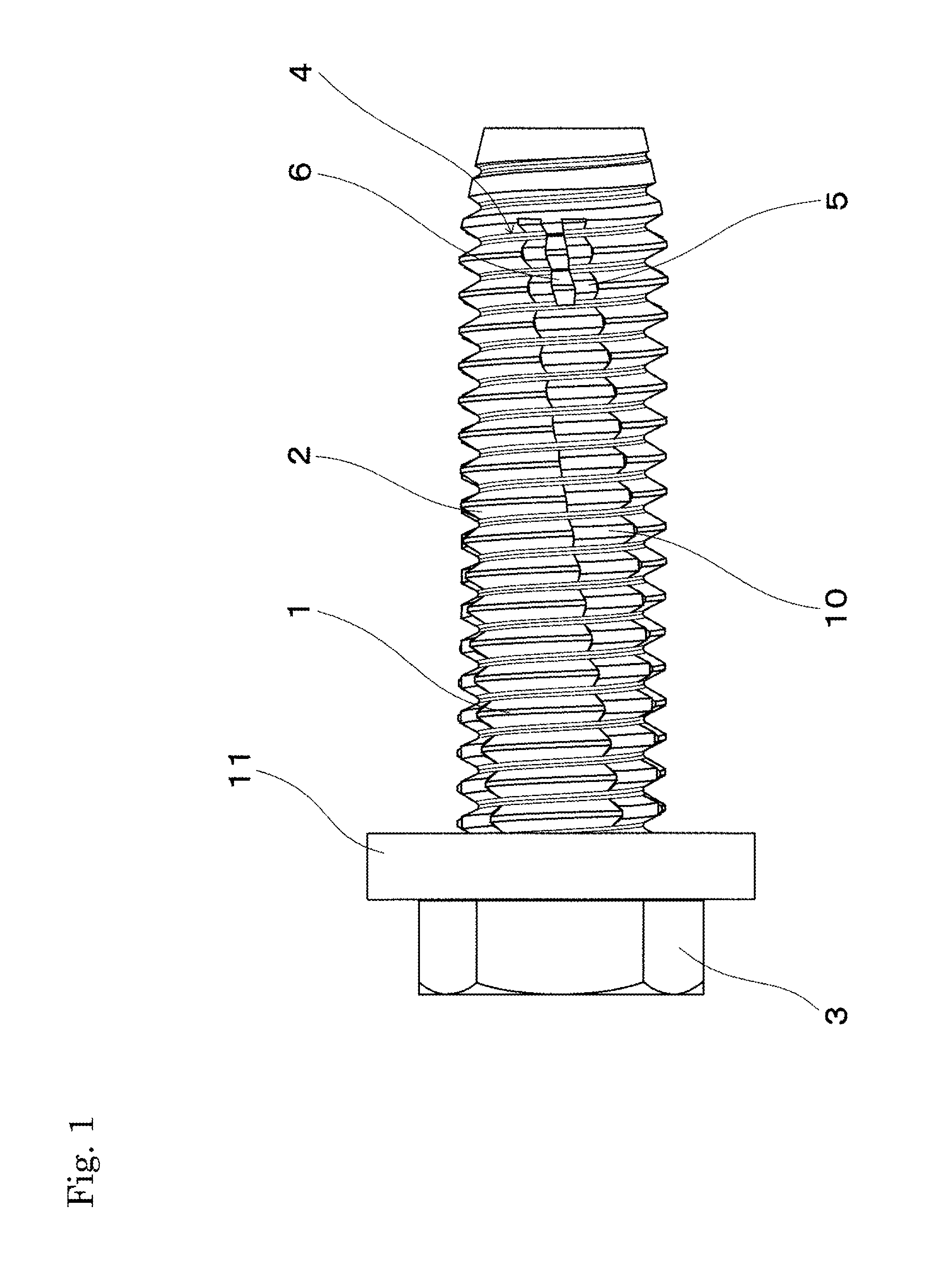

Bolt

Owner:AOYAMA SEISAKUSHO CO LTD

An automatic device for sleeving O-shaped ring

The invention relates to an automatic device for sleeving an O-shaped ring. The device comprises a fixed main body, a shell, a O-shaped ring sleeving mechanism and a driving mechanism; the O-shaped ring sleeving mechanism comprise a material stripping sleeve, an elastic returning part, a moving rod, a plurality of material taking claws which are positioned in the material stripping sleeve and arein linkage fit with the moving rod and a material stripping rod which corresponds to the position above the material stripping sleeve and is in linkage with the moving rod; and a through hole allowingone ends of the plurality of material taking claws to penetrate through is formed in the material stripping sleeve, the plurality of material taking claws are distributed in an annular array and aremovably arranged on the moving rod, returning components are arranged between the moving rod and the plurality of material taking claws, one ends of the plurality of material taking claws act along with the moving rod and can penetrate through the through hole of the material stripping sleeve and are mutually supported to be opened, and the material stripping rod moves along with the moving rod and can be used for driving one end of the material stripping sleeve to extend out of the shell. The device has the advantages of being simple in structure, stable and reliable in performance, high in efficiency and capable of saving manpower.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

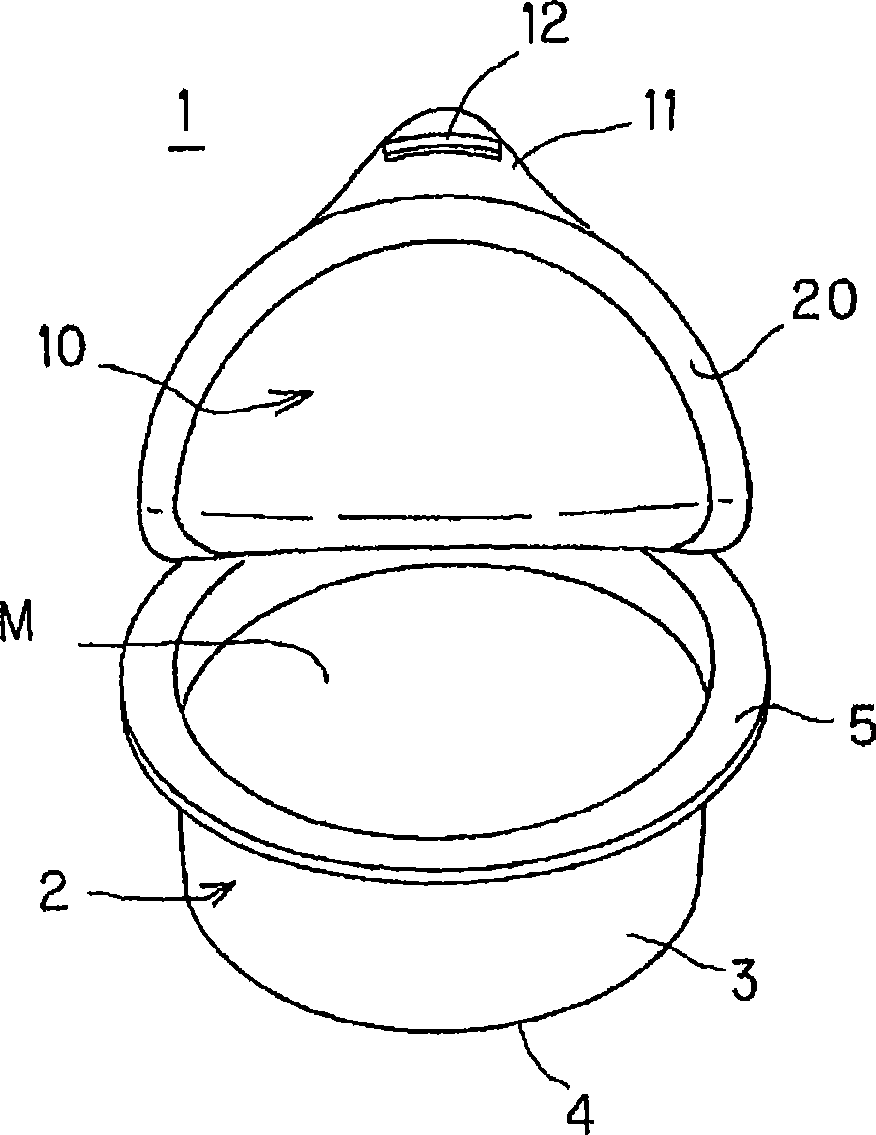

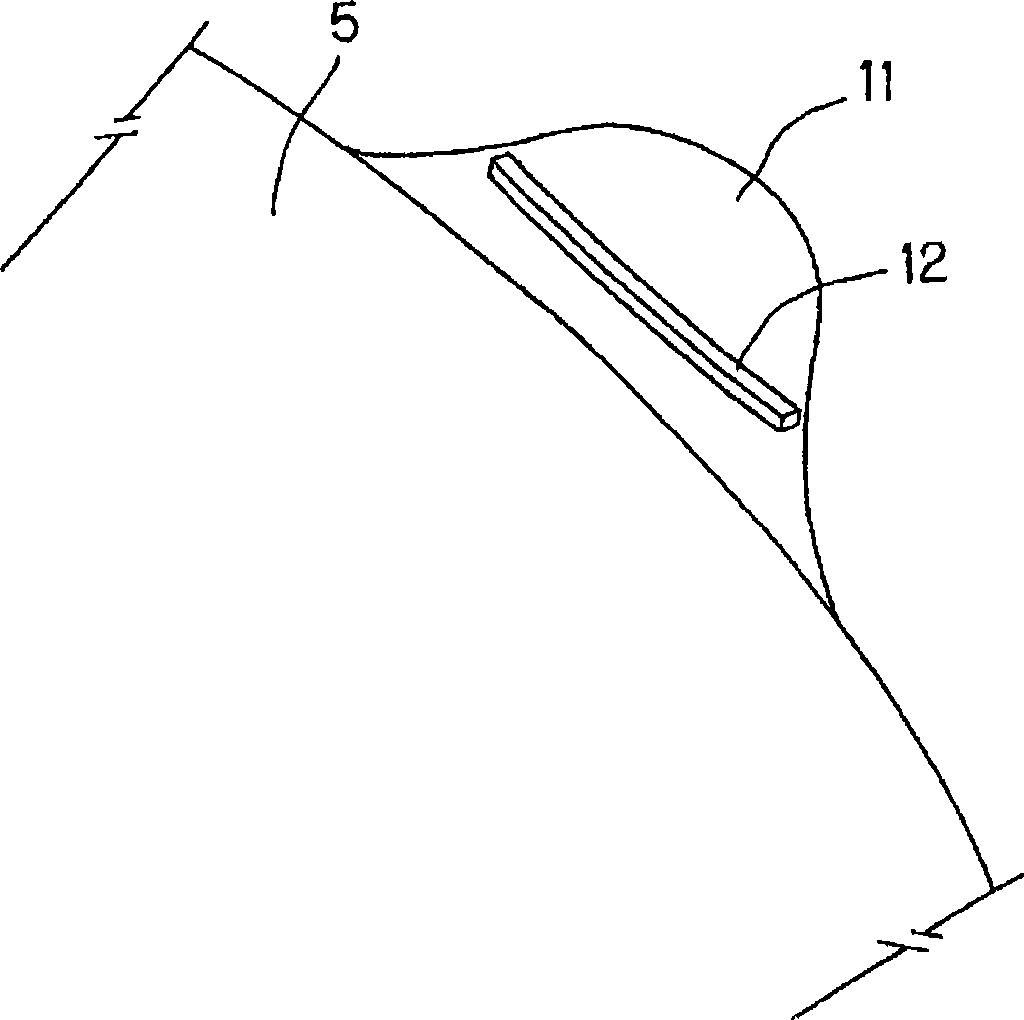

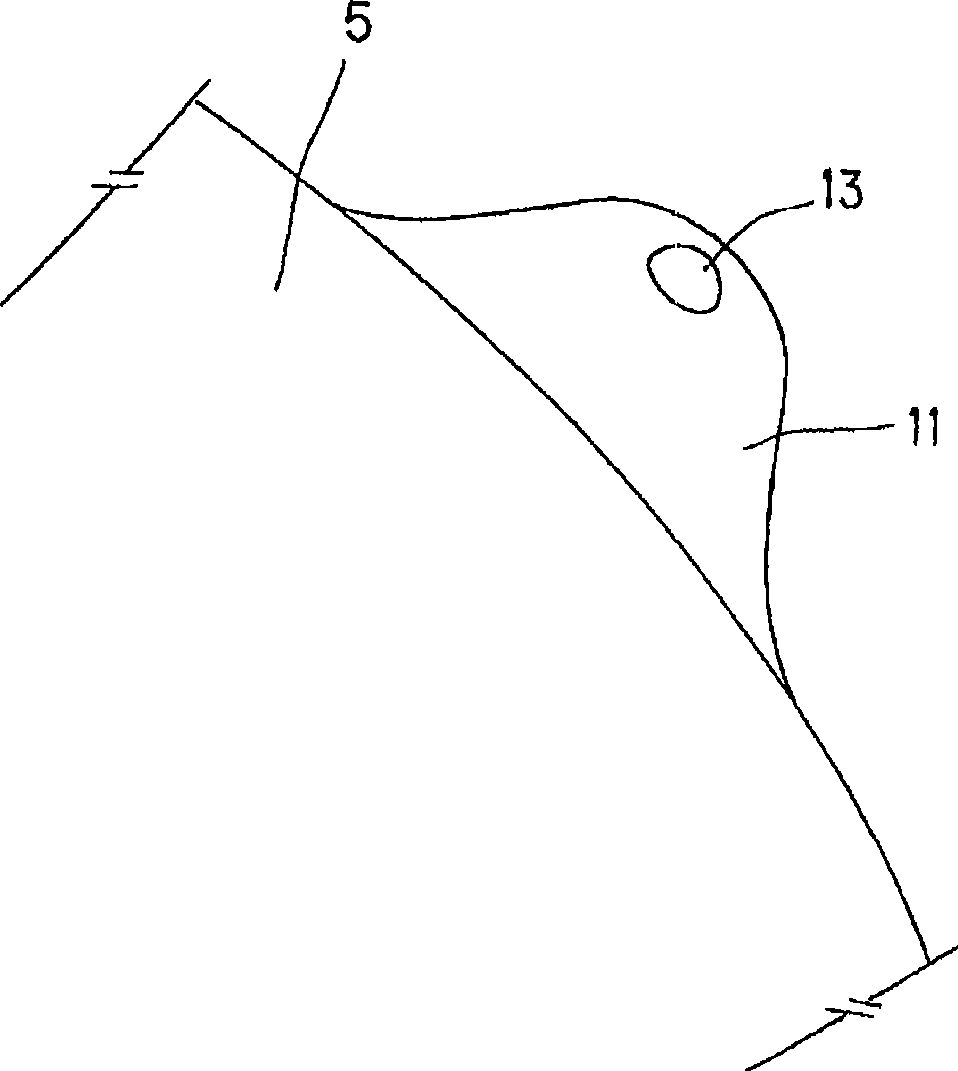

Packaging body

A packaging body (1) that is unsealed by peeling off a lid member from a container, wherein the unsealing is facilitated. The packaging body (1) has the container (2) open in the upper part and also has the lid member (10) placed on the upper part of the container to close it. The portion between a flange (5) formed on the upper part of the container (2) and the peripheral edge of the lid member (10) is processed to facilitate peeling off of the lid member (10), and the packaging body (1) is unsealed by peeling off the lid member (10) from the container (2). A tab (11) is formed on the lid member (10), and the tab (11) projects outward from the peripheral edge that is in intimate contact with the flange section (5). A fingerhold (12) is provided on the backside of the tab (11).

Owner:HOSOKAWA YOKO CO LTD

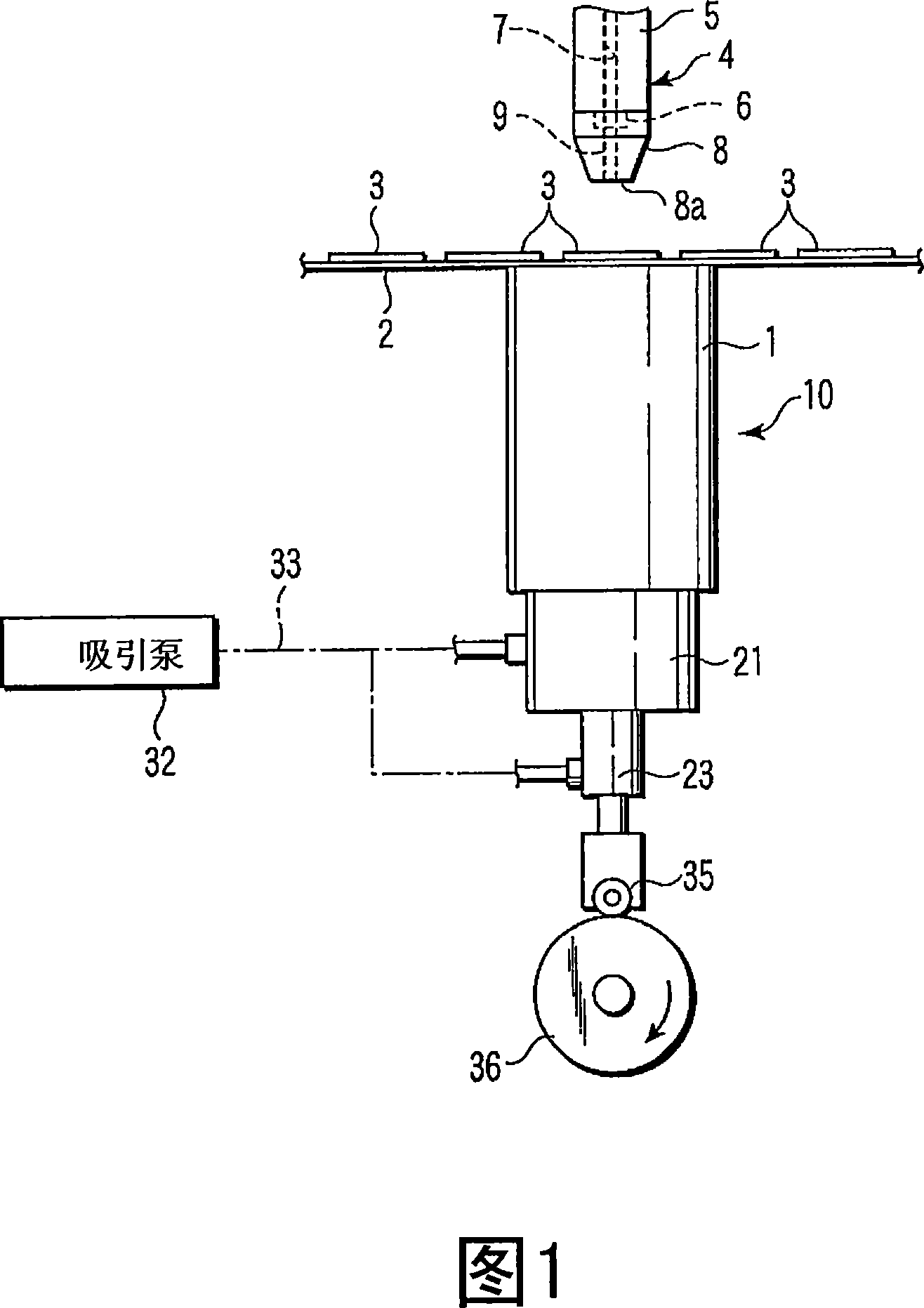

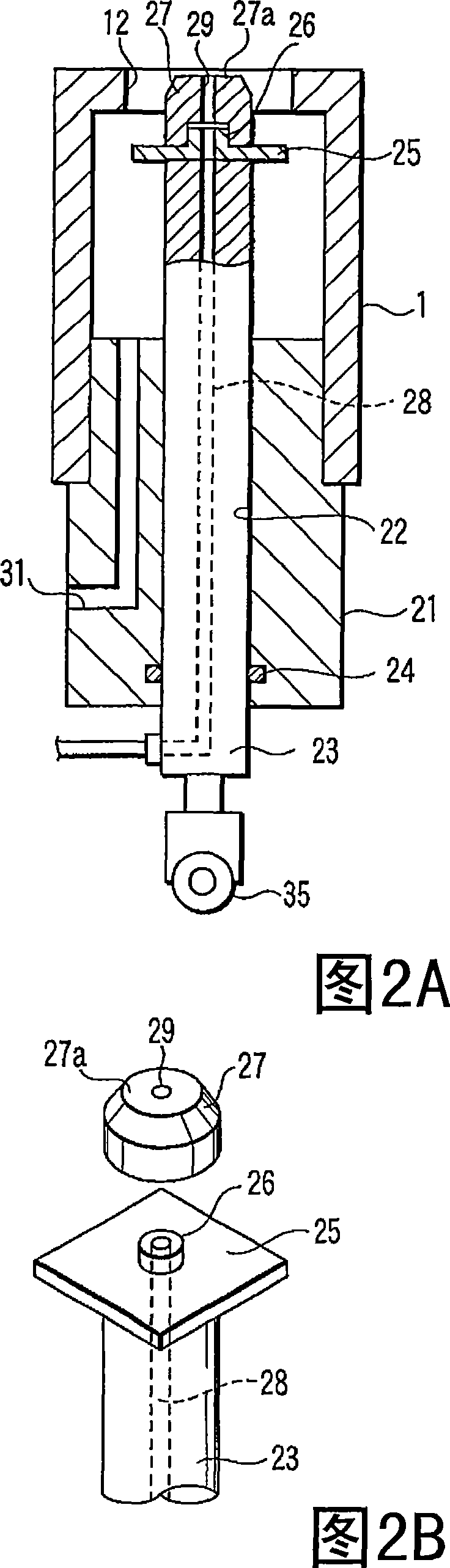

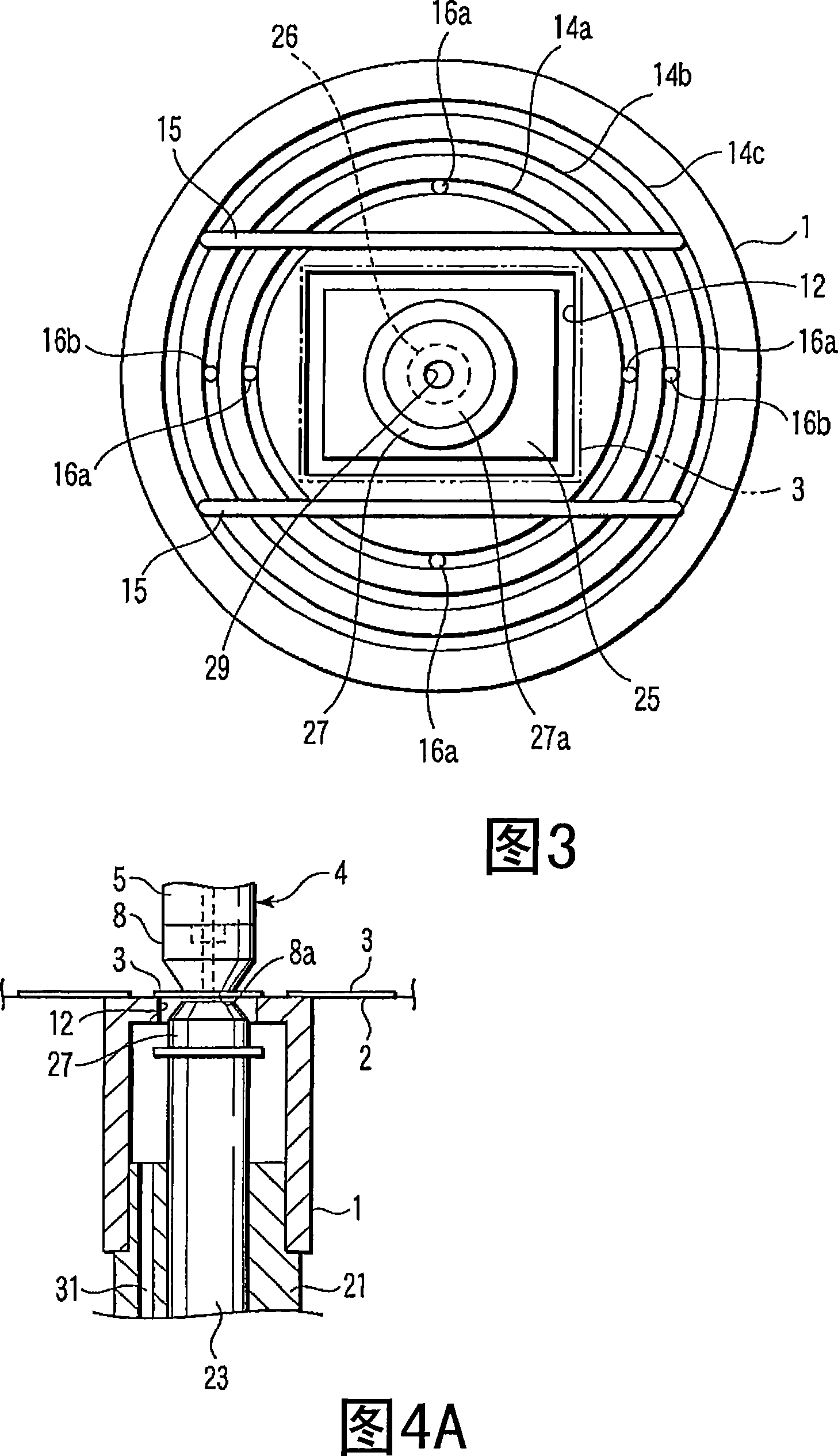

Device and method for picking up semiconductor chip

InactiveCN101253613AReliable strippingSemiconductor/solid-state device manufacturingElectrical componentsSemiconductor chipNozzle

A device for picking up a semiconductor chip stuck on a tacky adhesive sheet. The device comprises a backup body (1) having an upper surface formed on the sucking surface of the tacky adhesive sheet (2) holdingly sucking the peripheral portion of the semiconductor chip (3) to be picked up, a push-up shaft (23) vertically drivingly installed in the backup body and having a lower suction nozzle body (27) pressing the portion of the tacky adhesive sheet where the semiconductor chip to be picked up is stuck to push up the semiconductor chip from the upper surface of the backup body, and a suction nozzle body (4) suckingly holding the upper surface of the semiconductor chip to be picked up to pick up the semiconductor chip pushed up by the push-up shaft from the tacky adhesive sheet.

Owner:SHIBAURA MECHATRONICS CORP

Method of water disposal

InactiveCN101765564AIncrease concentrationReduce volumeMembranesTreatment using aerobic processesSludgeMembrane surface

A biological method of water disposal that avoids disadvantages caused by an increase of the number of membrane filter units attributed to an increase of the volume of sludge disposed of, maintaining a given rate of sludge disposed of. Four or more membrane filter units (5) are immersed and laid at given intervals in series in aeration tank (4). The amount of suctioned filtrate water of each membrane filter unit (5) and / or the amount of air emitted toward each membrane filter unit (5) is sequentially increased from the raw water inflow side to the sludge discharge side. Accordingly, in response to the amount of solid matter adhering to the membrane surface of membrane filter units (5) on the sludge recovery side, the solid matter can be unfailingly detached from the membrane surface. Simultaneously, the sludge concentration at edge portions of the recovery side exhibiting the highest sludge concentration would be increased, thereby facilitating the discarding operation of recovered sludge and further realizing reduction of drying energy at discarding. Moreover, the discharge of filtrate water can be efficiently carried out.

Owner:MITSUBISHI RAYON CO LTD

Cladding power stripping device and laser device

PendingCN109921270APrevent backlight heatingAvoid overall overheatingActive medium shape and constructionLaser cooling arrangementsBare fiberEngineering

The invention relates to the technical field of cladding light stripping, and specifically relates to a cladding power stripping device and a laser device. The cladding power stripping device comprises a cooling shell, an optical fiber and adhesive layers, wherein the cooling shell comprises a cooing cavity, a first passage and a second passage, the first passage and the second passage are communicated with the cooling cavity, and the interior of the cooling shell is filled with a cooling fluid; coating segments on two sides of the optical fiber are installed on the first passage and the second passage so that a bare fiber segment is placed inside the cooling cavity in a suspended mode; the coating segments are coated with the adhesive layers so that the coating segments on two sides are adhered with the first passage and the second passage in a sealing mode respectively. The coating segments of the optical fiber are adhered with the cooling shell by using the adhesive layers, on one hand, stray light returned back to an optical fiber coating layer is peeled, and the coating layer is prevented from being heated by return light; and on the other hand, the optical fiber coating layeris refrigerated effectively through the contact with the cooling shell, and the optical fiber is prevented from being overheated, so that the stripping cladding power can be improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

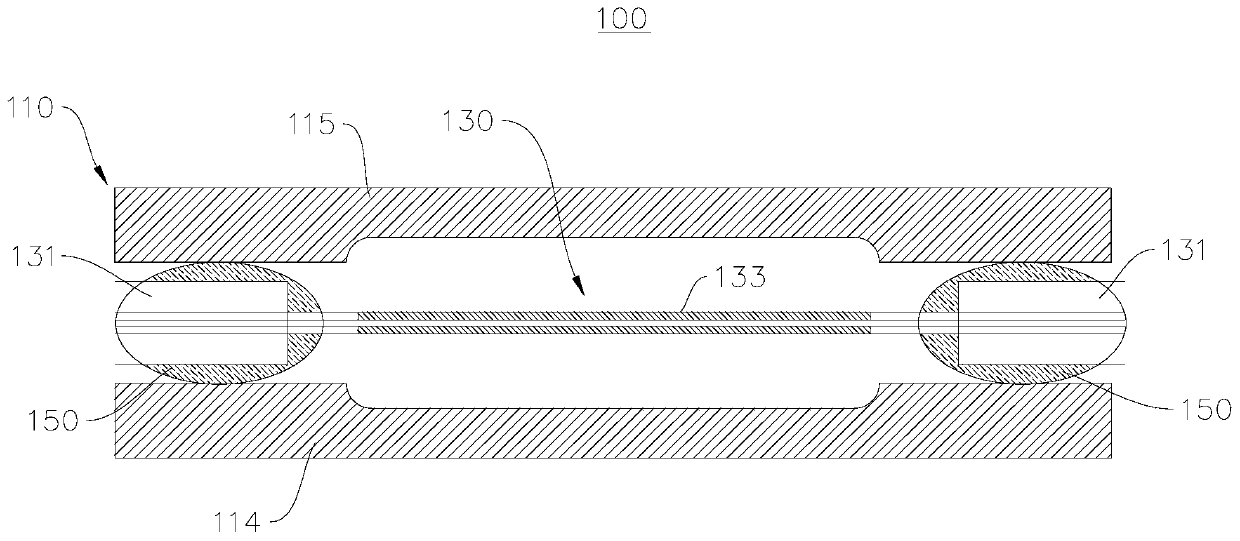

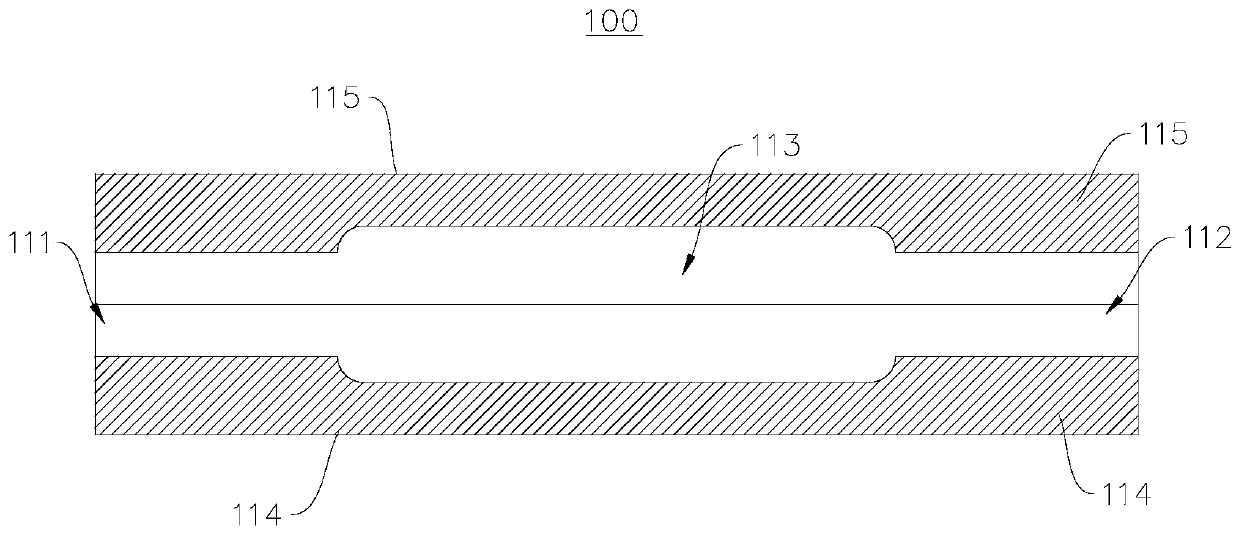

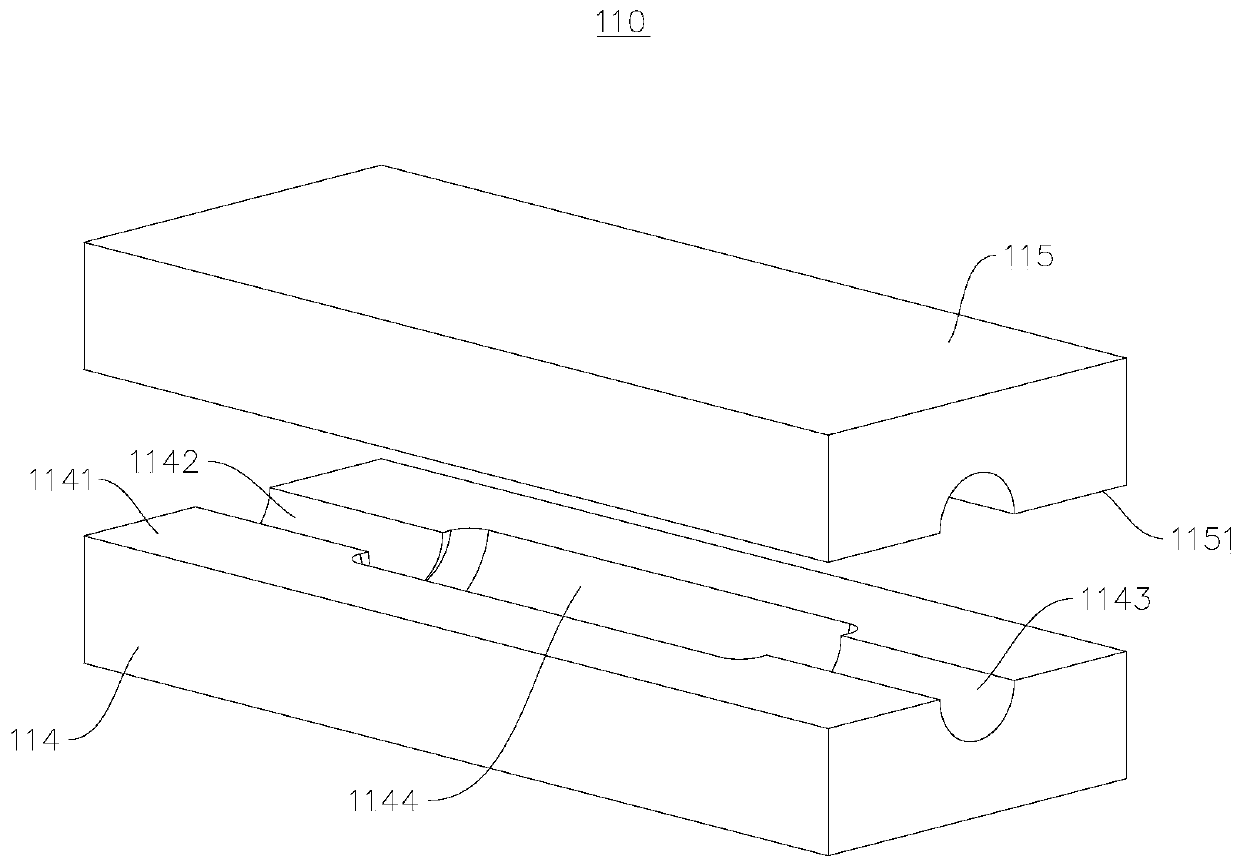

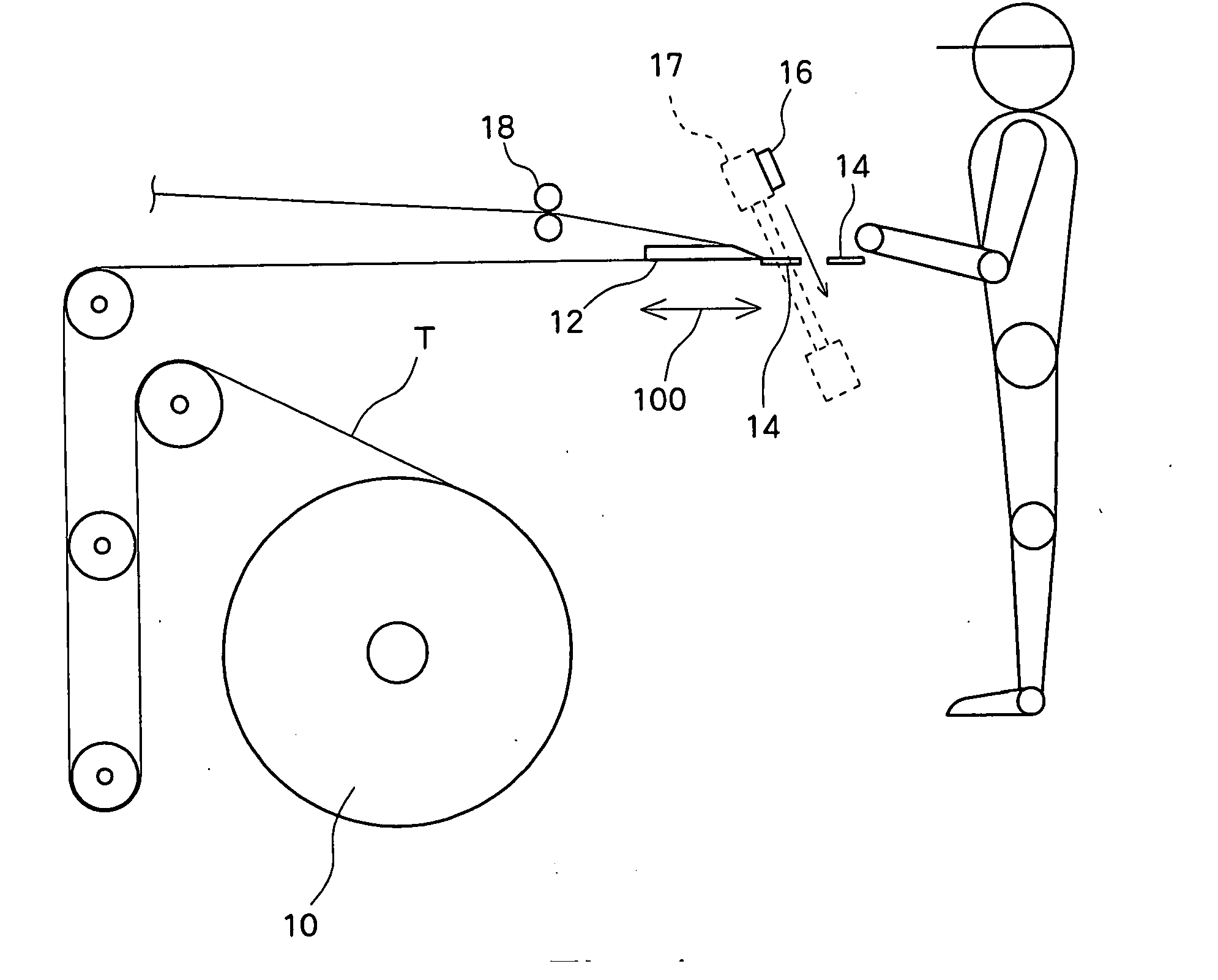

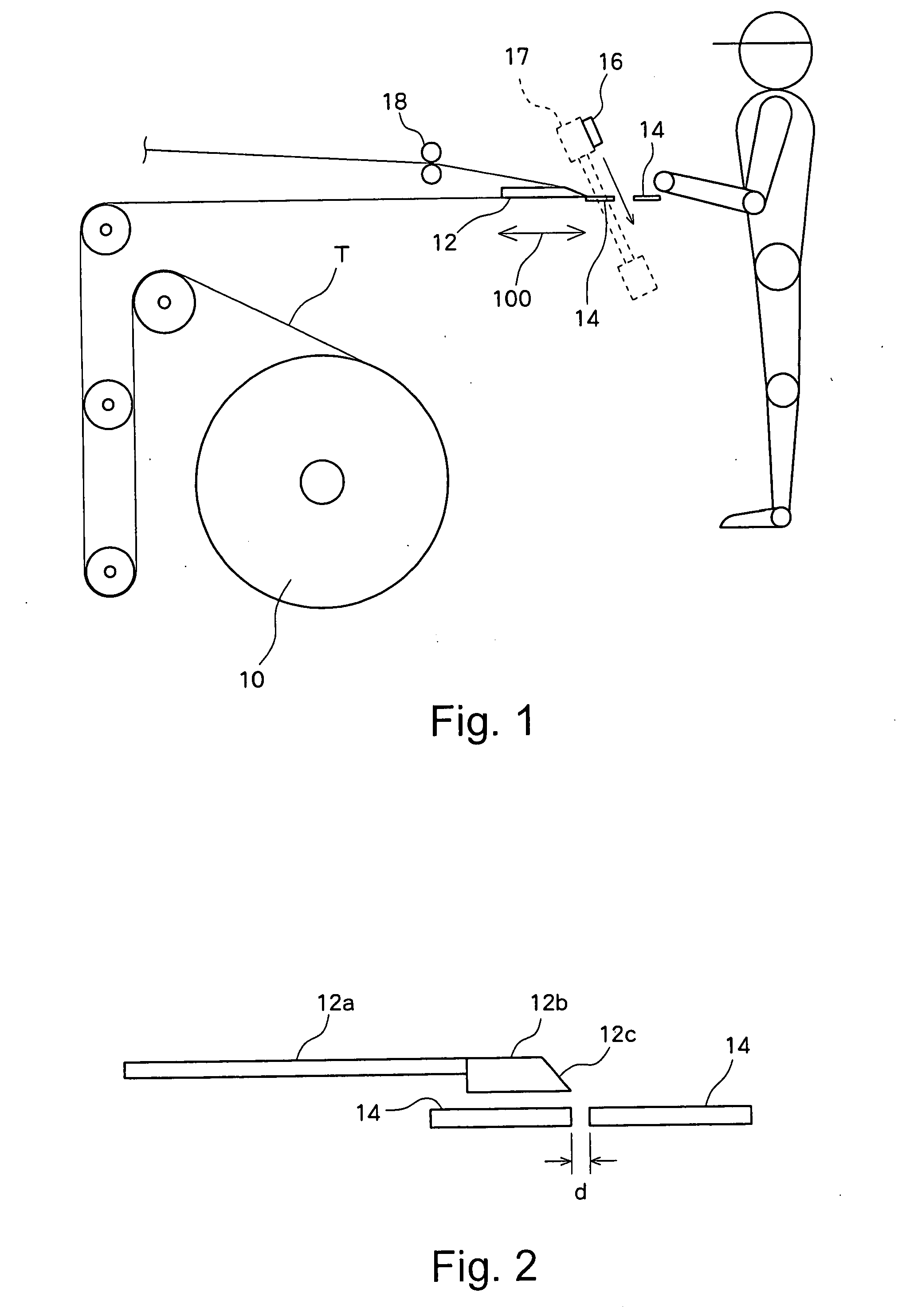

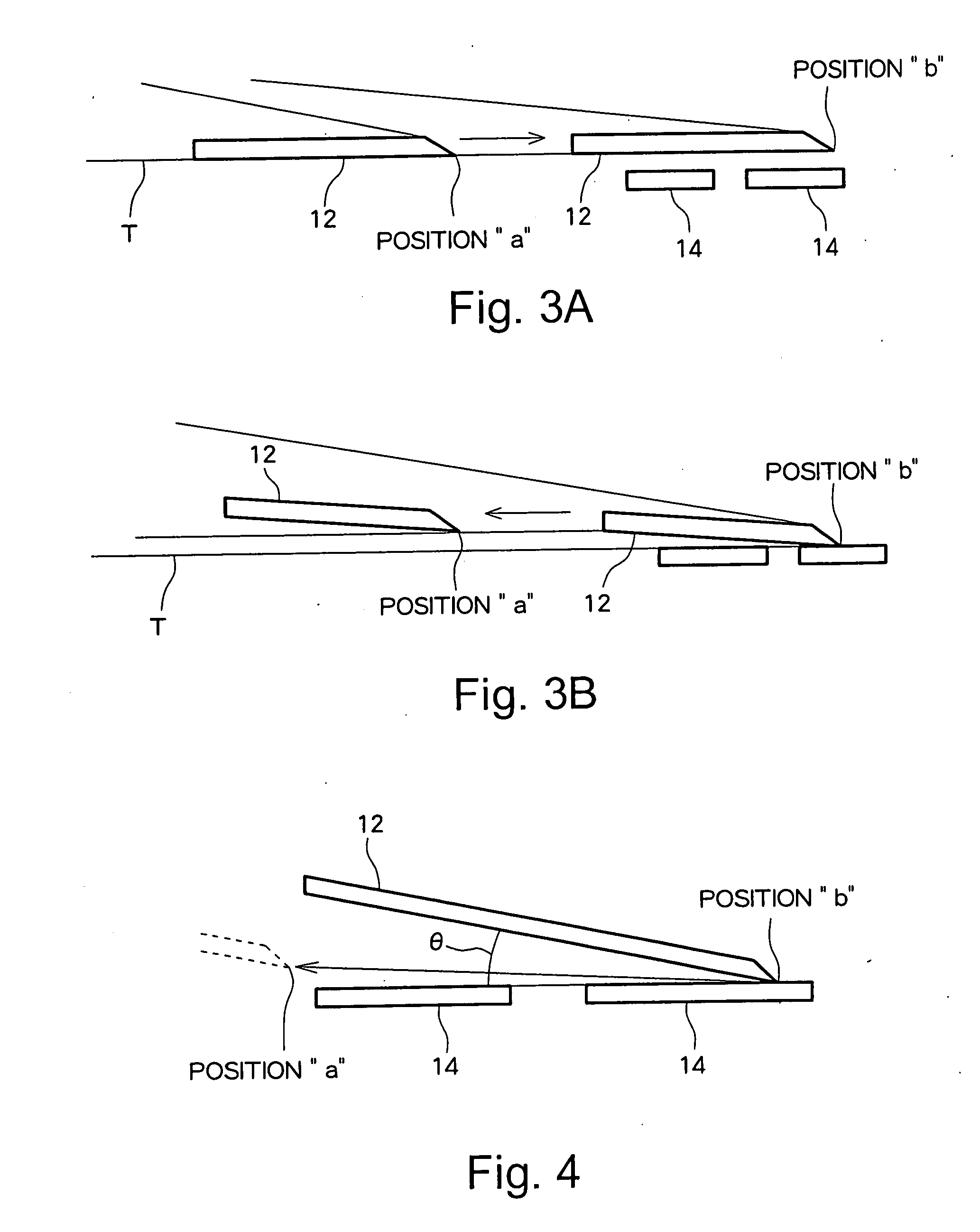

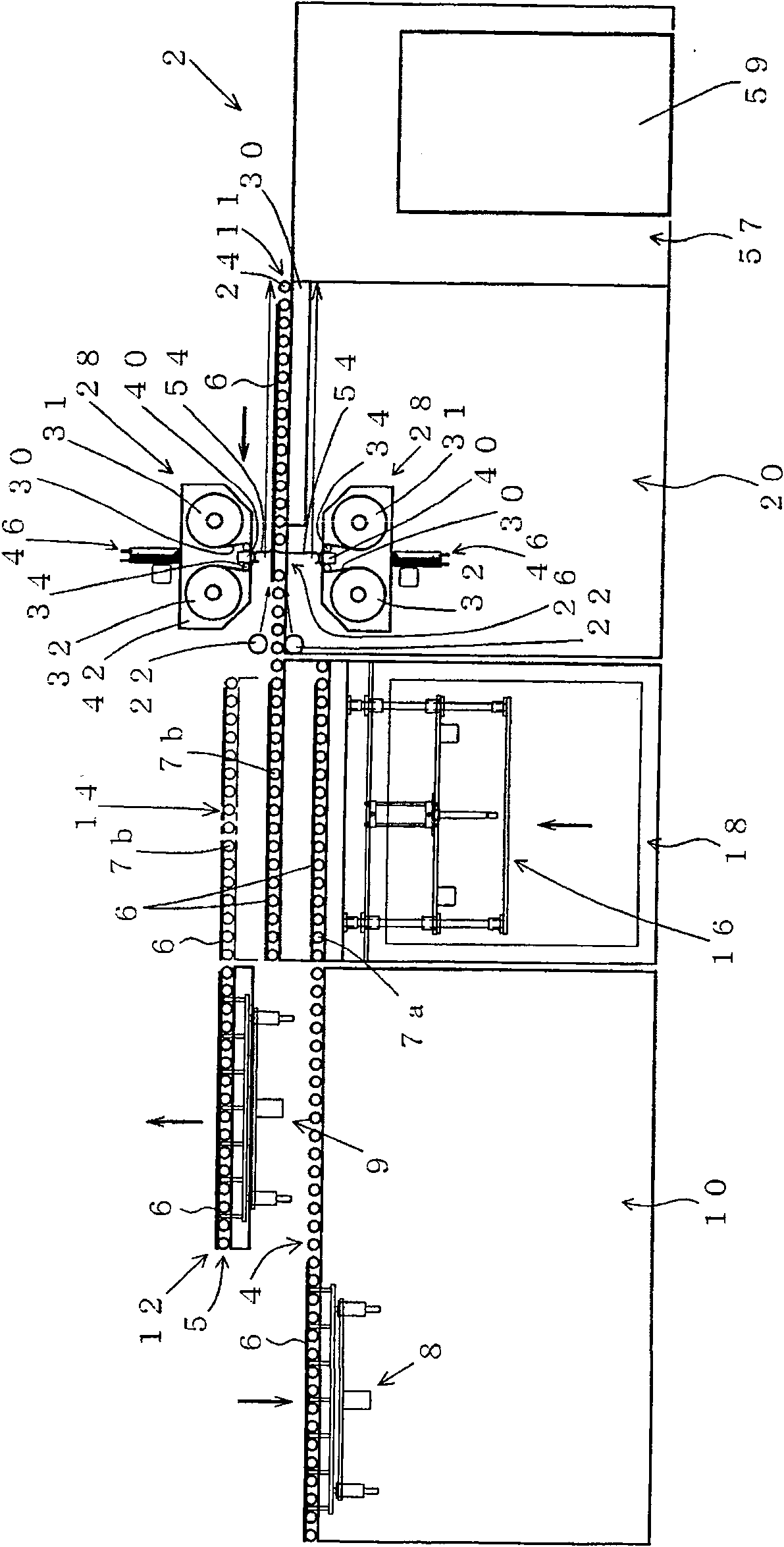

Tape exfoliation apparatus and tape-affixing apparatus

InactiveUS20070281120A1Reliable strippingHighly-accurate affixingDecorative surface effectsLaminationReciprocating motionElectrical and Electronics engineering

An apparatus for automatically peeling a removal tape from a removal-tape-attached adhesive tape and affixing the adhesive tape to a battery module. A removal-tape-attached adhesive insulation tape supplied from an uncoiler is held in a folded state by means of a carrier plate. The carrier plate reciprocates between a first position and a second position. When the carrier plate has moved from the first position to the second position, a tape holding unit holds the tape by means of suction. Subsequently, as a result of movement of the carrier plate from the second position to the first position, the removal tape is peeled from the removal-tape-attached adhesive insulation tape T, thereby uncovering an adhesive surface of the adhesive tape. The battery module is dropped toward the adhesive tape at an inclination with reference to the vertical direction, whereby the adhesive tape is affixed to the battery module.

Owner:PANASONIC EV ENERGY CO LTD

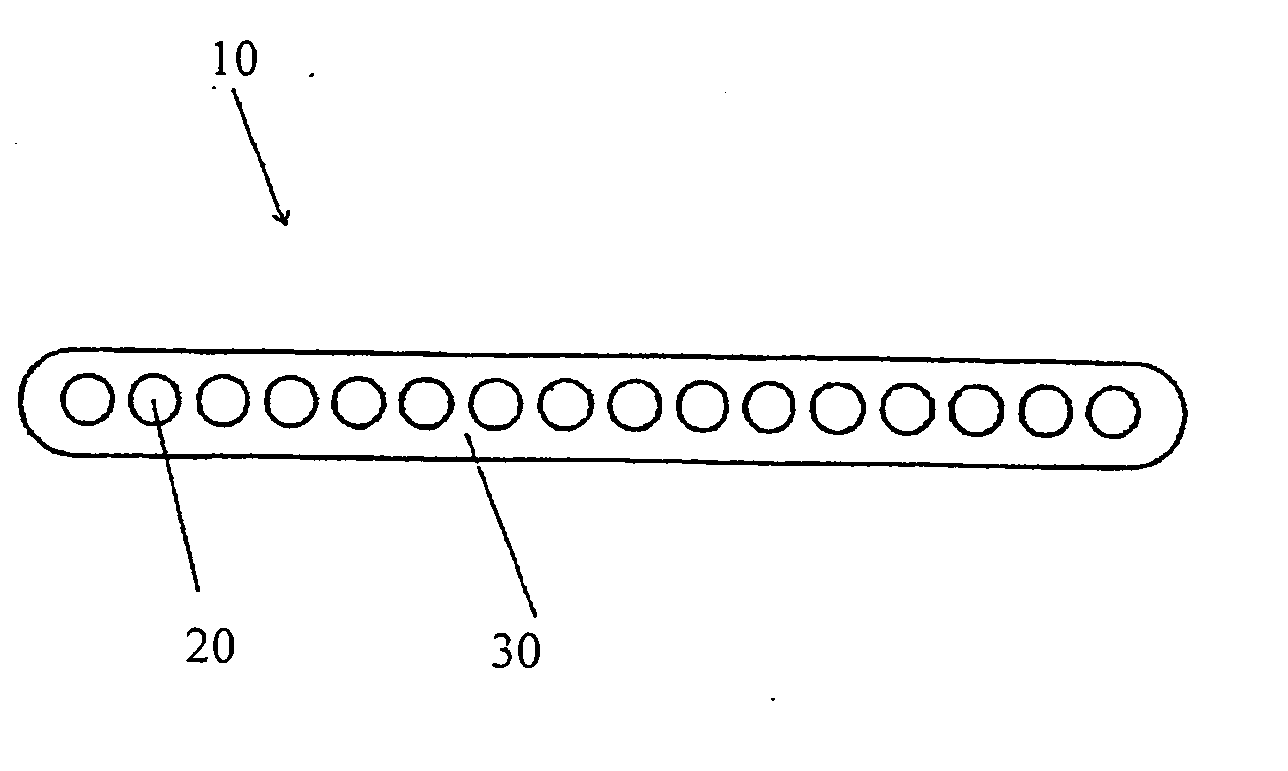

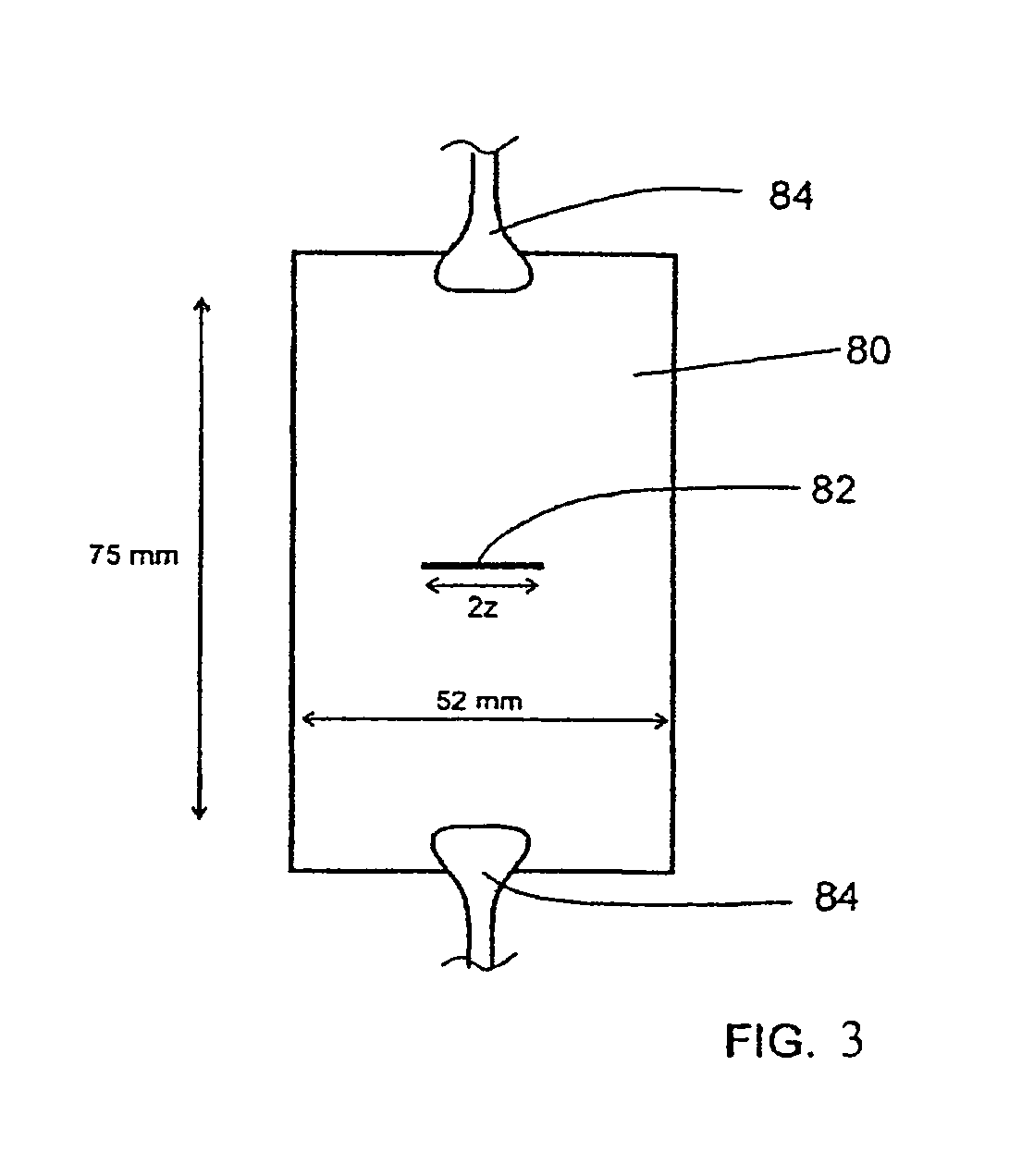

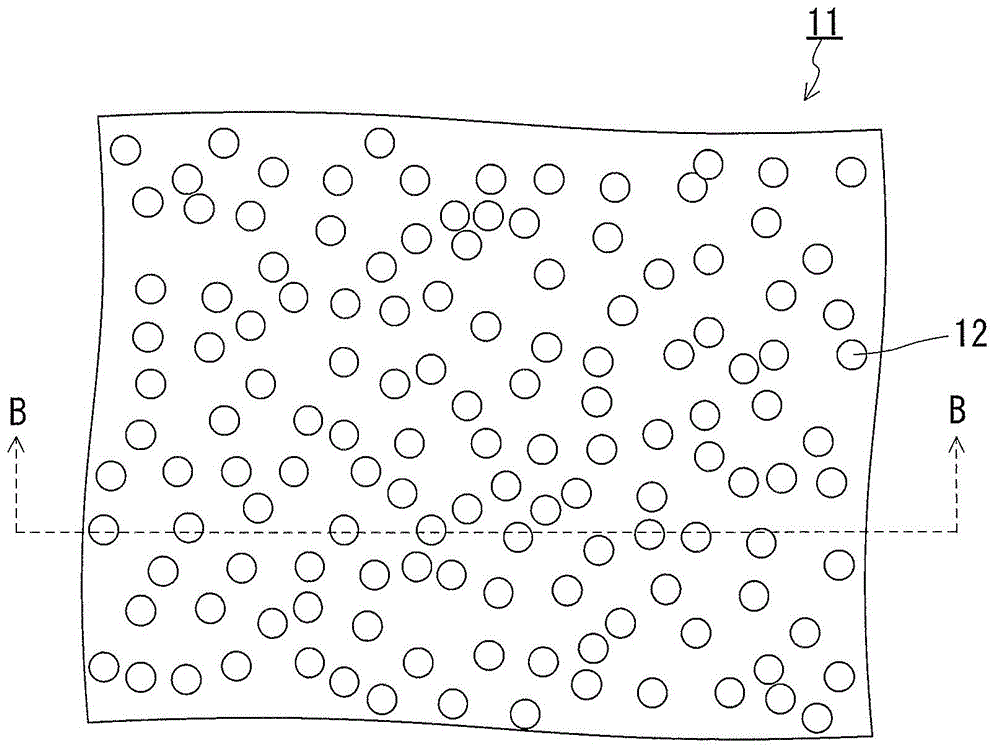

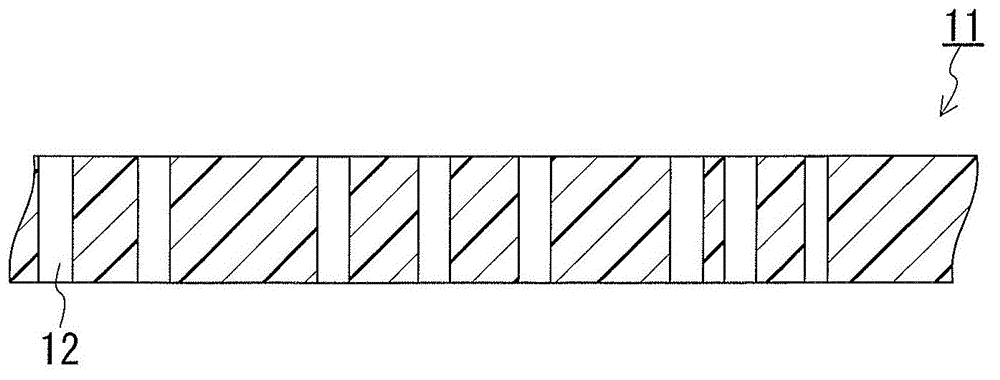

Method of suction of object to be worked upon suction unit and method of manufacture of ceramic capacitor

InactiveCN102725111AAvoid direct contactAvoid deformationGripping headsFixed capacitor dielectricCeramic capacitorEngineering

Disclosed is a method of suction of an object to be worked (15) upon a suction unit (14) and a method of manufacturing a ceramic capacitor, which employ a plastic sheet (11) being air permeable in the thickness dimension thereof as a suction sheet, having improved air permeability while maintaining a small diameter for the pores (aperture diameters) that are the air permeable paths for ensuring the air-permeability. The plastic sheet (11) is a non-porous sheet whereupon two or more through holes are formed that pass therethrough in the thickness direction. The through holes are straight holes that pass through the plastic sheet in direct lines. The diameter of the through hole is less than or equal to 20[mu]m. The air-permeability of the plastic sheet in the thickness direction is less than or equal to 10seconds / 100mL, a Gurley number measured in accordance with JIS P8117. Under the methods disclosed herein, the plastic sheet (11) is positioned upon the suction face of the suction unit (14).

Owner:NITTO DENKO CORP

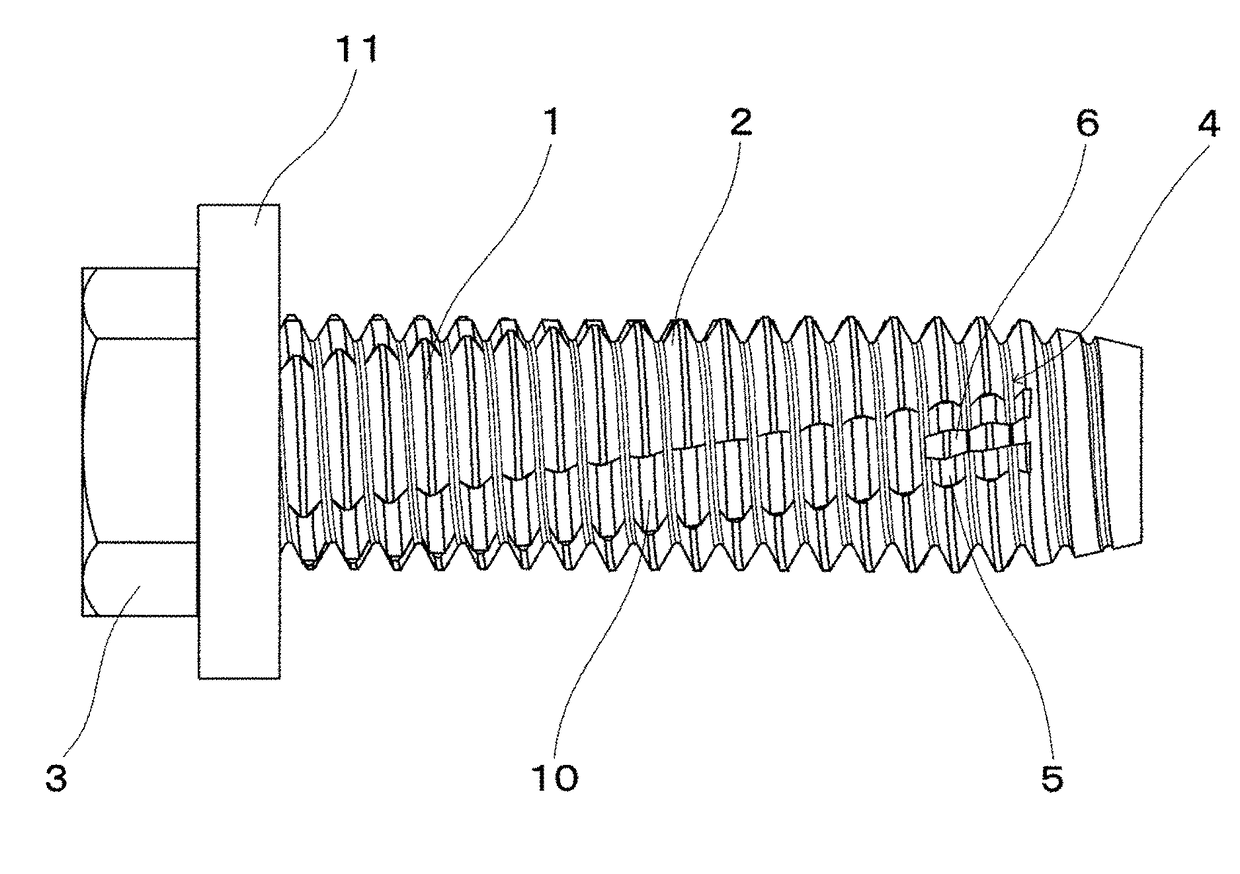

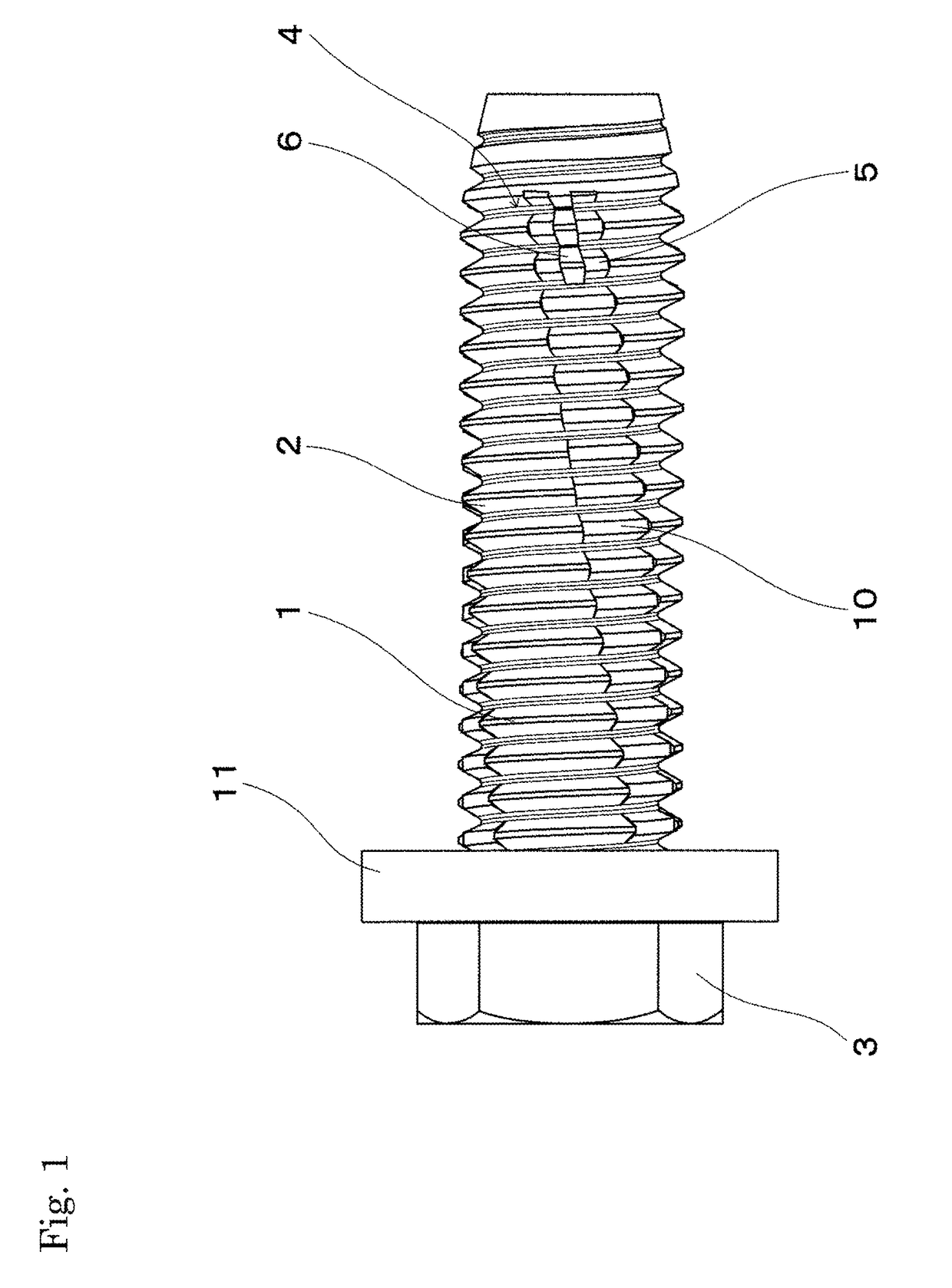

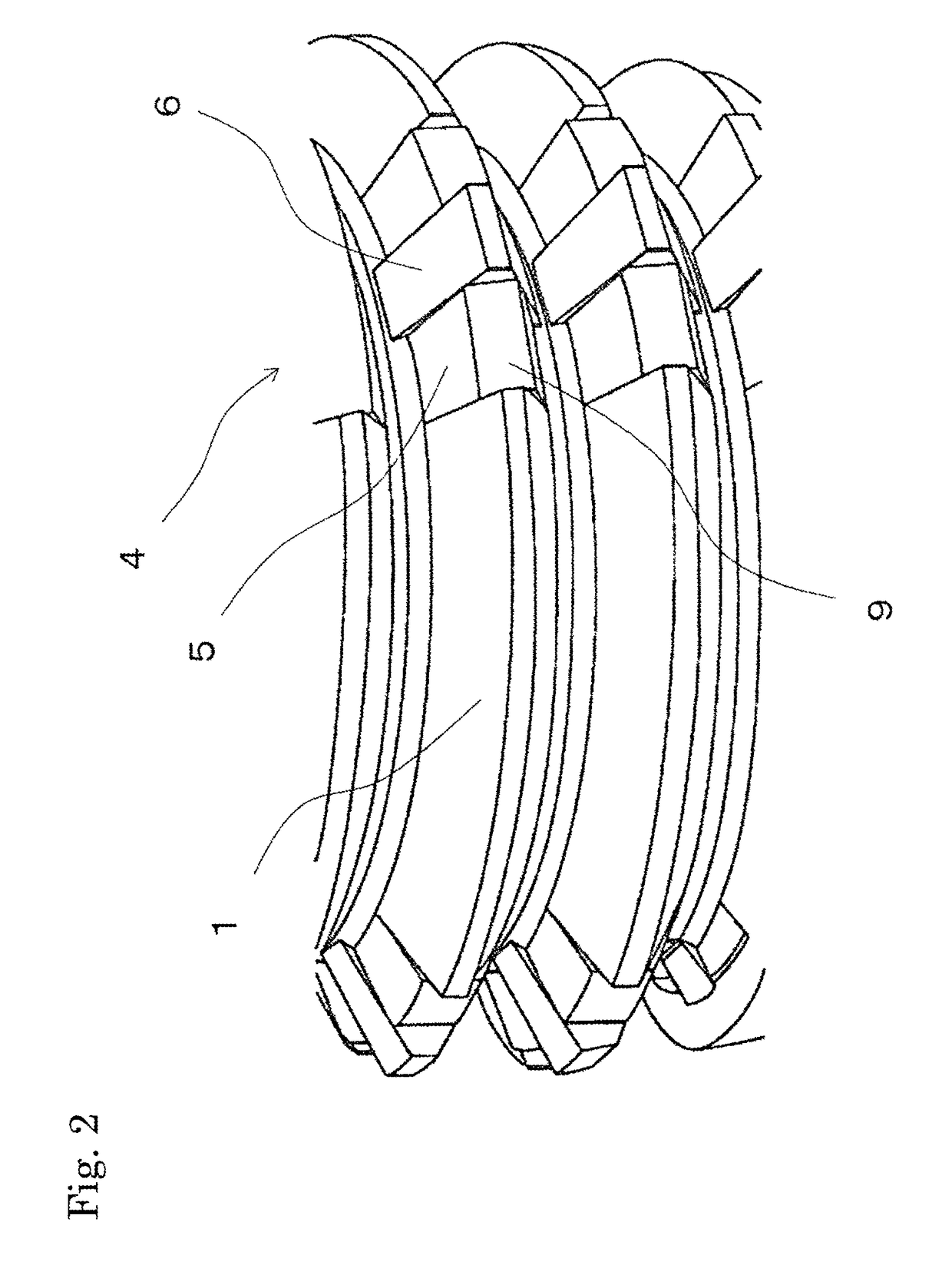

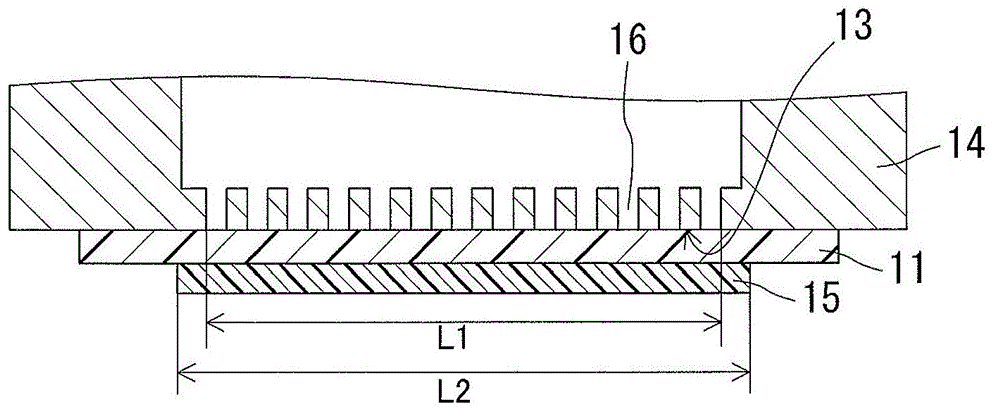

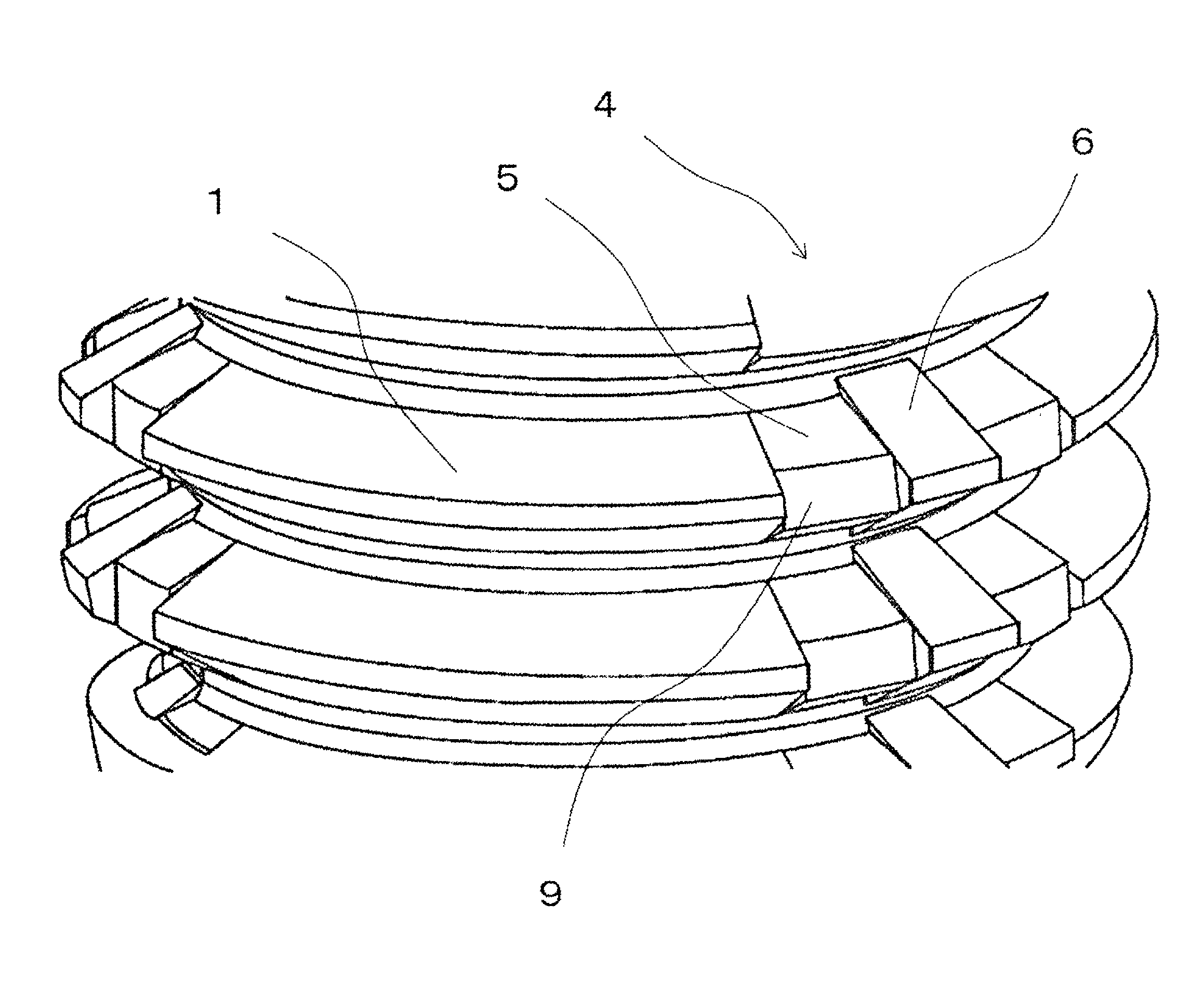

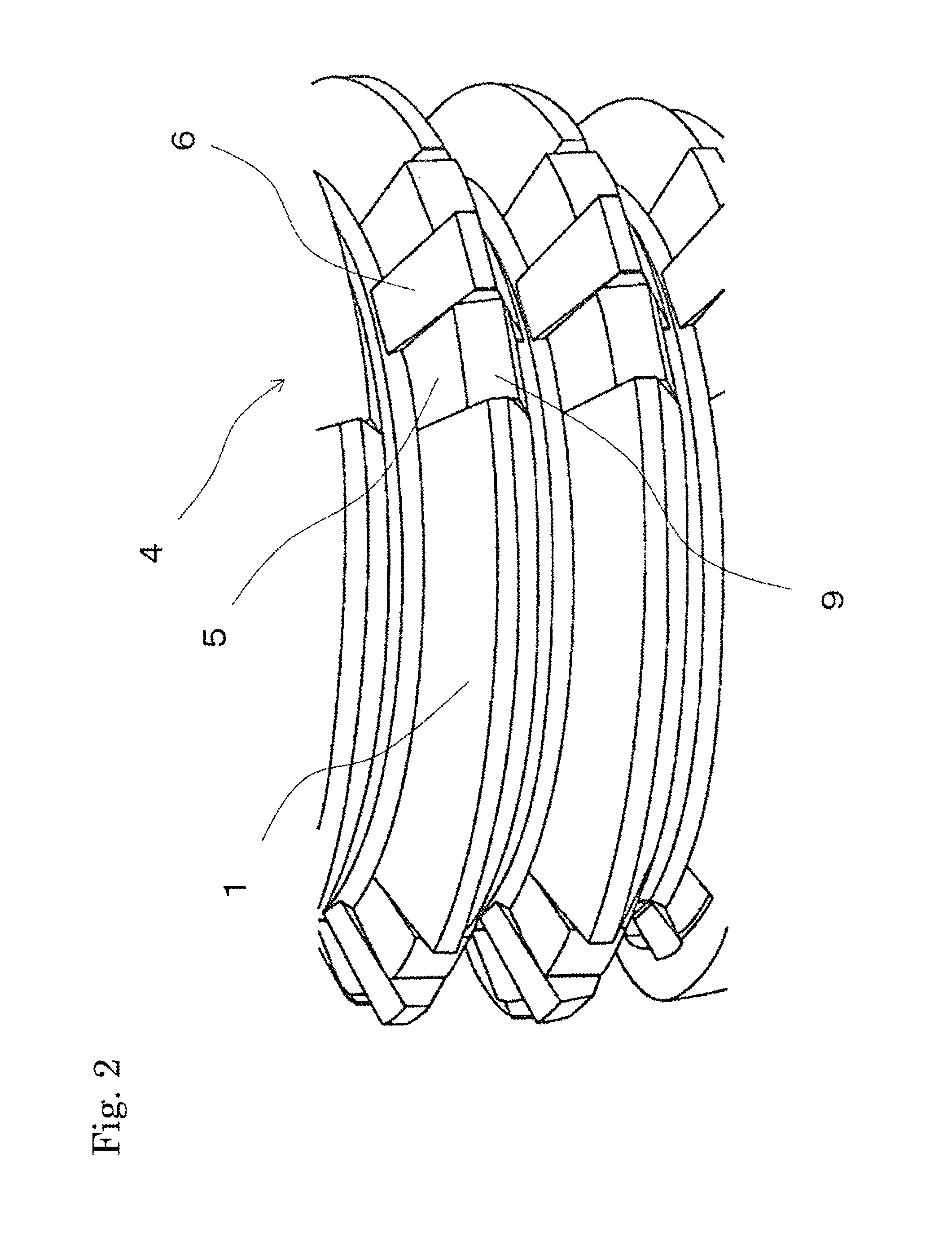

Bolt

ActiveUS20160138639A1Suppress conduction failureHigh conductivityNutsBoltsEngineeringMechanical engineering

The bolt of the present invention can reliably peel coating even when fastened with a low torque, and can secure sufficient conductivity. A coating peeling part 4 for peeling coating is formed at a tip end of an axis part 2 in which a regular screw part 1 is formed. The coating peeling part 4 includes crushing parts 5 having a trapezoidal top part and having a flank which is projected at a different angle with respect to the flank of the regular screw part 1; and a protruding part 6 which is arranged adjacent to the crushing parts 5 and whose top part projects beyond the outer diameter of the regular screw part 1.

Owner:AOYAMA SEISAKUSHO CO LTD

Method for bonding adhesive tape, apparatus for bonding adhesive tape and method for transporting adhesive tape

InactiveCN108400104AReliable strippingAvoid splicing errorsSemiconductor/solid-state device manufacturingConveyor partsAdhesion beltEngineering

The invention provides a method for bonding an adhesive tape, an apparatus for bonding an adhesive tape, and a method for transporting an adhesive tape, which can reliably bond the ends of an adhesivetape to each other and perform various kinds of handling even if the adhesive tape has strong adhesive force. A push-out member (33) protrudes a part of the adhesive tape (Tp) out of a long adhesivetape (T) in a direction (R) substantially perpendicular to a release direction (L). A pressing roller (35) presses the protruding adhesive tape (Tp) to make a part of the adhesive tape (T) as a gripping portion. Since the gripping portion protrudes by a predetermined length in the direction (R) at a predetermined position (Tf), the gripping portion can be easily and reliably held to operate the adhesive tape (T). In addition, since the length of the gripping portion in the release direction (L) is very short, it is possible to improve the positional accuracy of the region where handling is performed on the long adhesive tape by holding the gripping portion for handling, and it is possible to apply a large force to the limited region of the adhesive tape (T).

Owner:NITTO DENKO CORP

rotary valve

ActiveCN103287809BStrong adhesionStripping of material that adheres reliably to the rotorRotary conveyorsRotary valveEngineering

Owner:FUJIWARA TECHNO ART CO LTD

Method and device for peeling off film

InactiveCN100540431CReliable strippingReduce consumptionAdhesivesNon-linear opticsTectorial membraneEngineering

The invention provides a film peeling method and device. It is provided with an adhesive tape (30) located near the end of a glass substrate (6) with a protective film (54) affixed to its front and back surfaces, and an adhesive surface (38) of the adhesive tape (30) facing the glass substrate ( 6) Side-pressing peeling head (40). There is a method for pulling the adhesive tape (30) adhered to the end portion of the protective film (54) away from the surface of the glass substrate (6) and partially peeling the protective film (54) from the glass substrate (6). drive(46). A film clamping device (58) is provided to hold the end of the peeled protective film (54). The glass substrate (6) is driven by a roller conveyor (4), and the protective film (54) held by the film clamping device (58) is ) peel off.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com