Substrate transfer mechanism and subtrate transfer apparatus, particle removal method, program, and storage medium

A substrate conveying and substrate technology, which is used in conveyor objects, transportation and packaging, lighting and heating equipment, etc., and can solve problems such as etching residues and film quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

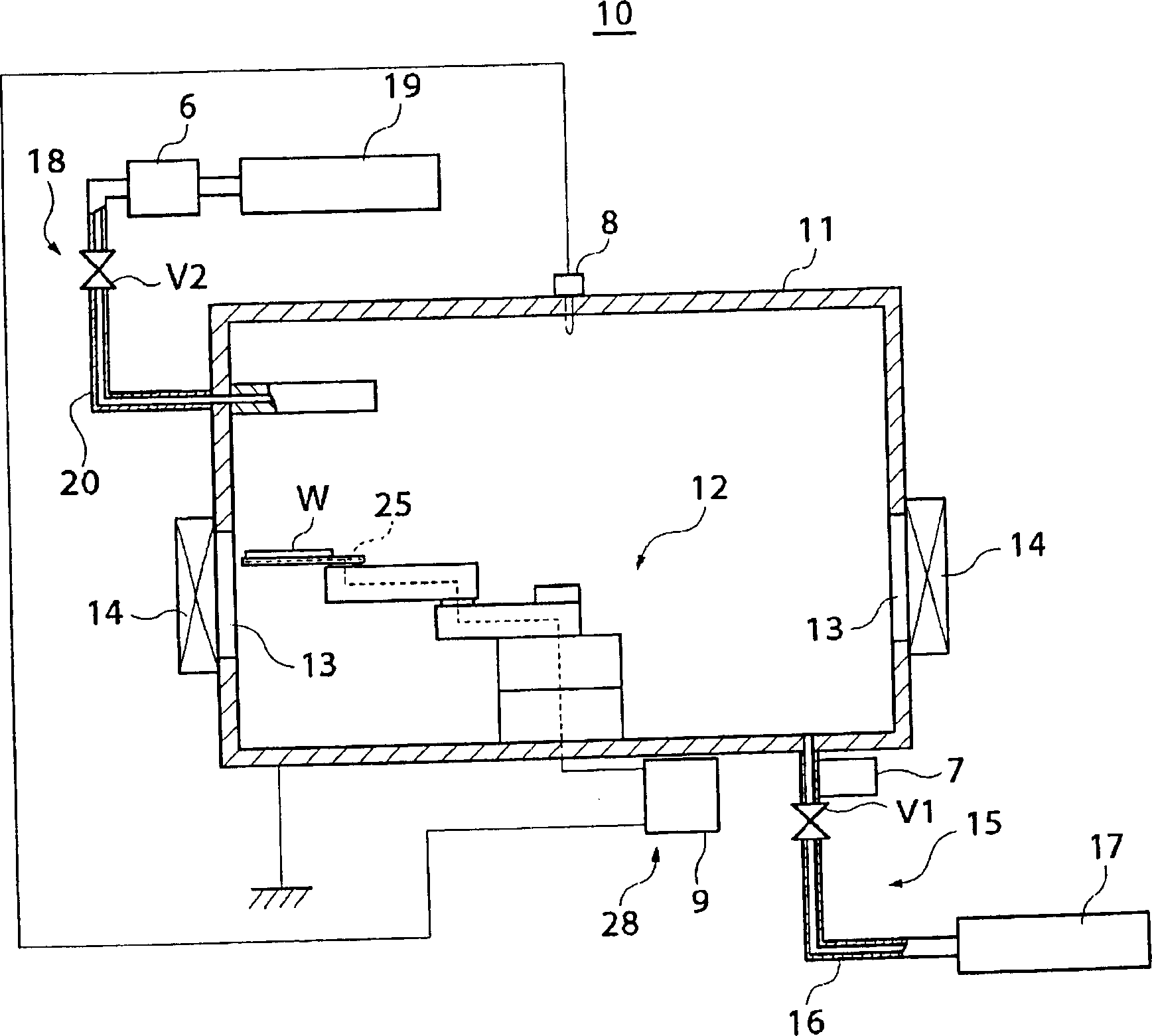

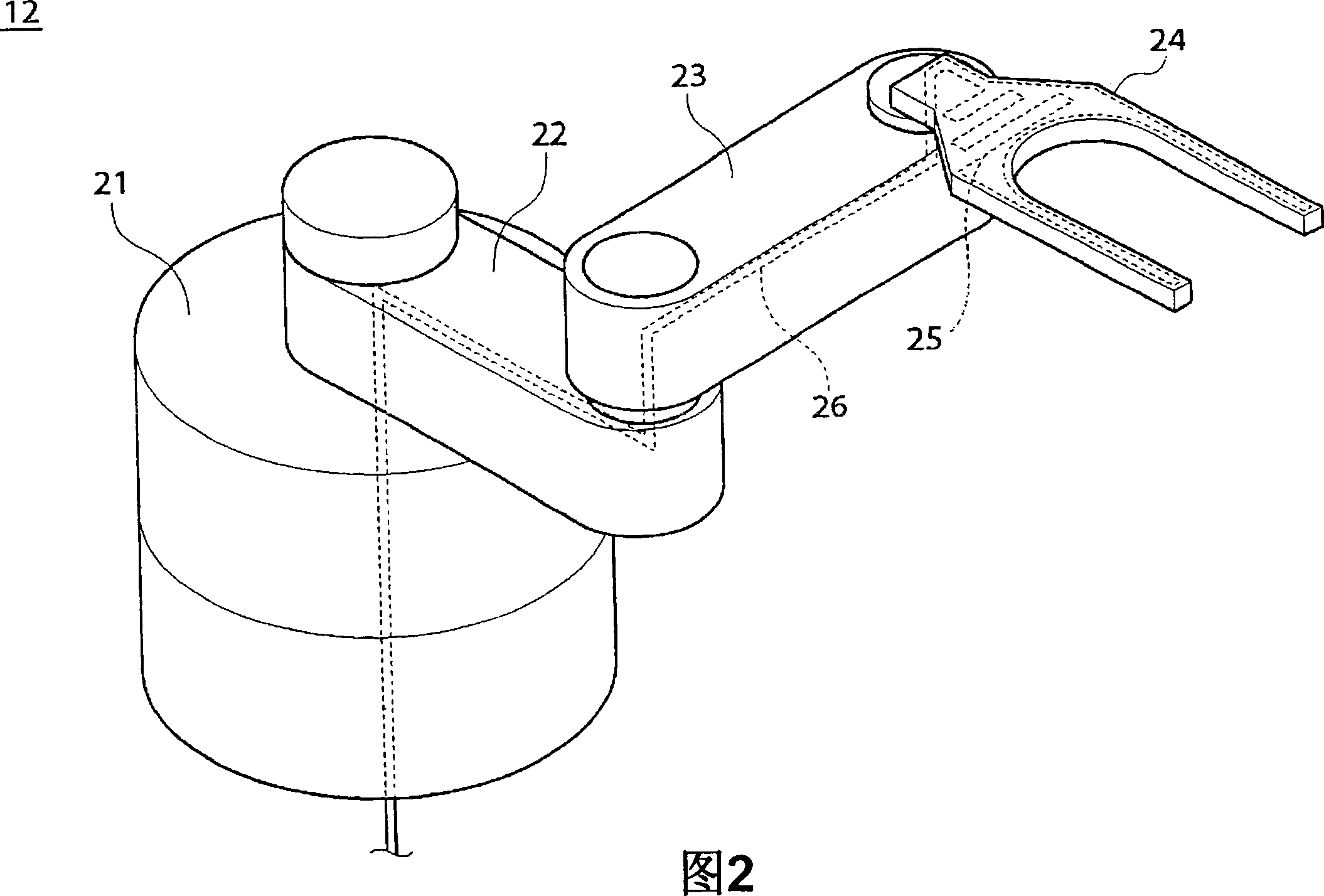

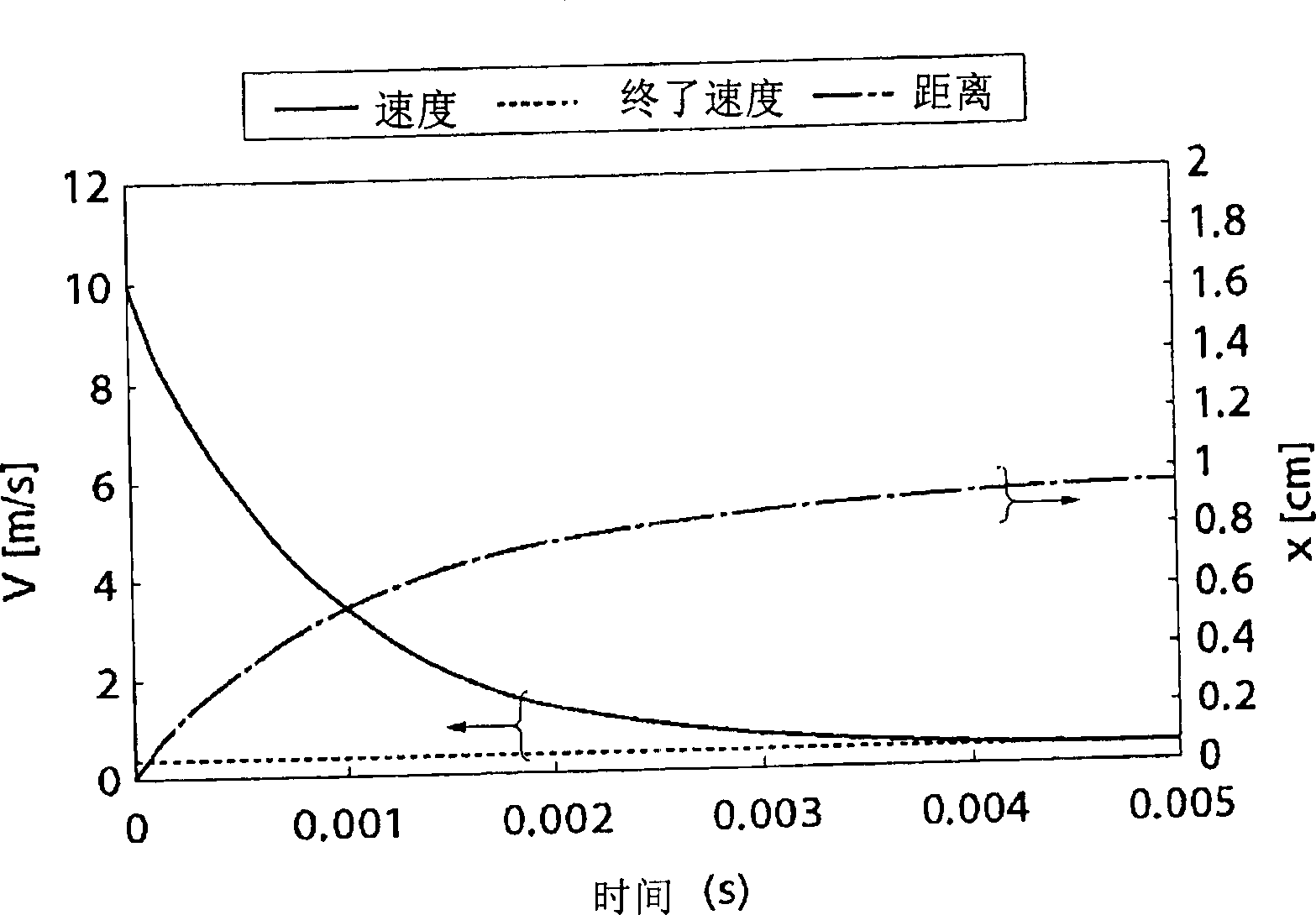

[0173] Next, examples of the present invention will be described in detail. In addition, in the following examples, a simulation experiment was performed in a processing chamber of a processing apparatus in which the substrate transfer device 10 and the substrate transfer device 30 were set.

[0174] First, in the processing chamber of the substrate transfer device 10, prepare SiO with a particle diameter of 0.6 μm in advance. 2 The Si wafer with particles attached to the surface is placed on the lower electrode of the transfer arm that sets the processing chamber. Next, while controlling the pressure in the processing chamber to 0.13kPa (1.0Torr), the temperature of the lower electrode was raised, and the amount of SiO peeled off from the Si wafer during the temperature rise was measured. 2 The number of particles (pieces / minute). In addition, the temperature difference of the upper electrode and the temperature difference of the Si wafer which set the temperature differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com