Component cleaning method

A part and part of the technology, applied in the field of cleaning components, can solve the problems of pattern collapse, liquid can not be removed, etc., to achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

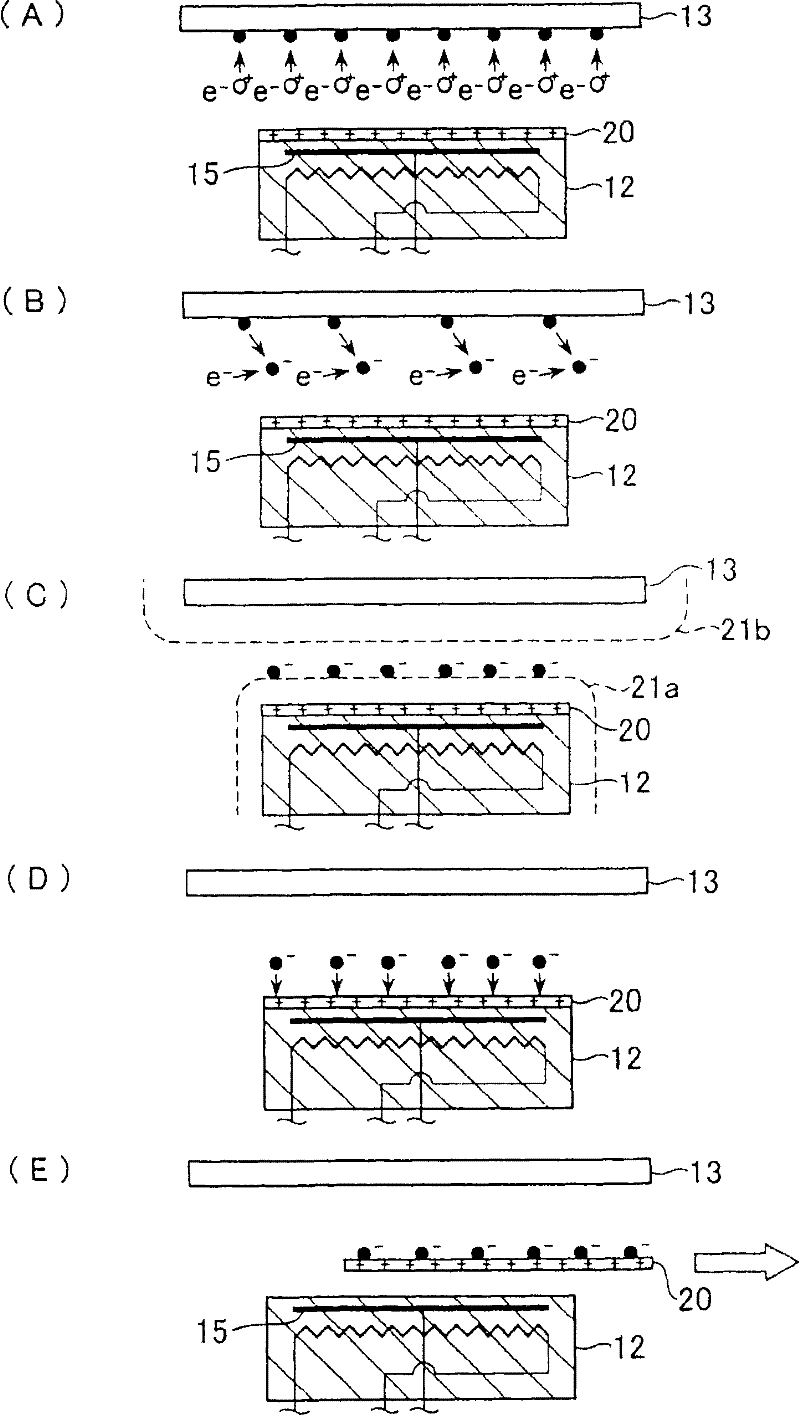

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0055] First, a method of cleaning components according to the first embodiment of the present invention will be described.

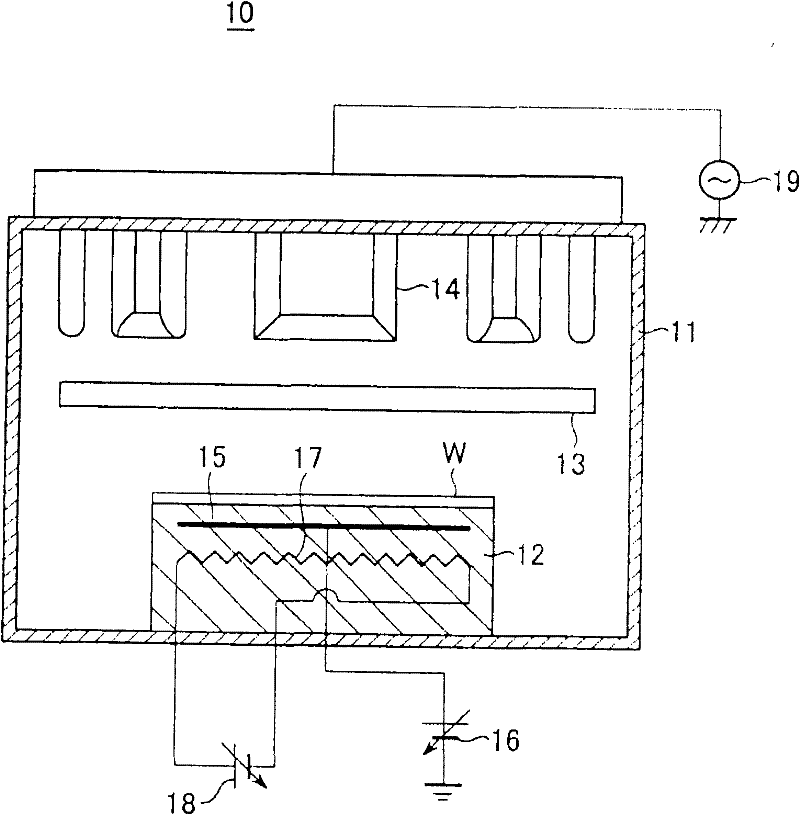

[0056] figure 1 It is a cross-sectional view schematically showing the structure of a wafer dry cleaning apparatus that executes the method for cleaning components according to this embodiment. This wafer dry cleaning apparatus removes foreign substances (hereinafter referred to as "particles") adhering to the surface of a semiconductor wafer (hereinafter simply referred to as "wafer") W without using a solvent or solution.

[0057] figure 1 Among them, the wafer dry-cleaning apparatus 10 (substrate processing apparatus) has: a processing chamber 11, a mounting table 12 provided at the inner bottom of the processing chamber 11, and a collecting plate 13 disposed above the mounting table 12 with a predetermined interval therebetween (configurati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com