Water-resistant sound transmitting member, production method therefor, and water-resistant sound transmitting member carrier

A waterproof and sound-permeable, manufacturing method technology, applied to electrical components, sensor parts, transducers used underwater, etc., can solve the problems of difficult installation of waterproof and sound-permeable membranes, achieve reliable peeling, and improve adhesive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

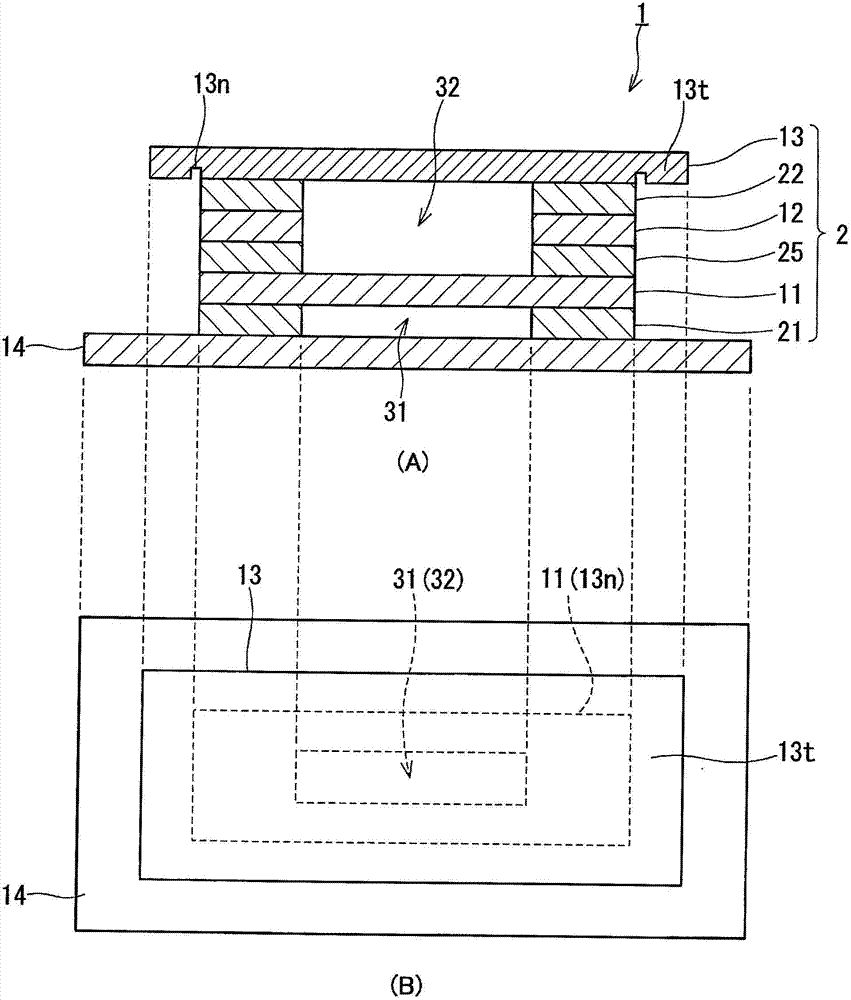

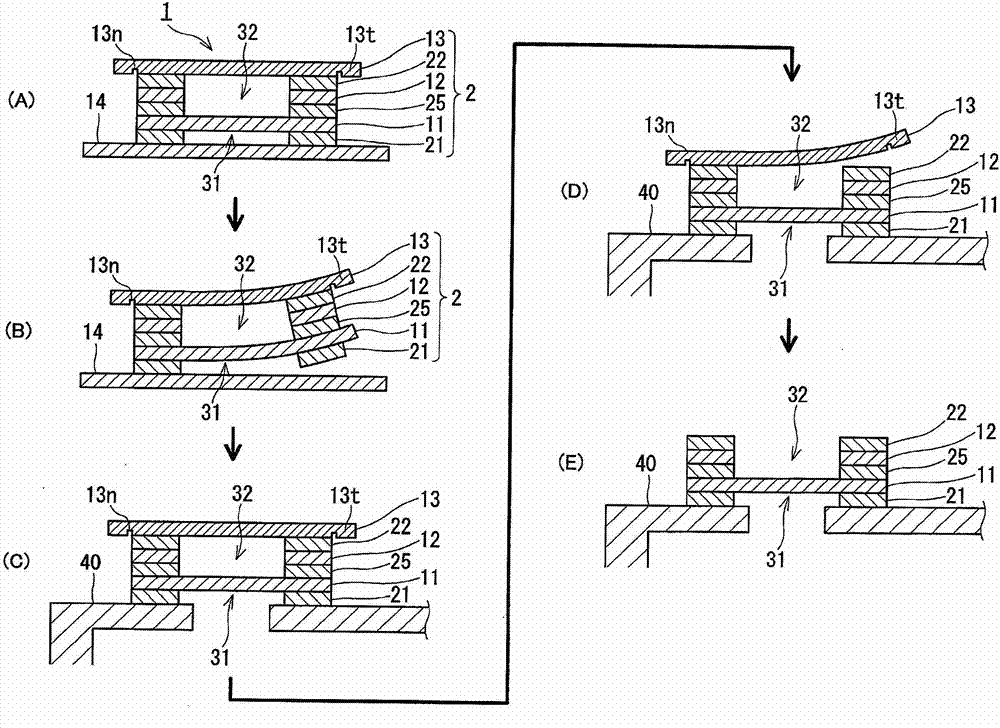

[0060] As an example, make figure 1 The shown waterproof and sound-permeable component carrier. Specifically, first, double-sided tape A (No. 5636 manufactured by Nitto Denko), a waterproof sound-permeable membrane (NTF610AP manufactured by Nitto Denko), .5605), cushioning material (PORON SR-S-70P manufactured by Rogers Inoue Co., Ltd.), double-sided tape C (No.5603 manufactured by Nitto Denko Co., Ltd.) SS4 series A) sequentially layered, making Figure 4 The laminate shown in (A). Then, a blade is inserted from the double-sided tape A of the produced laminate toward the tab, the double-sided tape A, the waterproof sound-permeable film, the double-sided tape B, the cushioning material, and the double-sided tape C are cut into a predetermined shape, and grooves are formed on the chip, whereby, fabricating Figure 4 The laminate shown in (C). Then, a blade is inserted into the lug of the produced laminate to cut the lug, thereby producing Figure 4 The waterproof sound-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com